Artificial Neural Network for Vertical Displacement Prediction of a Bridge from Strains (Part 2): Optimization of Strain-Measurement Points by a Genetic Algorithm under Dynamic Loading

Abstract

:1. Introduction

2. Methods

2.1. Artificial Neural Networks (ANNs)

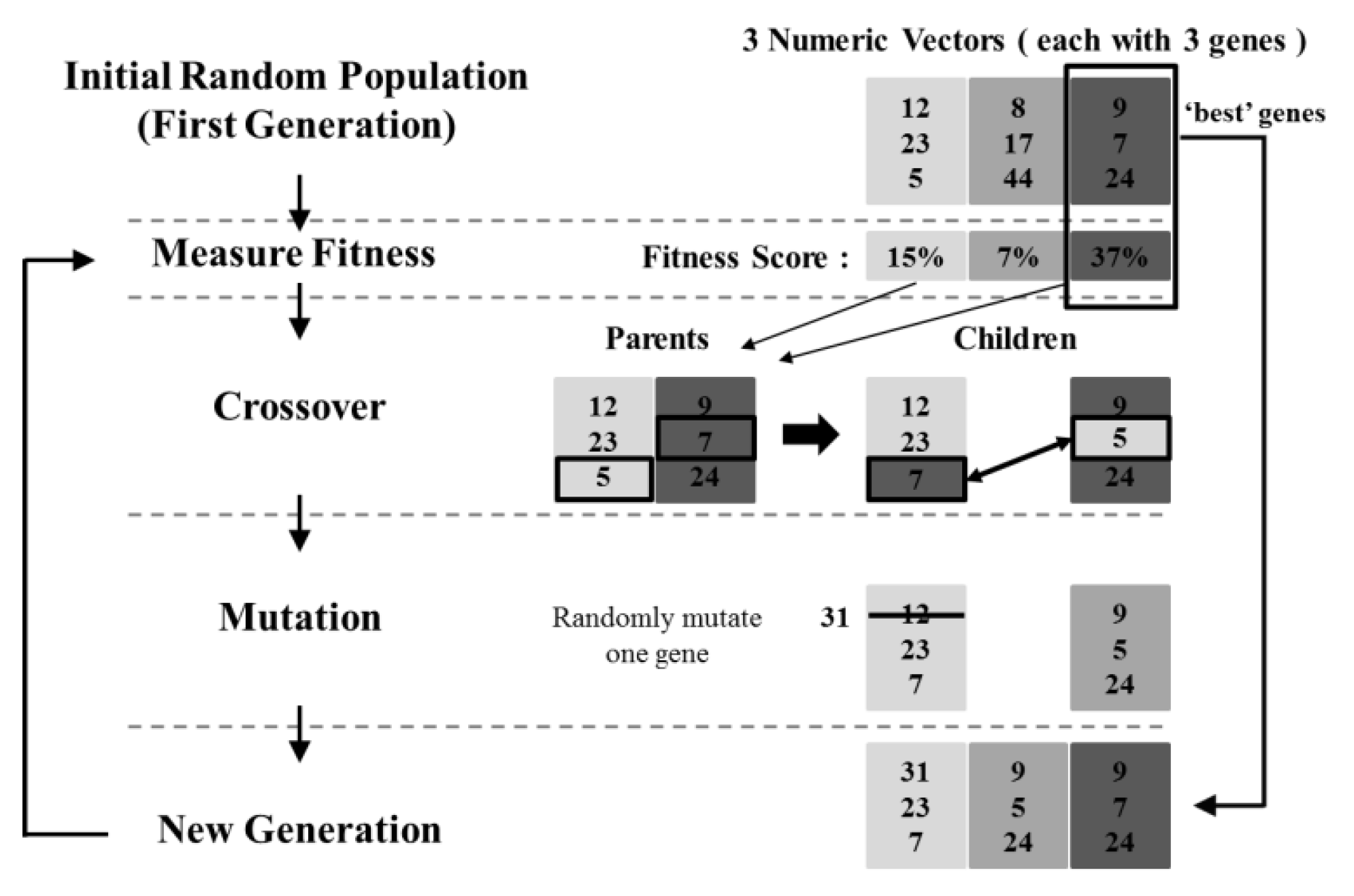

2.2. Genetic Algorithm (GA)

2.3. Optimizing the Number and Locations of Strain-Measurement Points

3. Verification through a Simple Beam Under Sinusoidal Loads

3.1. Collecting Training and Test Data

3.2. Optimization Results

4. Application to a Plate Girder Bridge under Vehicle Load

4.1. Collecting Training and Test Data

4.2. Optimization Results

5. Experimental Verification with Cantilever Beam

6. Conclusions

- (1)

- The ANN prediction accuracy can be improved by optimizing the ANN input values using GA. In this study, the number and locations of strains were optimized to accurately predict displacements. The optimization results show that at least two strains at the optimized locations are sufficient to predict the displacements;

- (2)

- By comparing the ANN displacement prediction results from the strain at the optimized locations and the strain at the arbitrary locations, the difference between the MSE and the R value was found. In particular, the difference was prominent in the graph. Therefore, if the number and locations of strain-measurement points are optimized by using the proposed method, the displacements can be predicted very economically and accurately;

- (3)

- When the proposed method was applied to a vibrating cantilever beam, the feasibility of the proposed method was confirmed. As with the two cases using the numerical model, the predicted displacements from the measured strains showed good agreements with the measure displacements for the real cantilever beam. From laboratory experiment results, the applicability to actual bridges in the field can be confirmed.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Moses, F. Weigh-in-motion system using instrumented bridges. J. Transp. Eng. 1979, 105, 233–249. [Google Scholar]

- Lee, J.-J.; Shinozuka, M. Real-time displacement measurement of a flexible bridge using digital image processing techniques. Exp. Mech. 2006, 46, 105–114. [Google Scholar] [CrossRef]

- Xu, L.; Guo, J.J.; Jiang, J.J. Time–frequency analysis of a suspension bridge based on GPS. J. Sound Vib. 2002, 254, 105–116. [Google Scholar] [CrossRef]

- Nassif, H.H.; Gindy, M.; Davis, J. Comparison of laser Doppler vibrometer with contact sensors for monitoring bridge deflection and vibration. NDT E Int. 2005, 38, 213–218. [Google Scholar] [CrossRef]

- Pieraccini, M.; Luzi, G.; Mecatti, D.; Fratini, M.; Noferini, L.; Carissimi, L.; Franchioni, G.; Atzeni, C. Remote sensing of building structural displacements using a microwave interferometer with imaging capability. NDT E Int. 2004, 37, 545–550. [Google Scholar] [CrossRef]

- Stephen, G.A.; Brownjohn, J.M.W.; Taylor, C.A. Measurements of static and dynamic displacement from visual monitoring of the Humber Bridge. Eng. Struct. 1993, 15, 197–208. [Google Scholar] [CrossRef] [Green Version]

- Olaszek, P. Investigation of the dynamic characteristic of bridge structures using a computer vision method. Measurement 1999, 25, 227–236. [Google Scholar] [CrossRef]

- Wahbeh, A.M.; Caffrey, J.P.; Masri, S.F. A vision-based approach for the direct measurement of displacements in vibrating systems. Smart Mater. Struct. 2003, 12, 785. [Google Scholar] [CrossRef]

- Faulkner, B.C. Determination of Bridge Response Using Acceleration Data; Report No. FHWA/VA-97-R5; Virginia Transportation Research Council: Charlottesville, VA, USA, 1996. [Google Scholar]

- Park, K.-T.; Kim, S.-H.; Park, H.-S.; Lee, K.-W. The determination of bridge displacement using measured acceleration. Eng. Struct. 2005, 27, 371–378. [Google Scholar] [CrossRef]

- Wang, Z.-C.; Geng, D.; Ren, W.-X.; Liu, H.-T. Strain modes based dynamic displacement estimation of beam structures with strain sensors. Smart Mater. Struct. 2014, 23, 125045. [Google Scholar] [CrossRef]

- Chung, W.; Kim, S.; Kim, N.-S.; Lee, H.-U. Deflection estimation of a full scale prestressed concrete girder using long-gauge fiber optic sensors. Constr. Build. Mater. 2008, 22, 394–401. [Google Scholar] [CrossRef]

- Glaser, R.; Caccese, V.; Shahinpoor, M. Shape monitoring of a beam structure from measured strain or curvature. Exp. Mech. 2012, 52, 591–606. [Google Scholar] [CrossRef]

- Kang, L.-H.; Kim, D.-K.; Han, J.-H. Estimation of dynamic structural displacements using fiber Bragg grating strain sensors. J. Sound Vib. 2007, 305, 534–542. [Google Scholar] [CrossRef]

- Rapp, S.; Kang, L.-H.; Han, J.-H.; Mueller, U.C.; Baier, H. Displacement field estimation for a two-dimensional structure using fiber Bragg grating sensors. Smart Mater. Struct. 2009, 18, 025006. [Google Scholar] [CrossRef]

- Kim, H.-I.; Kang, L.-H.; Han, J.-H. Shape estimation with distributed fiber Bragg grating sensors for rotating structures. Smart Mater. Struct. 2011, 20, 035011. [Google Scholar] [CrossRef]

- Kim, N.-S.; Cho, N.-S. Estimating deflection of a simple beam model using fiber optic Bragg-grating sensors. Exp. Mech. 2004, 44, 433–439. [Google Scholar] [CrossRef]

- Moon, H.S.; Ok, S.; Chun, P.-J.; Lim, Y.M. Artificial neural network for vertical displacement prediction of a bridge from strains (Part 1): Girder bridge under moving vehicles. Appl. Sci. 2019, 9, 2881. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.; Topac, T.; Smith, W.; Ladpli, P.; Liu, C.; Chang, F.K. Characterization of Distributed Microfabricated Strain Gauges on Stretchable Sensor Networks for Structural Applications. Sensors 2018, 18, 3260. [Google Scholar] [CrossRef] [Green Version]

- Glišić, B.; Yao, Y.; Tung, S.T.E.; Wagner, S.; Sturm, J.C.; Verma, N. Strain sensing sheets for structural health monitoring based on large-area electronics and integrated circuits. Proc. IEEE 2016, 104, 1513–1528. [Google Scholar] [CrossRef]

- Yi, T.H.; Li, H.N.; Zhang, X.D. Health monitoring sensor placement optimization for Canton Tower using immune monkey algorithm. Struct. Control Health Monit. 2015, 22, 123–138. [Google Scholar] [CrossRef]

- Jung, B.K.; Cho, J.R.; Jeong, W.B. Sensor placement optimization for structural modal identification of flexible structures using genetic algorithm. J. Mech. Sci. Technol. 2015, 29, 2775–2783. [Google Scholar] [CrossRef]

- Papadimitriou, C. Optimal sensor placement methodology for parametric identification of structural systems. J. Sound Vib. 2004, 278, 923–947. [Google Scholar] [CrossRef]

- Kincaid, R.K.; Padula, S.L. D-optimal designs for sensor and actuator locations. Comput. Oper. Res. 2002, 29, 701–713. [Google Scholar] [CrossRef]

- Papadimitriou, C.; Beck, J.L.; Au, S.-K. Entropy-based optimal sensor location for structural model updating. J. Vib. Control 2000, 6, 781–800. [Google Scholar] [CrossRef]

- Worden, K.; Burrows, A.P. Optimal sensor placement for fault detection. Eng. Struct. 2001, 23, 885–901. [Google Scholar] [CrossRef]

- Liu, W.; Gao, W.-C.; Sun, Y.; Xu, M.-J. Optimal sensor placement for spatial lattice structure based on genetic algorithms. J. Sound Vib. 2008, 317, 175–189. [Google Scholar] [CrossRef]

- Yi, T.-H.; Li, H.-N. Methodology developments in sensor placement for health monitoring of civil infrastructures. Int. J. Distrib. Sens. Netw. 2012, 8, 612726. [Google Scholar] [CrossRef]

- Meo, M.; Zumpano, G. On the optimal sensor placement techniques for a bridge structure. Eng. Struct. 2005, 27, 1488–1497. [Google Scholar] [CrossRef]

- Yi, T.-H.; Li, H.-N.; Gu, M. Optimal sensor placement for health monitoring of high-rise structure based on genetic algorithm. Math. Probl. Eng. 2011, 2011, 1–12. [Google Scholar] [CrossRef]

- Papadimitriou, C.; Lombaert, G. The effect of prediction error correlation on optimal sensor placement in structural dynamics. Mech. Syst. Signal Proc. 2012, 28, 105–127. [Google Scholar] [CrossRef]

- Chow, H.M.; Lam, H.F.; Yin, T.; Au, S.K. Optimal sensor configuration of a typical transmission tower for the purpose of structural model updating. Struct. Control Health Monit. 2011, 18, 305–320. [Google Scholar] [CrossRef]

- Rao, A.R.M.; Anandakumar, G. Optimal placement of sensors for structural system identification and health monitoring using a hybrid swarm intelligence technique. Smart Mater. Struct. 2007, 16, 2658. [Google Scholar] [CrossRef]

- Rapaic, M.; Kanovic, Z.; Jelicic, Z. Discrete particle swarm optimization algorithm for solving optimal sensor deployment problem. J. Autom. Control 2008, 18, 9–14. [Google Scholar] [CrossRef]

- Kukunuru, N.; Thella, B.R.; Davuluri, R.L. Sensor deployment using particle swarm optimization. Int. J. Eng. Sci. Technol. 2010, 2, 5395–5401. [Google Scholar]

- Dutta, R.; Ganguli, R.; Mani, V. Swarm intelligence algorithms for integrated optimization of piezoelectric actuator and sensor placement and feedback gains. Smart Mater. Struct. 2011, 20, 105018. [Google Scholar] [CrossRef]

- Yi, T.-H.; Li, H.-N.; Zhang, X.-D. A modified monkey algorithm for optimal sensor placement in structural health monitoring. Smart Mater. Struct. 2012, 21, 105033. [Google Scholar] [CrossRef]

- Yi, T.-H.; Li, H.-N.; Gu, M. A new method for optimal selection of sensor location on a high-rise building using simplified finite element model. Struct. Eng. Mech. 2011, 37, 671–684. [Google Scholar] [CrossRef]

- McCulloch, W.S.; Pitts, W. A logical calculus of the ideas immanent in nervous activity. Bull. Math. Biophys. 1943, 5, 115–133. [Google Scholar] [CrossRef]

- Cook, D.F.; Ragsdale, C.T.; Major, R.L. Combining a neural network with a genetic algorithm for process parameter optimization. Eng. Appl. Artif. Intell. 2000, 13, 391–396. [Google Scholar] [CrossRef]

- Momeni, E.; Nazir, R.; Armaghani, D.J.; Maizir, H. Prediction of pile bearing capacity using a hybrid genetic algorithm-based ANN. Measurement 2014, 57, 122–131. [Google Scholar] [CrossRef]

- Chen, H.; Zeng, Z. Deformation prediction of landslide based on improved back-propagation neural network. Cogn. Comput. 2013, 5, 56–62. [Google Scholar] [CrossRef]

- Benardos, P.G.; Vosniakos, G.-C. Optimizing feedforward artificial neural network architecture. Eng. Appl. Artif. Intell. 2007, 20, 365–382. [Google Scholar] [CrossRef]

- Yan, F.; Lin, Z.; Wang, X.; Azarmi, F.; Sobolev, K. Evaluation and prediction of bond strength of GFRP-bar reinforced concrete using artificial neural network optimized with genetic algorithm. Compos. Struct. 2017, 161, 441–452. [Google Scholar] [CrossRef]

- Najjar, Y.M.; Basheer, I.A. Utilizing computational neural networks for evaluating the permeability of compacted clay liners. Geotech. Geol. Eng. 1996, 14, 193–212. [Google Scholar]

- Shahin, M.A.; Maier, H.R.; Jaksa, M.B. Predicting settlement of shallow foundations using neural networks. J. Geotech. Geoenviron. Eng. 2002, 128, 785–793. [Google Scholar] [CrossRef]

- Jan, J.C.; Hung, S.-L.; Chi, S.Y.; Chern, J.C. Neural network forecast model in deep excavation. J. Comput. Civ. Eng. 2002, 16, 59–65. [Google Scholar] [CrossRef] [Green Version]

- Holland, J.H. Adaptation in Natural and Artificial Systems; The University of Michigan Press: Ann Arbor, MI, USA, 1975. [Google Scholar]

- Mohamad, E.T.; Faradonbeh, R.S.; Armaghani, D.J.; Monjezi, M.; Majid, M.Z.A. An optimized ANN model based on genetic algorithm for predicting ripping production. Neural Comput. Appl. 2017, 28, 393–406. [Google Scholar] [CrossRef]

- Osyczka, A. Evolutionary Algorithms for Single and Multicriteria Design Optimization; Physica: Heidelberg, Germany, 2002. [Google Scholar]

- Faghihi, V.; Reinschmidt, K.F.; Kang, J.H. Construction scheduling using genetic algorithm based on building information model. Expert Syst. Appl. 2014, 41, 7565–7578. [Google Scholar] [CrossRef]

- Chandwani, V.; Agrawal, V.; Nagar, R. Modeling slump of ready mix concrete using genetic algorithms assisted training of Artificial Neural Networks. Expert Syst. Appl. 2015, 42, 885–893. [Google Scholar] [CrossRef]

- RazaviAlavi, S.; AbouRizk, S. Site layout and construction plan optimization using an integrated genetic algorithm simulation framework. J. Comput. Civ. Eng. 2017, 31, 04017011. [Google Scholar] [CrossRef]

- Woodward, R.I.; Kelleher, E.J.R. Towards ‘smart lasers’: Self-optimisation of an ultrafast pulse source using a genetic algorithm. Sci. Rep. 2016, 6, 37616. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Patuwo, B.E.; Hu, M.Y. Forecasting with artificial neural networks: The state of the art. Int. J. Forecast. 1998, 14, 35–62. [Google Scholar] [CrossRef]

- Zuo, L.; Nayfeh, S.A. Structured H2 optimization of vehicle suspensions based on multi-wheel models. Veh. Syst. Dyn. 2003, 40, 351–371. [Google Scholar] [CrossRef]

- Ahmed, K.A.; Abdelhady, M.B.A.; Abouelnour, A.M.A.A. The improvement of ride comfort of a city bus which is fabricated on a lorry chassis. Eng. Res. J. 1997, 53, 19–35. [Google Scholar]

- Li, H. Dynamic Response of Highway Bridges Subjected to Heavy Vehicles; The Florida State University: Tallahassee, FL, USA, 2005. [Google Scholar]

- Chun, B.-J. Skewed Bridge Behaviors: Experimental, Analytical, and Numerical Analysis. Ph.D. Thesis, Wayne State University, Detroit, MI, USA, 2010. [Google Scholar]

- Ok, S.Y.; Moon, H.S.; Chun, P.-J.; Lim, Y.M. Estimation of dynamic vertical displacement using artificial neural network and axial strain in girder bridge. J. Korean Soc. Civ. Eng. 2014, 34, 1655–1665. [Google Scholar] [CrossRef] [Green Version]

- Mathew, T.V. Vehicle Arrival Models: Headway. In Transportation Systems Engineering; Chapter 12; Retrieved from website of National Programme on Technology Enhanced Learning (NPTEL); Indian Institute of Technology: Bombay, India, 2014; Available online: https://nptel.ac.in/courses/105101008/downloads/cete_12.pdf (accessed on 19 February 2014).

| Number of input nodes (strain values) | ns |

| Number of hidden layers | 1 |

| Number of hidden nodes | ns |

| Number of output nodes (displacement values) | Overall displacements |

| Training algorithm | Scaled conjugate gradient backpropagation |

| Transfer function | Logsig (hidden), Purelin (output) |

| Learning rate | 0.01 |

| Momentum | 0.9 |

| Period (T) | Δt (s) | Datasets (= 1 s/Δt) |

|---|---|---|

| 1 s (training) | 0.00625 | 161 |

| 0.5 s (training) | 0.003125 | 321 |

| 0.1 s (training) | 0.000625 | 1601 |

| 0.8 s (test) | 0.005 | 201 |

| Total number of datasets | - | 2083 (training), 201 (test) |

| No. of Strains (= ns) | Locations of Strain-Measurement Points (mm) | Training | Test | |||||

|---|---|---|---|---|---|---|---|---|

| Point 1 | Point 2 | Point 3 | Point 4 | MSE | R | MSE | ||

| Arbitrary | 4 | 75 | 150 | 2775 | 2850 | 8.0591 | 0.9945 | 7.4406 |

| 3 | 75 | 2850 | 2925 | - | 14.9554 | 0.9895 | 16.3313 | |

| 2 | 150 | 300 | - | - | 16.7763 | 0.9886 | 16.3592 | |

| Optimized | 4 | 450 | 1500 | 2250 | 2700 | 0.0113 | 0.9999 | 0.0125 |

| 3 | 900 | 1500 | 2250 | - | 0.0073 | 0.9999 | 0.0072 | |

| 2 | 1125 | 2025 | - | - | 0.0513 | 0.9999 | 0.0524 | |

| Type of bridge | I-shape girder bridge (5 girders) |

| Number of spans | 1 (simply supported) |

| Length of the slab | 36 m |

| Width of the slab | 15 m |

| Number of the lanes | 4 (two in each direction) |

| Material | Concrete(Slab), Steel(Girder) |

| Modulus of elasticity (GPa) | 30 (Slab), 200 (Girder) |

| Unit weight (kgf/m3) | 2300 (Slab), 8000 (Girder) |

| Training Data | Test Data | |||||

|---|---|---|---|---|---|---|

| Velocity (km/h) | 40 | 60 | 80 | 40 | 60 | 80 |

| Number of load scenarios | 24 | 24 | 24 | 1 | 1 | 1 |

| Number of datasets per scenario | 800 | 800 | 800 | 800 | 800 | 800 |

| Total number of datasets | 57,600 | 2400 | ||||

| No. of Strains(= ns) | Locations of Strain-Measurement Points (m) | Training | |||||

|---|---|---|---|---|---|---|---|

| Point 1 | Point 2 | Point 3 | Point 4 | MSE (×10−3) | R | ||

| 11 | 0~36 (interval 3.6 m) | 1.2007 | 0.9988 | ||||

| Arbitrary | 4 | 7.2 | 14.4 | 25.2 | 28.8 | 5.4946 | 0.9947 |

| 3 | 7.2 | 25.2 | 32.4 | - | 31.1106 | 0.9696 | |

| 2 | 14.4 | 21.6 | - | - | 44.0195 | 0.9575 | |

| Optimized | 4 | 7.2 | 14.4 | 21.6 | 32.4 | 1.4268 | 0.9986 |

| 3 | 7.2 | 18 | 25.2 | - | 1.7511 | 0.9983 | |

| 2 | 10.8 | 21.6 | - | - | 2.5370 | 0.9975 | |

| No. of Strains Per Girder | ANN Structure (Input–Hidden–Output) | Mean Squared Error (MSE, ×10−3) | |||

|---|---|---|---|---|---|

| 40 km/h | 60 km/h (Test 2) | 80 km/h (Test 3) | |||

| 11 | 55–55–55 | 0.6874 | 0.3712 | 4.4094 | |

| Arbitrary | 4 | 20–20–55 | 1.7815 | 1.7924 | 7.6117 |

| 3 | 15–15–55 | 15.0731 | 11.8733 | 31.2476 | |

| 2 | 10–10–55 | 15.0141 | 10.7792 | 43.6243 | |

| Optimized | 4 | 20–20–55 | 0.7987 | 0.4805 | 4.7009 |

| 3 | 15–15–55 | 0.8830 | 0.5789 | 5.0831 | |

| 2 | 10–10–55 | 1.1249 | 0.8025 | 5.7813 | |

| Type of Sensor | Location (mm) | ||

|---|---|---|---|

| X1 | X2 | X3 | |

| Strain | 100 | 600 | 700 |

| Displacement | 400 | 700 | 1000 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moon, H.S.; Chun, P.-J.; Kim, M.K.; Lim, Y.M. Artificial Neural Network for Vertical Displacement Prediction of a Bridge from Strains (Part 2): Optimization of Strain-Measurement Points by a Genetic Algorithm under Dynamic Loading. Appl. Sci. 2020, 10, 777. https://doi.org/10.3390/app10030777

Moon HS, Chun P-J, Kim MK, Lim YM. Artificial Neural Network for Vertical Displacement Prediction of a Bridge from Strains (Part 2): Optimization of Strain-Measurement Points by a Genetic Algorithm under Dynamic Loading. Applied Sciences. 2020; 10(3):777. https://doi.org/10.3390/app10030777

Chicago/Turabian StyleMoon, Hyun Su, Pang-Jo Chun, Moon Kyum Kim, and Yun Mook Lim. 2020. "Artificial Neural Network for Vertical Displacement Prediction of a Bridge from Strains (Part 2): Optimization of Strain-Measurement Points by a Genetic Algorithm under Dynamic Loading" Applied Sciences 10, no. 3: 777. https://doi.org/10.3390/app10030777