Femtosecond Laser Additive Manufacturing of Multi-Material Layered Structures

Abstract

:1. Introduction

2. Materials and Methods

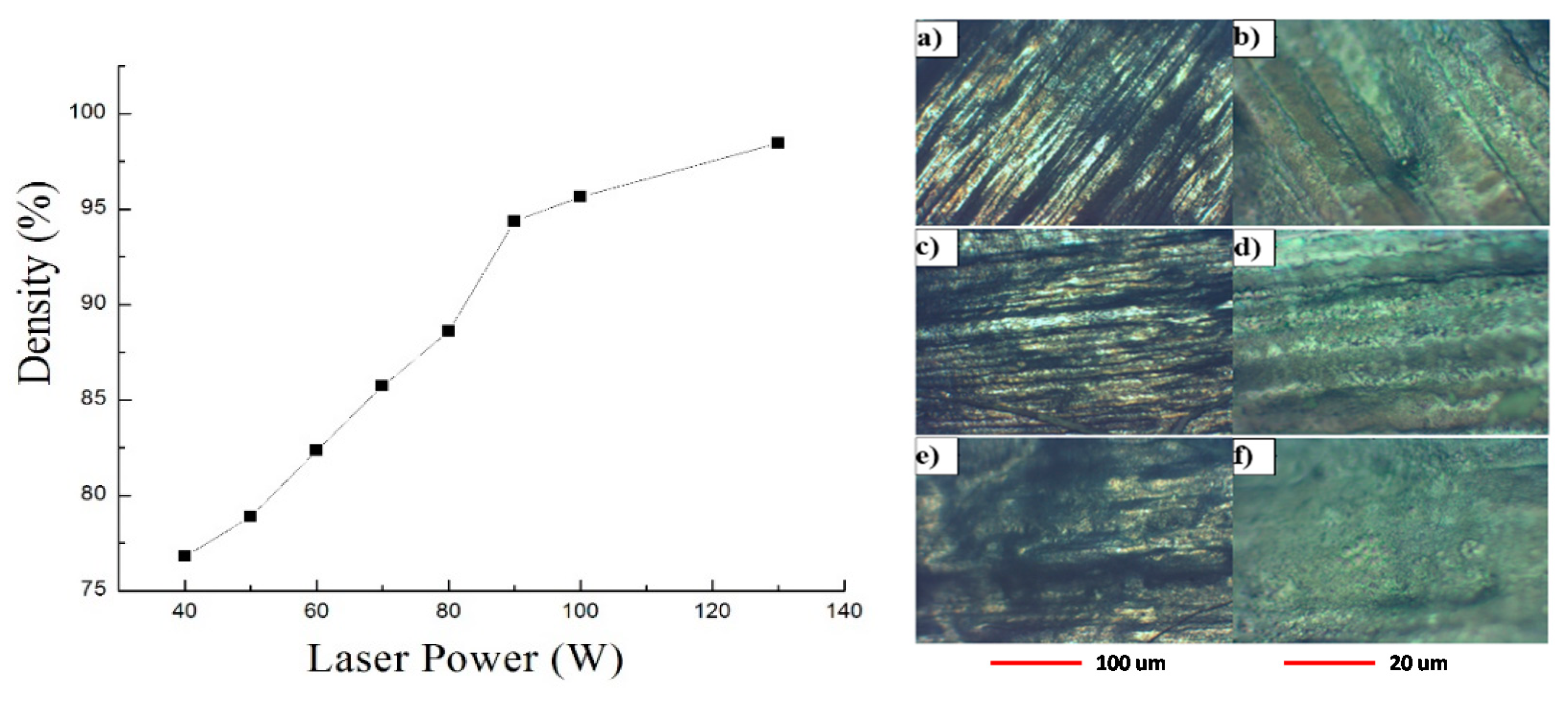

3. Results and Discussion

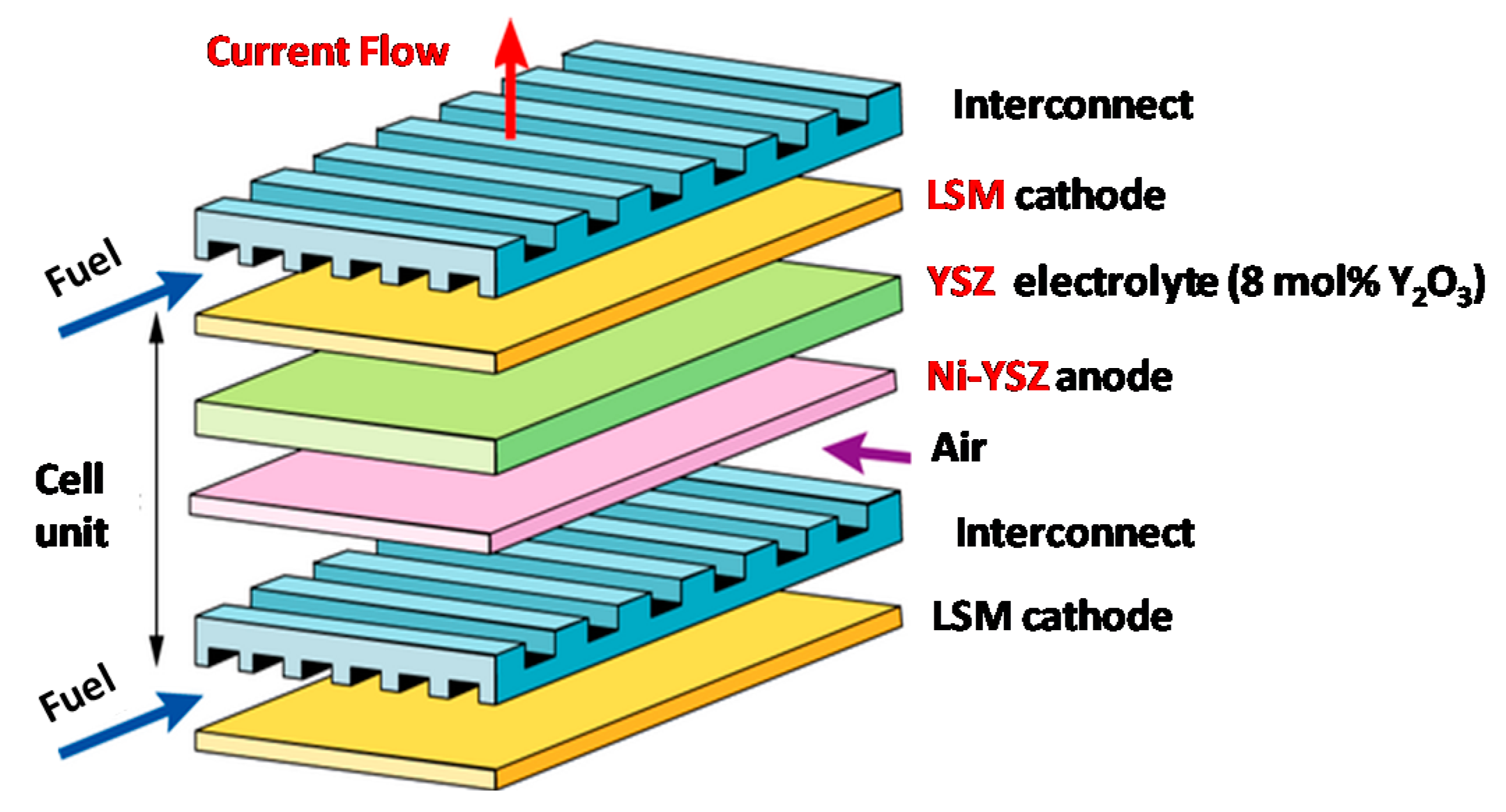

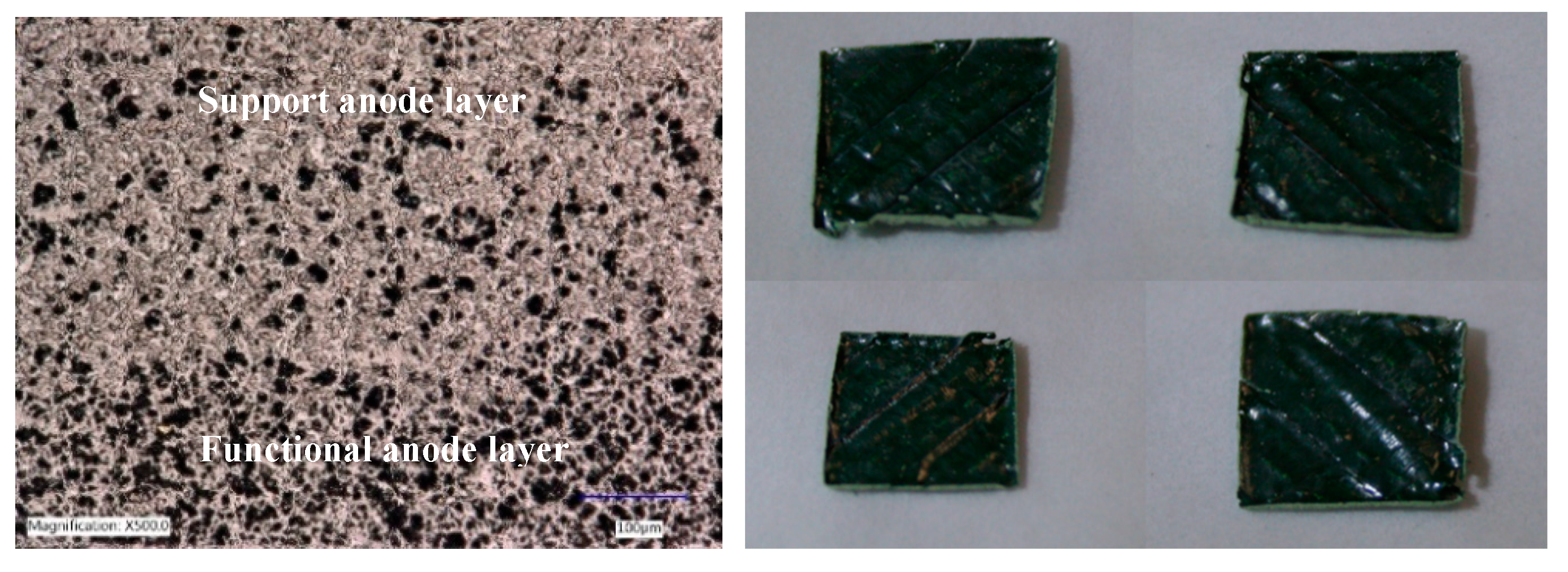

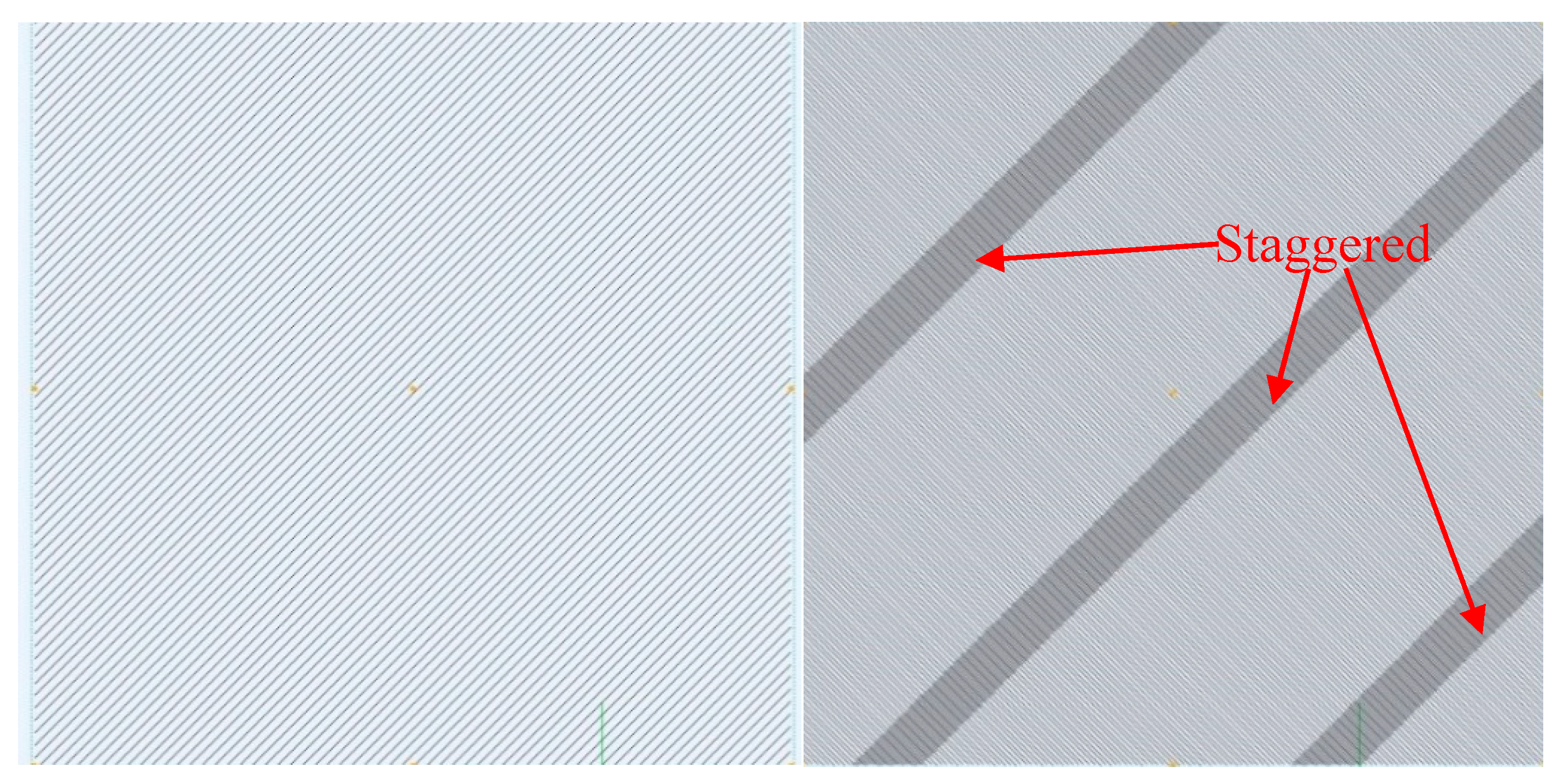

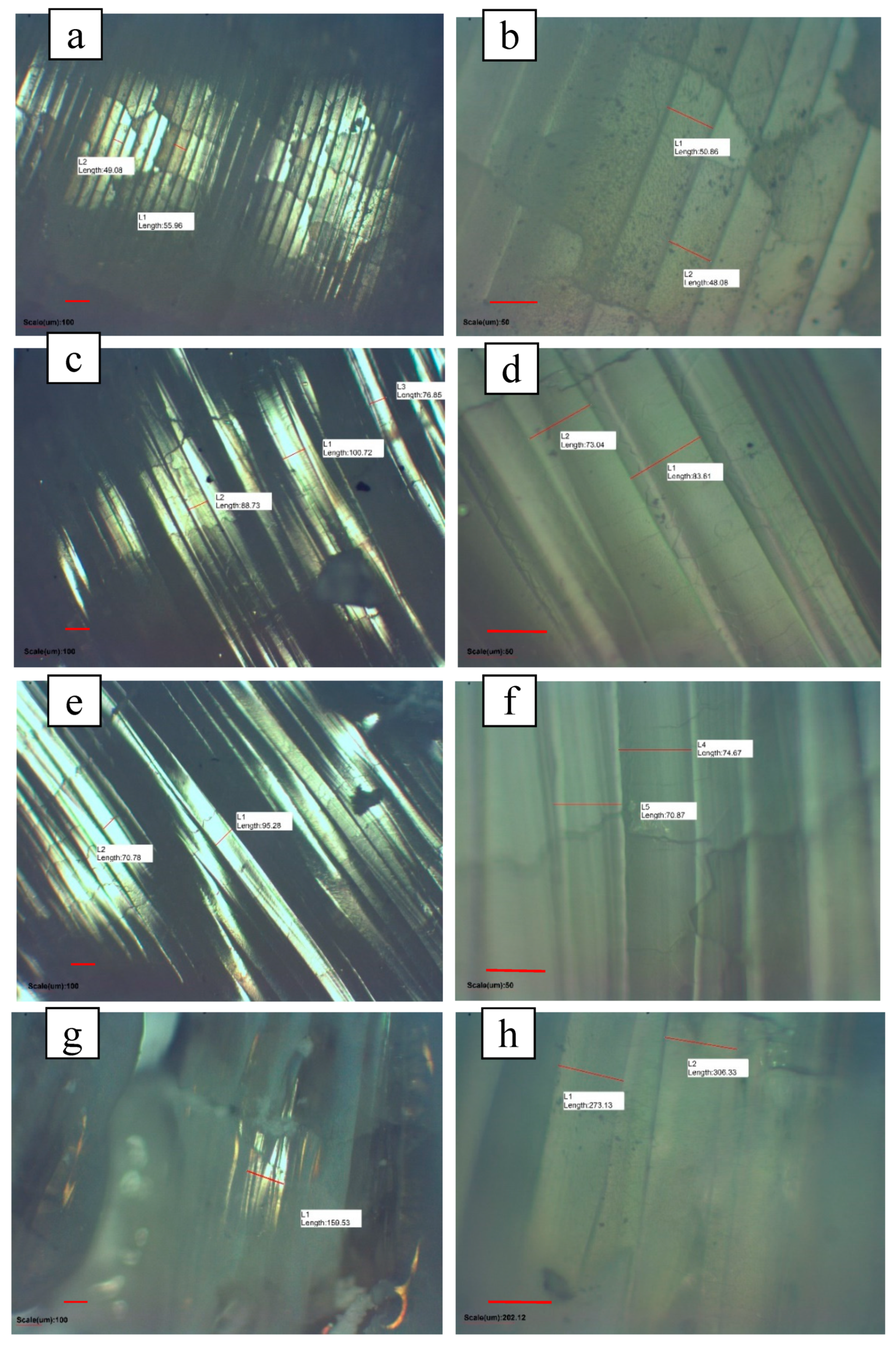

3.1. Fabrication of Multi-Layer and Multi-Material Structures

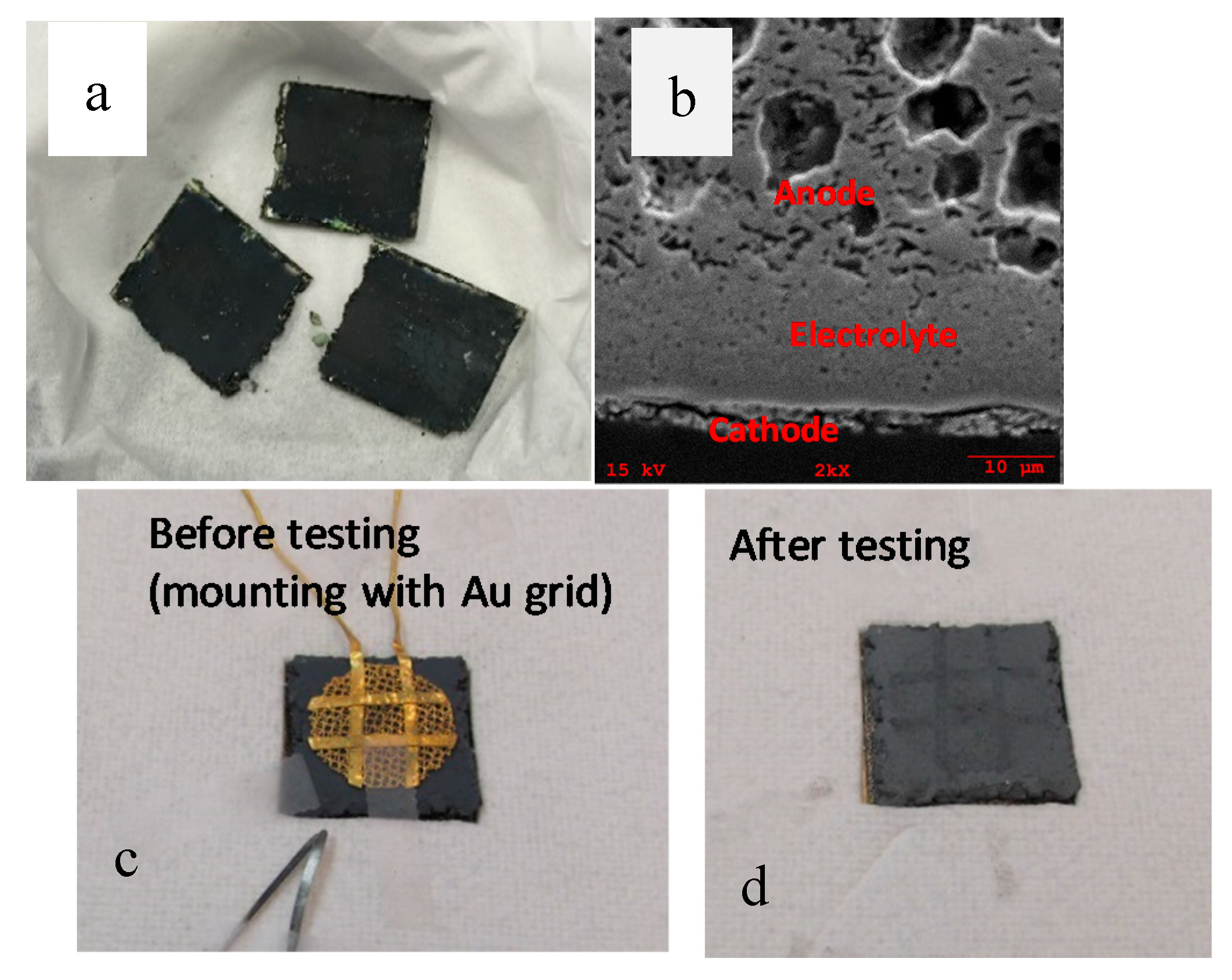

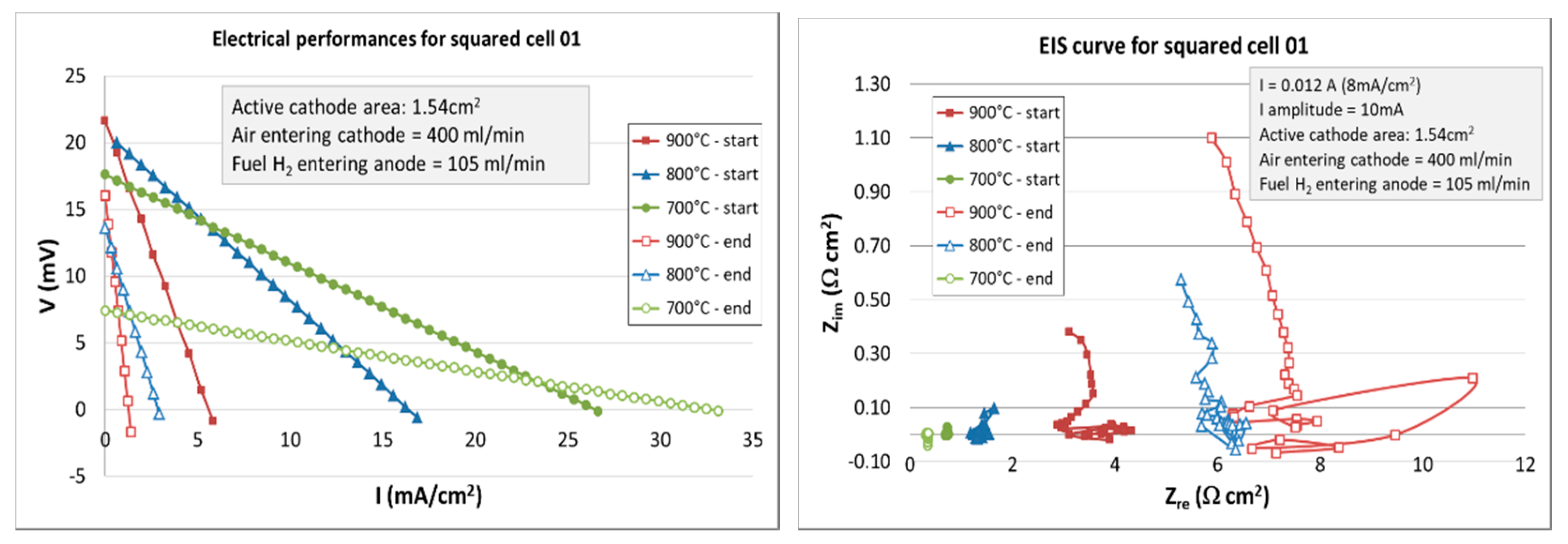

3.2. Three-Layered Cell Testing and Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kamath, C.; El-dasher, B.; Gallegos, G.F.; Gallegos, W.; King, W.E.; Sisto, A. Density of additively-manufactured, 316L SS parts using laser powder-bed fusion at powers up to 400 W. Int. J. Adv. Manuf. Technol. 2014, 74, 65–78. [Google Scholar] [CrossRef] [Green Version]

- Abe, F.; Osakada, K.; Shiomi, M.; Uematsu, K.; Matsumoto, M. The manufacturing of hard tools from metallic powders by selective laser melting. J. Mater. Process. Technol. 2001, 111, 210–213. [Google Scholar] [CrossRef]

- Bai, S.; Yang, L.; Liu, J. Manipulation of Microstructure in Laser Additive Manufacturing. Appl. Phys. A 2016, 122, 495. [Google Scholar] [CrossRef]

- Nie, B.; Huang, H.; Bai, S.; Liu, J. Femtosecond laser melting and resolidifying of high-temperature powder materials. Appl. Phys. A 2015, 118, 37–41. [Google Scholar] [CrossRef]

- Nie, B.; Yang, L.; Huang, H.; Bai, S.; Wan, P.; Liu, J. Femtosecond laser additive manufacturing of iron and tungsten parts. Appl. Phys. A 2015, 119, 1075–1080. [Google Scholar] [CrossRef]

- Fulcher, B. Effects of Laser Parameter Variation and Thermal Processing on Mechanical Properties and Microstructure of Laser-Melted Inconel 718. In Proceedings of the Additive Manufacturing with Powder Metallurgy Conference, Orlando, FL, USA, 19–20 May 2014; p. 146. [Google Scholar]

- Huang, W.L.; Zhu, Q.; Xie, Z. Gel-cast anode substrates for solid oxide fuel cells. J. Power Sour. 2006, 162, 464–468. [Google Scholar] [CrossRef]

- Sammes, N.M.; Du, Y.; Bove, R. Design and fabrication of a100W anode supported micro-tubular SOFC stack. J. Power Sour. 2005, 145, 428–434. [Google Scholar] [CrossRef]

- Lawlor, V. Review of the micro-tubular solid oxide fuel cell (PartII: Cell design issues and research activities). J. Power Sour. 2013, 240, 421–441. [Google Scholar] [CrossRef]

- Ding, J.; Liu, J.; Yuan, W.; Zhang, Y. Slip casting combined with colloidal spray coating in fabrication of tubular anode-supported solid oxide fuel cells. J Eur. Ceram. Soc. 2008, 28, 3113–3117. [Google Scholar] [CrossRef]

- Liu, J.; Bai, S. Femtosecond laser additive manufacturing of YSZ. Appl. Phys. A 2017, 123, 293. [Google Scholar] [CrossRef]

| Component | Material | Thickness | Porosity |

|---|---|---|---|

| Anode | Ni–YSZ | 0.3–0.6 mm | ~40% |

| Electrolyte | YSZ | 5–10 µm | <5% |

| Cathode | Conducting ceramic | 10–50 µm | ~30% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, S.; Liu, J. Femtosecond Laser Additive Manufacturing of Multi-Material Layered Structures. Appl. Sci. 2020, 10, 979. https://doi.org/10.3390/app10030979

Bai S, Liu J. Femtosecond Laser Additive Manufacturing of Multi-Material Layered Structures. Applied Sciences. 2020; 10(3):979. https://doi.org/10.3390/app10030979

Chicago/Turabian StyleBai, Shuang, and Jian Liu. 2020. "Femtosecond Laser Additive Manufacturing of Multi-Material Layered Structures" Applied Sciences 10, no. 3: 979. https://doi.org/10.3390/app10030979

APA StyleBai, S., & Liu, J. (2020). Femtosecond Laser Additive Manufacturing of Multi-Material Layered Structures. Applied Sciences, 10(3), 979. https://doi.org/10.3390/app10030979