Impact of Road Traffic Tendency in Europe on Fatigue Assessment of Bridges

Abstract

:1. Introduction

- the slow-lane traffic in Auxerre, assumed as reference traffic;

- the slow-lane traffic measured in May 2007 in Moerdijk (NL), on the A16 Breda–Rotterdam motorway, characterized by a high percentage of LHVs;

- the slow-lane traffic recorded in March 2003 in Igualada (ES), on the A2 Madrid–Barcelona motorway.

- the most consistent data in terms of traffic composition, inter-vehicle distances, inter-axles, weight, length and speed of each lorry were those recorded in Italy, France and Germany;

- the Spanish and Dutch data were excessively influenced by the peculiarities of the respective road networks, thus resulting not fully representative of European long-distance traffics; while,

- UK data resulted scarcely expressive of the continental situation.

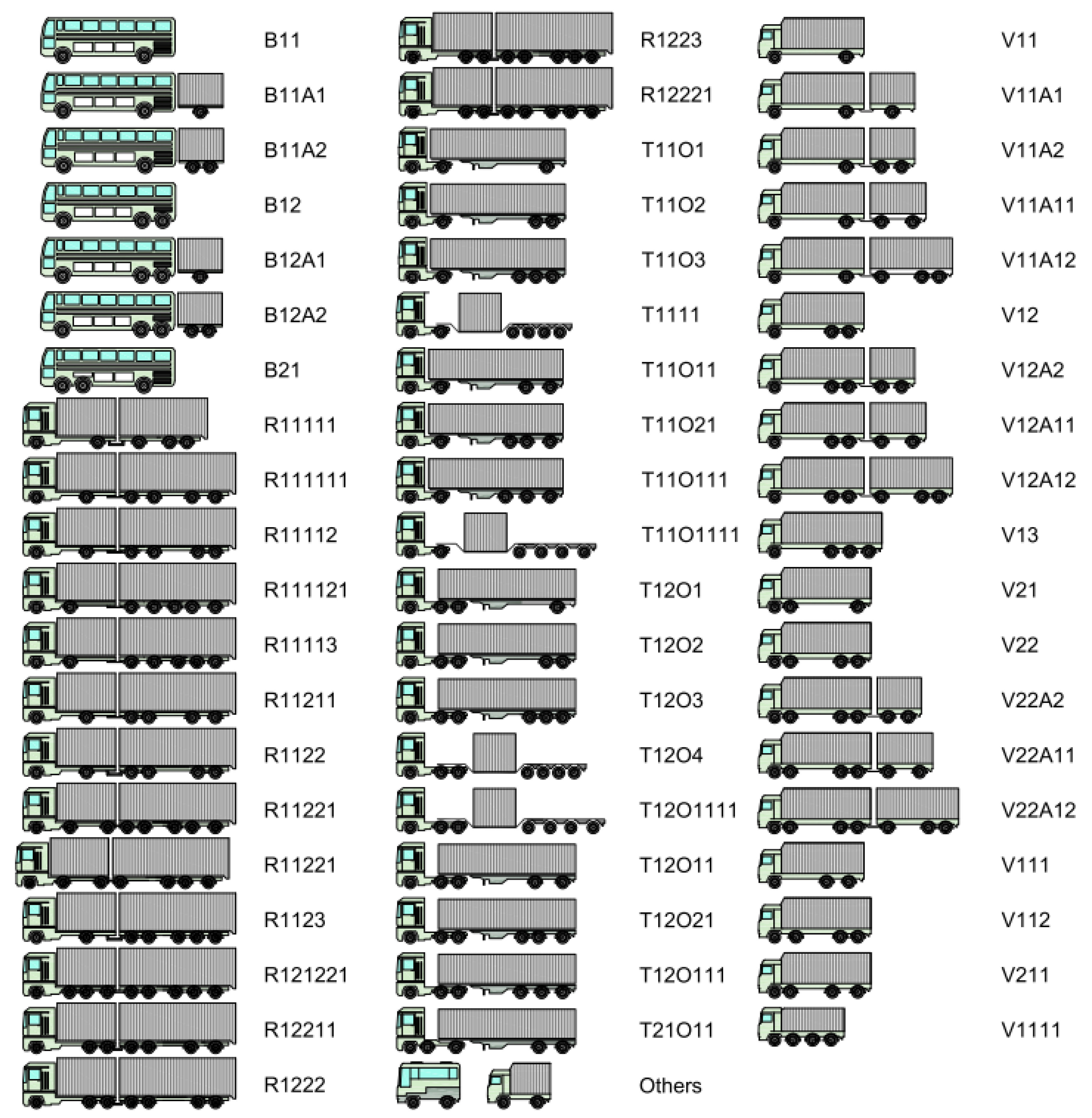

2. Real Traffic Measurements

- on the one hand, it gives information about actual traffic, so contributing to refine the assessment and to optimize the planning of the interventions;

2.1. European Traffic Measurements in Background Studies of Eurocodes

- HGV long-distance continental European traffic is satisfactorily homogeneous;

- over time, in long-distance European traffic:

- ○

- the percentage of articulated lorries tends to increase, opposite to a significant reduction of the percentage of lorries with trailers, which are commercially less profitable;

- ○

- due to more rational management of lorry fleets, the percentage of empty lorry trips descends, thus raising the mean vehicle loads;

- ○

- the percentage of single lorries, increasingly used on local routes declines;

- as expected, long-distance traffics are much heavier than local traffics;

- daily maxima of axle-loads and total weight of vehicles largely exceed the values legally admitted; to all appearances, the ceiling on overloads depends only on the mechanical strength of the vehicles;

- statistical distribution of the axle-load is generally unimodal, the mode being around 60 kN;

- statistical distribution of the total weight is often bimodal, with the first mode around 150 kN and the second mode around 400 kN;

- mean values of axle-load and total weight of heavy vehicles are strongly dependent on the traffic typology, i.e., on the road classification, and are very scattered;

- daily maxima values are much less sensitive to traffic typology: they are in the range 130–210 kN for single axles, in the range 240–340 kN for two axles in tandem, in the range 220–390 kN for three axles in tridem, and in the range 400–690 kN for the total lorry weight.

2.2. The Moerdijk (NL) Traffic

2.3. The Igualada (ES) Traffic

- 200 kN for single axle load;

- 340 kN for tandem axle load;

- 320 kN for tridem axle load;

- 580 kN for total lorry weigth.

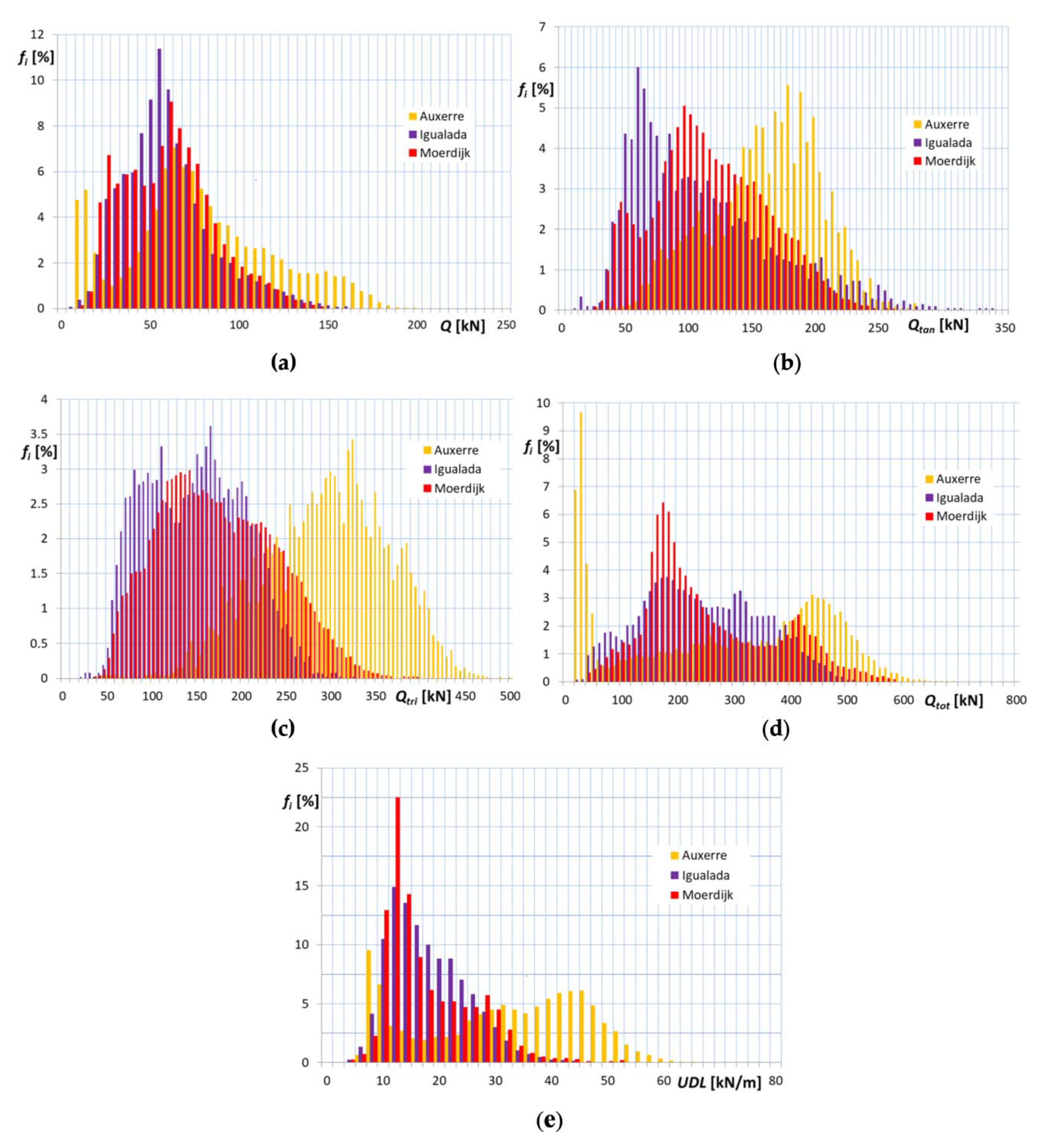

2.4. Comparison of Traffic Data

- distribution of axle loads is unimodal for Igualada traffic (mode around 55 kN); bimodal for Moerdijk traffic (first mode, not particularly manifest, around 45 kN; second mode around 60 kN); tetra-modal for Auxerre traffic (first mode around 15 kN, corresponding to light unloaded vehicles, second mode around 65 kN; third and fourth mode, not particularly marked, around 110 kN and 150 kN, respectively;

- distributions of axle loads of Igualada and Moerdijk traffics are characterized by similar upper tails, while that concerning the Auxerre traffic is much more significant;

- distributions of tandem axle loads are always bimodal: for Igualada traffic, the first mode is around 65 kN, the second mode, not particularly marked, is around 210 kN; for Moerdijk traffic, the two modes are around 45 kN and 100 kN, respectively; for Auxerre traffic, the first mode is around 110 kN, the second mode is around 180 kN;

- distributions of tandem axle loads of Igualada and Auxerre traffics are characterized by similar upper tails, well pronounced even beyond 250 kN; while that concerning the Moerdijk traffic is much less evident;

- except for Igualada traffic, distributions of tridem-axle loads are generally unimodal: the mode of Moerdijk traffic is around 150 kN; the mode of Auxerre traffic is around 330 kN;

- distribution of tridem-axle loads of Igualada traffic is tri-modal: the first mode is around 105 kN, the second and third mode around 170 kN and 210 kN, respectively;

- distributions of tridem-axle loads are characterized by clearly different upper tails: Auxerre traffic exhibits the most relevant one, followed by Moerdijk traffic and then by the Igualada traffic, characterized by the lowest;

- distributions of total weights for Igualada and Moerdijk traffic are bimodal: for Igualada traffic, the first mode is around 190 kN, the second mode, not particularly marked, is around 320 kN; for Moerdijk traffic, the first mode is again around 190 kN, the second mode is around 410 kN;

- distributions of total weights for Auxerre traffic is tri-modal: the first mode is around 30 kN, corresponding to light unloaded vehicles, the second mode, not particularly evident, is around 250 kN, the third mode is around 440 kN;

- distributions of total weights of Moerdijk and Auxerre traffics are characterized by similar upper tails, even if the one of Moerdijk is much more extended due to the presence of a small percentage of weighty LHVs, while that regarding Igualada is less pronounced; finally,

- distribution of is unimodal for Igualada traffic, with the mode around 12 kN/m; bimodal for Moerdijk traffic, with the first mode again around 12 kN/m and a second mode, marked weekly, around 28 kN/m; tri-modal for Auxerre traffic, with the first and the second mode, not particularly evident, around 12 kN/m and 32 kN/m, respectively, and the third mode around 45 kN/m;

- distributions of for Igualada and Moerdijk traffics are very similar, the upper tail being more pronounced in the case of Moerdijk traffic; on the opposite, the distribution of of Auxerre traffic is manifestly more heavy, with the upper tail extending well over 60 kN/m;

- total weight of lorry vehicles LHVs could attain very high value, but usually this level is associated with axle loads not beyond the legal limit;

- as clearly perceptible comparing distributions, Moerdijk traffic appears, in general, less demanding than Auxerre traffic, despite the fact that occasionally axle loads can be higher;

- excluding tandem-axle load distributions, which appear not dissimilar, Igualada traffic looks, in general, lighter than Auxerre traffic;

- apart from tandem-axle load distributions, Moerdijk traffic results, in general, moderately heavier than Igualada traffic.

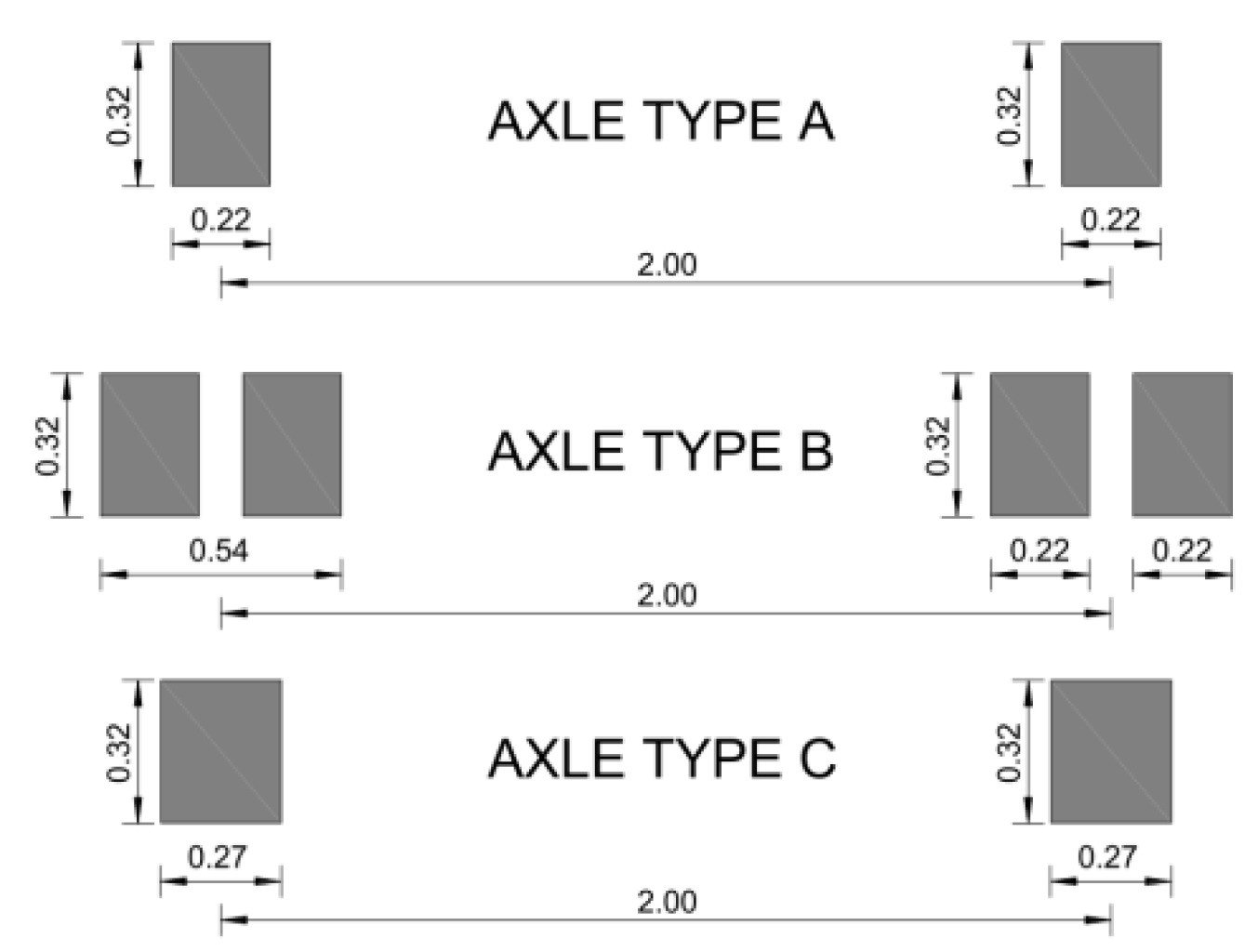

3. Fatigue Load Models

Fatigue Load Models LM2 and LM4 of Eurocode EN1991-2

- LM2 was calibrated referring to a kind of “frequent” value , representing the maximum stress range relevant for unlimited fatigue life assessment. This “frequent” value was calculated according to two alternative definitions as:

- ○

- the stress range exceeded about times during the notional design life of the structure; or, alternatively,

- ○

- the stress range corresponding to 99% of the total fatigue damage, calculated considering a curve with constant slope , i.e.,which means that damage produced by stress ranges is practically negligible;either way obtaining comparable values.

- the maximum axle load is 190 kN in LM2 and 270 kN in LM4; while the legal limit is 120 kN;

- the maximum tandem axle load is 280 kN in LM2 and 240 kN in LM4, while the legal limit is 200 kN;

- the maximum tridem axle load is 360 kN in LM2 and 270 kN in LM4, while the legal limit is 240 kN;

- the maximum vehicle weight is 630 kN in LM2 and 490 kN, while the legal limit is 440 kN.

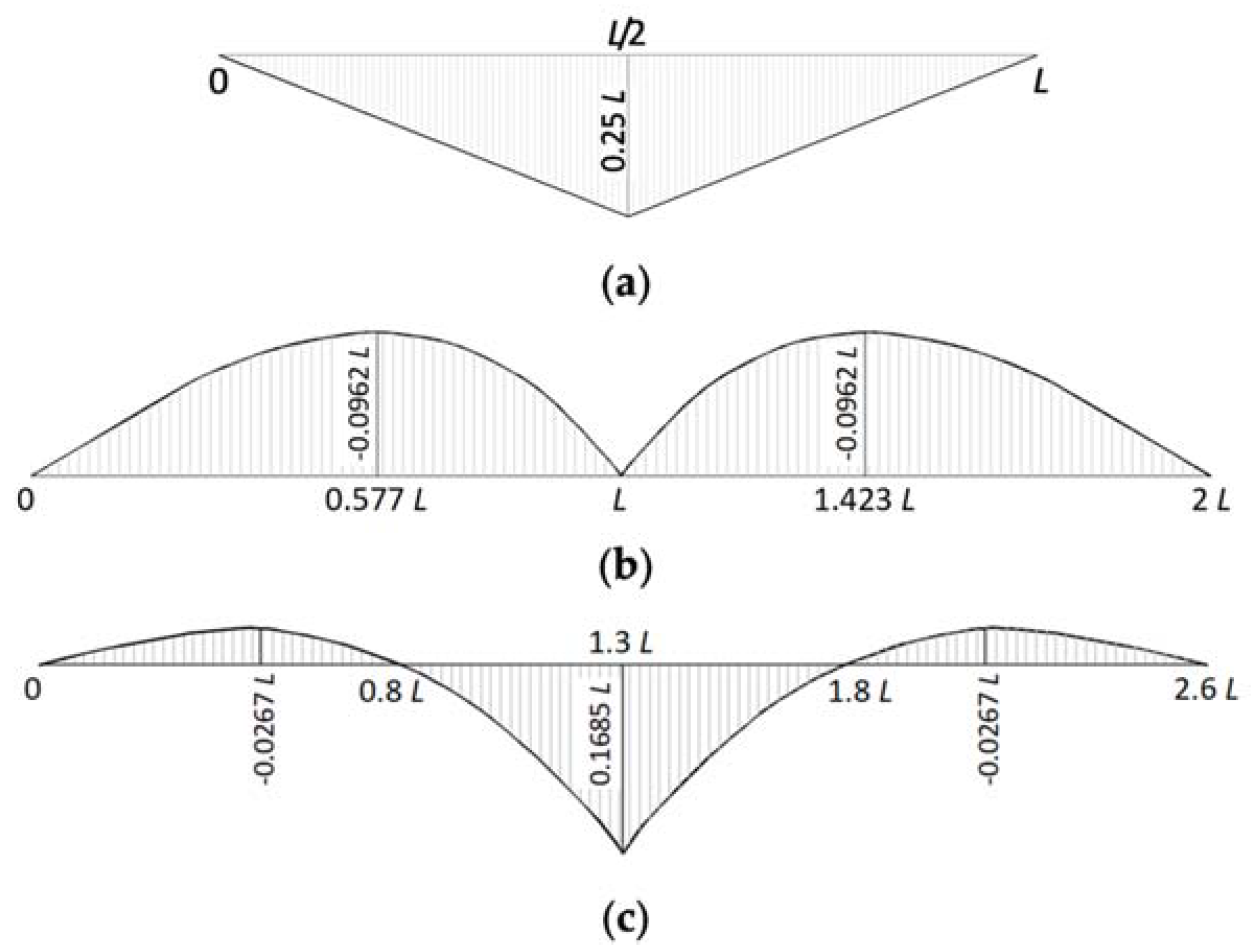

4. Case Studies

- case study no. 1: bending moment at midspan of a simple supported beam (Figure 6a);

- case study no. 2: hogging moment at the intermediate support of a two-span continuous beam having constant bending stiffness (Figure 6b);

- case study no. 3: bending moment at midspan of a three-span continuous beams with span ratios 0.8:1.0:0.8, having constant bending stiffness (Figure 6c).

4.1. Assessment of Fatigue Effects

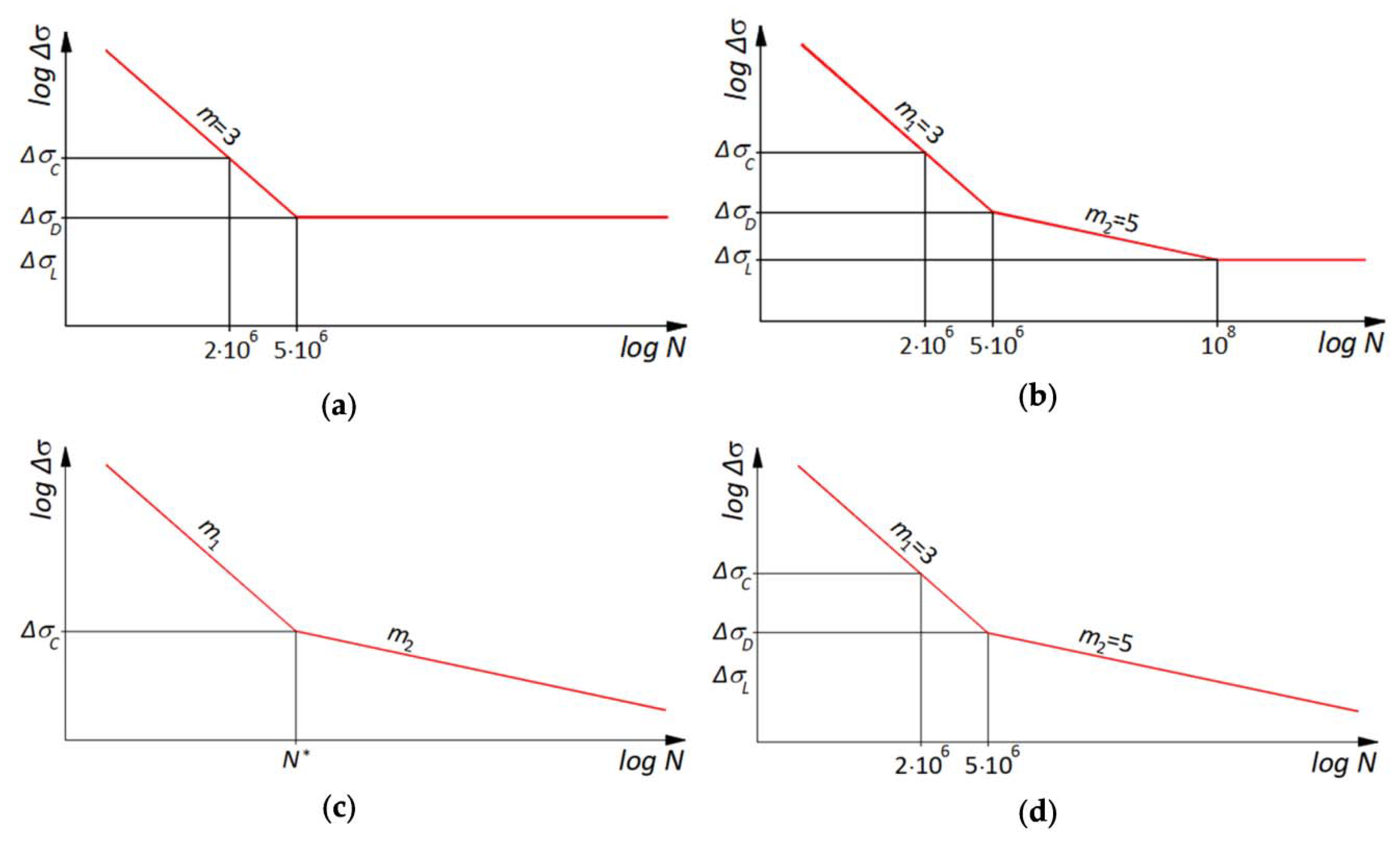

- Subcase 1, which deals with details and materials endowed with constant amplitude fatigue limit; like most of the structural steel details (EN1993-1-9 [23]), characterized by fatigue resistance bilinear or trilinear characteristic curves;

- Subcase 2, which deals with details and materials characterized by bilinear characteristic curves, lacking constant amplitude fatigue limit.

- when the assessment refers to unlimited fatigue life, a bilinear curve is adopted for steel details. The slope of the inclined branch is commonly assumed [23], but only the horizontal branch, whose ordinate is the constant amplitude fatigue limit , corresponding to cycles to failure, is significant for the verification (Figure 7a);

- when, instead, the assessment requires calculation of fatigue damage, the trilinear curve is adopted, characterized by two inclined linear branches; for steel details, the slopes of the branches are , for , and , for , where , corresponding to cycles to failure, is the so-called cut-off limit, given by the ordinate of the horizontal branch (Figure 7b).

4.2. Equivalent Fatigue Categories

- when detail category is the fatigue strength at cycles:

- ○

- the abscissa of the knee of the curve is located at cycles;

- ○

- and ;

thus is the solution of the equation: - whereas, when the detail category corresponds to the fatigue strength at cycles to failure, like in case of pre-stressing or reinforcing steel details:

- ○

- the abscissa of the knee of the curve is located at ;

therefore, is the solution of the equation:

- ; ;

- the detail category is the fatigue strength at cycles;

- the abscissas of the knees of the curve are at cycles and cycles, respectively;

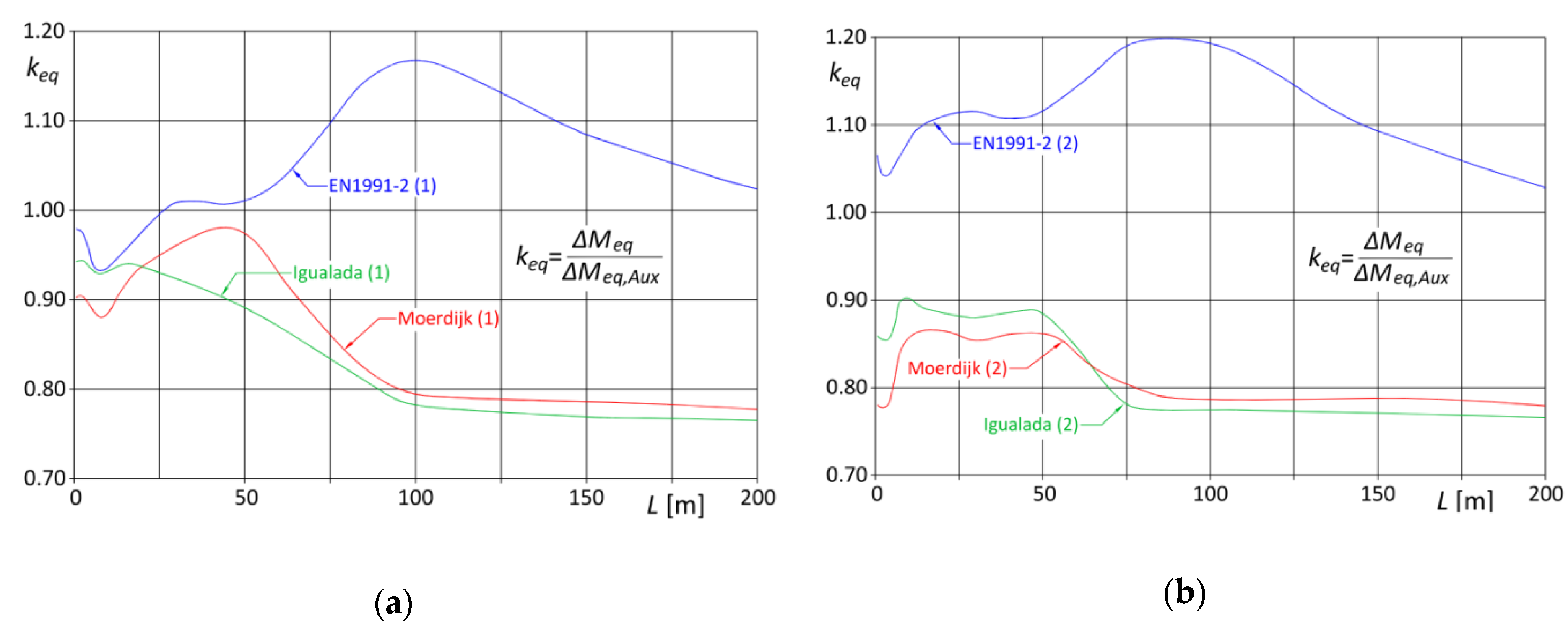

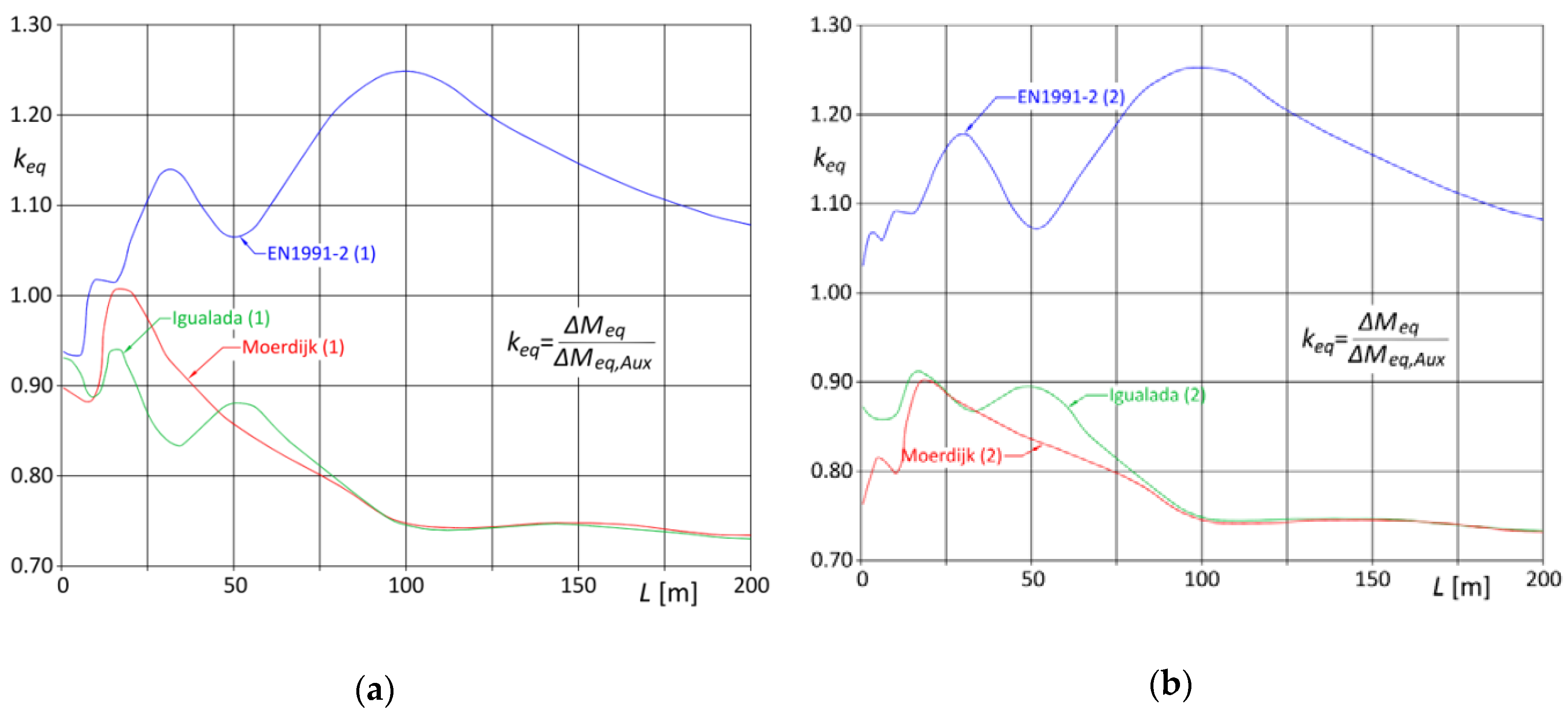

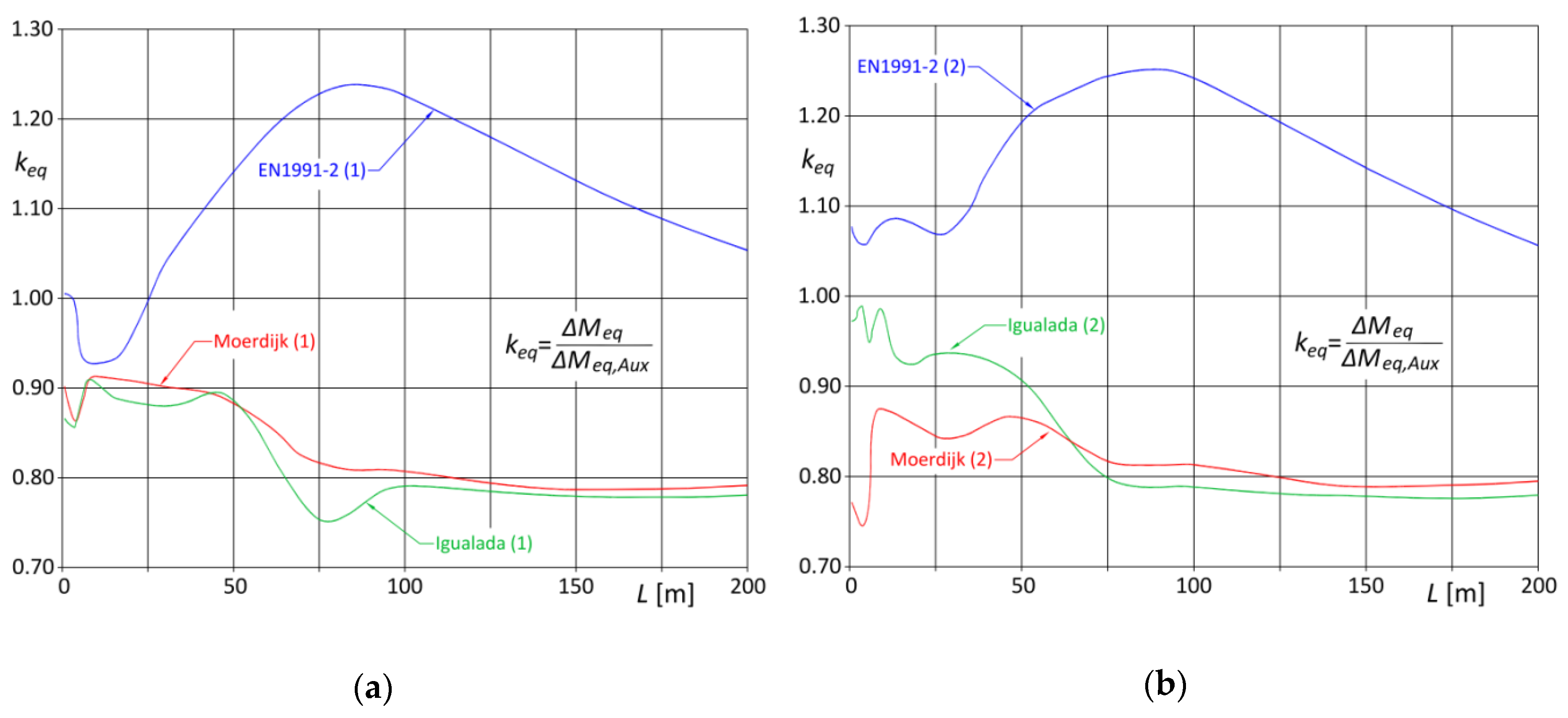

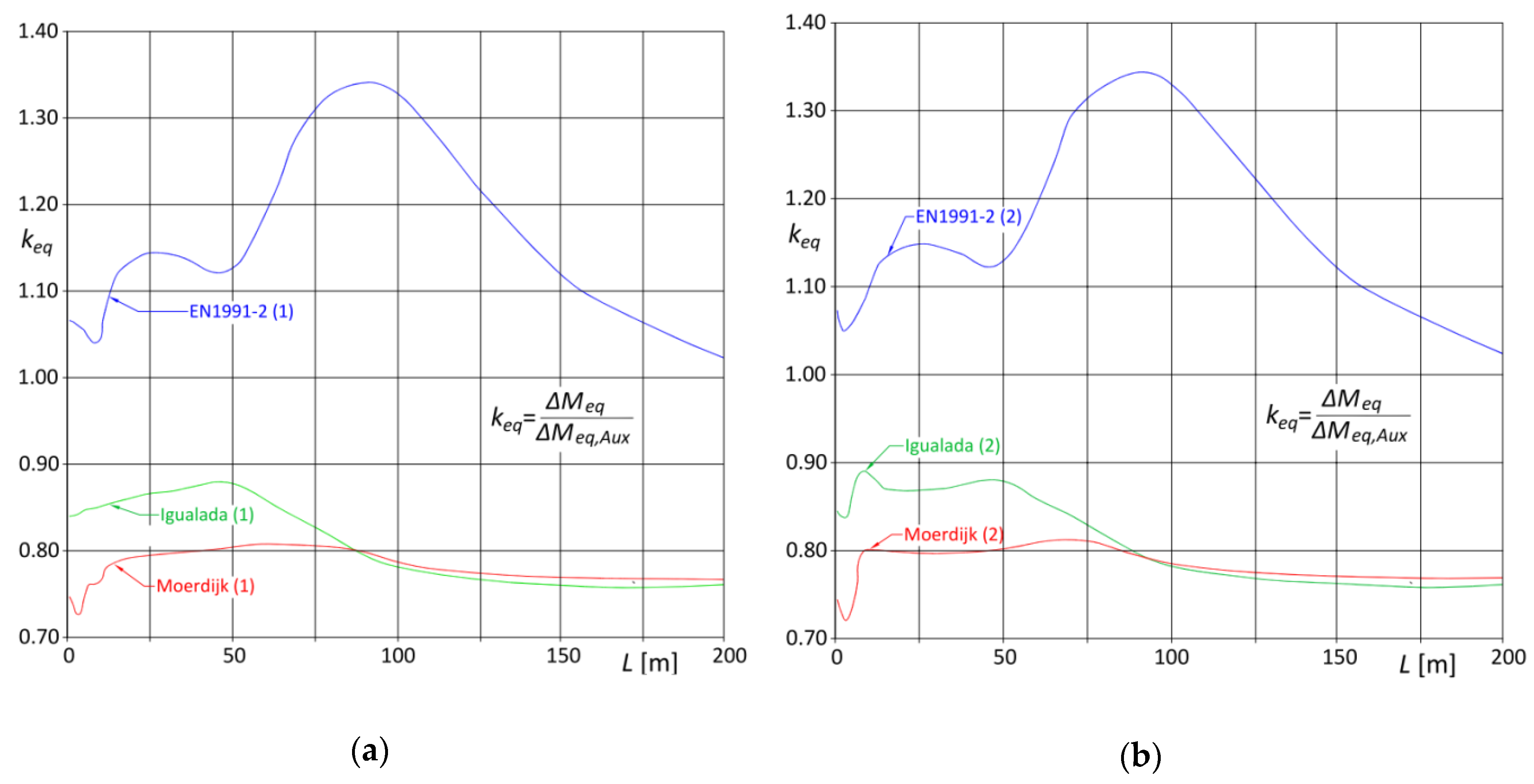

- if the inequality holds for a real traffic, it implies that the real traffic is less demanding than Auxerre traffic; therefore, considering the Auxerre traffic instead of the actual traffic would lead to results on the safe side; on the contrary,

- if the inequality holds for a fatigue load model of EN1991-2 [1], it implies that the load model is less demanding than Auxerre traffic: in this case, the load model underestimates the effects of the Auxerre traffic.

4.3. Outcomes of the Analysis and Discussion

- if curves are as per Figure 7c,d, i.e., details do not manifest constant amplitude fatigue limit (subcase 2), fatigue load model LM4 leads in all considered case studies to estimations of the fatigue life on the safe side;

- on the contrary, if curves are as per subcase 1 (Figure 7c,d), i.e., details are characterized by fatigue limit, fatigue load models of EN1991-2 could result in being slightly on the unsafe side in comparison with Auxerre traffic, when and high flow rate is assumed, i.e., the total lorry flow is lorries. In any case the error is generally smaller than 8%, except in case study no. 2 for (Figure 9a), when it attains about 15%.But, in the latter circumstance, besides observing that elements characterized by are rather uncommon, it should be highlighted that the differences are emphasized by the particular shape of the influence line considered in case study no. 2 (Figure 6b): in fact, when the typical inter-axle distances of tandem axles are close to the distance between the two absolute minima of that influence line, .In the other cases, the discrepancies can be explained considering that, in the particular context of and high flow rate, the assessment is governed by the set of “frequent” lorries included in fatigue load model LM2. In fact, in such a condition, the unavoidable differences that exist between standardized lorries and actual lorries, in terms of axle loads; vehicle weight; inter-axle distances of tandem and tridem axles, clearly maximize their effects.

- Fatigue load models are particularly on the safe side when is around 100 m.In that area, the fatigue assessment is certainly governed by the set of “equivalent” lorries given in LM4, but also interactions between consecutive vehicles traveling simultaneously the lane can be significant. The hypothesis that two consecutive lorries are both belonging to the standardized set of LM4 is thus evidently on the safe side, because the probability that the weights of consecutive lorries are regularly close to the equivalent values, which are in some cases outside the legal limits, is small.

- In any case, fatigue load models LM2 and LM4 of EN1991-2 generally reproduce very satisfactorily the fatigue effects induced by Auxerre traffic, so confirming the validity of pre-normative studies and the substantially accuracy of Eurocode fatigue models.

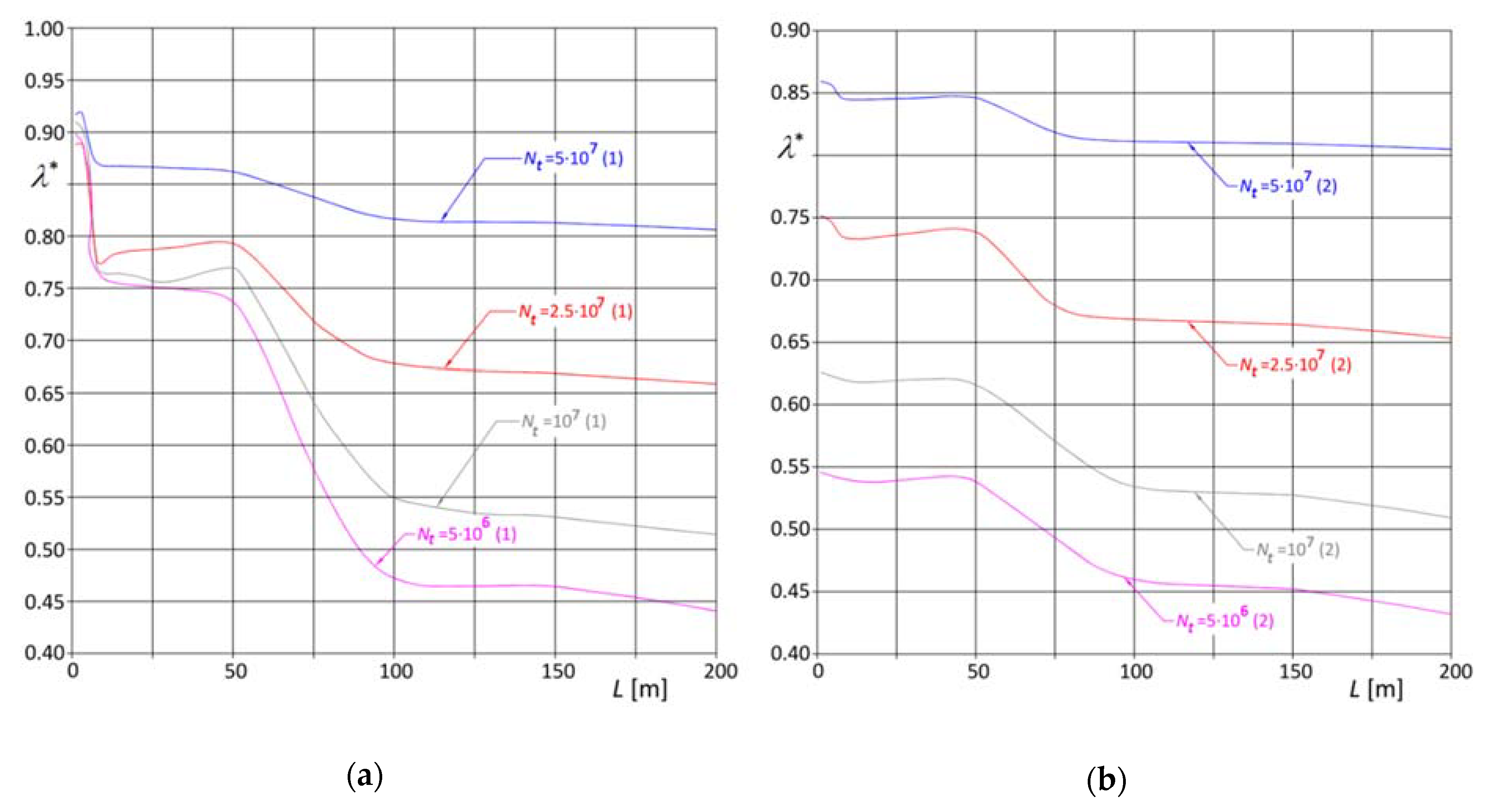

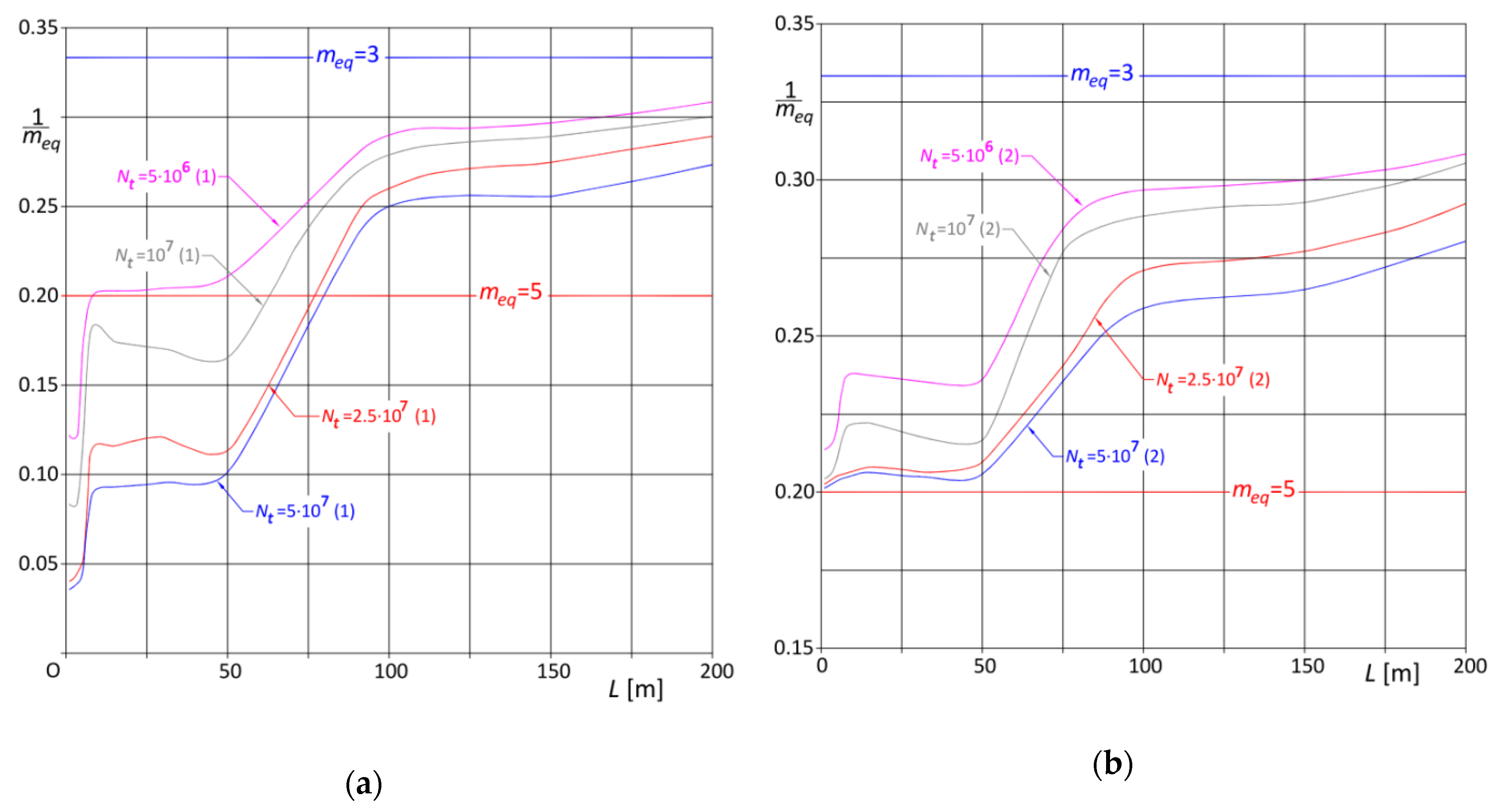

- As the total lorry flow decreases, increases and fatigue load models EN1991-2 tend to be constantly on the safe side (Figure 11).

- The curves associated with curves as per subcase 1 are generally below curves associated with curves as per subcase 2, but the differences become practically insignificant when is high, since for large value of the fatigue assessments depend on fatigue damage.

- Referring to Moerdijk and Igualada traffics and high global flow, the curves associated with subcase 1 are over the curves associated with subcase 2. In fact, contrary to what happens considering Auxerre traffic, in that field the minimum detail categories (Equation (8)) required by Moerdijk and Igualada traffics basically depend on the equivalent stress ranges , rather than on .

- In comparison with Igualada fatigue effects, those evaluated using EN1991-2 fatigue load models are always sensibly on the safe side.

- Moerdijk traffic is constantly less demanding than the Auxerre traffic, except for high global traffic flow in case study 2, subcase 1 (Figure 9a) when , when it results in ;Nonetheless, for , factors associated to Moerdijk traffic substantially results ; moreover tends to slightly reduce as the total flow decreases.

- Considering high flow rate and curves as per subcase 1:

- Considering low global flow, if , Moerdijk traffic composition is always less damaging than the Igualada traffic composition (Figure 11a,b).

- It can be remarked that, for a high value of , Moerdijk traffic looks generally more demanding than Igualada traffic in all examined cases.

- The differences between Moerdijk and Igualada traffics just pointed out can be rationally explained recalling the previous discussion about axle loads and total lorry weight distributions (see Section 2.4).

- Since curves pertaining to the fatigue load models LM2 and LM4 of EN1991-2 are constantly above the curves pertaining to Moerdijk and Igualada traffics, LM2 and LM4 always cover the fatigue effects induced by the non-Auxerre traffics.

5. Damage-Equivalence Factors

- considers the effects of the shape and of the basic length of the influence line on the stress history. In fact, since Equation (17) disregards secondary cycles, must be modified to duly include the increased fatigue damage caused by secondary cycles, if any. Clearly, depends on the static scheme, on the reference length, on the material and on the detail and it requires specific calibration.The scrutiny of this factor is out of the scope of the present work, so it will not be discussed further.

- considers the effects of the actual traffic in comparison with the Auxerre traffic, in terms of annual flow and traffic composition. According to the approach adopted in EN1993-2 [22], can be expressed by:where is a suitable equivalent slope of the curve, is the equivalent lorry weight of the Auxerre traffic; is the annual lorry flow of the Auxerre traffic, which, recalling Table 3 and considering around working days per year, corresponds to around lorries per year; is the annual lorry flow of the traffic considered and is the annual flow of lorries weighing in the traffic considered.In Equation (18), the equivalent lorry weight of the actual traffic can be easily recognized:

- considers the effects of the actual design working life, , in comparison with the reference design working life adopted for bridges, which is around 100 years:Again, in the Eurocodes a fixed value of is assumed.

- Finally, considers the effect of multilane traffic, also accounting for lorries simultaneously traveling the bridge.The evaluation of is a very complex issue, which is not solved in Eurocodes, where undoubtedly simultaneity is disregarded, and which will not be deepened here. Anyhow, for a more exhaustive discussion of the problem it is possible to refer to [35].

Damage-Equivalence Factors for Total Lorry Flow

- when bilinear curves as per Figure 7d (subcase 2) are considered:

- ○

- it is , if fatigue damage is mostly caused by cycles with stress ranges satisfying the inequality ;

- ○

- or , if the fatigue damage is mainly due to cycles for which ;

- when bilinear or trilinear curves as per Figure 7a,b (subcase 1) are considered, can result in being, even considerably, bigger than five if the number of cycles is so high that fatigue verification is governed by (unlimited fatigue life).

- as expected, increases as the traffic flow increases;

- independently on the shape of the curve, decreases as the span increases;

- for details characterized by constant amplitude fatigue limit, subcase 1, Figure 14a:

- ○

- in the interval , it results for lorries, for lorries, for lorries, and finally for lorries;

- ○

- when , it results for lorries, for lorries and for higher total flows;

- ○

- for , the curves approach these pertaining to details lacking a constant amplitude fatigue limit, which are discussed below.

- for details lacking a constant amplitude fatigue limit, subcase 2, Figure 14b:

- ○

- when , if lorries this results in , but reduces for smaller flows. More precisely, if lorries, it is for and for , while, if lorries, it is for and for ;

- ○

- when , this results in if lorries; if ; if lorries and, finally, if lorries.

6. Conclusions

- Fatigue load models LM2 and LM4 adequately reproduce the Auxerre traffic effect, generally resulting on the safe side; but, in case of details characterized by constant amplitude fatigue limit, very small spans and intense lorry flows, fatigue load models LM2, which governs fatigue assessment, can lead to results slightly on the unsafe side.

- In the span range , where simultaneity effects are important, if consecutive lorries are hypothesized belonging both to the standardized set of fatigue load model LM4, the adoption of LM4 is very much on the safe side; in fact, the probability that weights of consecutive lorries are close to the equivalent values is not important; moreover in that range fatigue assessments are often not crucial. However, if necessary, it may be opportune to use real traffic data or artificially generated traffic.

- Auxerre traffic and, consequently, EN1991-2 load models cover not only Igualada traffic, but also LHV effects, as deduced from the Moerdijk traffic. Since the differences are particularly marked, this conclusion appears sound enough, even if it could require further investigations, taking into account other LHVs traffics.

- Axle load distribution of Moerdijk traffic is not particularly severe, probably because the LHVs are better controlled than HGVs, thus explaining why in some cases Igualada traffic is more aggressive than Moerdijk traffic.

- The fatigue load models for road bridges provided in the Eurocode EN1991-2 do not require major updates.

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Symbols and Basic Nomenclature | |

| partial factor on fatigue actions; | |

| partial factor on fatigue resistance; | |

| basic stress range for damage equivalent factor method; | |

| fatigue category of the detail; | |

| detail category for which ; | |

| minimum detail category satisfying fatigue verifications; | |

| minimum detail category required by the Auxerre traffic; | |

| constant amplitude fatigue limit; | |

| detail category for which the Palmgren–Miner law provides unit fatigue damage ; | |

| stress range caused by fatigue load model LM3 of EN1991-2; | |

| cut-off limit; | |

| stress range in a cycle; | |

| maximum stress range relevant for fatigue assessment; | |

| additional amplification factor for fatigue verifications; | |

| damage-equivalence factor; | |

| single damage-equivalence factor ; | |

| damage-equivalence factor considering the effects of shape and length of the influence line; | |

| damage-equivalence factor considering the effects of the actual traffic in comparison with the Auxerre traffic; | |

| damage-equivalence factor considering the effects of the actual design working life; | |

| damage-equivalence factor considering the effects of multilane traffic; | |

| damage-equivalence factors; | |

| fatigue damage; | |

| reference fatigue damage caused by Auxerre traffic; | |

| fatigue damage caused by the actual traffic; | |

| equivalence factor ; | |

| , , | slopes of inclined branches of curves; |

| equivalent slope of the curve; | |

| abscissa of the knee point of a curve with two inclined branches; | |

| annual lorry flow of the Auxerre traffic; | |

| number of cycles in the stress spectrum at stress range; | |

| number of cycles to failure at ; | |

| annual flow of lorries weighing ; | |

| annual lorry flow; | |

| total lorry flow of the Auxerre traffic; | |

| total lorry flow; | |

| Q | single-axle load; |

| equivalent lorry weight; | |

| equivalent lorry weight of the Auxerre traffic ; | |

| tandem-axle load; | |

| total weights of lorry; | |

| tridem-axle load; | |

| curve | diagram giving the fatigue resistance as a function of number of cycles to failure in a constant amplitude fatigue test; |

| characteristic curve | characteristic curve: curve: curve corresponding to 5% probability of failure; : actual design working life; |

| equivalent uniformly distributed load of lorry; | |

Appendix B: Summary of the Procedure to Derive Equivalent Fatigue Categories

| The procedure to derive equivalent fatigue categories consists in the following steps: | |

| 1 | Assume an appropriate fatigue load model, represented by an appropriate conventional fatigue model or by a real traffic or by an artificially generated traffic; |

| 2 | Identify the number of occurrences of the given load model in the design working life of the bridge; |

| 3 | Identify the fatigue sensitive detail; |

| 4 | Identify the relevant shape of the curve, for example, considering if constant amplitude fatigue limit exists or not; |

| 5 | Identify the relevant influence surface for the fatigue effect considered; |

| 6 | Evaluate the stress history induced in the considered detail by the fatigue load model traveling the influence surface; |

| 7 | Determine, by means of a suitable cycle counting method (for example, the reservoir or the rainflow method), the stress spectrum; |

| 8 | Adopt the proper values of partial factors and ; |

| 9 | Magnify the stress spectrum multiplying each stress ranges by and ; |

| 10 | If fatigue limit does not exists go to step 15 |

| 11 | From the magnified stress spectrum (step 9), evaluate ; |

| 12 | ; |

| 13 | Determine from ; |

| 14 | Choose an “arbitrary” fatigue category of the detail; |

| 15 | Using the Palmgren–Miner formula, evaluate the fatigue damage induced by the magnified stress spectrum; |

| 16 | If change the fatigue category of the detail and go to step 14; |

| 17 | Set ; |

| 18 | If fatigue limit exists go to step 21 |

| 19 | Set |

| 20 | End the procedure; |

| 21 | Set ; |

| 22 | End the procedure. |

References

- EN1991-2 Eurocode 1: Actions on Structures—Part 2: Traffic Loads on Bridges; CEN: Brussels, Belgium, 2003.

- Bruls, A.; Croce, P.; Sanpaolesi, L.; Sedlacek, G. ENV 1991—Part 3: Traffic loads on bridges. Calibration of road load models for road bridges. In In Proceedings of the IABSE Colloquium Basis of Design and Actions on Structures; Background and Application of Eurocode 1, Delft, NL, 1996; IABSE Report, 74. IABSE: Zurich, Switzerland, 1996; pp. 439–454. [Google Scholar] [CrossRef]

- Croce, P.; Salvatore, W. Stochastic model for multilane traffic effects on bridges. J. Bridge Eng. 2001, 6, 136–143. [Google Scholar] [CrossRef]

- Jacob, B.; O’Brien, E.J.; Jehaes, S. (Eds.) Weigh-In-Motion of Road Vehicles; Final Report of COST 323 Action (WIM-LOAD); LCPC: Paris, France, 2002. [Google Scholar]

- O’Connor, A.J.; Jacob, B.; O’Brien, E.J.; Prat, M. Effects of traffic loads on road bridges—Preliminary studies for the re-assessment of the Eurocode 1, Part 3. In Proceedings of the 2nd European Conference on WIM of road vehicles, Lisbon, Portugal, 14–16 September 1998; pp. 231–242. [Google Scholar]

- Sedlacek, G.; Merzencih, G.; Paschen, M.; Bruls, A.; Sanapolesi, L.; Croce, P.; Calgaro, J.A.; Prat, M.; Jacob, B.; Leendertz, M.; et al. Background Document to EN1991—Part 2—Traffic Loads for Road Bridges and Consequences for the Design; JRC Scientific and Technical Reports; JRC: Ispra, Italy, 2008. [Google Scholar]

- Calgaro, J.A.; Tschumi, M.; Gulvanessian, H. Designer’s Guide to Eurocode 1: Actions on Bridges—EN 1991-2, EN 1991-1-1, -1-3 to -1-7 and EN 1990 ANNEX A2; Thomas Telford: London, UK, 2010. [Google Scholar]

- Directive 96/53/EC of 25 July 1996 Laying Down for Certain Road Vehicles Circulating Within the Community the Maximum Authorized Dimensions in National and International Traffic and the Maximum Authorized Weights in International Traffic, O.J. of European Union; European Union: Brussels, Belgium, 1996; Volume 235, pp. 59–75.

- OECD. Moving Freight with Better Trucks: Improving Safety, Productivity and Sustainability; OECD Publishing: Paris, France, 2011. [Google Scholar] [CrossRef]

- Aarts, L.; Honer, M.; Davydenko, I.; Quak, H.; de Bes van Staalduinen, J.; Verweij, K. Longer and Heavier Vehicles in The Netherlands: Facts, Figures and Experiences in the Period 1995–2010; Rijkswaterstaat Report; Directorate General for Public Works and Water Management: Utrecht, The Netherlands, 2010. [Google Scholar]

- Freundt, U.; Böning, S.; Kaschner, R. Road bridges between actual and future heavy load traffic—Road traffic loads according to DIN EN1991-2/NA. Beton Stahlbetonbau 2011, 11, 736–746. [Google Scholar] [CrossRef]

- Rymsza, J. Proposal to change the design load in the Eurocode 1 based on loads from vehicles with a mass of 60 tonnes. Transp. Res. Procedia 2016, 14, 4020–4029. [Google Scholar] [CrossRef] [Green Version]

- Lydon, M.; Taylor, S.E.; Robinson, D.; Mufti, A.; O’Brien, E.J. Recent developments in bridge weigh in motion (B-WIM). J. Civ. Struct. Health Monit. 2016, 6, 69–81. [Google Scholar] [CrossRef] [Green Version]

- Hellebrandt, L.; Blom, C.B.M.; Steenbergen, R.D.J.M. Probabilistic traffic load model for shortspan city bridges. Heron 2014, 59, 147–168. [Google Scholar]

- O’Brien, E.J.; Enright, B.; Getachew, A. Importance of the tail in truck weight modeling for bridge assessment. J. Bridge Eng. 2010, 15, 210–213. [Google Scholar] [CrossRef]

- O’Brien, E.J.; Enright, B. Modeling same-direction two-lane traffic for bridge loading. Struct. Saf. 2011, 33, 296–304. [Google Scholar] [CrossRef]

- Mohammed, O.; Gonzales, A.; Cantero, D. Dynamic impact of heavy long vehicles with equally spaced axles on short span highway bridges. Balt. J. Road Bridge Eng. 2018, 13, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Jagelčáka, J.; Kiktováa, M.; Frančáka, M.; Marienka, P. The possibilities of using longer and heavier vehicle combinations in Slovakia. Transp. Res. Procedia 2019, 40, 271–278. [Google Scholar] [CrossRef]

- Chatzis, M.G.; Tirkkonen, T.; Lilja, H. Calibrating Eurocode’s fatigue load model 3 to specific national traffic composition. Struct. Eng. Int. 2012, 22, 232–237. [Google Scholar] [CrossRef]

- Maddah, N.; Nussbaumer, A. Analytical approach for improving damage equivalence factors. Eng. Struct. 2014, 59, 838–847. [Google Scholar] [CrossRef] [Green Version]

- Leander, J. Reliability evaluation of the Eurocode model for fatigue assessment of steel bridges. J. Constr. Steel. Res. 2018, 141, 1–8. [Google Scholar] [CrossRef]

- van Bentum, C.A.; Dijkstra, O.D. Process Description of Equivalent Fatigue Load on Bridge Decks; TNO Report 366 B UK; TNO: Delft, The Netherlands, 2008. [Google Scholar]

- EN1993-1-9 Eurocode 3: Design of Steel Structures—Part 1-9: Fatigue; CEN: Brussels, Belgium, 2005.

- EN1993-2 Eurocode 3: Design of Steel Structures—Part 2: Steel Bridges; CEN: Brussels, Belgium, 2006.

- EN1992-1-1 Eurocode 2: Design of Concrete Structures—Part 1-1: Concrete Bridges—General Rules and Rules for Buildings; CEN: Brussels, Belgium, 2004.

- EN1992-2 Eurocode 2: Design of Concrete Structures—Part 2: Concrete Bridges—Design and Detailing Rules; CEN: Brussels, Belgium, 2005.

- Jacob, B.; Cottineau, M.L. Weigh-in-motion for direct enforcement of overloaded commercial vehicles. Transp. Res. Procedia 2016, 14, 1413–1422. [Google Scholar] [CrossRef] [Green Version]

- Jacob, B.; Feypell-de La Beaumelle, V. Improving truck safety: Potential of weigh-in-motion technology. IATSS Res. 2010, 34, 9–15. [Google Scholar] [CrossRef] [Green Version]

- O’Connor, A.; O’Brien, E.J. Traffic load modeling and factors influencing the accuracy of predicted extremes. Can. J. Civ. Eng. 2005, 32, 270–278. [Google Scholar] [CrossRef] [Green Version]

- O’Brien, E.J.; Enright, B. Using Weigh-In-Motion data to determine aggressiveness of traffic for bridge loading. J. Bridge Eng. 2013, 18, 232–239. [Google Scholar] [CrossRef]

- Jacob, B.; Labry, D. Evaluation of the effects of heavy vehicles on bridge fatigue. In Proceedings of the 7th International Symposium on Heavy Vehicle Weights and Dimensions, Delft, The Netherlands, 16–20 June 2002; pp. 185–194. Available online: https://road-transport-technology.org/conferenceproceedings/2000s/ishvwd-7/ (accessed on 4 November 2019).

- Clemente, P.; De Stefano, A. (Eds.) WIM (Weigh in Motion), Load capacity and bridge performance. In Proceedings of Civil Structural Health Monitoring 2 Workshop, Taormina, IT, 2008; ENEA: Rome, Italy, 2010; Available online: https://www.enea.it/it/seguici/pubblicazioni/pdf-volumi/2010/v2010_03-proceedings_cshm2.pdf (accessed on 8 November 2019).

- Croce, P. Background to fatigue load models for Eurocode 1: Part 2 Traffic loads. Prog. Struct. Eng. Mater. 2001, 4, 250–263. [Google Scholar] [CrossRef]

- Croce, P. Improvement of damage equivalence λ-factors for railway steel bridges. In Proceedings of the 34th International Symposium on Bridge and Structural Engineering: Large Structures and Infrastructures for Environmentally Constrained and Urbanised Areas, Venice, Italy, 22–24 September 2010; IABSE: Zurich, Switzerland, 2010. [Google Scholar]

- Croce, P. Probabilistic models for vehicle interactions in fatigue assessment of bridges. Appl. Sci. 2019, 9, 5338. [Google Scholar] [CrossRef] [Green Version]

- McKay, M.D.; Beckman, R.J.; Conover, V.J. A comparison of three methods for selecting values of input variables in the analysis of output from a computer code. Technometrics 1979, 21, 239–245. [Google Scholar]

- Dowling, N.E. Fatigue failure predictions for complicated stress–strain histories. J. Mater. 1972, 2, 71–87. [Google Scholar]

- Dowling, S.D.; Socie, D.F. Simple rainflow counting algorithms. Int. J. Fatigue 1982, 7, 31–40. [Google Scholar] [CrossRef]

- Hong, N. A modified rainflow counting method. Int. J. Fatigue 1991, 13, 465–469. [Google Scholar] [CrossRef]

- ASM. ASM Handbook 19 Fatigue and Fracture; ASM International: Materials Park, OH, USA, 1996. [Google Scholar]

- Matsuishi, M.; Endo, T. Fatigue of metals subjected to varying stress. Jpn. Soc. Mech. Eng. 1968, 68, 37–40. [Google Scholar]

- Rychlik, I. A new definition of the rainflow cycle counting method. Int. J. Fatigue 1987, 9, 119–121. [Google Scholar] [CrossRef]

- Palmgren, A.G. Die Lebensdauer von Kugellagern. Z. Ver. Dtsch. Ing. 1924, 68, 339–341. (In German) [Google Scholar]

- Miner, M.A. Cumulative damage in fatigue. J. Appl. Mech. 1945, 12, 149–164. [Google Scholar]

| Daily Flow | σ [kN] | |||

|---|---|---|---|---|

| Brohltal (DE) | 19,970 | 59.0 | 28.4 | 165.0 |

| Garonor (FR) 1982 | 8470 | 57.6 | 27.6 | 180.0 |

| Garonor (FR) 1984 | 11,593 | 59.3 | 30.0 | 195.0 |

| Auxerre (FR) (slow lane) | 10,442 | 82.5 | 35.2 | 195.0 |

| Auxerre (FR) (fast lane) | 581 | 73.1 | 41.2 | 200.0 |

| Fiano R. (IT) | ~15,000 | 56.8 | 32.9 | 192.01 |

| Piacenza (IT) | ~20,000 | 61.8 | 31.0 | 185.01 |

| Sasso Marconi (IT) | ~13,000 | 61.9 | 30.8 | 185.01 |

| Daily Flow | σ [kN] | |||

|---|---|---|---|---|

| Brohltal (DE) | 4793 | 245.8 | 127.3 | 650.0 |

| Garonor (FR) 1982 | 2570 | 189.8 | 107.5 | 550.0 |

| Garonor (FR) 1984 | 3686 | 186.5 | 118.0 | 560.0 |

| Auxerre (FR) (slow lane) | 2630 | 326.7 | 144.9 | 630.0 |

| Auxerre (FR) (fast lane) | 153 | 277.2 | 163.6 | 670.0 |

| Fiano R. (IT) | ~4000 | 204.5 | 130.3 | 590.0 |

| Piacenza (IT) | ~5000 | 235.2 | 140.0 | 630.0 |

| Sasso Marconi (IT) | ~3500 | 224.9 | 149.0 | 620.0 |

| Speed [m/s] | Inter-Axle [m] | Weight [kN] | Front Axle Load [kN] | Rear Axle Load [kN] |

|---|---|---|---|---|

| 30.6 | 21.02 | 707 | 398 | 309 |

| 3.3 | 13.05 | 613 | 208 | 405 |

| 3.3 | 62.02 | 684 | 318 | 366 |

| 27.2 | 11.32 | 689 | 353 | 336 |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Croce, P. Impact of Road Traffic Tendency in Europe on Fatigue Assessment of Bridges. Appl. Sci. 2020, 10, 1389. https://doi.org/10.3390/app10041389

Croce P. Impact of Road Traffic Tendency in Europe on Fatigue Assessment of Bridges. Applied Sciences. 2020; 10(4):1389. https://doi.org/10.3390/app10041389

Chicago/Turabian StyleCroce, Pietro. 2020. "Impact of Road Traffic Tendency in Europe on Fatigue Assessment of Bridges" Applied Sciences 10, no. 4: 1389. https://doi.org/10.3390/app10041389