Microwave Healing Performance of Asphalt Mixture Containing Electric Arc Furnace (EAF) Slag and Graphene Nanoplatelets (GNPs)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

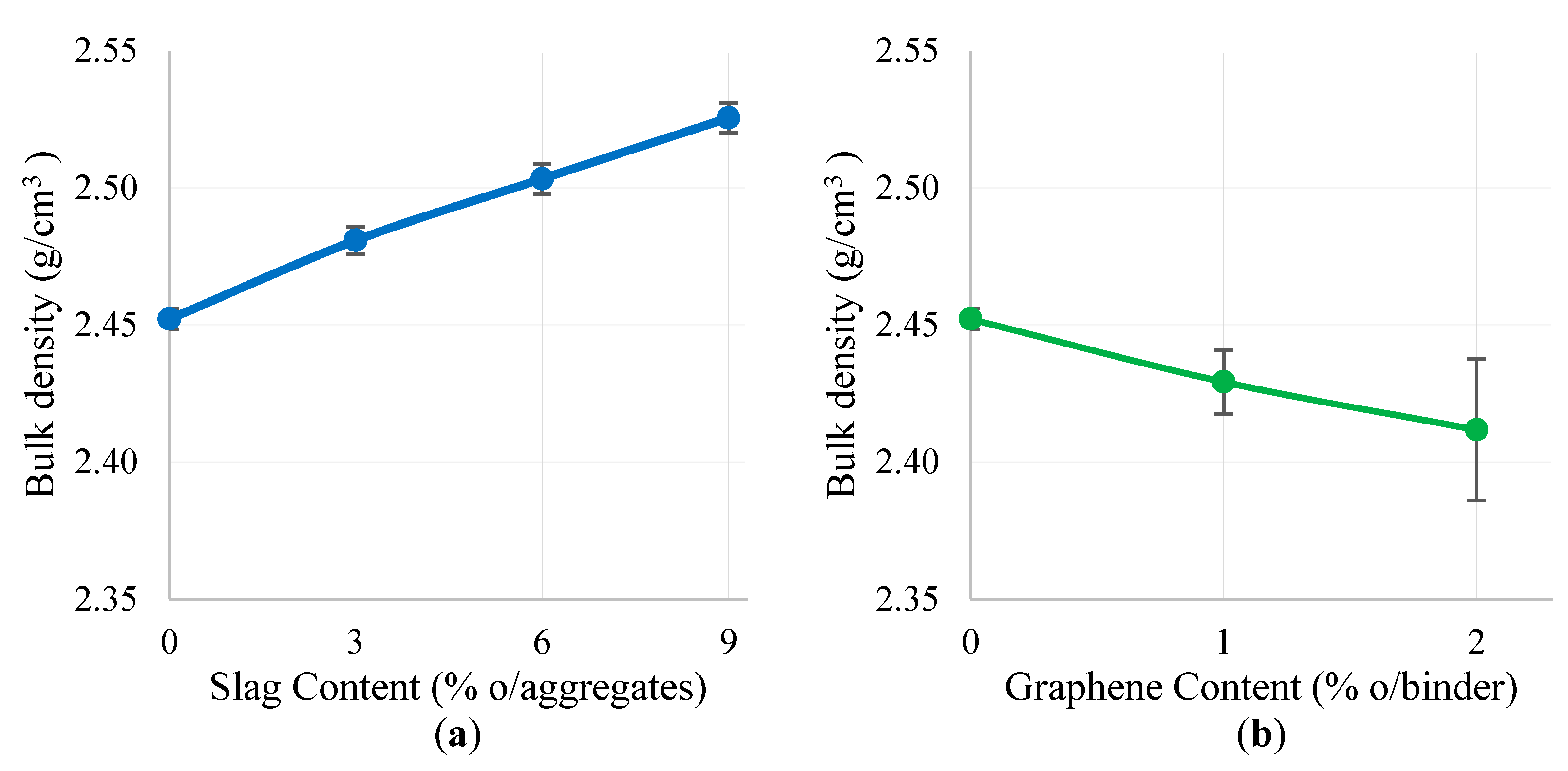

2.2. Bulk Density of the Asphalt Mixtures

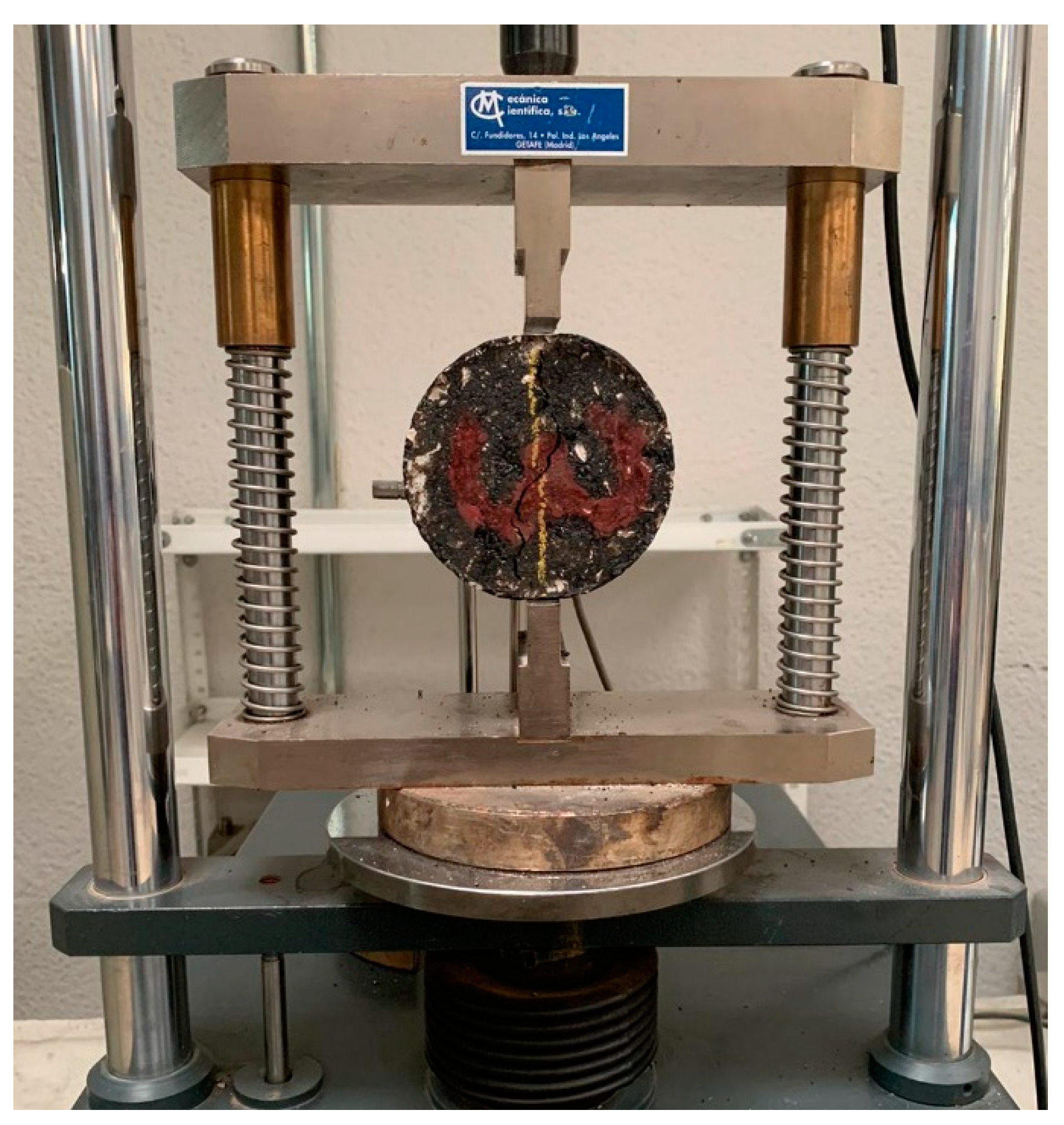

2.3. Indirect Tensile Strength (ITS) Test

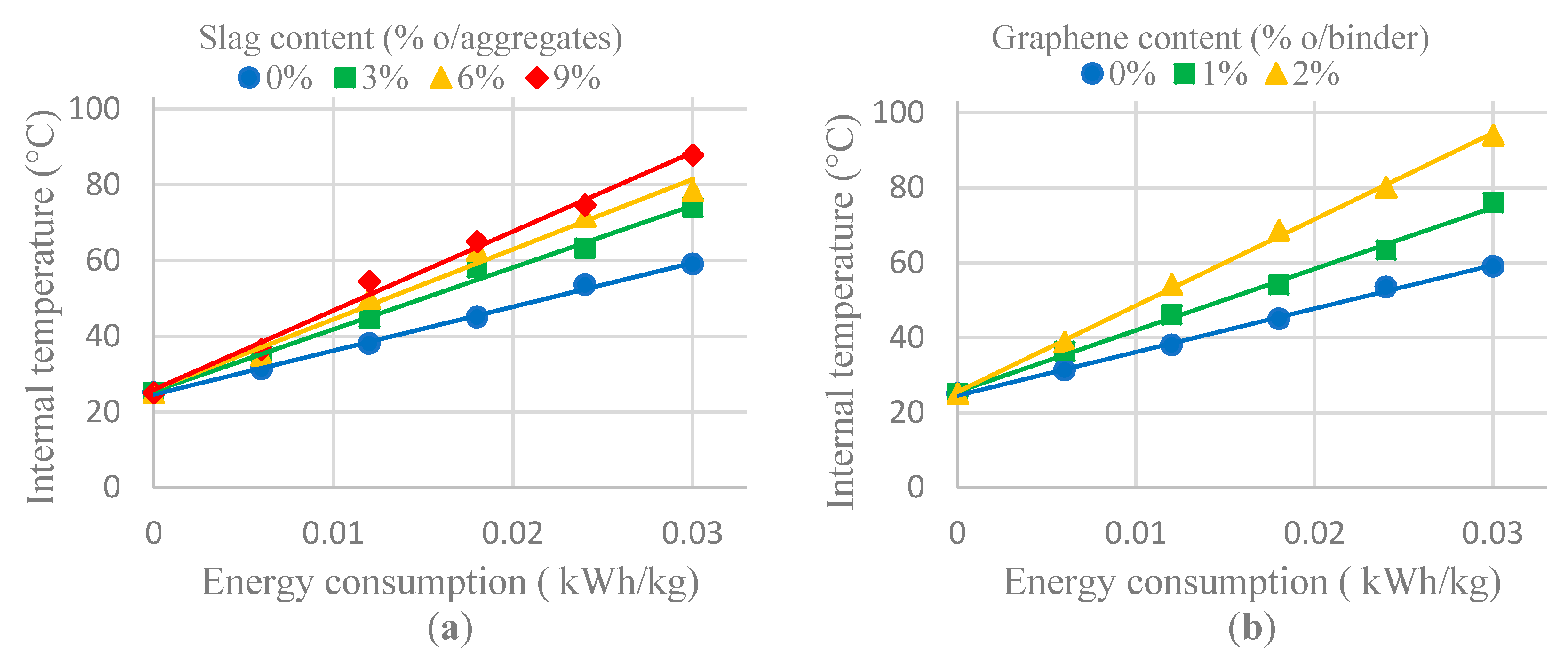

2.4. Microwave Heating

2.5. Electrical Resistivity Measurement

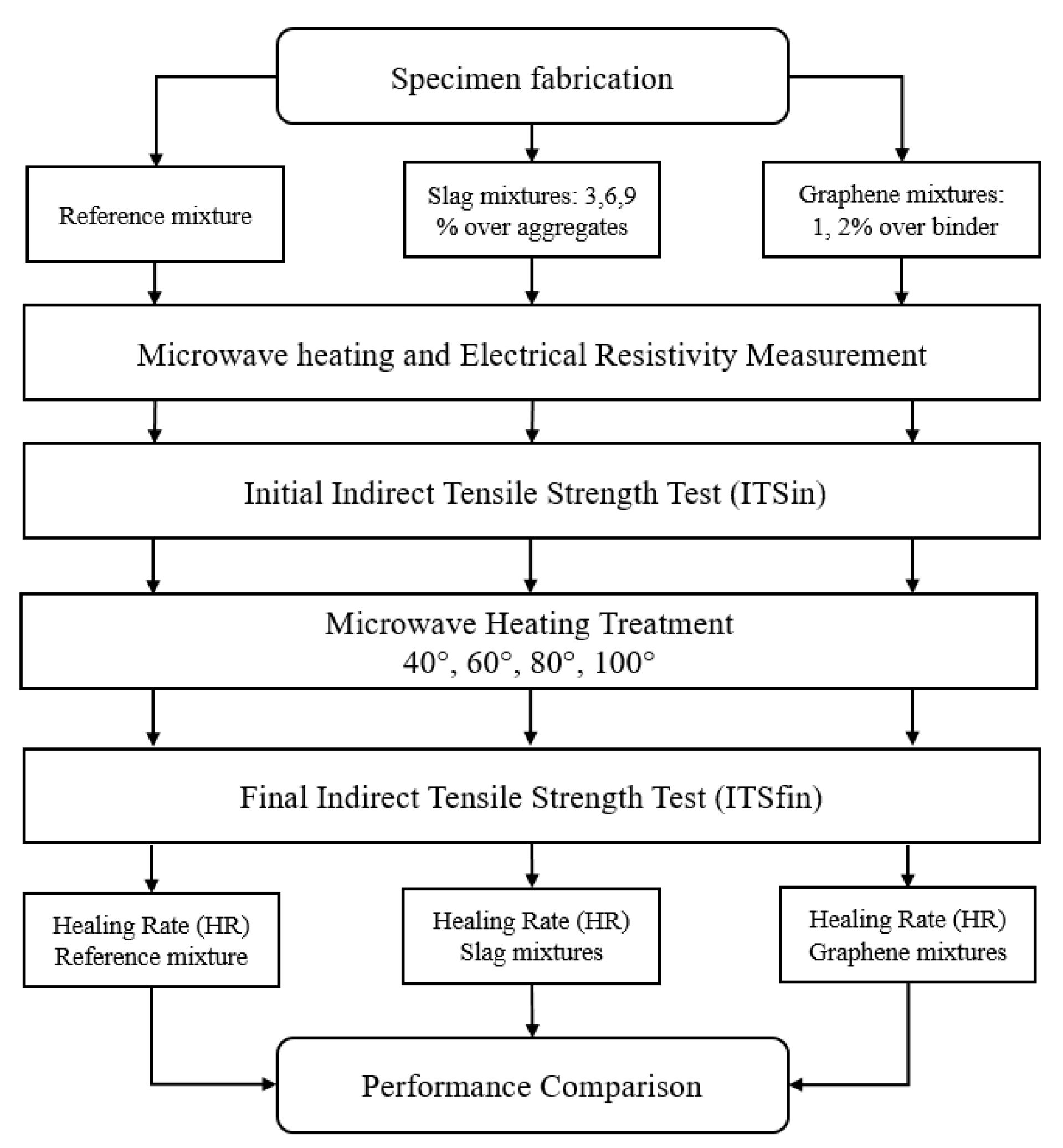

2.6. Self-healing Test Procedure

3. Results

3.1. Influence of Slag and Graphene on the Physical and Mechanical Properties of the Asphalt Mixtures

3.2. Influence of Slag and Graphene on the Heating Efficiency of the Asphalt Mixtures

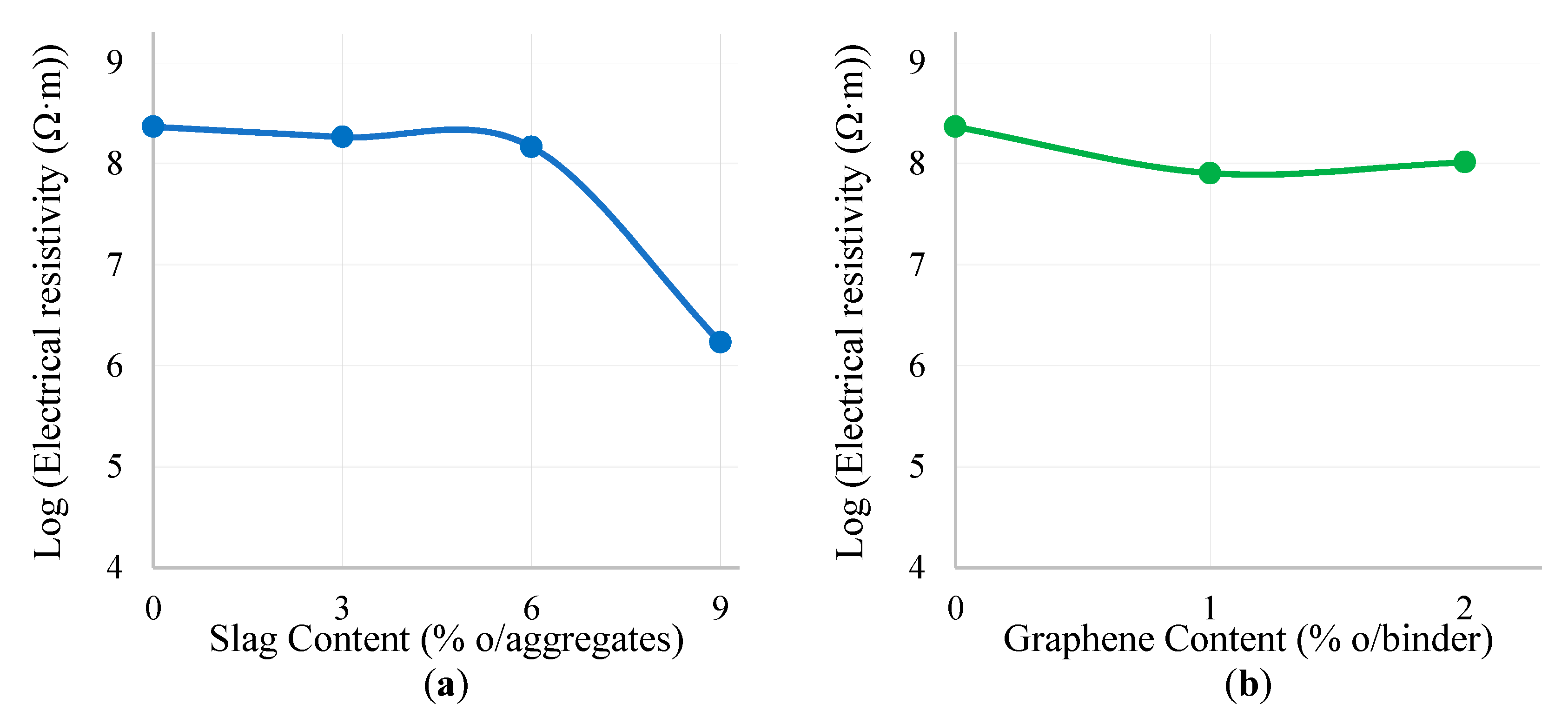

3.3. Influence of Slag and Graphene on the Electrical Resistivity of the Asphalt Mixtures

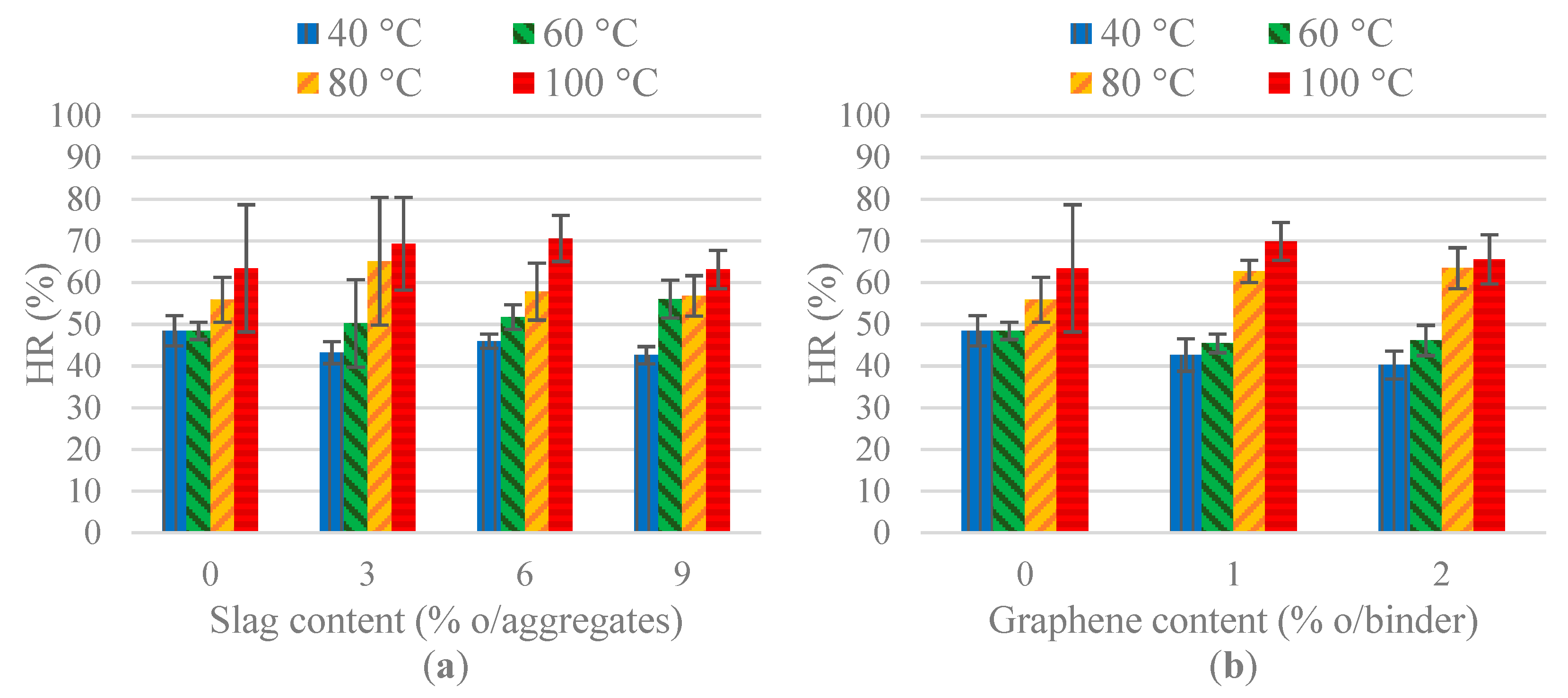

3.4. Influence of Slag and Graphene on the Healing Properties of the Asphalt Mixtures

4. Conclusions

- It was found that the higher temperatures enhanced the healing performances of the asphalt mixtures, with and without the addition of slag or graphene.

- Although the asphalt mixture without additives can be heated with microwaves, both the slag and graphene allow saving approximately 50% of the energy during the heating process.

- The addition of slag or graphene does not seem to enhance the healing rates of the mixture. However, for the same healing rate, the addition of slag or graphene can halve the energy consumption during pavements maintenance operations. In accordance with the laboratory findings, the addition of 3% of slag (o/aggregates) or 2% of graphene (o/binder) is sufficient to obtain these savings of energy.

- Finally, it was observed that apparently, the contribution of the electrical conductivity to the microwave heating is low. Therefore, microwave heat generation could be attributed mostly to the oscillating electromagnetic fields that excite molecules rather than to eventual electrical currents generated in the mixture and the resulting Joule’s effect.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Norambuena-Contreras, J.; Serpell, R.; Vidal, G.V.; Gonzalez, A.; Schlangen, E. Effect of fibres addition on the physical and mechanical properties of asphalt mixtures with crack-healing purposes by microwave radiation. Constr. Build. Mater. 2016, 127, 369–382. [Google Scholar] [CrossRef]

- Li, C.; Wu, S.; Chen, Z.; Tao, G.; Xiao, Y. Enhanced heat release and self-healing properties of steel slag filler based asphalt materials under microwave irradiation. Constr. Build. Mater. 2018, 193, 32–41. [Google Scholar] [CrossRef]

- Qiu, J. Self Healing of Asphalt Mixtures: Towards a Better Understanding of the Mechanism; Delft University of Technology: Delft, The Netherlands, 2012. [Google Scholar]

- Tabaković, A.; Schlangen, E. Self-Healing Technology for Asphalt Pavements. In Advances in Polymer Science; Springer: New York, NY, USA, 2015; Volume 273, pp. 285–306. [Google Scholar] [CrossRef] [Green Version]

- Little, D.N.; Bhasin, A. Exploring Mechanism of Healing in Asphalt Mixtures and Quantifying Its Impact; Springer: Dordrecht, The Netherlands, 2007; pp. 205–218. [Google Scholar]

- Sun, D.; Lin, T.; Zhu, X.; Cao, L. Calculation and evaluation of activation energy as a self-healing indication of asphalt mastic. Constr. Build. Mater. 2015, 95, 431–436. [Google Scholar] [CrossRef]

- García, Á. Self-healing of open cracks in asphalt mastic. Fuel 2012, 93, 264–272. [Google Scholar] [CrossRef]

- Li, C.; Wu, S.; Chen, Z.; Tao, G.; Xiao, Y. Improved microwave heating and healing properties of bitumen by using nanometer microwave-absorbers. Constr. Build. Mater. 2018, 189, 757–767. [Google Scholar] [CrossRef]

- Xiang, H.; He, Z.; Chen, L.; Zhu, H.; Wang, Z. Key Factors and Optimal Conditions for Self-Healing of Bituminous Binder. J. Mater. Civ. Eng. 2019, 31, 04019172. [Google Scholar] [CrossRef]

- García, A.; Norambuena-Contreras, J.; Bueno, M.; Partl, M.N. Single and multiple healing of porous and dense asphalt concrete. J. Intell. Mater. Syst. Struct. 2015, 26, 425–433. [Google Scholar] [CrossRef]

- Sun, D.; Sun, G.; Zhu, X.; Guarin, A.; Li, B.; Dai, Z.; Ling, J. A comprehensive review on self-healing of asphalt materials: Mechanism, model, characterization and enhancement. Adv. Colloid Interface Sci. 2018, 256, 65–93. [Google Scholar] [CrossRef]

- Kim, Y.R.; Little, D.N.; Benson, F.C. Chemical and mechanical evaluation on healing mechanism of asphalt concrete. J. Assoc. Asph. Paving Technol. 1990, 59, 240–275. [Google Scholar]

- Sun, D.; Yu, F.; Li, L.; Lin, T.; Zhu, X.Y. Effect of chemical composition and structure of asphalt binders on self-healing. Constr. Build. Mater. 2017, 133, 495–501. [Google Scholar] [CrossRef]

- Cheng, D.; Little, D.N.; Lytton, R.L.; Holste, J.C. Surface Energy Measurement of Asphalt and Its Application to Predicting Fatigue and Healing in Asphalt Mixtures. Transp. Res. Rec. J. Transp. Res. Board 2002, 1810, 44–53. [Google Scholar] [CrossRef]

- Molenaar, A.A.A. Design of Flexible Pavements; Delft University of Technology: Delft, The Netherlands, 2007. [Google Scholar]

- Ayar, P.; Moreno-Navarro, F.; Rubio-Gámez, M.C. The healing capability of asphalt pavements: A state of the art review. J. Clean. Prod. 2016, 113, 28–40. [Google Scholar] [CrossRef]

- Zhu, X.; Cai, Y.; Zhong, S.; Zhu, J.; Zhao, H. Self-healing efficiency of ferrite-filled asphalt mixture after microwave irradiation. Constr. Build. Mater. 2017, 141, 12–22. [Google Scholar] [CrossRef]

- Zhu, X.; Ye, F.; Cai, Y.; Birgisson, B.; Lee, K. Self-healing properties of ferrite-filled open-graded friction course (OGFC) asphalt mixture after moisture damage. J. Clean. Prod. 2019, 232, 518–530. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; Garcia, A. Self-healing of asphalt mixture by microwave and induction heating. Mater. Des. 2016, 106, 404–414. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; Gonzalez, A.; Concha, J.L.; Gonzalez-Torre, I.; Schlangen, E. Effect of metallic waste addition on the electrical, thermophysical and microwave crack-healing properties of asphalt mixtures. Constr. Build. Mater. 2018, 187, 1039–1050. [Google Scholar] [CrossRef] [Green Version]

- García, Á.; Schlangen, E.; van de Ven, M.; Sierra-Beltrán, G. Preparation of capsules containing rejuvenators for their use in asphalt concrete. J. Hazard. Mater. 2010, 184, 603–611. [Google Scholar] [CrossRef]

- Garcia, A.; Schlangen, E.; van de Ven, M. Two Ways of Closing Cracks on Asphalt Concrete Pavements: Microcapsules and Induction Heating. Key Eng. Mater. 2009, 417–418, 573–576. [Google Scholar] [CrossRef]

- Schlangen, E.; Sangadji, S. Addressing Infrastructure Durability and Sustainability by Self Healing Mechanisms—Recent Advances in Self Healing Concrete and Asphalt. Procedia Eng. 2013, 54, 39–57. [Google Scholar] [CrossRef] [Green Version]

- Liu, Q.; Wu, S.; Schlangen, E. Induction heating of asphalt mastic for crack control. Constr. Build. Mater. 2013, 41, 345–351. [Google Scholar] [CrossRef]

- Liu, Q.; García, Á.; Schlangen, E.; van de Ven, M. Induction healing of asphalt mastic and porous asphalt concrete. Constr. Build. Mater. 2011, 25, 3746–3752. [Google Scholar] [CrossRef]

- Garcia, A.; Bueno, M.; Norambuena-Contreras, J.; Partl, M.N. Induction healing of dense asphalt concrete. Constr. Build. Mater. 2013, 49, 1–7. [Google Scholar] [CrossRef]

- Wu, S.; Mo, L.; Shui, Z.; Chen, Z. Investigation of the conductivity of asphalt concrete containing conductive fillers. Carbon N. Y. 2005, 43, 1358–1363. [Google Scholar] [CrossRef]

- García, Á.; Schlangen, E.; van de Ven, M.; Liu, Q. Electrical conductivity of asphalt mortar containing conductive fibers and fillers. Constr. Build. Mater. 2009, 23, 3175–3181. [Google Scholar] [CrossRef]

- Arabzadeh, A.; Ceylan, H.; Kim, S.; Sassani, A.; Gopalakrishnan, K.; Mina, M. Electrically-conductive asphalt mastic: Temperature dependence and heating efficiency. Mater. Des. 2018, 157, 303–313. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; Yang, J.; Liao, H.; Chen, X. Electrical and mechanical properties of asphalt concrete containing conductive fibers and fillers. Constr. Build. Mater. 2016, 122, 184–190. [Google Scholar] [CrossRef] [Green Version]

- Von Starck, A.; Muhlbauer, A.; Kramer, C. Handbook of Thermoprocessing Technologies: Fundamentals, Processes, Components, Safety; Vulkan-Verlag: Essen, Germany, 2005. [Google Scholar]

- Metaxas, A.; Meredith, R. Industrial Microwave Heating; The Institution of Electrical Engineers: London, UK, 1983. [Google Scholar]

- Benedetto, A.; Calvi, A. A pilot study on microwave heating for production and recycling of road pavement materials. Constr. Build. Mater. 2013, 44, 351–359. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, Y.; Zhang, Y.; Feng, S.; Lu, G.; Cao, L. Laboratory and Numerical Investigation of Microwave Heating Properties of Asphalt Mixture. Materials 2019, 12, 146. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ding, L.; Wang, X.; Zhang, W.; Wang, S.; Zhao, J.; Li, Y. Microwave Deicing Efficiency: Study on the Difference between Microwave Frequencies and Road Structure Materials. Appl. Sci. 2018, 8, 2360. [Google Scholar] [CrossRef] [Green Version]

- Jaselskis, E.J.; Grigas, J.; Brilingas, A. Dielectric Properties of Asphalt Pavement. J. Mater. Civ. Eng. 2003, 15, 427–434. [Google Scholar] [CrossRef]

- Liu, W.; Miao, P.; Wang, S.-Y. Increasing Microwave Heating Efficiency of Asphalt-Coated Aggregates Mixed with Modified Steel Slag Particles. J. Mater. Civ. Eng. 2017, 29, 04017171. [Google Scholar] [CrossRef]

- Gallego, J.; del Val, M.A.; Contreras, V.; Páez, A.; Páez, A. Use of additives to improve the capacity of bituminous mixtures to be heated by means of microwaves. Mater. Construcción 2017, 67, 110. [Google Scholar] [CrossRef] [Green Version]

- Gallego, J.; del Val, M.A.; Contreras, V.; Paez, A. Heating asphalt mixtures with microwaves to promote self-healing. Constr. Build. Mater. 2013, 42, 1–4. [Google Scholar] [CrossRef]

- Gonzalez, A.; Norambuena-Contreras, J.; Storey, L.; Schlangen, E. Effect of RAP and fibers addition on asphalt mixtures with self-healing properties gained by microwave radiation heating. Constr. Build. Mater. 2018, 159, 164–174. [Google Scholar] [CrossRef]

- Phan, T.M.; Park, D.-W.; Le, T.H.M. Crack healing performance of hot mix asphalt containing steel slag by microwaves heating. Constr. Build. Mater. 2018, 180, 503–511. [Google Scholar] [CrossRef]

- Gonzalez, A.; Norambuena-Contreras, J.; Storey, L.; Schlangen, E. Self-healing properties of recycled asphalt mixtures containing metal waste: An approach through microwave radiation heating. J. Environ. Manag. 2018, 214, 242–251. [Google Scholar] [CrossRef] [Green Version]

- Pérez, I.; Agzenai, Y.; Pozuelo, J.; Sanz, J.; Baselga, J.; García, A.; Pérez, V. Self-healing of asphalt mixes, containing conductive modified bitumen, using microwave heating. In Proceedings of the 6th Eurasphalt & Eurobitume Congress, Prague, Czech Republic, 1–3 June 2016. [Google Scholar] [CrossRef] [Green Version]

- Trigos, L.; Gallego, J.; Escavy, J.I. Heating potential of aggregates in asphalt mixtures exposed to microwaves radiation. Constr. Build. Mater. 2020, 230, 117035. [Google Scholar] [CrossRef]

- Skaf, M.; Manso, J.M.; Aragón, Á.; Fuente-Alonso, J.A.; Ortega-López, V. EAF slag in asphalt mixes: A brief review of its possible re-use. Resour. Conserv. Recycl. 2017, 120, 176–185. [Google Scholar] [CrossRef]

- Crucho, J.; Picado-Santos, L.; Neves, J.; Capitão, S. A Review of Nanomaterials’ Effect on Mechanical Performance and Aging of Asphalt Mixtures. Appl. Sci. 2019, 9, 3657. [Google Scholar] [CrossRef] [Green Version]

- Wu, S.; Tahri, O. State-of-art carbon and graphene family nanomaterials for asphalt modification. Road Mater. Pavement Des. 2019, 1–22. [Google Scholar] [CrossRef]

- Hafeez, M.; Ahmad, N.; Kamal, M.A.; Rafi, J.; Zaidi, S.B.A.; Nasir, M.A. Experimental Investigation into the Structural and Functional Performance of Graphene Nano-Platelet (GNP)-Doped Asphalt. Appl. Sci. 2019, 9, 686. [Google Scholar] [CrossRef] [Green Version]

- Le, J.-L.; Marasteanu, M.O.; Turos, M. Mechanical and compaction properties of graphite nanoplatelet-modified asphalt binders and mixtures. Road Mater. Pavement Des. 2019, 1–16. [Google Scholar] [CrossRef]

- Gallego, J.; Gulisano, F.; Picado, L.; Crucho, J. Optimizing asphalt mixtures to be heated by microwave. In Proceedings of the 17th International Conference on Microwave and High Frequency Heating, Valencia, Spain, 9–12 September 2019. [Google Scholar] [CrossRef]

- Crucho, J.M.L.; Neves, J.M.C.d.; Capitão, S.D.; de Picado-Santos, L.G. Mechanical performance of asphalt concrete modified with nanoparticles: Nanosilica, zero-valent iron and nanoclay. Constr. Build. Mater. 2018, 181, 309–318. [Google Scholar] [CrossRef]

- Gao, J.; Sha, A.; Wang, Z.; Tong, Z.; Liu, Z. Utilization of steel slag as aggregate in asphalt mixtures for microwave deicing. J. Clean. Prod. 2017, 152, 429–442. [Google Scholar] [CrossRef]

- Tabaković, A.; O’Prey, D.; McKenna, D.; Woodward, D. Microwave self-healing technology as airfield porous asphalt friction course repair and maintenance system. Case Stud. Constr. Mater. 2019, 10, e00233. [Google Scholar] [CrossRef]

- Magadi, K.L.; Anirudh, N.; Mallesh, K.M. Evaluation of Bituminous Concrete Mixture Properties with Steel Slag. Transp. Res. Procedia 2016, 17, 174–183. [Google Scholar] [CrossRef]

- Neves, J.; Crucho, J.; Santos, L.P.; Martinho, F. The influence of processed steel slag on the performance of a bituminous mixture. In Proceedings of the Ninth International Conference on Bearing Capacity of Roads, Railways and Airfields, Trondhein, Norway, 25–27 June 2013; pp. 617–625. [Google Scholar]

- Sun, Y.; Wu, S.; Liu, Q.; Zeng, W.; Chen, Z.; Ye, Q.; Pan, P. Self-healing performance of asphalt mixtures through heating fibers or aggregate. Constr. Build. Mater. 2017, 150, 673–680. [Google Scholar] [CrossRef]

| Sieve (mm) | % Passing |

|---|---|

| 22 | 100 |

| 16 | 83 |

| 8 | 56 |

| 4 | 42 |

| 2 | 34 |

| 0.5 | 19 |

| 0.063 | 5 |

| Chemical Composition | % |

|---|---|

| Al2O3 | 8.81 |

| CaO | 24.28 |

| Fe2O3 | 40.49 |

| MgO | 3.02 |

| MnO | 4.72 |

| SiO2 | 12.60 |

| P2O5 | 0.36 |

| Other substances | 5.72 |

| Additive | Content (%) | Linear Regression Equation | R2 | °C/ kWh/kg | °C/s |

|---|---|---|---|---|---|

| - | 0 | y = 1160x + 24.57 | 0.998 | 1160 | 0.232 |

| Slag (% o/aggregates) | 3 | y = 1634x + 25.48 | 0.993 | 1634 | 0.327 |

| 6 | y = 1850x + 25.98 | 0.987 | 1850 | 0.370 | |

| 9 | y = 2089x + 25.89 | 0.992 | 2089 | 0.418 | |

| Graphene (%o/binder) | 1 | y = 1638x + 25.60 | 0.996 | 1638 | 0.328 |

| 2 | y = 2301x + 25.58 | 0.998 | 2301 | 0.460 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gulisano, F.; Crucho, J.; Gallego, J.; Picado-Santos, L. Microwave Healing Performance of Asphalt Mixture Containing Electric Arc Furnace (EAF) Slag and Graphene Nanoplatelets (GNPs). Appl. Sci. 2020, 10, 1428. https://doi.org/10.3390/app10041428

Gulisano F, Crucho J, Gallego J, Picado-Santos L. Microwave Healing Performance of Asphalt Mixture Containing Electric Arc Furnace (EAF) Slag and Graphene Nanoplatelets (GNPs). Applied Sciences. 2020; 10(4):1428. https://doi.org/10.3390/app10041428

Chicago/Turabian StyleGulisano, Federico, João Crucho, Juan Gallego, and Luis Picado-Santos. 2020. "Microwave Healing Performance of Asphalt Mixture Containing Electric Arc Furnace (EAF) Slag and Graphene Nanoplatelets (GNPs)" Applied Sciences 10, no. 4: 1428. https://doi.org/10.3390/app10041428

APA StyleGulisano, F., Crucho, J., Gallego, J., & Picado-Santos, L. (2020). Microwave Healing Performance of Asphalt Mixture Containing Electric Arc Furnace (EAF) Slag and Graphene Nanoplatelets (GNPs). Applied Sciences, 10(4), 1428. https://doi.org/10.3390/app10041428