Effect of Chemical Composition of Bio- and Petroleum-Based Modifiers on Asphalt Binder Rheology

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Asphalt Binder Modification

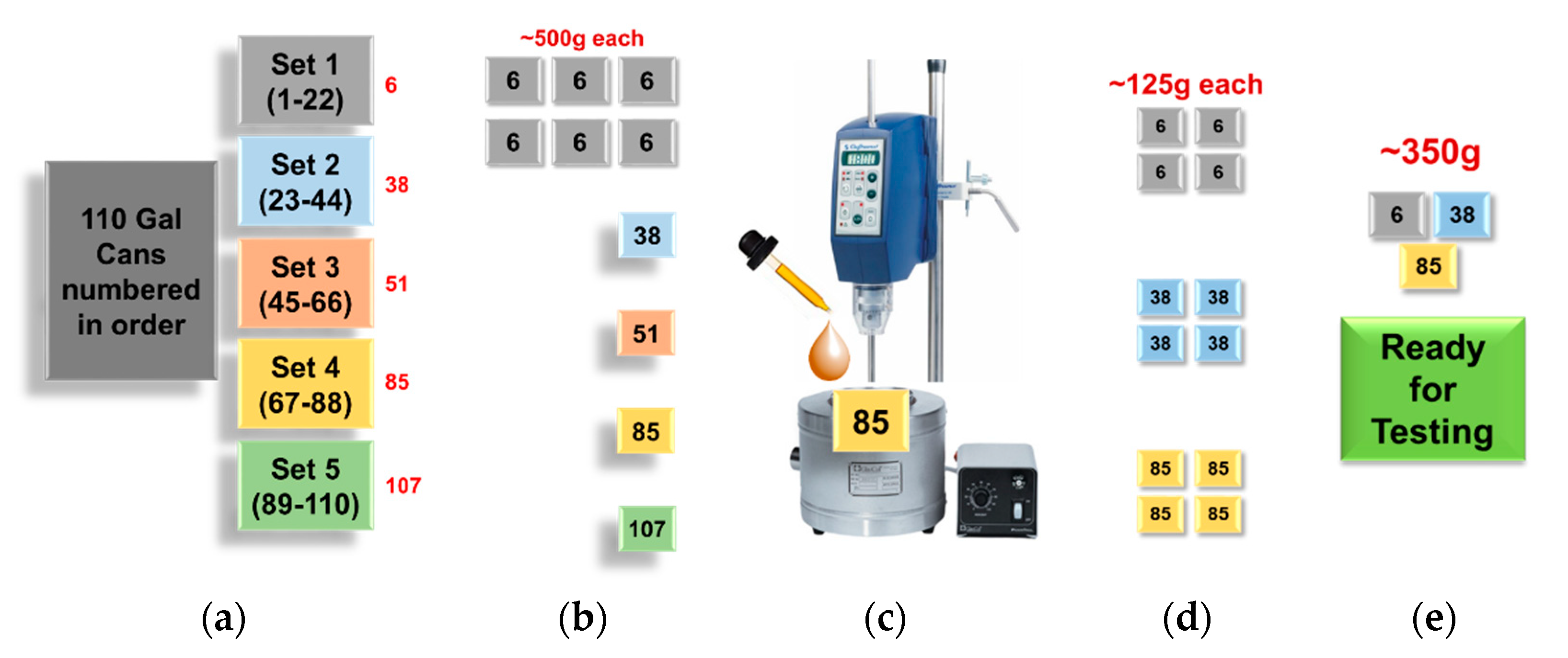

- PG 64-22 binder was sampled from the refinery terminal in 110–3.8 L cans. They were labelled from 1 to 110 in the order they were collected. The base binder was then grouped in five different sets as shown in Figure 1a.

- Binder from each set was split to 6 cans of around 500 g each (Figure 1b). Each can was heated to 135 °C for 2 h to reach a flowing state and was stirred prior to splitting. The split samples were then stored for modification.

- Before modification, the split base binder (S1) was heated for 30 min in a heating mantle (Figure 1c) to reach 130 ± 10 °C to ensure that material was steadily flowing prior to blending.

- The modifier was added (weight measured with a 0.01 g readability scale), the propeller was inserted half-way into the depth of the material and was set to 1000 rpm for 20 min. During blending, the temperature was maintained at 130 ± 10 °C and formation of vortices was prevented to avoid air bubbles in the blend.

- After blending, the MAB was divided into 4–240 mL cans (Figure 1d).

- Steps 3 to 5 were repeated for the binders from different sets mentioned in Step 1 for obtaining representative samples.

- Later, 3–240 mL cans from different batches of each MAB were combined to proceed with aging conditioning (Figure 1e).

2.3. Modifier Chemistry Experimental Program

2.3.1. Elemental Analysis

2.3.2. Chemical Functional Groups

2.3.3. Molecular Weight Analysis

2.3.4. Binder Fractionation

2.4. Binder Rheology Experimental Program

2.4.1. Superpave Performance Grading (PG)

2.4.2. ΔTc Parameter

2.4.3. Frequency Sweep Test

Glover–Rowe Parameter (GR)

3. Results

3.1. Chemical Characterization of Modifiers

3.1.1. Elemental Analysis

3.1.2. Fourier Transform Infrared Spectroscopy (FTIR)

- All modifiers show characteristic peaks in the range of 2800–3000 cm−1 and 1300–1460 cm−1 which correspond to C-H stretching and C-H bending, respectively (Figure 2a).

- Peaks at 2850, 2920, 2955, and 3008 cm−1 correspond to C-H stretching and are observed in modifiers A, C, D, E, and K (Figure 2c). These peaks are absent in G. Instead, a distinct broad peak at 2860 cm−1 in G was observed (Figure 2c). This peak is representative of N-H stretching specific to amine salt.

- The common peak at 1460 cm−1 in all the modifiers shows the presence of C-H bending for alkanes (Figure 2b). It is the most common functional group present in hydrocarbons.

- Series of peaks were observed from 1000–1300 cm−1 in all modifiers (Figure 2a). This may reflect the presence of either alkoxy (-C-O-), phenyl (=C-O-), or C-N stretching.

- Peaks for modifiers A, C, D, and E at 1165 cm−1 show the presence of a common functional group which can be either of alkoxy (-C-O-), phenyl (=C-O-), or C-N (Figure 2b). Because a negligible amount of nitrogen was observed in these modifiers, the probability of alkoxy (-C-O-) or phenyl (=C-O-) groups presence is higher.

- An accentuated peak at 1120 cm−1 for G and a smaller peak around 1050 cm−1 for C might correspond to C-N stretching (Figure 2b). This is characteristic of amine stretching (1000–1250 cm−1).

- Smaller peaks at 1350 and 1375 cm−1 for modifier K correspond to stretching of sulfoxide (-S=O) group (Figure 2b).

- Strong peaks of carbonyl (-C=O) stretching were observed in modifiers A, C, D, and E between 1650–1800 cm−1. The peaks are close to wavenumber 1742 cm−1 which may reflect the presence of aldehydes, ketones, esters, or carboxylic groups (-C=O). However, a very small peak for modifier G was also observed closer to wavenumber 1650 cm−1 which is characteristic of amides (-NC=O) (Figure 2b). There is no peak for modifier K in this region.

- Modifier G and C have a single broad peak in range of 3100–3500 cm−1 (Figure 2a). This peak is usually due to the stretching in alcohols (O-H) or secondary amines (-R1R2N-H). Based on elemental analysis, G and C have higher nitrogen content compared to other modifiers. Therefore, presence of secondary amines is highly likely in these modifiers.

- The spectral analysis results of modifiers confirm the type as provided by the suppliers (Table 1). No information on modifier A’s composition was provided; however, the FTIR results suggest that modifier A has characteristics similar to the bio-oil blend (modifier D).

3.1.3. Gel Permeation Chromatography

- The molecular weight distribution in modifier A and D showed two peaks at similar retention times but with different intensities. The larger peak occurred at lower retention times than the smaller peak, which indicates presence of two different sized molecules with higher proportion of larger size particles.

- Modifier C has a similar two peak distribution to A and D. However, the two peaks occur at longer retention times, indicating that the respective weights are smaller than A and D.

- Modifiers E and G have one sharp peak indicating the presence of single weight molecule. However, the peaks occur at different retention times which represent different particles.

- Modifier G has the largest retention time suggesting lower average molecular weight.

- Modifier K has the largest molecular weights among the modifiers. The molecular size distribution is wider compared to all other modifiers with two peaks. The wider distribution indicates a wide range of molecular size present in modifier K, resulting in a high PDI.

3.1.4. Thin Layer Chromatography Flame Ionization Detection (TLC-FID)

- Modifiers A, C, D, and E are primarily composed of resins.

- Modifiers A and D consist of some aromatics (A = 19.7% and D = 10.5%), limited asphaltenes (A = 4.6% and D = 7.5%), and some saturates (A = 8.3% and D = 1.1%).

- Modifiers C and E show limited or no presence of aromatics and saturates. They are primarily composed of resins (C = 70.1% and E = 83.4%) and asphaltenes (C = 23.2% and E = 13%).

- Modifier K has a significant proportion of saturates (59.3%) and exceptionally high residue content (26%) compared to other modifiers.

3.2. Rheological Characterization of Modified Binders

3.2.1. Superpave Grading

3.2.2. Delta Tc (ΔTc)

3.2.3. Frequency Sweep Test

Complex Shear Modulus Master Curves

- In Figure 6a, after RTFO aging, modified binders are difficult to differentiate based on their shear modulus values. All the binders have similar master curves representing similar stiffnesses.

- As the aging progressed to PAV condition, modified binder containing K separates from the rest of the binders at the lower frequency range (Figure 6b) representing a stiffer behavior. Other binders (A, C, D, E, G, and S5) show similar behavior.

- Upon further aging (2PAV), modified binder containing G slightly separates from the rest of the binders towards lower moduli (Figure 6c), showing a softer behavior. K is again the stiffest and separates from the rest (A, C, D, E, and S5) in this condition.

- At 3PAV, modified binders containing G and K have clear distinction in moduli, G being the softest and K being the stiffest. All other binders have similar variation in the complex shear modulus as shown in Figure 6d.

Black Space Diagram

- For the selected range of G* at RTFO (Inset Figure 7a) aged condition, K-modified binder has the lowest δ with clear distinction compared to other binders. The remaining binders have higher δ values than K-modified binder and are close to each other. C-modified binder has highest δ.

- As the aging progresses to PAV aging, the separation in δ can be distinguished clearly. K-modified binder is separated from rest of the binders with lower δ (Inset Figure 7b), while G-modified binder has the highest δ followed by C, S5, E, D, and A, respectively (close to each other).

- Upon further aging (2PAV and 3PAV), the trends for highest and lowest δ are again similar to that of PAV aging. However, the separation in δ became more evident (Inset Figure 7c,d). At 3PAV, K-modified binder has the lowest δ, followed by E, D, S5, C, and G. The δ values for G-modified binder suggest a greater viscous component in the complex shear modulus, indicating a flowing behavior, thus possibly lower cracking susceptibility.

Glover–Rowe (GR) Parameter

4. Discussion

4.1. Summary of Modifier Chemistry

4.2. Summary of Modified Asphalt Binder Rheology

4.3. Relationship between Modifier Chemistry and Binder Rheology

5. Summary and Findings

- Nitrogen-rich modified binders appear to have superior rheological properties. They have higher ΔTc, higher phase angles, and lower GR for 2PAV and 3PAV conditions. Hence, it can be assumed that the presence of nitrogen would boost anti-oxidizing properties and reduce susceptibility to cracking. Further research is needed to validate this hypothesis.

- Sulfur presence may have a detrimental impact on modified binder performance.

- Lower molecular size/weight of modifiers appears to be related to better cracking resistance potential of modified asphalt binders. Further research towards validating this idea is encouraged.

- Modifiers A and D have similar chemical characteristics and molecular weight distributions. This suggests that modifier A may have a bio-based origin.

- The methodology employed in the SARA analysis may not be able to characterize some modifiers. An alternative test method should be considered for some modifiers.

- Phase angle parameter in conjunction with complex modulus (G*) was shown to be sensitive to laboratory aging of modified and unmodified binders. Therefore, such a parameter has potential to identify phase-incompatible asphalt binders, is able to distinguish potential mechanical behavior, and could be associated with field performance.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Williams, B.A.; Willis, R.J.; Ross, C.T. Annual Asphalt Pavement Industry Survey on Recycled Materials and Warm-Mix Asphalt Usage 2018; National Asphalt Pavement Association: Greenbelt, MD, USA, 2018. [Google Scholar]

- Van Krevelen, D.W.; Te Nijenhuis, K. Chemical Degradation. In Properties of Polymers; Elsevier: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Kriz, P.; Noel, J.; Quddus, M.; Maria, S. Rheological Properties of Phase-Incompatible Bituminous Binders. In Proceedings of the 56th Peterson Asphalt Research Conference, Laramie, WY, USA, 14–17 July 2019. [Google Scholar]

- Asphalt Institute and Eurobitume The Bitumen Industry-A Global Perspective: Production, Chemistry, Use, Specification and Occupational Exposure; Asphalt Institute and Eurobitume: Lexington, KY, USA, 2015.

- Ozer, H.; Renshaw, G.; Hasiba, K.; Al-Qadi, I.L. Evaluation of the Impacts of Re-Refined Engine Oil Bottoms (ReOB) on Performance Graded Asphalt Binders and Asphalt Mixtures, Report No. FHWA-ICT-16-006; Illinois Center for Transportation: Rantoul, IL, USA, 2016. [Google Scholar]

- Rose, A.A.; Lenz, I.R.; Than, C.T.; Glover, C.J. Investigation of the effects of recycled engine oil bottoms on asphalt field performance following an oxidation modeling approach. Pet. Sci. Technol. 2016, 34, 1768–1776. [Google Scholar] [CrossRef]

- Jia, X.; Huang, B.; Moore, J.A.; Zhao, S. Influence of waste engine oil on asphalt mixtures containing reclaimed asphalt pavement. J. Mater. Civ. Eng. 2015, 27, 1–9. [Google Scholar] [CrossRef]

- Reinke, G.; Hanz, A.; Anderson, R.M.; Ryan, M.; Engber, S.; Herlitzka, D. Impact of re-refined engine oil bottoms on binder properties and mix performance on two pavements in Minnesota. In Proceedings of the E&E Congress 2016, 6th Eurasphalt & Eurobitume Congress, Prague, Czech Republic, 1–3 June 2016. [Google Scholar]

- Golalipour, A.; Bahia, H. Investigation of Effect of Bio-based and Re-refined Used Oil Modifiers on Asphalt Binder’s Performance and Properties. Transp. Res. Board 2016, 1–14. [Google Scholar]

- Fini, E.H.; Oldham, D.; Buabeng, F.S.; Nezhad, S.H. Investigating the Aging Susceptibility of Bio-Modified Asphalts. Airf. Highw. Pavement 2015, 62–73. [Google Scholar] [CrossRef]

- Borghi, A.; del Barco Carrión, A.J.; Lo Presti, D.; Giustozzi, F. Effects of Laboratory Aging on Properties of Biorejuvenated Asphalt Binders. J. Mater. Civ. Eng. 2017, 29, 1–13. [Google Scholar] [CrossRef]

- Al-Qadi, I.L.; Wu, S.; Lippert, D.L.; Ozer, H.; Barry, M.K.; Safl, F.R. Impact of high recycled mixes on HMA overlay crack development rate. Asph. Paving Technol. Assoc. Asph. Paving Technol. Tech. Sess. 2017, 86, 427–447. [Google Scholar]

- Al-Qadi, I.L.; Ozer, H.; Zhu, Z.; Singhvi, P.; Ali, M.U.; Sawalha, M.; Luque, A.E.F.; Mainieri, J.J.G.; Zehr, T.G. Development of Long-Term Aging Protocol for Implementation of the Illinois Flexibility Index Test (I-FIT); Illinois Center for Transportation: Rantoul, IL, USA, 2019. [Google Scholar]

- Doll, B.; Ozer, H.; Rivera-Perez, J.J.; Al-Qadi, I.L.; Lambros, J. Investigation of viscoelastic fracture fields in asphalt mixtures using digital image correlation. Int. J. Fract. 2017, 205, 37–56. [Google Scholar] [CrossRef]

- Ozer, H.; Al-Qadi, I.L.; Lambros, J.; El-Khatib, A.; Singhvi, P.; Doll, B. Development of the fracture-based flexibility index for asphalt concrete cracking potential using modified semi-circle bending test parameters. Constr. Build. Mater. 2016, 115, 390–401. [Google Scholar] [CrossRef]

- Ozer, H.; Al-Qadi, I.L.; Singhvi, P.; Khan, T.; Rivera-Perez, J.; El-Khatib, A. Fracture Characterization of Asphalt Mixtures with High Recycled Content Using Illinois Semicircular Bending Test Method and Flexibility Index. Transp. Res. Rec. 2016, 2575, 130–137. [Google Scholar] [CrossRef]

- Wu, S.; Al-Qadi, I.L.; Lippert, D.L.; Ozer, H.; Luque, A.F.E.; Safi, F.R. Early-age performance characterization of hot-mix asphalt overlay with varying amounts of asphalt binder replacement. Constr. Build. Mater. 2017, 153, 294–306. [Google Scholar] [CrossRef]

- Wu, S.; Lippert, D.L.; Al-Qadi, I.L.; Ozer, H.; Said, I.M.; Barry, M.K. Impact of High Asphalt Binder Replacement on Level Binder Properties for Controlling Reflective Cracking. Transp. Res. Rec. J. Transp. Res. Board 2017, 2630, 118–127. [Google Scholar] [CrossRef]

- Anderson, M.R.; King, G.N.; Hanson, D.I.; Blankenship, P.B. Evaluation of the Relationship between Asphalt Binder Properties and Non-Load Related Cracking. J. Assoc. Asph. Paving Technol. 2011, 80, 615–662. [Google Scholar]

- Asphalt Institute. Use of the Delta Tc Parameter to Characterize Asphalt Binder Behavior IS-240; Asphalt Institute: Lexington, KY, USA, 2019. [Google Scholar]

- Kandhal, P. Low-Temperature Ductility in Relation to Pavement Performance; ASTM International: West Conshohocken, PA, USA, 1977. [Google Scholar]

- Glover, C.J.; Davison, R.R.; Domke, C.H.; Ruan, Y.; Juristyarini, P.; Knorr, D.B.; Jung, S.H. Development of a New Method for Assessing Asphalt Binder Durability with Field Validation; Texas Transportation Institute: College Station, TX, USA, 2005.

- Rowe, G. Analysis of SHRP core asphalts—New 2013/14 test results. In Proceedings of the Binder Expert Task Group Meeting, San Antonio, TX, USA, 1–2 April 2014. [Google Scholar]

- Hintz, C.; Velasquez, R.; Johnson, C.; Bahia, H. Modification and Validation of Linear Amplitude Sweep Test for Binder Fatigue Specification. Transp. Res. Rec. 2011, 2207, 99–106. [Google Scholar] [CrossRef]

- Elwardany, M.D.; Rad, F.Y.; Castorena, C.; Richard Kim, Y. Climate-, Depth-, and Time-based Laboratory Aging Procedure for Asphalt Mixtures. Asph. Paving Technol. Assoc. Asph. Paving Technol. Tech. Sess. 2018, 87, 467–511. [Google Scholar] [CrossRef]

- D’Angelo, J.A. Asphalt Binders and aging 20hr or 40hr PAV. In Proceedings of the Binder Expert Task Group Meeting, Fall River, MA, USA, 9–10 May 2018. [Google Scholar]

- Singhvi, P.; Karakas, A.; Ozer, H.; Al-Qadi, I.L.; Hossain, K. Impact of Asphalt Modifier Dosage on Modified Binder Rheology and Chemistry with Long-Term Aging. In Proceedings of the Airfield and Highway Pavements 2019, Chicago, IL, USA, 21–24 July 2019. [Google Scholar]

- Petersen, J.C. Chemical Composition of Asphalt As Related To Asphalt Durability: State of the Art. Transp. Res. Rec. 1984, 999, 13–30. [Google Scholar]

- Sharma, B.K.; Ma, J.; Kunwar, B.; Singhvi, P.; Ozer, H.; Rajagopalan, N. Modeling the Performance Properties of Ras and Rap Blended Asphalt Mixes Using Chemical Compositional Information; Illinois Center for Transportation: Rantoul, IL, USA, 2017. [Google Scholar]

- Sharma, B.K.; Singhvi, P.; Kunwar, B.; Kohli, K.; Ma, J.; Ozer, H.; Al-Qadi, I.L. Aging and recycling effect on the relationship between the chemistry and rheological parameters for binders. Fuel, (under review).

- Sáda Costa, M.; Farcas, F.; Santos, L.F.; Eusébio, M.I.; Diogo, A.C. Chemical and Thermal Characterization of Road Bitumen Ageing. Mater. Sci. Forum 2010, 636–637, 273–279. [Google Scholar]

- Xiang, L.; Cheng, J.; Kang, S. Thermal oxidative aging mechanism of crumb rubber/SBS composite modified asphalt. Constr. Build. Mater. 2015, 75, 169–175. [Google Scholar] [CrossRef]

- Abbas, A.R.; Mannan, U.A.; Dessouky, S. Effect of recycled asphalt shingles on physical and chemical properties of virgin asphalt binders. Constr. Build. Mater. 2013, 45, 162–172. [Google Scholar] [CrossRef]

- Sun, Z.; Yi, J.; Huang, Y.; Feng, D.; Guo, C. Properties of asphalt binder modified by bio-oil derived from waste cooking oil. Constr. Build. Mater. 2016, 102, 496–504. [Google Scholar] [CrossRef]

- Poulikakos, L.D.; Santos, S.; dos Bueno, M.; Kuentzel, S.; Hugener, M.; Partl, M.N. Influence of short and long term aging on chemical, microstructural and macro-mechanical properties of recycled asphalt mixtures. Constr. Build. Mater. 2014, 51, 414–423. [Google Scholar] [CrossRef]

- Robertson, R.E. Chemical Properties of Asphalts and Their Relationship to Pavement Performance; Western Research Institute: Laramie, WY, USA, 1991. [Google Scholar]

- Liu, G.; Nielsen, E.; Komacka, J.; Leegwater, G.; van de Ven, M. Influence of soft bitumens on the chemical and rheological properties of reclaimed polymer-modified binders from the “old” surface-layer asphalt. Constr. Build. Mater. 2015, 79, 129–135. [Google Scholar] [CrossRef]

- Branthaver, J.F.; Petersen, J.C.; Robertson, R.E.; Duvall, J.J.; Kim, S.S.; Harnsberger, P.M.; Mill, T.; Ensley, E.K.; Barbour, F.A.; Schabron, J.F. Binder Charact. Eval 1993, 2, 1–467. [Google Scholar]

- Yu, X.; Zaumanis, M.; dos Santos, S.; Poulikakos, L.D. Rheological, microscopic, and chemical characterization of the rejuvenating effect on asphalt binders. Fuel 2014, 135, 162–171. [Google Scholar] [CrossRef]

- Huang, S.-C.; Pauli, A.T.; Grimes, R.W.; Turner, F. Ageing characteristics of RAP binder blends – what types of RAP binders are suitable for multiple recycling? Road Mater. Pavement Des. 2014, 15, 113–145. [Google Scholar] [CrossRef]

- Gong, M.; Yang, J.; Zhang, J.; Zhu, H.; Tong, T. Physical–chemical properties of aged asphalt rejuvenated by bio-oil derived from biodiesel residue. Constr. Build. Mater. 2016, 105, 35–45. [Google Scholar] [CrossRef]

- Anderson, D.A.; Chris, D.W.; Bahia Hussain, U.; Dongre, R.; Sharma, M.G.; Antle Charles, E.; Button, J. Binder Characterization and Evaluation Volume 3. Phys. Charact. 1994, 3, 1–475. [Google Scholar]

- Pauli, A.; Farrar, M.; Huang, S.-C. Characterization of Pavement Performance Based on Field Validation Test Site Data Interpreted by an Asphalt Composition Model of Binder Oxidation. Transp. Res. Circ. 2018, E-C234, 34–62. [Google Scholar]

- Airey, G.D. Use of Black Diagrams to Identify Inconsistencies in Rheological Data. Road Mater. Pavement Des. 2002, 3, 403–424. [Google Scholar] [CrossRef]

- Speight, J.G. The Chemistry and Technology of Petroleum. In The Chemistry and Technology of Petroleum; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Peterson, J.C. A Dual, Sequential Mechanism for the Oxidation of Petroleum Asphalts. Pet. Sci. Technol. 1998, 16, 1023–1059. [Google Scholar] [CrossRef]

| Modifier | Type 1 |

|---|---|

| A | NA 2 |

| C | Fatty acid derivative |

| D | Bio-oil blend |

| E | Modified vegetable oil |

| G | Glycol amine |

| K | ReOB |

| Sample | C (%) | H (%) | N (%) | O (%) | S (%) |

|---|---|---|---|---|---|

| A | 77.3 | 11.9 | 0.4 | 10.4 | 0.001 |

| C | 70.1 | 11.5 | 3.5 | 14.9 | 0.004 |

| D | 76.1 | 11.8 | 0.8 | 11.3 | 0.03 |

| E | 77.1 | 11.5 | 0.6 | 9.9 | 0.33 |

| G | 47.9 | 10.0 | 9.0 | 33.1 | 0.00 |

| K | 79.7 | 12.7 | 0.9 | 5.7 | 0.98 |

| Modifier | Number-Average Molecular Weight (Mn) | Weight Average Molecular Weight (Mw) | Polydispersity Index (PDI) |

|---|---|---|---|

| A | 4450 | 4616 | 1.04 |

| C | 3709 | 3971 | 1.07 |

| D | 4345 | 4909 | 1.13 |

| E | 4684 | 4805 | 1.03 |

| G | 2349 | 2596 | 1.11 |

| K | 8933 | 48,784 | 5.46 |

| Sample ID | Saturates (%) | Aromatics (%) | Resins (%) | Asphaltenes (%) | Residue (%) | Total (%) |

|---|---|---|---|---|---|---|

| A | 8.3 | 19.7 | 62.5 | 4.6 | 4.9 | 100.0 |

| C | 0.0 | 0.0 | 70.1 | 23.3 | 6.6 | 100.0 |

| D | 1.2 | 10.5 | 78.5 | 7.5 | 2.3 | 100.0 |

| E | 0.0 | 0.1 | 83.4 | 13.0 | 3.5 | 100.0 |

| K | 59.3 | 0.4 | 10.3 | 4.0 | 26.0 | 100.0 |

| Binder ID | High PG | Low PG | Continuous PG | Superpave PG |

|---|---|---|---|---|

| S1 | 66.4 | −23.7 | 66.4-23.7 | 64-22 |

| S5 | 61.1 | −29.5 | 61.1-29.5 | 58-28 |

| S1-A-3.5 | 61.6 | −30.0 | 61.6-30.0 | 58-28 |

| S1-C-3.1 | 61.4 | −30.1 | 61.4-30.1 | 58-28 |

| S1-D-3.1 | 62.1 | −28.3 | 62.1-28.3 | 58-28 |

| S1-E-3.1 | 62.3 | −30.7 | 62.3-30.7 | 58-28 |

| S1-G-6.5 | 60.8 | −28.5 | 60.8-28.5 | 58-28 |

| S1-K-10 | 59.4 | −27.3 | 59.4-27.3 | 58-22 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Singhvi, P.; García Mainieri, J.J.; Ozer, H.; Sharma, B.K.; Al-Qadi, I.L. Effect of Chemical Composition of Bio- and Petroleum-Based Modifiers on Asphalt Binder Rheology. Appl. Sci. 2020, 10, 3249. https://doi.org/10.3390/app10093249

Singhvi P, García Mainieri JJ, Ozer H, Sharma BK, Al-Qadi IL. Effect of Chemical Composition of Bio- and Petroleum-Based Modifiers on Asphalt Binder Rheology. Applied Sciences. 2020; 10(9):3249. https://doi.org/10.3390/app10093249

Chicago/Turabian StyleSinghvi, Punit, Javier J. García Mainieri, Hasan Ozer, Brajendra K. Sharma, and Imad L. Al-Qadi. 2020. "Effect of Chemical Composition of Bio- and Petroleum-Based Modifiers on Asphalt Binder Rheology" Applied Sciences 10, no. 9: 3249. https://doi.org/10.3390/app10093249

APA StyleSinghvi, P., García Mainieri, J. J., Ozer, H., Sharma, B. K., & Al-Qadi, I. L. (2020). Effect of Chemical Composition of Bio- and Petroleum-Based Modifiers on Asphalt Binder Rheology. Applied Sciences, 10(9), 3249. https://doi.org/10.3390/app10093249