1. Introduction

In recent years, the number of tractors of different forms has greatly increased, as they are the main type of agricultural power machinery. The inefficiency and high fuel consumption of traditional tractors lead to energy waste and environmental pollution [

1]. A tractor uses 345,000 kL of oil, accounting for 48.5% of the total oil consumption of agricultural machines. Thus, developing an efficient tractor is necessary [

2].

Battery-powered electric vehicles have been proven to be one of the most effective ways to reduce emissions and energy consumption. With the rapid development of battery technology and motor technology, there is growing interest in the electrification of agricultural tractors [

3]. Pure electric tractors (PETs) seem to be a promising solution in the context of more sustainable farming as they can use a wide range of power sources which can be obtained from a variety of renewable or clean energy sources [

4]. However, at the current technical level, the biggest bottleneck in the development of PET is their limited operation time. Optimizing transmission efficiency is a practical method to increase operation time before the energy density of the battery displays evident improvement. The improvement of transmission efficiency depends on the development of an efficient powertrain and effective control strategies.

At present, the powertrains of PETs on the market are mostly driven by a single motor, whereby the diesel engine is replaced by batteries and a motor and the original multi-gear transmission is retained [

5,

6,

7]. Considering the different power requirements of tractors under various working conditions, the motor often works in a low-efficiency region under low-load conditions. Moreover, research shows that the tractors’ multi-speed mechanical gearboxes will bring more energy losses [

8]. It has been found that in the powertrain configuration of “single motor + multi-speed transmission”, it is difficult to change the current situation of tractors, whereby they present low efficiency and high power consumption. Therefore, it is necessary to find other powertrain structures that can improve tractor efficiency. Many studies have shown that dual-input coupling powertrain systems (DICPSs) have been widely used in electric vehicles to reduce energy consumption and improve efficiency [

9,

10,

11,

12]. By using two smaller motors instead of a single high-power source, the torque capacity of a single motor can be reduced, which is beneficial to the development of high-speed motors, thereby increasing the power density of the driving system. Moreover, the operating points of the two motors can be adjusted to optimize the efficiency of the drive system.

Most studies on DICPS in the agricultural tractor field have focused on hybrid tractors, while the PET concept is applied less frequently. Lee et al. designed a powertrain simulation model and proved the fuel consumption reduction of the parallel hybrid tractor through the power distribution ratio strategy. The results showed that the fuel efficiency of the hybrid tractor was 11.78% higher than the conventional tractor [

13]. Lee et al. developed a parallel hybrid tractor, which had three control modes: idle, power assist, and battery charge. The results showed that the performance of the hybrid tractor was better than the conventional tractor at the higher load condition, and the fuel efficiency was 74% lower than that of the conventional tractor [

2]. Deng et al. designed a parallel hybrid tractor transmission system with a planetary gear set as the power coupling device, and a design theory and calculation method for the transmission system were proposed. The simulation results showed that the hybrid tractor could save energy by up to 24% under plowing operations compared to the equivalent power fuel tractor [

14].

The literature studies described above show that hybrid tractors with a dual-input powertrain can effectively improve fuel efficiency. However, hybrid tractors do not meet the development trend of new energy vehicles for zero emissions. Moreover, the motors of hybrid tractors are mainly used as an auxiliary power source to improve the fuel efficiency of the engine, which cannot fully provide the characteristics of high efficiency and motor precision. Therefore, the DICPS was adopted to improve the overall efficiency of PETs. When the power demand is low, the PET can be driven by a single motor to increase the torque utilization factor of the motor. When the power demand is high, the PET can be driven by two motors to improve the operating efficiency of the DICPS.

After the powertrain structure is determined, reasonable parameter sizing and control strategies are necessary to realize efficient operation of the dual-motor-driven electric tractor (DMET). However, the parameter-matching design method of a conventional tractor was not entirely suitable for DMET. For conventional tractors, only the dynamic performance indexes need to be satisfied, but the parameter matching of DICPSs should not only consider the dynamic indexes, but also the high-efficiency region distribution of the two motors [

15,

16]. Chen et al. proposed a method of powertrain parameter-matching and optimization design for a dual-motor-driven electric tractor, and used a particle swarm optimization algorithm based on a mixed penalty function to optimize the parameters [

17]. The results showed that the selected optimization objectives had made evident progress after the optimization. However, they did not optimize the structure parameters according to the actual working condition data of the tractor. Therefore, it is necessary to study the matching optimization between the high-efficiency region of the two motors and the actual working conditions of the tractor.

There have been some studies on control strategies for DICPSs. Wu et al. proposed a real-time control strategy for a dual-input power-split transmission system [

18]. The control strategy improved the overall efficiency of the vehicle at low speed and at frequent deceleration. However, the three PI controllers required a lot of debugging to obtain the best control parameters, a time-consuming process that was not able to guarantee robustness and timeliness. Zhang et al. used Pontryagin’s minimum principle (PMP) algorithm to optimize the control strategy of an electric bus driven by two motors under three driving cycles [

19]. Jia et al. proposed optimization-based energy management strategies for hybrid electric agricultural tractors to minimize fuel consumption in typical working cycles [

20]. Compared with the typical rule-based strategy, these optimal energy management strategies (EMSs) showed significant improvements in fuel efficiency. Both PMP and Dynamic programming (DP) strategies require information of the entire cycle condition, and can only achieve global optimization under specific conditions. Computational complexity makes real-time operation difficult to achieve.

The objectives of this study were to design a DICPS for a PET which could improve the PET’s economic performance without compromising its dynamic performance. Furthermore, the system needs a reasonable parameter configuration and an effective energy management strategy to ensure the efficient operation of the PET. Furthermore, this study aimed to find the optimal parameter configuration for tractor working conditions through simulation experiments.

The paper is organized as follows:

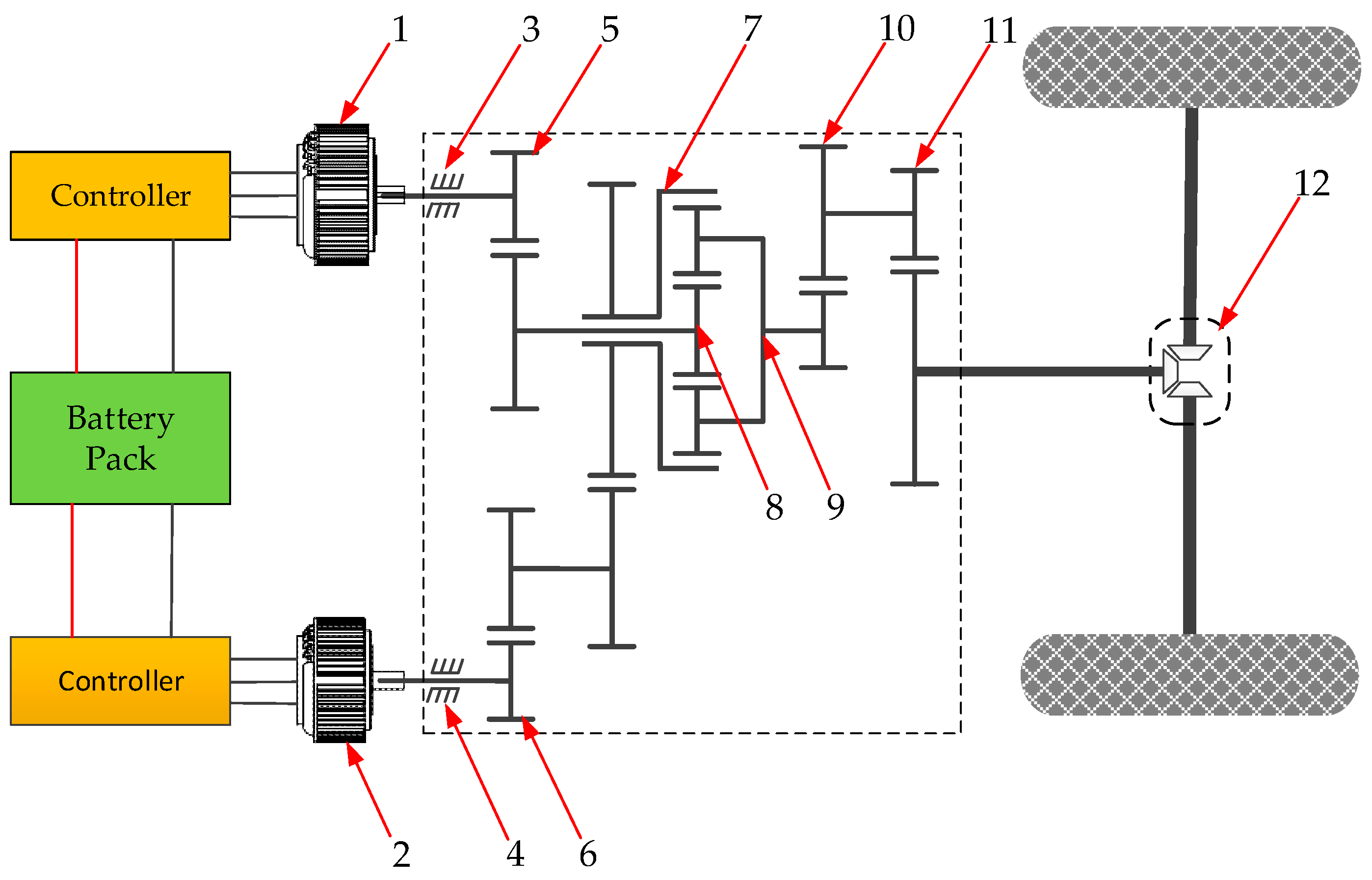

Section 2.1 introduces the overall configuration of the DICPS. The modeling and driving modes of the DICPS are displayed in

Section 2.2. The system parameters are matched and determined in

Section 2.3. In

Section 2.4, an EMS developed to minimize power loss and maximize overall system efficiency is explained. The simulation results and discussion are given in

Section 3, where two typical working conditions were used to validate the effectiveness of the proposed method. Finally, conclusions are presented in

Section 4.