Study on the Mechanical Responses of Plastic Pipes Made of High Density Polyethylene (HDPE) in Water Supply Network

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

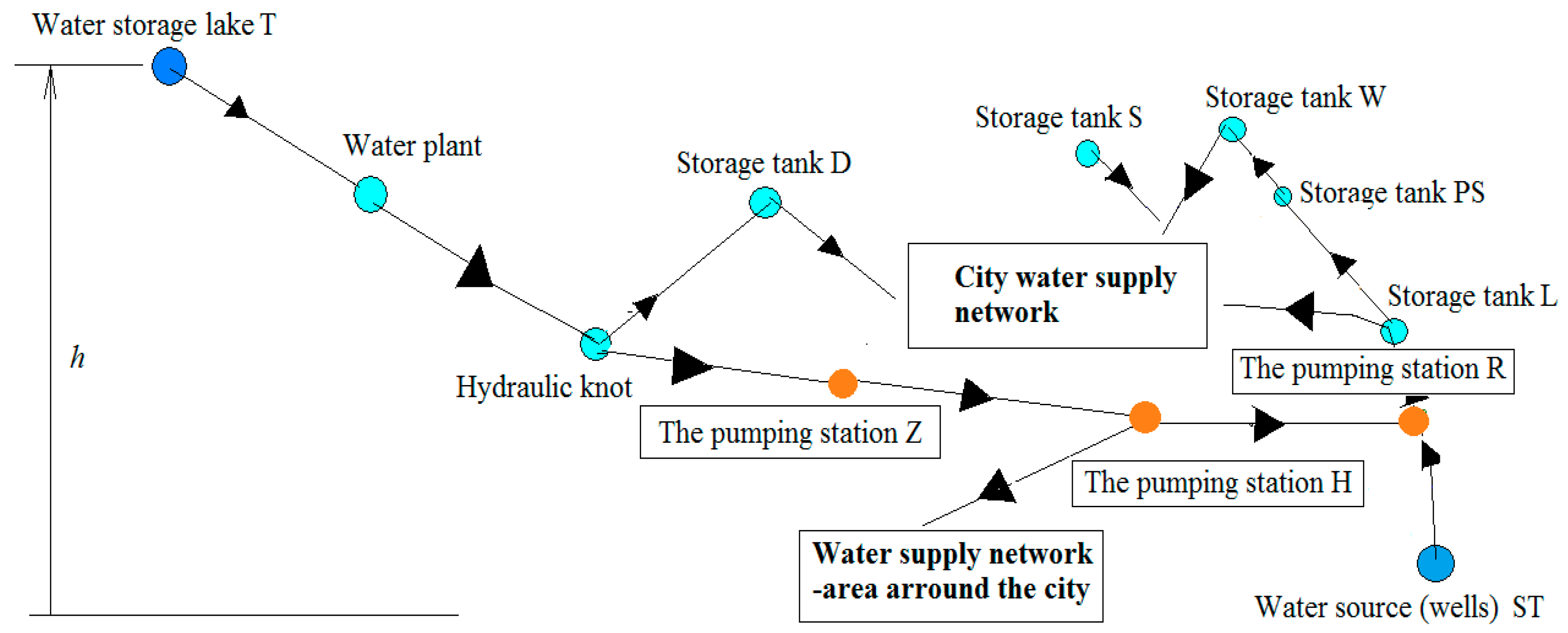

2.1. Diagram of a Water Supply Network

- The water taken from the T. storage lake is treated in the Water Plant, and then, by gravity, it is sent to the storage tanks in D and to the pumping stations Z, H and, partially to R. From storage tank D, through gravitational pipelines, the water is transported to the city’s distribution network (Figure 1).

- The water from the storage tank S, through a gravitational pipe, supplies the high-pressure area of the city’s distribution network.

- The water from water sources (wells) ST, passed through pumping stations R, is charged into the storage tank L. and from there, through arteries in the distribution network of the municipality.

2.2. Types of HDPE Pipes Used in Water Supply Networks

2.3. Methods

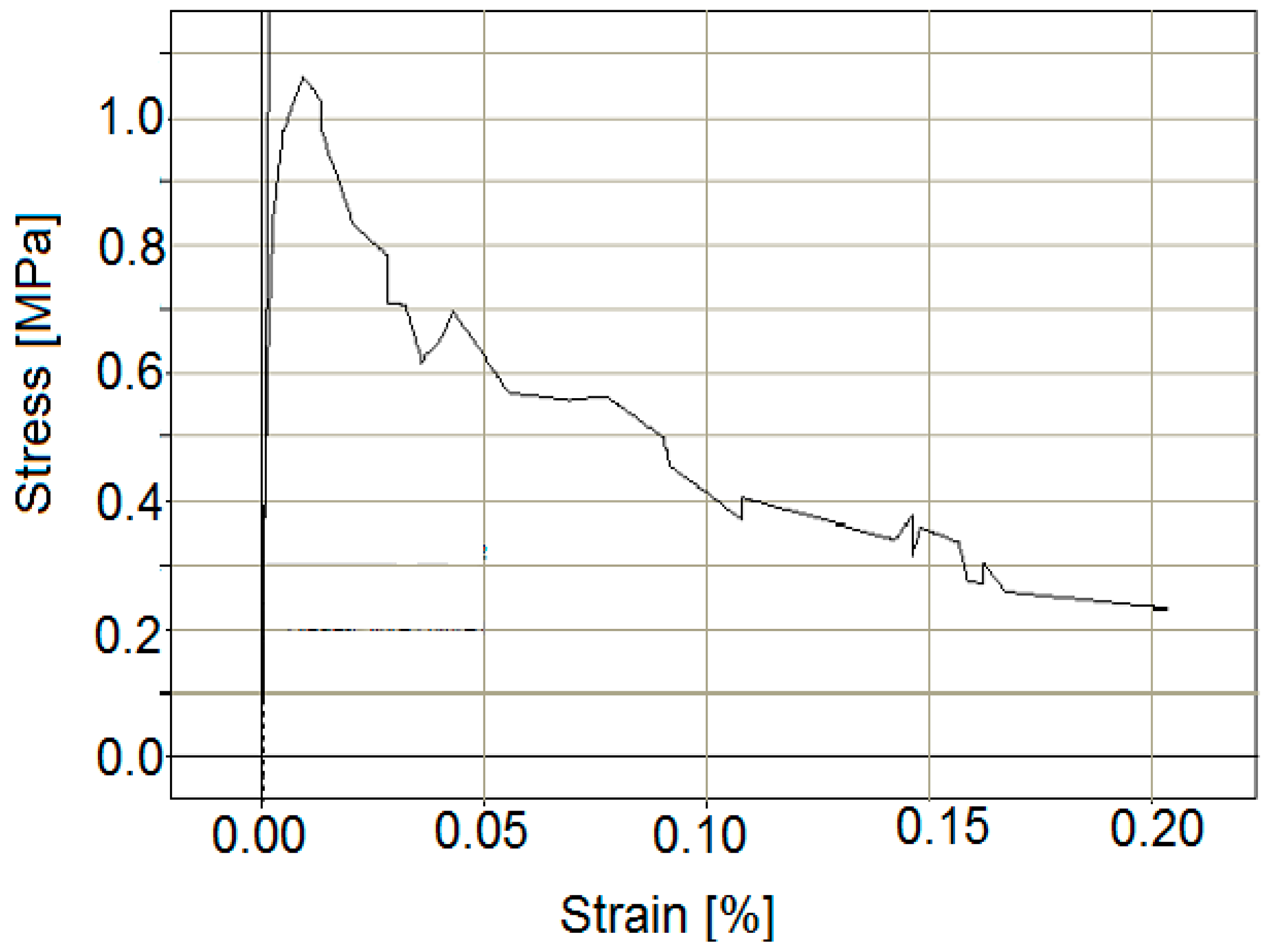

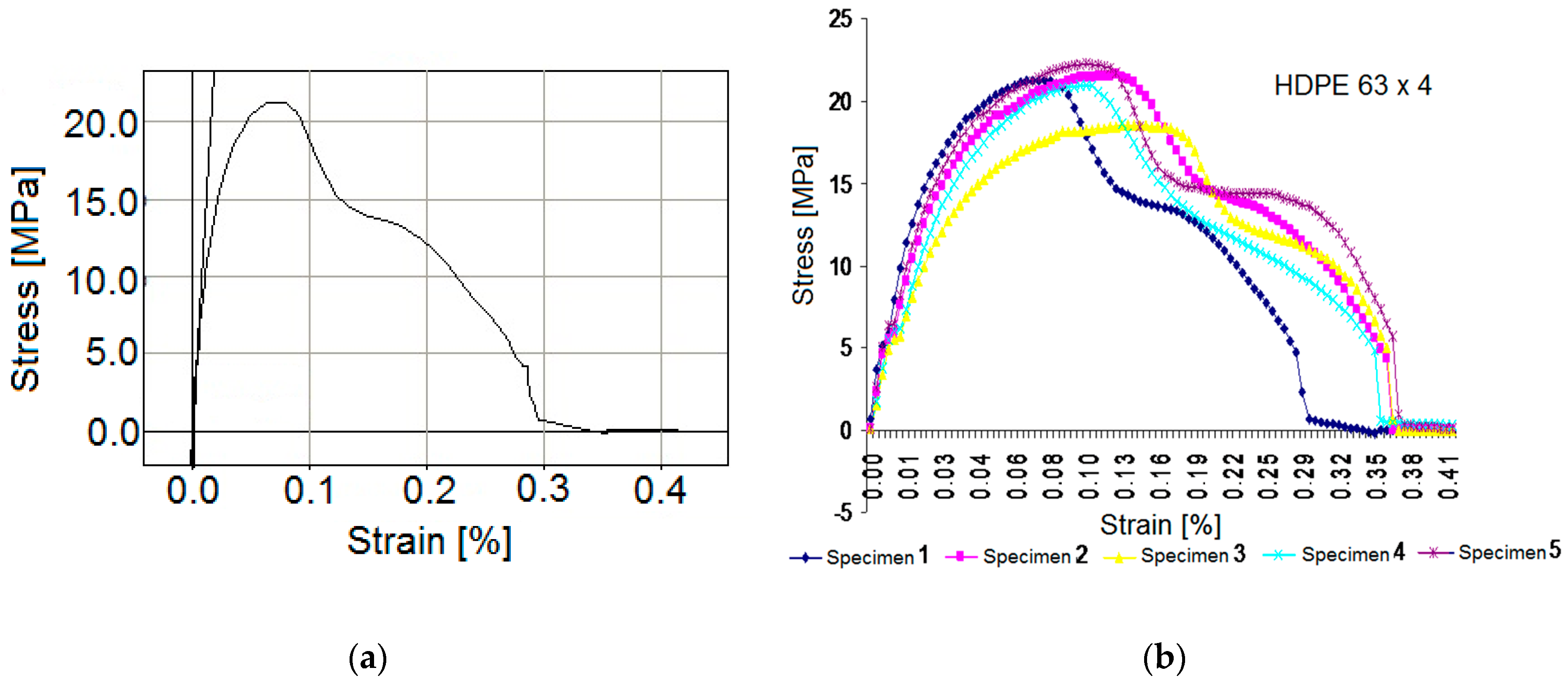

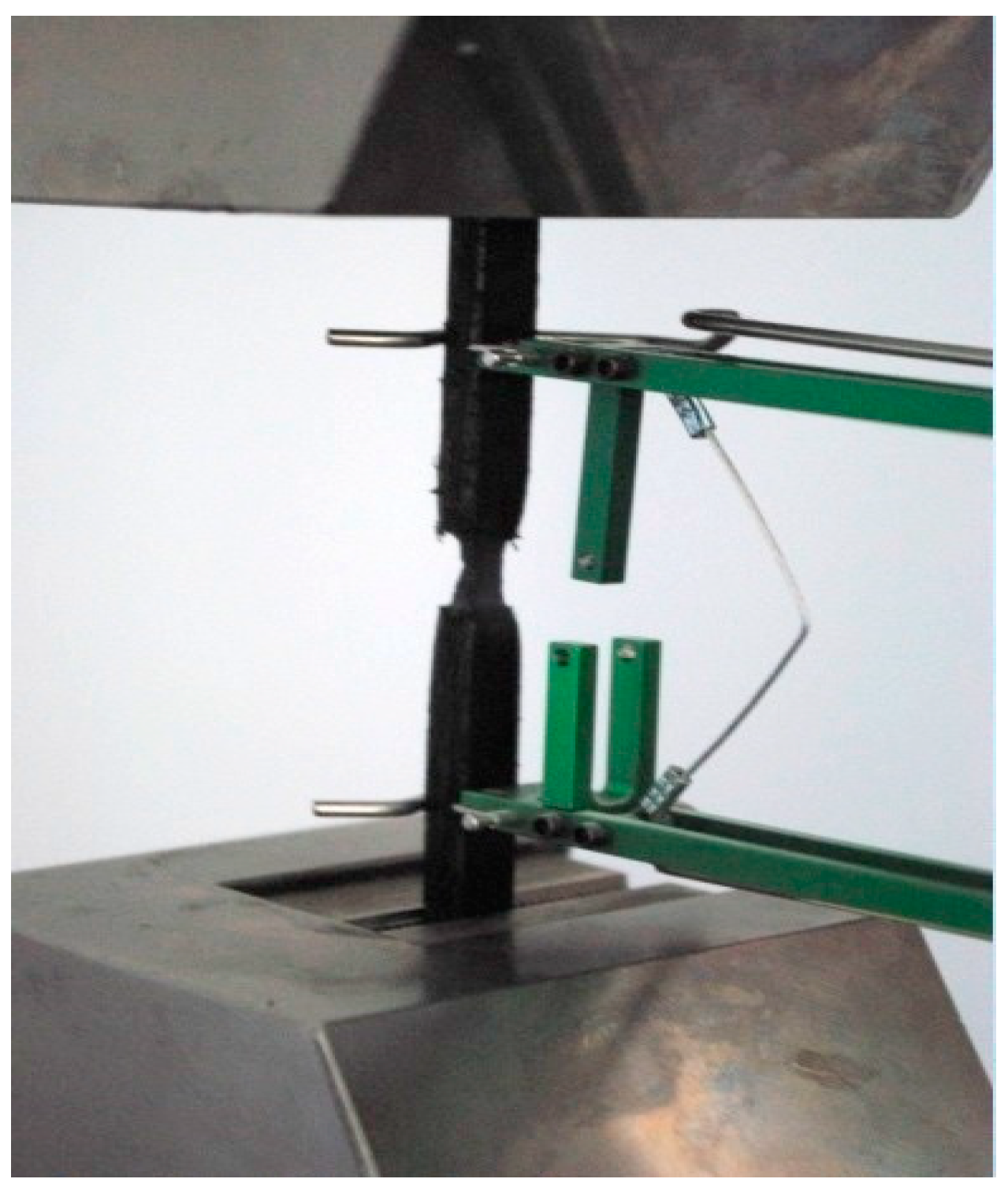

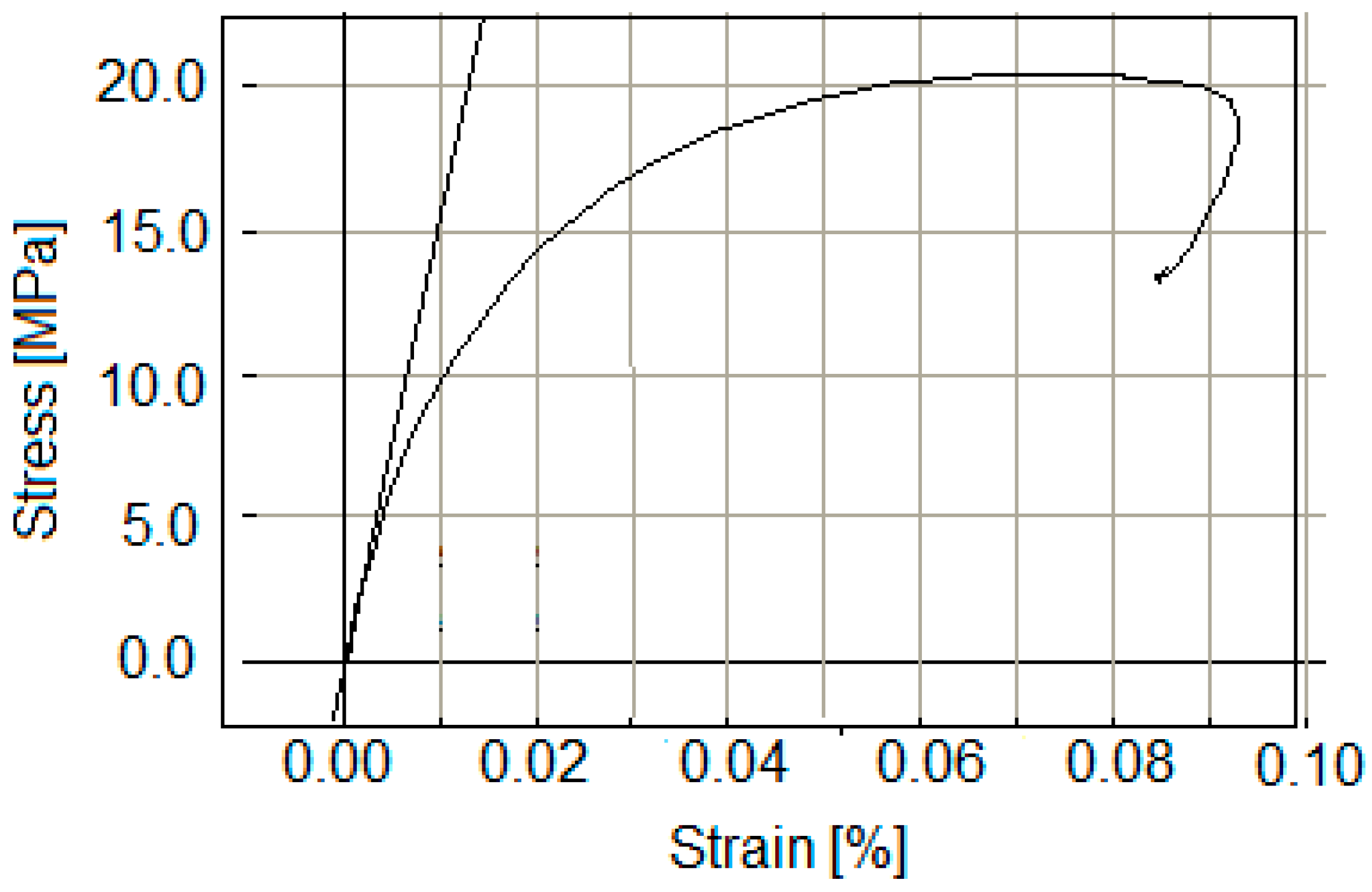

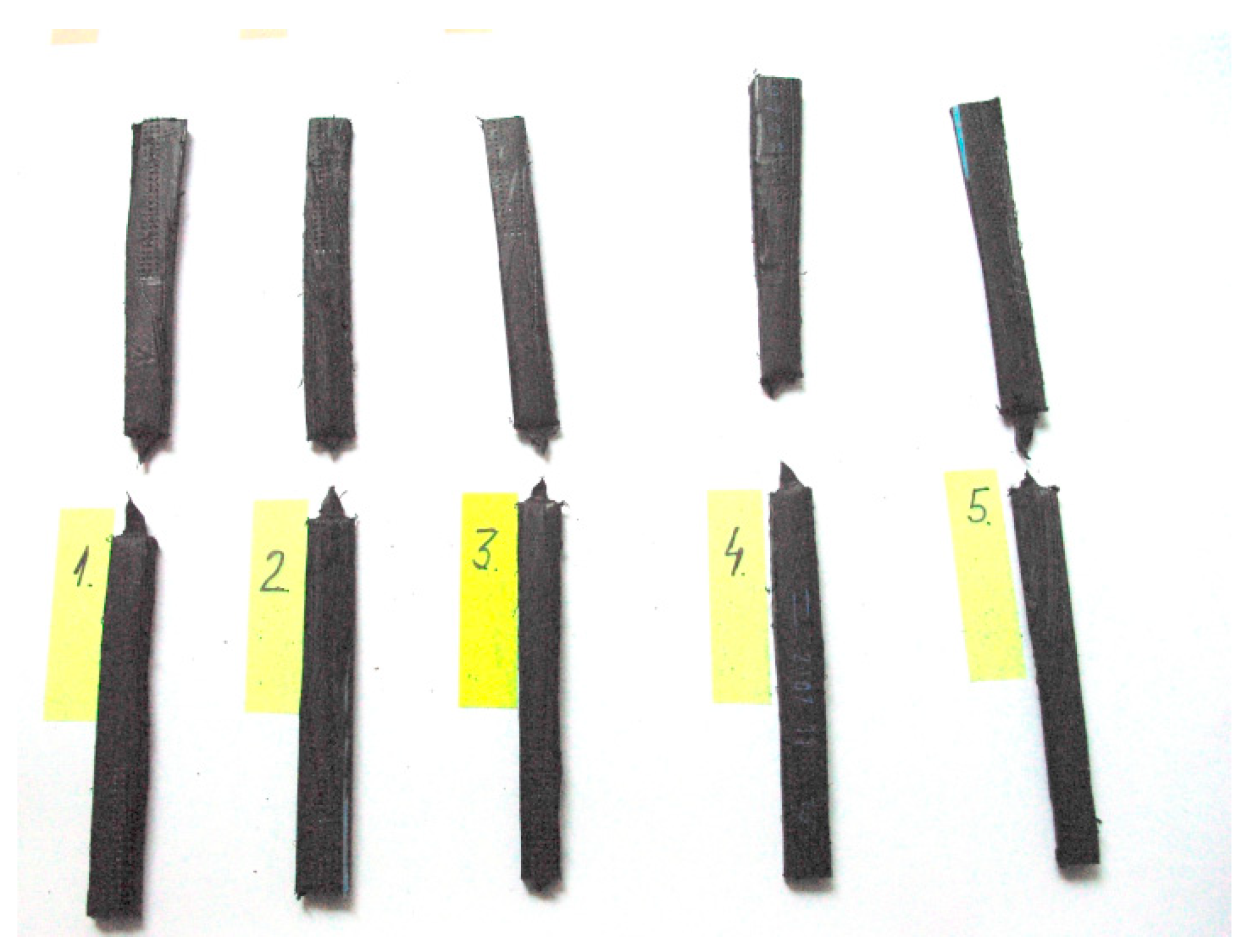

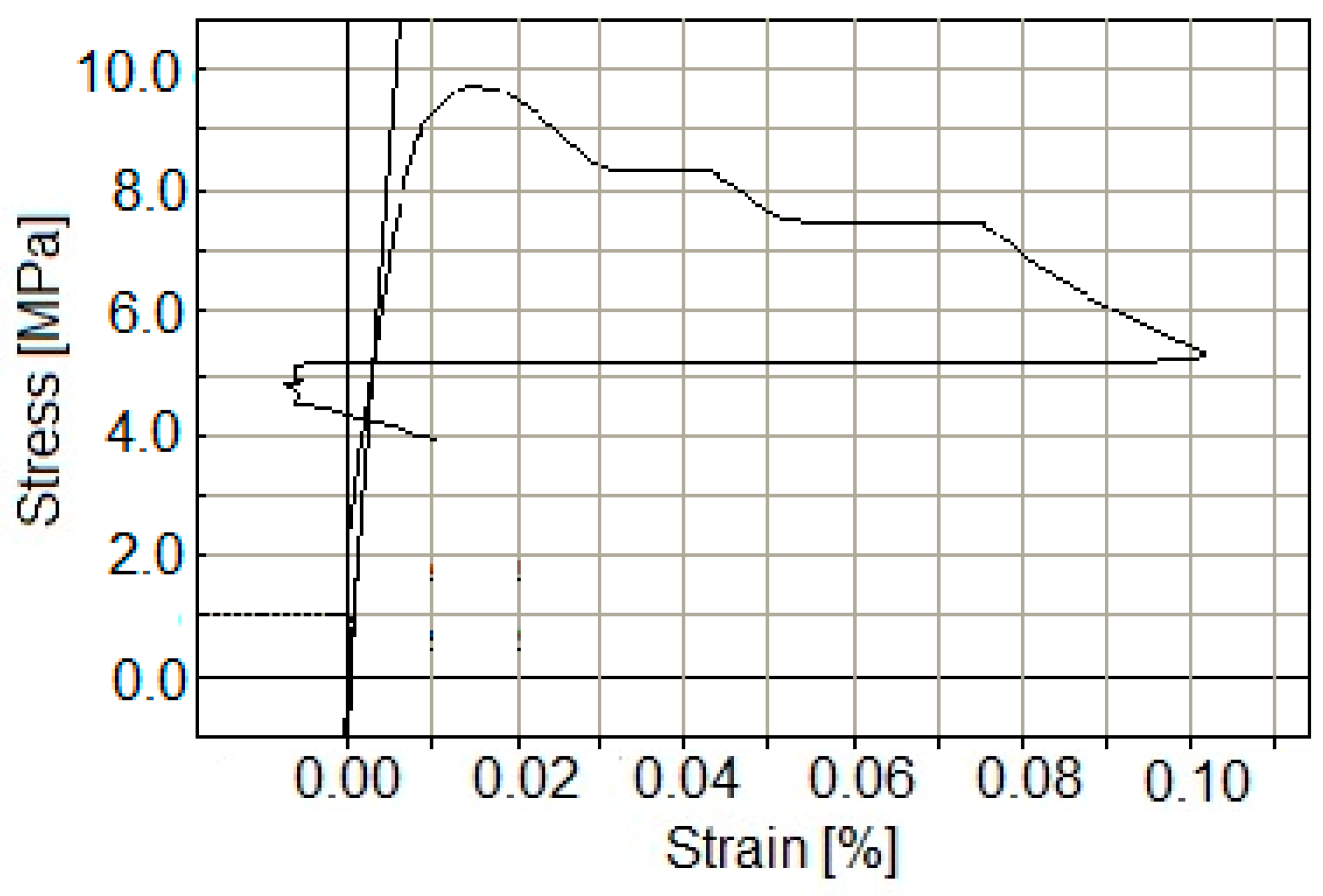

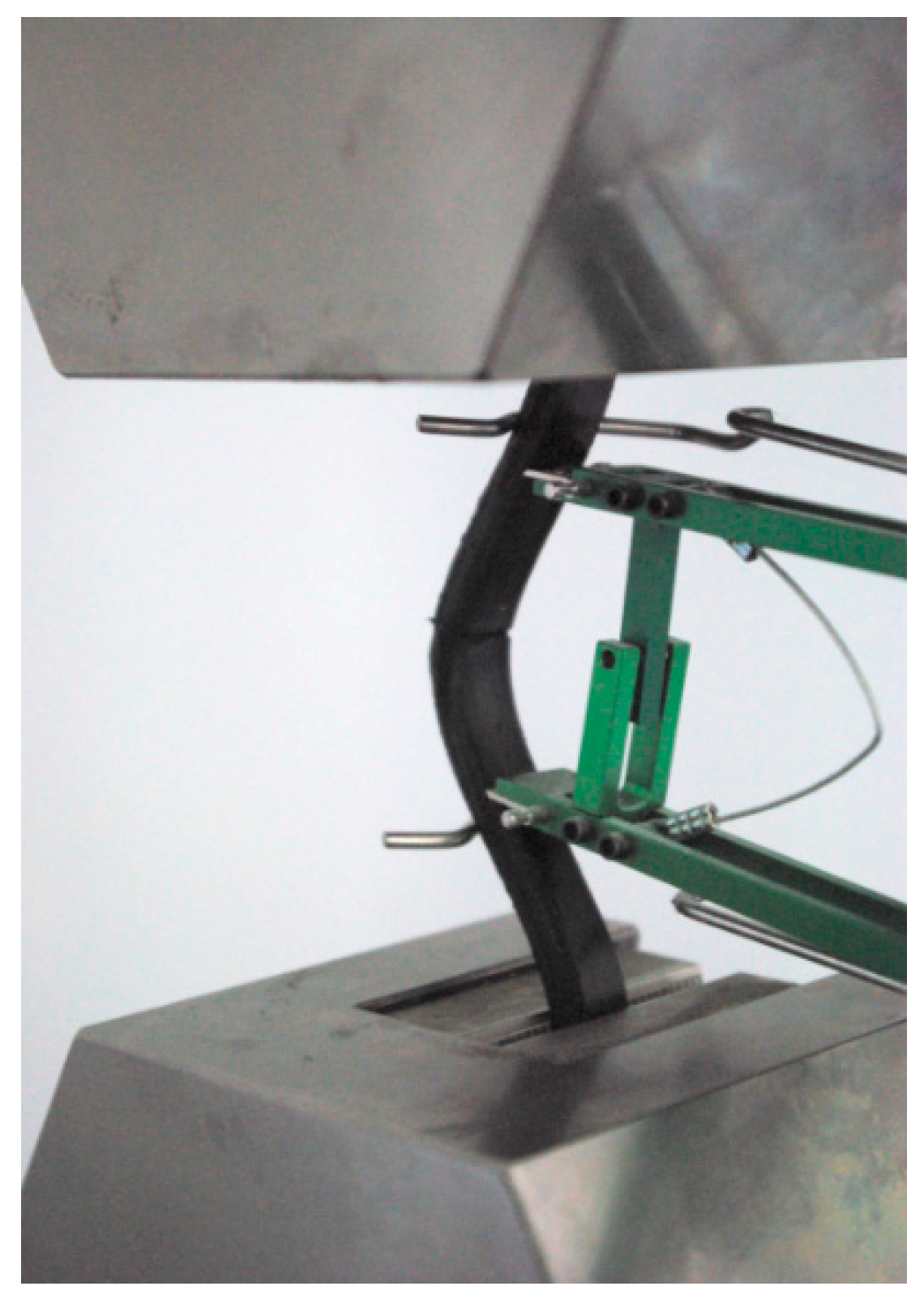

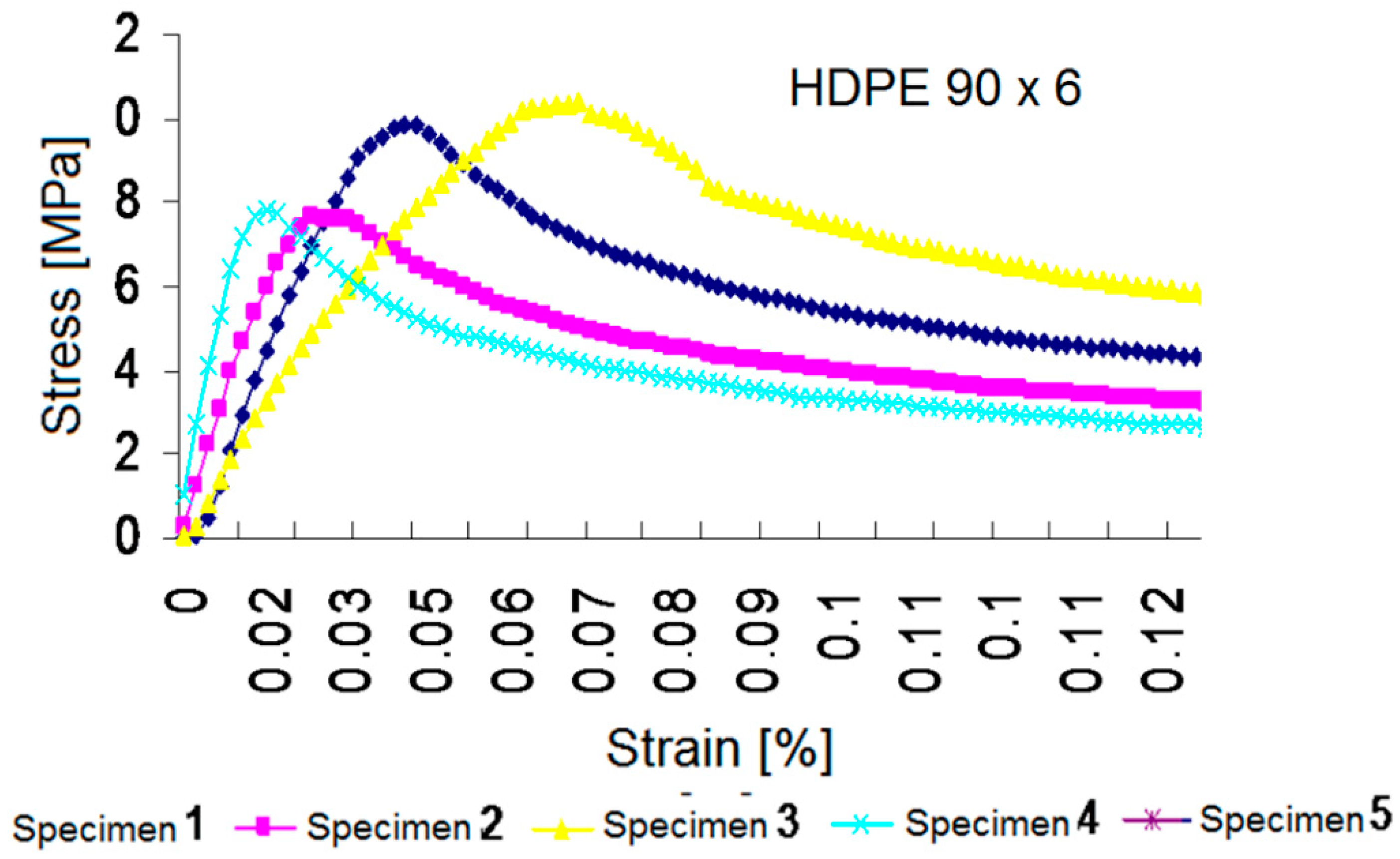

3. Experimental Determination of Mechanical Properties

4. Strain and Stress Field in the Elbow of the Pipes

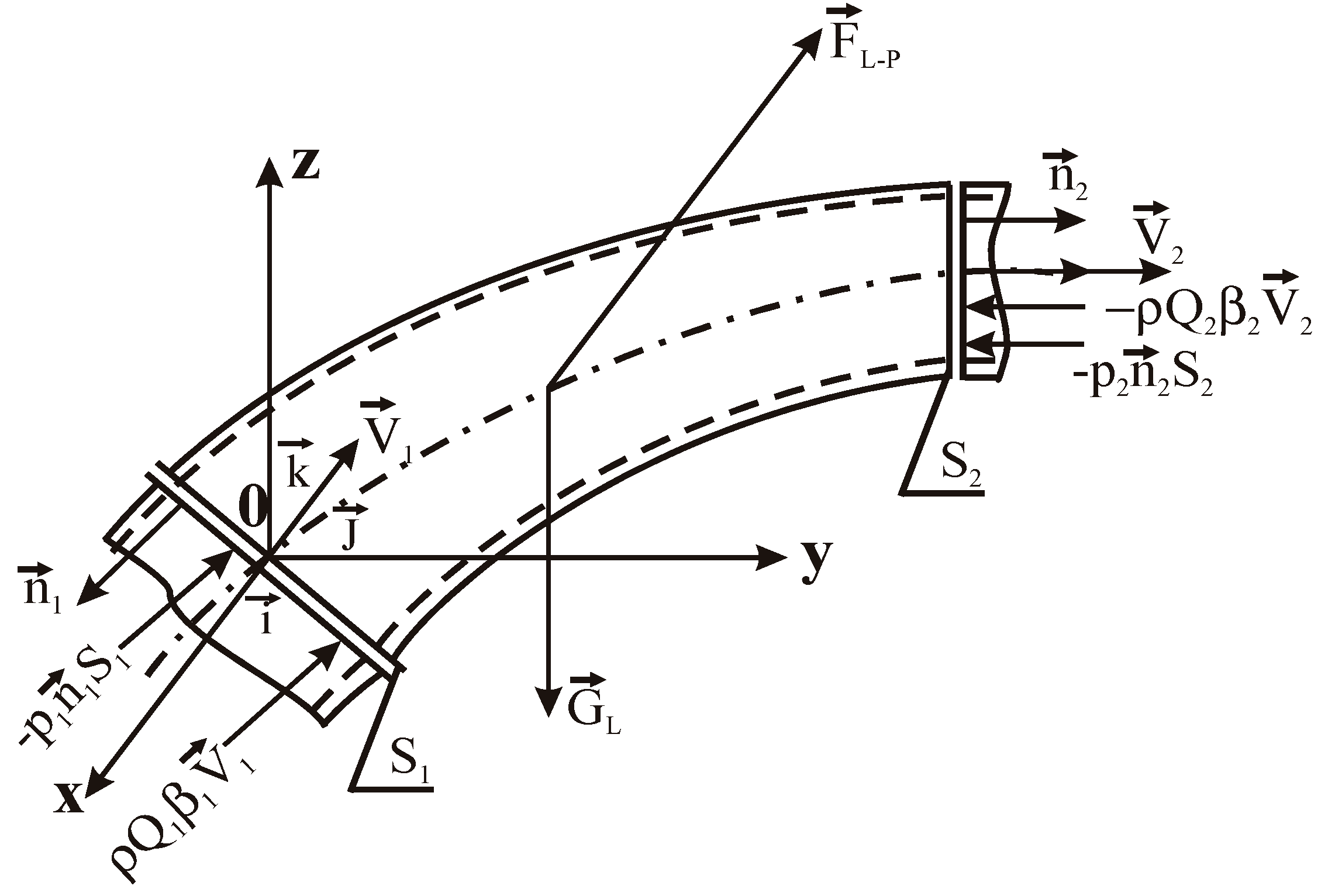

4.1. Analytical Calculus of the Hydrodynamic Force at an Angle α = 45°

- the theorem of momentum to determine the hydrodynamic force on the wall of the pipe;

- the continuity equation;

- Bernoulli’s formula.

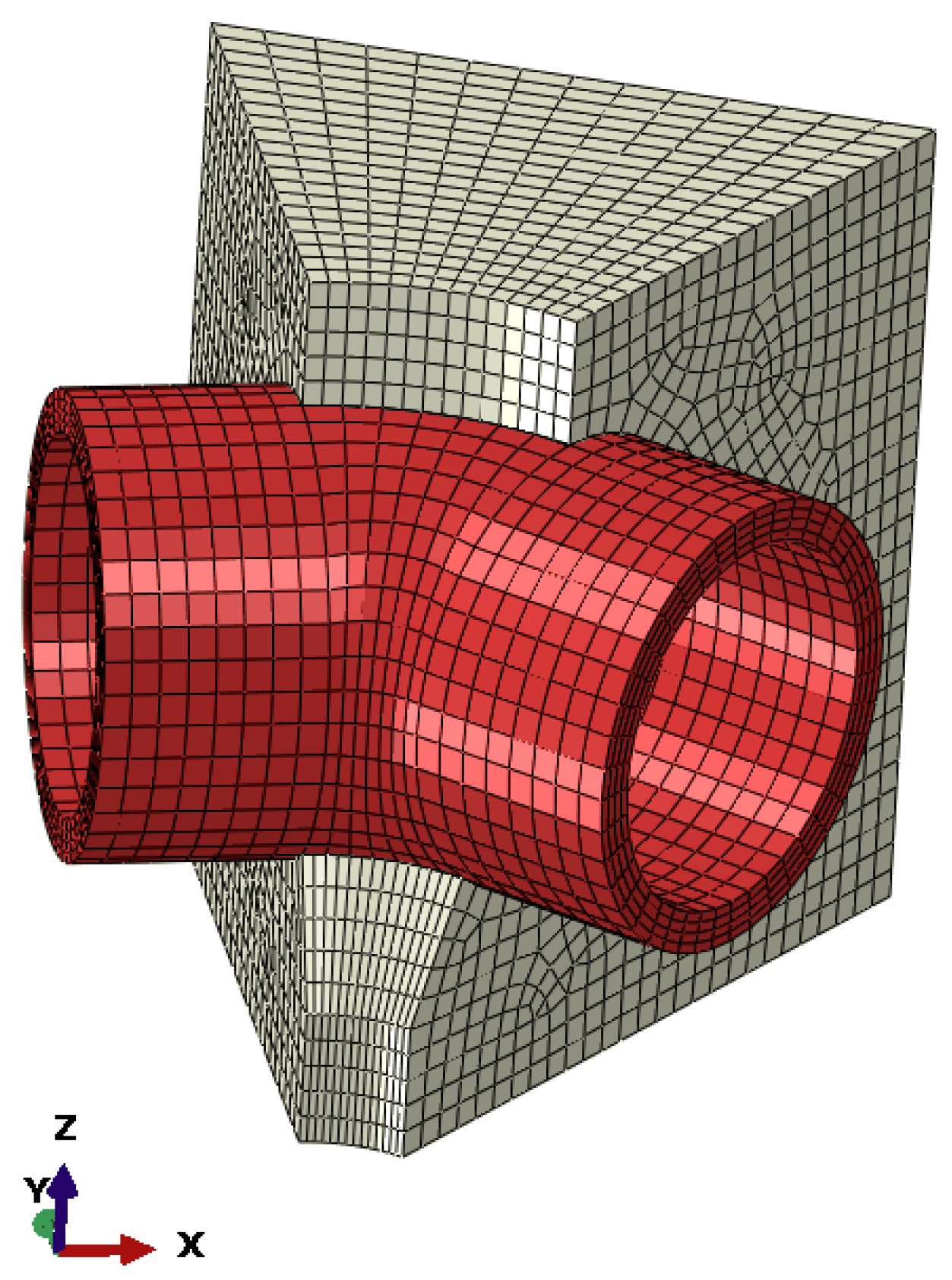

4.2. Structural Model of an Elbow in an Anchorage

- The pressure inside the elbow, resulting from the analytical calculation, taken as a reference pressure perpendicular to the inner wall of the elbow;

- Clamping: the ends of the elbow, the concrete anchor on the outside, so that all these degrees of freedom are canceled. Thus, for the performed analysis, the constraints regarding the clamping were imposed, through the input data, to the model.

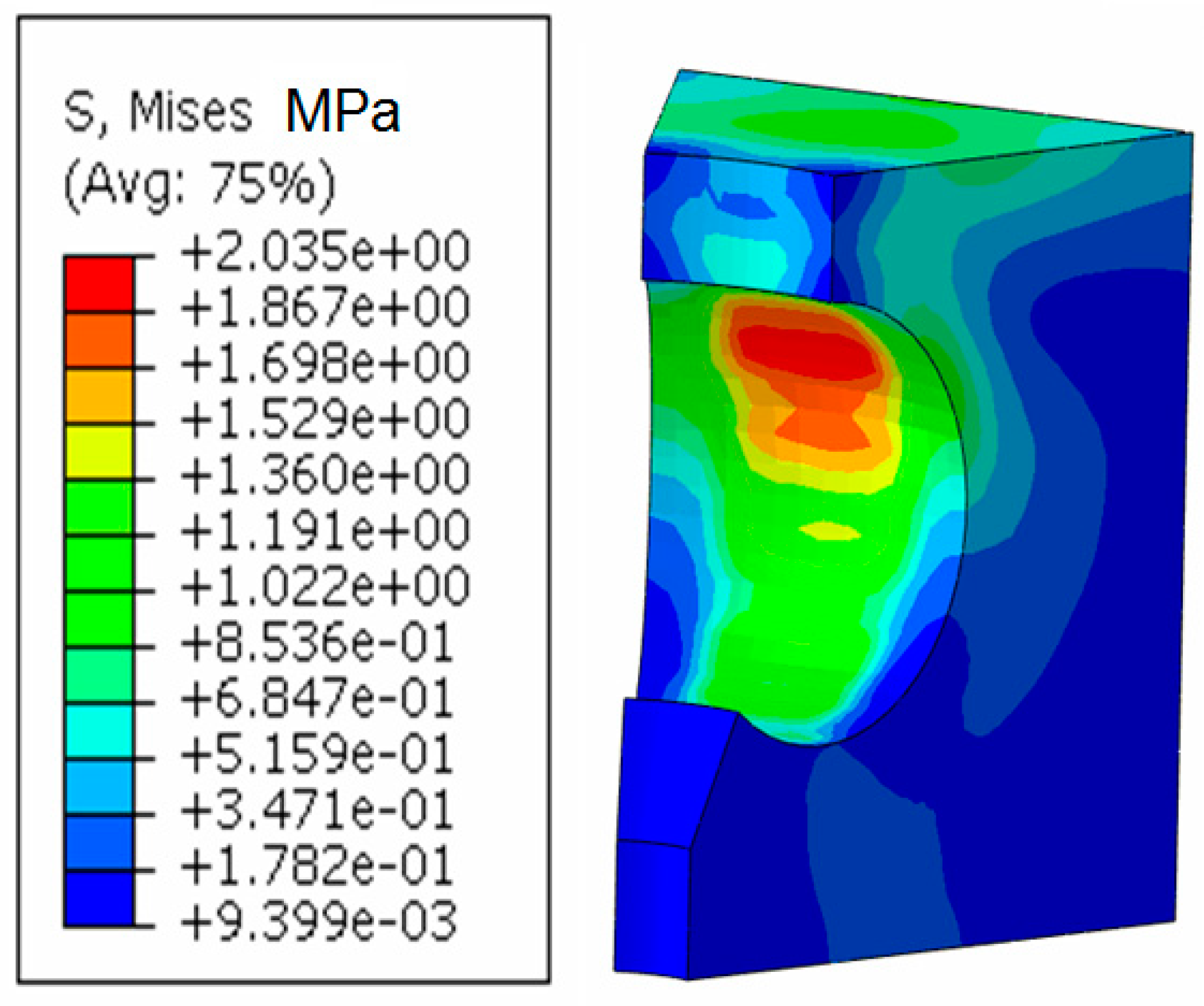

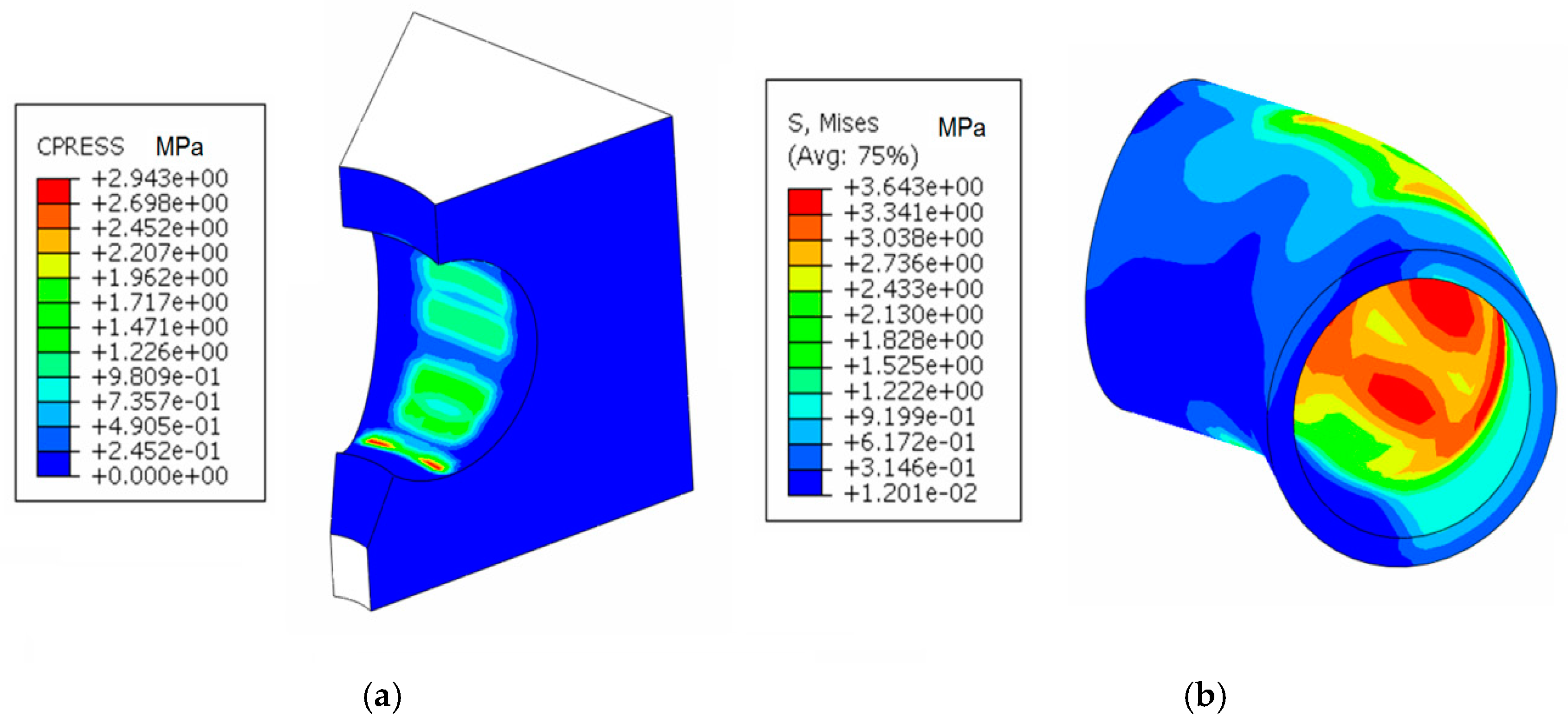

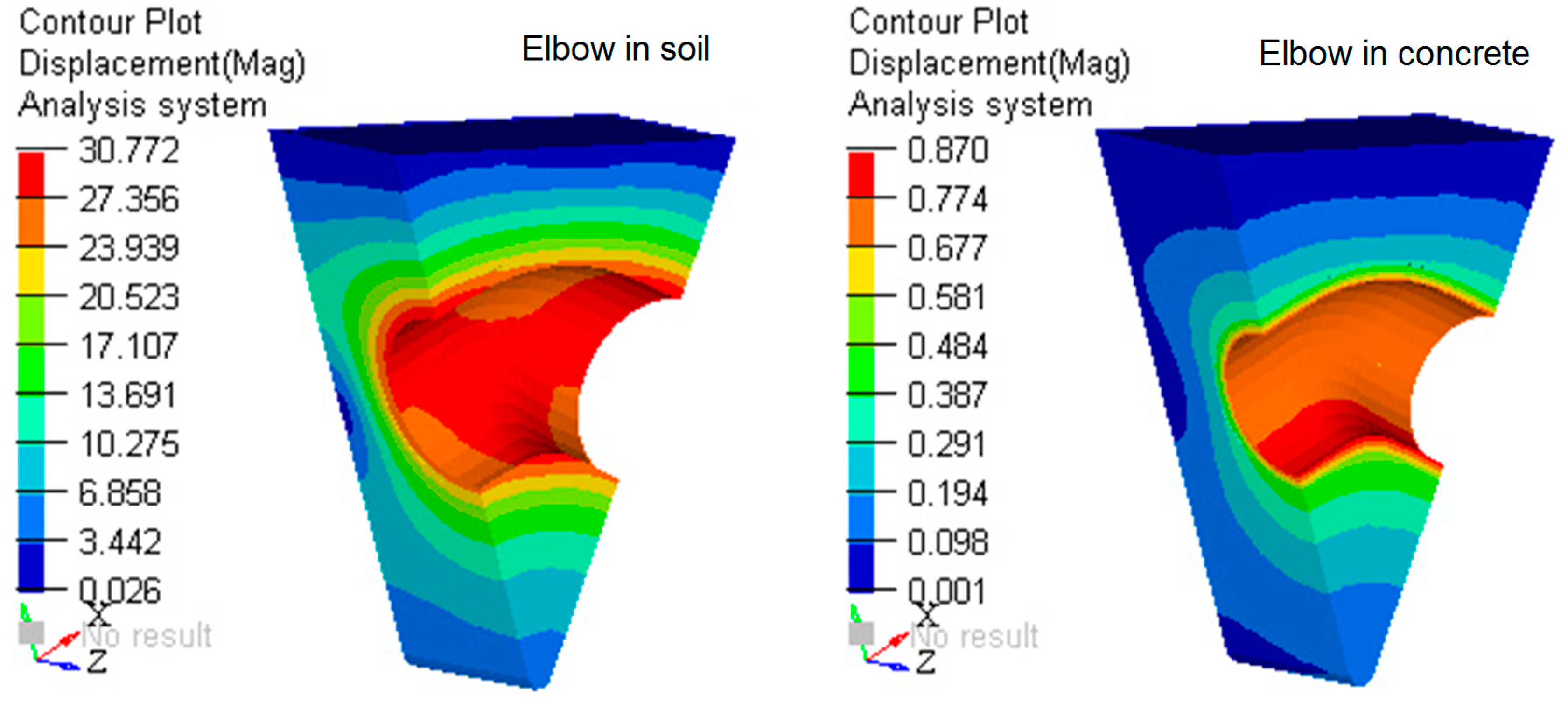

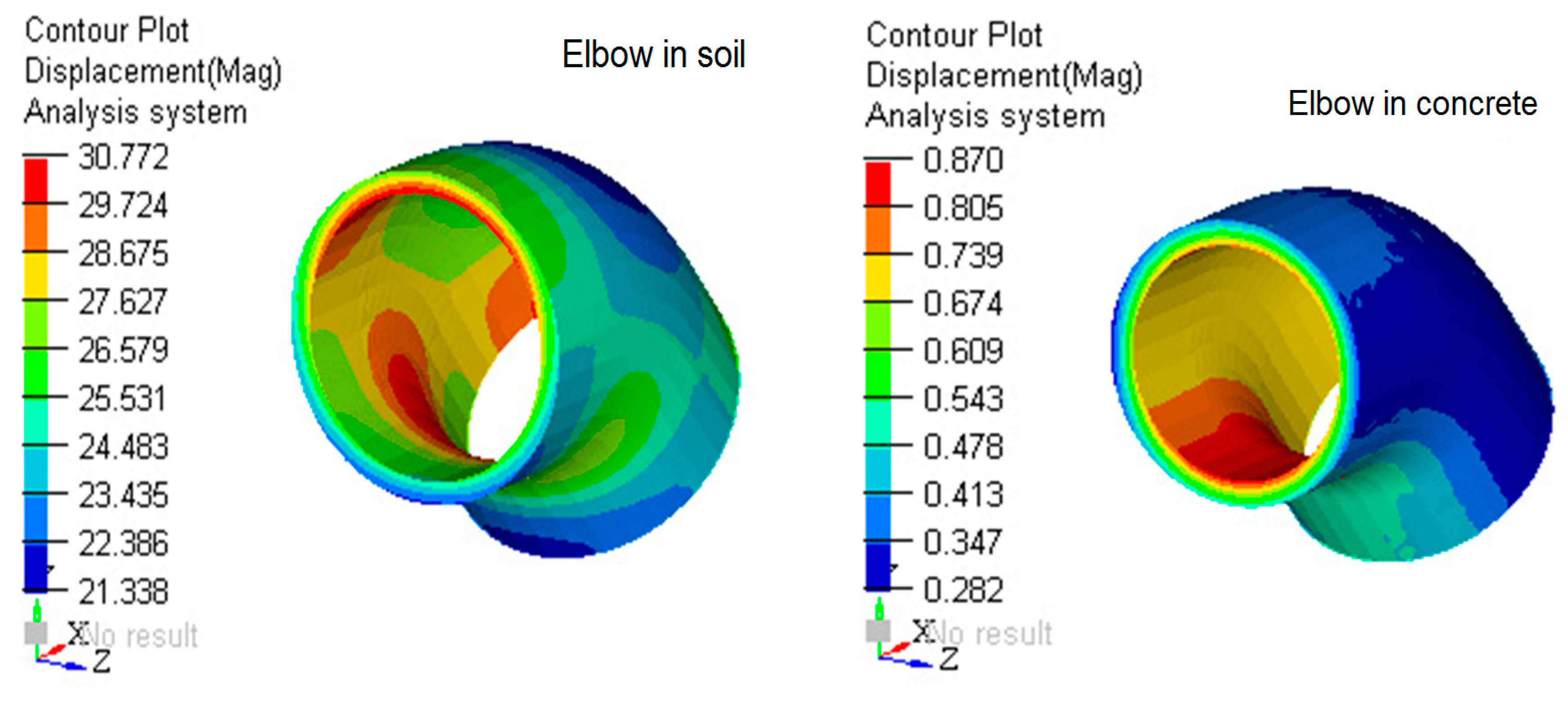

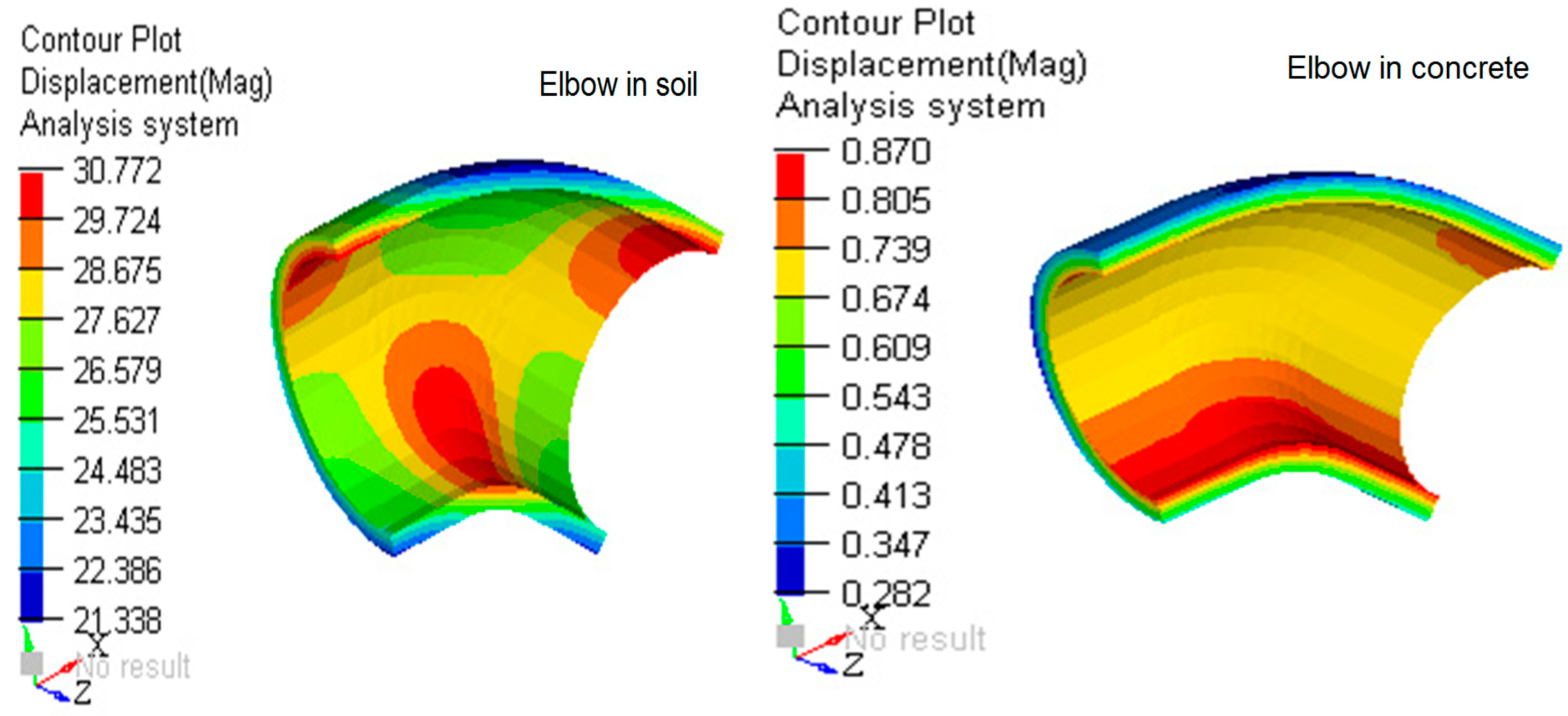

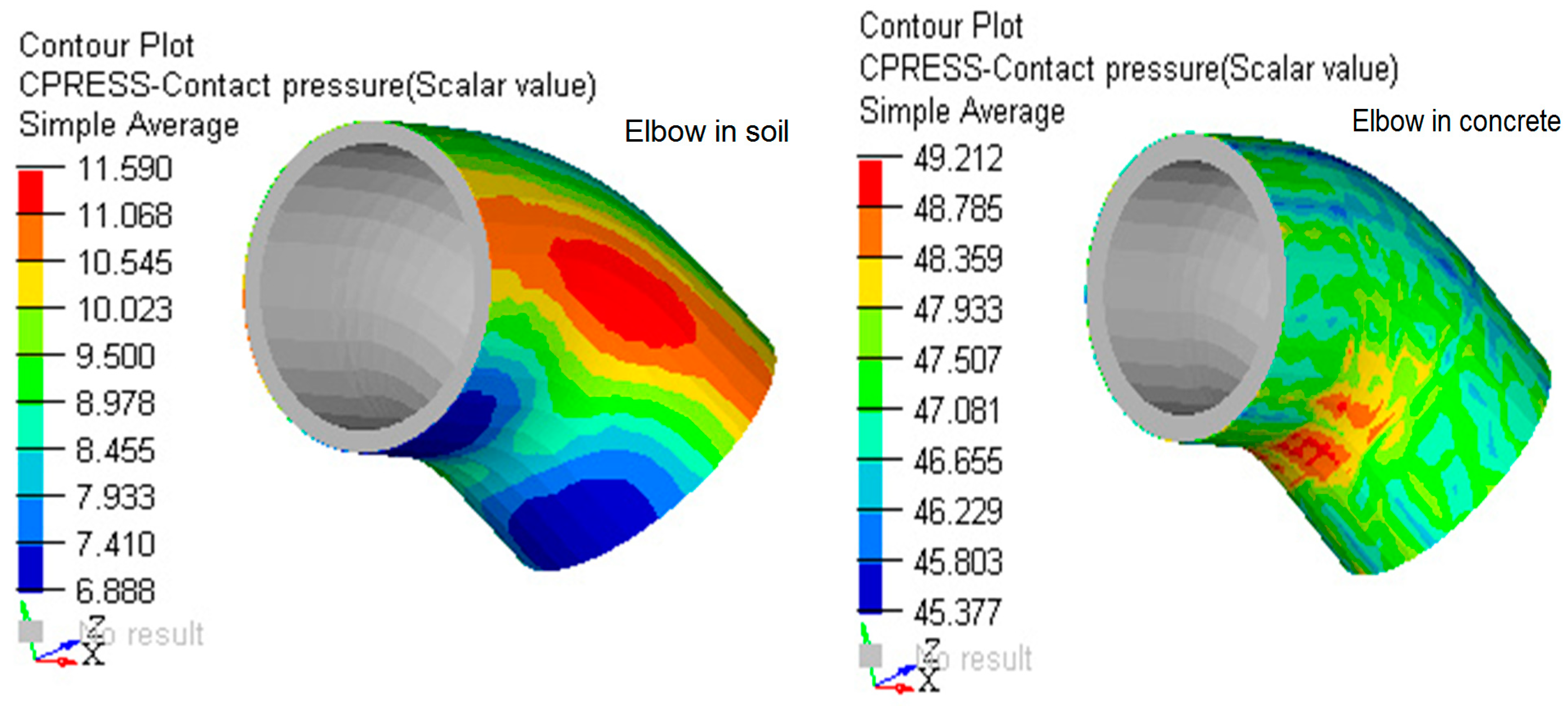

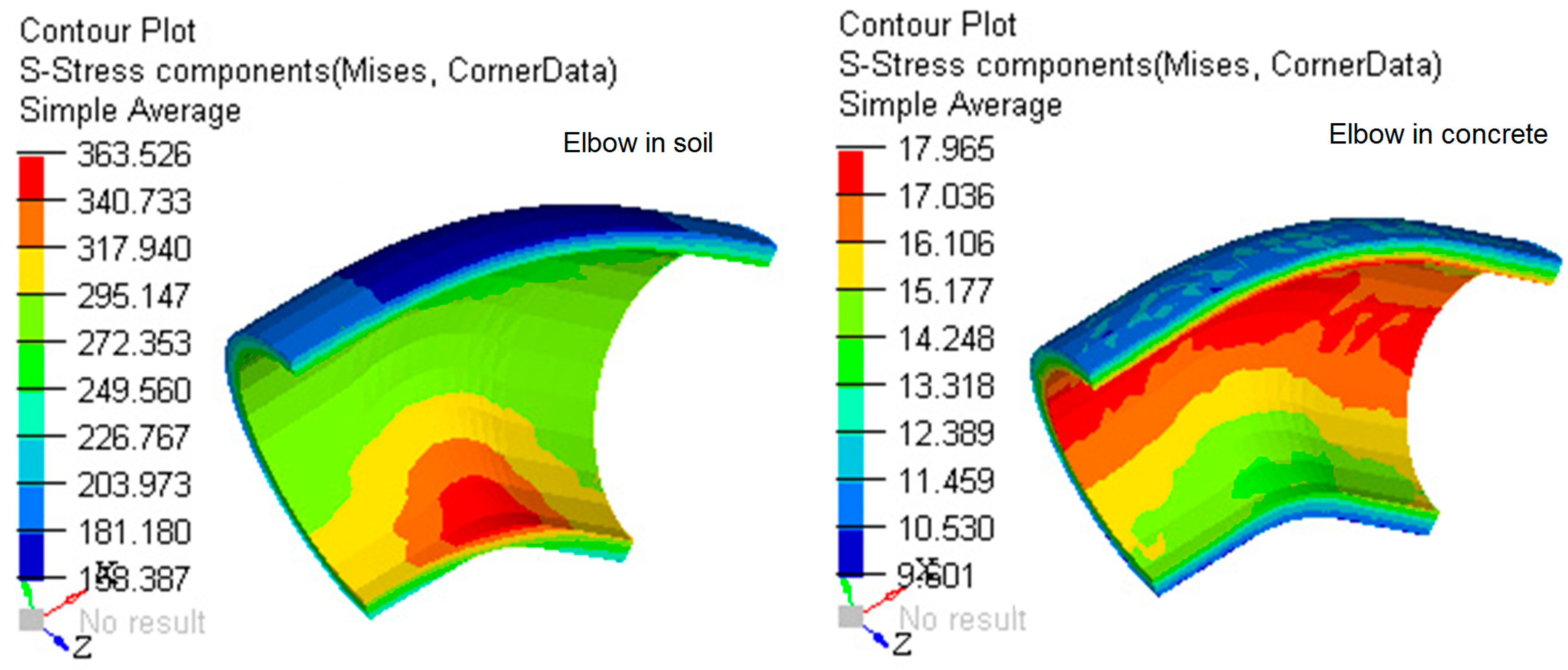

4.3. Comparative analysis of the Results Obtained with the MEF in the Case of Elbow DN 315, Buried in the Ground and Anchored in Concrete

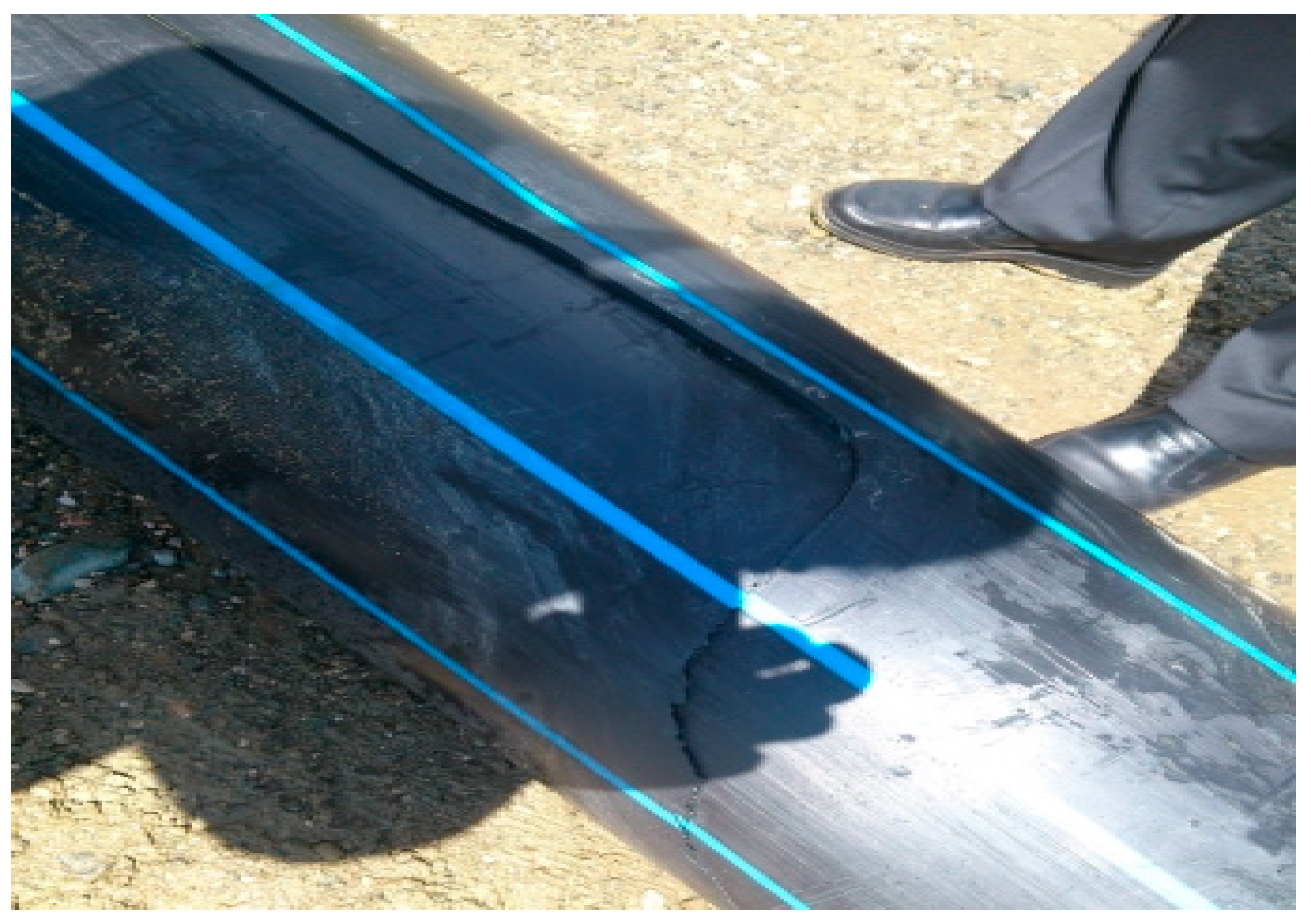

5. Results on HDPE Pipe Damage

- Internal conditions (high pressure, fluctuating pressure, medium-transported temperature);

- Installation-pipe laying (poor design, laying errors, material handling errors);

- Damaged material (initial defects, incorrect choice of pipe material, previous crushing);

- Geothermal forces (bark movements, seismic forces, flotation);

- External loads (construction loads, heavy traffic, explosions).

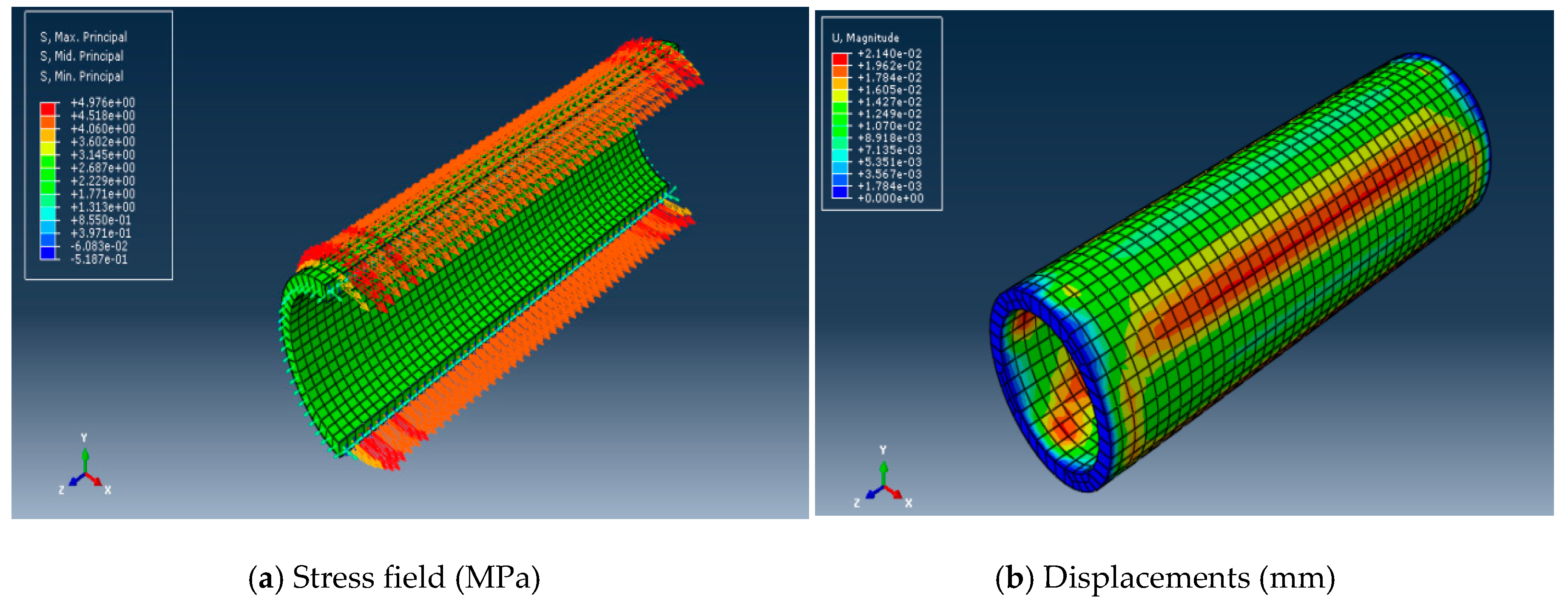

5.1. FEA of Pipe HDPE-DN 315 Subjected to a Hydraulic Pressure

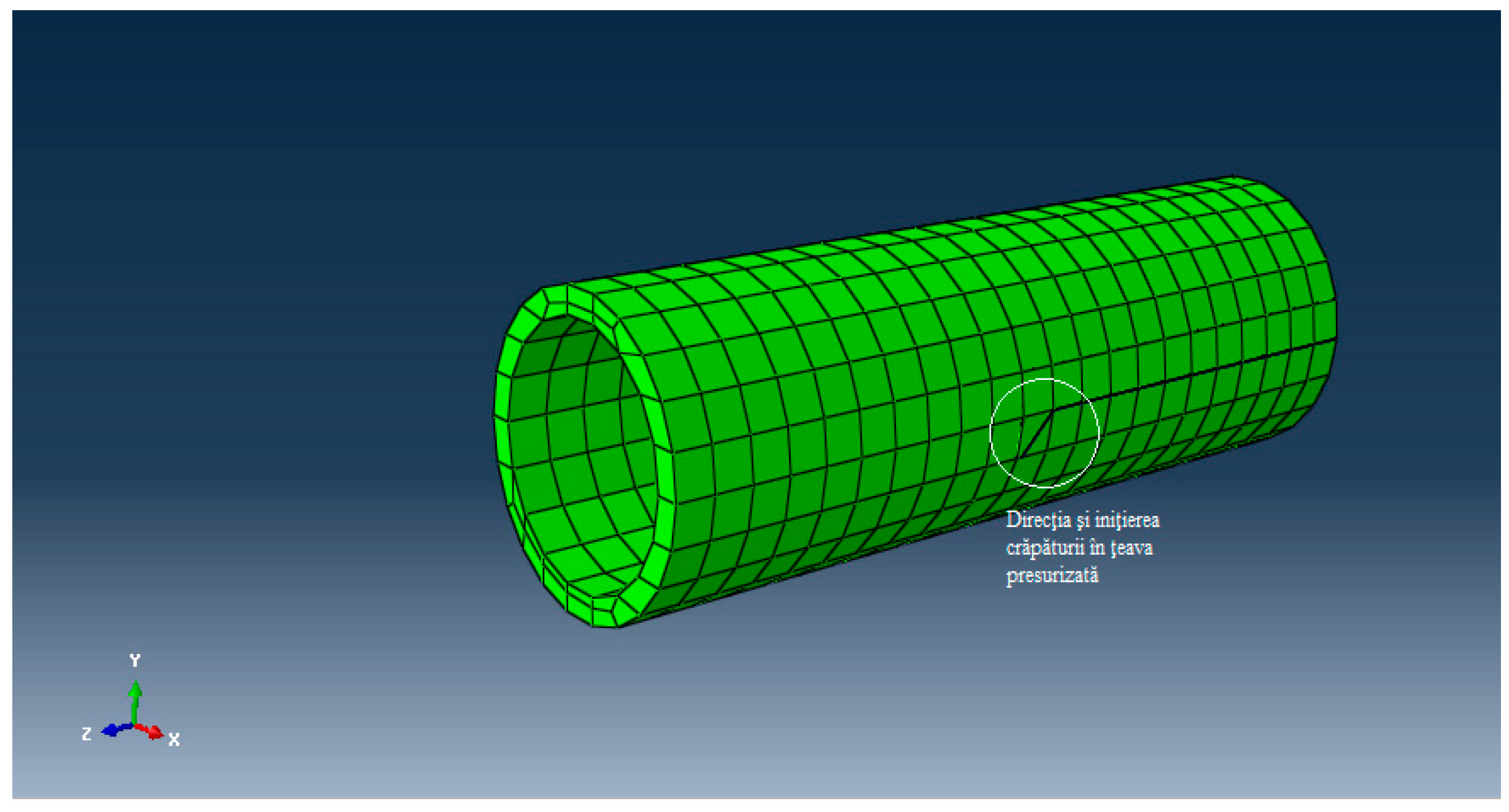

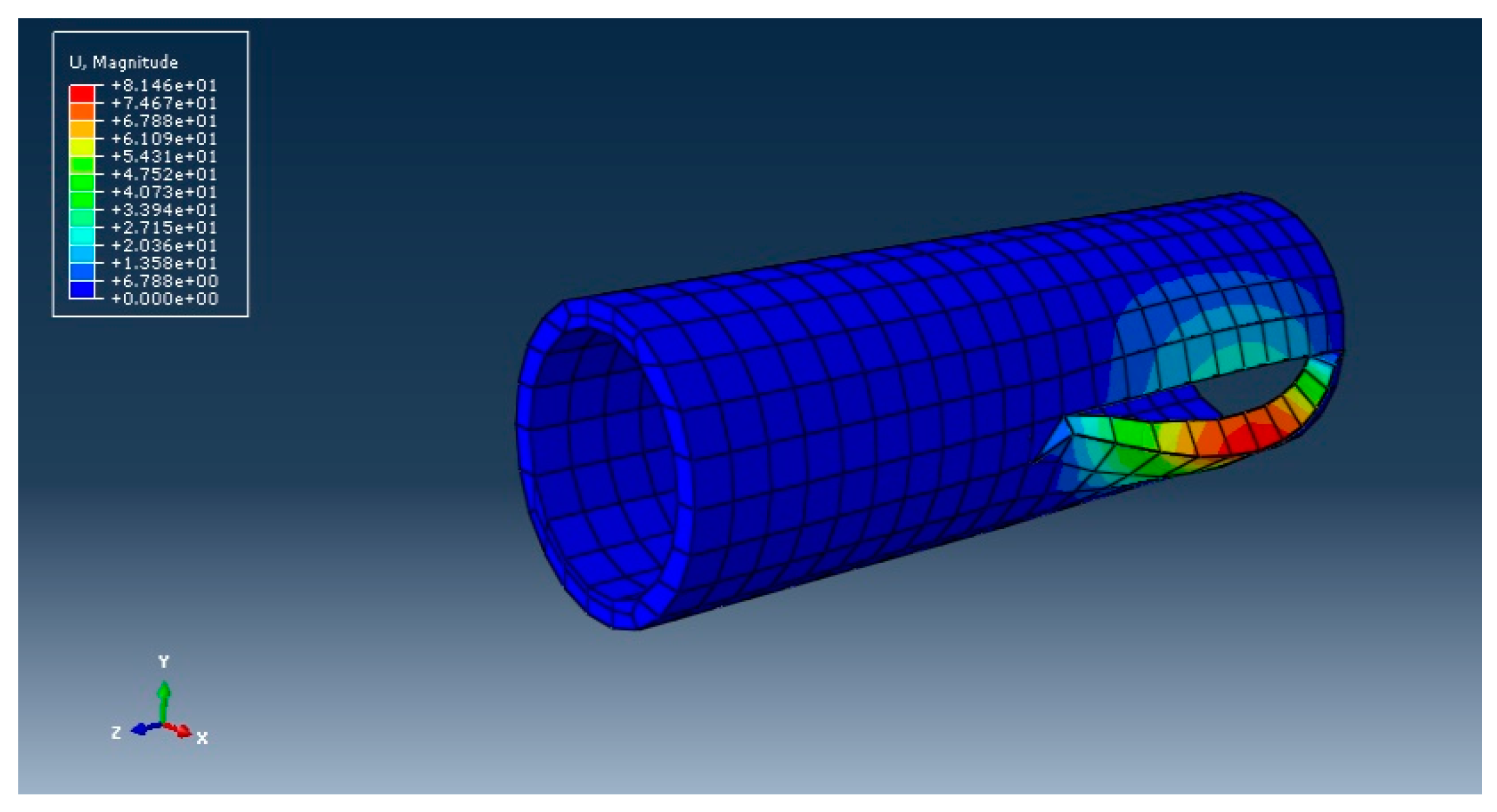

5.2. Simulation of the Ductile Crack of a Straight Pipe

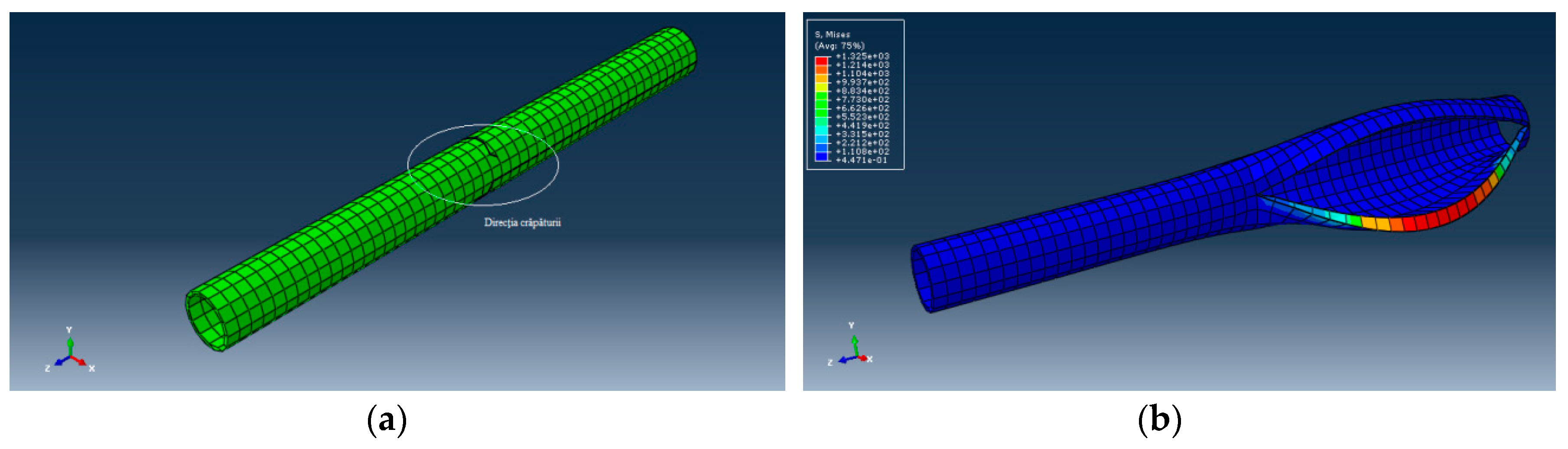

5.3. Study of the Crack of the Elbow DN 315 Buried in the Ground

6. Discussion and Conclusions

- The maximum stress the concrete massif (Figure 16) was: so that the concrete massif will not be destroyed due to the existing load;

- The maximum stress in the elbow was so that the elbow will not be destroyed due to the working demands;

- The comparison between elbow DN 315 buried in the ground and elbow DN 315 anchored in concrete mass, presented in Figure 19, Figure 20, Figure 21, Figure 22, Figure 23 and Figure 24, where the values of tension and deformation are shown in soil and concrete, justify anchoring the elbow in the concrete massif.

- The proposal of quality assurance and control systems for receiving pipes, which will comply in all respects with the conditions of the reference standards;

- Elaboration of quality control procedures of the companies that manage the water networks, with the right of these companies to control or try the products they purchase during any stage of their manufacture, which can affect the quality of the products and also the possibility of testing the raw materials used in the manufacture of pipes or fittings;

- Elaboration of storage techniques of all the information attesting the quality of the product delivered by a certain supplier and the possibility of comparing price/quality analysis, but also the knowledge of the mechanical characteristics, for similar products from different suppliers;

- Introducing in the quality system the mention “the obligation of the supplier of plastic pipes to present the regression diagrams of the pipe material”;

- The digital map of the network and the study of rings with specialized software (EPANET, WATERCAD);

- Requesting an express requirement of the beneficiary of the plastic pipe—in the manufacture of the batch of pipes, molds, and samples of the same material as one of the pipes are made, known that for mechanical tests, the samples must have a certain form [36].

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Available online: https://www.youtube.com/watch?v=e7uypR7RUoQ (accessed on 2 January 2020).

- Available online: https://www.uponor.com/int/products/drinking-water-delivery/flexible-pipe-system (accessed on 2 January 2020).

- Available online: https://www.wavin.com/en-en/solutions/solutions-for-drinking-water (accessed on 2 January 2020).

- Williams, J.G. Fracture Mechanics of Polymers; Elis Horwood Limited: California, USA, 1984. [Google Scholar]

- Ayres, R.L. Basics of Polyethylene Manufacture Structureand Properties. In Proceedings of the American Gas Association Distribution Conference Anaheim, Los Angeles, CA, USA, 1981. [Google Scholar]

- Harper, C.A. Handbook of Plastics and Elastomers; Mc Graw-Hill Book Company: New York, NY, USA, 1975. [Google Scholar]

- Powell, P.C. Engineering with Polymers; Chapman and Hall: London, UK, 1982. [Google Scholar]

- Zhang, J.F.; Li, Y.; Xing, D.; Wang, Q.W.; Wang, H.G.; Koubaa, A. Reinforcement of continuous fibers for extruded wood-Flour/HDPE composites: Effects of fiber type and amount. Constr. Build. Mater. 2019, 228, 1–8. [Google Scholar] [CrossRef]

- Zhou, M.; Moore, I.D.; Lan, H.T. Experimental Study of Structural Response of Lined-Corrugated HDPE Pipe Subjected to Normal Fault. J. Geotech. Environ. Eng. 2019, 145, 04019117. [Google Scholar] [CrossRef]

- Sayem, A.M.; Haider, J.; Sayeed, M.A. Development and characterisation of multi-Layered jute fabric-Reinforced HDPE composites. J. Compos. Mater. 2019. [Google Scholar] [CrossRef]

- Kashfipour, M.A.; Guo, M.L.; Mu, L.W.; Mehra, N.; Cheng, Z.H.; Olivio, J.; Zhu, S.S.; Maia, J.M.; Zhu, J.H. Carbon nanofiber reinforced Co-Continuous HDPE/PMMA composites: Exploring the role of viscosity ratio on filler distribution and electrical/thermal properties. Compos. Sci. Technol. 2019, 184, 107859. [Google Scholar] [CrossRef]

- Gama, N.; Barros-Timmons, A.; Ferreira, A.; Evtuguin, D. Surface treatment of eucalyptus wood for improved HDPE composites properties. J. Appl. Polym. Sci. 2019, 48619. [Google Scholar] [CrossRef]

- Mosavi-Mirkolaei, S.T.; Najafi, S.K.; Tajvidi, M. Physical and Mechanical Properties of Wood-Plastic Composites Made with Microfibrillar Blends of LDPE, HDPE and PET. Fibers Polym. 2019, 20, 2156–2165. [Google Scholar] [CrossRef]

- Singh, N.; Singh, R.; Ahuja, I.P.S. Thermomechanical investigations of SiC and Al2O3-Reinforced HDPE. J. Thermoplast. Compos. Mater. 2019, 32, 1347–1360. [Google Scholar] [CrossRef]

- Awad, A.H.; Abd El-Wahab, A.A.; El-Gamsy, R.; Abdel-latif, M.H. A study of some thermal and mechanical properties of HDPE blend with marble and granite dust. Ain Shams Eng. J. 2019, 10, 353–358. [Google Scholar] [CrossRef]

- Sun, Y.; Jia, Y.F.; Haroon, M.; Lai, H.S.; Jiang, W.C.; Tu, S.T. Welding Residual Stress in HDPE Pipes: Measurement and Numerical Simulation. J. Press. Vessel Technol.-Trans. ASME 2019, 141, 041404. [Google Scholar] [CrossRef]

- Zheng, X.T.; Zhang, X.H.; Ma, L.W.; Wang, W.; Yu, J.Y. Mechanical characterization notched high density polyethylene (HDPE) pipe: Testing and prediction. Int. J. Press. Vessels Pip. 2019, 173, 11–19. [Google Scholar] [CrossRef]

- Majid, F.; Elghorba, M. Critical lifetime of HDPE pipes through damage and reliability models. J. Mech. Eng. Sci. 2019, 13, 5228–5241. [Google Scholar]

- Ghabeche, W.; Chaoui, K. An Investigation into Property Variances Between Outer and Inner HDPE Pipe Layers. Mechanika 2019, 25, 99–106. [Google Scholar] [CrossRef]

- Kilic, H.; Akinay, E. Investigation of Buried HDPE Pipe Deflection Behavior. Teknik Dergi 2018, 30, 9373–9398. [Google Scholar]

- Bouaziz, M.A.; Guidara, M.A.; Schmitt, C.; Hadj-Taieb, E.; Azari, Z.; Dmytrakh, I. Structural integrity analysis of HDPE pipes for water supplying network. Fatigue Fracture Eng. Mater. Struct. 2019, 42, 792–804. [Google Scholar] [CrossRef]

- Duan, H.-F.; Ghidaoui, M.S.; Lee, P.J.; Tung, Y.-K. Unsteady friction and visco-Elasticity in pipe fluid transients. J. Hydraul. Res. 2010, 48, 354–362. [Google Scholar] [CrossRef]

- Duan, H.F.; Ghidaoui, M.S.; Yeou-Koung, T. Energy Analysis of Viscoelasticity Effect in Pipe Fluid Transients. J. Appl. Mech. 2010, 77. [Google Scholar] [CrossRef]

- Pan, B.; Duan, H.F.; Meniconi, S.; Urbanowicz, K.; Che, T.C.; Brunone, B. Multistage frequency-Domain transient-Based method for the analysis of viscoelastic parameters of plastic pipes. J. Hydraul. Eng.–ASCE 2020, 146, 04019068. [Google Scholar] [CrossRef]

- Tscheikner-Gratl, F.; Sitzenfrei, R.; Rauch, W.; Kleidorfer, M. Enhancement of limited water supply network data for deterioration modelling and determination of rehabilitation rate. Struct. Infrastruct. Eng. 2018, 12, 366–380. [Google Scholar] [CrossRef]

- Malinowski, J. A Newly Developed Method for Computing Reliability Measures in a Water Supply Network. Oper. Res. Decis. 2016, 26, 49–64. [Google Scholar]

- Szpak, D.; Tchorzewska-Cieslak, B. Modelling of failure rate of water supply network using the Bayes theorem. In Proceedings of the 10TH Conference on Interdisciplinary Problems in Environmental Protection and Engineering EKO-DOK, Polanica-Zdrój, Poland, 16–18 April 2018; Volume 44, p. AR 00175. [Google Scholar]

- Zhang, S.H.; Yang, J.S.; Wan, Z.Y.; Yi, Y.J. Multi-Water Source Joint Scheduling Model Using a Refined Water Supply Network: Case Study of Tianjin. Water 2018, 10, 1580. [Google Scholar] [CrossRef] [Green Version]

- Hughes, T.J.R. The Finite Element Method: Linear Static and Dynamic Finite Element Analysis; Prentice Hall: Englewood Cliffs, NJ, USA, 2000. [Google Scholar]

- Available online: http://manual.1search.cc/search.php?utm_source=abaqus%20analysis%20user%27s%20manual%206.14%20vol%202%20pdf (accessed on 2 January 2020).

- Modrea, A.; Hebert, H.; Scǎrlǎtescu, D.D. FEM Applied to Determine the Stress-strain Field in the Tubes of the Water Supply Networks. Procedia Manuf. 2019, 32, 187–193. [Google Scholar] [CrossRef]

- Modrea, A.; Scǎrlǎtescu, D.D.; Gligor, A. Mechanical Behavior of the HDPE Tubes Used in Water Supply Networks Determined with the Four-Point Bending Test. Procedia Manuf. 2019, 32, 194–200. [Google Scholar] [CrossRef]

- Florea, J.; Seteanu, I.; Zidaru, G.; Pancutescu, V. Technical Description for Polyethylene Pipes. Fluid Mechanics and Hydropneumatic Machines; Didactic and Pedagogical Publishing House Bucharest: Bucharest, Romania, 1982. [Google Scholar]

- Bordeaşu, I.Ș.A. Theoretical Notions and Problems of Hydrodynamics, Pipes, Channels and Hydraulic Machines; Politehnica Publishing House: Timişoara, Romania, 2005. [Google Scholar]

- Bordeaşu, I.; Baciu., I.D. Applied Hydraulics. Hydrostatic. Theoretical Notions and Applications; Politehnica Publishing House: Romania, 2002. [Google Scholar]

- Available online: http://www.performancepipe.com/en-us/Documents/PPI%20Handbook.pdf (accessed on 2 January 2020).

- Dumitrescu, I.; Marşavina, L. Introduction to Fracture Mechanics; Mirton Publishing House: Timişoara, Romania, 2001. [Google Scholar]

- Posea, N.; Anghel, A.; Grigore, N.; Mincu, V. Statics and Dynamics of Pipeline Systems; Romanian Academy Publishing House: Bucharest, Romanian, 1996. [Google Scholar]

- Vlase, S.; Scărlătescu, D.D.; Scutaru, M.L. Stress Field in Tubes Made of High Density Polyethylene Used in Water Supply Systems. Acta Tech. Napoc. 2019, 62, 273–280. [Google Scholar]

- Vlase, S.; Scărlătescu, D.D.; Marin, M.; Öchsner, A. Finite Element Analysis of an Elbow Tube in Concrete Anchor Used in Water Supply Networks. J. Mater. Des. Appl. J. Mater. Des. Appl. 2019. [Google Scholar] [CrossRef]

- Scărlătescu, D.D.; Vlase, S.; Crisan, A. Traction Test to Determine the Behaviour of the Materials Used in Water Supply Networks. Acta Tech. Napoc. Ser.-Appl. Math. Mech. Eng. 2019, 62, 175–182. [Google Scholar]

- Rueda, F.; Marquez, A.; Otegni, J.L.; Frontini, P.M. Buckling collapse of HDPE liners. Experimental set-Up and FEM simulations. Thin-Walled Struct. 2016, 109, 103–112. [Google Scholar] [CrossRef]

- Citarella, R.; Lepore, M.; Maligno, A.; Shlyannikov, V. FEM simulation of a crack propagation in a round bar under combined tension and torsion fatigue loading. Fract. Struct. Integrit. 2015, 31, 138–147. [Google Scholar] [CrossRef] [Green Version]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vlase, S.; Marin, M.; Scutaru, M.L.; Scărlătescu, D.D.; Csatlos, C. Study on the Mechanical Responses of Plastic Pipes Made of High Density Polyethylene (HDPE) in Water Supply Network. Appl. Sci. 2020, 10, 1658. https://doi.org/10.3390/app10051658

Vlase S, Marin M, Scutaru ML, Scărlătescu DD, Csatlos C. Study on the Mechanical Responses of Plastic Pipes Made of High Density Polyethylene (HDPE) in Water Supply Network. Applied Sciences. 2020; 10(5):1658. https://doi.org/10.3390/app10051658

Chicago/Turabian StyleVlase, Sorin, Marin Marin, Maria Luminița Scutaru, Dumitru Daniel Scărlătescu, and Carol Csatlos. 2020. "Study on the Mechanical Responses of Plastic Pipes Made of High Density Polyethylene (HDPE) in Water Supply Network" Applied Sciences 10, no. 5: 1658. https://doi.org/10.3390/app10051658

APA StyleVlase, S., Marin, M., Scutaru, M. L., Scărlătescu, D. D., & Csatlos, C. (2020). Study on the Mechanical Responses of Plastic Pipes Made of High Density Polyethylene (HDPE) in Water Supply Network. Applied Sciences, 10(5), 1658. https://doi.org/10.3390/app10051658