Experimental Study of Environmental Conditions on In-Situ Engineered Cementitious Composites-Steel Deck Interface

Abstract

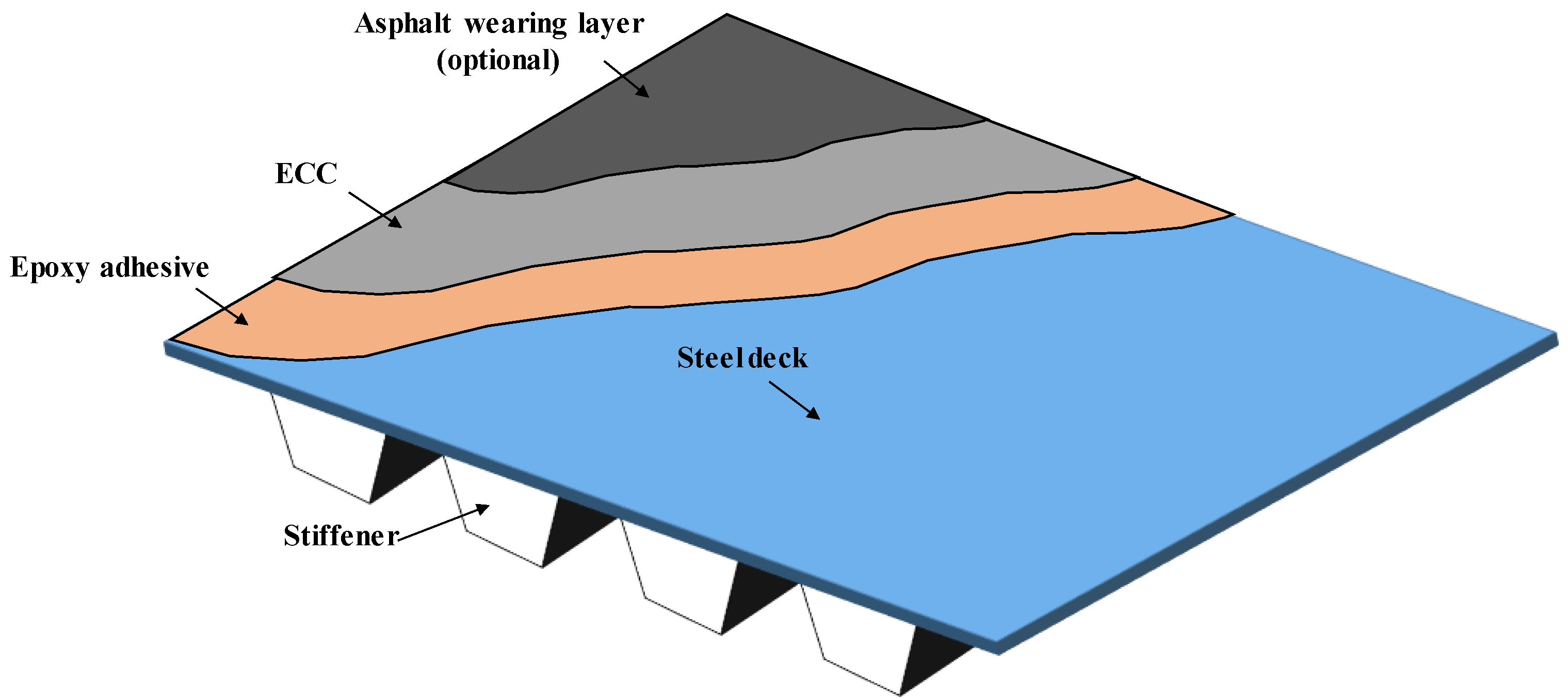

:1. Introduction

2. Materials and Experiments

2.1. Materials

2.2. Specimen Preparation

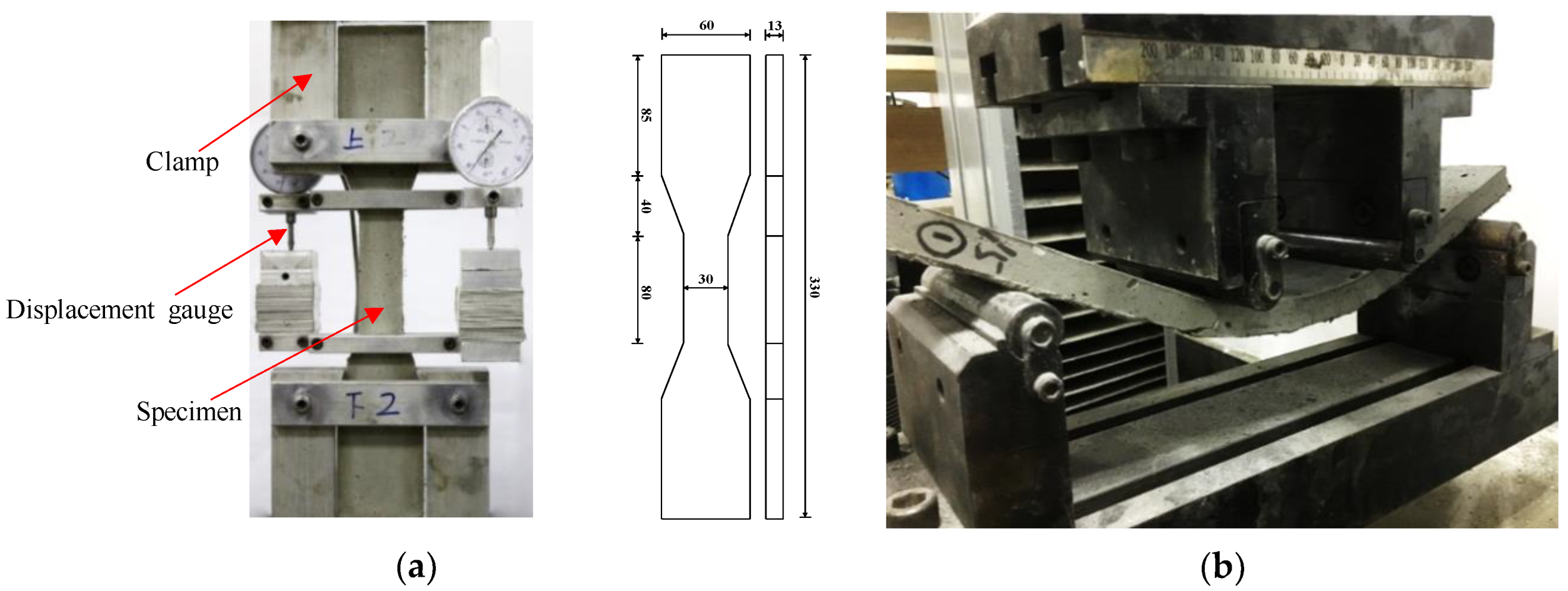

2.3. Mechanical Performance of ECC

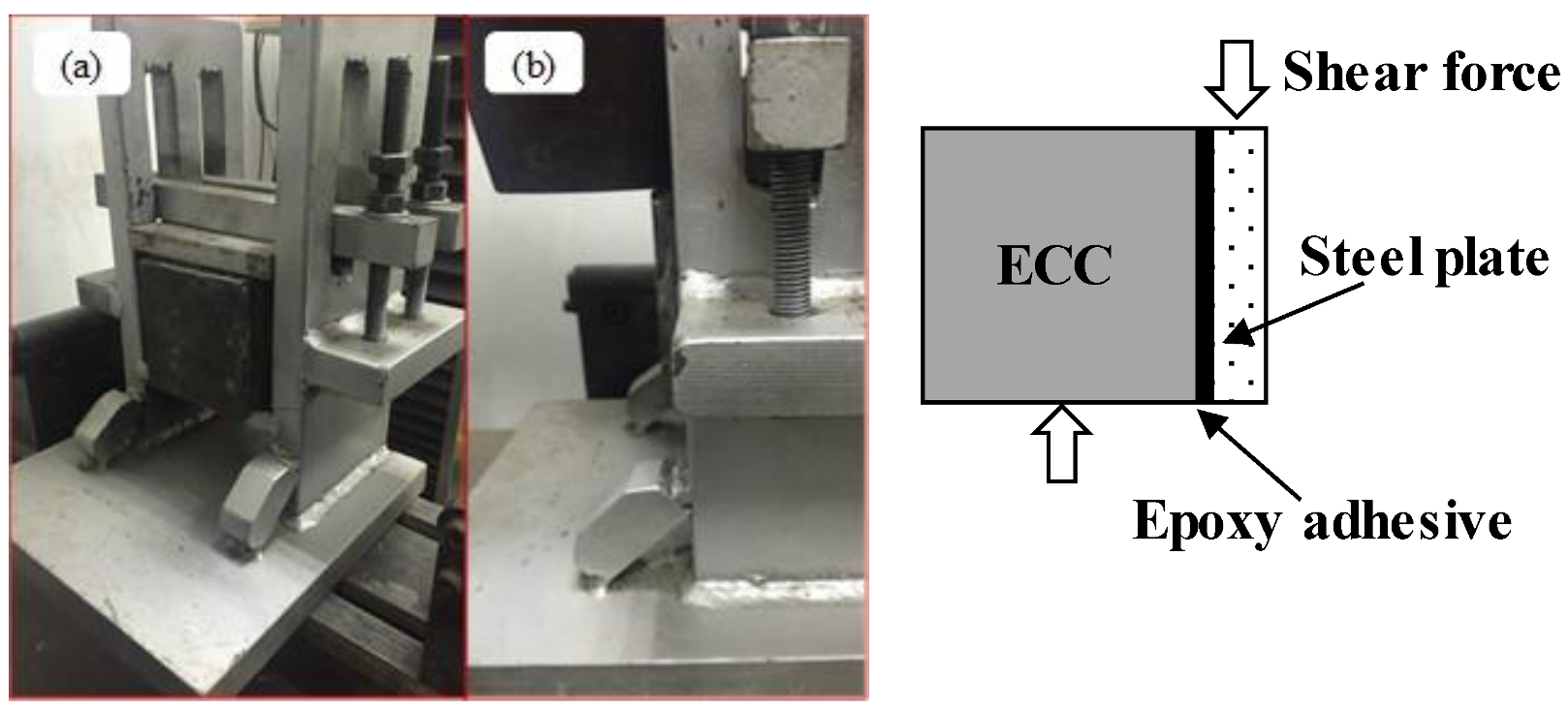

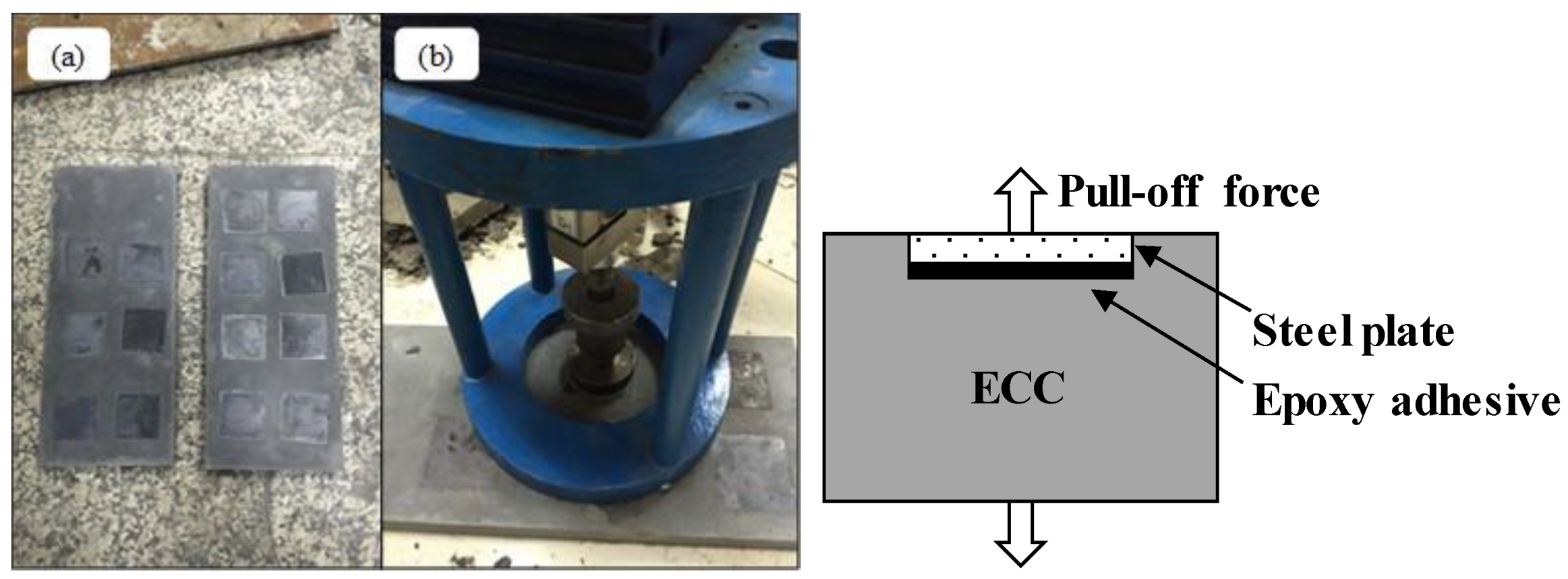

2.4. Bonding Properties of Steel/ECC Interface

2.4.1. Single Shear Test

2.4.2. Pull-Off Test

2.4.3. Inclined Shear Test

2.5. Effects of Hostile Environment on Interfacial Properties

2.6. Microscopic Interface Observation

3. Results and Discussion

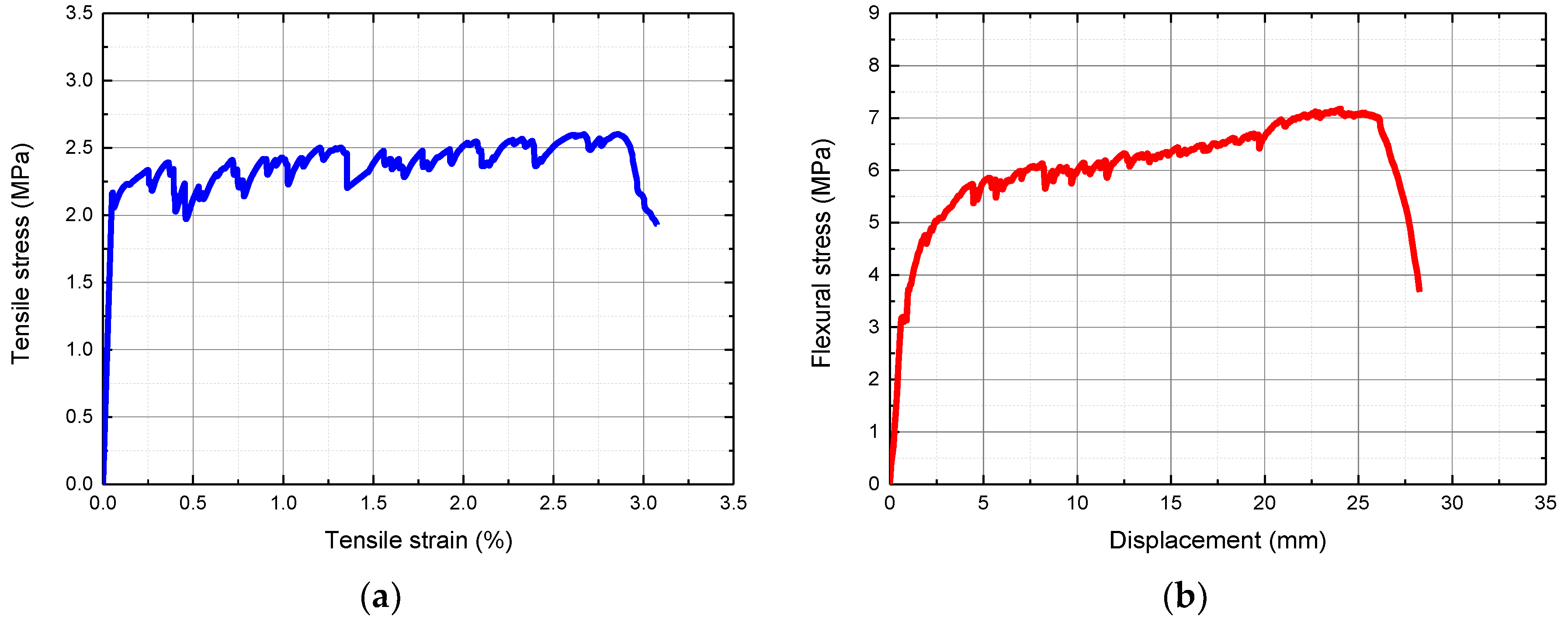

3.1. Mechanical Properties of ECC

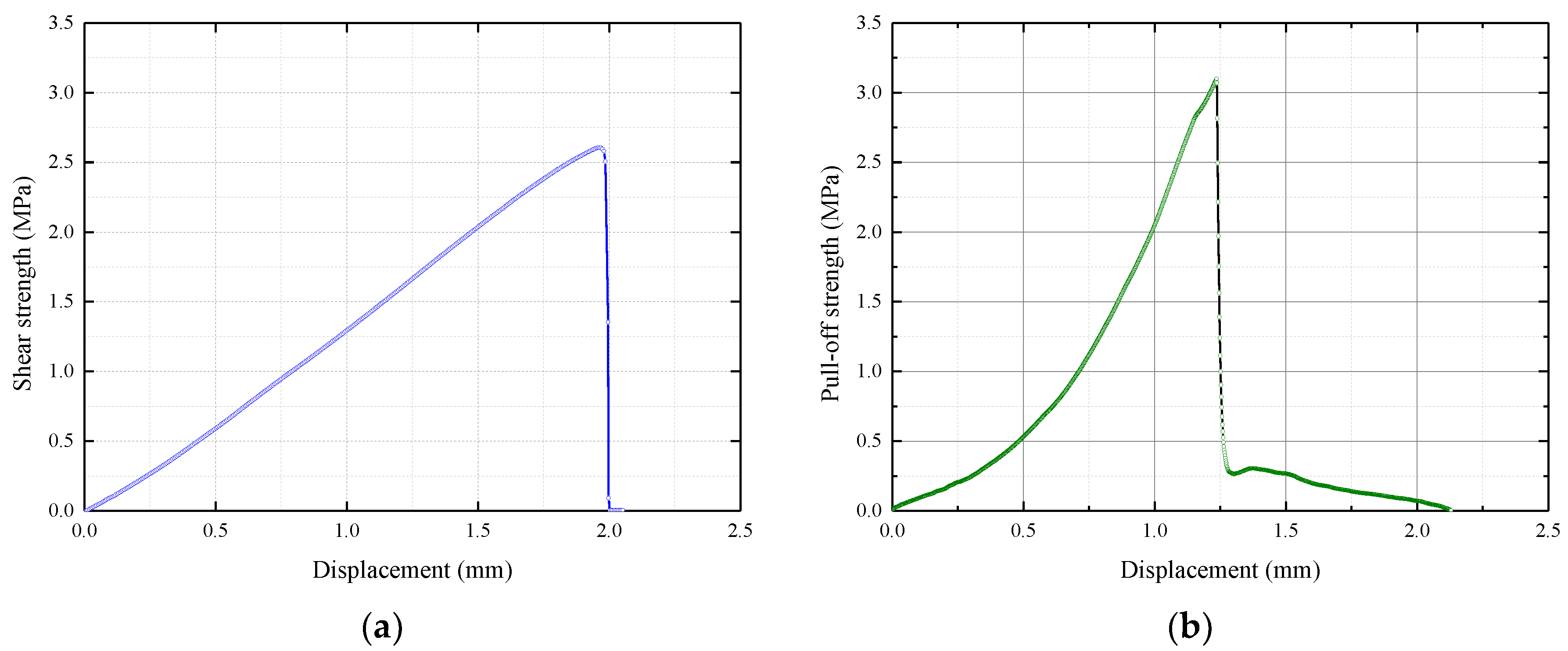

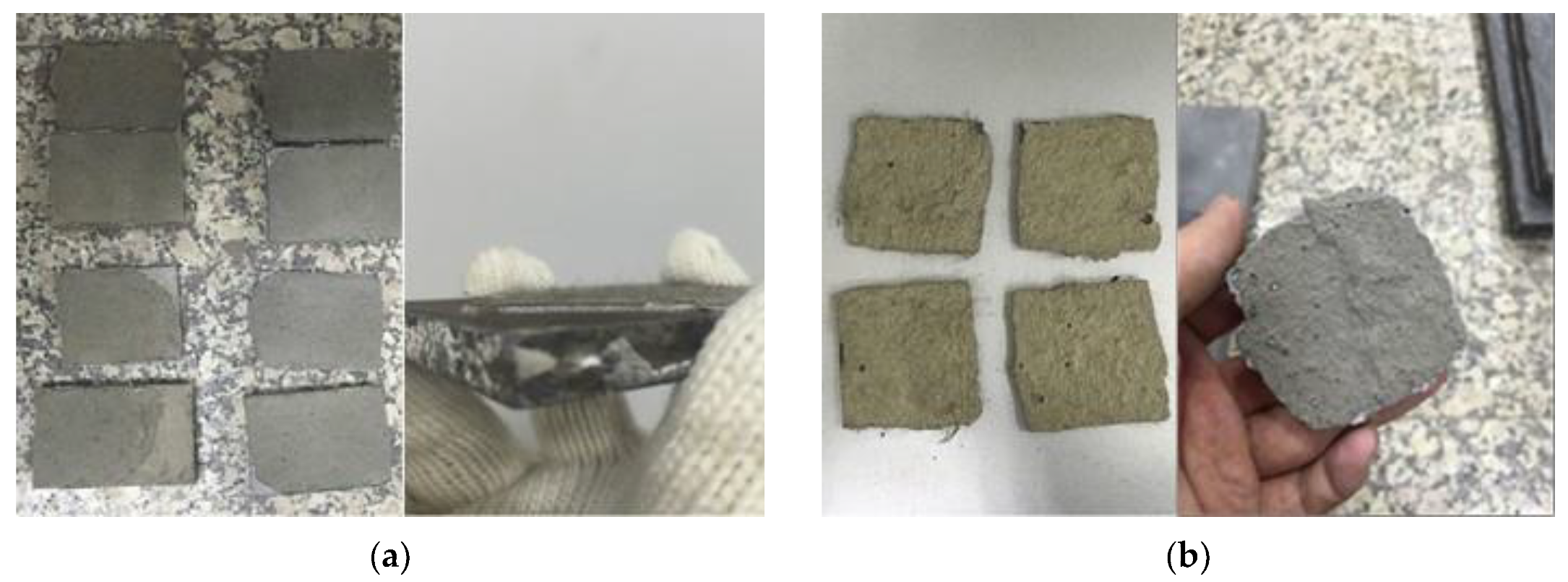

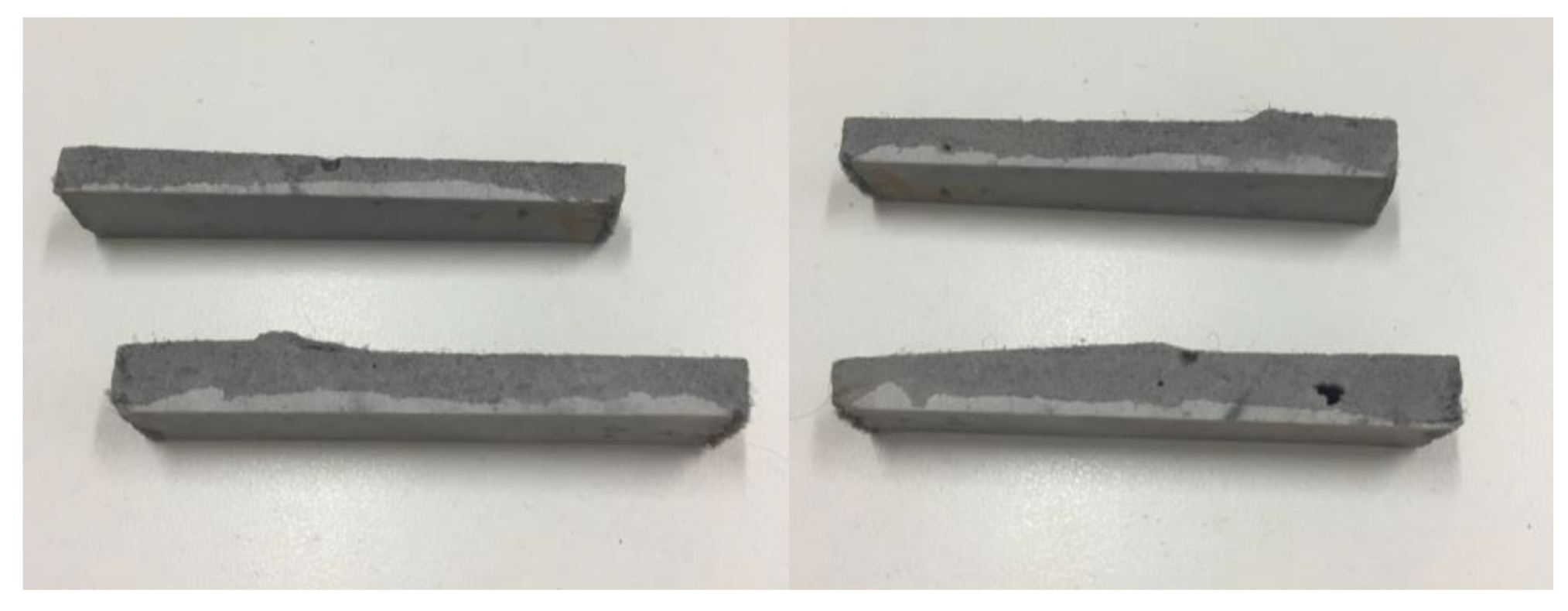

3.2. Failure Mode of Steel-ECC Interface

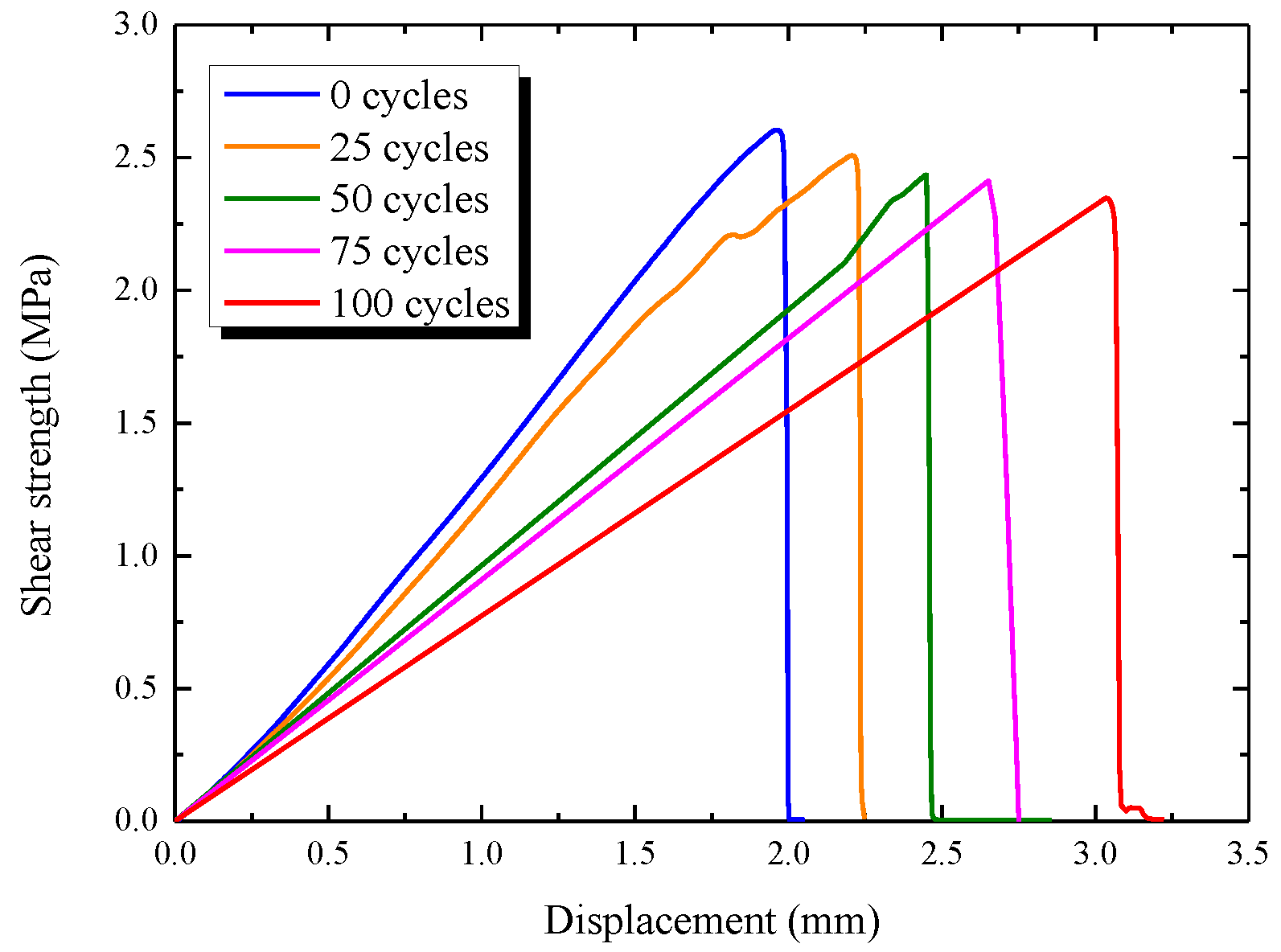

3.3. Effect of Freeze-Thaw on Interfacial Strength

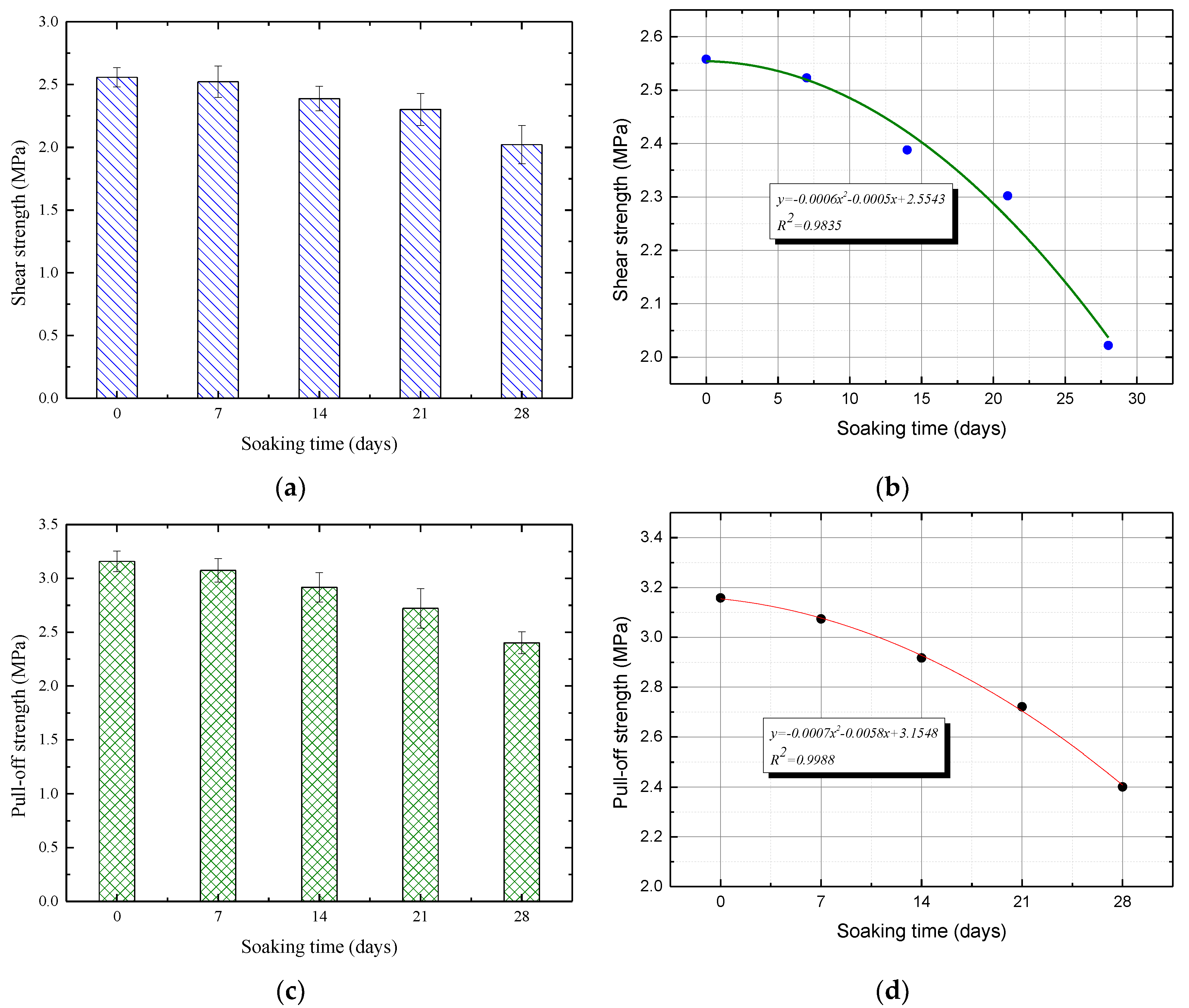

3.4. Effect of Hydrothermal Aging on Interfacial Strength

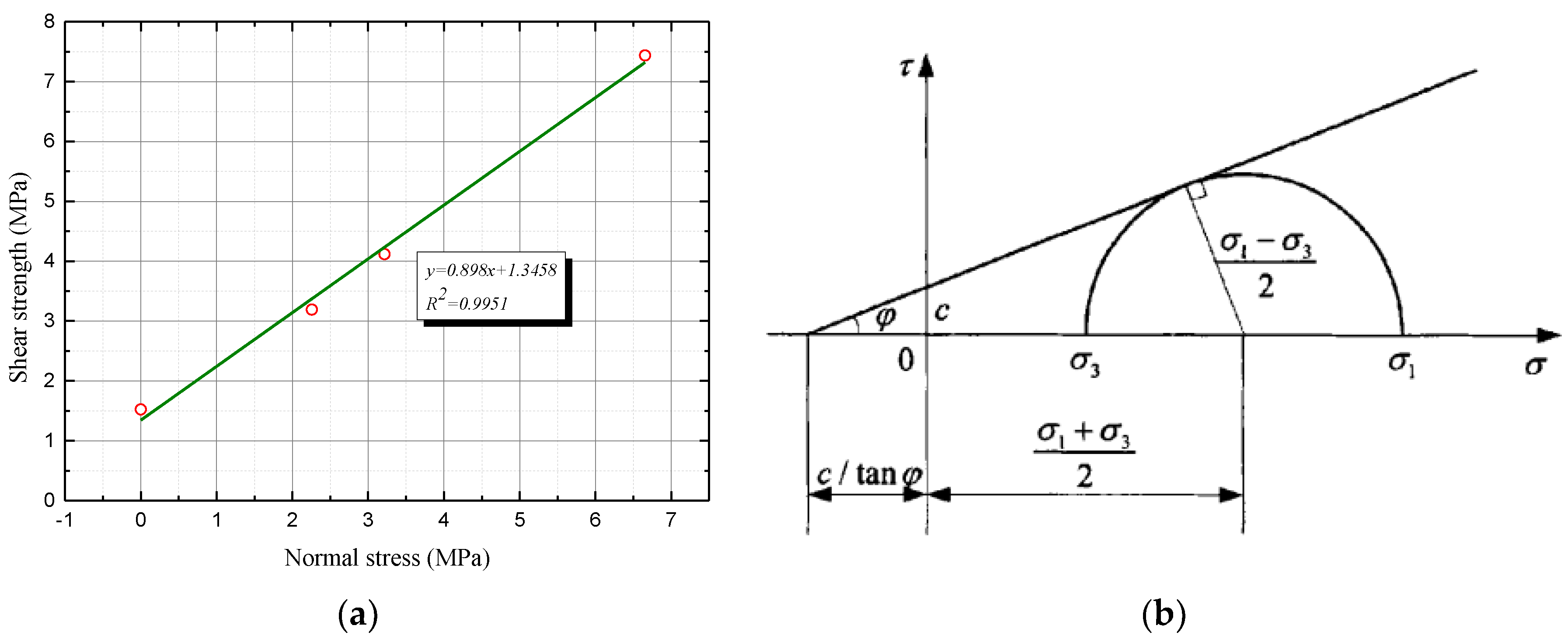

3.5. Criterion of Interfacial Failure Based on Inclined Shear Test

- (1)

- The initiation of interface failure occurs at the maximum interfacial shear stress.

- (2)

- The initiation of interface failure is influenced by normal stress at the interface. The greater the interfacial compressive stress, the greater the maximum interfacial shear stress.

- (3)

- The interface failure criterion is similar to Mohr–Coulomb criterion (shown in Figure 13b), i. e., the effect of interface compressive stress on the maximum interface shear stress is linear when failure occurs. The criterion is found to exclude the effect of experimental conditions and reflect the intrinsic strength characteristics of interface.

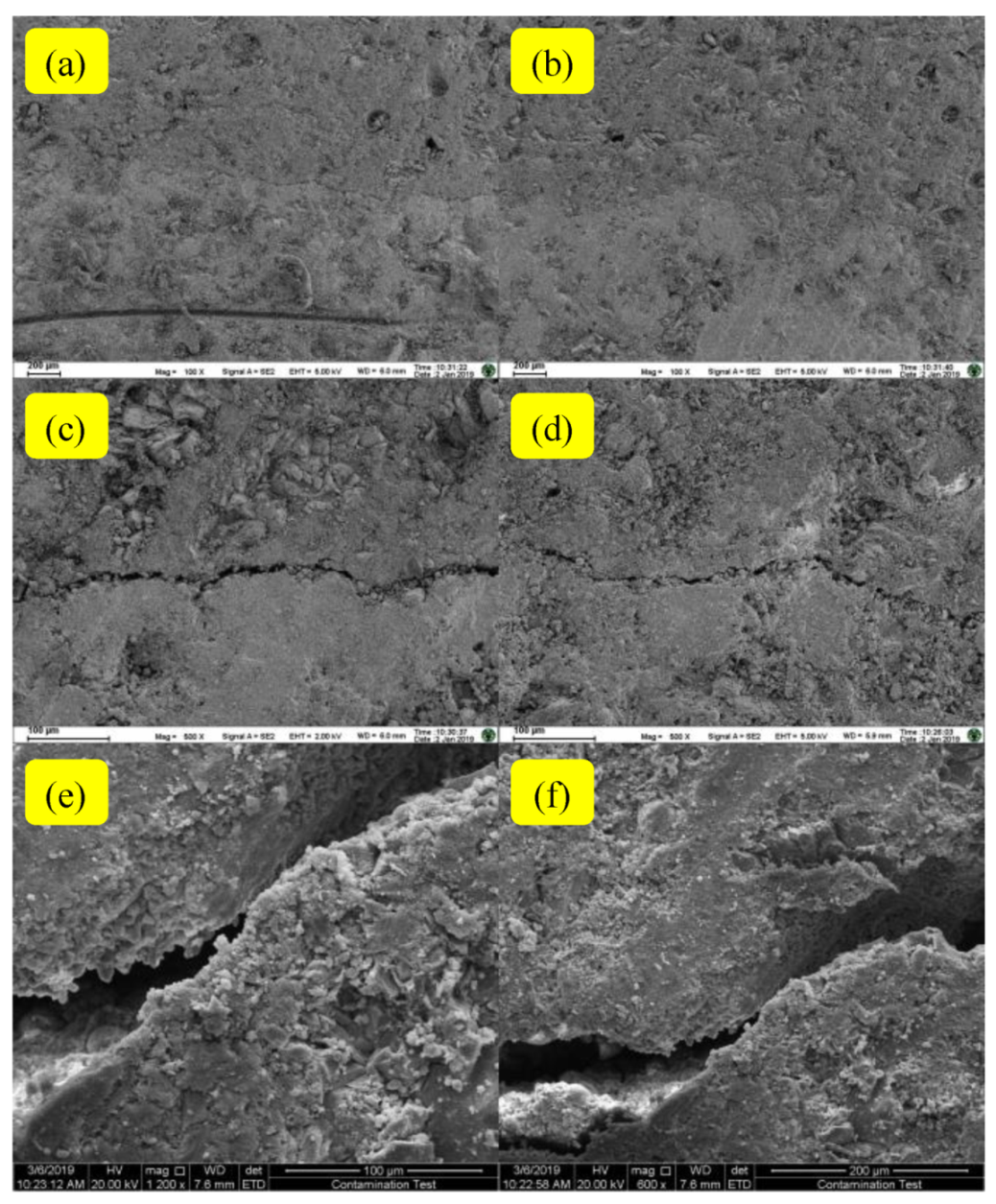

3.6. Micromechanism of Bonding Property Reduction

4. Conclusions

- (1)

- Wet-bonding technology using epoxy adhesive can provide a convenient alternative to the traditional mechanical shear key bonding method and introduce opportunities to develop new overlay structures for orthotropic steel deck bridges.

- (2)

- The interfacial shear and pull-off strength decrease with an increase in the freeze-thaw cycles and with the duration of immersion in hot and humid environment. The strength is approximately linear with the number of freeze-thaw cycles. Perfect fitting can be obtained while using a quadratic polynomial to fit the relationship between strength and duration of immersion in hot water.

- (3)

- The SEM images show the presence of microvoids or microcracks at the interface. Exposure to freeze-thaw cycles and hot and humid environment increased interfacial defects. The presence of water reduces the effective bearing area, worsens the interface bonding ability, and degrades the macroperformance.

- (4)

- The interfacial shear stress is linear with the normal stress. The failure criterion under normal stress for the steel-ECC bonding interface can be obtained as , which is similar to Mohr–Coulomb criterion.

Author Contributions

Funding

Conflicts of Interest

References

- Li, J.L.; Liu, X.Y.; Scarpas, T.; Tzimiris, G. Numerical simulation of orthotropic steel deck bridges with two membrane layers systems. J. Traffic Transp. Eng. 2013, 13, 1–8. [Google Scholar]

- Murakoshi, J.; Yanadori, N.; Ishii, H. Research on steel fiber reinforced concrete pavement on orthotropic steel deck. In Proceedings of the 2nd International Orthotropic Bridge Conference, Sacramento, CA, USA, 25–29 August 2008. [Google Scholar]

- Walter, R.; Olesen, J.F.; Stang, H.; Vejrum, T. Analysis of an orthotropic deck stiffened with a cement-based overlay. J. Bridge Eng. 2007, 12, 350–363. [Google Scholar] [CrossRef] [Green Version]

- Li, V.C. From Micromechanics to structural engineering-the design of cementitious composites for civil engineering application. J. Struct. Eng. Earthq. Eng. 1993, 10, 37–48. [Google Scholar]

- Kequan, Y.; Lingzhi, L.; Jiangtao, Y.; Jianzhuang, X.; Junhong, Y.; Yichao, W. Feasibility of using ultra-high ductility cementitious composites for concrete structures without steel rebar. Eng. Struct. 2018, 170, 11–20. [Google Scholar]

- Qian, S.; Kim, Y.Y.; Li, V.C. Influence of concrete material ductility on shear response of stud connections. ACI Mater. J. 2011, 103. [Google Scholar]

- Shao, Y.; Wu, Z.; Bian, J. Wet-bonding between FRP laminates and cast-in-place concrete. In Proceedings of the International Symposium on Bond Behaviour of FRP in Structures, Hong Kong, China, 7–9 December 2005; pp. 91–96. [Google Scholar]

- Wu, Z.S.; Yin, J. Fracture behaviours of FRP-strengthened concrete structures. Eng. Fract. Mech. 2003, 70, 1339–1355. [Google Scholar] [CrossRef]

- Wu, Z.; Li, W.; Sakuma, N. Innovative externally bonded FRP/concrete hybrid flexural members. Compos. Struct. 2006, 72, 289–300. [Google Scholar] [CrossRef]

- Deskovic, N.; Triantafillou, T.C.; Meier, U. Innovative design of FRP combined with concrete: Short-term behavior. J. Struct. Eng. 1995, 121, 1069–1078. [Google Scholar] [CrossRef]

- Canning, L.; Hollaway, L.; Thorne, A.M. An investigation of the composite action of an FRP/concrete prismatic beam. Constr. Build. Mater. 1999, 13, 417–426. [Google Scholar] [CrossRef]

- Hulatt, J.; Hollaway, L.; Thorne, A. Short term testing of hybrid t beam made of new prepreg material. J. Compos. Constr. 2003, 7, 135–144. [Google Scholar] [CrossRef]

- Shao, X.; Yi, D.; Huang, Z.; Zhao, H.; Chen, B.; Liu, M. Basic performance of the composite deck system composed of orthotropic steel deck and ultrathin RPC layer. J. Bridge Eng. 2013, 18, 417–428. [Google Scholar] [CrossRef]

- Bizindavyi, L. Transfer lengths and bond strengths for composites bonded to concrete. J. Compos. Constr. 1999, 3, 153–160. [Google Scholar] [CrossRef]

- Nakaba, K.; Kanakubo, T.; Furuta, T.; Yoshizawa, H. Bond behavior between fiber-reinforced polymer laminates and concrete. ACI Struct. J. 2001, 98, 359–367. [Google Scholar]

- Li, L.; Shao, Y.X.; Wu, Z.S. Durability of wet bond of hybrid laminates to cast-in-place concrete. J. Compos. Constr. 2010, 14, 209–216. [Google Scholar] [CrossRef]

- Ren, H.; Yao, Q.; Hu, A. Experimental study on durability of fiber reinforced composites. J. Build. Mater. 2005, 8, 520–526. [Google Scholar]

- GB/T 714-2015. Structural steel for bridge. In General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China (AQSIQ) and Standardization Administration of the People’s Republic of China (SAC); AQSIQ: Beijing, China, 2015. [Google Scholar]

- Liu, S.; Yang, J.; Chen, X.; Yang, G. Application of mastic asphalt waterproofing layer in high-speed railway track in cold regions. Appl. Sci. 2018, 8, 667. [Google Scholar] [CrossRef] [Green Version]

- Subramaniam, K.V.; Ali-Ahmad, M.; Ghosn, M. Freeze-thaw degradation of FRP-concrete interface: Impact on cohesive fracture response. Eng. Fract. Mech. 2008, 75, 3924–3940. [Google Scholar] [CrossRef]

- Biscaia, H.C.; Chastre, C.; Borba, I.S.; Silva, C.; Cruz, D. Experimental evaluation of bonding between CFRP laminates and different structural materials. J. Compos. Constr. 2015, 20, 04015070. [Google Scholar] [CrossRef]

- GB/T 50082-2009. Standard for test methods of long-term performance and durability of ordinary concrete. In General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China (AQSIQ) and Ministry of Housing and Urban-Rural Development of the People’s Republic of China (MOHURD); AQSIQ: Beijing, China, 2009. [Google Scholar]

- Lu, C.; Li, V.C.; Leung, C.K.Y. Flaw characterization and correlation with cracking strength in engineered cementitious composites (ECC). Cem. Concr. Res. 2018, 107, 64–74. [Google Scholar] [CrossRef]

- Chen, J.; Yao, C.; Wang, H.; Huang, W.; Ma, X.; Qian, J. Interface Shear Performance between Porous Polyurethane Mixture and Asphalt Sublayer. Appl. Sci. 2018, 8, 623. [Google Scholar] [CrossRef] [Green Version]

- Tian, J.; Wang, W.; Du, Y. Damage behaviors of self-compacting concrete and prediction model under coupling effect of salt freeze-thaw and flexural load. Constr. Build. Mater. 2016, 119, 241–250. [Google Scholar] [CrossRef]

- Yao, B.; Zhang, Y.; Li, F. Shear characteristics of interface between steel bridge deck and epoxy asphalt pavement. China J. Highw. Transp. 2017, 30, 132–138. [Google Scholar]

| Material | Chemical Components (by Weight, %) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | CaO | Al2O3 | Fe2O3 | SO3 | P2O5 | K2O | Na2O | TiO2 | MgO | |

| Cement | 21.26 | 57.82 | 7.67 | 2.88 | 4.04 | 5.26 | 0.78 | - | 0.21 | - |

| Fly ash | 56.18 | 2.82 | 31.46 | 3.85 | 0.69 | 0.91 | - | 1.32 | - | 1.33 |

| Diameter (μm) | Length (mm) | Elongation (%) | Density (g/cm3) | Elastic Modulus (GPa) | Tensile Strength (MPa) |

|---|---|---|---|---|---|

| 35 | 12 | 7.3 | 1.3 | 31.3 | 1287 |

| Cement | Fly Ash | Water | Sand | Fiber | Water Reducer |

|---|---|---|---|---|---|

| 479 | 719 | 359 | 431 | 26 | 9.6 |

| Strength (MPa) | Modulus(GPa) | Elongation Rate | ||||

|---|---|---|---|---|---|---|

| Tension | Compression | Shear | Tension | Compression | Shear | |

| 25 | 75 | 8.9 | 4.6 | 5.0 | 3.05 | 0.30% |

| Inclination Angle (°) | Shear Strength (MPa) | Normal Stress (MPa) | ||||

|---|---|---|---|---|---|---|

| Measured Value | Mean Value | Standard Deviation | Measured Value | Mean Value | Standard Deviation | |

| 26.57 | 7.653 | 7.439 | 0.235 | 6.845 | 6.654 | 0.211 |

| 7.187 | 6.428 | |||||

| 7.477 | 6.687 | |||||

| 38.66 | 3.925 | 4.119 | 0.223 | 3.065 | 3.217 | 0.174 |

| 4.363 | 3.407 | |||||

| 4.069 | 3.177 | |||||

| 45.00 | 2.988 | 3.193 | 0.206 | 2.113 | 2.258 | 0.146 |

| 3.192 | 2.257 | |||||

| 3.399 | 2.404 | |||||

| 90.00 | 1.564 | 1.525 | 0.034 | 0.000 | 0.000 | 0.000 |

| 1.503 | 0.000 | |||||

| 1.507 | 0.000 | |||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, S.; Sun, X.; Yang, J.; Yang, R.; Zhu, J. Experimental Study of Environmental Conditions on In-Situ Engineered Cementitious Composites-Steel Deck Interface. Appl. Sci. 2020, 10, 2123. https://doi.org/10.3390/app10062123

Wu S, Sun X, Yang J, Yang R, Zhu J. Experimental Study of Environmental Conditions on In-Situ Engineered Cementitious Composites-Steel Deck Interface. Applied Sciences. 2020; 10(6):2123. https://doi.org/10.3390/app10062123

Chicago/Turabian StyleWu, Shuyin, Xiaoyin Sun, Jun Yang, Ruochong Yang, and Jipeng Zhu. 2020. "Experimental Study of Environmental Conditions on In-Situ Engineered Cementitious Composites-Steel Deck Interface" Applied Sciences 10, no. 6: 2123. https://doi.org/10.3390/app10062123

APA StyleWu, S., Sun, X., Yang, J., Yang, R., & Zhu, J. (2020). Experimental Study of Environmental Conditions on In-Situ Engineered Cementitious Composites-Steel Deck Interface. Applied Sciences, 10(6), 2123. https://doi.org/10.3390/app10062123