Abstract

Electron beam welding (EBW) is widely used to weld titanium alloy parts such as aero-engine casing and blades. The surface quality after EBW has a significant influence on the aero-engine performance of those parts. We propose a surface treatment method with grinding on a titanium alloy electron beam weld. We analyze the influence of grinding parameters on the characteristics of the grinding surface. The experiment shows the applicability of ground surface by belt grinding on EBW and its impact on aero-engine performance. After belt grinding, both the welded surface and the surface connected with the substrate are smooth. The extra height of the seam was less than 0.2 mm, and the surface roughness (Ra) of the weld after grinding can be less than 0.98 μm. The microstructure of the weld after grinding was analyzed. Two types of bionic shapes were obtained, a sawtooth shape with a width of 40 μm and a height of 10 μm and a wavy shape with a width of 20 μm and a height of 3 μm. From the analysis above, the bionic surface can be obtained by grinding on the weld with an abrasive belt.

1. Introduction

Electron beam welding is widely used in industry, especially in aeronautics and aerospace engineering. The weld seam connects the welded parts and the base metal after electron beam welding (EBW). The weld seam has a certain excess height, and the surface quality cannot meet the requirements. Grinding is an effective way to improve the aero-engine performance of aero-engine components. Grinding is used to treat the surface of aero-engine parts, grinding the extra height to produce a uniform surface, and improving its surface quality. Grinding has the characteristics of flexibility and precision, which are widely used in the precision processing of aero-engine parts. However, few scholars in the field of belt grinding have explored the formation mechanism of the ribbed surface by belt grinding and its influence on aerodynamic performance. Therefore, it is necessary to study the aerodynamic performance of the ground surface by belt grinding on titanium alloy EBW.

Scholars have done a great deal of research on the properties of titanium alloy welded and EBW. Kar et al. [1] studied the effect of electron beam scanning on the porosity generation and fatigue performance of welding joints of TC4 titanium alloy, and the results showed that electron beam scanning could reduce the porosity of welding joints and improve the fatigue performance of joints. Garud et al. [2] elaborated on the relationship between mechanical strength and working life of welded joints as weak links of mechanical equipment. Experiments show that the fatigue life of the welded toe by hemispherical burr tool is 76% higher than that of the welded toe without polishing. Liu et al. [3] evaluated the influence of the microstructure unevenness of the electron beam weld of TC4 thin plate on the tensile performance and low-cycle fatigue performance and found that the tensile ductility and low-cycle fatigue strength of the joint was lower than that of the base material. Baptista et al. [4] polished the toes of the welds of two different sheets of steel under different environmental conditions. The results showed that the fatigue life of the welds polished in a 3% sodium chloride environment was longer, and the fatigue strength was higher. Through experiments, Lan et al. [5] studied the effect of welding pores on the fatigue life of titanium alloy EBW joints. It was shown that the dispersion of pore size and depth was the key factor leading to the widespread dispersion of the fatigue life of welded joints. A model of the influence of a welding pore on the fatigue life of welded joints was established.

In the field of belt grinding, there is also much research, which includes robotic belt grinding technology, prediction of surface roughness of belt grinding, and precision grinding methods of aviation parts belt grinding, to name a few areas of interest. Single factor belt grinding tests of titanium alloy aero-engine blades were carried out by Chai et al. [6]. The effects of belt speed and belt feed speed on belt blockage during grinding were analyzed. Xiao et al. [7] developed an adaptive belt grinding method for an integral blade disc. The deformation error of the blade was compensated by measuring and controlling contact pressure. Precision grinding was achieved by controlling the rotating speed. Experiments showed that the method can be used as a precision processing method for the blade disc. Pandiyan [8] developed a machine learning belt grinding system based on deep learning, which can monitor and predict the new height distribution of welding seams and the endpoint of belt grinding in extra real-time height. Wang and Yan et al. [9,10] studied robot belt grinding technology from two aspects—the robot belt grinding model and surface quality—which laid a theoretical foundation for robot belt grinding technology.

Many scholars have conducted research on ground surfaces and their characteristics. Some achievements have been made in reducing noise, improving hydrophobicity, and improving aerodynamic performance. Frohnapfel et al. [11] studied the surface of turtle skin and simplified the groove structure on the surface of turtle skin; they found that the blade surface had the best drag reduction effect, and the turbulence dissipation rate between the grooves had a significant impact on the final drag reduction effect. Chen et al. [12] prepared strip textures with different spacing on the surfaces of 3Cr2W8V, H13, and HD(4Cr3Mo2NiVNb) materials, and compared them with smooth surfaces to investigate changes in the wear amount. The study found that, compared with smooth surfaces, the wear amount of strip textures was smaller, and the wear resistance of texture surfaces decreased with the increase of stripe spacing. Ma et al. [13] studied the ground surface and found that it had excellent drag reduction performance. Xiao and colleagues [14] established a parameterized mathematical model for grinding a multi-particle abrasive belt and proposed a method for grinding a micro-bionic serrated surface abrasive belt. Finally, with the blade profile of titanium alloy as the object, a primary experimental platform for grinding the micro-bionic serrated surface abrasive belt with titanium alloy as the typical material was built, and the bionic surface was tested and verified, making it possible to process the rib surface.

From the analyses above, many scholars have focused on the welding performance of titanium alloy electron beams and improving the welding quality. Belt grinding, as a standard finishing method for aero-engine blade surfaces, is very useful for blade surface processing, but research on the ground surface is relatively minimal at present. Therefore, it is of considerable significance to explore the belt grinding performance of complex surfaces with bionic structures; thus, belt grinding experiments were carried out on the welds of titanium alloy EBW. The surface quality of the welds and the aerodynamic performance of the ground surfaces were analyzed to judge the property of titanium alloy EBW belt grinding with a bionic structure.

2. Experimental Methods and Devices

2.1. Experimental Scheme

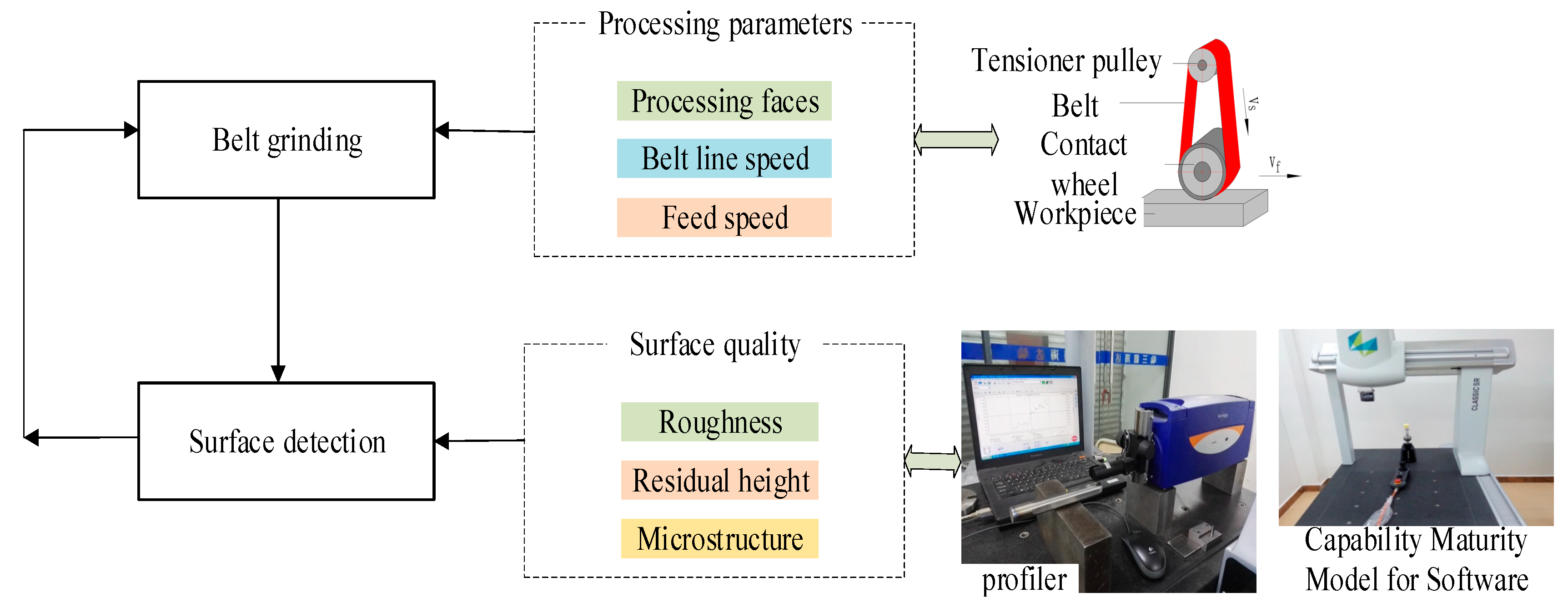

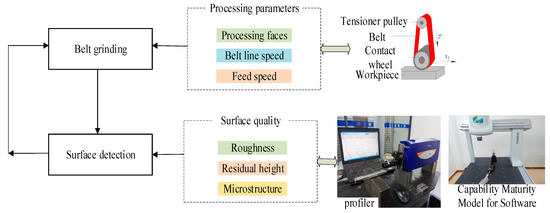

To explore the performance of the belt grinding belt rib surface, the test scheme, as shown in Figure 1, was established. Firstly, belt grinding experiments were carried out on titanium alloy EBW parts. The grinding parameters, such as belt speed and feed speed, were controlled. After the belt grinding was completed, the surface quality and surface morphology characteristics were detected. The surface quality of the grinding weld, such as Ra and extra height distribution, were identified by a microscope. Ra and micro-surface morphology of grinding surfaces were measured by profilometer and ultra depth of field electron microscopy. The test results were used to discuss the applicability and effect of the ground surface by belt grinding of titanium alloy EBW parts. Then they were used to examine the relationship between different process parameters and the quality of grinding surface and ground surface morphology.

Figure 1.

Block diagram of experimental scheme.

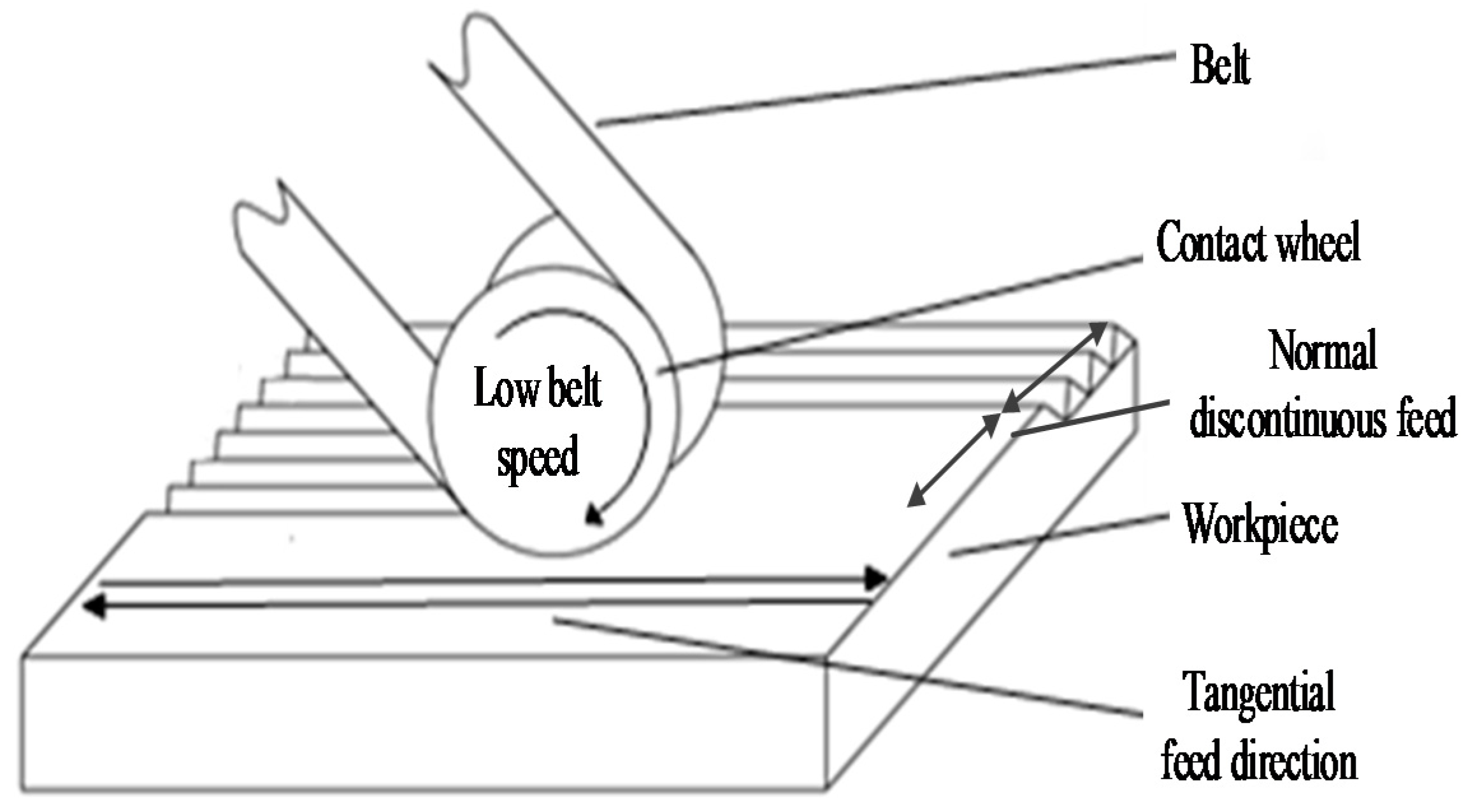

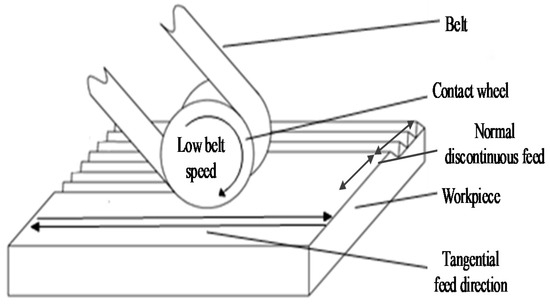

As shown in Figure 2, a method was put forward to grind the electron beam weld of titanium alloy to obtain the ground surfaces. As for the conventional belt grinding method, high belt speed is often used to ensure a workpiece surface with small roughness. At the same time, the standard continuous feeding method was used to grind the machined surface repeatedly. In this experiment, the way of the ribbed surface by belt grinding was different from conventional belt grinding. In the grinding process, minimum belt speed was adapted to grind the parts. As for traditional belt grinding, the standard feed was continuous to guarantee the processed surface grinding enough times; but for ground surface by belt grinding, the standard feed was discontinuous. The grinding head would raise after grinding one section of the surface, and then move to the next section and lay the grinding head down to continue grinding. The grinding head and workpiece were installed on the belt grinder. Before the experiment began, the grinding angle was pre-set; that is, the angle between the grinding head and the extension direction of the rib line of the part design was pre-set. During this experiment, the surface of our design workpiece was ground at an angle of 90 degrees. Then the machine tool would control the grinding head to get close to the processing surface. When the grinding head reached the designed distance from the workpiece, the spindle accurately controlled the speed of the belt, and the belt rotated and moved along the designed angle to complete the ground surface processing of one stroke. Then the grinding head was lifted, and the position adjusted. This was repeatedly performed until all required processing surfaces were finished.

Figure 2.

Belt grinding method for bionic surface.

2.2. Experimental Equipment

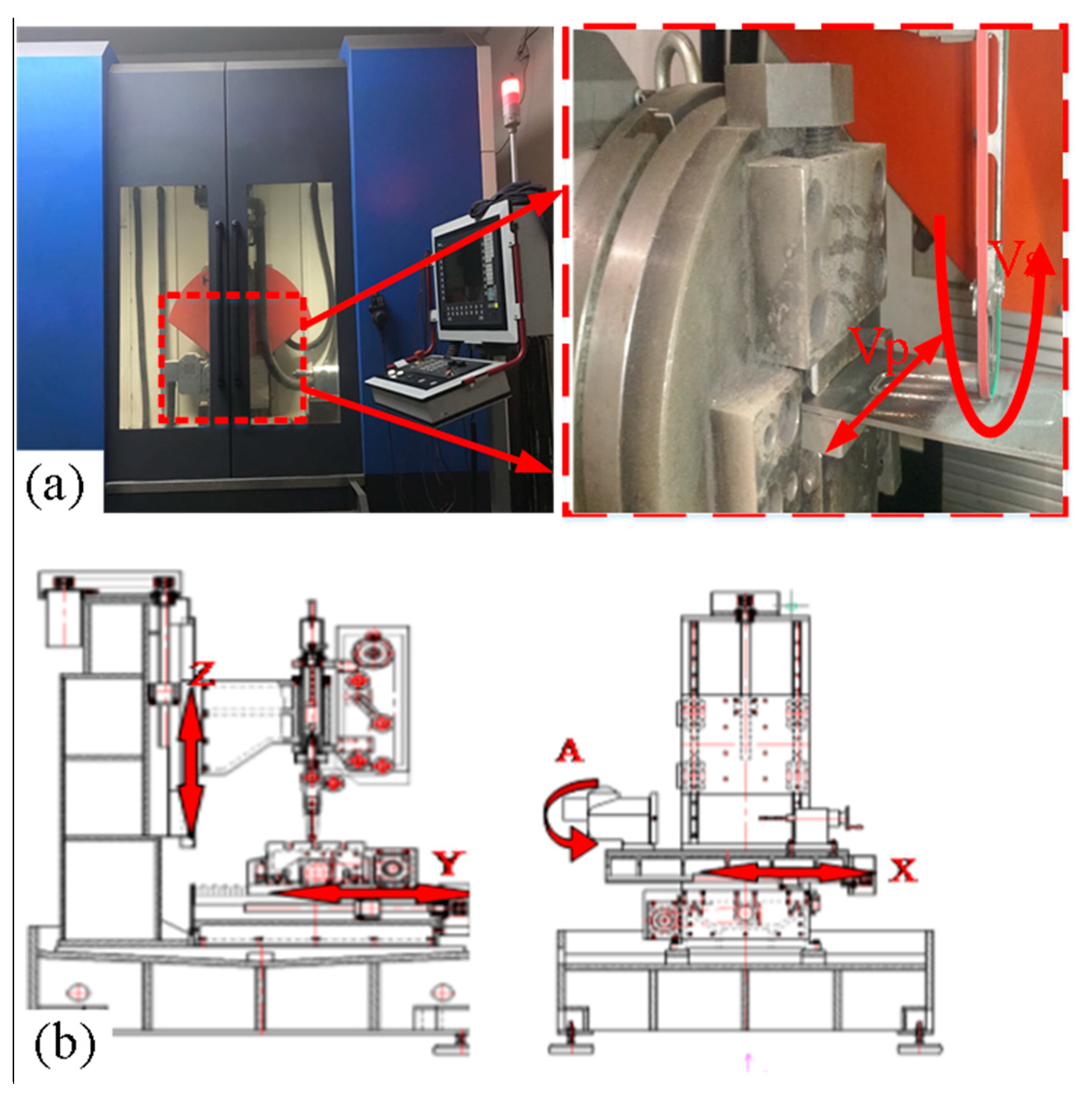

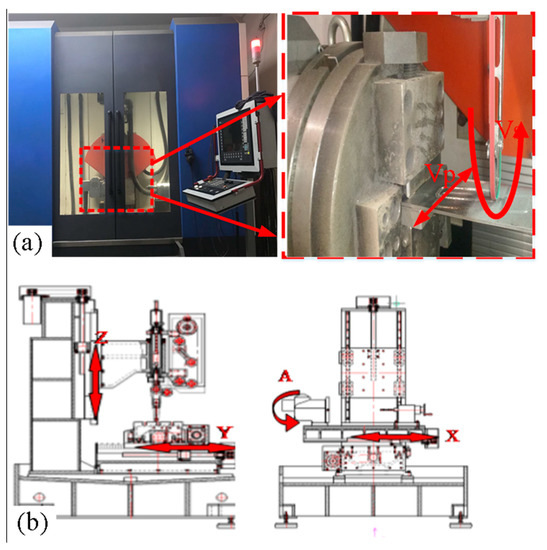

The experiment was carried out on the Computer numerical control (CNC) belt grinding machine tool of Chongqing Sanmo Haida Grinding Machine Co., Ltd. Its structure is shown in Figure 3. A high-grade CNC system controlled the complex surface grinding head. The processed parts were clamped on the A-axis tooling. The precision belt grinding head was installed on the grinding head rack, which moves along two coordinates (Y, Z). The machine automatically grinds, finishes, and polishes the complex surface. In addition, the grinding pressure is controlled by a servo motor in real-time, which adjusts the machining allowance of the workpiece to achieve accurate material removal.

Figure 3.

(a) MGY5540A-7NC CNC belt grinding machine tool. (b) 2D schematic diagram of grinding machine.

2.3. Experimental Materials

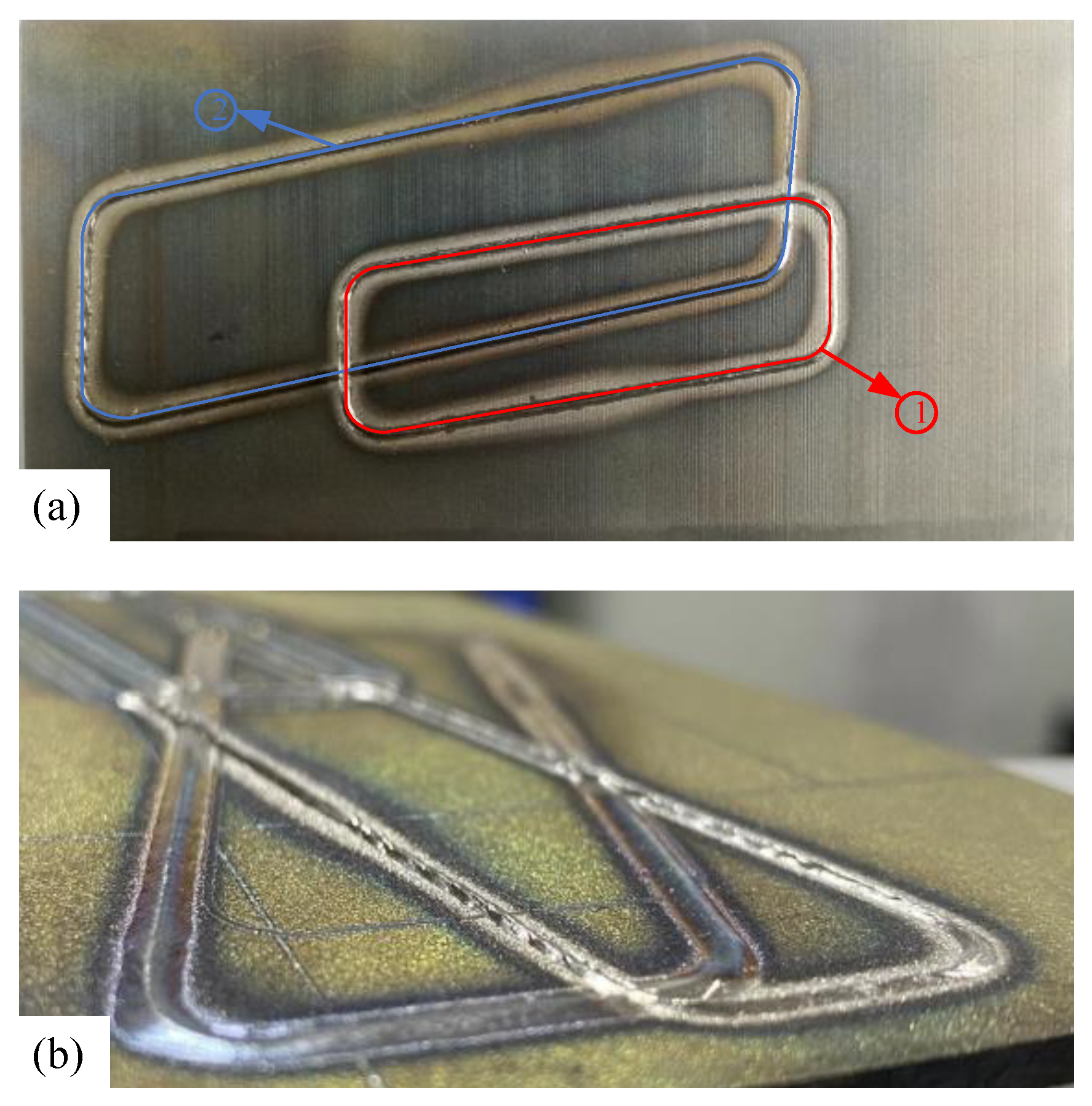

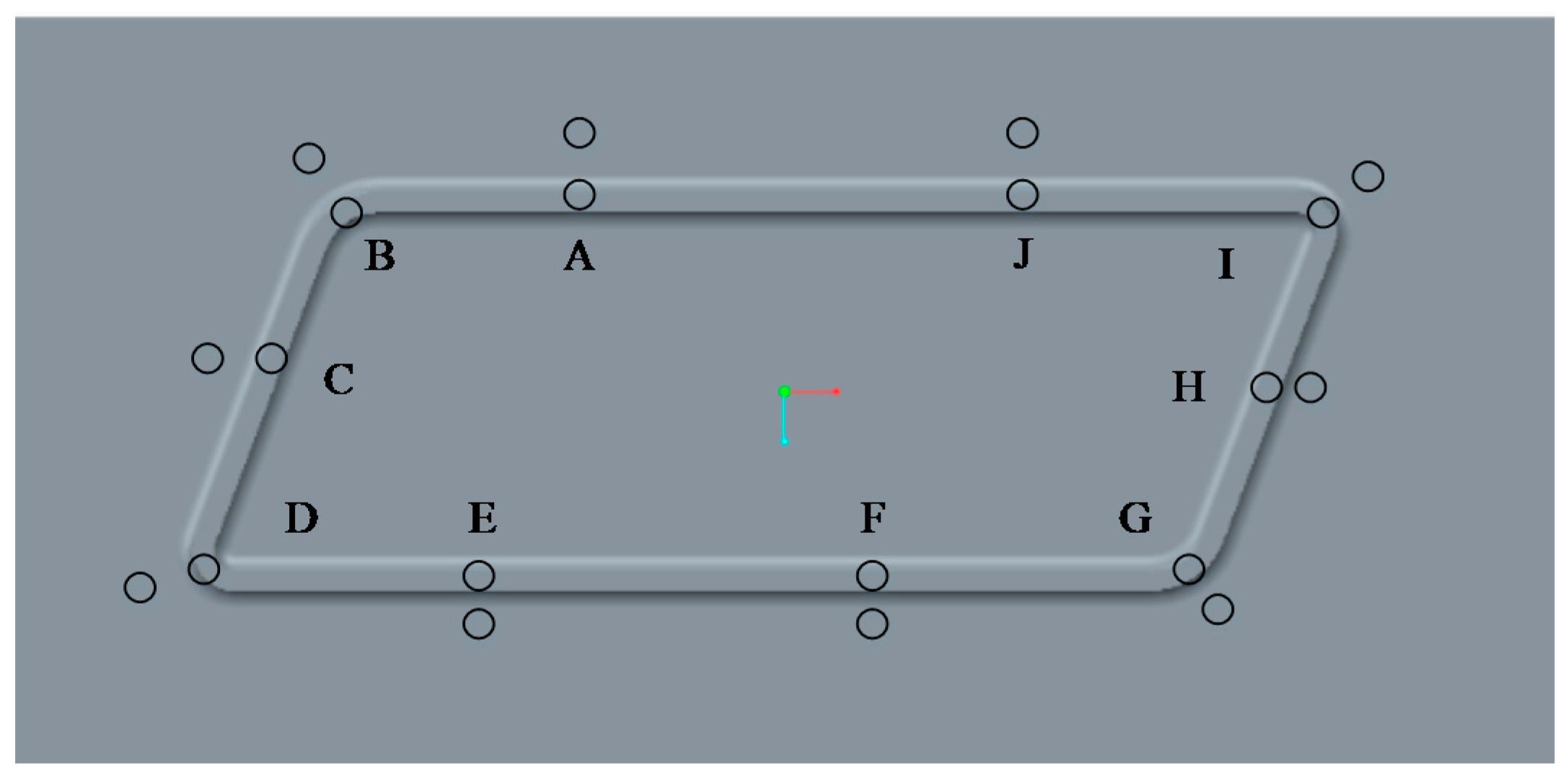

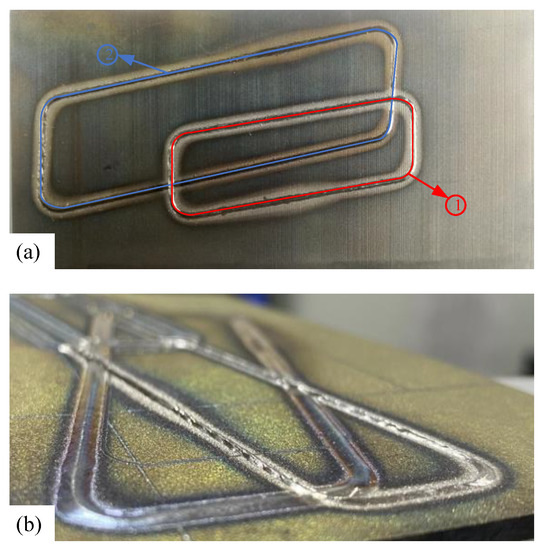

The samples used in this experiment were titanium alloy sheets by EBW, as shown in Figure 4. The size of the sheets was 150 mm × 75 mm, and the thickness was 2.6 mm. Due to the high power of EBW, it welded through the whole plate at one time. In conclusion, the welding quality was good, and the margins of the welded face and welded ridge were evenly distributed on the sheet.

Figure 4.

Electron beam welding of titanium alloy sheet. (a) The face of the weld. (b) The ride of the weld.

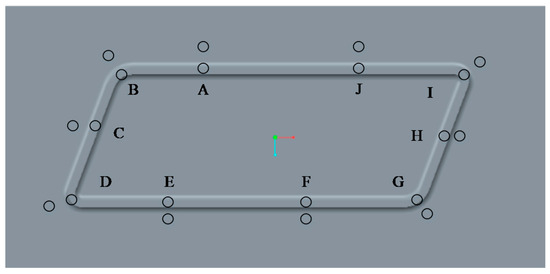

In Figure 4a, the weld of ① was selected for measurement. The 3D Cartesian coordinate system was used to measure the extra height of the electron beam weld of titanium alloy. A group of measuring points was formed by taking two adjacent locations, and a total of ten groups of measuring points was taken. We detected their absolute coordinates and calculated the differences of their absolute coordinates to obtain the extra height. According to the distribution of weld height, we established a reasonable feed speed to ensure the reasonable removal of extra weld height. The detection points and results are shown in Figure 5 and Table 1. The extra height on the face of the weld was smaller, ranging from 0.2 mm to 0.5 mm. The extra height on the weld ridge was more significant, ranging from 0.5 mm to 0.9 mm.

Figure 5.

Distribution map of measuring points of weld extra height.

Table 1.

Measurements of weld height (unit: mm).

Single-factor experiments were carried out with different grinding speeds and feed rates, which were divided into eight groups. There were four groups on the front side of the weld and four groups on the reverse side. The grinding parameters are shown in Table 2 and Table 3 below. Eight groups of process schemes were used to grind a section of the weld seam for data detection.

Table 2.

Grinding parameters.

Table 3.

Experimental parameters.

3. Analysis of Experimental Results

3.1. Analysis of Grinding Surface Quality

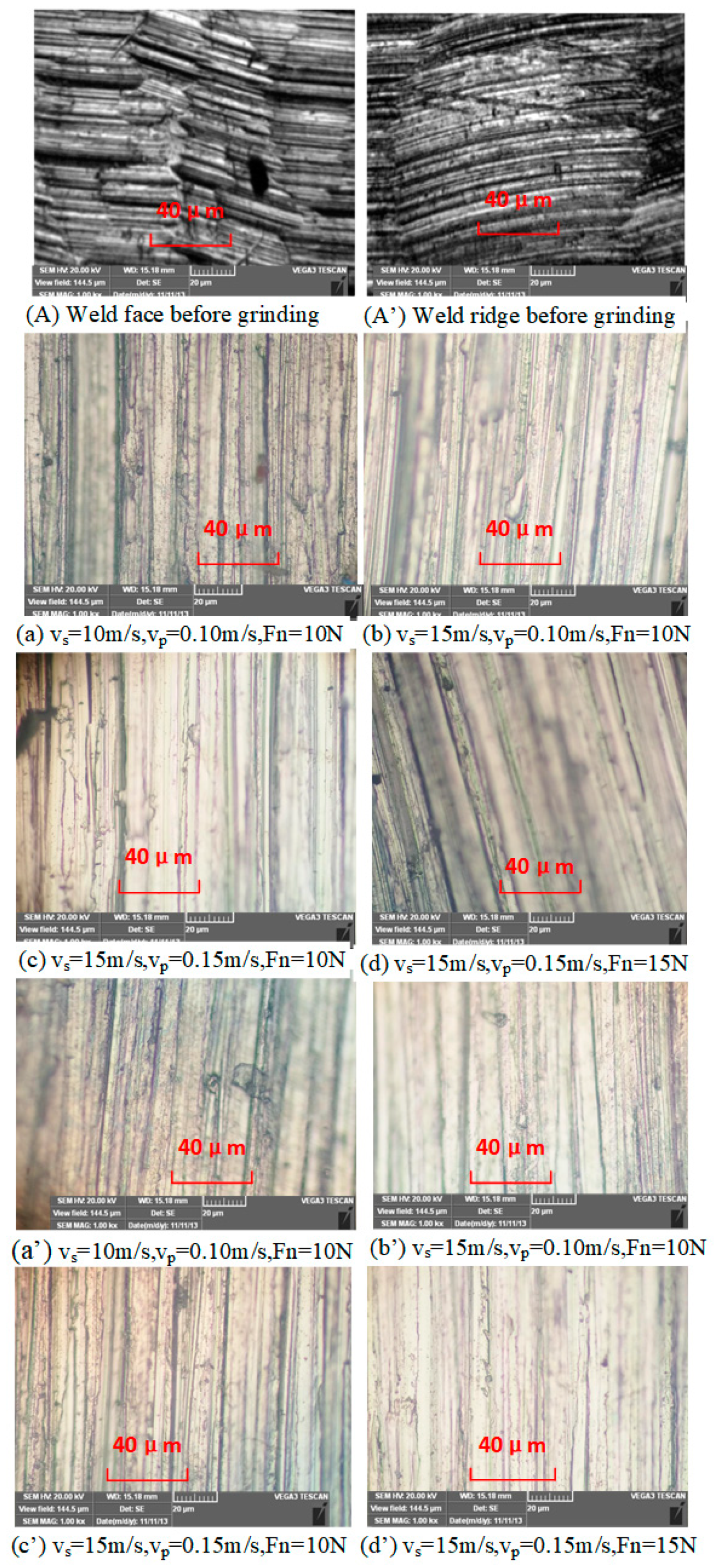

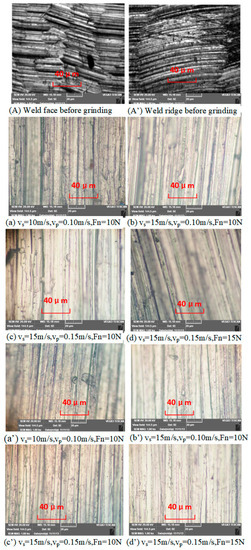

Grinding is often used for material removal, eliminating excess weld height, or polishing, which also makes the weld surface smoother. The surface of the grinding workpiece is observed by an optical microscope at 50× magnification. We obtained an observation graph, as shown in Figure 6A,A’, respectively, which show the micrographs of the weld surface and the weld ridge before grinding. By comparing the micrographs before and after grinding, it can be seen from the figure that the surface texture before grinding is relatively messy with obvious texture fracture, while the surface texture after grinding is uniform and continuous. Figure 6 (a)–(d), (a’)–(d’) represents the surface machined under the grinding parameters in Table 3. Under different parameter conditions, the surface after grinding is different, but compared with the surface without grinding, it is relatively smooth, and the consistency of surface texture is very good. It can be seen that the diamond belt grinding can eliminate well the welding margin of titanium alloy electron beam welds so that the welding margin meets the requirements of parts and achieves a smooth transition between the machined surface and the substrate.

Figure 6.

Surface of welded seam after grinding as seen through an optical microscope.

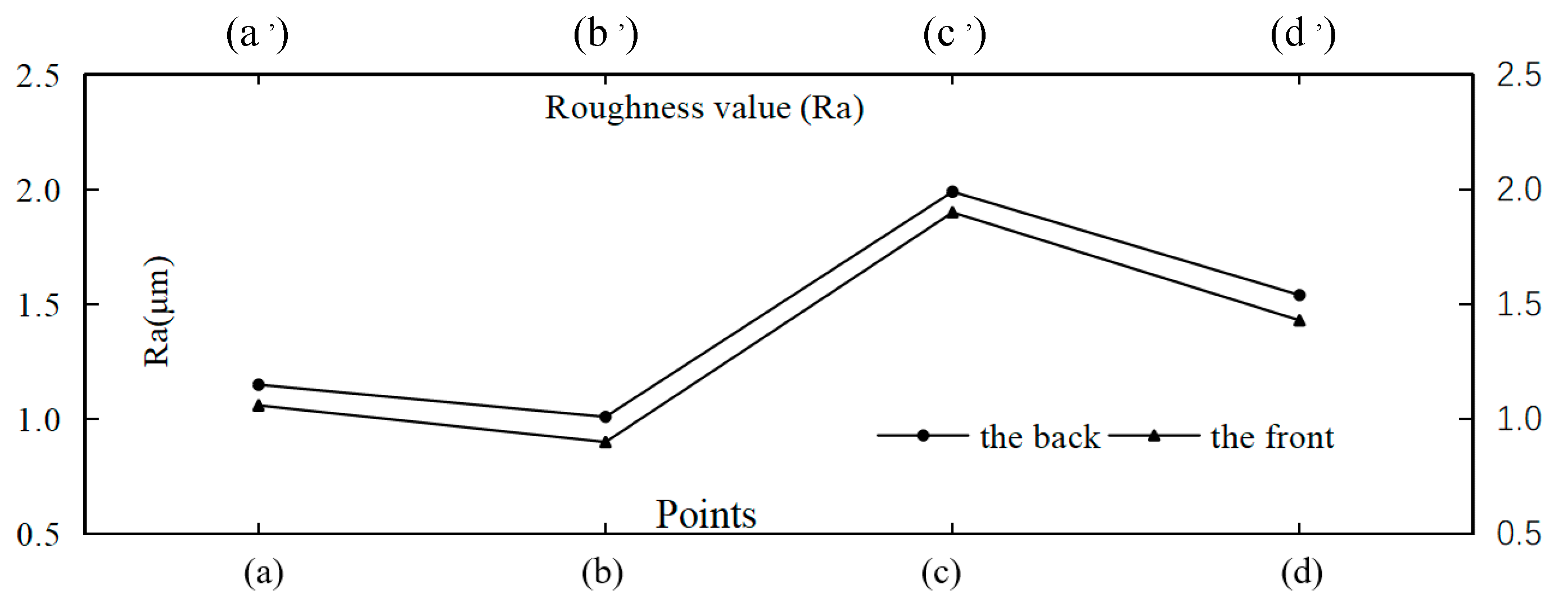

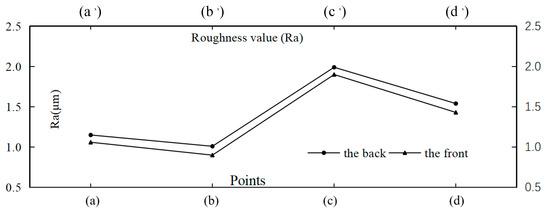

In this experiment, the roughness instrument TR200 was used to measure the roughness parameter Ra. The surface roughness of the welded surface under the grinding parameters in Table 3 is measured, asshown in Figure 7.

Figure 7.

Trend line of roughness change.

From the results of the roughness measurement, it can be seen that the roughness decreased after grinding with the decrease in feed speed. With the increase of belt speed, the roughness decreased after grinding. The surface roughness of the welded face was generally lower than that of the welded ridge, which shows better grinding machinability.

Due to the larger width of the welding surface, grinding can reduce the surface roughness of the workpiece and improve the surface finish. Therefore, the face of EBW should be the main working face of the workpiece, while the ridge of welding should be the secondary working face or non-working face of the workpiece. Similarly, the belt grinding of titanium alloy EBW seam follows the basic rule of material removal. With an increase in cutting speed and decrease in feed speed, the surface quality and roughness improve. Therefore, when choosing the grinding speed of the belt, we should try to choose a faster belt speed and lower feed speed when considering the factor of roughness.

3.2. Analysis of Formation Law of Ground Surface

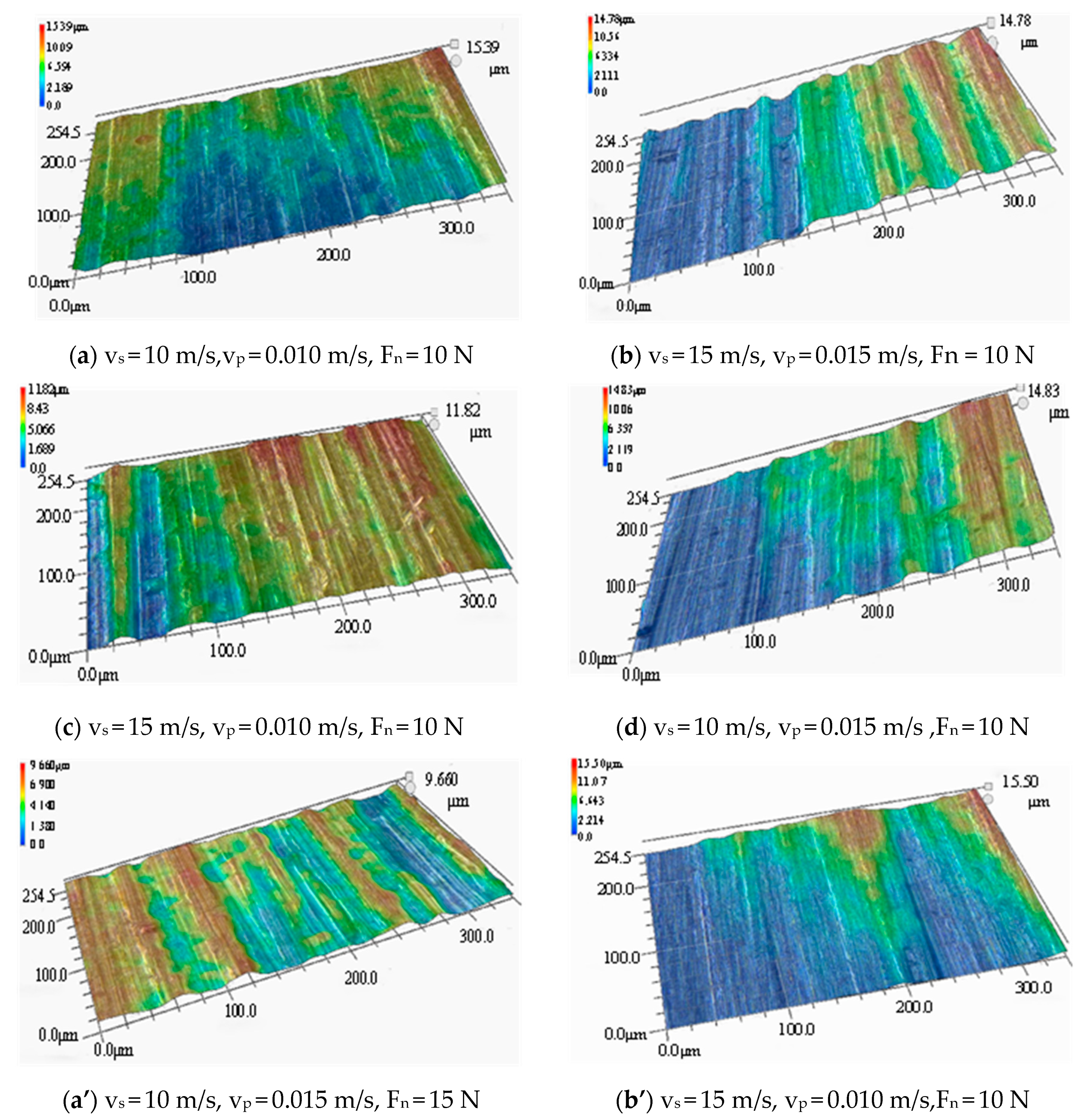

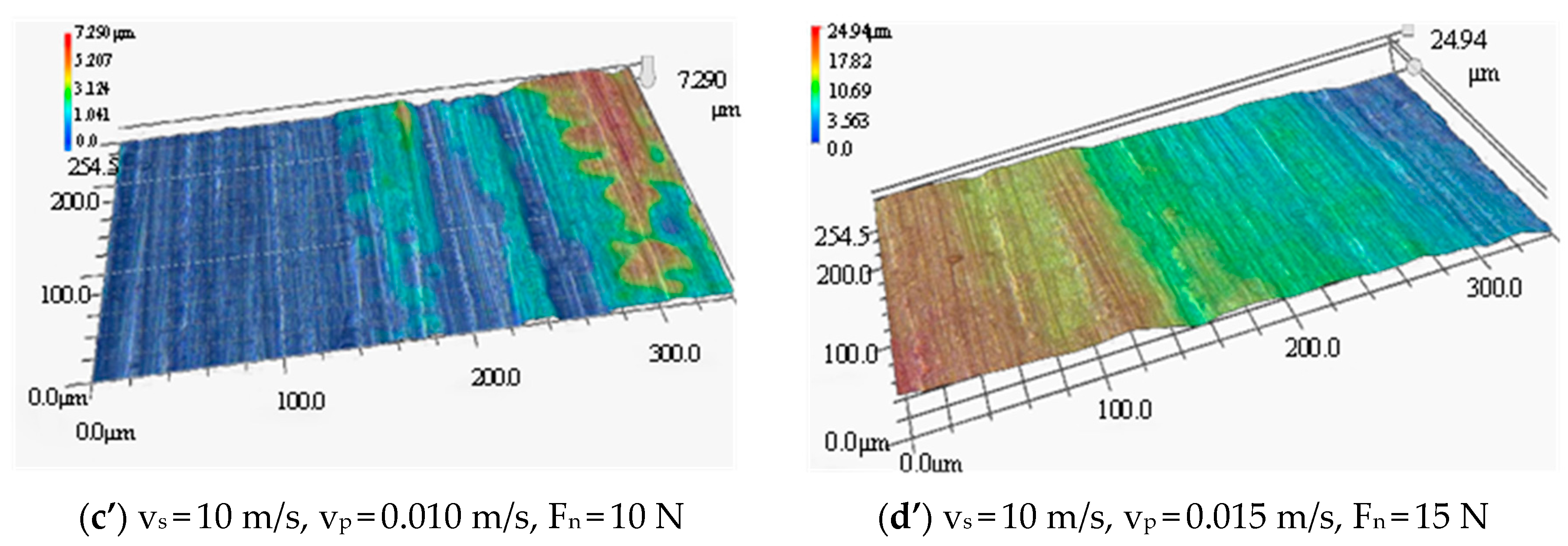

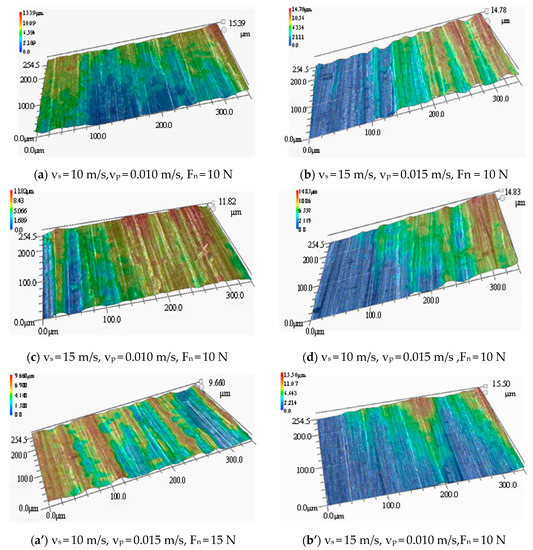

In order to better observe the surface, microscopic observation on the processed surface was conducted by an ultra depth of field electron microscope. The test results are shown in Figure 8, where (a)–(d) and (a’)-(d’) represent the surface under the grinding parameters in Table 3.

Figure 8.

Results of ground surface detection by ultra depth of field electron microscope.

From the detected results of ultra depth of field electron microscopy, it can be seen that the belt rows out the ravines on the surface of the welded seam, and the ravines distribute on the surface of the weld. The ground ribbed surfaces range in width from 20 to 40 μm and in height from 3 to 10 μm. The angles of the ribs are about 50 to 70 degrees. In the case of lower belt speed and grinding speed, the microstructure of the grinding surface is more prominent. The low feed speed is beneficial in prolonging the processing time between the strip and the workpiece surface and the overall surface treatment. The lower linear velocity of the friction band can avoid the damage of friction particles to the surface of the rib.

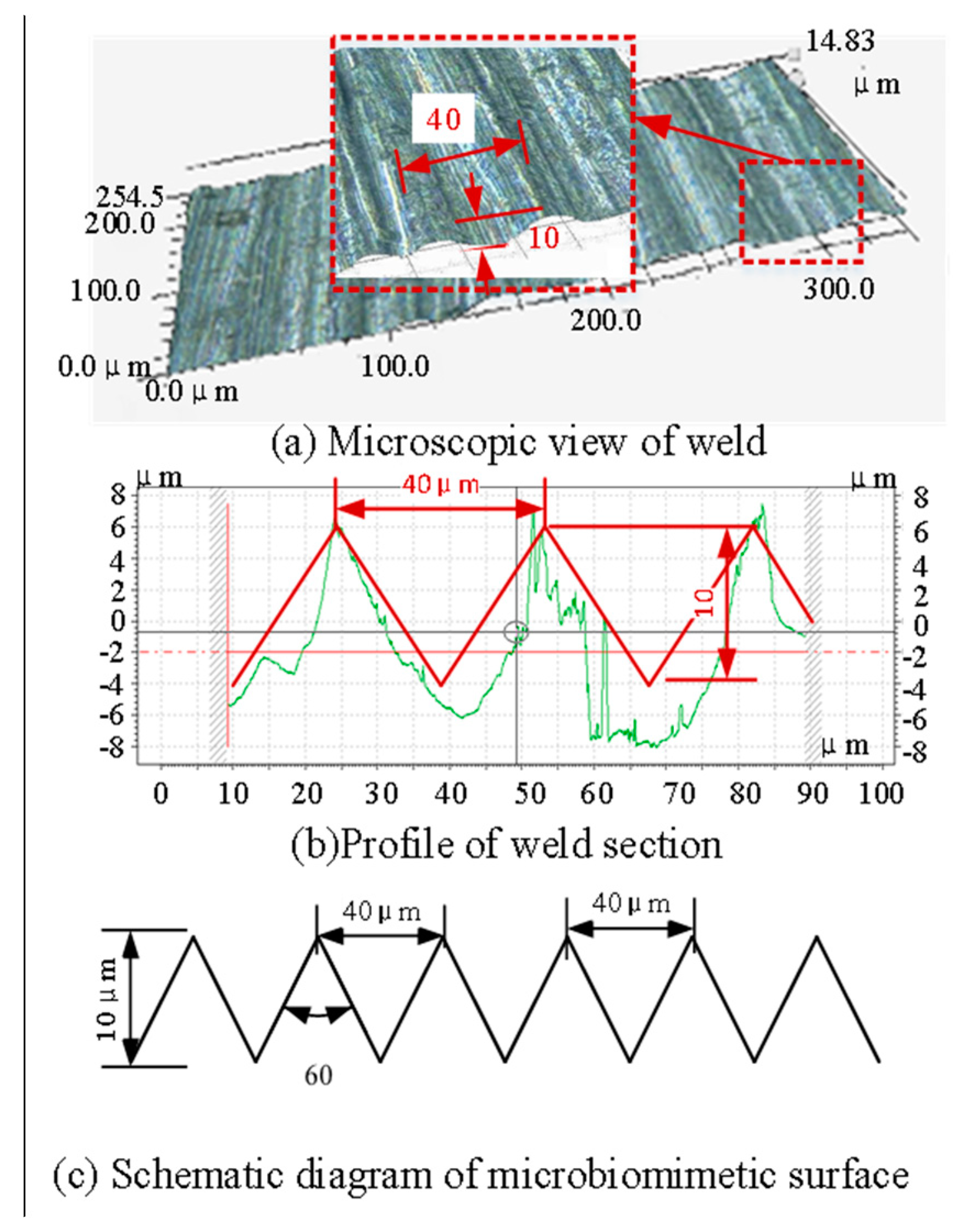

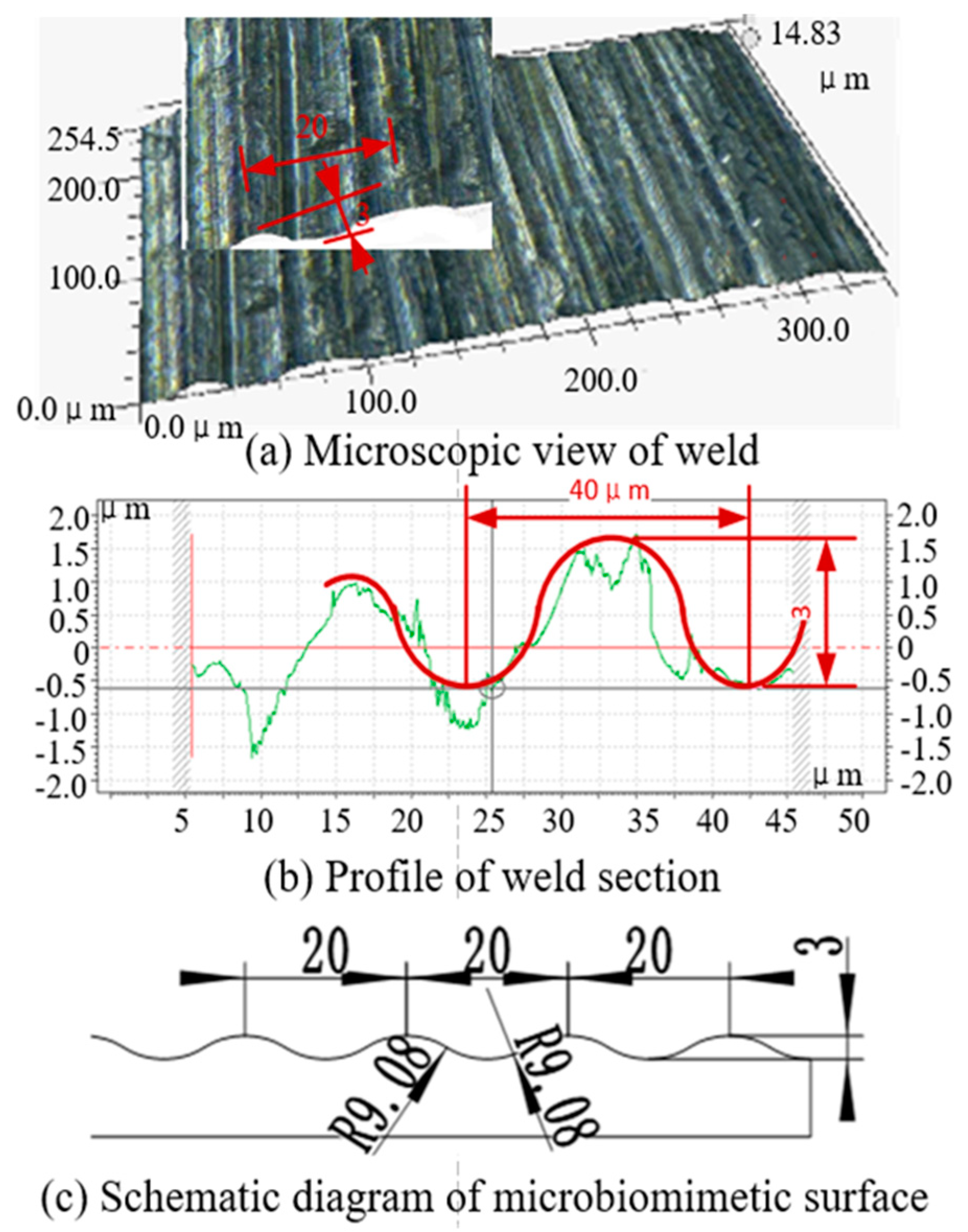

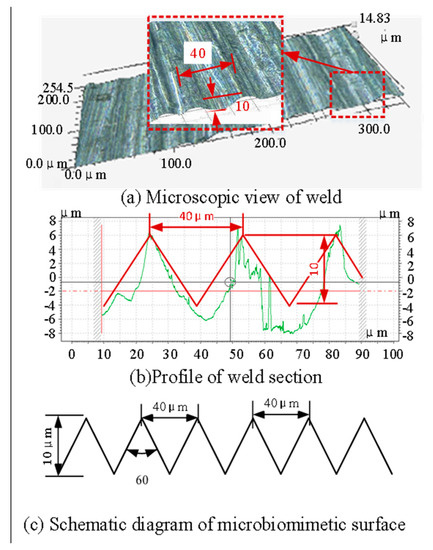

In order to facilitate the study of the surface characteristics of the stiffened ribs, some stiffened surfaces were selected to simplify the geometric surface models analyzed and make the stiffened rib surface more scientific and reasonable. The fifth group and the third group of experiments have visible ground surface characteristics, so this paper extracted the geometric features of the two groups of surfaces. Two kinds of 3D models were modeled according to the geometric elements, referred to as type I and type II. The smooth surface was also modeled to contrast, called type II. Figure 9 and Figure 10 are the geometric feature extraction models and simulation analysis models of the ground surface.

Figure 9.

Ground surface of type I.

Figure 10.

Ground surface of type II.

Figure 9 shows the type I model. Figure 9a represents the microscopic view of the weld, while Figure 9b represents the profile of the weld section, and a standard model was used to fit the monitoring results. By analyzing the detection results, the average depth of the valley floor was equal to 10 μm, and the average width between the two valley peaks was 40 μm; thus, the model in Figure 9c was obtained. It can be seen from the figure that the reinforcing rib presents a gully shape. The width of the gully is about 40 μm, the height is 10 μm, and the angle is about 60–70 degrees. For this reason, we simplified the model, as shown in Figure 10. Figure 10 shows the type II model. Figure 10a represents the microscopic view of the weld, while Figure 10b represents the profile of the weld section. A standard model was used to fit the monitoring results. By analyzing the detection results, the average depth of the valley floor is equal to 3 μm, and the average width between the two valley peaks was 20 μm; thus, the model in Figure 10c was obtained.

3.3. Analysis of Ground Parameters

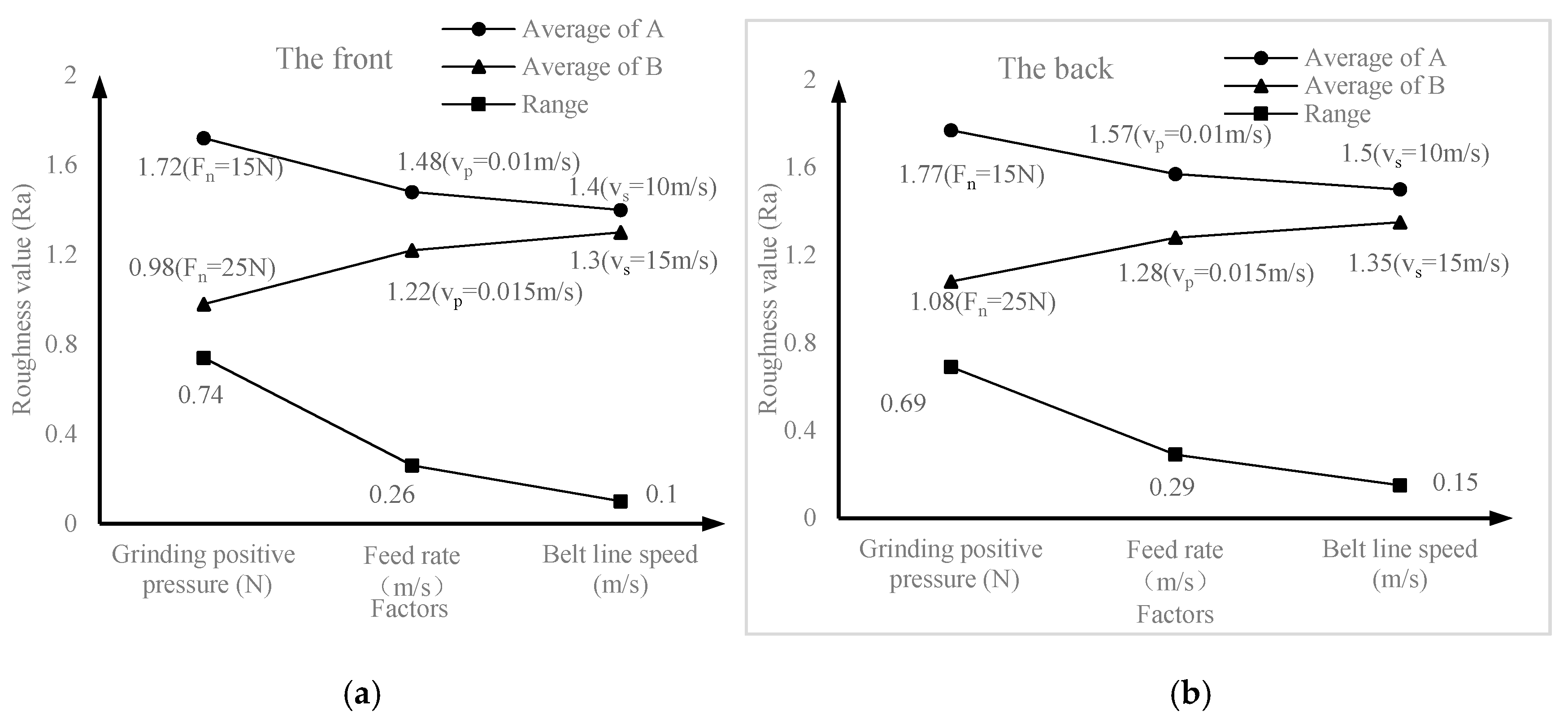

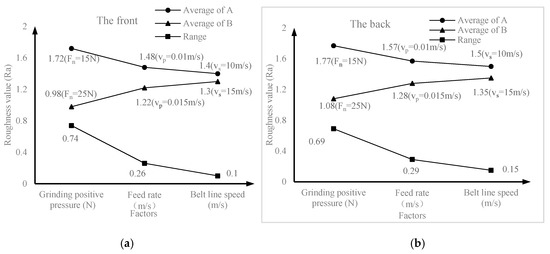

According to the above orthogonal test results, the influence of grinding parameters on the grinding effect of welds was analyzed. The results are shown in Figure 11.

Figure 11.

Parameter analysis of (a) weld face and (b) weld ridge.

As shown in Figure 11, the influence of grinding parameters such as grinding pressure, feed speed, and grinding line speed on Ra of the face and ridge surfaces of the weld is shown. Under the conditions of grinding pressure of 15 N and 25 N, the face Ra of the weld was 1.72 μm and 0.98 μm, and the ridge Ra was 1.77 μm and 1.03 μm, respectively. Under the feed rate of 0.01 m/s and 0.015 m/s, the Ra of the face of the weld was 1.48 μm and 1.22 μm, and the Ra of the ridge of the weld was 1.57 μm and 1.28 μm, respectively. When the grinding speed was 10 m/s and 15 m/s, the Ra of the face of the weld was 1.4 m/s and 1.3 m/s, and Ra of the ridge of the weld was 1.5 m/s and 1.35 m/s, respectively. The range indicates the difference between different grinding parameters under the same grinding factor.

From the above experimental results, it can be seen that the surface roughness of titanium alloy EBW can be reduced to less than 0.15 μm after grinding. Ra will decrease with the increase of belt speed, the decrease of feed speed, and the improvement of grinding positive pressure. At the same time, it can be seen that the range of grinding positive force is more significant than the other two factors. We can thus say that the effect of Fn on Ra is followed by vp then vs. This conforms to the fundamental technological rules of cutting. In addition, the surface roughness on the weld face is generally lower than weld ridge. This is mainly because the width of the weld face is more comprehensive, and the grinding smoothness is better.

4. Conclusions

- (1)

- The experimental platform of titanium alloy EBW with bionic surface grinding was established; two bionic surface geometric models with rib width of 20 μm and 40 μm, and rib height of 3 μm and 10 μm were established to explore the influence of feed speed and belt speed on the bionic surface. If the feeding speed is too high, the rib surface is not obvious; if the belt speed is too high, the ribbed surface is damaged.

- (2)

- Belt polishing improves the quality of the weld surface, making the weld surface and the base material surface form a better and smoother surface; Ra can reach 0.98 μm. The weld margin can also be effectively eliminated. The additional height of the ground weld surface may be less than 0.2 mm, effectively removing the weld surface margin.

- (3)

- The grinding quality of the weld surface is better than that of the weld ridge. With the decrease of vp and vs, the size of the bionic structure formed by grinding decreased, as did the surface structure of the overall bionic. The effect of Fn on Ra is followed by vp then vs.

Author Contributions

Conceptualization, S.H. and G.X.; methodology, G.X.; software Y.H (Yi He); validation, Y.Z., G.X., Y.H. (Yi He), and Y.H. (Yun Huang); investigation, J.X. and K.S.; resources, G.X.; data curation, G.X. and S.H.; writing—original draft preparation, S.H and G.X.; writing—review and editing, G.X., and Y.H. (Yun Huang); visualization, G.X. and Y.H. (Yi He); supervision, G.X.; project administration, G.X.; funding acquisition, G.X. and Y.H. (Yun Huang). All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Natural Science Foundation of China under grant (51875064); the National Natural Science Foundation of China under grant (U1908232); the National Science and Technology Major Project (2017-VII-0002-0095).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Kar, J.; Chakrabarti, D.; Roy, S.K.; Roy, G.G. Beam oscillation, porosity formation and fatigue properties of electron beam welded Ti-6Al-4V alloy. J. Mater. Process. Technol. 2019, 266, 165. [Google Scholar] [CrossRef]

- Garud, V.U.; Lakade, S.S.; Bhoite, S.; More, S.; Ingale, S.; Gaikwad, N.; Gavhane, K. Burr Grinder: Advanced & Effective Post Weld Toe Treatment to Optimize Fatigue Life of Welded Structures. In Proceedings of the 2016 International Conference on Electrical, Electronics, and Optimization Techniques (ICEEOT), Chennai, India, 3–5 March 2016; pp. 196–203. [Google Scholar]

- Liu, J.; Gao, X.L.; Zhang, L.J.; Zhang, J.X. Effects of the Heterogeneity in the Electron Beam Welded Joint on Mechanical Properties of Ti6Al4V Alloy. J. Mater. Eng. Perform. 2015, 24, 319. [Google Scholar] [CrossRef]

- Baptista, R.; Infante, V.; Branco, C.M. Study of the fatigue behavior in welded joints of stainless steels treated by weld toe grinding and subjected to salt water corrosion. Int. J. Fatigue 2008, 3, 453–462. [Google Scholar] [CrossRef]

- Lan, Y.; Zhang, W.; Liu, X.; Li, N.; Dai, W. Effects of Welded Pores on Fatigue Life of Titanium Alloy Electron-Beam Welded Joints. In Proceedings of the 2018 Prognostics and System Health Management Conference (PHM-Chongqing), Chongqing, China, 26–28 October 2018; pp. 1144–1148. [Google Scholar]

- Chai, H.; Huang, Y.; Zhao, Y.; Zhang, X.D. Experimental Research on the Abrasive Belt Grinding Titanium Alloy Blade of Aviation Engine. In Proceedings of the 15th International Symposium on Advances in Abrasive Technology (ISAAT2012), Singapore, 25–28 September 2012; Volume 565, pp. 64–69. [Google Scholar]

- Xiao, G.J.; Huang, Y. Adaptive belt precision grinding for the weak rigidity deformation of blisk leading and trailing edge. Adv. Mech. Eng. 2017, 9, 1–12. [Google Scholar] [CrossRef]

- Pandiyan, V.; Murugan, P.; Tjahjowidodo, T.; Caesarendra, W.; Manyar, O.M.; Then, D.J.H. In-process virtual verification of weld seam removal in robotic abrasive belt grinding process using deep learning. Robot. Comput. Integr. Manuf. 2019, 6, 477–487. [Google Scholar] [CrossRef]

- Wang, J.W.; Xu, J.J.; Wang, X.F. A comprehensive study on surface integrity of nickel-based superalloy Inconel 718 under robotic belt grinding. Mater. Manuf. Process. 2019, 34, 61–69. [Google Scholar] [CrossRef]

- Yan, S.J.; Xu, X.H.; Yang, Z.Y. An improved robotic abrasive belt grinding force model considering the effects of cut-in and cut-off. J. Manuf. Process. 2019, 37, 496–508. [Google Scholar] [CrossRef]

- Frohnapfel, B.; Jovanovic, J.; Delgado, A. Experimental investigations of turbulent drag reduction by surface-embedded grooves. J. Fluid Mech. 2007, 590, 107–116. [Google Scholar] [CrossRef]

- Chen, L.; Zhou, H.; Zhao, Y.; Ren, L.Q.; Li, X.Z. Abrasive particle wear behaviors of several die steels with non-smooth surfaces. J. Mater. Process. Technol. 2007, 190, 211–216. [Google Scholar] [CrossRef]

- Ma, F.L.; Zeng, Z.X.; Gao, Y.M.; Liu, E.Y.; Xue, Q.J. Research status and progress of bionic surface drag reduction. China Surf. Eng. 2016, 29, 7–15. [Google Scholar]

- Xiao, G.J.; He, Y.; Huang, Y.; Li, W.; Li, Q. Based on the Single Particle Model of the Air Blade Belt Grinding Micro Bionic Serrated Surface Formation and Test. Available online: http://kns.cnki.net/kcms/detail/11.1929.V.20190929.1657.008.html (accessed on 29 February 2020).

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).