Abstract

This paper describes an organosolv pretreatment of corncob waste to improve its anaerobic digestion for biogas production. Through a thermochemical process based on the use of ethanol and acetic acid, it was possible to separate the fractions of lignin, considered to be a natural inhibitor of anaerobic digestion processes. In addition, with this organosolv pretreatment, the available sugars in the carbohydrates present as monosaccharides, or simple sugars, were depolymerised, facilitating the digestion process. The obtained results include the chemical characterisation of the corncob, the hydrolysate, and the mixture with cow manure, finding that these substrates have potential to be used in anaerobic digestion. The total reducing sugars consumed were 96.8%, and total sugars were 85.75%. It was clearly observed that with the use of pretreatment with organosolv, the production of biogas was superior, because 484 NmL/gVS was obtained compared to the other reported treatments. It was also observed that adding the hydrolysate organosolv increased the production because the values of the control without hydrolysate were 120 NmL/gVS in the bottle experiment. When the experiment was scaled to the 5L reactor, the total volumes of biogas that were accumulated in 15 days of production were 5050 NmL/gVS and 1212 NmL/gVS with and without hydrolysate, respectively. This indicates that the organosolv pretreatment of corncob waste is effective in improving biogas production.

1. Introduction

Energy demand, as well as the use of water resources, is growing proportionally as the population increases. As a sustainable alternative, the use of renewable such as biogas has been proposed. The process of biogas production involves anaerobic digestion, which is characterised as a process that transforms organic matter into biogas (methane, 60%–70%; carbon dioxide, 30%–40%) [1,2]. Anaerobic digestion is a very complex process in terms of both the number of biochemical reactions that take place and the microorganisms involved in them. In fact, many of these reactions occur simultaneously [3]. During the process, several groups of microorganisms participate to carry out a coordinated metabolism in four stages. The first is hydrolysis, where complex polymers present in the organic matter are broken down into simple monomers. Fermentation occurs in the second step with acidogenesis, which produces organic acids, and the third step is acetogenesis, which is the conversion of organic acids to acetate. Propionate and butyrate are products of acidogenesis/fermentation. The fourth stage is methanogenesis, where microorganisms produce methane through the acetoclastic and hydrogenotrophic pathways [4].

This fermentation process is usually hindered by various factors related to the nature of the substrate, such as nutrient balance, pH, or the presence of toxins and inhibitors [5]. The organic matter that can be used in the anaerobic digestion process is diverse [6]. Studies have reported various solid wastes being used, such as waste sludge from water treatment plants, agricultural livestock waste, and lignocellulosic waste [7]. With the aim of achieving an adequate final disposal of organic waste and/or a reduction thereof in an environmentally sustainable way, it is relevant to conduct research on the feasibility of a process of digestion of widely distributed organic waste and to stabilise it for the production of gaseous biofuels [2].

As a lignocellulosic organic residue, corncob was chosen due to its high availability and limited use otherwise. In Mexico, it is estimated that the annual quantity of residues fluctuates around 45 million tonnes of dry material among the ten principal crops (corn, sorghum, wheat, beans, rice, barley, soy, cotton, safflower, and sesame). Stubble and corncob represent 25,500,000 tonnes that are usually used to feed livestock at times when traditional food is scarce [8]. Although corncob could be used as a substrate for biogas production, its lignocellulosic nature presents difficulties for its direct use [9].

The specific pretreatment needed to improve anaerobic digestion depends on the type of organic matter. In the case of lignocellulosic material, a large part of its composition is carbohydrates that are not readily available because they are embedded in a lignin matrix, so pretreatment is necessary before the digestion process [2,4,10]. Organosolv pretreatment is an economic and efficient method to improve the anaerobic digestion process [11]. This is a method that utilises organic solvents such as methanol, ethanol, acetone, or ethylene glycol mixed with or without an inorganic catalyst at high temperatures to remove the lignin from the lignocellulosic material. In this way, the material is fractionated into a liquid hydrolysate containing dissolved lignin and hemicellulose and a solid fraction known as holocellulose, which comprises hemicellulose with cellulose [12]. The main advantage of organosolv over other chemical pretreatments is that relatively pure and low-molecular-weight lignin is recovered as a by-product, and the solvents that are used can be recovered and recycled to reduce the operation costs [2,13].

The main objective of this study was to improve the performance of the anaerobic digestion of hydrolysed corncob by applying organosolv pretreatment for biogas production. The effects of the pretreatment parameters, that is, temperature and duration, on the methane yield were determined by liquid-state batch anaerobic digestion assays. The biogas production concentration and total volume were investigated for the pretreated substrate.

2. Materials and Methods

Corncob was obtained from the area of Nextipac, in the municipality of Zapopan Jalisco, Mexico. The inoculum used was obtained from cow manure collected from a farm in the area of Tonalá, Mexico. For the organosolv method, the following reagents were used: ethanol (CH3CH2OH un-denaturalised 96%), acetic acid (CH3COOH 99.7%), and 3.5 dinitrosalicylic acid (DNS), all of them supplied by Sigma-Aldrich (Toluca, México).

2.1. Corncob Characterisation

The chemical characterisation of the corncob was determined using the standards of the Technical Association of the Pulp and Paper Industry (TAPPI). The cellulose content was determined using the T 203 cm-99 standard. The acid soluble lignin content was determined using the T 222 om-02 standard. The extractable compounds in acetone were determined according to T 280 pm-99, the extractable compounds in water using T 207 cm-99, and the ash content with T 211 om-02 [14]. An elemental analysis (C, H, N, and S) of the corncob was also performed. The elemental analysis was based on the volatilisation of a sample by total combustion under an atmosphere of pure oxygen, releasing the elements to be measured in the form of CO2, H2O, NOx, and SOx, respectively.

2.2. Organosolv Hydrolysate from Corncob

An ethanol to acetic acid ratio of 1:10 was used as an organic solvent. The process included high-temperature cooking inside a Jaime type reactor. This consisted of using 400 g (dry weight) of corncob with 50% solution of ethanol (2 L of distilled water and 2 L of ethanol) and 12 mL of acetic acid at a temperature of 175 °C and boiling for 2.5 h [15]. The liquid fraction, containing dissolved lignin and hemicelluloses, was separated. The hydrolysate was then broken up to evaporate to remove the lignin and to recover the used solvents.

To compare the results of the organosolv hydrolysate, a hydrolysate with soda was prepared, which is a widely used pretreatment. First, 400 g (dry weight) of corncob and 70 g of NaOH in a ratio of 1:10 with water as a solution were added in a Jaime type reactor at 195 °C for 1 h. As with the organosolv treatment, the liquid fraction was taken after the cooking time.

2.3. Characterisation of Corncob Hydrolysate

The reducing sugars (RS) present in the hydrolysate were determined by the DNS colorimetry method using a UV–visible spectrophotometer, for which a calibration curve was created from a standard glucose solution (2.0 g. L−1) [16]. Total sugars (TS) were also determined by the colorimetric phenol–sulphuric technique [17]. This technique is based on the formation of furfural (aldose) and 5-hydroxymethylfurfural (ketose) in a strongly acidic and dehydrating medium.

The determination of monosaccharides or individual sugars was determined by TAPPI Standard T 249 cm-09 [14]. The carbohydrate composition of extractive-free wood and wood pulp was determined by gas-liquid chromatography using Agilent 1200 equipment for high-performance liquid chromatography (HPLC). The bromatological analysis was performed following the techniques established by the Association of Official Analytical Chemists [18] and was performed by the Laboratory of Chemical and Bromatological Analysis of CIAJ, Guadalajara. The percentages of moisture, ethereal extract, crude protein, ash, and raw fibre were determined. During hydrolysis, the chemical oxygen demand (COD) was also measured to determine the amount of hydrolysate to use to feed the bacteria in the reactor. The COD was determined by using the colorimetric method according to standard methods [19]. Volatile fatty acids (VFAs) were measured before the fermentation stage and at day 17 of the fermentation stage by HPLC [20]. The inhibitory compounds, such as furfural, were also measured at day 17 by HPLC [21].

2.4. Preparation of Inoculum from Cow Manure

A mixture was made in three equal parts with soil, cow manure, and water and left for stirring for 24 h at 37 °C for the microorganisms to achieve stabilisation in the conditions of development within a mesophilic environment (between 34 and 36 °C). Organic composition parameters, such as total solids (TS), volatile suspended solids (VSS), and pH [20], were evaluated.

2.5. Experimental Design

Batch anaerobic digestion experiments were carried out in three bottles with a liquid volume of 300 mL and then escalated to a Labfors batch-type biological reactor with a capacity of 5 L. To both reactors was added a mixture of water, methanogenic inoculum of cow manure, and hydrolysed corncob and non-hydrolysed corncob at a concentration of 10 g COD/L. Additionally, a blank test without the addition of corncob hydrolysate was carried out. The process was performed in batches, and the operating conditions were the following: pH 7, agitation 300 rpm, time 20 days, and temperature 36 °C. All tests were performed in triplicate, and the variables were controlled and monitored by an automated system with sensors.

Biogas production was recorded with a gas meter, where the amount of gas generated for 20 days was quantified. For gas production in the period of time when the accumulation of produced biogas could be measured, a measurement unit of mL per day (mL/d) was used or quantified per unit of raw material in normalised biogas in mL per gram of volatile solid (NmL/g VS) to determine the effectiveness of the anaerobic digestion process [22]. To analyse the composition of the biogas obtained in the digestion process, biogas samples were taken and analysed with an Agilent Technologies 6820 GC gas chromatograph with a DB-35 capillary column to determine the type and percentage of biogas generated.

3. Results and Discussion

The organosolv process is a delignification process that consists of breaking the internal lignin and hemicellulose bonds of the lignocellulose material; in this case, a corncob. Table 1 shows the chemical composition of corncob before performing the organosolv pretreatment: 45% cellulose, 34% hemicellulose, 16% lignin, and 6% extractives. These values are comparable to the data published by several authors, who indicated that the cellulose, hemicellulose and lignin ratios were 45%, 35% and 15%, respectively [23,24]. The high percentage of hemicelluloses in the corncob makes it a suitable material for thermochemical pretreatments such as organosolv. The pretreated corncob had 22% cellulose, 72% hemicellulose, 5% lignin, and 2% extractives, from which it could be verified that the organosolv treatment solubilised and de-polymerised lignin and hemicelluloses, dividing them into separate liquid streams (hydrolysate) and leaving behind solid fractions rich in cellulose for other applications [25,26].

Table 1.

Corncob characterisation.

The percentages (%; w/w) obtained for C: 46.6 and N: 0.4, as shown in Table 1, are in agreement with data reported in the literature (C: 41.7% and N: 0.1%) [22], suggesting that corncob is a material that can be used in an anaerobic process. However, the C:N ratio of corncob is 61:0.5, which is considerably higher than the optimal value reported in the literature for other biomasses used in anaerobic digestion [3]. The decomposition of materials with high carbon content, greater than 35:1, occurs more slowly, because the multiplication and development of bacteria are low, due to the lack of nitrogen, but the biogas production period is longer. On the other hand, with a C:N ratio less than 8:1, bacterial activity is inhibited due to the formation of an excessive ammonium content, which in large quantities is toxic and inhibits the process [4].

3.1. Characterisation of Corncob Hydrolysate

To confirm the solubility of the simple sugars in corncob hydrolysate, the hydrolysate obtained after the organosolv pretreatment was analysed. Table 2 represents the carbohydrates of the hydrolysate corresponding to the available sugars for use by the inoculum. It is important to know that the parameters as proteins constitute a very important substrate in the anaerobic digestion process because, in addition to being a source of carbon and energy, the amino acids derived from their hydrolysis have high nutritional value.

Table 2.

Bromatological analysis of corncob hydrolysate.

Table 3 shows the results of the sugars present in the organosolv hydrolysate and soda hydrolysate, showing that, with the organosolv pretreatment, the total reducing sugars (TRS) were higher (65.84 g/L) than the TRS with the soda pretreatment (4.64 g/L). This indicates that the hydrolysate is suitable for use in the anaerobic reactor. As with the TRS, the concentration of total sugar in the organosolv pretreatment was 157.7 g/L, which is higher than after the soda pretreatment (20.80 g/L), meaning that a greater amount of total sugars was extracted. Organosolv pretreatment improved the formation of sugars or the ability to subsequently form sugars by enzymatic hydrolysis, thus preventing the loss or degradation of carbohydrates and avoiding the formation of inhibitors, the by-products of subsequent hydrolysis and fermentation processes [27]. The non-reducing sugars obtained concentrations that exceeded the totals of TRS, demonstrating an incomplete depolymerisation from the organosolv pretreatment.

Table 3.

Characterisation of corncob hydrolysate.

The chemical oxygen demand (COD) of the corncob hydrolysate was 690 g/L. This result is considered high when compared with soda hydrolysate (195 g/L) and lower results of residues commonly present in the paper industry and its effluents without prior treatment, not exceeding a value of 52 g/L, taking into account that thermochemical processes are also carried out in this industry. The COD of the organosolv hydrolysate exceeded the results characteristic of residues from other types of pretreatment, where values ranging from 179 to 193 g/L for soluble COD and total COD, respectively, have been reported [28]. The COD increased with the organosolv process because the organic solvents used for the removal of lignin in the corncob leave the hydrolysate rich in depolymerised hemicelluloses (glucose, xylose, galactose, and mannose), thus increasing the organic matter available for the digestion process.

3.2. Anaerobic Digestion Process

The percentage of total solids contained in the mixture with which the digester is loaded is an important factor to consider to ensure that the process is carried out satisfactorily. The accessibility of methanogenic bacteria within the substrate is increasingly limited as the solids content increases, and the gas efficiency and production can therefore be affected. Table 4 shows the results of the characterisation of the substrate of cow manure and corncob hydrolysate obtained in this project. Experimentally, it has been shown that the load in semicontinuous digesters should not have more than 8% to 12% total solids to ensure the proper functioning of the process, unlike discontinuous digesters, which can handle between 40% and 60% total solids. In this case, the total solids value was 14.82%, which is attributed to the cow manure [29].

Table 4.

Characterisation of substrate (cow manure + corncob hydrolysate).

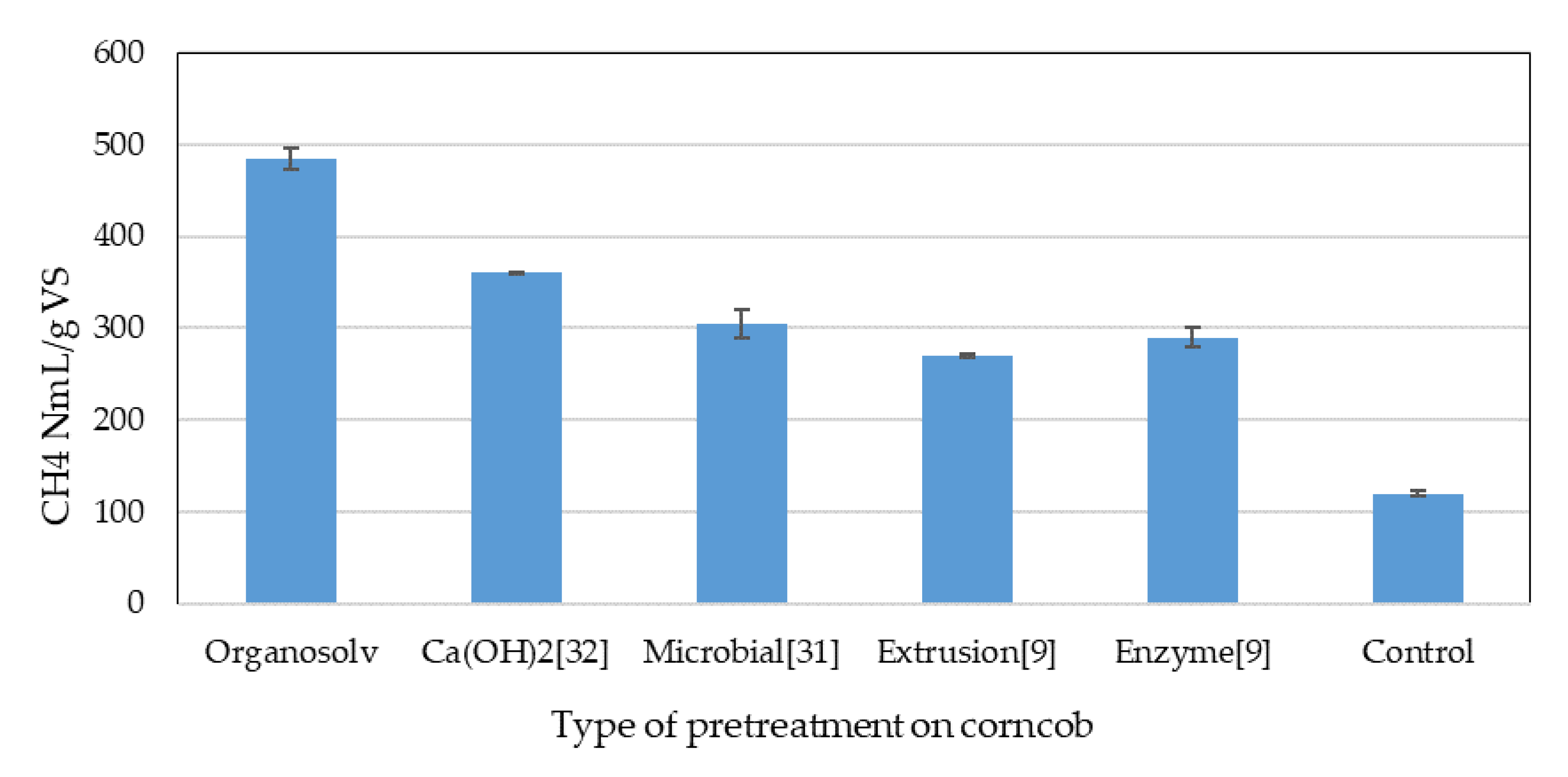

Figure 1 shows the maximum value of biogas production in the bottles reactor obtained with the hydrolysate corncob at 15 days compared with a control corncob without the hydrolysate organosolv pretreatment and with different pretreatments in the bottles reactor reported by other authors [9,30,31]. Hua (2016) reported the effect of microbial pretreatment on the biogas production of non-sterile, rotted silage maize straw, finding 305 NmL/gVS [30], while Perez-Rodríguez (2017) reported extrusion and enzymatic hydrolysis, finding 279 and 290 NmL/gVS, respectively [9]. Shah (2018) reported 360 NmL/gVS using lime (Ca(OH)2) soaking as a pretreatment [31]. It was clearly observed that, with the use of pretreatment with organosolv, the production of biogas was superior, because 484 NmL/gVS was obtained compared to the other reported treatments. It was also observed that adding the hydrolysate organosolv increased the production because the values of the control without hydrolysate were 120 NmL/gVS.

Figure 1.

Comparison of different pretreatments in the production of biogas from corncob.

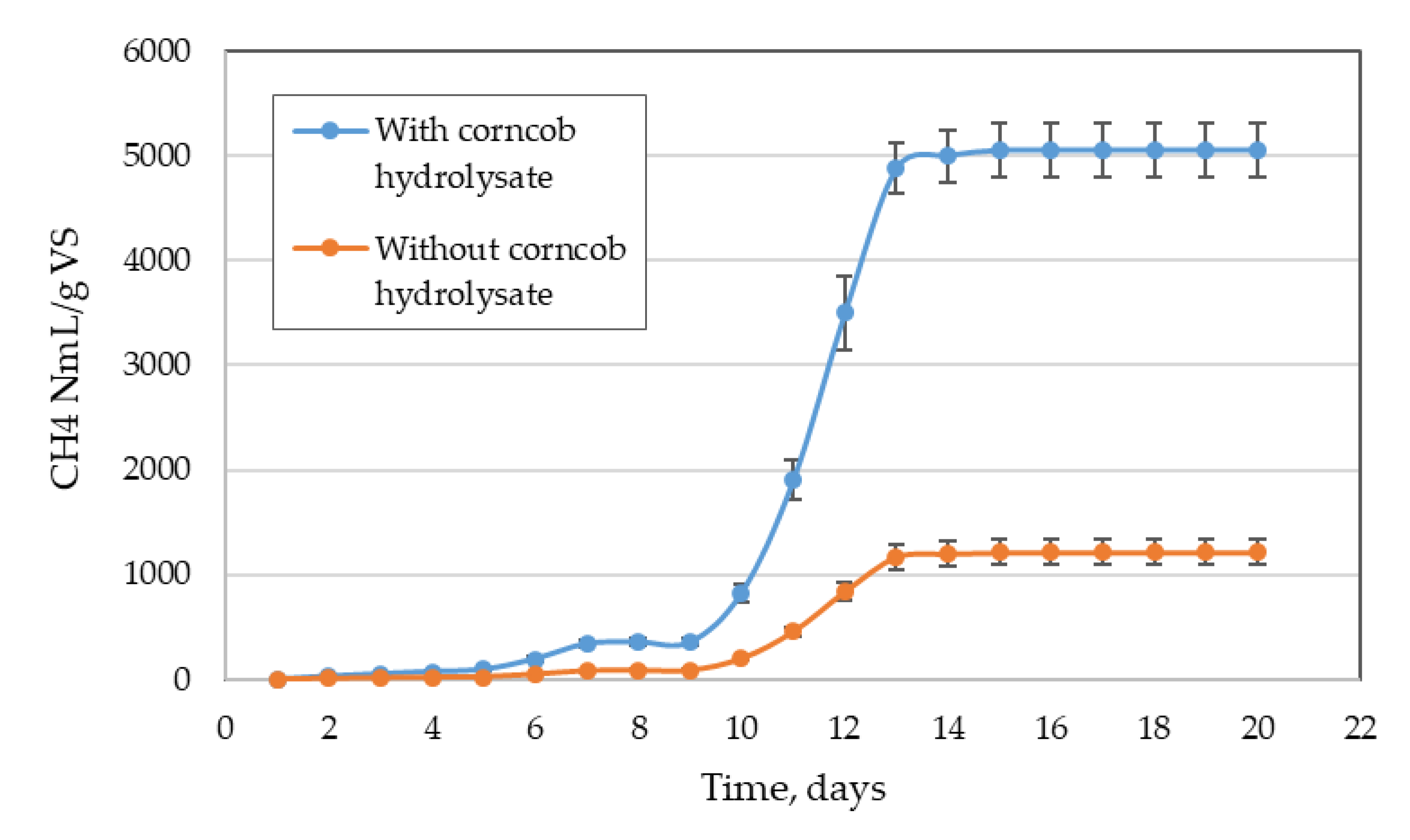

Figure 2 shows a representative evolution in cumulative biogas production in the Labfors batch-type biological reactor. In this section, the values found with and without corncob hydrolysate are compared. The biogas production was observed to be very low for the first nine days in both cases, but began from day 10. In the corncob hydrolysate test, the biogas production was higher than the non-hydrolysate test. Biogas production was monitored until day 20, but there was no production from days 15 to 20, so there was a constant line, and all the added organic substrate was consumed by day 15. The total biogas accumulated in 15 days of production was 5050 ± 253 NmL/gVS and 1212 ± 120 NmL/g VS with and without hydrolysate, respectively. The increase in biogas production was notable when the organosolv hydrolysate of corncob was added.

Figure 2.

Cumulative biogas production in daily and total accumulated intervals.

Table 5 makes clear that the concentration of total reducing sugars is one of the factors that can affect methanogenic production in the anaerobic digestion process, directly and correlationally [32]. The consumption of TRS and total sugars during the anaerobic digestion was 96.8% and 85.75%, respectively. The COD was reduced to 79% with a COD reduction of 7.9 g, which is proportional to 639.24 NmLbiogas/g COD. Clearly confirming the influence of sugars in biogas production, the sugar content had the maximum reduction on the final day, demonstrating the potential of corncob residues, rich in sugars, as viable substrates in biogas production.

Table 5.

Results of concentrations of total reducing sugars (TRS), Total sugars (TS) and chemical oxygen demand (COD) of the digestate with respect to the substrate.

Table 6 shows the results obtained from the daily biogas production and composition. The biogas composition was CH4 with a concentration of 35.7% to 72.80% (v / v), CO2 of 63.8% to 26.18%, and 0.5% to 1% (v/v) for other biogas (H2, O2, etc.) during anaerobic digestion (15 days). The CH4 concentration is in line with values reported by previous studies of the contents of biogas, ranging from 50% to 65% (v/v) for CH4 and from 35% to 50% (v/v) for CO2 during sludge anaerobic digestion [33]. The production of CH4 indicated the presence of methanogens, and the anaerobic digestion was effective.

Table 6.

Composition of biogas produced.

Other important parameters during anaerobic digestion are the concentrations of volatile fatty acids (VFA), which increased with respect to the values obtained in the recovery of the substrate material. This is a clear indicator of the microbiological activity of the system during the time of the experimentation with a single feeding and periodic evaluation of the volume of biogas. During anaerobic degradation, complex organic matter is hydrolysed and fermented in low-molecular-weight compounds, including short-chain fatty acids (C2-C6). As shown in Table 7, the VFAs found in both the substrate (initial) and digestate (day 17) were acetic acid in the highest proportion, followed by butyric and propionic acid and lesser quantities of furfural.

Table 7.

Characterisation of volatile fatty acids in the substrate and digestate.

During the hydrolytic–acidogenic stage, different organic acids are generated and even biogas rich in H2, depending on the operating conditions. Table 7 shows the concentration of the main metabolic intermediaries detected at this stage. These precursors are metabolised to CH4 during the methanogenesis stage. It should be noted that during the assays, about 70% of the volume of biogas corresponded to CH4, which implies benefits for its subsequent exploitation. Finally, no accumulation of organic acid was detected throughout the methanogenesis operating period, indicating that the anaerobic digestion process was carried out efficiently with an overall COD balance of 79%.

4. Conclusions

Lignocellulosic residues from agroindustrial sources, such as corncob, are a raw material of the second generation with a permanent supply for anaerobic digestion. Thermochemical pretreatment with organosolv based on organic solvents is effective for the delignification and fractionation of sugars to monomers present in corncob. The corncob hydrolysate obtained in the organosolv pretreatment is a highly digestible carbohydrate substrate that increases the efficiency of biogas production. The results show that organosolv pretreatment is an efficient process for the improvement of anaerobic digestion from corncob lignocellulosic materials, removing lignin as an important inhibitor; however, its effectiveness greatly depends on the type of lignocellulose material.

Author Contributions

Methodology and experimental work: J.S.A.A. and L.B.-D.; writing—review and editing: K.J.G.T. and J.d.R.-O.; writing—original draft preparation: J.S.A.A. and B.S.-R.; conceptualisation and supervision: K.J.G.T. and B.S.-R. Funding acquisition: K.J.G.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Council of Science and Technology México (CONACyT) project number 258960 Basic Science.

Acknowledgments

The authors are grateful for the financial support of student grants from CONACyT.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Gurubel, K.; Sanchez, E.N.; Coronado-Mendoza, A.; Zuniga-Grajeda, V.; Sulbaran-Rangel, B.; Breton-Deval, L. Inverse optimal neural control via passivity approach for nonlinear anaerobic bioprocesses with biofuels production. Optim. Control Appl. Methods 2019, 40, 848–858. [Google Scholar] [CrossRef]

- Millati, R.; Wikandari, R.; Ariyanto, T.; Putri, R.U.; Taherzadeh, M.J. Pretreatment technologies for anaerobic digestion of lignocelluloses and toxic feedstocks. Bioresour. Technol. 2020, 304, 122998. [Google Scholar] [CrossRef] [PubMed]

- Ward, A.J.; Hobbs, P.J.; Holliman, P.J.; Jones, D.L. Optimisation of the anaerobic digestion of agricultural resources. Bioresour. Technol. 2008, 99, 7928–7940. [Google Scholar] [CrossRef] [PubMed]

- Kainthola, J.; Kalamdhad, A.S.; Goud, V.V. A review on enhanced biogas production from anaerobic digestion of lignocellulosic biomass by different enhancement techniques. Process Biochem. 2019, 84, 81–90. [Google Scholar] [CrossRef]

- Bah, H.; Zhang, W.; Wu, S.; Qi, D.; Kizito, S.; Dong, R. Evaluation of batch anaerobic co-digestion of palm pressed fiber and cattle manure under mesophilic conditions. Waste Manag. 2014, 34, 1984–1991. [Google Scholar] [CrossRef] [PubMed]

- Paudel, S.R.; Banjara, S.P.; Choi, O.K.; Park, K.Y.; Kim, Y.M.; Lee, J.W. Pretreatment of agricultural biomass for anaerobic digestion: Current state and challenges. Bioresour. Technol. 2017, 245, 1194–1205. [Google Scholar] [CrossRef]

- Shilpi, S.; Lamb, D.; Bolan, N.; Seshadri, B.; Choppala, G.; Naidu, R. Waste to watt: Anaerobic digestion of wastewater irrigated biomass for energy and fertiliser production. J. Environ. Manag. 2019, 239, 73–83. [Google Scholar] [CrossRef]

- SAGARPA. Plan de manejo de residuos generados en actividades agrícolas primera etapa: Diagnóstico nacional. In Secretaría de Agricultura, Ganadería, Desarrollo Rural, Pesca y Alimentación (SAGARPA) y Universidad Autónoma de Zacatecas “Francisco Garcia Salinas” México. 2015. Available online: https://www.gob.mx/cms/uploads/attachment/file/346978/Manejo_de_residuos_Detallado.pdf (accessed on 19 March 2020).

- Perez-Rodríguez, N.; García-Bernet, D.; Domínguez, J.M. Extrusion and enzymatic hydrolysis as pretreatments on corn cob for biogas production. Renew. Energy 2017, 107, 597–603. [Google Scholar] [CrossRef]

- Triolo, J.M.; Sommer, S.G.; Møller, H.B.; Weisbjerg, M.R.; Jiang, X.Y. A new algorithm to characterize biodegradability of biomass during anaerobic digestion: Influence of lignin concentration on methane production potential. Bioresour. Technol. 2011, 102, 9395–9402. [Google Scholar] [CrossRef]

- Ferreira, J.A.; Taherzadeh, M.J. Improving the economy of lignocellulose-based biorefineries with organosolv pretreatment. Bioresour. Technol. 2020, 299, 122695. [Google Scholar] [CrossRef]

- Kabir, M.M.; Rajendran, K.; Taherzadeh, M.J.; Horváth, I.S. Experimental and economical evaluation of bioconversion of forest residues to biogas using organosolv pretreatment. Bioresour. Technol. 2015, 178, 201–208. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; Zhao, J. Pretreatment of lignocellulosic biomass for enhanced biogas production. Prog. Energy Combust. Sci. 2014, 42, 35–53. [Google Scholar] [CrossRef]

- TAPPI. Technical Association of the Pulp & Paper Industry TAPPI Test Methods; TAPPI test methods; TAPPI: Atlanta, GA, USA, 1988. [Google Scholar]

- Hernández, J.A.; Romero, V.H.; Escalante, A.; Toriz, G.; Rojas, O.J.; Sulbarán, B.C. Agave tequilana bagasse as source of cellulose nanocrystals via organosolv treatment. BioResources 2018, 13, 3603–3614. [Google Scholar] [CrossRef]

- Miller, G.L. Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal. Chem. 1959, 31, 426–428. [Google Scholar] [CrossRef]

- Dubois, M.; Gilles, K.A.; Hamilton, J.K.; Rebers, P.A.; Smith, F. A colorimetric method for the determination of sugars. Nature 1951, 168, 167. [Google Scholar] [CrossRef]

- Baur, F.J.; Ensminger, L.G. The Association of Official Analytical Chemists (AOAC). J. Am. Oil Chem. Soc. 1977, 54, 171–172. [Google Scholar] [CrossRef]

- Baird, R.; Bridgewater, L. Standard Methods for the Examination of Water and Wastewater; American Public Health Association, Ed.; American Public Health Association: Washington, DC, USA, 2017. [Google Scholar]

- Breton-Deval, L.; Méndez-Acosta, H.O.; González-Álvarez, V.; Snell-Castro, R.; Gutiérrez-Sánchez, D.; Arreola-Vargas, J. Agave tequilana bagasse for methane production in batch and sequencing batch reactors: Acid catalyst effect, batch optimization and stability of the semi-continuous process. J. Environ. Manag. 2018, 224, 156–163. [Google Scholar] [CrossRef]

- Lins, P. Reduction of accumulated volatile fatty acids by an acetate-degrading enrichment culture. Fems Microbiol. Ecol. 2010, 71, 469–478. [Google Scholar] [CrossRef]

- Surra, E.; Bernardo, M.; Lapa, N.; Esteves, I.; Fonseca, I.; Mota, J.P. Maize cob waste pre-treatments to enhance biogas production through co-anaerobic digestion with OFMSW. Waste Manag. 2018, 72, 193–205. [Google Scholar] [CrossRef]

- Prasad, S.; Singh, A.; Joshi, H.C. Ethanol as an alternative fuel from agricultural, industrial and urban residues. Resour. Conserv. Recycl. 2007, 50, 1–39. [Google Scholar] [CrossRef]

- Zabed, H.; Sahu, J.N.; Suely, A.; Boyce, A.N.; Faruq, G. Bioethanol production from renewable sources: Current perspectives and technological progress. Renew. Sustain. Energy Rev. 2017, 71, 475–501. [Google Scholar] [CrossRef]

- Haghighi Mood, S.; Golfeshan, A.H.; Tabatabaei, M.; Jouzani, G.S.; Najafi, G.H.; Gholami, M.; Ardjmand, M. Lignocellulosic biomass to bioethanol, a comprehensive review with a focus on pretreatment. Renew. Sustain. Energy Rev. 2013, 27, 77–93. [Google Scholar] [CrossRef]

- Kumari, D.; Singh, R. Pretreatment of lignocellulosic wastes for biofuel production: A critical review. Renew. Sustain. Energy Rev. 2018, 90, 877–891. [Google Scholar] [CrossRef]

- Sun, Y.; Cheng, J. Hydrolysis of lignocellulosic materials for ethanol production: A review. Bioresour. Technol. 2002, 83, 1–11. [Google Scholar] [CrossRef]

- Houbron, E.; Sandoval Rojas, M.E.; Hernández Muñoz, A.F. Tratamiento de vinazas en un reactor de lecho fluidizado inverso anaerobio. Rev. Int. Contam. Ambient. 2016, 32, 255–266. [Google Scholar] [CrossRef]

- Zhang, C.; Xiao, G.; Peng, L.; Su, H.; Tan, T. The anaerobic co-digestion of food waste and cattle manure. Bioresour. Technol. 2013, 129, 170–176. [Google Scholar] [CrossRef]

- Hua, B.; Dai, J.; Liu, B.; Zhang, H.; Yuan, X.; Wang, X.; Cui, Z. Pretreatment of non-sterile, rotted silage maize straw by the microbial community MC1 increases biogas production. Bioresour. Technol. 2016, 216, 699–705. [Google Scholar] [CrossRef]

- Shah, T.A.; Tabassum, R. Enhancing biogas production from lime soaked corn cob residue. Int. J. Renew. Energy Res. 2018, 18, 761–766. [Google Scholar]

- Zou, S.; Kang, D. Relationship between anaerobic digestion characteristics and biogas production under composting pretreatment. Renew. Energy 2018, 125, 485–494. [Google Scholar] [CrossRef]

- Yang, G.; Zhang, P.; Zhang, G.; Wang, Y.; Yang, A. Degradation properties of protein and carbohydrate during sludge anaerobic digestion. Bioresour. Technol. 2015, 192, 126–130. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).