1. Introduction

The first straw houses were built in Nebraska around 1890, in the central plains of the United States. The scarce availability of timber and sandy soils did not facilitate traditional construction methods. Thanks to the invention of a machine for packing straw, and therefore the transformation of straw into “big bricks”, these began to be stacked one on top of the other, with staggered joints as in load-bearing walls, taking the name of Nebraska style or loadbearing style construction. Initially, these houses were considered temporary, but time and the progressive improvement of the construction system made them recognized as durable houses. A few years later, straw construction also arrived in France. At the end of 1920, the Maison Feuillette in Montargis was completed, the oldest known existing building in Europe constructed with straw.

In England, around 1970, through studies and experiments conducted by a carpenter and teacher named Barbara Jones, the construction techniques were refined and adapted to modern requirements—the steel structure was replaced by a wooden structure, cement was substituted with lime, and lime- or clay-based plaster was utilized exclusively. This increased the breathability of the walls and helped to resolve problems related to the formation of mold in the most humid zones of the house. In 1990, Barbara Jones introduced these methods in England, where she made further adjustments to account for the different climatic conditions in a site [

1].

One of the first buildings made with this technique in Italy dates back to 2004, located in Pramaggiore (Venice). It was built using a self-construction method under the guidance of Barbara Jones, Bee Rowan, and Stefano Soldati, who is considered to be the pioneer builder of straw houses in Italy, having worked on 48 buildings, 30 of which are within Italy.

Interest in straw houses has become even more widespread in Italy, starting in the early 2000s. Since then, more than 180 houses have been built, from common one-story houses to the Ecovillage in San Rocco del Tretto in Schio (Vicenza), which was built in 2012. Other virtuous examples of architecture with a strong social commitment include the houses in Pescomaggiore (L’Aquila), a small village of early medieval origin [

2].

Italy, with its Mediterranean climate, is more suitable for straw construction than Northern European countries, where, paradoxically, this type of construction is widespread. The most probable cause of the lack of use of straw in construction in Italy may be due to the fact that this material only became a fully-fledged building material after the “Technical Standards for Construction” were drawn up during 2008–2010. However, this legislation does not permit the use of the self-supporting bale method, because unlike in other countries, straw is not recognized as a material that has structural resistance.

No particular procedure is required for the construction of straw houses or for retrofitting interventions that use straw panels. Apart from the architectural project, only a check of the minimum energy performance requirements of the envelope elements and of the building is required.

In this work, after an introduction to the straw building technology, the thermal performance of straw walls is analyzed with reference to two experimental campaigns conducted during the heating season.

2. Straw Construction

Usually “unpacked straw”, used together with materials such as clay and bamboo, is the most typical and widespread construction system in developing countries.

However, in this work, we have analyzed “compressed straw bales”, which are similar to large bricks, as a building material that may be inserted into elaborate construction systems and refined over time by designers and carpenters from all over the world. As straw is a non-traditional material, it is necessary to treat it in a different way; that is, with an in-depth design phase and the use of specialized designers and craftsmen.

Therefore, we proceed with an analysis of the straw buildings that have been built in developed countries with a high-income economy, such as in European countries. The straw material, the construction technologies, and the thermal characteristics of straw walls are described and then compared with standard materials.

Straw construction is not associated with a predefined aesthetic typology and does not stipulate a particular architectural design. Some design elements are closely linked to both the place and the climate, while respecting the local typological features.

From an operational point of view, the range of technical opportunities with straw building systems is quite wide. The essential characteristics of the construction systems can be summarized briefly by grouping them into three broad categories [

3] (

Figure 1):

Load bearing. In this construction system, there are no load-bearing structures made of wood or other materials. This technique requires that the straw bales, together with the plaster that covers them and all the materials that make up the stratigraphic package, transfer the loads from the roof and from the horizontal elements to the foundations, thus guaranteeing both structural support and thermal insulation. The cost-effectiveness and speed of execution are offset by the reduced bearing capacity of the walls and by some construction site issues.

In-fill. This system uses straw bales as an insulation filler between supporting structures, which are able to fully satisfy the structural function requirements of the building. In some cases, other insulating materials are also used to fill the remaining cavities, and therefore to facilitate the completion of the work. The position and thickness of the structural elements have to be adapted to the needs of the project, while the placement distance between them depends on the size of the chosen bales.

Mixed system. In these systems, straw co-operates with other materials to fulfill the structural functions of the project. Straw, wood, and plaster are normally used for the finishing layer.

The choice of which technological system to adopt depends on technical, cultural, and economic aspects. The load-bearing structures have been particularly developed thanks to self-builders. This is especially true in countries where the technical building regulations are not particularly restrictive (i.e., France and England) or in regions where this construction technique was immediately codified because it was considered of great value (such as Arizona and New Mexico). At the moment, the load-bearing system is regulated by the International Residential Code [

4].

In-fill construction has become popular thanks to the use of well-known and regulated construction techniques regarding the structural components. These techniques make it possible to provide a greater sense of security to clients and builders and more design flexibility to designers. The use of wooden “containment cages” has favored the creation of pre-assembled structures, which reduce costs and construction times.

The main guidelines on in-fill systems were published by the French association Réseau Français de la Construction Paille—Les Compaillons in 2012 [

5] and by the German Association Fachverband Strohballenbau Deutschland, which published the ground rules for straw buildings in 2014 [

6]. These guidelines and technical standards provide useful information concerning the physical properties of straw and its interactions with the infill, wall, or roofing system, in a similar way to European Construction Product Regulation 305/11. The French rules also deal with construction details in order to increase the durability of the building.

The efforts made by these organizations show the extent to which certain international communities believe in straw construction. The common goal is to extend knowledge on such construction and to build structures according to a shared “rule of art”.

The durability of a natural material construction is influenced to a great extent by the presence of water. Excessive humidity can cause physical and chemical alterations of the materials, which in turn lead to a lowering of the mechanical resistance and thermal performance of the components. Straw, unlike other hygroscopic materials used in construction, does not draw moisture into the inner layers, meaning most of the problems connected to humidity are, therefore, limited to areas where water stagnation can occur.

The durability of the structure is, therefore, closely related to the quality of the raw material, its appropriate storage, and the installation method, as well as to the correct execution of the construction procedures.

Straw as a Building Material

It is firstly important to distinguish straw from hay. Hay is the product of the mowing of grass (green, moist, and nutritious) for animals. Straw is the dry part of the plant, which is cut when ripening has been completed. This process guarantees a humidity percentage lower than 12%, which is optimal for construction (

Figure 2 and

Figure 3).

It is possible to distinguish, as a function of the dimensions and the placement of straw bales, two bale positions for construction [

7]:

placed on their edges (sides), face up, with a thickness of 37 cm and a height of 47 cm;

flat, with the edges (sides) visible, with a thickness of 47 cm and a height of 37 cm.

Table 1 shows data taken from the literature [

8,

9,

10] referring to the thermal characteristics of straw, straw bales, and straw walls. It can be observed that the thermal conductivity of straw is generally higher than a standard insulating material, such as expanded polystyrene (EPS) or rock wool, with a conductivity of about 0.035–0.04 W/m/K.

Straw can be produced from different plants, including wheat, rye, barley, and rice. Each and every cereal gives a different final product in terms of thermal resistance and durability. The growth of the plants in the fields is much more important than the variety; for example, the presence of too many weeds could seriously compromise the durability of a construction material. From an environmental point of view, the ideal scenario would be to collect straw from a field close to the construction site, thereby ensuring a short-chain production cycle.

Straw bales should be stored in a dry place and protected from bad weather conditions.

However, it is also possible to deposit bales outside, arranging them in a pyramid shape, and to cover them with a waterproof cover. Pallets can then be used as a base to lift them and avoid contact with damp earth. Particular attention should be paid during the construction phases; if the construction site protection systems are not sufficient to shield the straw from rain, further quality controls should be conducted to verify the degree of dryness before proceeding with subsequent coating layers (

Figure 4).

Straw quality alone is not enough to guarantee that a building will have good performance and meet requirements similarly to standard buildings. In fact, it is necessary to monitor all the straw bale supply phases of the process and the implementation of the construction system. This is the only way of ensuring good thermohygrometric and energy-saving performance in straw buildings.

Once the construction of the straw house has been successfully completed, it is advisable to avoid prolonged exposure to humidity, as previously mentioned. The presence of water in the construction elements may be related to poor sealing of the roof covering and the plaster, the capillary rise of water from the ground, leakage from plumbing, or condensation. It is equally important to prevent water from entering the structure and to let the humidity produced in the rooms out. Furthermore, through analysis of the construction site, all the morphological elements designed to limit the water loads to which the construction will be subjected should be deduced (the design of an adequate roof overhang, balconies, walls exposed to winds, etc.). Moreover, the first layer of straw bales must be appropriately separated from the foundations by means of a drainage system that will drain away any water that may accumulate in the walls.

3. Case Studies

The selected straw buildings were designed by the architects Maurizio Macrì and Stefania Mancuso (

www.macrimancuso.com), who also oversaw the construction processes.

In both cases, scrupulous attention was paid to the details, because of the non-traditional nature of the used material and the predetermined energy and durability objectives.

The first example, Casa Cembo in Saluggia (Vercelli), which was designed in 2010 and built in 2012, represents the architects’ attempt to combine the advantages of load-bearing buildings, such as reduced use of timber and wall homogeneity, with those of in-fill structures, namely structural reliability and architectural flexibility (

Figure 5). The second house, which is located in Verrès (Aosta) and was designed and built in 2014 [

11], is an experimental prototype of a pre-assembly technique that is particularly suitable for construction in mountain or countryside areas (

Figure 6). This prototype was presented at the “Maison et Loisir” fair in Aosta (Italy) to publicize this type of construction, and to disseminate its environmental sustainability principles obtained through the use of straw as an insulating material, as well as its versatility as a modular system, the very rapid construction time, and the good resistance of the structure.

Table 2 summarizes the main features of the two straw building case studies.

3.1. Casa Cembo

The walls of the Casa Cembo house were made of straw bales placed flat and plastered on both the inside and outside for a total thickness of about 55 cm (48 cm of straw and 3.5 cm per part of plaster).

The external plaster consists of 3 layers. The first two layers, which were made of lime putty, metakaolin, sand, and straw (albeit more in the first layer), were placed at close intervals. The last layer, which had reduced thickness and consisted of lime putty, sand, and fragments of earthenware or brick (as a hydraulic and coloring agent), was placed after the first two had dried completely.

With the aim of maintaining the greatest possible material uniformity, the straw bales were inserted into a 180 cm wooden frames. For the same purpose, the pillars, which had a reduced cross-section with respect to the thickness of the wall (22 cm versus 55 cm for the wall), were completely incorporated between the straw fibers, which had filled the spaces in front of the wooden structure during compression.

The vertical compression of the wall, measuring about 2 cm per row, was exerted on wooden slats by means of 2 or 3 hydraulic jacks every wall and was maintained by constraining the system at three points: in the center, with a polyester textile composite strap; and on the sides, with screws fixed to the uprights (

Figure 7 and

Figure 8). Finally, the straw bales weighed 17 kg and had a density of about 104 kg/m

3.

Calcium silicate panels were used for the window edgings to solve the thermal bridging problem related to the wall–window connections and also to characterize the building from an aesthetic point of view (

Figure 9 and

Figure 10).

This choice also led to the use of expanding ribbons, with which sealing of the enclosure from air and protection against seepage water were ensured.

The same attention paid to avoiding water infiltration was also paid to the foundations, where a sort of wooden formwork filled with granular cork keeps the first layer of straw bales away from the ground, including a uniform draining and insulating material support (

Figure 11 and

Figure 12).

A Foamglass® panel on the outside protects the plinth from rain splash-back, and in continuity with the Foamglass® laid on the ground, maintains and guarantees thermal insulation and waterproofing of the foundations.

3.2. The Pre-Assembled Prototype

The pre-assembled prototype was designed as a set of modular elements, which are repeated on the six sides of the building. By placing the straw bales on their edges (sides)

, it was possible to make the most of their insulating capacity and reduced thickness (35 cm of straw plus coating). In this case, the pre-compression of the wall was carried out in two distinct phases. Each single straw bale was first pre-stressed and bound with a specially designed baler machine (

Figure 13). After being inserted into the wooden formwork, the tying ropes of the bales were removed. This operation allowed them to expand and to resume their initial shape and size, thereby avoiding the formation of empty spaces that would otherwise have been generated by the irregular shapes that characterize straw bales collected in the field. In this way, it was possible to ensure a more homogeneous density.

A wooden containment structure, featuring two stud walls connected by transverse elements that interrupt the continuity of the heat flow, was used to reduce thermal bridges (

Figure 14).

The empty spaces created by the separation of the stud wall were filled with wood fiber. The same insulation was also placed around the window frames. Finally, in order to improve the breathability and thermal and acoustic insulation of the pre-assembled module, a coating layer was added to both sides—lime plaster on the external side and lime or clay plaster on the inner side. The wooden structure also serves as a windward element and is covered on both sides with reed panels, the classic “arelle”. This improvement was not considered in the Verrès prototype, and for logistical reasons, it was deemed necessary to opt for an oriented strand board (OSB) coating on both sides. The OSB technology is composed of layers of wooden particles or fibers united with resin and oriented at an angle of 90° with each other and pressed for consolidation (ISO 16894:2009); this feature gives the panel greater mechanical strength and moisture resistance than plywood.

4. Materials and Methods

In this work, the conductance of two straw walls was measured in situ through the heat flow meter method described in the ISO 9869-1:2014 standard [

12]. Since the in situ operating conditions are not stationary, the progressive averaging method is used to calculate the thermal conductance. This method assumes that conductance can be obtained by dividing the mean heat flow rate (

q) by the difference in the mean temperature of the inside and outside surfaces (

Tsi and

Tse):

A good result is considered to have been obtained over a period of more than 72 h if the resulting thermal conductance does not deviate by more than ±5% from the value obtained 24 h before.

The locations for conductance measurements were decided with the help of a thermal imaging camera, in order to avoid problems that could alter the results related to thermal bridges or climatic perturbations, such as incident solar irradiation.

Figure 15 and

Figure 16 show some thermal images of the facades of the analyzed straw buildings for both of the case studies; homogeneous areas exposed to the north, without incident solar radiation problems, were chosen for the experimental campaigns. The thermal conductance measurements were performed with the “ST-1100 Lombard and Marozzini” system with the sensors shown in

Table 3 for 2 weeks during the months of January and February 2019, with a time step of 10’.

The thermal transmittance,

U, can be obtained from thermal conductance

C if the thermal resistances of the inside and external surfaces,

Rsi and

Rse, are known (for walls:

Rsi = 0.13 m

2KW

−1 and

Rse = 0.13 m

2KW

−1), according to the EN ISO 6946:2017 standard [

13]:

5. Results

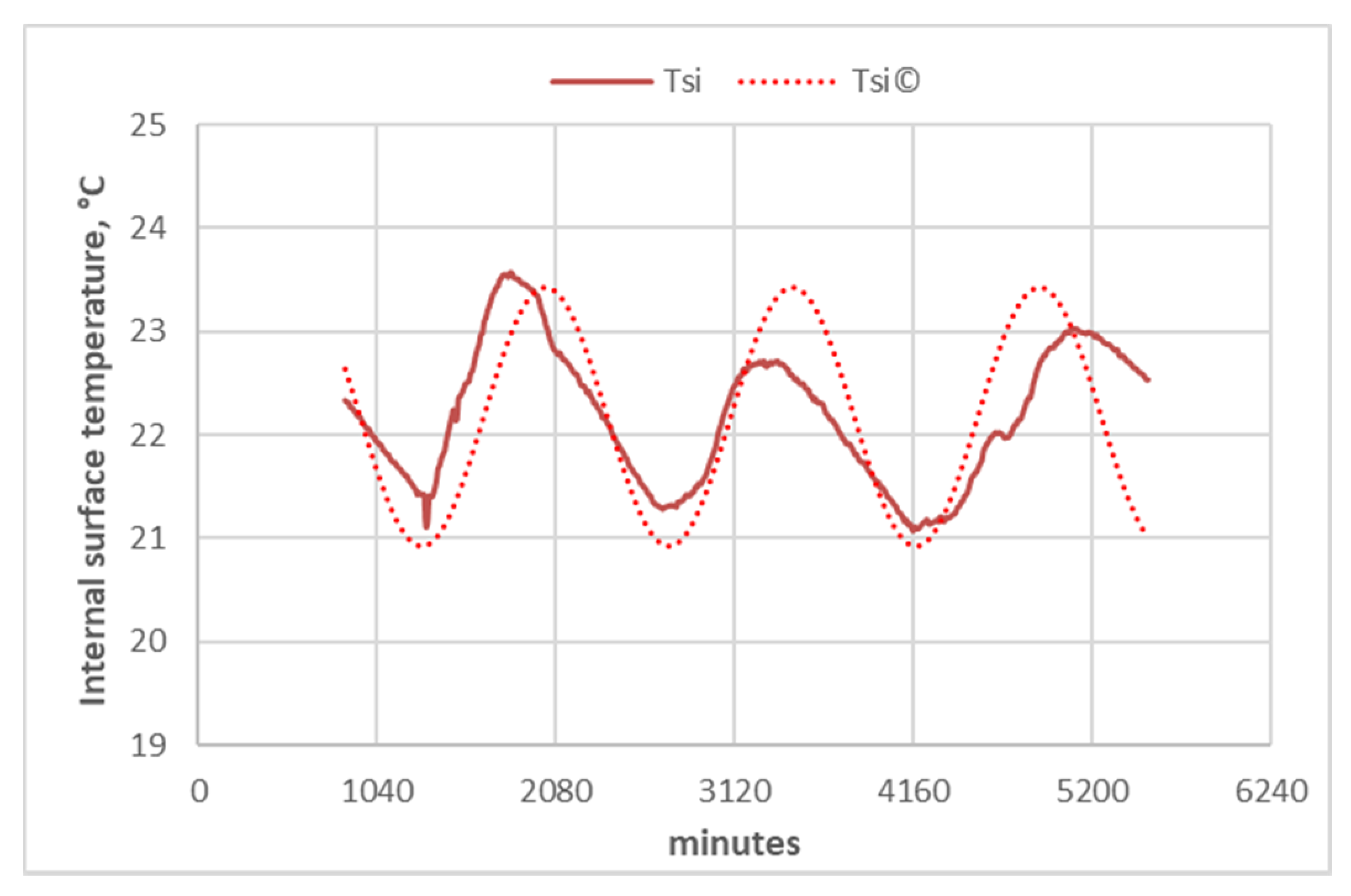

Figure 17 and

Figure 18 show the internal and external surface temperatures and the heat flux recorded during the measurement campaigns, considering a time interval of 10 min (January 23–30 2019 for Casa Cembo and February 9–23 2019 for the pre-assembled prototype). In

Figure 17, it is possible to see that the inside surface temperature of Casa Cembo is quite constant, while the inside surface temperature of the pre-assembled prototype in

Figure 18 increases because of the absence of a thermostat. In both case studies, the difference in temperatures of about 20 °C and the constant internal temperature, T

si, (in the last 1000 measurements), guarantee the feasibility of the measurements.

Figure 19 and

Figure 20 show that the conductance did not deviate by more than ±5% (dotted lines) from the obtained value in the last 3–6 days for 500–1000 measurements.

Table 4 summarizes the main results of this investigation, which show marked differences between the two case studies. Casa Cembo shows very good results, which satisfy the

Ulim limits established by Italian Ministerial Decree 26/6/2015 [

14], and with straw conductivity

λ and wall transmittance

U that are comparable with the data in

Table 1 and in [

15].

The straw wall in the pre-assembled prototype disperses twice the amount of heat as that of Casa Cembo and more than results in the literature (

Table 1 and [

15]). Moreover, thermal transmittance

U does not satisfy the Italian

Ulim limits. It should be recalled that the pre-assembled prototype had only been built for demonstration purposes, without taking the precautions that are instead necessary for real buildings. Moreover, this result could also be related to transport issues, which could have involved movement of the straw inside the walls of the pre-assembled prototype.

The dynamic behavior of the Casa Cembo straw wall was also evaluated according to EN ISO 13786:2017 [

16]. The first three days were selected for the measurement campaign and the measurement results were elaborated to calculate any sinusoidal variations of the external and internal surface temperatures,

Tsi and

Tse, respectively, as a function of time t with the equation:

where

is the average daily surface temperature;

is the daily amplitude of the surface temperature;

is the angular frequency (2π/24, with a time period of 24 h);

is the time in hours;

is the initial phase in hours.

Figure 21 and

Figure 22 show comparisons between the measured and calculated (with Equation (3)) surface temperatures of a straw wall in Casa Cembo.

A time shift, ∆

T, of 19.3 h and an attenuation of the heat flow of 0.23 were also calculated by comparing the initial phases of the equations for T

si and T

se. The same methodology had been applied and tested in previous research [

17,

18,

19].

Finally, the dynamic characteristics of the straw walls were calculated using the equivalent thermal conductivities of straw obtained from the two experimental campaigns; in particular, the periodic thermal transmittance YIE, the decrement factor, and the time shift of the straw walls were calculated according to the EN ISO 13786:2017 standard.

Low values of

YIE and f and a high value of ∆

t can be observed in

Table 4, which also shows out high thermal inertia and good thermal behavior for straw walls in warm climates. A similar time shift value, ∆

t, to the one at 19.3 h calculated from the measurements can also be observed for Casa Cembo.

The excellent thermal performance of the straw buildings, in particular for the inhabited residential building Casa Cembo, demonstrate why these buildings are starting to be successful, in particular in Northern Italy, as well as in France and other European countries.

The analyzed straw wall has a thermal transmittance value,

U, that is well below the values required by the Italian laws (D.M. 26/6/2015 and subsequent amendments and additions) for the reference building and for existing retrofitted buildings. Thermal transmittance values of about 0.15 Wm

−2K

−1 are in fact typical of nearly-zero-energy buildings (nZEB) in Italy [

20].

Furthermore, as is already known, these buildings have excellent performance during summertime, as can be seen from the low periodic thermal transmittance values of YIE and decrement factor f and the high time shift value ∆t.

It can be observed in

Table 4 that the calculated periodic thermal transmittance value,

YIE, is much lower than the values required by the Italian laws (D.M. 26/6/2015 and subsequent amendments and additions), and that the time shift is higher than the values at 12 h, with a consequent reduction in the perceived thermal load peak due to the high daytime temperatures in summertime.

These periodic thermal transmittance, time shift, and decrement factor values indicate that the considered straw structures have a high thermal inertia, with consequent positive effects on energy savings in both summer and in winter. The use of high inertia envelopes in the northern part of Italy may lead to energy savings of about 10% in wintertime and 20% in summertime [

21,

22].

6. Technical and Economic Feasibility

The use of straw as a building material is quite widespread throughout the world. A high concentration of straw buildings can usually be observed where there is intensive cultivation of wheat, barley, and rice. The use of straw material in construction is usually regulated in these countries [

15]. It is not easy to obtain reliable information on the precise distribution of straw buildings around the world. The data obtained from censuses, which are drawn up on a voluntary basis, and from private data collections are not uniform. For example, over 5000 straw bale buildings were estimated to exist in France in 2019, with an increase of around 500 new houses per year. However, according to a census, there were only 564 [

23]. According to census data, the United States has the largest number of straw bale buildings, with a total of 784 buildings [

15]. This technology is used in Italy, mainly in the northern regions of Lombardy, Piedmont, Veneto, Emilia Romagna, and Tuscany, with the number of straw buildings ranging from 176 to 365, depending on the literature source. However, this number has been growing rapidly over the last decade [

24] and straw buildings have shown very good energy performances during both the heating and cooling seasons [

15,

21,

22].

As a result of their low energy consumption, straw buildings have low operating costs. Casa Cembo, with its wood stove, solar collectors, and photovoltaic modules, but without any mechanical ventilation system, has proved to be a nearly-zero-energy building, with an energy performance index of EP

H,nd = 23.4 kWh/m

2/y. The annual consumption of wood for space heating amounts to 1200–1300 kg, which corresponds to a cost of €100–150. Comparing

Figure 5 and

Figure 10, it can be seen that a greenhouse has been installed on the south façade, and therefore it is likely that heating consumption may still decrease.

A phase of the study conducted on Casa Cembo concerns an analysis of the building’s behavior in summer. On the basis of the technical data reported in

Table 4 and the experience of the occupants, it is possible to affirm that (with good bioclimatic design) thermal comfort can be achieved without the use of air conditioning systems. This aspect allows the increase in energy-use trends for space cooling to be reversed [

25].

Straw buildings offer two other very important advantages: lower costs and shorter construction times. In Northern Italy, the price of constructing a straw building is about 1200 €/m2, which is lower than that of a standard building, which is about 1500 €/m2. This difference, which is not large, is linked to the lower cost of materials and to the high cost of labor related to specialized construction. However, the nature of the materials used is fundamental for self-construction, an option that could be adopted by clients to reduce labor costs.

Another important advantage that should not be underestimated is related to the possibility of reducing construction times, thus of saving money. Straw structures can be pre-assembled on wooden beams with modular elements. The pre-assembled prototype in Verres (AO) was built with basic modules for the walls, other types of modules that allowed windows and doors of various sizes to be inserted, and other modules again for the floor and the roof. These straw modules are made in sheds and then assembled on site very quickly. Careful planning and qualified personnel are naturally very important for this kind of work. A single-family detached house can generally be built in 4–5 months. However, the pre-assembled prototype for the “Maison et Loisir” at the Aosta fair (Italy) was built in only one day and the building was completed on the second day. Electrical and hydraulic systems can be installed in a shed, lowering the overall costs. The Verres prototype cost around €20,000, corresponding to 1000 €/m2. If the cost of the foundations, the bathroom, and the heating system are added to this cost, we arrive at around 1400–1500 €/m2, which is similar to the average cost of standard construction, but is 10%–15% lower than an nZEB building.

In Italy, single-family detached houses are the most widespread typology, and this type of buildings is suitable for the use of straw technology. There are several agricultural areas where this technology could have a lower environmental impact thanks to the use of on-site construction materials. Tools are already available that could give a further boost to this type of construction. The best known example is the municipal building regulation, with its environmental energy attachment. In order to contribute to achieving the national objectives of limiting greenhouse gas emissions, the municipal building regulation allows the energy performance of buildings to be improved by taking into account local climatic conditions in order to encourage the development, enhancement, and integration of renewable sources and energy diversification, and gives preference to lower environmental impact technologies.

Since straw buildings have higher thermal performance than standard buildings, the construction of these buildings should be incentivized, for example with a discount of the urbanization costs and a volumetric premium that would allow an increase of the building volume capacity. These are voluntary actions that could be incentivized with building regulations in the northern parts of Italy. The use of green roofs is one of these voluntary actions that are incentivized through the reduction of concession fees.

In 2008, the Veneto region, where many straw bale houses have been built, encouraged the construction of green buildings with funding of up to €25,000. Today, this region continues to support straw technology by encouraging training in the construction of green building for small- and medium-sized enterprises with the advice of specialized technicians.

7. Conclusions

The ever-increasing use of land, together with the ongoing climate changes, could lead to an increase in energy consumption for cooling in buildings, especially in temperate countries in Central and Southern Europe. The new European and national policies combine regulatory measures, energy labeling, and market incentives to achieve good solutions for each territory and to avoid trade-offs between adaptation behavior and mitigation objectives [

25].

The “Clean Energy for all Europeans Package” is a set of initiatives that is aimed at making the European Union more competitive in energy transition [

26]. The European Commission is encouraging Europe to take on a leading role in this challenge, which will revolutionize the energy sector through three main objectives: to achieve energy efficiency, to become a leader in renewables, and to promote the consumer as an active player in the electricity market. These objectives were implemented in Italy in December 2019 with the publication of the Integrated National Plan for Energy and Climate (INPEC) [

27]. INECP considers the transition of all sectors of society to a new energy model that combines economic development and environmental sustainability through the strengthening of skills, training, research, and innovation. The energetic, environmental, and economic impacts of the construction sector are very important in Italy and in Europe as a whole. Our work falls into this context, as straw bale buildings offer good energy performance, low energy consumption, and low GHG emissions, and also have a low environmental impact, since local natural materials are used. Straw buildings can provide considerable benefits from environmental and economic perspectives.

Straw houses have always been used as a low cost, eco-sustainable model, especially in rural areas and in developing countries. They have recently been rediscovered throughout the world as a good alternative to standard buildings, even in developed countries [

15].

In this work, two different typologies of straw bale building have been analyzed, considering their thermal performance and specific characteristics in terms of time and construction costs, which could make this technology attractive in areas where straw is available as a resource that can be exploited.

The results of the experimental campaigns show very good thermal performance for the straw walls during the heating and cooling seasons, with low thermal transmittance, low periodic transmittance, and high time shifts. Through the use of renewable energy sources, straw buildings can become nZEB, with lower construction costs and time, especially for pre-assembled elements.

A greater use of straw in the building sector, with its consequent very low environmental impact, should be boosted by “ad hoc” energy policies. Initiatives are already available that can encourage the use of this technology, namely municipal building regulations. These building regulations are part of the Integrated National Energy and Climate Plan, as they combine energy and economic transitions by increasing the resources of a territory with the most suitable technologies for that territory. In the Piedmont region, around 1700 residential detached houses are built each year, some of which could adopt straw technology [

28]. In the Vercelli province, where Casa Cembo was built, about 60 single-family houses are built each year. The area is certainly agricultural, with straw being readily available. If straw bale buildings were to become widespread, the energy efficiency and eco-compatibility requirements of the province would be met.