1. Introduction

The exponential growth of the world’s population and of industrial activity have compromised the sustainability of life on land. While fossil fuels are still the main energy source, biomass will eventually become the prominent source of energy because lignocellulosic materials are the most abundant forms on earth and a potential option for generating energy for the current planetary population [

1]. The use and exploitation of renewable energy sources in recent years has generated a tendency towards improving practices that produce waste and utilizing residues to manufacture new products or generate energy by trying to maximize the utilization of lignocellulosic waste as an alternative energy source. The objective is to optimize sources of materials that consist of biomass and so reduce the pressure on natural and planted forests [

2].

Currently, the global energy matrix depends on fossil fuels, although numerous countries have begun to take actions and accept commitments to promote an energy transition towards greater use of renewable sources [

3]. Biomass could be an alternative to fossil fuels that can be transformed into liquid, gaseous, and solid products [

4]. According to the report published by the Renewable Energy Policy Network for the 21st Century, renewable energy contributed 19.2% of worldwide consumption of human energy in 2016, 8.9% of which was provided by traditional biomass

Pinus spp. and

Quercus spp. [

4]. This has entailed identifying new, more environmentally friendly processes for converting these materials [

5]. Generating energy from forest resources opens the possibility that woodlands and other treed areas can provide natural, environmentally-friendly energy to meet the needs of distant regions through hybrid systems that combine forest and aeolic energy with methods for controlling energy storage that, together, would contribute to preserving forest resources [

6]. This proposal, while still a work in progress, seeks to foster forest conservation by focusing on wood-based resources that can be exploited to satisfy basic energy needs; in the present case, wood waste derived from the transformation of necessary commercial products such as furniture. This proposal has not been replicated in countries with characteristics similar to Mexico.

Today, wood byproducts like sawdust and shavings are severely sub-utilized but take up enormous physical spaces without providing any form of added value or being used as fuel [

7]. In the current conditions of the energy revolution, these lignocellulosic raw materials can offer a sustainable source of components for producing bioenergy, biofuels, and novel biomaterials [

8]. These materials are being used to some degree as precursors of the production of activated carbon [

9], and the possibility of using hemp biomass for energy purposes even was evaluated [

10]. Analyses of the potential of these materials for combustion, gasification, and pyrolysis have identified their thermo-chemical conversion capacity to produce energy and biofuels [

5]. One way of utilizing wood waste is to transform it into pellets or briquettes; that is, forms called solid, densified biofuels [

11,

12]. Producing briquettes requires a process that densifies the biomass. The adequate selection and preparation of materials determines whether the briquettes produced will provide an effective fuel [

13], because the quality of the final product depends on several factors, including particle size and moisture content [

14].

Estimates from most developing countries indicate that over 3 billion people–representing around 75% of rural homes–still satisfy their energy needs for cooking with fuels derived from wood burned in traditional stoves [

15], including burning biomass in traditional three-stone type hearths. Those open systems, however, are inefficient as only 5–10% of the potential energy obtained from the biomass actually cooks the food, the rest is wasted [

15]. The environmental problem derived from these practices has led researchers to evaluate biomass as a potential second-generation biofuel, one that transforms lignocellulosic material obtained from forest or wood waste into energy [

16]. Recent studies [

6,

17] illustrate two short-term scenarios based on analyses of the potential for converting forest biomass into an energy source. Their respective authors included restrictions related to sustainability. The first scenario points out that the technical availability of forest biomass for energy use decreased in 2013 but assumes that the number of hectares will increase within a certain time period. Related to this, the second scenario estimates that the availability of energy will increase to 60.22 PJ by 2023. The sustainable exploitation of forest biomass–including the transformation of bioenergy–which considers local socioeconomic development accompanied by strategies designed to mitigate the loss of biodiversity while conserving natural resources, seems to be a feasible option for strengthening Mexico’s bioeconomy [

18].

Given that the use of wood to satisfy Mexico’s energy needs is limited compared to the potential of utilizing the waste materials produced by wood-cutting and forest industries, studies published in the scientific literature suggest that much more research is required on exploiting waste forest resources to produce solid biofuels in the form of pellets or briquettes [

17]. Indeed, briquettes made from wood biomass could have a significant impact in low-income communities because of the availability of raw material and their low cost [

3]. Studies of the production of solid biofuels in Portugal show the economic viability of converting wood biomass waste to generate energy, not only for the domestic, tourism, and industrial sectors but, in a broader vision, for producing electrical energy to be distributed through entire regions [

19]. Poland is producing briquettes from wood biomass using a process called “briquetting”. This method requires piston-based presses to fabricate a solid fuel suitable for burning in automatic boilers. Those briquettes offer a potential, and very promising, means of generating heat for homes [

20].

Producing briquettes entails evaluating the following factors: chemical properties, ash, volatility, and calorific power [

21], while key physical properties include moisture content, particle size, and apparent density [

22,

23,

24,

25,

26]. Several types of binding material have been tested in the production of biomass-based briquettes, including yucca paste, wastepaper pulp, molasses, dried cow manure, clay, asphalt, and starch [

27,

28,

29,

30,

31]. The most interesting material, however, is chemically treated rice chaff, because it has shown a good binding capacity that significantly improves the characteristics of briquettes [

32].

While several methods exist for making briquettes and pellets, the minimum requirements are a simple pressing machine and some type of binding agent or blinder. The scientific literature reports, for example, mixing 230 g of starch, 500 mL of water, and 1 kg of yucca to manufacture a briquette [

33]. In our research, however, we used quantities of wood waste instead of yucca, cornstarch as the binding agent, and tripled the amount of water. This allowed us to produce 4 briquettes that averaged 7.2 cm in diameter and 9–10.5 cm in length. Some methods require more sophisticated mechanisms, high temperatures, and a laboratory equipped with a hydraulic briquette-making machine that can reach a temperature of 120 °C [

34], while others produce individual granules using a uniaxial piston-cylinder compression device [

35]. Although the moist densification method–that is, production using simple mechanical machines–reduces the heating value of the raw materials, increases water consumption and treatment, requires large amounts of space [

26], and is time-consuming because the compressed briquettes need to be left to dry under conditions of direct sunlight and adequate ventilation, it has one significant advantage; namely, it is a simple and economical way to make briquettes [

36]. While many materials have been used to produce briquettes with varying physicochemical characteristics utilizing high-volume production methods [

7,

37,

38], there are no reports on the suitability of those processes for rural communities, which is the focus of our work.

The present study describes the use of the wood waste generated during the elaboration of various furniture and artisanal products, as an alternative to the production for low cost briquettes that are thermally-efficient, easy to make, have little environmental impact, and can be used immediately in small, traditional cooking systems and systems designed to maximize the thermal yield of the fuel used [

39], such as the

Patsari® stove, for example [

40]. The briquettes were physicochemically characterized; functionality was evaluated through calorific power and combustion capacity in traditional cooking systems; In addition, an economic study and a comparative analysis with traditional biomass fuels were carried out to determine the relevance of the use of briquettes in the study community.

3. Results and Discussion

3.1. Characterization of the Biomass

For the samples of sawdust and shavings collected, the moisture content for both of the wood of the genus

Pinus ranged from 18.00–67.82% (

Figure 5). This figure is lower than in earlier studies [

51], but adequate for elaborating densified materials, since they will not require a lengthy drying process to reach a value suitable for producing solid biofuels [

38,

52].

The granulometry results for the samples of sawdust generated an average of 78.32–79.92% in the 0.5 mm screen. These particle size percentages are similar to those reported in other studies, which range from 75.8% [

38,

53], to 76.9% [

51]. In our work, the particle size that resulted from using the 0.5–2.00 mm screens was 30.05–79.92%, a size range suitable for making briquettes, as reported in a previous study that determined a percentage of 73.1% for wood of the genus

Pinus after filtering through the same screen sizes [

54]. The granulometric analysis of the sawdust showed that 54.9% by volume can be used to produce briquettes, while another 30.05% can be incorporated into the production of other types of biofuel; pellets, for example. There are two suggestions for utilizing the remaining 15.05%: first, re-milling it to obtain a new percentage; second, mixing it with another lot of biomass for re-screening. The granulometry of the sample of shavings produced an average of 64.1–86.3% through a 3.35 mm screen. These percentages are similar to those reported in earlier studies [

38,

53], where values were 75.8% and 76.9% [

51].

These results indicate that the material used does not require extensive milling to obtain a suitable particle size for briquette-making, as the 0.5 to 2.00 mm screens separated an average of 13.7–35.9% [

55]. Those screens produced an estimated percentage of 26.9% for wood of the genus

Pinus. The granulometric analysis of the shavings showed that 26.2% can be utilized to produce briquettes, and 13.7% to manufacture other types of biofuel, such as pellets. The remaining 60.1% can be re-processed as indicated above for the sawdust (i.e., re-milling or mixing). Both cases are illustrated in

Figure 6.

The apparent densities reported for conifer wood show values of 160–330 kgm

−3 [

56]. The bulk density reported for our samples of sawdust and shavings had values of 160 and 170 kgm

−3, respectively, though other studies report figures of 160 and 235 kgm

−3 [

54]. The apparent density determined in our study lies within the acceptable parameters published in earlier reports [

52].

The results of this analysis were in a range of 0.49–1.55% for the samples of sawdust, while the value for the shavings was 0.38–1.78%. These satisfy this parameter and concur with figures reported in previous studies, which indicate a range of 0.28–1.25%. In fact, these values surpass those determined elsewhere [

51,

55,

56,

57,

58]. For the case of the wood used in our work, the results for ash content satisfy the established standard.

The samples of shavings had a range of 91.26–95.01% for volatility, while the figure for the sawdust was 65.3–90.29%. These values are higher than in other reports, which found a range of volatile material of 80.84–81.27% for samples of the genus

Pinus [

48]. Other studies show carbon-compound sawdust with volatility of 49.4–53.3% for briquettes that possess low volatility [

59].

Table 2 shows the results obtained for the fixed carbon content of the samples of sawdust and shavings collected in Pichátaro.

These data indicate that the amount of fixed carbon in the samples of sawdust and shavings ranges from 4.49% to 34.3%. Sample 3 of sawdust in

Table 2 had a high carbon content, but it is actually lower than the ranges reported in other work, which were 48.80–50.30% for samples of the genus

Pinus [

60]. Other published studies found fixed carbon values of 12.20% [

61], 16.76% [

62], and 15.96% [

63]. Therefore, most of the data from the results of our analyses of fixed carbon are below the figures reported in the literature for the genus

Pinus. 3.2. Fabrication of the Briquettes

The process described below was followed to produce the briquettes (

Figure 7):

Mixing the materials: sawdust, shavings, water and the binding agent.

Emptying the mixture into molds for compaction to produce the briquettes using a manual apparatus.

Removing the briquettes from the molds for drying.

Considering the optimal concentration for briquette-making (

Figure 3b), the result of each extraction process was 4 briquettes that measured 10.7 cm long by 7.2 cm in diameter. For the purposes of this project we produced 500 briquettes, which constituted the total lot used for the analyses (

Figure 8).

3.3. Physicochemical and Energetic Properties of the Briquettes

According to standard UNE-IN 14774-1 (2010) [

35,

41], the final moisture content of the briquettes made in this study ranged from 11.52–13.26% ± 0.57, a value that is within acceptable parameters compared to other results reported in the literature, where moisture content was 14–16% [

38,

53], and 8–10%. Those projects, however, employed electric machines to produce the briquettes, which accelerated the drying of the raw material [

38]. In the present study, in contrast, the briquettes were left to dry in the open air after a production process that utilized a simple, innovative mechanical briquette-making apparatus (

Figure 2).

The calorific power of the briquettes analyzed fell into a range of 17.0–18.3 MJ/kg ± 0.75, while in other studies briquettes made of splinter material had a range of 13.0–19.52 MJ/kg [

64], and pellets made from similar material presented a range of 16–19 MJ/kg [

38,

52,

65]. Clearly, the values we obtained are acceptable.

The values calculated for the density of the briquettes varied from 930–1240 kg/m

3. Data reported in other studies oscillate between 810 and 1060 kg/m

3 [

66] and from 890 to 1080 kg/m

3 [

56]. Thus, the density of our briquettes did not differ significantly from those produced in other studies and can be deemed acceptable [

38].

Table 3 presents the results of the chemical analysis of the wood waste; that is, the cellulose, hemicellulose, and lignin content obtained from the material collected in the study community.

The analysis of the samples of

Pinus spp. with respect to hemicellulose content produced an average of 14.5%, while for cellulose the average was 53.3%, and for lignin 25.8%, with 6.53 of other components (extractives and soluble sugars, among others). These results are also similar to those reported in earlier research, where values ranged from 68.1–74.7% for holocellulose and 24.7–28.5% for lignin [

5,

34,

67]. Since lignin is the main structural element for generating energy, our study obtained an average similar to other reports for species of the genus

Pinus spp., which indicate a figure of 24.59% for lignin [

68,

69]. Published studies mention hemicellulose and cellulose values of 12.37% and 54.81%, respectively, for the species

Abies Religiosa, giving a total of 67.18% of holocellulose, and an average lignin content of 24.68% [

50]. These results indicate the potential of the materials suggested in this study for exploitation as sources of bioenergy.

3.4. Evaluation of the Combustion of the Briquettes

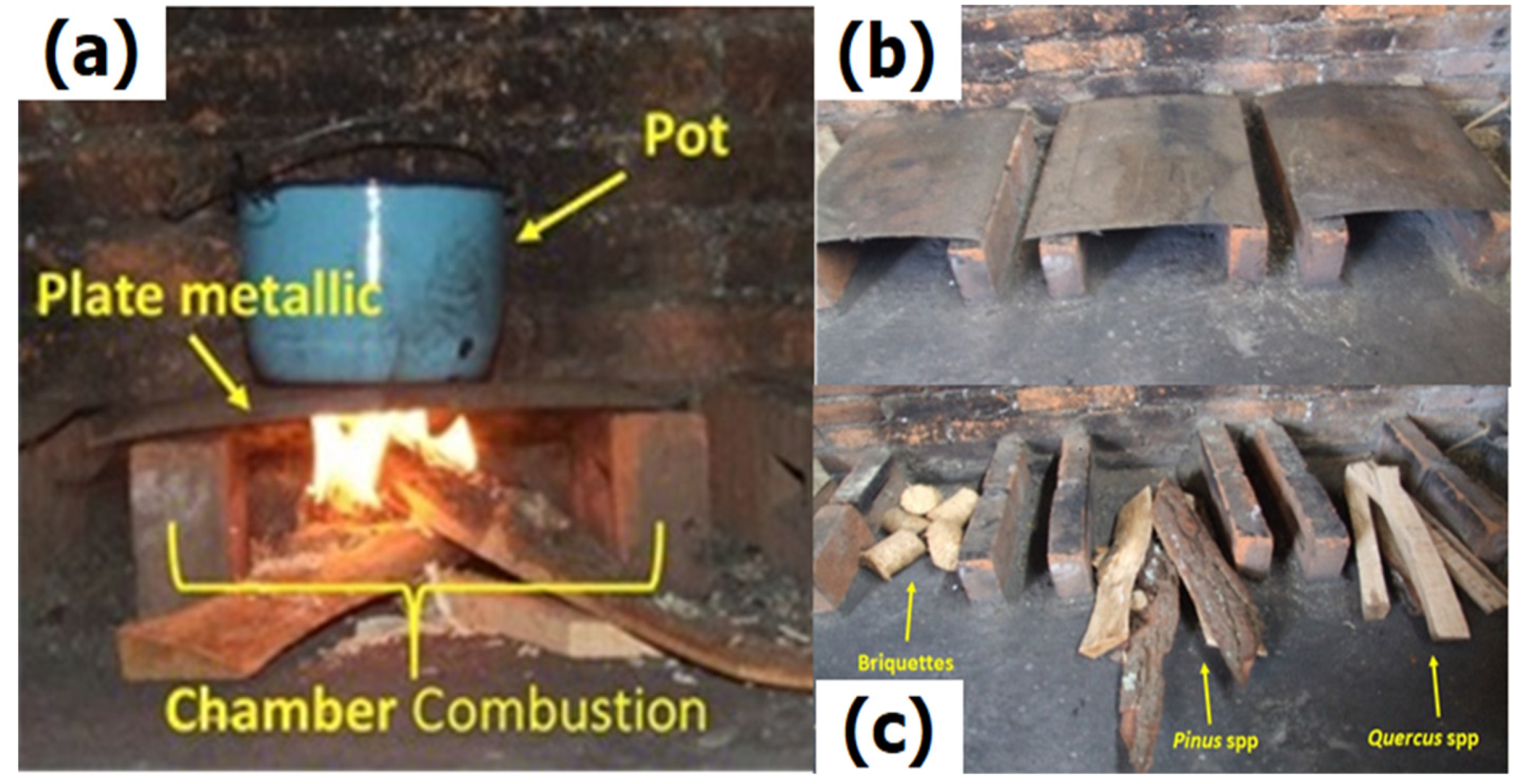

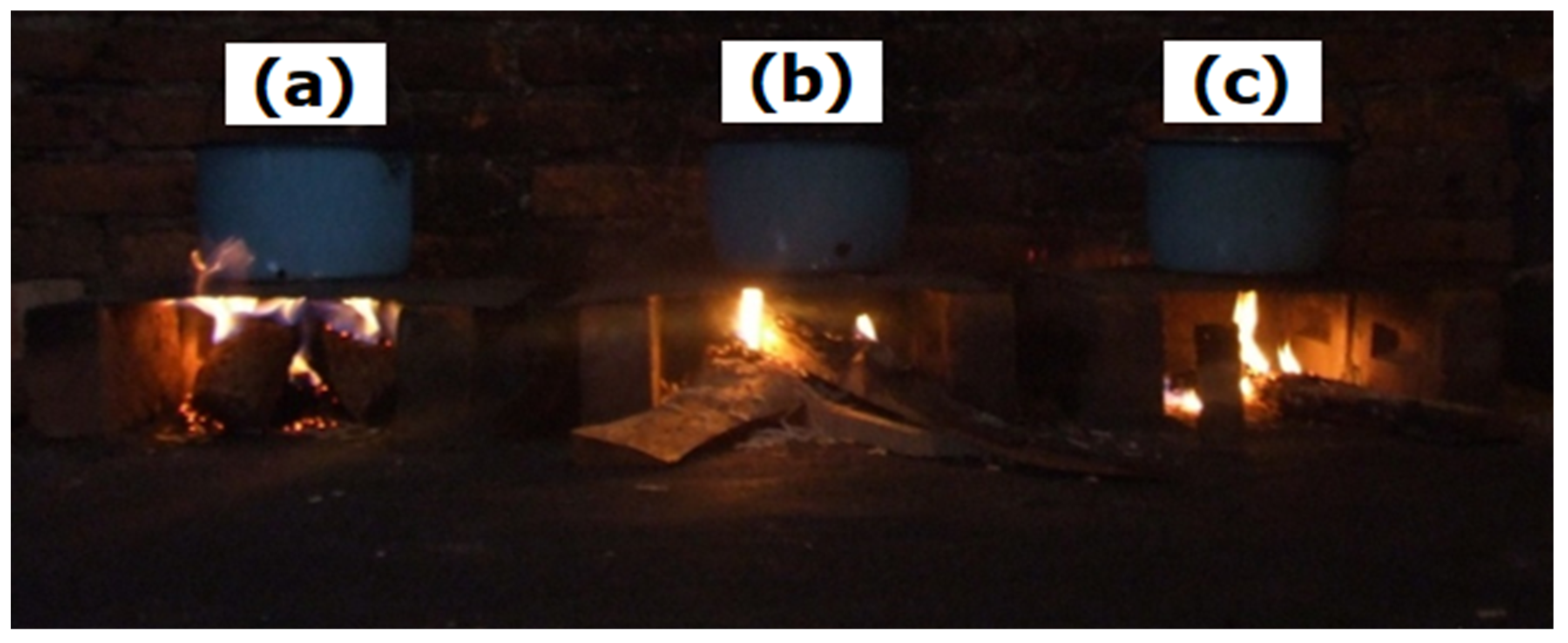

For this analysis, 1 kg of each fuel was placed in the combustion chamber under the metallic plate. Each sample was ignited with 50 g of

ocote (wood impregnated with pine resin,

Pinus leiophylla), which were introduced simultaneously in the three combustion chambers to systematize the experiment and ensure adequate ignition (

Figure 9).

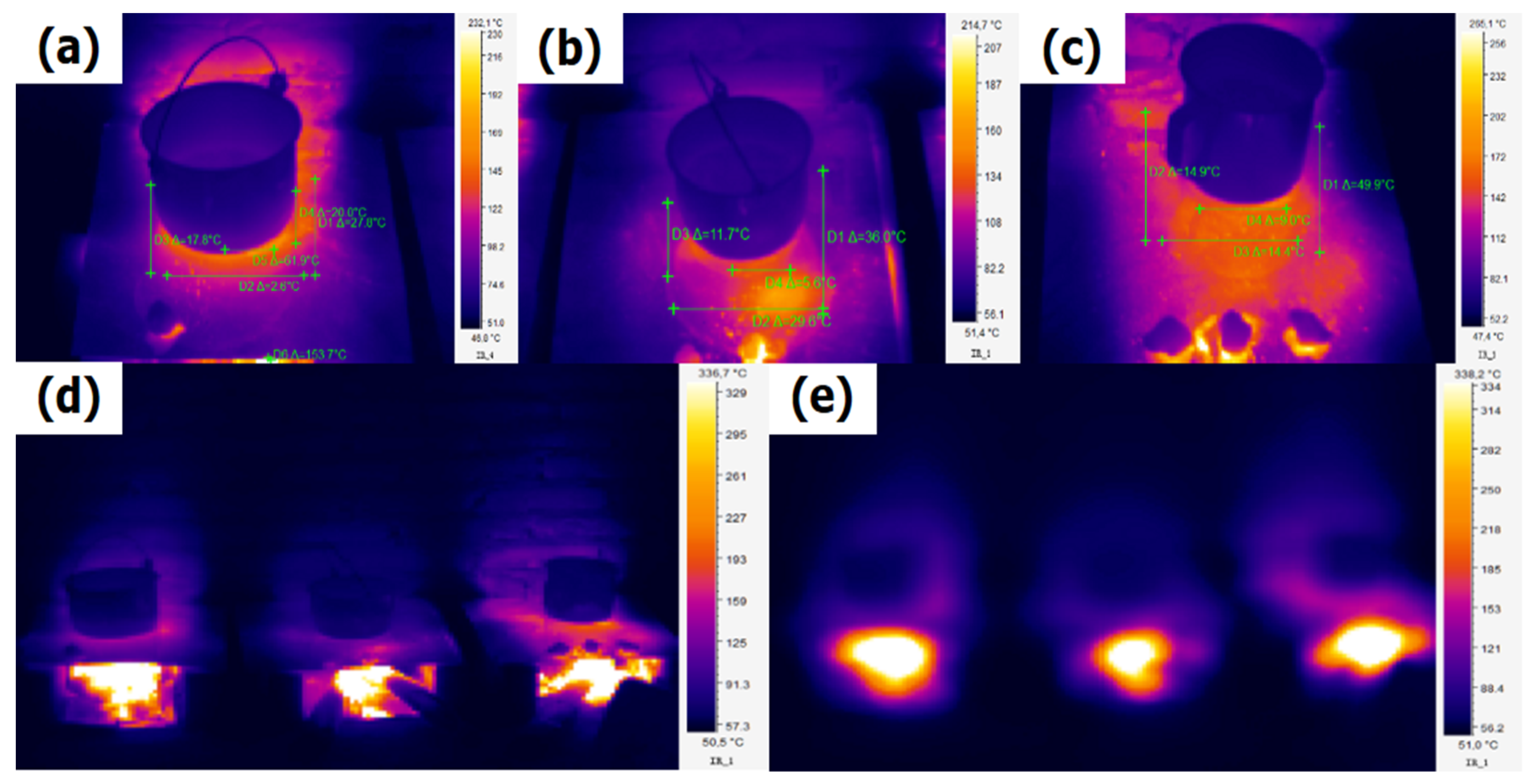

Figure 10 shows the results of the thermographic analysis conducted at 20 min after initial combustion.

According to the radiative thermographic spectrum, the combustion of the briquettes and the pine and oak firewood reached maximum temperatures of 330.2 °C, 178.1 °C, and 327.2 °C, respectively, during the first combustion period of 20 min.

Figure 10d shows that all three fuels emitted energy in the form of a radiant body, where all the temperatures emitted in a given area are observable. This figure reveals that the briquettes had a radiative thermographic spectrum with temperatures of 54.8–335.6 °C, while the pine firewood reached temperatures between 69.2 and 102 °C, and the oak firewood a range of 102–215 °C.

Figure 10e presents an integrated image to compare the three fuels. In this stage, the briquette emitted the highest thermal yield at 321.1 °C.

Figure 11 presents the thermal yield of the three fuels analyzed after 45 min of combustion. In that period, the briquettes and pine and oak firewood reached maximum temperatures of 335.7, 336.8, and 323.6 °C, respectively.

This analysis found that the three fuels emitted energy in the form of a radiant body in a given area. The briquettes and pine and oak firewood reached temperatures of 87.0–335.9 °C, 54.8–335.9 °C, and 49.7–335.9 °C, respectively. This image was taken after 50 min of combustion.

Figure 12 presents the thermal yield achieved by the fuels after 70 min of combustion. The radiative thermographic spectrum shows that the briquette reached a maximum temperature of 232.1 °C, while the pine and oak firewood had maximum temperatures of 214.7 and 265.1 °C, respectively.

Figure 12d shows the three fuels analyzed. In this stage, the oak firewood had the highest thermal yield, emitted at 336.7 °C.

Figure 12e presents the energy emission in the form of radiant bodies emitted by the three fuels in a given area. Here, the briquettes emitted a temperature of 56.2–338.2 °C, the temperature for the pine firewood was 60–338.2 °C, and for the oak firewood it was 51.0–338.2 °C. The termination of the combustion process, after a time interval of 1 h and 50 min, can be observed.

Figure 13b shows the energy emission in the form of radiant bodies. The temperature range in this stage was determined to be 49.1–262.0 °C.

This thermographic analysis allowed us to determine the velocities of the ignition, combustion, and degradation of the materials during total combustion. Compared to traditional fuels, Pinus spp. and Quercus spp., the briquettes of this research easily combustion, have a long burning time, and their calorific power is corroborated with the useful energy for a domestic task (heating water). This was complemented by an analysis of energy efficiency that is described in the following section.

3.5. Energy Efficiency Based on Loss of Mass

To obtain the quality of combustion for final use apparatuses and the useful effect of the process, we recorded the temperature of the water in the recipients in each combustion chamber. Results are shown in

Figure 14.

The values obtained for the temperature of the water during 45 min (10 repetitions, SD 0.62) of combustion reflect the performance of the fuels analyzed. During the first 10 min—setting out from an initial water temperature of 17 °C—the combustion results show that the briquette raised the water temperature to 36 °C, the pine firewood to 52 °C, and the oak firewood to 39 °C. At 25 min of combustion, the briquette raised the temperature of the water to 53 °C, the pine firewood to 58 °C, and the oak firewood to 55 °C. Finally, at 40 min of combustion, the briquettes increased the temperature of the water to 89 °C to conclude this analysis.

3.6. Economic Evaluation of Briquette Production

One result of the community diagnosis conducted as part of our study was that we verified that each workshop generates an average of one sack of sawdust and one sack of shavings per day; the wood waste that was used to produce briquettes.

Table 4 shows the waste material produced in kg/day in the form of sawdust and shavings in Pichátaro.

The waste material produced per day is sufficient to produce the briquettes described in

Table 5.

Table 5 shows the production of briquettes per sack of waste material. In agreement with the results of

Figure 1, the mixture of sawdust and shavings is acceptable for the production of briquettes, because it represents a high production value, with better humidity and texture conditions. The cost of production is detailed in

Table 6.

One kilo of cornstarch, 1200 g of shavings/sawdust, and 4 L of water are needed to produce 12 briquettes (10 cm high by 7.2 cm in diameter). The cost of the materials is $0.76 USD, or $0.053 USD per briquette.

There are no briquette sales in the study community. But the production cost of the briquettes in this research are very similar to the cost of conventional fuels, such as firewood (comparative in terms of fuel by activity carried out)

3.7. Comparative Analysis with Other Traditional Fuels

We applied a multi-criteria methodology to evaluate the indicators of the parameter of sustainability [

70]. This approach, which has been used in integrated evaluations of technologies that utilize renewable and ecotechnical energy sources [

71,

72], took parameters of energy, physicochemical properties, and economic-environmental factors into account to generate the quantifiable indicators presented in

Table 7.

For each one of the above indicators we considered maximum and minimum values (

Table 8) to define the best- and worst-case scenarios.

Elaborating

Table 8 entailed considering the following:

- -

the maximum calorific power reported in the literature for species of the genus

Pinus spp.: 20.92 MJ/kg [

21];

- -

the maximum initial moisture content reported: 56% [

51].

- -

the highest lignin content recorded in the specialized literature: 35% [

21], and

- -

the maximum ash content: 18.20% [

21].

Based on these parameters, the unitary production cost is $80/kg. However, this figure reflects the highest purchase price of firewood in the study community. In contrast, the amount of first-use wood required is just 1 kg, considering (i) that the waste produced is not used and (ii) the material was burned only to test combustion.

The multi-criteria methodology is not a tool

per se, but must be applied comparatively, so we analyzed the three fuels mentioned previously: (1) briquettes; (2) pine firewood (

Pinus spp.); and (3) oak firewood

(Quercus spp.). The results of the evaluation of these indicators for the three cases are shown in

Table 9.

These values (

Table 10) were then normalized with those in

Table 8 to establish a scale of 0–10, where 0 and 10 represent, respectively, the worst and best possible scenarios.

Table 10 shows the normalized values.

The processing and graphing of the data were carried out using MULTIBERSO software, a tool for multi-criteria analysis and indicators of sustainability that presents results in the form of graphs, as can be observed in

Figure 15.

Figure 15 shows the indicators used in the analysis to identify the potential of the briquettes produced compared to conventional fuels. This graphic presentation allows the reader to appreciate the strengths and weaknesses of various aspects, from a focus on energy, to one on economics, to one on the environment. The indicator calorific power shows that the relation of the three fuels is similar, as no significant differences were found. In terms of lignin content, the relevant indicators report similar values, although the oak-based fuel was higher. With respect to the unitary production cost, the graph shows that the cost of producing briquettes is higher than that of pine or oak firewood, but it is important to understand that firewood is simply extracted from forests directly, and does not undergo any transformation process to turn it into fuel. The material for the briquettes, in contrast, is obtained from the sawing process so the cost added is only that of converting wood into densified material. For the indicator amount of first-use wood, the graph shows that the briquettes–a non-first-use wood–are made of waste material that is exploited to generate added value to a process (sawing) that produces solid waste. In terms of this indicator, then, the briquettes represent the ideal case. Turning to the ash content of the three fuels, we find that it is low, a property that makes them ideal for combustion, especially for all manner of domestic tasks. Finally, for the factor moisture content the study found that the initial moisture of the material used to make the briquettes is much lower than the values for pine and oak firewood. Thus, in this aspect, the briquettes differ significantly from the other two fuels. In synthesis, the briquettes represent a fuel that is competitive with pine and oak firewood in all three parameters considered: economic, energy, and environment. Conclusion: these briquettes constitute a fuel source that has positive indicators of sustainability.

5. Conclusions

The wood waste of Pinus spp. produced in the community of San Francisco Pichátaro is voluminous and has high potential for producing solid, densified biofuels, since the particles are suitable for densification, and the immediate analytical values indicate good properties for conversion into briquettes. The availability of raw material in the study community is approximately 6628 tons of sawdust and 9108 tons of shavings per workshop per month, which translates to an annual volume of 188,832 tons of wood waste, based only on a representative sample of 35% of the artisanal workshops surveyed.

The physicochemical and energy analyses of the lignocellulosic waste generated in this community show the bioenergy potential of the briquettes produced, given that the moisture content–a fundamental parameter for combustion–is lower than the standard (average: 11.52–13.26). The ash content also satisfies the established standards and is actually below the average of 0.49–1.55%. These properties help mitigate problems of combustion in end-use apparatuses. The calorific value determined for the briquettes was in a range of 17–18 MJ/kg due, in part, to the structural content of the wood, as we found that the lignin concentration and holocellulose content of the wood of the genus Pinus spp. are comparable, especially the former, which contributes to the high calorific power determined in this study.

The results of the tests of thermal yield and heating time of water demonstrated that the briquettes had a higher yield than the conventional fuels. Finally, the production of these briquettes using simple mechanical devices and a natural binding agent is economically viable since the average production cost determined herein was $0.054–$0.058 USD. Moreover, this production is socially attractive for potential consumers, so local policies could provide incentives for generating projects of this kind, due to their environmental and social character. These biofuels are potentially scalable and could lead to the development of a line of production that generates added value for these types of wood waste, while simultaneously providing opportunities for employment and promoting renewable energy sources.