Comparative Life Cycle Assessment of Glucose Production from Maize Starch and Woody Biomass Residues as a Feedstock

Abstract

Featured Application

Abstract

1. Introduction

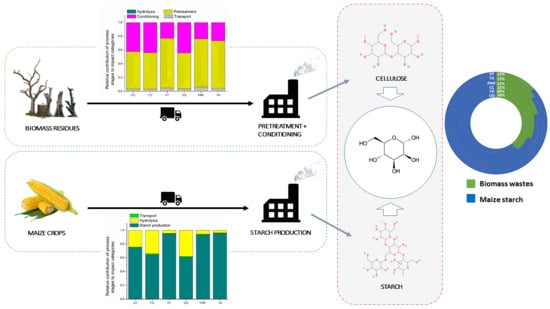

2. Materials and Methods

2.1. Goal & Scope

2.2. Life Cycle Inventory (LCI)

2.2.1. Maize Starch-Based Process

2.2.2. Woody Biomass Residues Based Process

2.2.3. Hydrolysis

2.3. Life Cycle Impacts Assessment

2.4. Assumptions and Limitations

- The fixed CO2 by the growth of biomass (either maize crops or wood) was excluded from calculations. The principal reason was the difficulty of obtaining reliable data, and the consequent deviations generated in the comparative LCA.

- The physical and chemical properties of cellulose were used for the simulation of the starch hydrolysis process, given the similarities between the two polymers.

- Potential uses for the lignin streams have not been included in the scope of this work, as well as the impacts derived from wastewater treatment processes.

- Secondary products and allocation methods were not considered. This involved both systems that were evaluated under the worst environmental scenario since the impacts are not shared with the by-products obtained in the processes. At this point, it must be taken into account that the Ecoinvent 2.2 database includes an allocation method for the maize starch production process. Specifically, the applied economic allocation assigns 83% of the environmental impacts on starch. Despite this fact slightly affects the absolute values of the mid-point indicators obtained for the maize system and comparative LCA results are barely influenced, it has been taking into account for calculations. Thus, mid-point indicators of MS-bp were obtained, excluding the allocation method considered within the Ecoinvent 2.2 database. For comparison purposes, values of mid-point indicators of MS-bp showed in the supporting information are presented in both ways (with and without allocation).

- Procedures downstream of the hydrolysis stage, such as the purification of the glucose, were not included in the scope of this analysis. Purification main impacts arise from the evaporation of the exceeding process water to reach a suitable product concentration for commercial applications [2]. As identical starting and end concentrations of the glucose solutions in both analyzed processes would lead to identical results, this stage has not been considered.

- Other auxiliary processes, such as wastewater treatment, heat integration, or solid combustion, were not taken into account.

3. Results

3.1. Maize Starch-Based Process (MS-bp)

3.2. Woody Biomass Residues Based Process (WBR-bp)

3.2.1. Pretreatment of Lignocellulosic Biomass

3.2.2. Conditioning

3.3. MS-bp and WBR-bp Comparison

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Delidovich, I.; Palkovits, R. Catalytic Isomerization of Biomass-Derived Aldoses: A Review. ChemSusChem 2016, 9, 547–561. [Google Scholar] [CrossRef]

- Moreno, J.; Iglesias, J.; Blanco, J.; Montero, M.; Morales, G.; Melero, J.A. Life-cycle sustainability of biomass-derived sorbitol: Proposing technological alternatives for improving the environmental profile of a bio-refinery platform molecule. J. Clean. Prod. 2020, 250, 119568. [Google Scholar] [CrossRef]

- Vercalsteren, A.; Boonen, K. Life Cycle Assessment Study of Starch Products for the European Starch Industry Association (Starch Europe): Sector Study; Flemish Institute for Technological Research NV (“VITO”): Flanders, Belgium, 2015. [Google Scholar]

- Robak, K.; Balcerek, M. Review of second generation bioethanol production from residual biomass. Food Technol. Biotechnol. 2018, 56, 174–187. [Google Scholar] [CrossRef] [PubMed]

- Li, A.; Antizar-Ladislao, B.; Khraisheh, M. Bioconversion of municipal solid waste to glucose for bio-ethanol production. Bioprocess Biosyst. Eng. 2007, 30, 189–196. [Google Scholar] [CrossRef] [PubMed]

- Pleissner, D.; Lin, C.S.K. Valorisation of food waste in biotechnological processes. Sustain. Chem. Process. 2013, 1, 21. [Google Scholar] [CrossRef]

- Lam, W.C.; Pleissner, D.; Lin, C.S.K. Production of fungal glucoamylase for glucose production from food waste. Biomolecules 2013, 3, 651–661. [Google Scholar] [CrossRef]

- Uçkun Kiran, E.; Trzcinski, A.P. Optimizing the Conversion of Food Waste to Sugars using Fungal Enzymes. EC Microbiol. 2017, 8, 98–112. [Google Scholar]

- Díaz, A.I.; Laca, A.; Laca, A.; Díaz, M. Treatment of supermarket vegetable wastes to be used as alternative substrates in bioprocesses. Waste Manag. 2017, 67, 59–66. [Google Scholar] [CrossRef]

- Vynios, D.H.; Papaioannou, D.A.; Filos, G.; Karigiannis, G.; Tziala, T.; Lagios, G. Enzymatic production of glucose from waste paper. BioResources 2009, 4, 509–521. [Google Scholar]

- Liu, S.; Lu, H.; Hu, R.; Shupe, A.; Lin, L.; Liang, B. A sustainable woody biomass biorefinery. Biotechnol. Adv. 2012, 30, 785–810. [Google Scholar] [CrossRef]

- Duque, A.; Manzanares, P.; Ballesteros, I.; Ballesteros, M. Steam Explosion as Lignocellulosic Biomass Pretreatment. In Biomass Fractionation Technologies for a Lignocellulosic Feedstock Based Biorefinery; Elsevier: Amsterdam, The Netherlands, 2016; pp. 349–368. ISBN 9780128025611. [Google Scholar]

- Binder, J.B.; Raines, R.T. Fermentable sugars by chemical hydrolysis of biomass. Proc. Natl. Acad. Sci. USA 2010, 107, 4516–4521. [Google Scholar] [CrossRef]

- Lali, A.M.; Odaneth, A.A.; Victoria, J.J.; Choudhari, V.G.; Wadekar, P.C.; Patil, M.L.; Patil, P.S. Process for Production of Pure Glucose from Cellulose. WO Patent 013684, 26 January 2017. [Google Scholar]

- Roy, P.; Tokuyasu, K.; Orikasa, T.; Nakamura, N.; Shiina, T. A Review of Life Cycle Assessment (LCA) of Bioethanol from Lignocellulosic Biomass. Jpn. Agric. Res. Q. 2012, 46, 41–57. [Google Scholar] [CrossRef]

- Prasad, A.; Sotenko, M.; Blenkinsopp, T.; Coles, S.R. Life cycle assessment of lignocellulosic biomass pretreatment methods in biofuel production. Int. J. Life Cycle Assess. 2016, 21, 44–50. [Google Scholar] [CrossRef]

- Patel, M.; Zhang, X.; Kumar, A. Techno-economic and life cycle assessment on lignocellulosic biomass thermochemical conversion technologies: A review. Renew. Sustain. Energy Rev. 2016, 53, 1486–1499. [Google Scholar] [CrossRef]

- Pierobon, F.; Eastin, I.L.; Ganguly, I. Life cycle assessment of residual lignocellulosic biomass-based jet fuel with activated carbon and lignosulfonate as co-products. Biotechnol. Biofuels 2018, 11, 139. [Google Scholar] [CrossRef] [PubMed]

- Renouf, M.A.; Wegener, M.K.; Nielsen, L.K. An environmental life cycle assessment comparing Australian sugarcane with US corn and UK sugar beet as producers of sugars for fermentation. Biomass Bioenergy 2008, 32, 1144–1155. [Google Scholar] [CrossRef]

- Tsiropoulos, I.; Cok, B.; Patel, M.K. Energy and greenhouse gas assessment of European glucose production from corn-a multiple allocation approach for a key ingredient of the bio-based economy. J. Clean. Prod. 2013, 43, 182–190. [Google Scholar] [CrossRef]

- Moncada, J.; Vural Gursel, I.; Huijgen, W.J.J.; Dijkstra, J.W.; Ramírez, A. Techno-economic and ex-ante environmental assessment of C6 sugars production from spruce and corn. Comparison of organosolv and wet milling technologies. J. Clean. Prod. 2018, 170, 610–624. [Google Scholar] [CrossRef]

- Salim, I.; González-García, S.; Feijoo, G.; Moreira, M.T. Assessing the environmental sustainability of glucose from wheat as a fermentation feedstock. J. Environ. Manag. 2019, 247, 323–332. [Google Scholar] [CrossRef] [PubMed]

- Morales, M.; Pielhop, T.; Saliba, P.; Hungerbühler, K.; Rudolf von Rohr, P.; Papadokonstantakis, S. Sustainability assessment of glucose production technologies from highly recalcitrant softwood including scavengers. Biofuels Bioprod. Biorefin. 2017, 11, 441–453. [Google Scholar] [CrossRef]

- Cherubini, F.; Strømman, A.H.; Ulgiati, S. Influence of allocation methods on the environmental performance of biorefinery products—A case study. Resour. Conserv. Recycl. 2011, 55, 1070–1077. [Google Scholar] [CrossRef]

- Nemecek, T.; Kägi, T. Life Cycle Inventories of Agricultural Production Systems; Ecoinvent Centre. Swiss Centre For Life Cycle Inventories: Dübendorf, Zurich, Switzerland, 2007. [Google Scholar]

- Davis, R.; Tao, L.; Scarlata, C.; Tan, E.C.D.; Ross, J.; Lukas, J.; Sexton, D. Process Design and Economics for the Conversion of Lignocellulosic Biomass to Hydrocarbons: Dilute-Acid and Enzymatic Deconstruction of Biomass to Sugars and Catalytic Conversion of Sugars to Hydrocarbons Process Design and Economics for the Conversion o; National Renewable Energy Laboratory: Golden, CO, USA, 2015. [Google Scholar]

- Dietrich, F.; Gerd, W. Wood: Chemistry, Ultrastructure, Reactions; Walter de Gruyter: Berlin, Germany, 2011. [Google Scholar]

- International Organization for Standardization. Environmental Management—Life Cycle Assessment—Requirements and Guidelines; ISO 14044: 2006; ISO: Geneva, Switzerland, 2006; pp. 1–46. [Google Scholar]

- Akmalina, R. Environmental Impacts Evaluation of Sorbitol Production from Glucose. Eksergi 2019, 16, 7–12. [Google Scholar] [CrossRef]

- Alvira, P.; Ballesteros, M.; Negro, M.J. Bioresource Technology Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: A review. Bioresour. Technol. 2010, 101, 4851–4861. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.Y.; Pan, X.J. Woody biomass pretreatment for cellulosic ethanol production: Technology and energy consumption evaluation. Bioresour. Technol. 2010, 101, 4992–5002. [Google Scholar] [CrossRef] [PubMed]

- Sims, R.; Taylor, M. From 1st- to 2nd-Generation BioFuel technoloGies. Biofuel Technology; International Energy Agency (IEA): Paris, France, 2008. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Blanco, J.; Iglesias, J.; Morales, G.; Melero, J.A.; Moreno, J. Comparative Life Cycle Assessment of Glucose Production from Maize Starch and Woody Biomass Residues as a Feedstock. Appl. Sci. 2020, 10, 2946. https://doi.org/10.3390/app10082946

Blanco J, Iglesias J, Morales G, Melero JA, Moreno J. Comparative Life Cycle Assessment of Glucose Production from Maize Starch and Woody Biomass Residues as a Feedstock. Applied Sciences. 2020; 10(8):2946. https://doi.org/10.3390/app10082946

Chicago/Turabian StyleBlanco, Jorge, Jose Iglesias, Gabriel Morales, Juan A. Melero, and Jovita Moreno. 2020. "Comparative Life Cycle Assessment of Glucose Production from Maize Starch and Woody Biomass Residues as a Feedstock" Applied Sciences 10, no. 8: 2946. https://doi.org/10.3390/app10082946

APA StyleBlanco, J., Iglesias, J., Morales, G., Melero, J. A., & Moreno, J. (2020). Comparative Life Cycle Assessment of Glucose Production from Maize Starch and Woody Biomass Residues as a Feedstock. Applied Sciences, 10(8), 2946. https://doi.org/10.3390/app10082946