1. Introduction

Laser cladding is a coating technology, which use the high-energy laser beam irradiating on the substrate surface and powder, causing the powder rapid melting and cooling to form the desired metallic bond coating with the substrate [

1,

2,

3]. Due to the high energy density, high efficiency, outstanding mechanical and physical properties, laser cladding has been widely used on surface restoration to form low dilution rate condensed coating for multiple purposes [

4,

5]. Composite material coating restoration has been rapidly developed in the recent years [

6,

7]. The 316L stainless steel powder is widely used in industry because of its low cost, corrosion resistance, and self-fluxing [

8]. However, the limitation of 316L also exists due to its low hardness and inadequate wear resistance [

9]. With the development of composite material, these limitations could be improved by adding reinforcement particles [

10]. SiC particle possesses the advantage of high micro-hardness and wear resistance. Thus, SiC is a favorable reinforcement material used in composite materials [

11]. This study focuses on investigating the micro-hardness and wear resistance of the cladding layer manufactured by SiC reinforced 316L stainless steel powder in laser cladding.

Wen et al. found the micro-hardness and corrosion resistance of 316L were effectively improved by conducting the laser cladding in the solution with 3.5 wt% NaCl [

12]. Mei et al. studied the selective laser cladding with 316L and Inconel 718. They found the contacting zone between these two materials had different micro-hardness and micro-structure, with pores and cracks [

13]. Murkute et al. investigated 316L coating on the AISI 1018 steel substrate, and found the nano-indentation hardness was reduced with the increasing scanning speed [

14]. Riquelme et al. deposited Al, Si, Ti and SiC composite coating on ZE41 magnesium alloy. They discovered that the micro-hardness and mechanical property was improved with ratio of alloying elements [

15]. Ramakrishnan et al. manufactured SiC reinforced Haynes 282 (HY282) functional gradient super alloy with different SiC composition, structure and property. They found the micro-hardness and wear resistance of the super alloy were significant improved with the increased SiC particles composition [

16]. Zhao et al. produced 8.5 vol% SiC/AlSi10 Mg SiC ceramic reinforced Al-based composites by selective laser melting. They addressed that the nano-hardness and elastic modulus in the center and boundary were better than the conventional materials [

17].

Regarding multiple objectives optimization, Ma et al. designed a polynomial model of dilution rate and residual stress through response surface methodology. The minimal dilution rate and residual stress was obtained by using the quadratic models as the constraint functions and multi-objective quantum-behaved particle swarm optimization. In the end, the optimal processing parameters were achieved and high entropy alloy coating was produced [

18]. Sohrabpoor developed an adaptive neuro-fuzzy inference system (ANFIS), which is capable to model the response based on the processing parameters in the laser powder deposition process. The prediction accuracy was improved by associating the ANFIS with imperialist competitive algorithm [

19]. Shi et al. utilized Taguchi orthogonal array (OA) to reduce number of experiments and Technique for Order Preference by Similarity to an Ideal Solution (TOPSIS) to complete multiple objectives optimization in the laser cladding. The improved micro-hardness and wear resistance of the gradient composite coating were predicted and verified by ANOVA method [

20].

The current research focus on 316L stainless steel powder laser cladding are primarily concentrated on improving the micro-hardness and wear resistance by adding reinforcement material [

21,

22,

23]. The influence of laser cladding processing parameters and reinforcement composite composition on the micro-hardness and wear volume in the cladding layer was rarely discovered. The performance of the cladding layer determines the successful of restoration. The micro-hardness and wear resistance are important indicators for the performance of cladding layer. This study was carried out with Taguchi orthogonal design for initial experimental runs. After analysis on the processing parameters, optimization and prediction were conducted with grey relational analysis to obtain the maximal micro-hardness and minimal wear volume simultaneously in cladding layer deposited by 316L stainless steel and SiC composite.

2. Materials and Methods

The ASTM-5140 steel was selected as the substrate in this study with the size of 40 mm × 20 mm × 10 mm, in the background of crankshaft restoration in industrial application; its elemental composition was shown in

Table 1. The powder used in laser cladding process was the mixture of 316L stainless steel powder and SiC powder produced by Xiangcheng Yuteng Ceramic Product CO., LTD (Zhangzhou, China) with both particle sizes ranging from 48 to 106 μm, which met the requirement for the equipment specifications.

Table 1 also shows the elemental composition of the aforementioned two type of cladding powders.

The laser cladding system used in this study was schematically illustrated in

Figure 1. Four sub-systems build up the whole system, consisting control system, laser system, chamber system, powder and gas delivery system. The whole system was operated under the PLC control system made by Mitsubishi, Japan. The laser system included YLS-3000 laser generator and SX14-012PULSE laser pulse control produced by IPG Photonics (Burbach, Germany). The generated laser energy was transmitted into the FDH0273 laser cladding nozzle with 300 mm focal length (Lasermech, Novi, MI, USA) to complete the laser cladding process in the chamber system, where the M-710iC/50 industrial robot (FANUC, Yamanashi, Japan) and the TFLW-4000WDR-01-3385 water cooling system (Sanhe Tongfei, Sanhe, China) were equipped. Argon gas was utilized as the carrier and protective gas by the CR-PGF-D-2 powder and gas delivery system (Songxing, Fuzhou, China) during the cladding process.

Before the laser cladding process, the surface of ASTM-5140 steel substrate was cleaned with acetone. In the preparation of the laser cladding powder mixture, the 316L stainless steel powder and SiC powder were mixed in a MITR-YXQM-2L ball mill at a 400 rpm speed for 30 min, and then dried in a vacuum dryer at 80 °C for another 30 min afterwards [

24,

25]. This study utilized an orthogonal array with five factors and four levels, with one factor as blank. The other four factors were the four processing parameters to be investigated in this study, as shown in

Table 2. A full factorial experimental design would require 4

4 = 256 runs to include all the combinations in the four factors and four levels design. The Taguchi orthogonal design is a method of designing the experiment, which reduces the number of runs versus the full factorial design and obtains the optimal combination through orthogonal matrix [

26,

27]. Thus, a L

16 (4

4) Taguchi orthogonal design was developed with 16 runs, as shown in

Table 3.

The laser cladding process was conducted following the setup in

Table 3, one sample was obtained for each run. After the completion, the 16 samples were prepared by linear cutting, grinding, and aqua regia immersing for measurement and testing in latter steps. After the sample preparation, the micro-hardness was tested by a 402TS micro-hardness tester (HDNS, Shanghai, China) with applying 500 g force for 30-s duration. The measurement location was at the subsurface of the clad to guarantee the accuracy, since the incomplete melted material on top surface of the clad, while the bottom layer of the clad was diffused by the Cr and C element from the substrate. The wear resistance was interpreted by the indicator of wear volume. The wear volume was tested by a UMT-2 high load scratch tester (Bruker, Billerica, MA, USA) applying constant reciprocating scratch for 30 min. Then the 3D morphology was obtained for the scratch surface on each sample by white light interferometry. Afterwards, the wear volume was acquired for each sample [

24,

25].

Table 3 shows the micro-hardness and wear volume for each sample clad manufactured under different processing parameters. For instance, it can be found that the micro-hardness of pure 316L stainless steel coating was in a range of 17.4 HRC to 19.0 HRC, which can be derived from run #1, #9, #12, and #14 (0% SiC powder ratio).

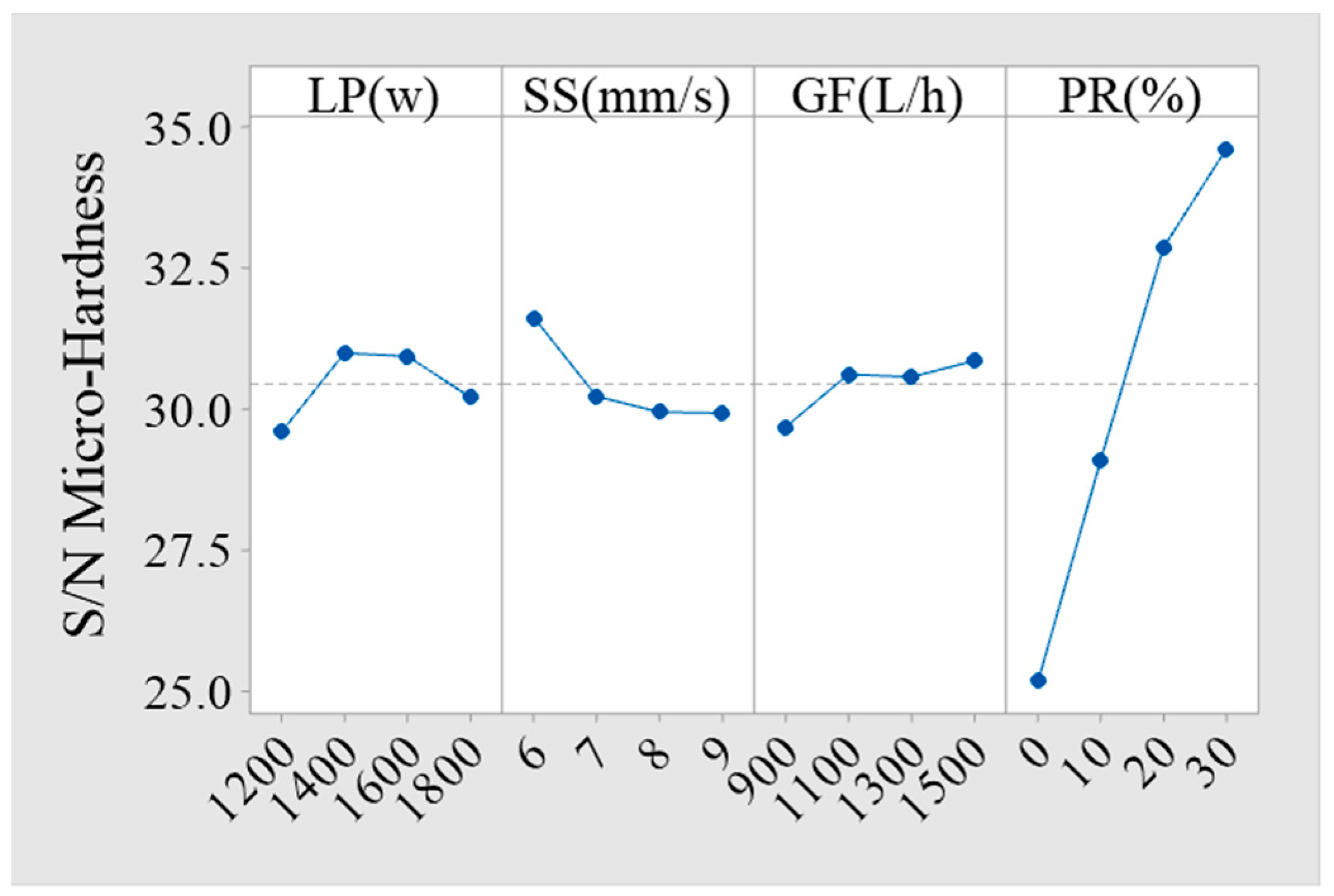

Signal to noise ratio (S/N) is the indicator of the stability in experiments. The conversion from the raw data to S/N reduces the variability in the raw data resulted from the uncontrollable noise factor, where the noise factor lead to unpredictable error on the result. S/N indicates the influence of error on the result by measuring the difference between the expected result value and actual result value [

27,

28,

29]. Therefore, S/N conversion is an applicable tool used for optimization in data analysis [

30,

31]. According to the purpose of this study: the micro-hardness is expected to be the larger the better, while the wear volume is expected to be the smaller the better, Equation (1) and (2) were used to covert the actual values shown in

Table 3 to its corresponding S/N for the micro-hardness and wear volume, respectively. The S/N conversion results for micro-hardness and wear volume are shown in

Table 4.

where n is the number of replica for each run, as n = 1 in this study, Equation (1) and (2) are simplified as shown above; Y

i (i = 1, 2, 3, …, 16) is the corresponding result in the ith run [

32,

33,

34,

35]. Afterwards, analysis of variance (ANOVA) was conducted to investigate the influence of different processing parameters on the micro-hardness and wear volume. The significance level, α was set at 0.05. In the end, grey relational analysis was used in simultaneous multi-objectives optimization to achieve the maximal micro-hardness and minimal wear volume.