Experimental Study on Flexural Capacity of Corroded RC Slabs Reinforced with Basalt Fiber Textile

Abstract

1. Introduction

2. Experimental Program

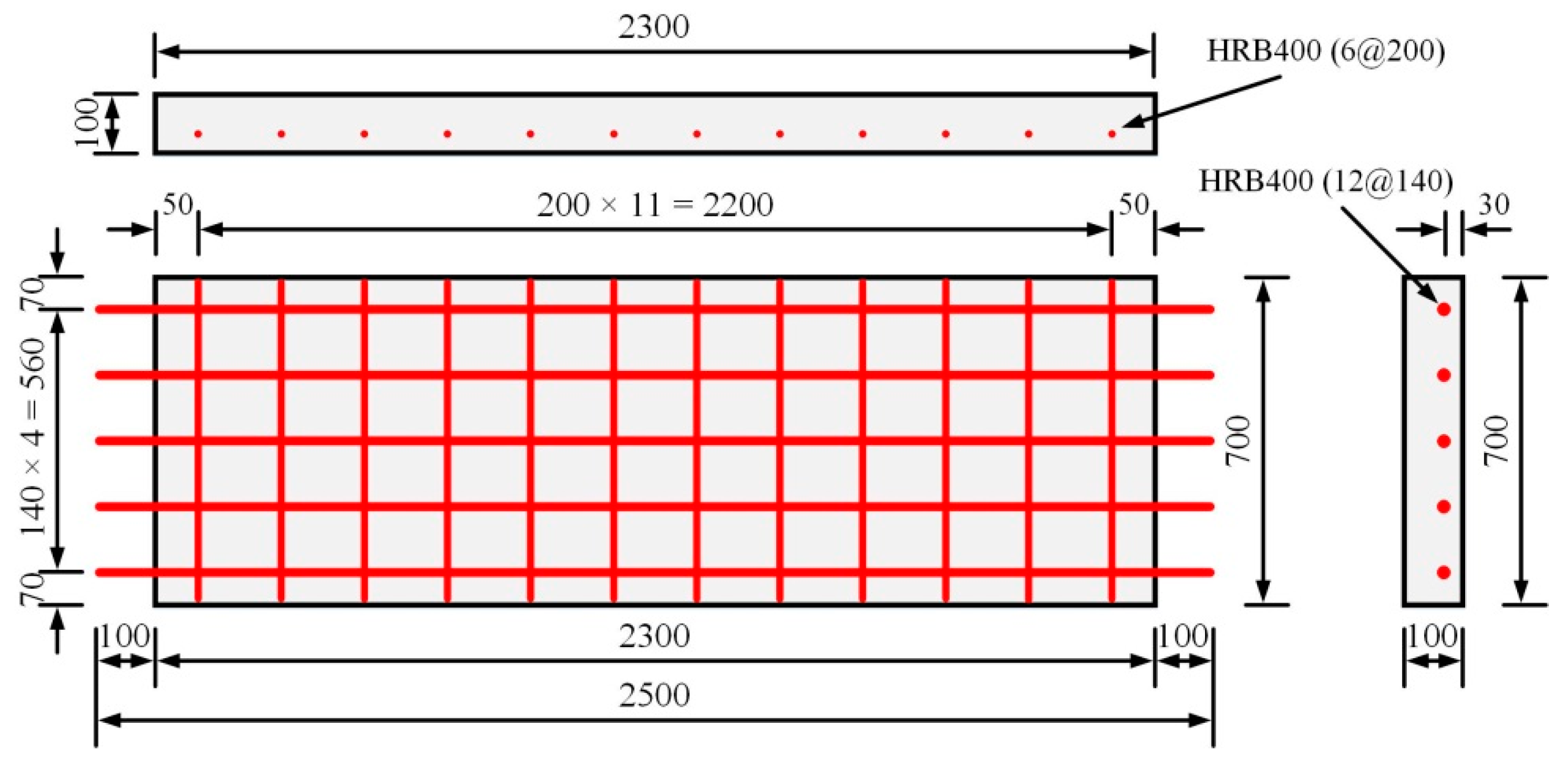

2.1. Test Specimens

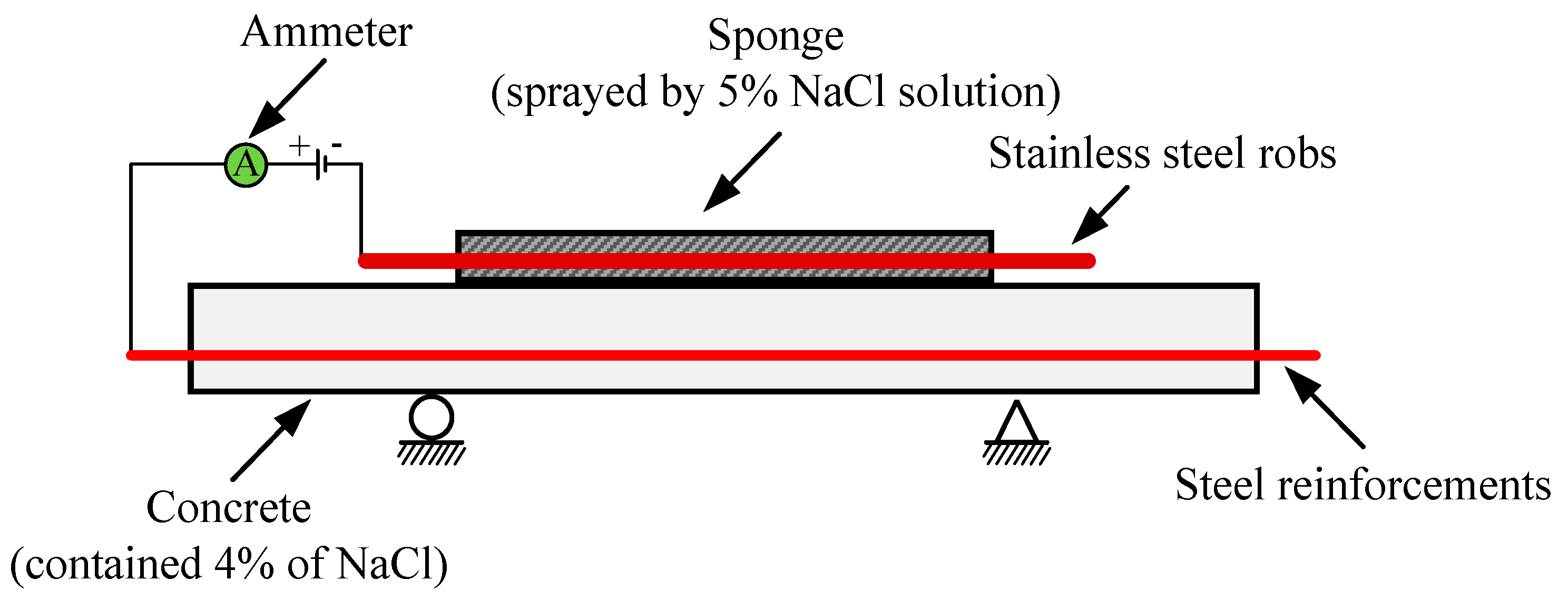

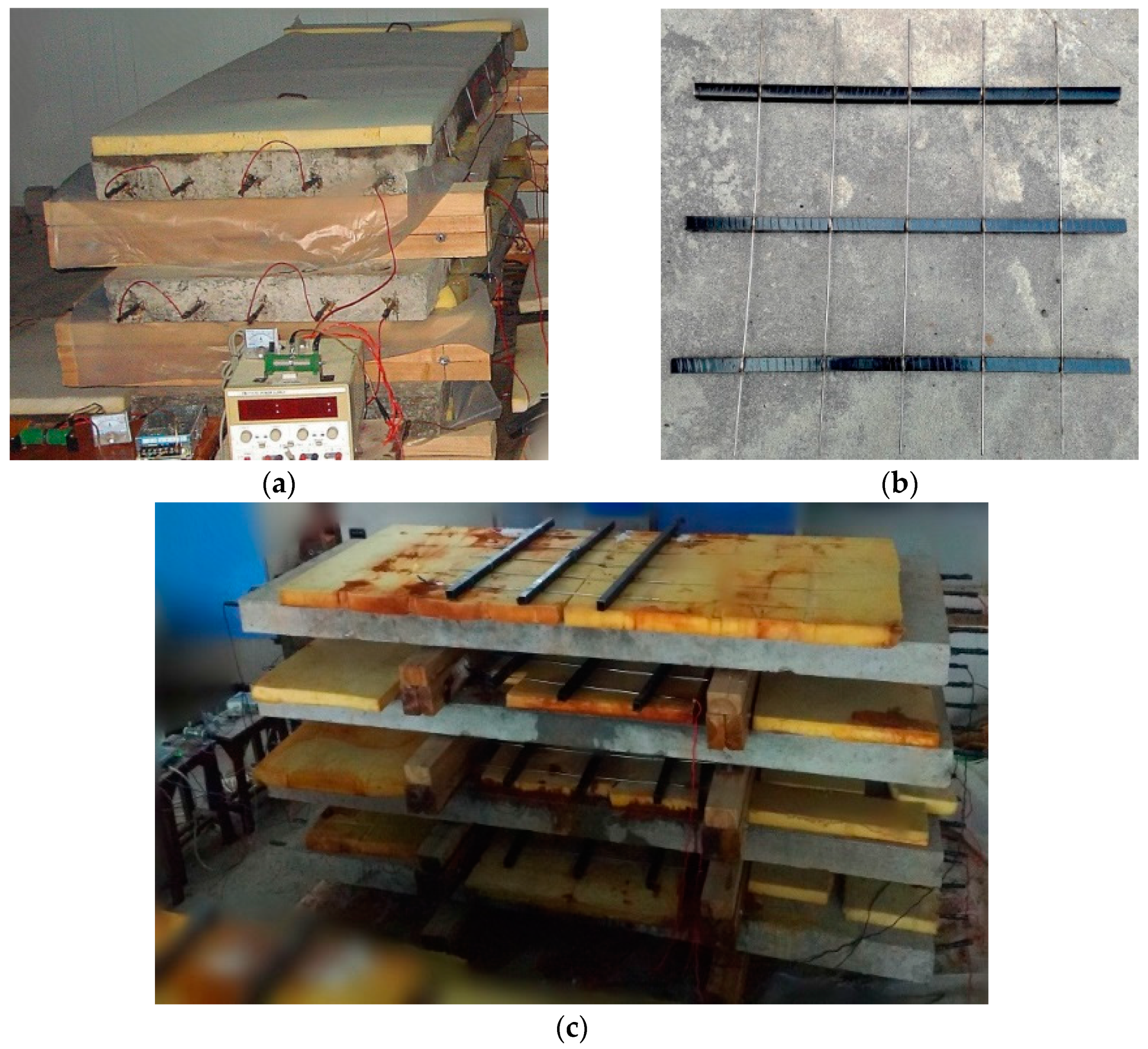

2.2. Accelerated Corrosion Scheme

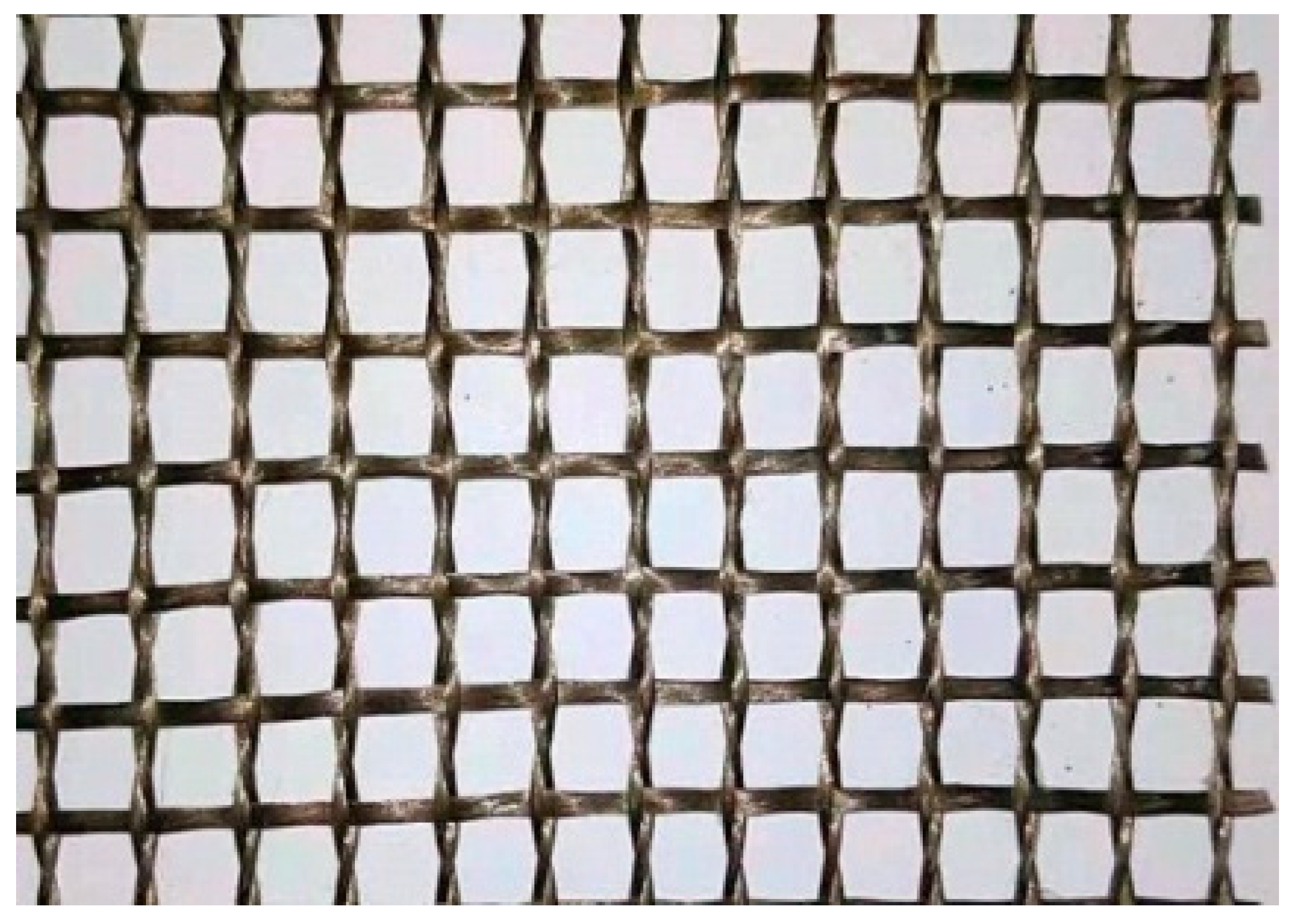

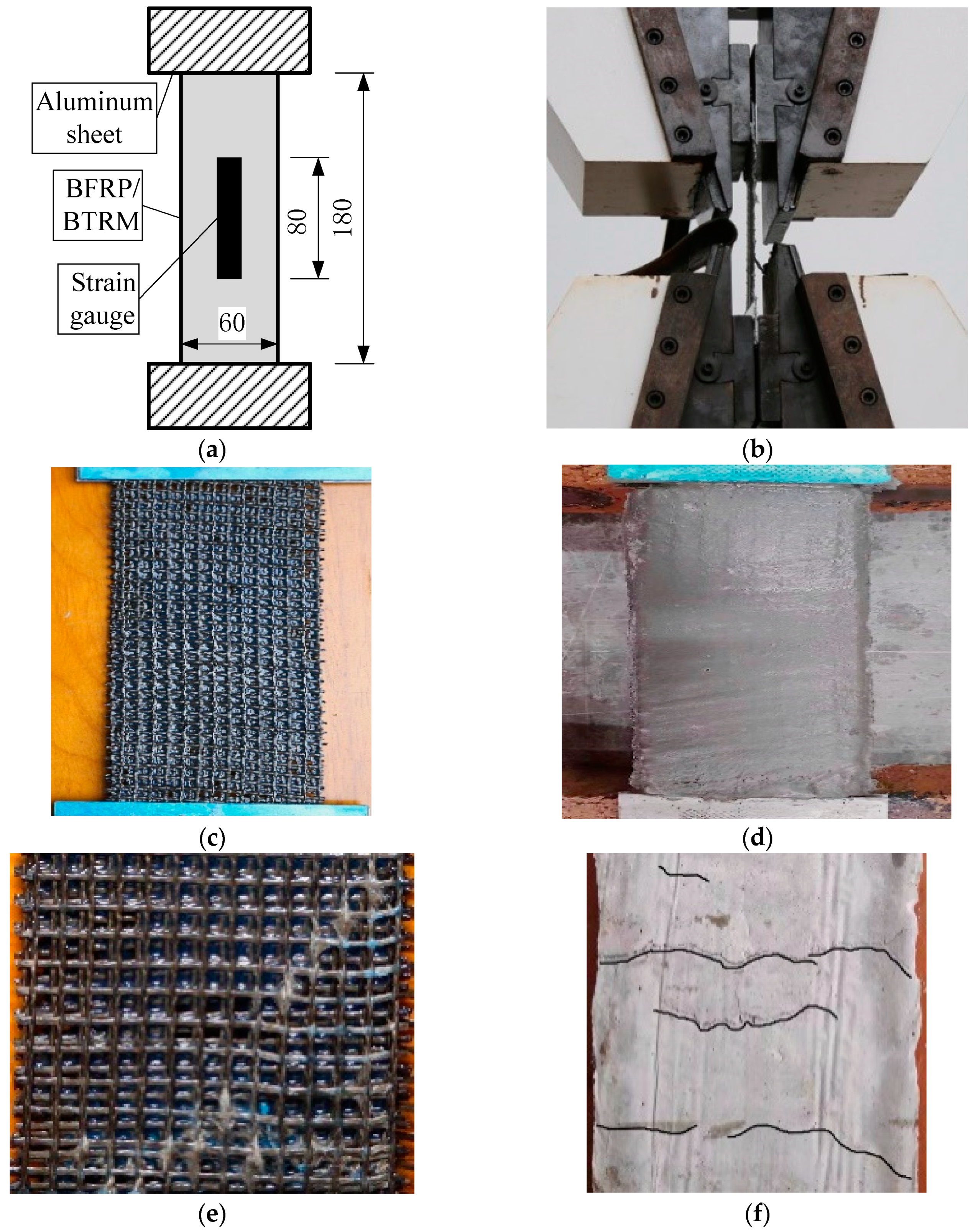

2.3. Strengthening Material Properties

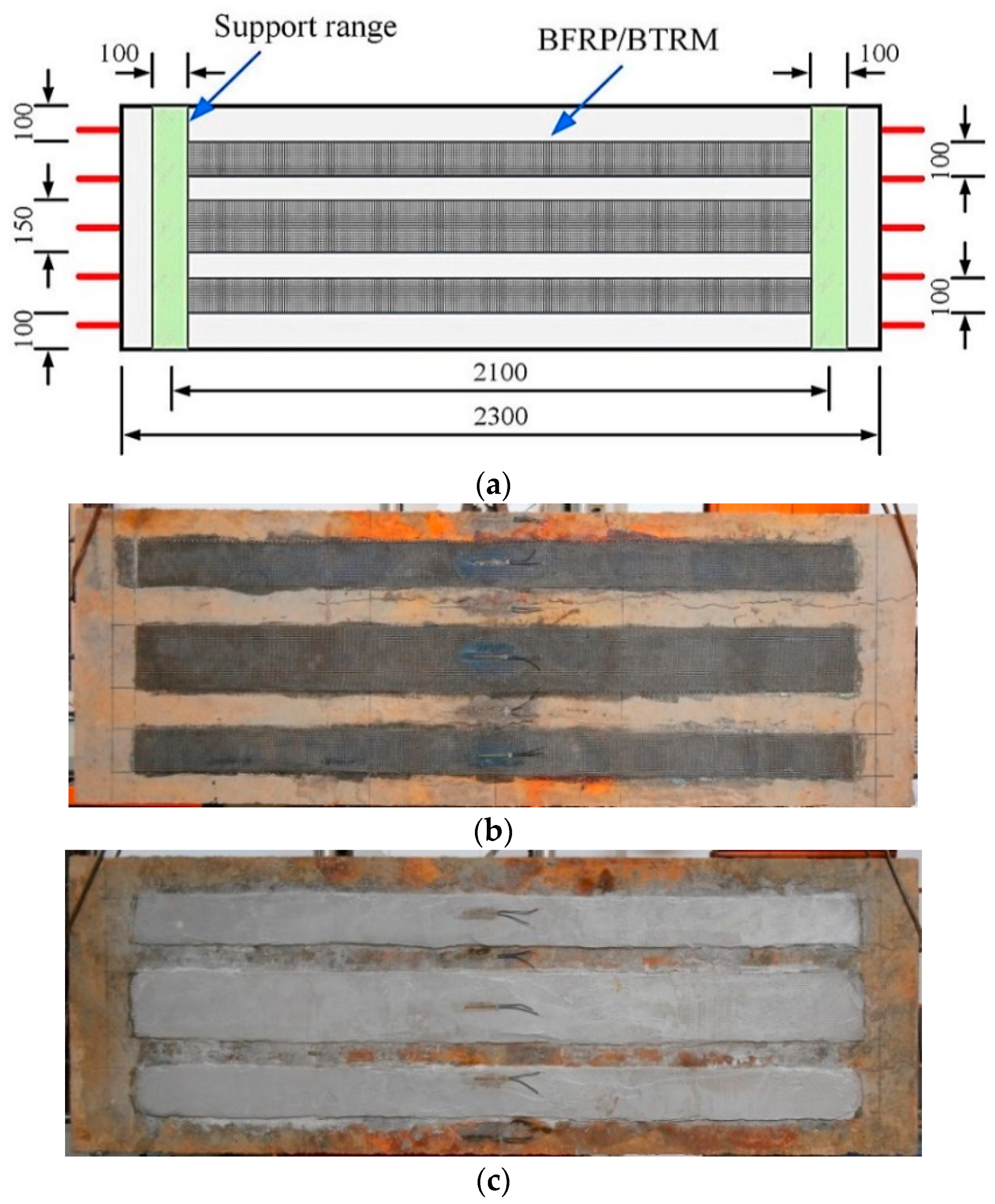

2.4. Strengthening Scheme

- (1)

- The concrete surface was prepared as follows: firstly, marking out the areas where the BFRP or BTRM should be bonded; then, roughening the surface concrete with a bush hammer for to a depth of approximately 3 mm; and finally cleaning the dust with compressed air.

- (2)

- The procedure for BFRP-strengthened specimens included: brushing textile with adhesive layer by layer and then compacting the layers with a plastic roller. To satisfy the adhesive soaking sufficiently and remove the excess polymer, each layer of the composite material was rolled 5 times by using a plastic roller.

- (3)

- The procedure for BTRM-strengthened specimens included: (a) wetting the concrete surface with water; (b) paving mortar and textile layer by layer to ensure good impregnation of mortar for the textile; and controlling overall thickness of BTRM by 10 mm. In detail, the first and last layers of BTRM were mortar layers, the thickness of each being 2 mm. The thickness of intermediate layers was uniform and related to the number of textile layers. For example, if the BTRM contained 3 textile layers, the thickness of each intermediate layer would be 2 mm.

2.5. Test Setup and Instrumentation

3. Experimental Results and Discussion

3.1. Accelerated Corrosion Results

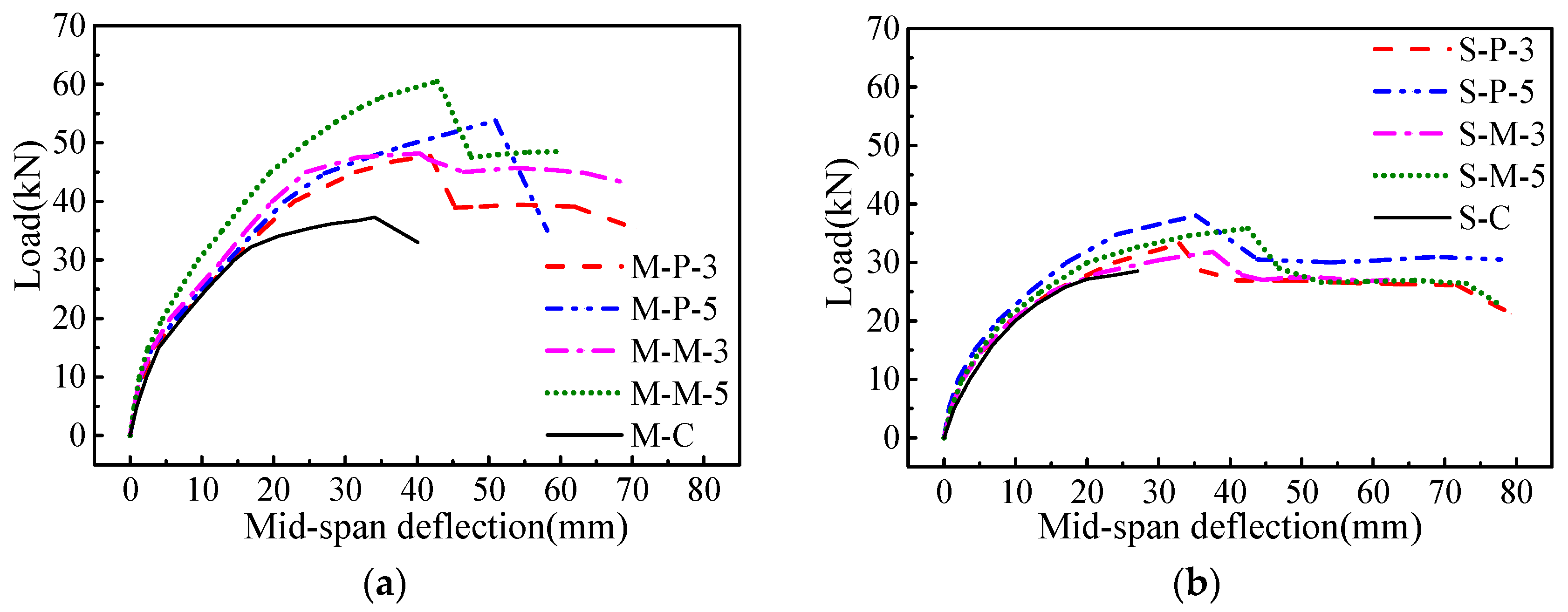

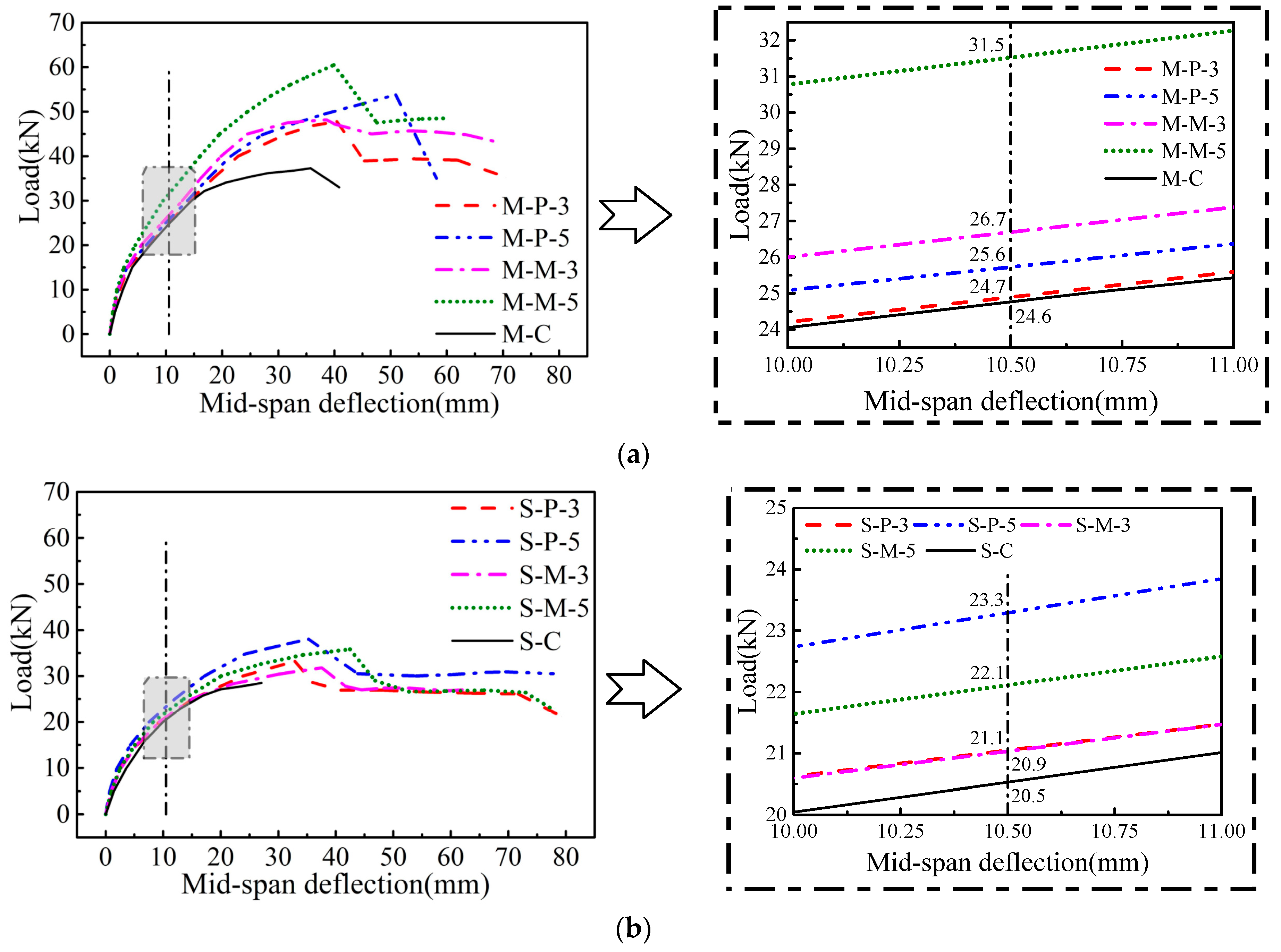

3.2. Load–Deflection Curves

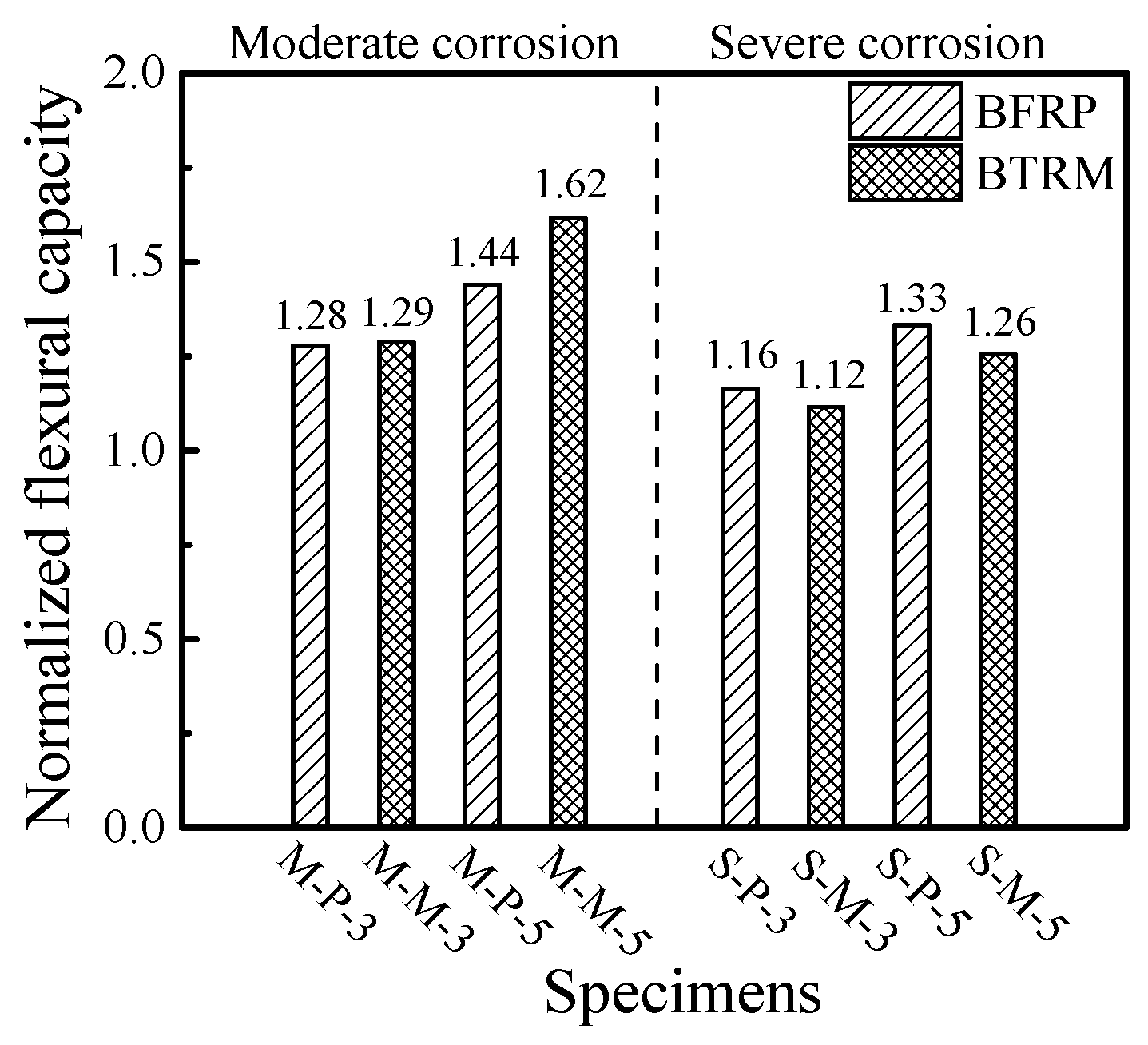

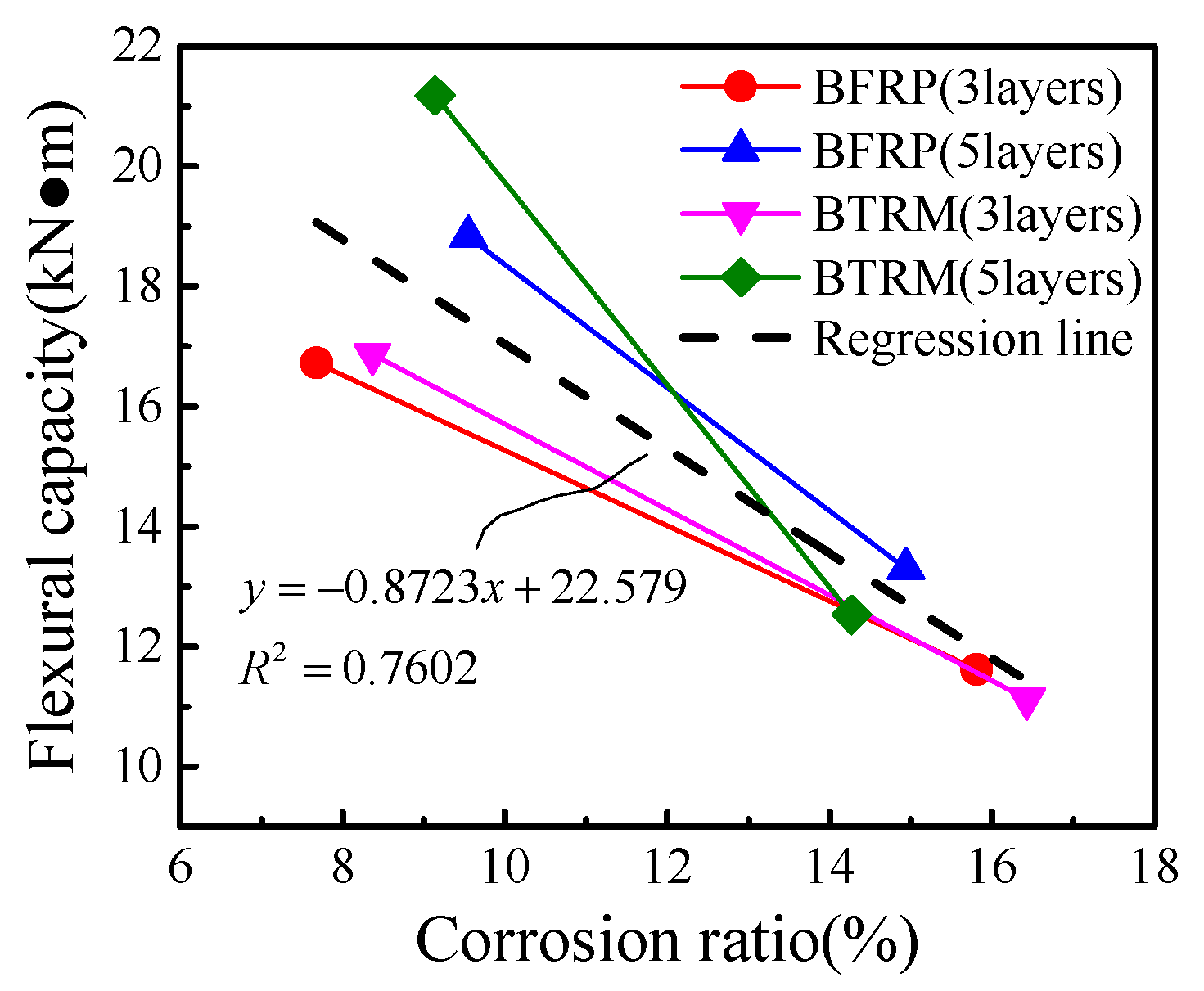

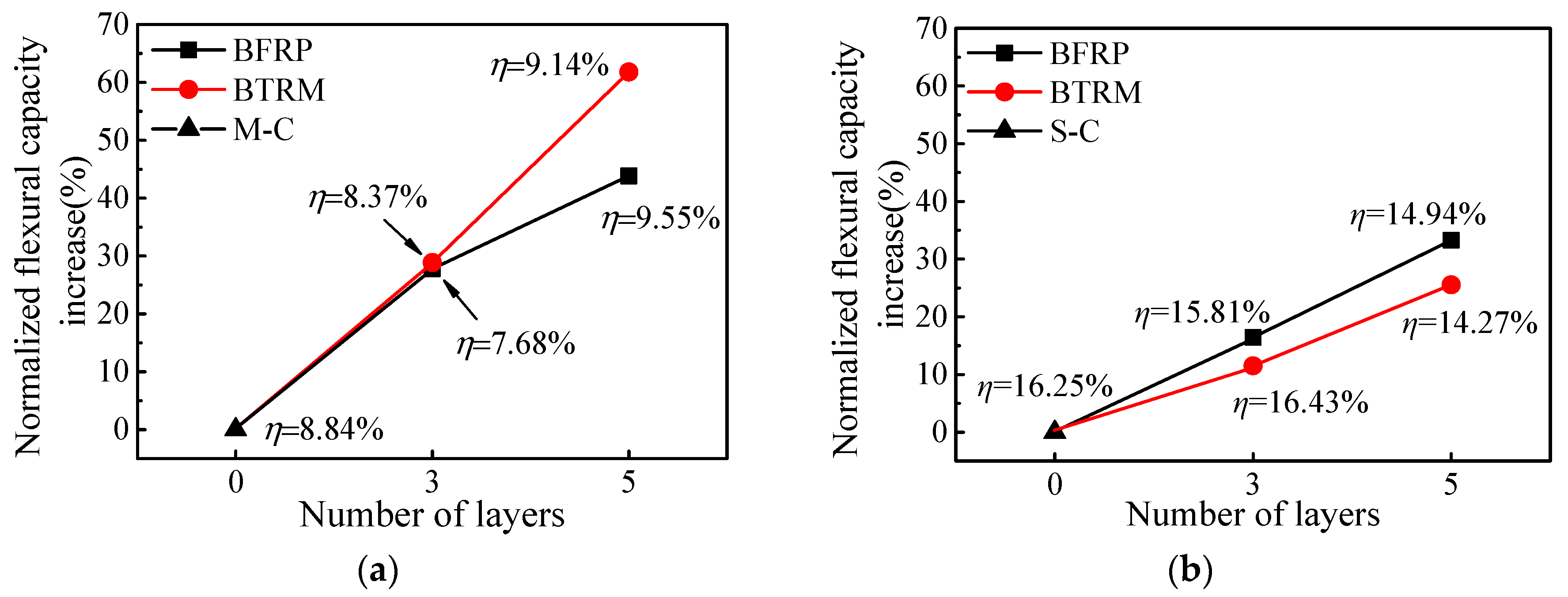

3.3. Flexural Capacity Analysis

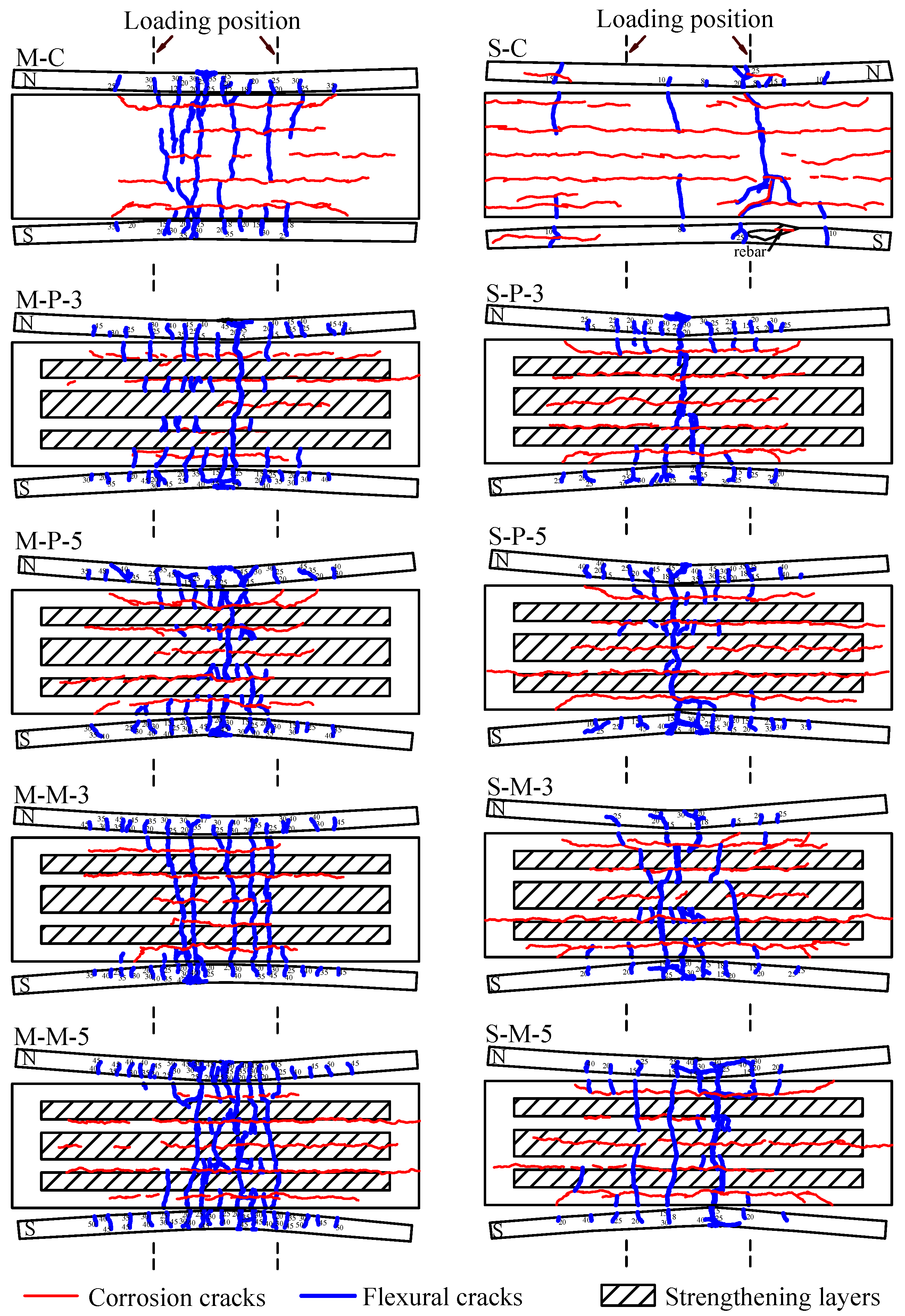

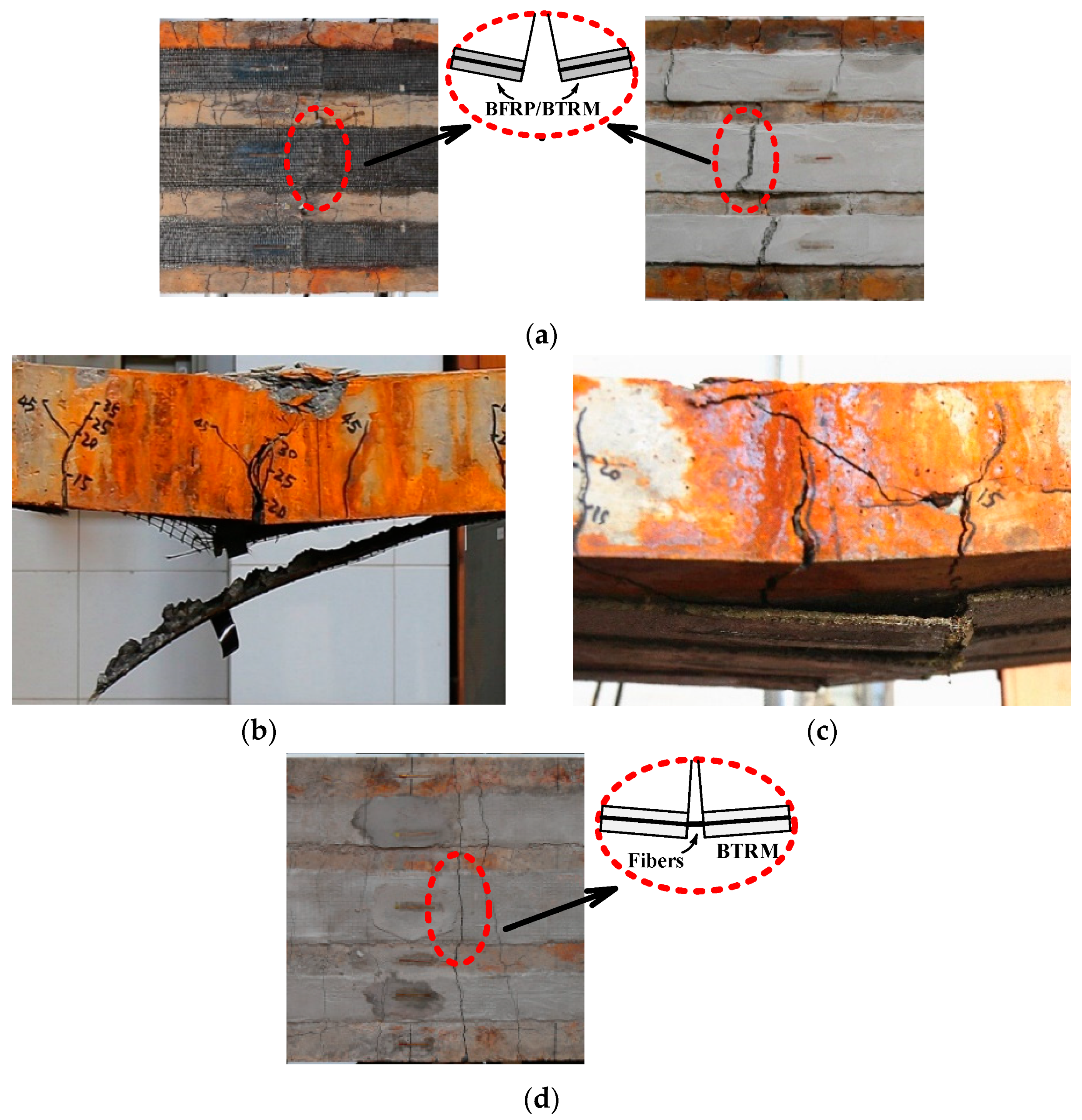

3.4. Failure Patterns

3.5. Bending Deformation Analysis

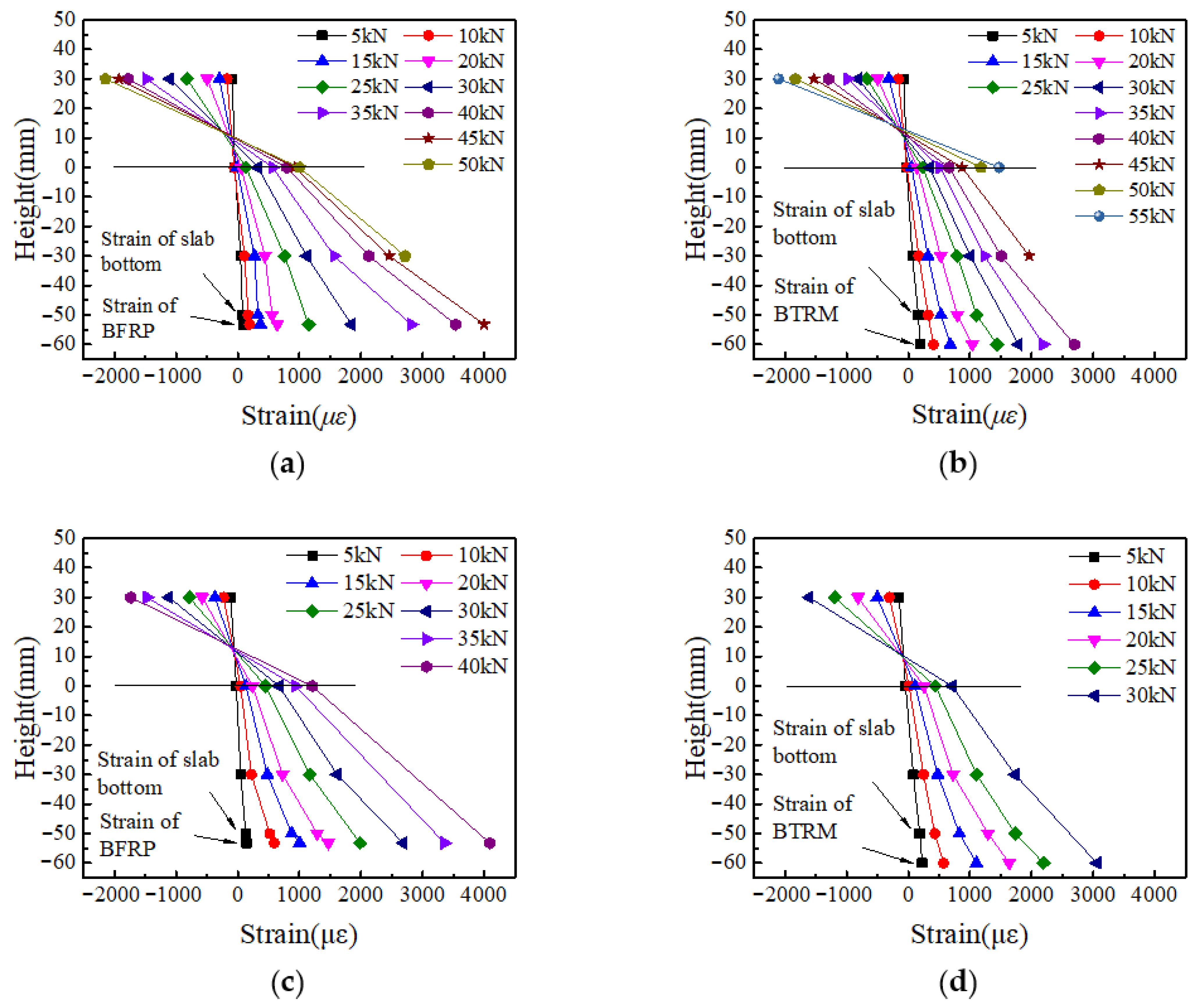

3.6. Distribution of Cross-Sectional Strain

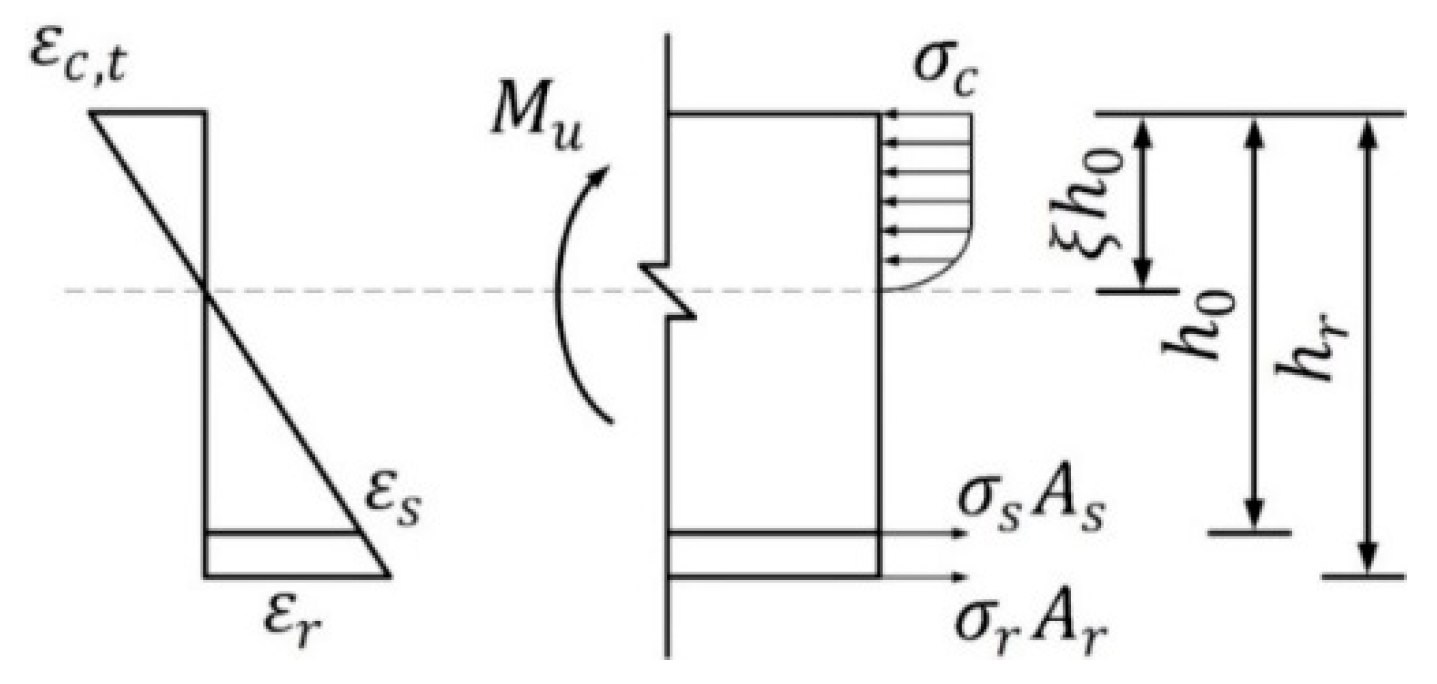

4. Flexural Capacity Analysis

4.1. Theory Assumptions

4.2. Parameters Calibration

5. Conclusions

- (1)

- The corroded RC slabs strengthened by BFRP or BTRM showed better flexural performance when compared with the un-strengthened ones in the serviceability limit state. Compared with the control slabs, the service loads of the strengthened corroded RC slabs improved by 0.41% to 28.05% in the serviceability limit state (Ds = l0/200 mm). Moreover, the service load of BTRM-strengthened slabs increased more significantly than that of BFRP-strengthened slabs, which shows that BTRM composites are more effective in terms of improving the flexural performance of corroded slabs in the serviceability limit state.

- (2)

- Both BFRP and BTRM composites can be fully used to improve the flexural capacity of corroded RC slabs in the ultimate limit state. The improvement effect of flexural capacity by BFRP and BTRM composites has a certain relationship with the initial corrosion ratio. The flexural capacities were increased by 27.81%~61.85% under the moderate corrosion condition and 11.52%~33.27% under the severe corrosion condition, respectively. Under the same strengthening condition, the flexural capacities of moderately corroded RC slabs improved more significantly than that of the severely corroded slabs. The flexural capacity improvement also increased with the number of strengthening layers. By increasing the number of textile layers from three to five, the increments of the flexural capacity of the strengthened slabs almost doubled under different corrosion conditions.

- (3)

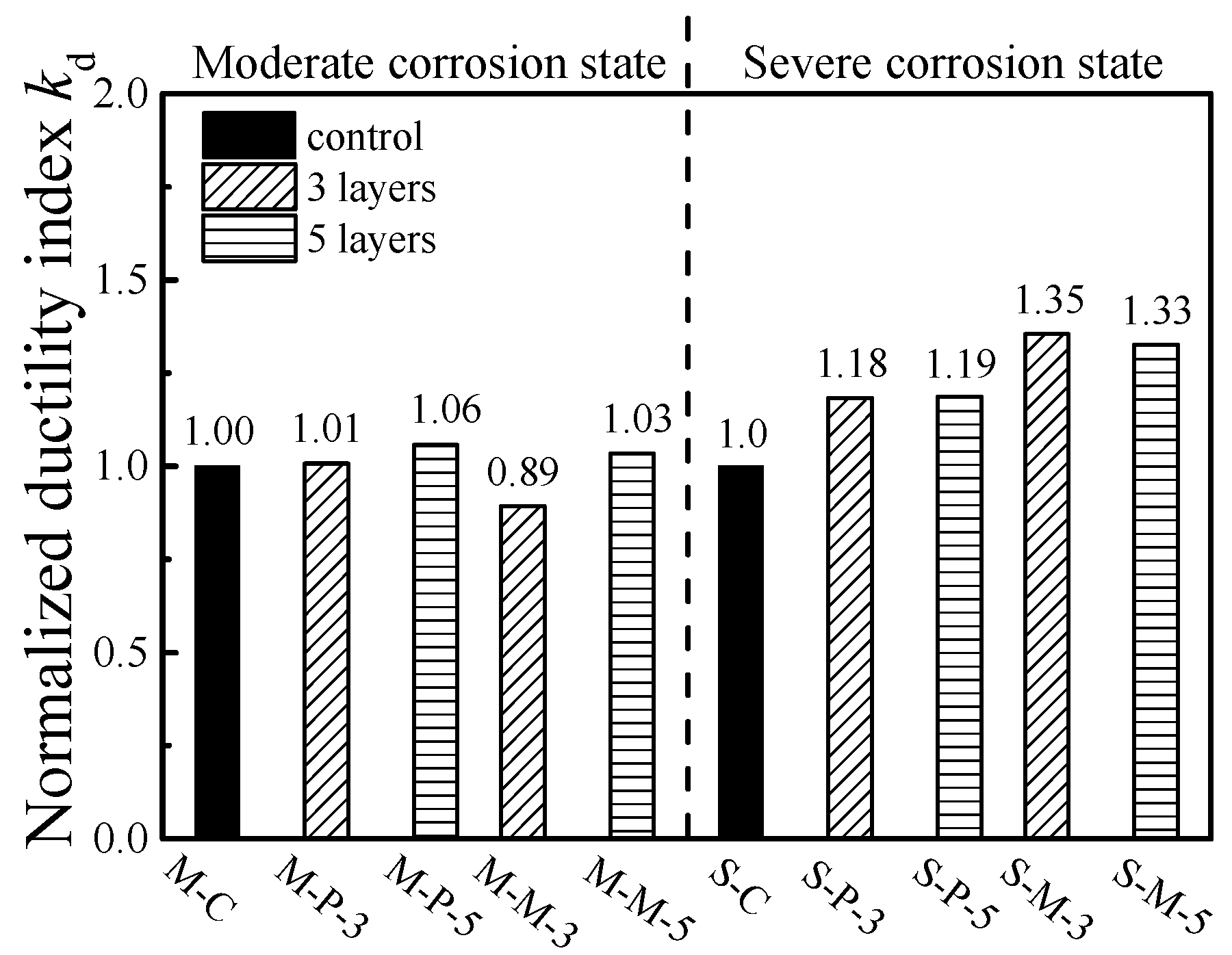

- The experiments showed that both BFRP and BTRM can improve the deformation performance of corroded RC slabs, especially under severe corrosion conditions. Compared with the control slabs, the ductility indexes of strengthened slabs increased slightly under the moderate corrosion condition, even a little lower than that of the control slabs. However, these indexes increased by 18%~35% under the severe corrosion condition. It was observed from the test that all strengthened slabs, except for M-P-5, undergo a long ductile deformation process at the post-peak stage.

- (4)

- Based on the damage characteristics of the specimens and the plane section assumption, this study proposed a scheme for calculating the flexural capacity of strengthened corroded RC slabs, which included consideration of the reduction in tensile and bonding performance of corroded steel bars. By comparison, the calculated flexural capacity values of corroded RC slabs strengthened with BFRP and BTRM are in a good agreement with the test results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Al-Saidy, A.; Al-Harthy, A.; Al-Jabri, K.; Abdul-Halim, M.; Al-Shidi, N. Structural performance of corroded RC beams repaired with CFRP sheets. Compos. Struct. 2010, 92, 1931–1938. [Google Scholar] [CrossRef]

- Chen, Z.; Lee, S.; Ng, M.; Tang, J.; Wan, L.; Liu, M.; Lee, L. Study of Design Configurations for Strengthening RC Slabs using BFRP. Sci. Eng. Compos. Mater. 2008, 15, 165–174. [Google Scholar] [CrossRef]

- Zhou, Y. Research on Flexural Performance and Durability of Corroded Reinforced Concrete Beams Strengthened with CFRP. Master’s Thesis, The School College of Aerospace Engineering, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2018. (In Chinese). [Google Scholar]

- Ray, I.; Parish, G.C.; Davalos, J.F.; Chen, A. Effect of Concrete Substrate Repair Methods for Beams Aged by Accelerated Corrosion and Strengthened with CFRP. J. Aerosp. Eng. 2011, 24, 227–239. [Google Scholar] [CrossRef]

- Zhou, S.; Lǚ, H.; WU, Y.; Gao, J. Flexural behavior of middle (serious) deteriorated RC beams strengthened with CFRP. J. China Univ. Min. Technol. 2016, 45, 62–69. (In Chinese) [Google Scholar]

- Luan, H.-Y.; Fan, Y.-F.; Chen, A.; Zhang, S.-Y. Exploratory experimental study on flexural behavior of CFRP-reinforced concrete beams subjected to acidic loading effect. Adv. Struct. Eng. 2018, 21, 2184–2197. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, J.; Jin, F.; Zhang, C. Effect of corroded tension reinforcements on flexural performance of reinforced recycled aggregate concrete beams strengthened with CFRP. Compos. Part B Eng. 2019, 162, 589–599. [Google Scholar] [CrossRef]

- Hu, B.; Zhou, Y.; Xing, F.; Sui, L.; Luo, M. Experimental and theoretical investigation on the hybrid CFRP-ECC flexural strengthening of RC beams with corroded longitudinal reinforcement. Eng. Struct. 2019, 200, 109717. [Google Scholar] [CrossRef]

- Liu, Y.; Fan, Y. Experimental Study on Flexural Behavior of Prestressed Concrete Beams Reinforced by CFRP under Chloride Environment. Adv. Civ. Eng. 2019, 2019. [Google Scholar] [CrossRef]

- EI-Maaddawy, T.; Soudki, K. Carbon-Fiber-Reinforced Polymer Repair to Extend Service Life of Corroded Reinforced Concrete Beams. J. Compos. Constr. 2005, 9, 187–194. [Google Scholar] [CrossRef]

- Raoof, S.M.; Koutas, L.N.; Bournas, D.A. Textile-reinforced mortar (TRM) versus fibre-reinforced polymers (FRP) in flexural strengthening of RC beams. Constr. Build. Mater. 2017, 151, 279–291. [Google Scholar] [CrossRef]

- Ai, S.; Ying, S.; Xu, S. A review on the development of research and application of textile reinforced concrete. China Civ. Eng. J. 2015, 48, 27–40. (In Chinese) [Google Scholar]

- Bernat-Maso, E.; Escrig, C.; Aranha, C.A.; Gil, L. Experimental assessment of Textile Reinforced Sprayed Mortar strengthening system for brickwork wallettes. Constr. Build. Mater. 2014, 50, 226–236. [Google Scholar] [CrossRef]

- Koutas, L.N.; Tetta, Z.; Bournas, D.A.; Triantafillou, T.C. Strengthening of Concrete Structures with Textile Reinforced Mortars: State-of-the-Art Review. J. Compos. Constr. 2019, 23, 03118001. [Google Scholar] [CrossRef]

- Long, N.M.; Phuong, P.V.; Duong, T.-T.; Truong, Q.P.T.; Pham, T.M.; Ngo-Huu, C.; Rovňák, M. Flexural-strengthening efficiency of CFRP sheets for unbonded post-tensioned concrete T-beams. Eng. Struct. 2018, 166, 1–15. [Google Scholar]

- Gao, W.-Y.; Dai, J.-G.; Teng, J.G. Fire resistance design of un-protected FRP-strengthened RC beams. Mater. Struct. 2016, 49, 5357–5371. [Google Scholar] [CrossRef]

- Sim, J.; Park, C.; Moon, D.Y. Characteristics of basalt fiber as a strengthening material for concrete structures. Compos. Part B Eng. 2005, 36, 504–512. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Di Bella, G.; Valenza, A. A review on basalt fibre and its composites. Compos. Part B Eng. 2015, 74, 74–94. [Google Scholar] [CrossRef]

- Ouyang, L.; Gao, W.; Zhen, B.; Lu, Z. Seismic retrofit of square reinforced concrete columns using basalt and carbon fiber-reinforced polymer sheets: A comparative study. Compos. Struct. 2017, 162, 294–307. [Google Scholar] [CrossRef]

- Nerilli, F.; Vairo, G. Strengthening of reinforced concrete beams with basalt-based FRP sheets: An analytical assessment. AIP Conf. Proc. 2016, 1738, 270016. [Google Scholar]

- Monaldo, E.; Nerilli, F.; Vairo, G. Basalt-based fiber-reinforced materials and structural applications in civil engineering. Compos. Struct. 2019, 214, 246–263. [Google Scholar] [CrossRef]

- Wang, H.; Sun, W.; Yang, X. Experimental research on flexural behavior of reinforced concrete beams strengthened by basalt fiber cloth in chlorine salt environment. Build. Struct. 2015, 45, 86–89. (In Chinese) [Google Scholar]

- Wang, H.; Wang, B.; Yang, X.; Sheng, P. Effects of acid, alkaline and chlorine salt on flexural behavior of reinforced concrete beams strengthened by basalt fiber cloth. Build. Struct. 2015, 45, 81–85. (In Chinese) [Google Scholar]

- Wang, H.; Zhang, J.; Yang, X. Experimental study of flexural performance of damaged RC beams strengthened with BFRP sheets. Build. Struct. 2015, 45, 152–156. (In Chinese) [Google Scholar]

- Zhu, J. Reinforced Beam Strengthened with Fiber Reinforced Polymer Considering the Feature of Rebar Corosion. Master’s Thesis, Architectural Engineering Institute, Zhejiang University, Hangzhou, China, 2013. (In Chinese). [Google Scholar]

- Qin, L. Research on Mechanical Behavior of Damaged Concrete Beams Strengthened with BFRP Sheet. Ph.D. Thesis, School of Transportation Science and Technology, Harbin Institute Technology, Harbin, China, 2014. (In Chinese). [Google Scholar]

- Bournas, D.A.; Lontou, P.V.; Papanicolaou, C.G.; Triantafillou, T. Textile-Reinforced Mortar versus Fiber-Reinforced Polymer Confinement in Reinforced Concrete Columns. ACI Struct. J. 2007, 104, 740–748. [Google Scholar]

- Yin, S.-P.; Sheng, J.; Wang, X.-X.; Li, S.-G. Experimental Investigations of the Bending Fatigue Performance of TRC-Strengthened RC Beams in Conventional and Aggressive Chlorate Environments. J. Compos. Constr. 2016, 20, 04015051. [Google Scholar] [CrossRef]

- Yin, S.-P.; Na, M.-W.; Yu, Y.-L.; Wu, J. Research on the flexural performance of RC beams strengthened with TRC under the coupling action of load and marine environment. Constr. Build. Mater. 2017, 132, 251–261. [Google Scholar] [CrossRef]

- Escrig, C.; Gil, L.; Bernat-Maso, E. Experimental comparison of reinforced concrete beams strengthened against bending with different types of cementitious-matrix composite materials. Constr. Build. Mater. 2017, 137, 317–329. [Google Scholar] [CrossRef]

- Loreto, G.; Leardini, L.; Arboleda, D.; Nanni, A. Performance of RC slab-type elements strengthened with fabric-reinforced cementitious-matrix composites. J. Compos. Constr. 2014, 18, A4013003. [Google Scholar] [CrossRef]

- Gopinath, S.; Murthy, A.R.; Iyer, N.R.; Prabha, M. Behaviour of reinforced concrete beams strengthened with basalt textile reinforced concrete. J. Ind. Text. 2014, 44, 924–933. [Google Scholar] [CrossRef]

- Lampros, N.K.; Dionysios, A.B. Flexural strengthening of two-way RC slab with textile-reinforced motar: Experimental investigation and design equations. J. Compos. Constr. 2017, 21, 04016065. [Google Scholar]

- Elsanadedy, H.M.; Almusallam, T.H.; Alsayed, S.H.; All-Salloum, Y. Flexural strengthening of RC beams using textile reinforced mortar-experimental and numerical study. Compos. Struct. 2013, 97, 40–55. [Google Scholar] [CrossRef]

- El-Maaddawy, T.; El-Refai, A. Innovative repair of severely corroded t-beams using fabric-reinforced cementitious matrix. J. Compos. Constr. 2016, 20, 04015073. [Google Scholar] [CrossRef]

- Elghazy, M.; Refai, A.E.; Ebead, U.A.; Nanni, A. Performance of corrosion-aged reinforced concrete (RC) beams rehabilitated with fabric-reinforced cementitious matrix (FRCM). In Proceedings of the 4th International Conference in Sustainable Construction Materials and Technologies, Las Vegas, NV, USA, 7–11 August 2016. [Google Scholar]

- Elghazy, M.; Elrefai, A.; Ebead, U.; Nanni, A. Corrosion-Damaged RC Beams Repaired with Fabric-Reinforced Cementitious Matrix. J. Compos. Constr. 2018, 22, 04018039. [Google Scholar] [CrossRef]

- Elghazy, M.; El-Refai, A.; Ebead, U.; Nanni, A. Post-repair flexural performance of corrosion-damaged beams repaired with fabric-reinforced cementitious matrix (FRCM). Constr. Build. Mater. 2018, 166, 732–744. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Development of China (MOHURD). Code for Design of Concrete Structures (GB50010-2010); China Architecture & Building Press: Beijing, China, 2015.

- Standardization Technology Committee of Fiber Reinforced Plastics (TC39). Test Method for Tensile Properties of Orientation Fiber Reinforced Polymer Matrix Composite Materials (GB/T 3354-2014); Standardization Administration of China: Beijing, China, 2014.

- Standardization Technology Committee of Fiber Reinforced Plastics (TC39). Fiber-Reinforced Plastics Composites Determination of Tensile Properties (GB/T 1447-2005); Standardization Administration of China: Beijing, China, 2005.

- Ministry of Housing and Urban-Rural Development of China (MOHURD). Technical Code for Safety Appraisal of Engineering Structural Strengthening Materials (GB50728-2011); China Architecture & Building Press: Beijing, China, 2011.

- Ministry of Housing and Urban-Rural Development of China (MOHURD). Chinese National Standard, Standard for Test Method of Concrete Structure (GB/T 50152-2012); China Architecture & Building Press: Beijing, China, 2012.

- Fang, L.; Zhou, Z.; Yi, D. Research on flexural behavior of corroded reinforced concrete slabs with HRB500 bars. J. Hunan Univ. 2020, 47, 84–94. (In Chinese) [Google Scholar]

- Wu, Q.; Zhuang, Y. Calculation method for flexural capacity of corroded RC beams reinforced concrete beams. Concrete 2011, 8, 10–14. (In Chinese) [Google Scholar]

- Jin, W.; Yuan, Y.; Wei, J.; Wang, H.L. Durability Theory and Design Method of Concrete Structures in Chloride Environment; Science Press: Beijing, China, 2011. (In Chinese) [Google Scholar]

- Caurns, J. Strength of concrete beams during concrete breakout. In Proceedings of the IABSE Symposium on Extending the Lifespan of Structures, San Francisco, CA, USA, 23–25 August 1995; pp. 500–504. [Google Scholar]

| Textile | Weight Per Area (g/m2) | Cross Section Area (mm2) | No. of Yarns | Elasticity Modulus (GPa) | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|---|---|---|

| Basalt | 221 | 0.201 | 12 | 35.1 (0.068) * | 725.95 (0.062) | 2.07 (0.055) |

| Types | Layers (n) | Nominal Thickness * (mm) | Tensile Strength (MPa) | Elongation Ratio (%) | Elasticity Modulus (GPa) |

|---|---|---|---|---|---|

| BFRP | 3 | 1.071 (0.043) ** | 147.53 (0.062) | 2.87 (0.053) | 4.964 (0.063) |

| BFRP | 5 | 1.785 (0.047) | 153.10 (0.069) | 3.00 (0.048) | 5.032 (0.059) |

| BTRM | 3 | 10.000 | 17.97 (0.071) | 2.21 (0.071) | 0.798 (0.070) |

| BTRM | 5 | 10.000 | 23.61 (0.066) | 2.45 (0.064) | 0.918 (0.076) |

| Specimen ID | Initial Corrosion State (Expected Corrosion Ratio) (%) | Number of Textile Layers | Strengthening Material |

|---|---|---|---|

| M-C | 8 | − | − |

| M-P-3 | 8 | 3 | BFRP |

| M-P-5 | 8 | 5 | BFRP |

| M-M-3 | 8 | 3 | BTRM |

| M-M-5 | 8 | 5 | BTRM |

| S-C | 16 | − | − |

| S-P-3 | 16 | 3 | BFRP |

| S-P-5 | 16 | 5 | BFRP |

| S-M-3 | 16 | 3 | BTRM |

| S-M-5 | 16 | 5 | BTRM |

| Specimen ID | Expected Corrosion Ratio (%) | Actual Corrosion Period (days) | Measured Corrosion Ratio * η (%) | Mean Corrosion Crack Width (mm) | Maximum Corrosion Crack Width (mm) |

|---|---|---|---|---|---|

| M-C | 8% | 118 | 8.83 | 0.268 | 0.704 |

| M-P-3 | 8% | 115 | 7.68 | 0.320 | 0.680 |

| M-P-5 | 8% | 115 | 9.55 | 0.322 | 0.735 |

| M-M-3 | 8% | 115 | 8.37 | 0.217 | 0.490 |

| M-M-5 | 8% | 115 | 9.14 | 0.228 | 0.522 |

| H-C | 16% | 200 | 16.25 | 0.363 | 0.845 |

| H-P-3 | 16% | 210 | 15.81 | 0.446 | 1.210 |

| H-P-5 | 16% | 210 | 14.94 | 0.434 | 1.250 |

| H-M-3 | 16% | 215 | 16.43 | 0.410 | 1.381 |

| H-M-5 | 16% | 215 | 14.27 | 0.432 | 1.169 |

| Specimen ID | Corrosion Ratio η (%) | Yield Load Fy (kN) | Percentage Increase of Fy (%) | Ultimate Load Fu (kN) | Flexural Capacity Mu (kN∙m) | Percentage Increase of Mu (%) |

|---|---|---|---|---|---|---|

| M-C | 8.84 | 31.8 | − | 37.4 | 13.09 | − |

| M-P-3 | 7.68 | 38.7 | 21.70 | 47.8 | 16.73 | 27.81 |

| M-P-5 | 9.55 | 43.3 | 36.16 | 53.8 | 18.83 | 43.85 |

| M-M-3 | 8.37 | 44.5 | 39.94 | 48.2 | 16.87 | 28.88 |

| M-M-5 | 9.14 | 47.7 | 50.00 | 60.5 | 21.18 | 61.80 |

| S-C | 16.25 | 24.6 | − | 28.5 | 9.98 | − |

| S-P-3 | 15.81 | 25.0 | 1.63 | 33.2 | 11.62 | 16.43 |

| S-P-5 | 14.94 | 29.3 | 19.11 | 38.0 | 13.30 | 33.27 |

| S-M-3 | 16.43 | 25.7 | 4.47 | 31.8 | 11.13 | 11.52 |

| S-M-5 | 14.27 | 28.2 | 14.63 | 35.8 | 12.53 | 25.55 |

| Specimens | Initial Stiffness (kN/mm) | Cracking Stiffness (kN/mm) | Percentage Increase (%) | Post-Yielding Stiffness (kN/mm) | Percentage Increase (%) |

|---|---|---|---|---|---|

| M-C | 5.39 | 2.27 | - | 0.73 | - |

| M-P-3 | 7.04 | 2.40 | 5.73 | 0.86 | 17.81 |

| M-P-5 | 7.01 | 2.32 | 2.20 | 0.94 | 28.77 |

| M-M-3 | 8.46 | 2.44 | 7.49 | 0.79 | 4.20 |

| M-M-5 | 8.74 | 2.67 | 17.62 | 1.04 | 42.47 |

| S-C | 3.52 | 2.07 | - | 0.59 | - |

| S-P-3 | 5.22 | 2.46 | 18.84 | 0.71 | 20.34 |

| S-P-5 | 7.15 | 3.02 | 33.04 | 0.83 | 40.68 |

| S-M-3 | 5.21 | 2.34 | 13.04 | 0.67 | 13.56 |

| S-M-5 | 5.13 | 2.58 | 24.63 | 0.86 | 45.76 |

| Specimen ID | Corrosion Ratio η (%) | Yield Deflection Dy (mm) | Ultimate Deflection Du (mm) | Ductility Index kd | Maximum Deflection in Post-Peak Stage Dmax (mm) |

|---|---|---|---|---|---|

| M-C | 8.84 | 17.751 | 34.057 | 1.908 | 34.057 |

| M-P-3 | 7.68 | 21.783 | 41.850 | 1.921 | 61.624 |

| M-P-5 | 9.55 | 25.248 | 50.931 | 2.017 | 50.931 |

| M-M-3 | 8.37 | 23.719 | 40.361 | 1.702 | 57.837 |

| M-M-5 | 9.14 | 22.096 | 42.774 | 1.973 | 59.771 |

| S-C | 16.25 | 14.954 | 27.082 | 1.811 | 27.082 |

| S-P-3 | 15.81 | 15.362 | 32.900 | 2.141 | 71.730 |

| S-P-5 | 14.94 | 16.414 | 35.268 | 2.149 | 69.532 |

| S-M-3 | 16.43 | 15.306 | 37.550 | 2.453 | 62.030 |

| S-M-5 | 14.27 | 17.677 | 42.461 | 2.402 | 72.997 |

| Specimen ID | Corrosion Ratio (%) | (kN∙m) | (kN∙m) | |

|---|---|---|---|---|

| M-J-3 | 7.68 | 16.73 | 15.76 | 1.062 |

| M-J-5 | 9.55 | 18.83 | 19.06 | 0.988 |

| M-M-3 | 8.37 | 16.87 | 18.01 | 0.937 |

| M-M-5 | 9.14 | 21.18 | 19.02 | 1.114 |

| H-J-3 | 15.81 | 11.62 | 12.34 | 0.942 |

| H-J-5 | 14.94 | 13.30 | 14.60 | 0.911 |

| H-M-3 | 16.43 | 11.13 | 13.70 | 0.812 |

| H-M-5 | 14.27 | 12.53 | 14.71 | 0.852 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, L.; Zhou, Y.; Yi, D.; Yi, W. Experimental Study on Flexural Capacity of Corroded RC Slabs Reinforced with Basalt Fiber Textile. Appl. Sci. 2021, 11, 144. https://doi.org/10.3390/app11010144

Fang L, Zhou Y, Yi D, Yi W. Experimental Study on Flexural Capacity of Corroded RC Slabs Reinforced with Basalt Fiber Textile. Applied Sciences. 2021; 11(1):144. https://doi.org/10.3390/app11010144

Chicago/Turabian StyleFang, Liang, Yun Zhou, Duhang Yi, and Weijian Yi. 2021. "Experimental Study on Flexural Capacity of Corroded RC Slabs Reinforced with Basalt Fiber Textile" Applied Sciences 11, no. 1: 144. https://doi.org/10.3390/app11010144

APA StyleFang, L., Zhou, Y., Yi, D., & Yi, W. (2021). Experimental Study on Flexural Capacity of Corroded RC Slabs Reinforced with Basalt Fiber Textile. Applied Sciences, 11(1), 144. https://doi.org/10.3390/app11010144