A Theoretical Model with Which to Safely Optimize the Configuration of Hydraulic Suspension of Modular Trailers in Special Road Transport

Abstract

:1. Introduction

2. Materials and Methods

2.1. Modular Trailers

2.2. Stability Area

2.3. Forces Acting upon the Transportation Model

2.4. Stability Calculation

2.5. Reactions of the Suspension Groups

- Load (W) and reactions (F1, F2, and F3) are perpendicular to the stability plane.

- There are no forces in X or Y and/or moment in Z. Thus, the equilibrium equations are three in number.

- The system affects quasi-static loading. That is, it is assumed that the time and mass do not influence the load.

- The ground is assumed to be a completely rigid plane.

3. Results and Discussion

3.1. Experimental Validation of the Proposed Model

- Trailer: SPMT 6-axle: weight 23.5 and maximum capacity 216.3 Tn.

- The oil pressure is supplied to the hydraulic cylinders at the axles by a Power Unit (PPU).

- Even surface: camber and slope equal zero.

- Weight: 42,500 kg.

- Dimensions: 5133 × 2650 × 2975 mm.

- CoG position: 97.5 × 0 × −180 mm.

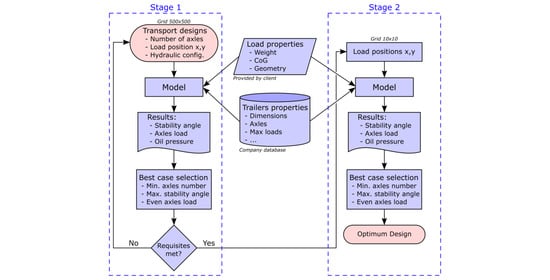

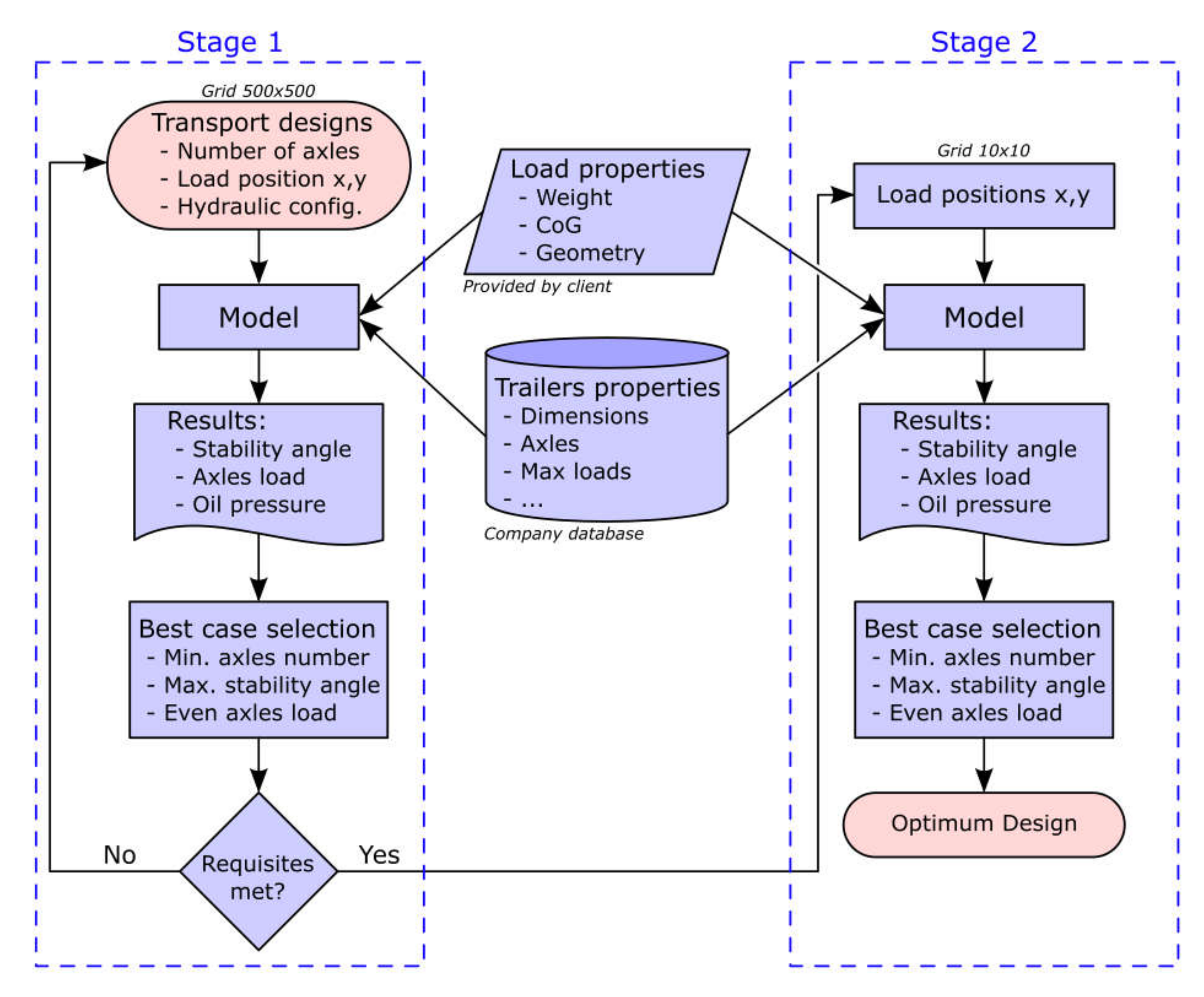

3.2. Optimization Process Proposed

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gong, I.; Lee, K.; Kim, J.; Min, Y.; Shin, K. Optimizing Vehicle Routing for Simultaneous Delivery and Pick-Up Considering Reusable Transporting Containers: Case of Convenience Stores. Appl. Sci. 2020, 10, 4162. [Google Scholar] [CrossRef]

- Conesa, J.; Cavas-Martínez, F.; Fernández-Pacheco, D.G. An agent-based paradigm for detecting and acting on vehicles driving in the opposite direction on highways. Expert Syst. Appl. 2013, 40, 5113–5124. [Google Scholar] [CrossRef]

- Water Preferred Policy: Guidelines for the Movement of Abnormal Indivisible Loads; UK Highways Agency: Birmingham, UK, 2012.

- Taylor, N.B. The Impact of Abnormal Loads on Road Traffic Congestion; Transport Research Laboratory: Berkshire, UK, 2005. [Google Scholar]

- El-Gindy, M.; Kenis, W. Influence of a Trailer’s Axle Arrangement and Load on the Stability and Control of a Tractor Tractor-Semitrailer; Federal Highway Administration: Washington, DC, USA, 1998; p. 178.

- Lisowski, F.; Lisowski, E. Testing and Fatigue Life Assessment of Timber Truck Stanchions. Appl. Sci. 2020, 10, 6134. [Google Scholar] [CrossRef]

- Kim, J. Truck Platoon Control Considering Heterogeneous Vehicles. Appl. Sci. 2020, 10, 5067. [Google Scholar] [CrossRef]

- Zhao, L.; Zhang, Y.; Yu, Y.; Zhou, C.; Li, X.; Li, H. Truck Handling Stability Simulation and Comparison of Taper-Leaf and Multi-Leaf Spring Suspensions with the Same Vertical Stiffness. Appl. Sci. 2020, 10, 1293. [Google Scholar] [CrossRef] [Green Version]

- Ervin, R.D.; Nisonger, R.L.; Mallikarjunarao, C.; Gillespie, T.D. The Yaw Stability of Tractor-Semitrailers during Cornering; Technical Report for Transportation Research Institute: Ann Arbor, MI, USA, 1979. [Google Scholar]

- Chen, Y.; Huang, S.; Davis, L.; Du, H.; Shi, Q.; He, J.; Wang, Q.; Hu, W. Optimization of Geometric Parameters of Longitudinal-Connected Air Suspension Based on a Double-Loop Multi-Objective Particle Swarm Optimization Algorithm. Appl. Sci. 2018, 8, 1454. [Google Scholar] [CrossRef] [Green Version]

- Guowei, D.; Wenhao, Y.; Zhongxing, L.; Khajepour, A.; Senqi, T. Sliding Mode Control of Laterally Interconnected Air Suspensions. Appl. Sci. 2020, 10, 4320. [Google Scholar] [CrossRef]

- Martínez, F.C.; Fernandez-Pacheco, D.G. Simulación virtual: Una tecnología para el impulso de la innovación y la competitividad en la industria. DYNA Ing. Ind. 2019, 94, 118–119. [Google Scholar]

- García, L.O.; Wilson, F.R.; Innes, J.D. Heavy truck dynamic rollover: Effect of load distribution, cargo type, and road design characteristics. Transp. Res. Rec. J. Transp. Res. Board 2003, 1851, 25–31. [Google Scholar] [CrossRef]

- Ervin, R.D.; Yoram, G. The Influence of Weights and Dimensions on the Stability and Control of Heavy Duty Trucks in Canada; Transportation Association of Canada: Ottawa, ON, Canada, 1986; Volume I, p. 132. [Google Scholar]

- Gertsch, J.; Eichelhard, O. Simulation of Dynamic Rollover Threshold for Heavy Trucks; SAE International: Warrendale, PA, USA, 2003. [Google Scholar]

- Bernard, J.; Shannan, J.; Vanderploeg, M. Vehicle Rollover on Smooth Surfaces; SAE International: Warrendale, PA, USA, 1989. [Google Scholar]

- Winkler, C.B.; Blower, D.; Ervin, R.; Chalasani, R.M. Rollover of Heavy Commercial Vehicle; University of Michigan Transportation Research Institute: Ann Arbor, MI, USA, 2000. [Google Scholar]

- BS EN 12195-1:2010. Load Restraining on Road Vehicles—Safety. Part 1: Calculation of Securing Forces; BSI: London, UK, 2013. [Google Scholar]

- Zhang, Q.; Su, C.; Zhou, Y.; Zhang, C.; Ding, J.; Wang, Y. Numerical Investigation on Handling Stability of a Heavy Tractor Semi-Trailer under Crosswind. Appl. Sci. 2020, 10, 3672. [Google Scholar] [CrossRef]

- Cooper, K.R.; Watkins, S. The Unsteady Wind Environment of Road Vehicles, Part One: A Review of the on-Road Turbulent Wind Environment; SAE International: Warrendale, PA, USA, 2007; pp. 1259–1276. [Google Scholar]

- Cai, C.S.; Chen, S.R. Framework of vehicle–bridge–wind dynamic analysis. J. Wind Eng. Ind. Aerodyn. 2004, 92, 579–607. [Google Scholar] [CrossRef]

- Hammache, M.; Browand, F. On the Aerodynamics of Tractor-Trailers. In The Aerodynamics of Heavy Vehicles: Trucks, Buses, and Trains; McCallen, R., Browand, F., Ross, J., Eds.; Springer: Berlin/Heidelberg, Germany, 2004; Volume 19, pp. 185–205. ISBN 978-3-642-53586-4. [Google Scholar]

- Mccallen, R.; Flowers, D.; Dunn, T.; Owens, J.; Browand, F.; Hammache, M.; Leonard, A.; Brady, M.; Salari, K.; Rutledge, W.; et al. Aerodynamic Drag of Heavy Vehicles (Class 7–8): Simulation and Benchmarking; SAE International: Warrendale, PA, USA, 2000. [Google Scholar]

- Bettle, J.; Holloway, A.G.L.; Venart, J.E.S. A Computational Study of the Aerodynamic Forces Acting on a Tractor-Trailer Vehicle on a Bridge in Cross-Wind. J. Wind Eng. Ind. Aerodyn. 2003, 91, 573–592. [Google Scholar] [CrossRef]

- Baker, C.J. The effects of high winds on vehicle behaviour. In Proceedings of the International Symposium on Advances in Bridge Aerodynamics, Copenhagen, Denmark, 10–13 May 1998; pp. 267–282. [Google Scholar]

- King, J.P.C.; Mikitiuk, M.J.; Davenport, A.G.; Isyumov, N. A Study of Wind Effects for the Northumberland Straits Crossing; Boundary Layer Wind Tunnel Laboratory, University of Western Ontario: London, ON, Canada, 1994. [Google Scholar]

- Scheuerle. Operating Instructions: Combi Modular Transport System. Available online: https://www.scheuerle.com/products/self-propelled-transporters/intercombi.html (accessed on 28 December 2020).

- Collett & Sons Ltd. Available online: https://www.collett.co.uk/ (accessed on 28 December 2020).

- Van Daal, M.J. The Art of the Heavy Transport; The Works international: London, UK, 2009. [Google Scholar]

- Corral Bobadilla, M.; Lostado Lorza, R.; Somovilla Gómez, F.; Escribano García, R. Adsorptive of Nickel in Wastewater by Olive Stone Waste: Optimization through Multi-Response Surface Methodology Using Desirability Functions. Water 2020, 12, 1320. [Google Scholar] [CrossRef]

- Somovilla-Gómez, F.; Lostado-Lorza, R.; Corral-Bobadilla, M.; Escribano-García, R. Improvement in determining the risk of damage to the human lumbar functional spinal unit considering age, height, weight and sex using a combination of FEM and RSM. Biomech. Model. Mechanobiol. 2020, 19, 351–387. [Google Scholar] [CrossRef] [PubMed]

- Íñiguez-Macedo, S.; Lostado-Lorza, R.; Escribano-García, R.; Martínez-Calvo, M.Á. Finite Element Model Updating Combined with Multi-Response Optimization for Hyper-Elastic Materials Characterization. Materials 2019, 12, 1019. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ruiz, L.; Torres, M.; Gómez, A.; Díaz, S.; González, J.M.; Cavas, F. Detection and Classification of Aircraft Fixation Elements during Manufacturing Processes Using a Convolutional Neural Network. Appl. Sci. 2020, 10, 6856. [Google Scholar] [CrossRef]

- Fisher, R.A. The Design of Experiments; Hafner Press: New York, NY, USA, 1974; ISBN 0-02-844690-9. [Google Scholar]

- Lendrem, D.; Owen, M.; Godbert, S. DOE (design of experiments) in development chemistry: Potential obstacles. Org. Process Res. Dev. 2001, 5, 324–327. [Google Scholar] [CrossRef]

- Weissman, S.A.; Anderson, N.G. Design of experiments (DoE) and process optimization. A review of recent publications. Org. Process Res. Dev. 2015, 19, 1605–1633. [Google Scholar] [CrossRef]

- R Core Team. R Core Team. R: A Language and Environment for Statistical Computing. Available online: https://www.r-project.org/ (accessed on 28 December 2020).

- InterCombi. Available online: https://www.scheuerle.com/products/self-propelled-transporters/intercombi.html (accessed on 28 December 2020).

| Inputs | Symbol | Unit | Levels | ||

|---|---|---|---|---|---|

| −1 | 0 | +1 | |||

| Longitudinal location of the load | X | mm | 0 | 675 | 1350 |

| Transversal location of the load | Y | mm | 0 | 175 | 350 |

| X | Y | Pressures [bar] | ||||

|---|---|---|---|---|---|---|

| A | B | C | D | |||

| 1 | 0 | 0 | 59 | 61 | 77 | 75 |

| 2 | 0 | 0 | 55 | 62 | 80 | 79 |

| 3 | 0 | 0 | 60 | 61 | 75 | 72 |

| 4 | 0 | 0 | 64 | 56 | 90 | 92 |

| 5 | 0 | 0 | 58 | 63 | 78 | 74 |

| 6 | 0 | 335 | 24 | 97 | 80 | 80 |

| 7 | 0 | 435 | 13 | 108 | 81 | 85 |

| 8 | 675 | 0 | 66 | 75 | 58 | 58 |

| 9 | 675 | 335 | 38 | 103 | 58 | 59 |

| 10 | 675 | 435 | 27 | 117 | 58 | 58 |

| 11 | 1350 | 0 | 79 | 85 | 39 | 40 |

| 12 | 1350 | 335 | 47 | 120 | 39 | 38 |

| 13 | 1350 | 435 | 38 | 127 | 38 | 38 |

| Case | Range | Mean [μ] | SD [s] |

|---|---|---|---|

| Pressure A | 9 bar | 59.2 bar | 2.9 bar |

| Pressure B | 7 bar | 60.6 bar | 2.4 bar |

| Pressure C | 15 bar | 80.0 bar | 5.3 bar |

| Pressure D | 20 bar | 78.4 bar | 7.2 bar |

| Average values | 69.55 bar | 4.45 bar |

| Case | Pressures | ||||

|---|---|---|---|---|---|

| A [bar] | B [bar] | C [bar] | D [bar] | MAPE [%] | |

| 1–5 | 59.0 | 58.0 | 84.4 | 84.4 | 4.4 |

| 6 | 28.0 | 89.3 | 84.4 | 84.4 | 8.8 |

| 7 | 18.3 | 98.7 | 84.4 | 84.4 | 13.6 |

| 8 | 69.8 | 68.9 | 62.6 | 62.6 | 7.4 |

| 9 | 38.6 | 100.2 | 62.6 | 62.6 | 4.6 |

| 10 | 29.2 | 109.6 | 62.6 | 62.6 | 7.6 |

| 11 | 80.7 | 79.8 | 40.9 | 40.9 | 3.8 |

| 12 | 49.4 | 111.1 | 40.9 | 40.9 | 6.2 |

| 13 | 40.1 | 120.4 | 40.9 | 40.9 | 6.4 |

| Average: | 7.0% | ||||

| Characteristics | Value |

|---|---|

| Load | Cylindrical tank |

| Dimensions | 19.5 × 3.2 × 2.5 m |

| Load weight | 108,500 kg |

| Trailer weight | 33,000 kg |

| Initial CoG coordinates | 0.0 × 0.2 × 2.1 m |

| Optimum CoG coordinates | 0.3 × 0.0 × 2.1 m |

| Number of trailers | 2 |

| Number of axles | 10 (4 + 6) |

| Tipping angle (on even road) | 7.2° |

| Maximum axle load | 21,600 kg |

| Oil pressures | 8.1 × 8.1 × 5.9 bar |

| Hydraulic configuration | 6, 7, 7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Escribano-García, R.; Corral-Bobadilla, M.; Somovilla-Gómez, F.; Lostado-Lorza, R.; Ahmed, A. A Theoretical Model with Which to Safely Optimize the Configuration of Hydraulic Suspension of Modular Trailers in Special Road Transport. Appl. Sci. 2021, 11, 305. https://doi.org/10.3390/app11010305

Escribano-García R, Corral-Bobadilla M, Somovilla-Gómez F, Lostado-Lorza R, Ahmed A. A Theoretical Model with Which to Safely Optimize the Configuration of Hydraulic Suspension of Modular Trailers in Special Road Transport. Applied Sciences. 2021; 11(1):305. https://doi.org/10.3390/app11010305

Chicago/Turabian StyleEscribano-García, Rubén, Marina Corral-Bobadilla, Fátima Somovilla-Gómez, Rubén Lostado-Lorza, and Ash Ahmed. 2021. "A Theoretical Model with Which to Safely Optimize the Configuration of Hydraulic Suspension of Modular Trailers in Special Road Transport" Applied Sciences 11, no. 1: 305. https://doi.org/10.3390/app11010305

APA StyleEscribano-García, R., Corral-Bobadilla, M., Somovilla-Gómez, F., Lostado-Lorza, R., & Ahmed, A. (2021). A Theoretical Model with Which to Safely Optimize the Configuration of Hydraulic Suspension of Modular Trailers in Special Road Transport. Applied Sciences, 11(1), 305. https://doi.org/10.3390/app11010305