Using a High-Power Fibre Laser to Cut Concrete

Abstract

:1. Introduction

2. Materials and Experiment Procedure

2.1. Materials

2.2. Laser Oscillator

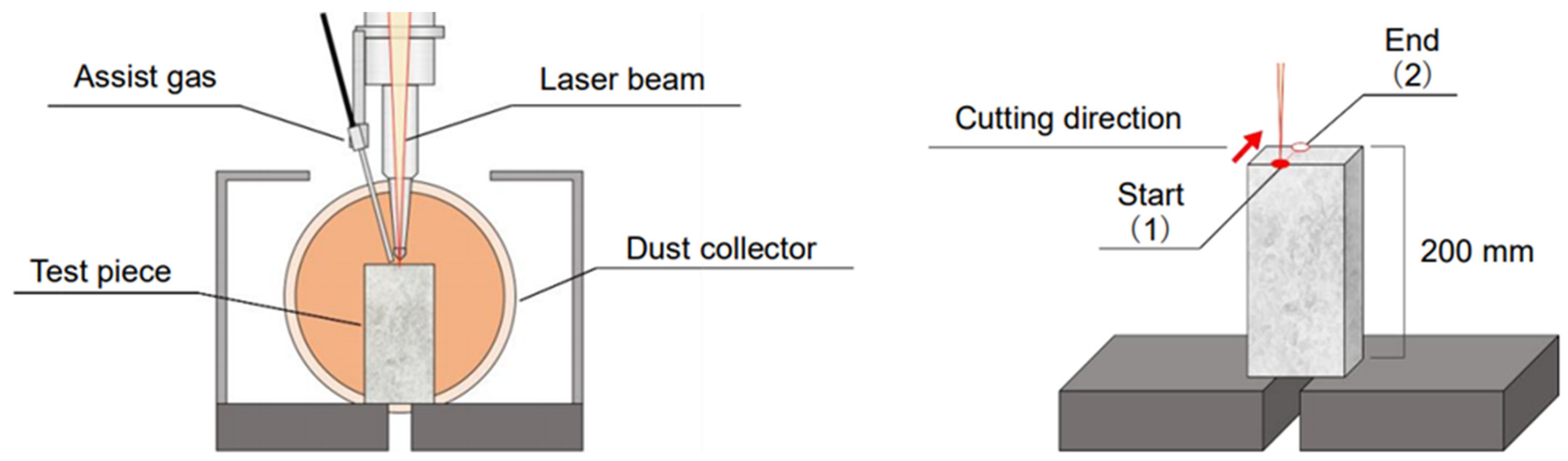

2.3. Method

2.4. Evaluation Method

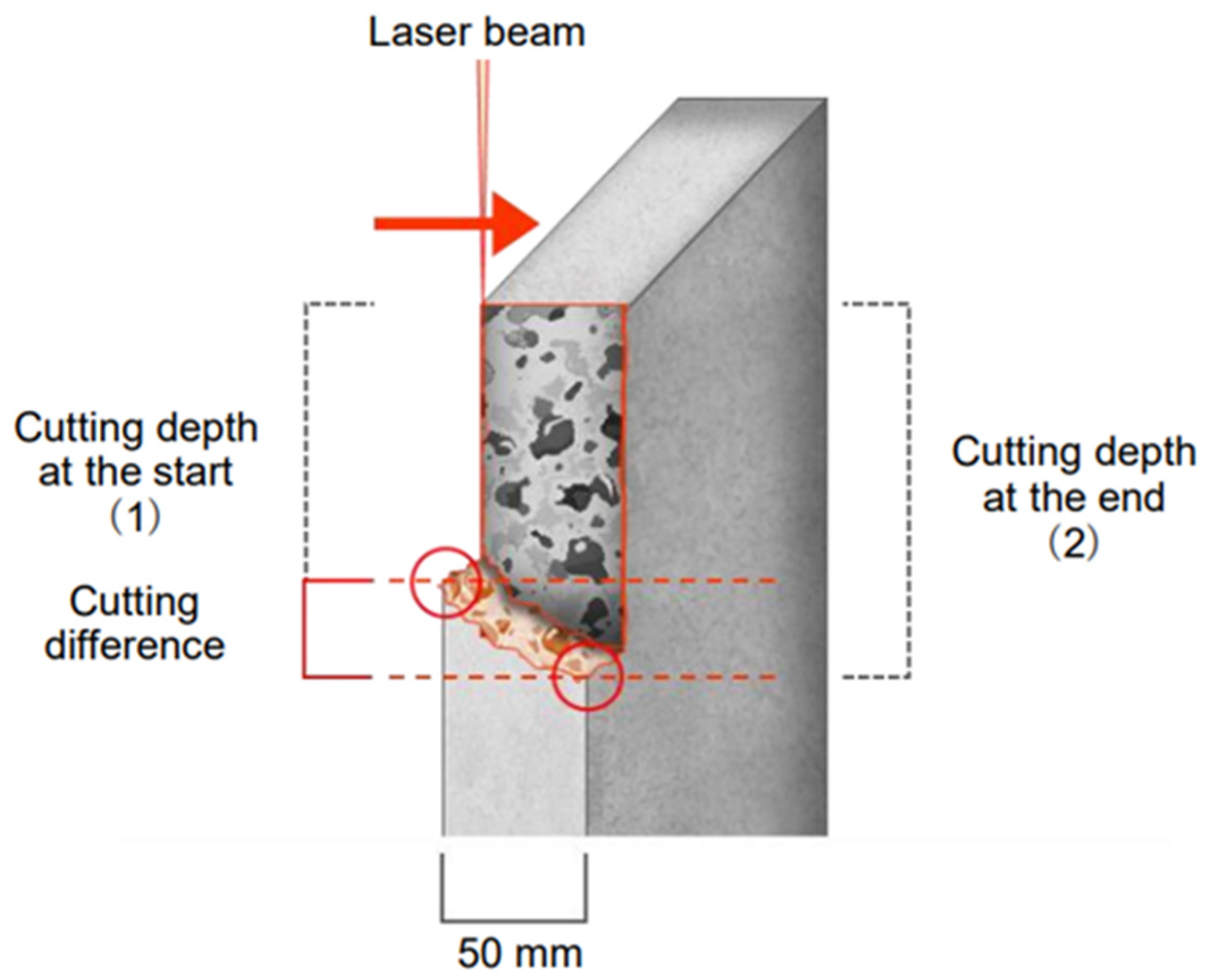

2.4.1. Measuring the Cutting Depth

2.4.2. Measuring the Presence of Vitrification, Cracking, etc.

3. Experimental Results and Discussion

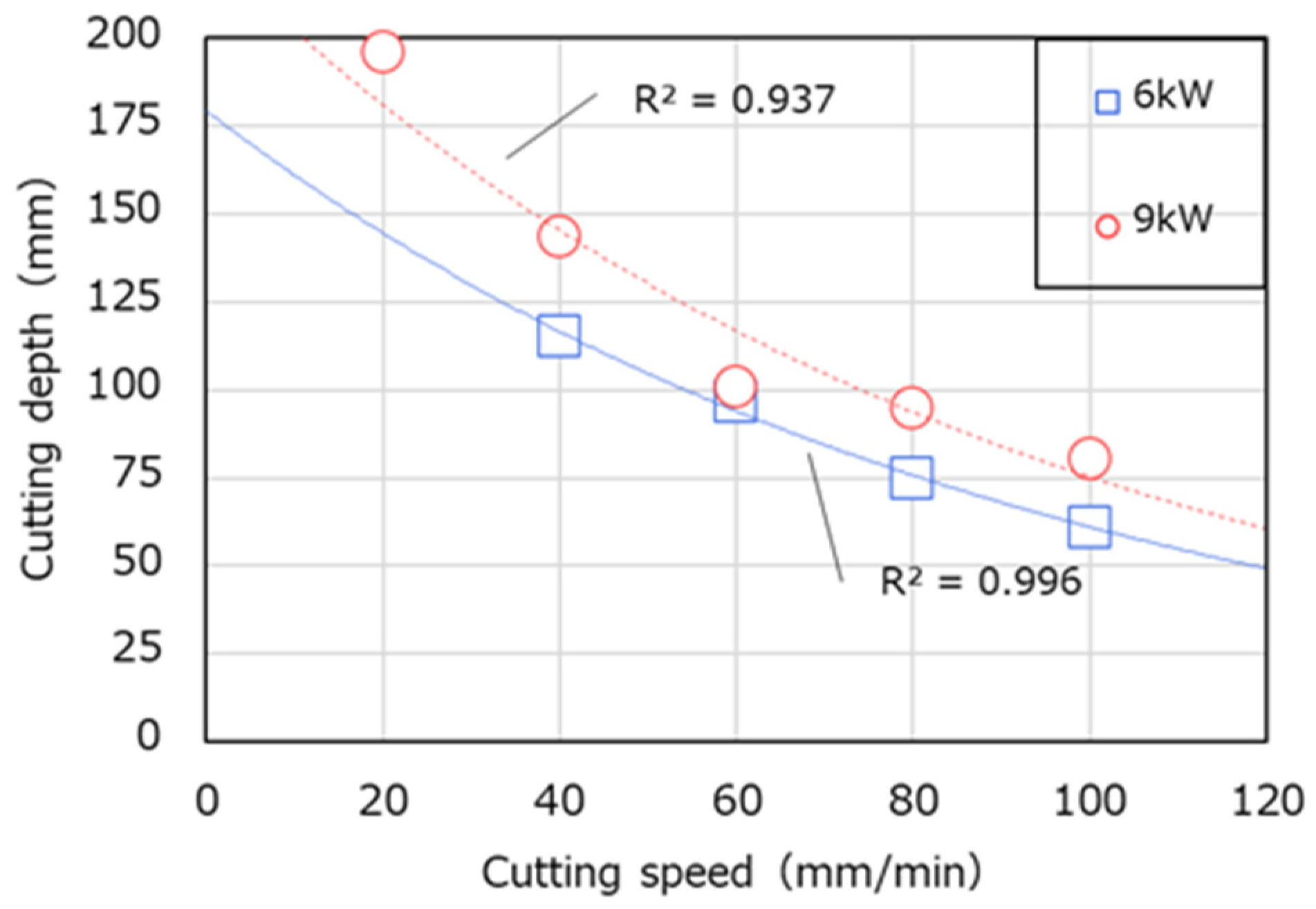

3.1. Comparison of Laser Power

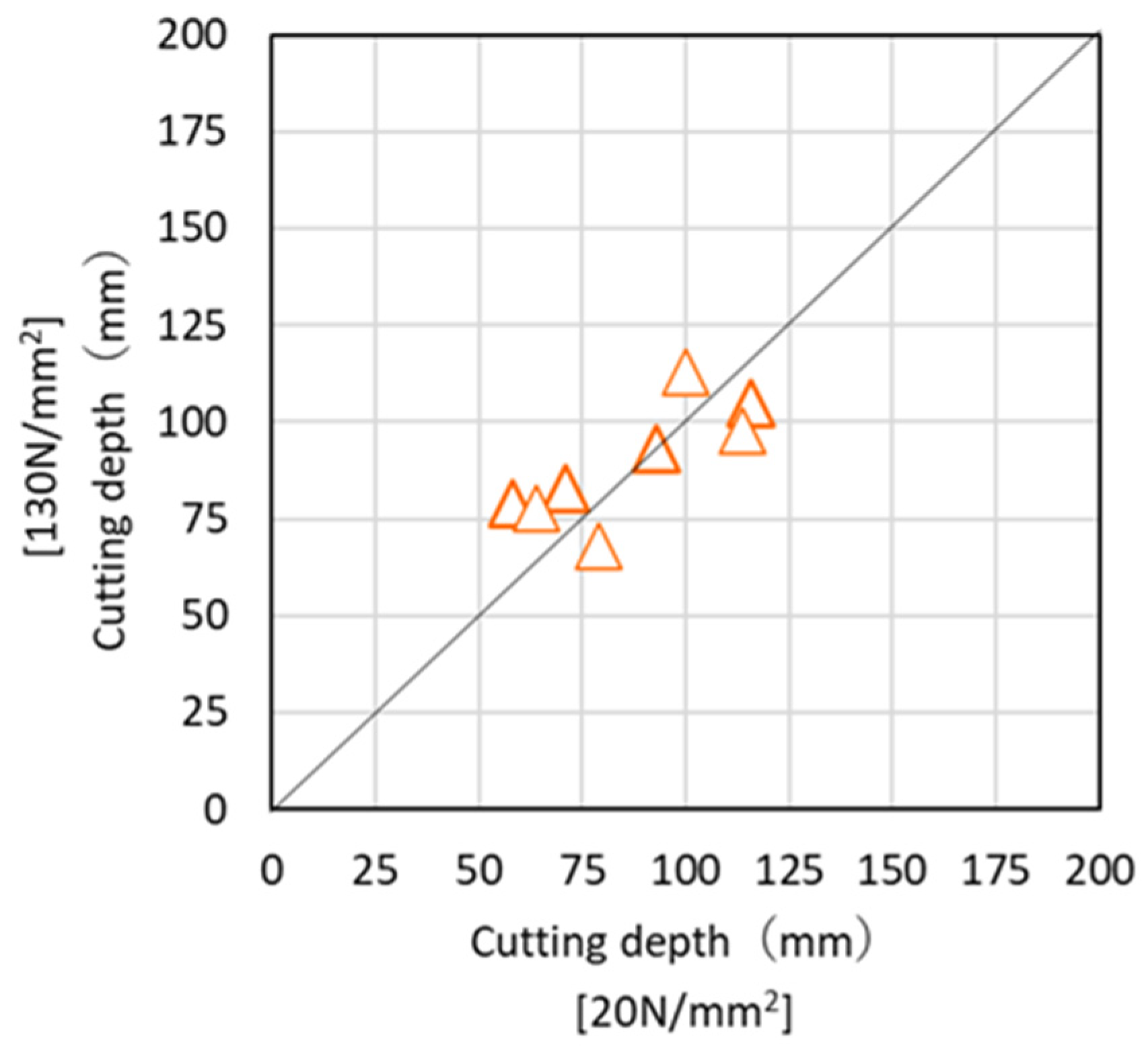

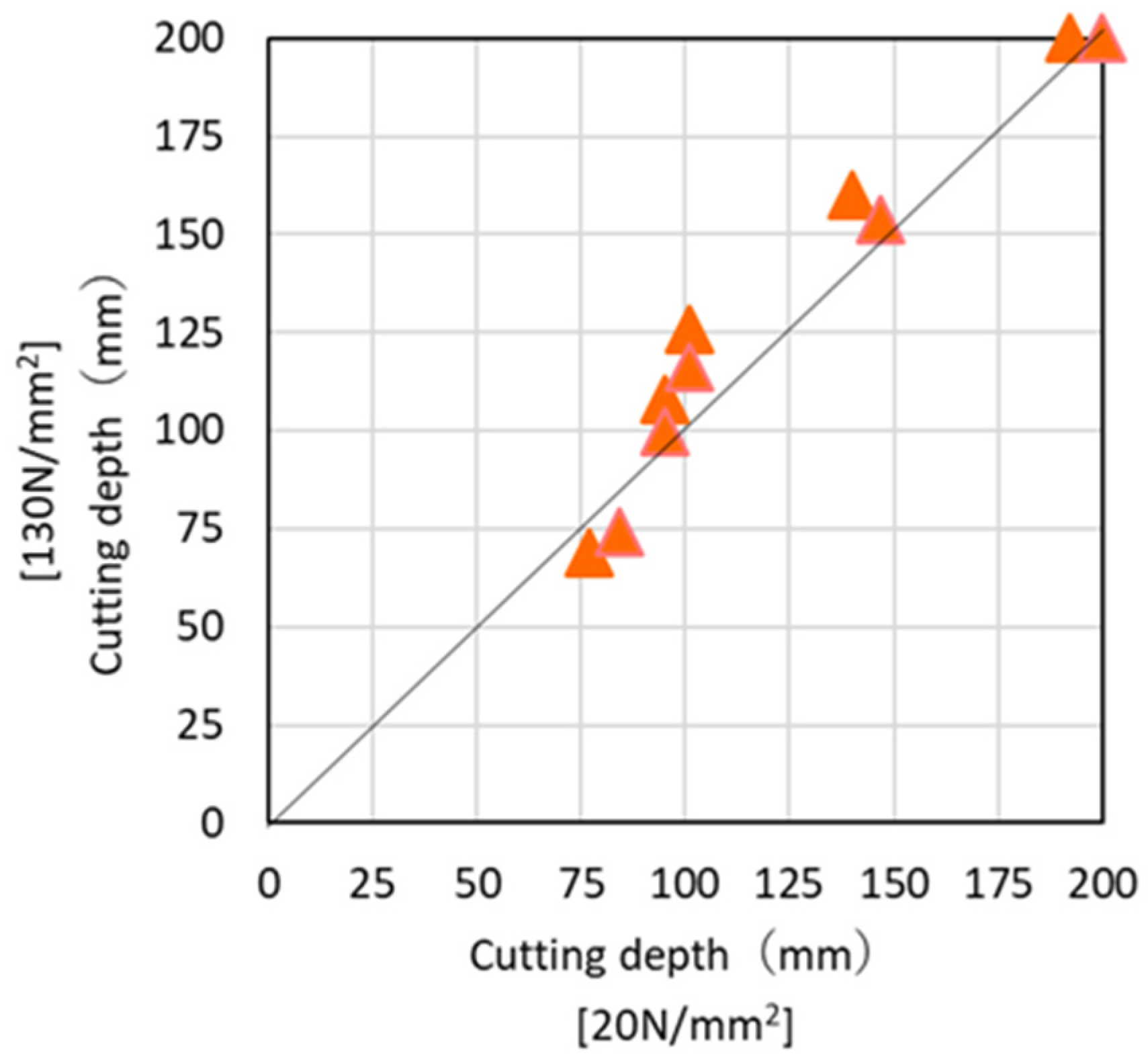

3.2. Comparison of Concrete Strength

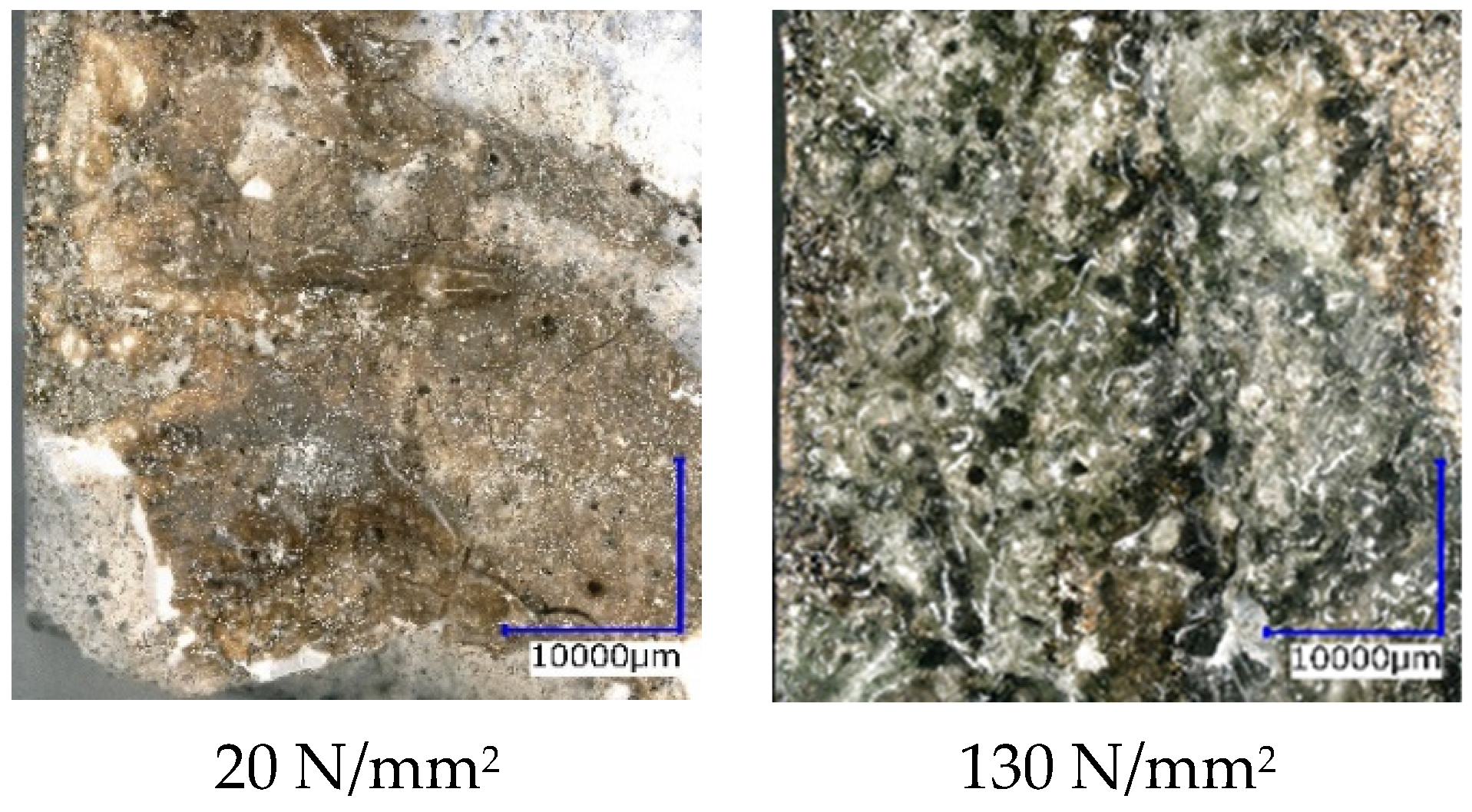

3.3. Differences in Cutting Surfaces Due to Different Concrete Strengths

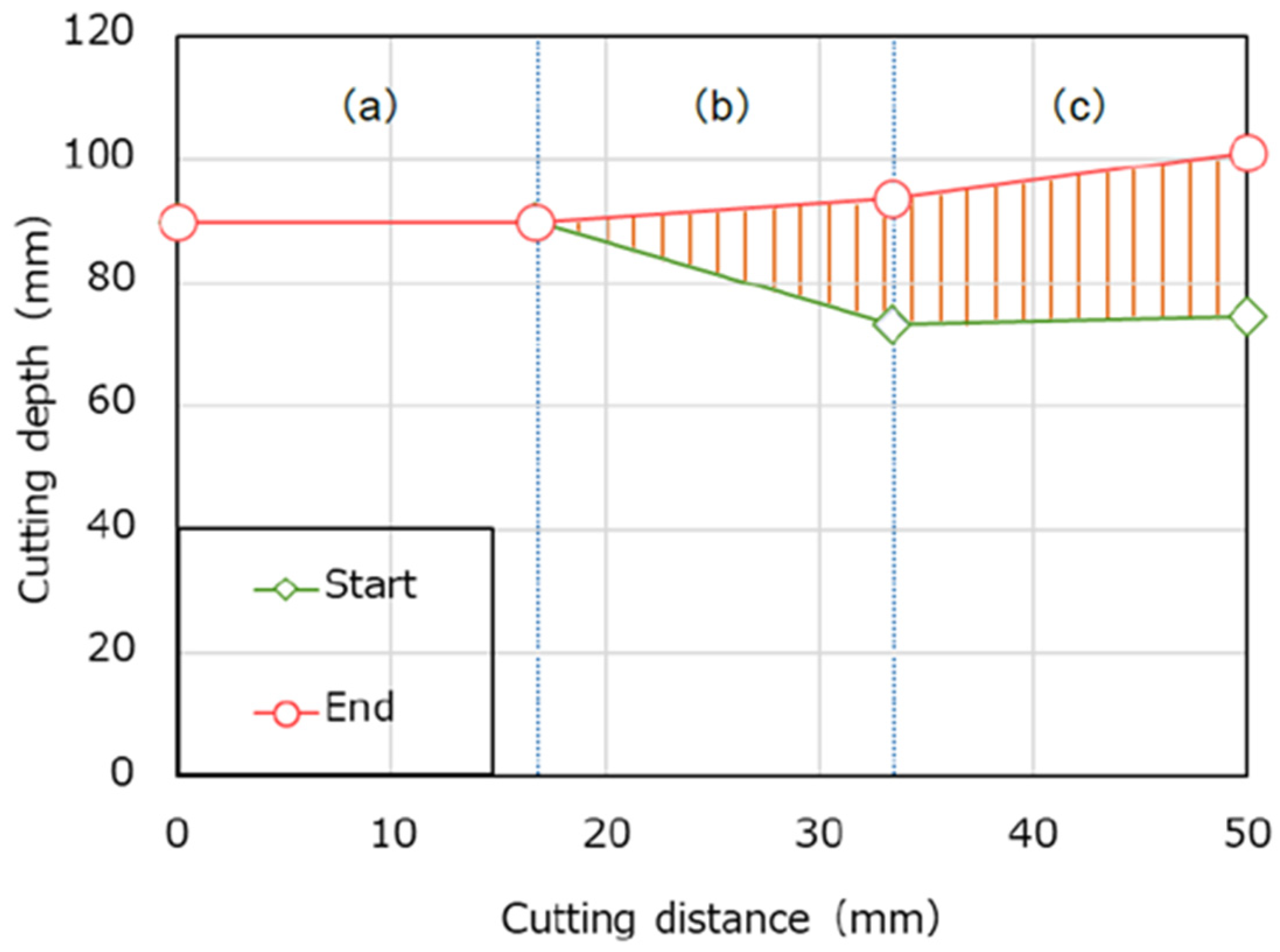

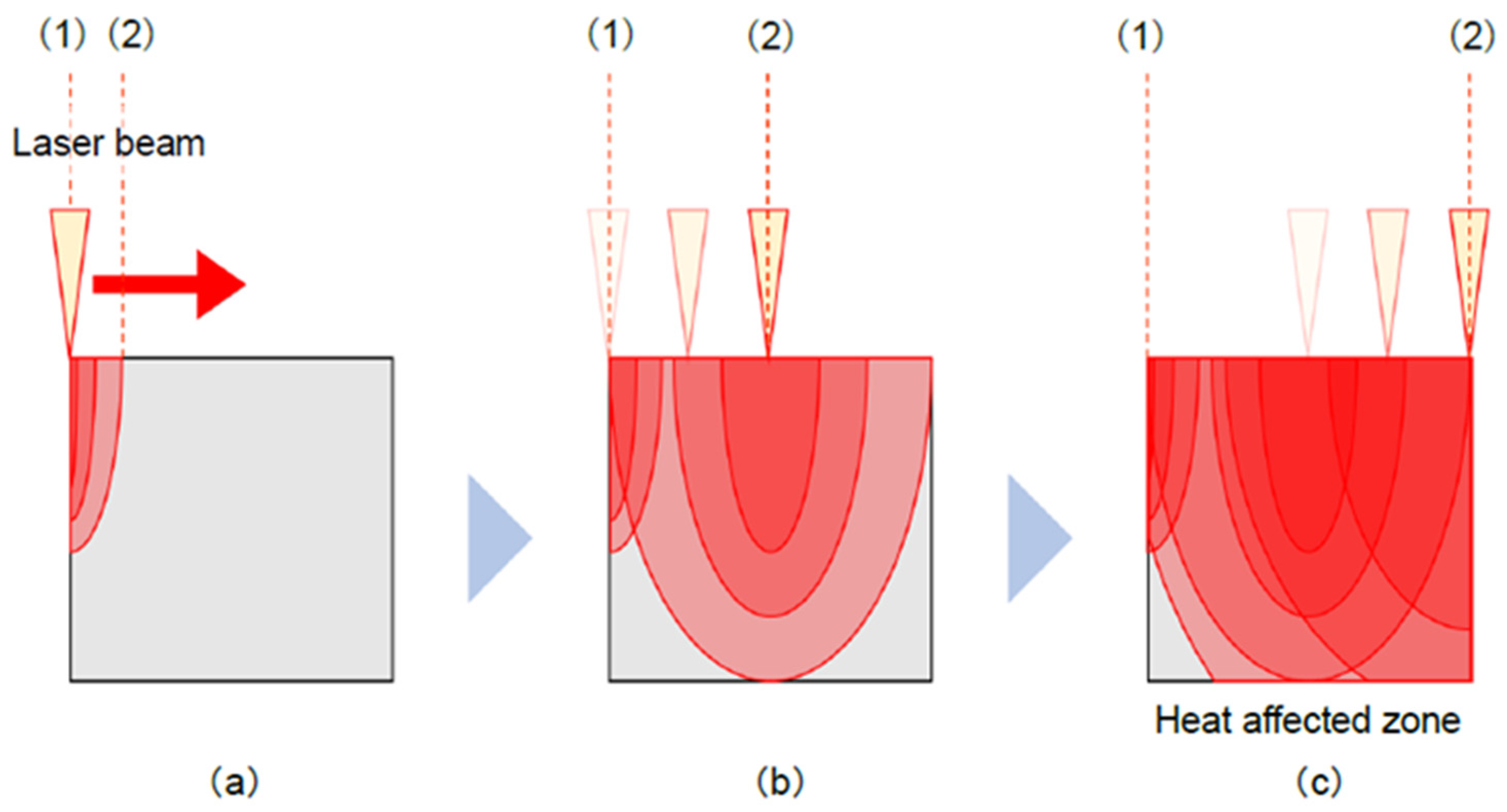

3.4. Difference in Cutting Depth

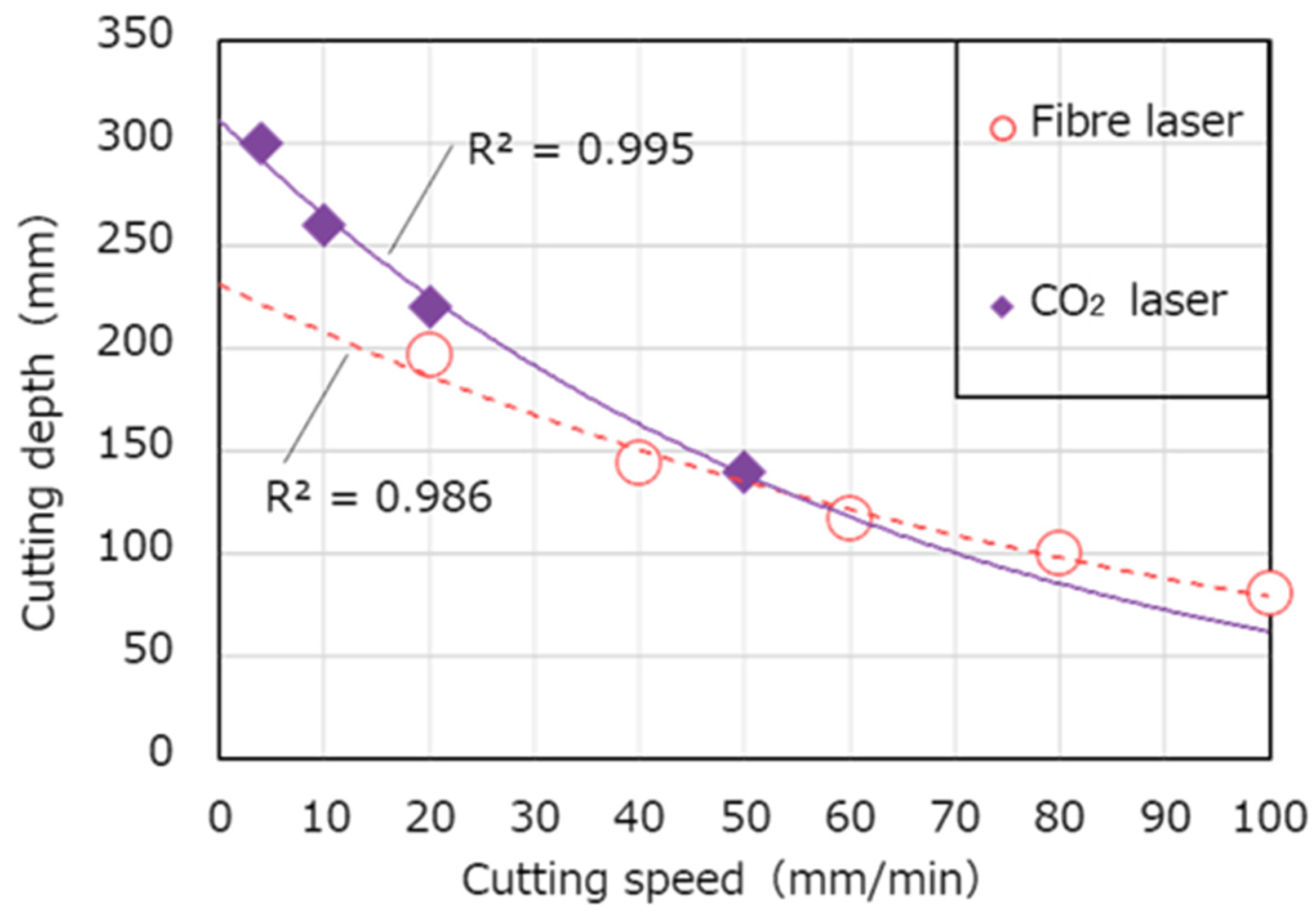

3.5. Cutting Effectiveness of the CO2 and Fibre Lasers

4. Conclusions

- At concrete strengths of 20 N/mm2, the trend of cutting depth was the same even if the laser output was different.

- At concrete strengths of 130 N/mm2, the same cutting depth was indicated when the speed was 100 mm, even if the laser output was different. However, when the speed decreased, the difference in laser output greatly affected the difference in cutting depth.

- Cutting to a depth of 200 mm or more required a laser power of 9 kW and a cutting speed of 20 mm/min.

- Regardless of the concrete strength, the concrete melted and vitrified if the heat effect became large.

- In laser cutting, the cutting depths at the start and end points of cutting differed depending on the cutting method.

- The CO2 and fibre lasers were roughly equivalent in terms of their cutting effectiveness in different concretes. However, the same cutting depth was indicated when the speed was 50 mm. Furthermore, the CO2 laser resulted in deeper cutting depths at slow speeds than those of the fibre laser.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kasai, Y. New dismantling method. Concr. J. 1973, 11, 39–48. [Google Scholar]

- Kasai, Y. History of concrete technology 4th Transition of demolition method. Concr. J. 1992, 30, 87–91. [Google Scholar]

- Kawashima, T.; Takagi, M. Dismantling method using a diamond wire saw. Concr. J. 1991, 29, 35–39. [Google Scholar]

- Yanagida, K. Reinforced concrete (RC) building demolition method ③ Low noise demolition method. Concr. J. 2016, 54, 398–402. [Google Scholar]

- Yuasa, N. Reinforced concrete (RC) building demolition method ① History of reinforced concrete demolition method. Concr. J. 2016, 54, 189–194. [Google Scholar]

- Kitani, Y. High Power Laser Welding in Vacuum. J. JWS 2020, 89, 51–55. [Google Scholar] [CrossRef]

- The Laser Society of Japan. Chapter 47 on Laser Applications; The Optronics Co., Ltd.: Tokyo, Japan, 1998; pp. 117–132. [Google Scholar]

- Nagai, K.; Beckemper, S.; Poprawe, R. Laser Drilling of Holes in Different Kinds of Concrete. Civ. Eng. J. 2018, 4, 766–775. [Google Scholar] [CrossRef] [Green Version]

- Sugita, K.; Mori, M.; Fujioka, T. Application of CO, Laser to Concrete Cutting. Concr. J. 1986, 24, 13–22. [Google Scholar] [CrossRef] [Green Version]

- Yoshizawa, H.; Wignarajah, S.; Saito, H. Study on laser cutting of concrete. Trans. Japan Weld. Soc. 1989, 20, 31–36. [Google Scholar]

- Nguyen, P. Experimental characterization of concrete removal by high-power quasi-continuous-wave fiber laser irradiation. J. Laser Appl. 2017, 29, 041501. [Google Scholar]

- Lee, D.; Seo, Y.; Pyo, S. Effect of Laser Speed on Cutting Characteristics of Cement-Based Materials. Materials 2018, 11, 1055. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kutsumizu, A.; Tomura, H.; Wakizaka, T.; Hishikawa, K.; Moriya, M. Experimental study on concrete cutting bu CO2 laser beam. J. Struct. Constr. Eng. AIJ 1994, 464, 43–52. [Google Scholar] [CrossRef] [Green Version]

- Nagai, K.; Sato, M.; Hattori, H.; Kinugasa, M. Rock excavation with laser. In High-Power Lasers in Civil Engineering and Architecture; SPIE-The International Society for Optical Engineering: Osaka, Japan, 2000; Volume 3887, pp. 277–286. [Google Scholar]

- Wignarajah, S.; Nagai, K. Between a rock and a hard place. Ind. Laser Solut. Mag. 2005, 20, 8–12. [Google Scholar]

- Nagai, K. Laser processing for construction site. Laser Inst. 2010, 39, 744–748. [Google Scholar]

- Seo, T.Y.; Lee, D.; Pyo, S. High-Power Fiber Laser Cutting for 50-mm-Thick Cement-Based Materials. Materials 2020, 13, 1113. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Saito, H. Optical Measurements in Experimental Mechanics; The Optical Society of Japan: Japan, 1965; pp. 3–10. [Google Scholar]

- Li, Z.; Li, Q. Relationship between Compressive Strength and Thermal Conductivity of Concrete; Japan Concrete Institute: Tokyo, Japan, 2014; Volume 36, pp. 2050–2055. [Google Scholar]

- Research Institute on Building Cost. Survey Report of “High-Strength Concrete”; New Technology Survey Report in Japan; Research Institute on Building Cost: Japan, 2010; pp. 80–85. [Google Scholar]

| Concrete | Ordinary | High-Strength |

|---|---|---|

| Strength (N/mm2) | 20 | 130 |

| Slump (cm) | 18 | 65 |

| Air content (%) | 4.5 | 2.0 |

| Water-cement ratio (%) | 63.3 | 14.0 |

| Sand-aggregate ratio (%) | 50.7 | 31.0 |

| Laser output (kW) | 6, 9 |

| Fibre core diameter (μm) | 100 |

| Cutting speed (mm/min) | 20, 40, 60, 80, 100 |

| Gas type | Air |

| Gas pressure (MPa) | 0.95 |

| DFS distance (mm) | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nagai, K.; Shimizu, K. Using a High-Power Fibre Laser to Cut Concrete. Appl. Sci. 2021, 11, 4414. https://doi.org/10.3390/app11104414

Nagai K, Shimizu K. Using a High-Power Fibre Laser to Cut Concrete. Applied Sciences. 2021; 11(10):4414. https://doi.org/10.3390/app11104414

Chicago/Turabian StyleNagai, Kaori, and Kazuki Shimizu. 2021. "Using a High-Power Fibre Laser to Cut Concrete" Applied Sciences 11, no. 10: 4414. https://doi.org/10.3390/app11104414

APA StyleNagai, K., & Shimizu, K. (2021). Using a High-Power Fibre Laser to Cut Concrete. Applied Sciences, 11(10), 4414. https://doi.org/10.3390/app11104414