An ISM-Based Methodology for Interrelationships of Critical Success Factors for Construction Projects in Ecologically Fragile Regions: Take Korla, China as an Example

Abstract

:1. Introduction

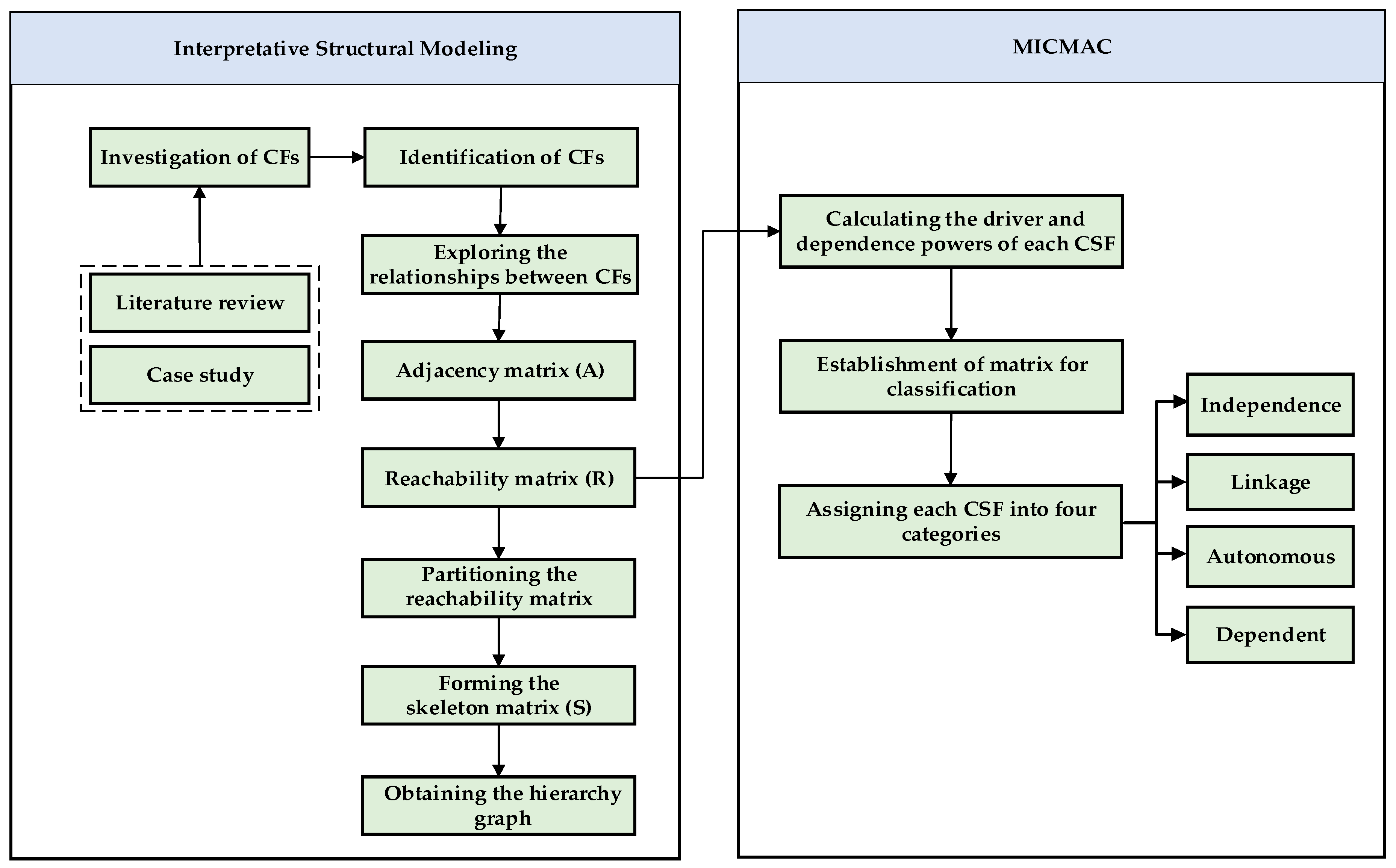

2. The Methodology of ISM and MICMAC

- Step1: investigation and identification are made to generate the list of CSFs though the combination of literature review and case studies.

- Step2: interrelationships between CSFs are explored by semi-structured interviews. In this step, a causal relationship analysis is processed through pairwise comparisons and the results are presented in the causal relationship network of CSFs.

- Step3: the causal relationship network of CSFs is converted to the adjacency matrix (A). Thereafter, a reachability matrix (R) is obtained from A and constructed to investigate the transitivity among CSFs. This process is undertaken via Boolean algebraic algorithms implemented in MATLAB software. Thereafter, a partition process is taken to break down the R into different levels. The location and distribution of CSFs in the final model are determined.

- Step4: skeleton-matrix (S) is implemented to determine the directional links between CSFs in different levels.

- Step5: the final model is generated with the obtained directional links to illustrate the causal relationship between each CSF.

3. CSFs for Construction Projects in EFRs

3.1. Literature Review

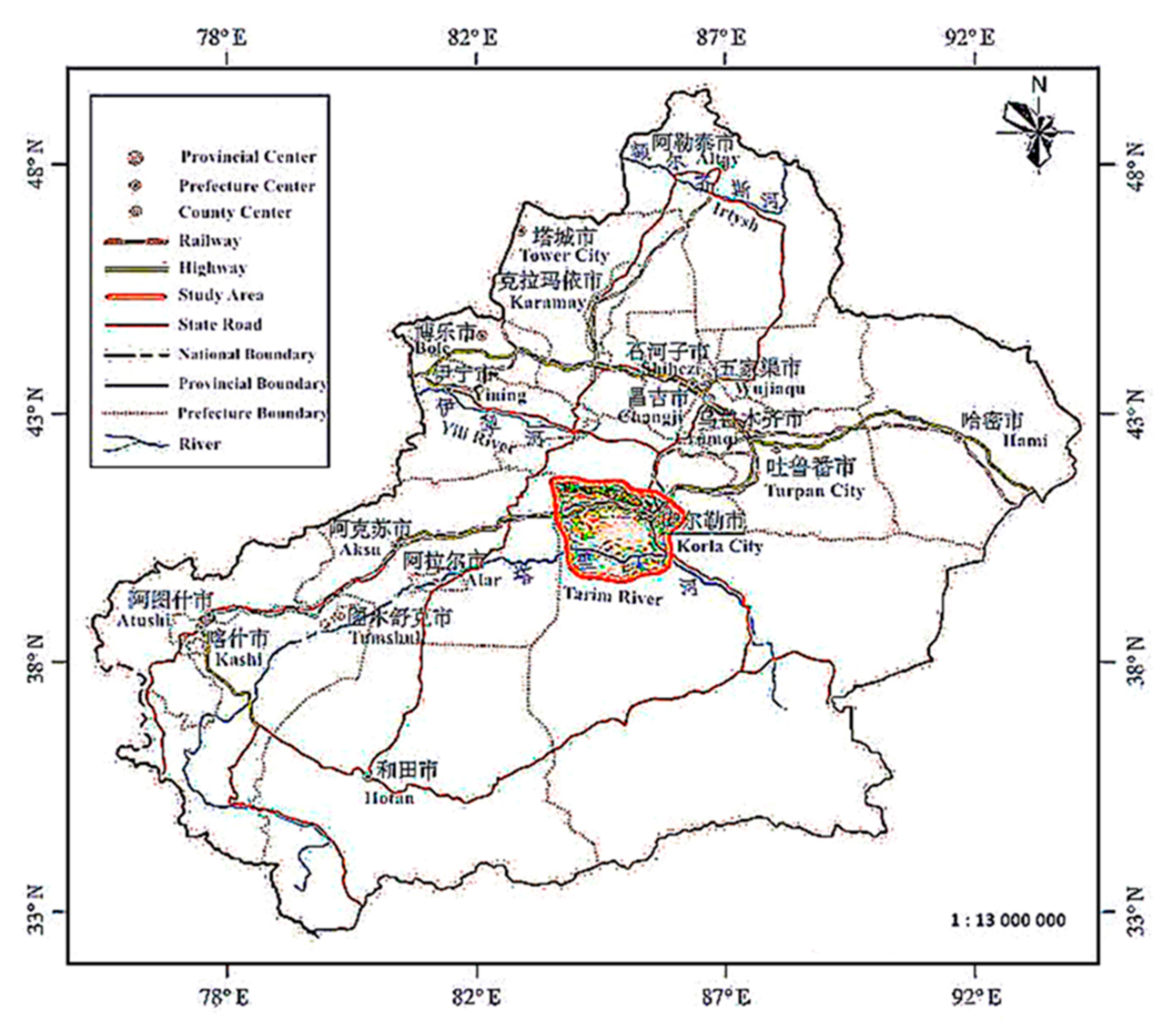

3.2. Case Study

3.3. Identification of CSFs

4. Hierarchical Structuring of CSFs

4.1. Causal Interrelationships between CSFs

4.2. Partitioning the Reachability Matrix (R) of CSFs

4.3. Forming the Skeleton Matrix (S) of CSFs

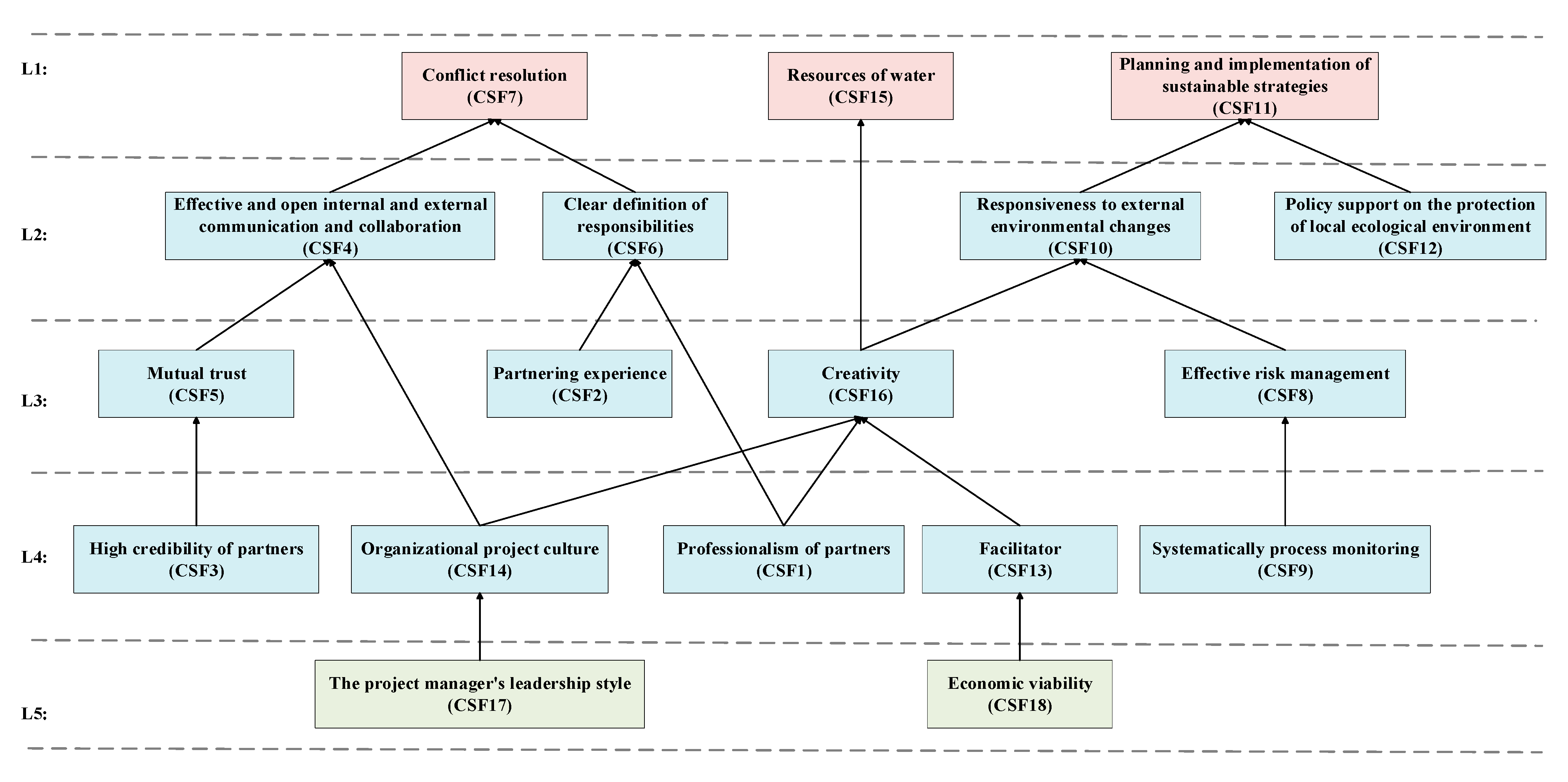

4.4. Obtaining the Hierarchy Graph

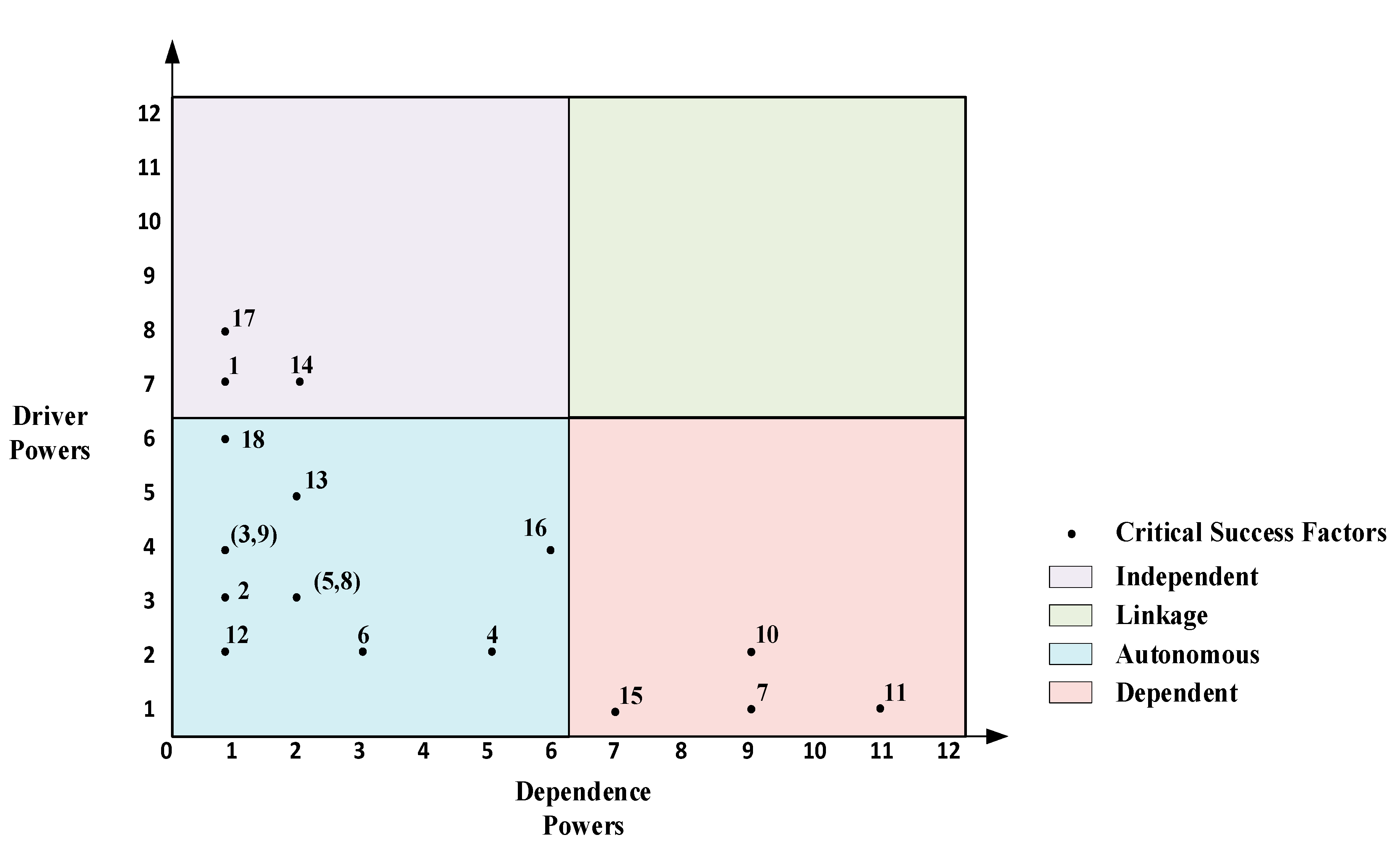

5. Classification of the CSFs Based on MIMAC Analysis

6. Discussions

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Peng, B.; Huang, Q.; Elahi, E.; Wei, G. Ecological Environment Vulnerability and Driving Force of Yangtze River Urban Agglomeration. Sustainability 2019, 11, 6623. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Cao, Z.; Long, H.; Liu, Y.; Li, W. Dynamic analysis of ecological environment combined with land cover and NDVI changes and implications for sustainable urban–rural development: The case of Mu Us Sandy Land, China. J. Clean. Prod. 2017, 142, 697–715. [Google Scholar] [CrossRef]

- Yang, Z.; Li, W.; Pei, Y.; Qiao, W.; Wu, Y. Classification of the type of eco-geological environment of a coal mine district: A case study of an ecologically fragile region in Western China. J. Clean. Prod. 2018, 174, 1513–1526. [Google Scholar] [CrossRef]

- Luo, W.; Bai, H.; Jing, Q.; Liu, T.; Xu, H. Urbanization-induced ecological degradation in Midwestern China: An analysis based on an improved ecological footprint model. Resour. Conserv. Recycl. 2018, 137, 113–125. [Google Scholar] [CrossRef]

- Yu, Q.; Yue, D.; Wang, Y.; Kai, S.; Fang, M.; Ma, H.; Zhang, Q.; Huang, Y. Optimization of ecological node layout and stability analysis of ecological network in desert oasis: A typical case study of ecological fragile zone located at Deng Kou County (Inner Mongolia). Ecol. Indic. 2018, 84, 304–318. [Google Scholar] [CrossRef]

- Sheng, W.; Zhen, L.; Xiao, Y.; Hu, Y. Ecological and socioeconomic effects of ecological restoration in China’s Three Rivers Source Region. Sci. Total Environ. 2019, 650, 2307–2313. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Li, W.; Li, X.; Wang, Q.; He, J. Assessment of eco-geo-environment quality using multivariate data: A case study in a coal mining area of Western China. Ecol. Indic. 2019, 107, 105651. [Google Scholar] [CrossRef]

- Li, Z.; Bai, Y.; Sun, J.; Dong, S.; Li, J. Ecological Civilization Construction in Ecologically Fragile Poverty-stricken Areas in Western China. Strateg. Study Chin. Acad. Eng. 2019, 21, 80–86. [Google Scholar] [CrossRef]

- Hu, Y.-C.; Zhou, W.; Yuan, T. Environmental impact assessment of ecological migration in China: A survey of immigrant resettlement regions. J. Zhejiang Univ. Sci. A 2018, 19, 240–254. [Google Scholar] [CrossRef]

- Peng, J.; Jia, J.L.; Hu, Y.N.; Tian, L.; Li, H.L. Construction of ecological security pattern in the agro-pastoral ecotone based on surface humid index: A case study of Hangjin Banner, Inner Mongolia Autonomous Region, China. Ying Yong Sheng Tai Xue Bao J. Appl. Ecol. 2018, 29, 1990–1998. [Google Scholar]

- Li, J.-X.; Chen, Y.-N.; Xu, C.-C.; Li, Z. Evaluation and analysis of ecological security in arid areas of Central Asia based on the emergy ecological footprint (EEF) model. J. Clean. Prod. 2019, 235, 664–677. [Google Scholar] [CrossRef]

- Shayan, S.; Pyung Kim, K.; Tam, V.W. Critical success factor analysis for effective risk management at the execution stage of a construction project. Int. J. Constr. Manag. 2019, 1–8. [Google Scholar] [CrossRef]

- Viswanathan, S.K.; Tripathi, K.K.; Jha, K.N. Influence of risk mitigation measures on international construction project success criteria–a survey of Indian experiences. Constr. Manag. Econ. 2020, 38, 207–222. [Google Scholar] [CrossRef]

- Banihashemi, S.; Hosseini, M.R.; Golizadeh, H.; Sankaran, S. Critical success factors (CSFs) for integration of sustainability into construction project management practices in developing countries. Int. J. Proj. Manag. 2017, 35, 1103–1119. [Google Scholar] [CrossRef]

- Yu, A.T.; Shen, G.Q. Critical success factors of the briefing process for construction projects. J. Manag. Eng. 2015, 31, 04014045. [Google Scholar] [CrossRef]

- Osei-Kyei, R.; Chan, A.P. Review of studies on the Critical Success Factors for Public–Private Partnership (PPP) projects from 1990 to 2013. Int. J. Proj. Manag. 2015, 33, 1335–1346. [Google Scholar] [CrossRef]

- Srimathi, S.; Dinesh, S.; Sethuraman, R. A review on critical success factors in construction project. Int. J. Sci. Res. Sci. Eng. Technol. 2017, 3, 477–481. [Google Scholar]

- Nunes, M.; Abreu, A. Applying social network analysis to identify project critical success factors. Sustainability 2020, 12, 1503. [Google Scholar] [CrossRef] [Green Version]

- Luthra, S.; Mangla, S.K.; Shankar, R.; Prakash Garg, C.; Jakhar, S. Modelling critical success factors for sustainability initiatives in supply chains in Indian context using Grey-DEMATEL. Prod. Plan. Control 2018, 29, 705–728. [Google Scholar] [CrossRef]

- Rockart, J.F. The changing role of the information systems executive: A critical success factors perspective. In Proceedings of the 3rd International Conference on Information Systems, Ann Arbor, MI, USA, April 1980; pp. 185–197. [Google Scholar]

- Sanvido, V.; Grobler, F.; Parfitt, K.; Guvenis, M.; Coyle, M. Critical success factors for construction projects. J. Constr. Eng. Manag. 1992, 118, 94–111. [Google Scholar] [CrossRef]

- Black, C.; Akintoye, A.; Fitzgerald, E. An analysis of success factors and benefits of partnering in construction. Int. J. Proj. Manag. 2000, 18, 423–434. [Google Scholar] [CrossRef]

- Chan, A.P.; Ho, D.C.; Tam, C. Design and build project success factors: Multivariate analysis. J. Constr. Eng. Manag. 2001, 127, 93–100. [Google Scholar] [CrossRef]

- Cheng, E.W.; Li, H. Construction partnering process and associated critical success factors: Quantitative investigation. J. Manag. Eng. 2002, 18, 194–202. [Google Scholar] [CrossRef]

- Lu, W.; Shen, L.; Yam, M.C. Critical success factors for competitiveness of contractors: China study. J. Constr. Eng. Manag. 2008, 134, 972–982. [Google Scholar] [CrossRef]

- Chan, A.P.; Lam, P.T.; Chan, D.W.; Cheung, E.; Ke, Y. Critical success factors for PPPs in infrastructure developments: Chinese perspective. J. Constr. Eng. Manag. 2010, 136, 484–494. [Google Scholar] [CrossRef]

- Esmaeili, B.; Pellicer, E.; Molenaar, K.R. Critical success factors for construction projects. In Project Management and Engineering Research, 2014; Springer: Berlin/Heidelberg, Germany, 2016; pp. 3–14. [Google Scholar]

- Osei-Kyei, R.; Chan, A.P. Implementing public–private partnership (PPP) policy for public construction projects in Ghana: Critical success factors and policy implications. Int. J. Constr. Manag. 2017, 17, 113–123. [Google Scholar] [CrossRef]

- El-Abidi, K.M.A.; Ofori, G.; Zakaria, S.A.S.; Mannan, M.A.; Abas, N.F. Identifying and Evaluating Critical Success Factors for Industrialized Building Systems Implementation: Malaysia Study. Arab. J. Sci. Eng. 2019, 44, 8761–8777. [Google Scholar] [CrossRef]

- Sariola, R. Utilizing the innovation potential of suppliers in construction projects. Constr. Innov. 2018, 18, 18. [Google Scholar] [CrossRef]

- Durdyev, S.; Hosseini, M.R.; Martek, I.; Ismail, S.; Arashpour, M. Barriers to the use of integrated project delivery (IPD): A quantified model for Malaysia. Eng. Constr. Archit. Manage. 2019, 27, 186–204. [Google Scholar] [CrossRef]

- Mavi, R.K.; Standing, C. Critical success factors of sustainable project management in construction: A fuzzy DEMATEL-ANP approach. J. Clean. Prod. 2018, 194, 751–765. [Google Scholar] [CrossRef]

- Pham, V.Q.; Nguyen, B.K.Q.; TU, B.V.; Pham, H.T.T.; Le, T.Q. Critical success factors of project management: The case of construction related projects in vietnam. J. Asian Financ. Econ. Bus. 2019, 6, 223–230. [Google Scholar] [CrossRef]

- Warfield, J.N. Toward interpretation of complex structural models. IEEE Trans. Syst. ManCybern. 1974, 5, 405–417. [Google Scholar] [CrossRef]

- Malone, D.W. An introduction to the application of interpretive structural modeling. Proc. IEEE 1975, 63, 397–404. [Google Scholar] [CrossRef]

- Sage, A.P.; Smith, T.J. On group assessment of utility and worth attributes using interpretive structural modeling. Comput. Electr. Eng. 1977, 4, 185–198. [Google Scholar] [CrossRef]

- Gavareshki, M.H.K.; Hosseini, S.J.; Khajezadeh, M. A case study of green supplier selection method using an integrated ISM-fuzzy MICMAC analysis and multi-criteria decision making. Ind. Eng. Manag. Syst. 2017, 16, 562–573. [Google Scholar]

- Fu, K.; Xia, J.-B.; Zhang, X.-Y.; Shen, J. System structural analysis of communication networks based on DEMATEL-ISM and entropy. J. Cent. South Univ. 2017, 24, 1594–1601. [Google Scholar] [CrossRef]

- Chauhan, A.; Singh, A.; Jharkharia, S. An interpretive structural modeling (ISM) and decision-making trail and evaluation laboratory (DEMATEL) method approach for the analysis of barriers of waste recycling in India. J. Air Waste Manag. Assoc. 2018, 68, 100–110. [Google Scholar] [CrossRef]

- Shen, J.; Li, F.; Shi, D.; Li, H.; Yu, X. Factors Affecting the Economics of Distributed Natural Gas-Combined Cooling, Heating and Power Systems in China: A Systematic Analysis Based on the Integrated Decision Making Trial and Evaluation Laboratory-Interpretative Structural Modeling (DEMATEL-ISM) Technique. Energies 2018, 11, 2318. [Google Scholar]

- Sandeepa, S.; Chand, M. Analysis of flexibility factors in sustainable supply chain using total interpretive structural modeling (T-ISM) technique. Uncertain Supply Chain Manag. 2018, 6, 1–12. [Google Scholar] [CrossRef]

- Kumar, A.; Dixit, G. An analysis of barriers affecting the implementation of e-waste management practices in India: A novel ISM-DEMATEL approach. Sustain. Prod. Consum. 2018, 14, 36–52. [Google Scholar] [CrossRef]

- Raut, R.; Narkhede, B.E.; Gardas, B.B.; Luong, H.T. An ISM approach for the barrier analysis in implementing sustainable practices. Benchmarking Int. J. 2018, 25, 1245–1271. [Google Scholar] [CrossRef]

- Ravi, V.; Shankar, R. Analysis of interactions among the barriers of reverse logistics. Technol. Forecast. Soc. Chang. 2005, 72, 1011–1029. [Google Scholar] [CrossRef]

- Faisal, M.N.; Banwet, D.K.; Shankar, R. Supply chain risk mitigation: Modeling the enablers. Bus. Process Manag. J. 2006, 12, 535–552. [Google Scholar] [CrossRef]

- Liu, H.; Skibniewski, M.J.; Wang, M. Identification and hierarchical structure of critical success factors for innovation in construction projects: Chinese perspective. J. Civ. Eng. Manag. 2016, 22, 401–416. [Google Scholar] [CrossRef] [Green Version]

- Dhir, S.; Dhir, S. Modeling of strategic thinking enablers: A modified total interpretive structural modeling (TISM) and MICMAC approach. Int. J. Syst. Assur. Eng. Manag. 2020, 11, 175–188. [Google Scholar] [CrossRef]

- Mandal, A.; Deshmukh, S. Vendor selection using interpretive structural modelling (ISM). Int. J. Oper. Prod. Manag. 1994, 14, 8. [Google Scholar] [CrossRef]

- Saxena, J.; Vrat, P. Hierarchy and classification of program plan elements using interpretive structural modeling: A case study of energy conservation in the Indian cement industry. Syst. Pract. 1992, 5, 651–670. [Google Scholar] [CrossRef]

- Sagheer, S.; Yadav, S.S.; Deshmukh, S. An application of interpretative structural modeling of the compliance to food standards. Int. J. Product. Perform. Manag. 2009, 58, 136–159. [Google Scholar] [CrossRef]

- Iyer, K.C.; Sagheer, M. Hierarchical structuring of PPP risks using interpretative structural modeling. J. Constr. Eng. Manag. 2010, 136, 151–159. [Google Scholar] [CrossRef] [Green Version]

- Yadav, G.; Desai, T.N. Analyzing lean six sigma enablers: A hybrid ISM-fuzzy MICMAC approach. Tqm J. 2017, 29, 488–511. [Google Scholar] [CrossRef]

- Agrawal, N.M. Modeling Deming’s quality principles to improve performance using interpretive structural modeling and MICMAC analysis. Int. J. Qual. Reliab. Manag. 2019, 36, 1159–1180. [Google Scholar] [CrossRef]

- Ruben, B.R.; Vinodh, S.; Asokan, P. ISM and Fuzzy MICMAC application for analysis of Lean Six Sigma barriers with environmental considerations. Int. J. Lean Six Sigma 2018, 9, 64–90. [Google Scholar]

- De Wit, A. Measurement of project success. Int. J. Proj. Manag. 1988, 6, 164–170. [Google Scholar] [CrossRef]

- Albert, M.; Balve, P.; Spang, K. Evaluation of project success: A structured literature review. Int. J. Manag. Proj. Bus. 2017, 10, 796–821. [Google Scholar] [CrossRef]

- Phong, N.T.; Quyen, N.L.H.T.T. Application fuzzy multi-attribute decision analysis method to prioritize project success criteria. In Proceedings of the 3rd International Conference on Construction and Building Engineering: Smart Construction Towards Global Challenges, Palembang, Indonesia, 14–17 August 2017; p. 070011. [Google Scholar]

- Kissi, E.; Agyekum, K.; Baiden, B.K.; Tannor, R.A.; Asamoah, G.E.; Andam, E.T. Impact of project monitoring and evaluation practices on construction project success criteria in Ghana. Built Environ. Proj. Asset Manag. 2019, 9, 364–382. [Google Scholar] [CrossRef]

- Osei-Kyei, R.; Chan, A.P. Comparative analysis of the success criteria for public–private partnership projects in Ghana and Hong Kong. Proj. Manag. J. 2017, 48, 80–92. [Google Scholar] [CrossRef] [Green Version]

- Alashwal, A.M.; Fareed, N.F.; Al-Obaidi, K.M. Determining success criteria and success factors for international construction projects for Malaysian contractors. Constr. Econ. Build. 2017, 17, 62–80. [Google Scholar] [CrossRef] [Green Version]

- Castro, M.S.; Bahli, B.; Farias Filho, J.R.; Barcaui, A. A contemporary vision of project success criteria. Braz. J. Oper. Prod. Manag. 2019, 16, 66–77. [Google Scholar] [CrossRef]

- Castro, M.S.; Bahli, B.; Barcaui, A.; Figueiredo, R. Does one project success measure fit all? An empirical investigation of Brazilian projects. Int. J. Manag. Proj. Bus. 2020, 14, 788–805. [Google Scholar] [CrossRef]

- Osei-Kyei, R.; Chan, A.P. Stakeholders’ perspectives on the success criteria for public-private partnership projects. Int. J. Strateg. Prop. Manag. 2018, 22, 131–142. [Google Scholar] [CrossRef] [Green Version]

- Wuni, I.Y.; Shen, G.Q. Critical success factors for modular integrated construction projects: A review. Build. Res. Inf. 2020, 48, 763–784. [Google Scholar] [CrossRef]

- Alreemy, Z.; Chang, V.; Walters, R.; Wills, G. Critical success factors (CSFs) for information technology governance (ITG). Int. J. Inf. Manag. 2016, 36, 907–916. [Google Scholar] [CrossRef] [Green Version]

- Adabre, M.A.; Chan, A.P. Critical success factors (CSFs) for sustainable affordable housing. Build. Environ. 2019, 156, 203–214. [Google Scholar] [CrossRef]

- Alias, Z.; Zawawi, E.; Yusof, K.; Aris, N. Determining critical success factors of project management practice: A conceptual framework. Procedia-Soc. Behav. Sci. 2014, 153, 61–69. [Google Scholar] [CrossRef] [Green Version]

- Zou, W.; Kumaraswamy, M.; Chung, J.; Wong, J. Identifying the critical success factors for relationship management in PPP projects. Int. J. Proj. Manag. 2014, 32, 265–274. [Google Scholar] [CrossRef] [Green Version]

- Marzagão, D.S.L.; Carvalho, M.M. Critical success factors for Six Sigma projects. Int. J. Proj. Manag. 2016, 34, 1505–1518. [Google Scholar] [CrossRef]

- Omoush, M.M. Assessing and Prioritizing the Critical Success Factors and Delays of Project Management Implementation: Empirical Evidence at Construction Projects in Jordan. Int. J. Bus. Manag. 2020, 15, 10. [Google Scholar]

- Parson, S.J. Relationship between US Construction Project Managers’ Leadership Styles and Construction Project Success. Ph.D. Thesis, Capella University, Minneapolis, MN, USA, 2020. [Google Scholar]

- Azman, M.H.N.; Mohamed, A.; Odzaly, E.E. A Theoretical Study on Project Delivery and Leadership Style. In Proceedings of the 3rd International Conference on Networking, Information Systems & Security, NISS 2020, Marrakech, Morocco, 31 March–2 April 2020; Volume 2, pp. 1–8. [Google Scholar]

- Nassar, M.S. Project Manager’s Leadership Competencies: The Influence of Emotional Intelligence on Project Success; The University of Salford: Salford, UK, 2016. [Google Scholar]

- Sun, A.Y.; Yazdani, A.; Overend, J.D. Achievement assessment for enterprise resource planning (ERP) system implementations based on critical success factors (CSFs). Int. J. Prod. Econ. 2005, 98, 189–203. [Google Scholar] [CrossRef]

- Valmohammadi, C. Investigation and assessment of critical success factors of knowledge management implementation in Iranian small-to-medium sized enterprises. J. Appl. Sci. (Faisalabad) 2010, 10, 2290–2296. [Google Scholar] [CrossRef]

- Shafiq, M.; Soratana, K. Lean readiness assessment model–a tool for Humanitarian Organizations’ social and economic sustainability. J. Humanit. Logist. Supply Chain Manag. 2020. [Google Scholar] [CrossRef]

- Brotherton, B.; Shaw, J. Towards an identification and classification of critical success factors in UK hotels plc. Int. J. Hosp. Manag. 1996, 15, 113–135. [Google Scholar] [CrossRef]

- Gorantiwar, V.S.; Shrivastava, R. Identification of critical success factors for quality-productivity management approach in different industries. Int. J. Product. Qual. Manag. 2014, 14, 66–106. [Google Scholar] [CrossRef]

- Tran, T.M.T.; Yuen, K.F.; Li, K.X.; Balci, G.; Ma, F. A theory-driven identification and ranking of the critical success factors of sustainable shipping management. J. Clean. Prod. 2020, 243, 118401. [Google Scholar] [CrossRef]

- Asemi, A.; Jazi, M.D. A comparative study of critical success factors (CSFs) in implementation of ERP in developed and developing countries. Int. J. Adv. Comput. Technol. 2010, 2, 99–110. [Google Scholar]

- Nour, M.A.; Mouakket, S. A classification framework of critical success factors for ERP systems implementation: A multi-stakeholder perspective. In Competition, Strategy, and Modern Enterprise Information Systems; IGI Global: Hershey, PA, USA, 2013; pp. 98–113. [Google Scholar]

- Panjehfouladgaran, H.; Shirouyehzad, H. Classification of critical success factors for reverse logistics implementation based on importance-performance analysis. Int. J. Product. Qual. Manag. 2018, 25, 139–150. [Google Scholar] [CrossRef]

- Salla, D.E. Comparing Performance Quality of Design-Bid-Build (DBB) and Design-Build (DB) Project Delivery Methods in Nigeria. Afr. J. Earth Environ. Sci. 2020, 2, 2. [Google Scholar]

- Demetracopoulou, V.; O’Brien, W.J.; Khwaja, N. Lessons learned from selection of project delivery methods in highway projects: The Texas experience. J. Leg. Aff. Disput. Resolut. Eng. Constr. 2020, 12, 04519040. [Google Scholar] [CrossRef]

- Franz, B.; Molenaar, K.R.; Roberts, B.A. Revisiting Project Delivery System Performance from 1998 to 2018. J. Constr. Eng. Manag. 2020, 146, 04020100. [Google Scholar] [CrossRef]

- Feghaly, J.; El Asmar, M.; Ariaratnam, S.T. State of Professional Practice for Water Infrastructure Project Delivery. Pract. Period. Struct. Des. Constr. 2020, 25, 04020018. [Google Scholar] [CrossRef]

- Zhu, J.-W.; Zhou, L.-N.; Li, L.; Ali, W. Decision Simulation of Construction Project Delivery System under the Sustainable Construction Project Management. Sustainability 2020, 12, 2202. [Google Scholar] [CrossRef] [Green Version]

- Ling, F.Y.Y.; Chan, S.L.; Chong, E.; Ee, L.P. Predicting performance of design-build and design-bid-build projects. J. Constr. Eng. Manag. 2004, 130, 75–83. [Google Scholar] [CrossRef]

- Chi, C.S.; Xu, J.; Xue, L. Public participation in environmental impact assessment for public projects: A case of non-participation. J. Environ. Plan. Manag. 2014, 57, 1422–1440. [Google Scholar] [CrossRef]

- Nguyen, L.H.; Watanabe, T. The impact of project organizational culture on the performance of construction projects. Sustainability 2017, 9, 781. [Google Scholar] [CrossRef] [Green Version]

- Sospeter, N.G.; Rwelamila, P.M.; Gimbi, J. Project management challenges for post-disaster reconstruction projects in Angola: A public sector perspective. Int. J. Manag. Proj. Bus. 2020, 14, 767–787. [Google Scholar] [CrossRef]

- Tiong, R.L. CSFs in competitive tendering and negotiation model for BOT projects. J. Constr. Eng. Manag. 1996, 122, 205–211. [Google Scholar] [CrossRef]

- Chen, Y.Q.; Zhang, Y.B.; Liu, J.Y.; Mo, P. Interrelationships among critical success factors of construction projects based on the structural equation model. J. Manag. Eng. 2012, 28, 243–251. [Google Scholar] [CrossRef]

- Chan, A.P.; Chan, D.W.; Chiang, Y.H.; Tang, B.-S.; Chan, E.H.; Ho, K.S. Exploring critical success factors for partnering in construction projects. J. Constr. Eng. Manag. 2004, 130, 188–198. [Google Scholar] [CrossRef]

- Gudienė, N.; Banaitis, A.; Podvezko, V.; Banaitienė, N. Identification and evaluation of the critical success factors for construction projects in Lithuania: AHP approach. J. Civ. Eng. Manag. 2014, 20, 350–359. [Google Scholar] [CrossRef] [Green Version]

- Yan, L.; Zhang, L. Interplay of contractual governance and trust in improving construction project performance: Dynamic perspective. J. Manag. in Eng. 2020, 36, 04020029. [Google Scholar] [CrossRef]

- Cheng, E.W.; Li, H.; Love, P. Establishment of critical success factors for construction partnering. J. Manag. Eng. 2000, 16, 84–92. [Google Scholar] [CrossRef]

- Chan, A.P.; Scott, D.; Chan, A.P. Factors affecting the success of a construction project. J. Constr. Eng. Manag. 2004, 130, 153–155. [Google Scholar] [CrossRef] [Green Version]

- Phong, N.T.; Quyen, N.L.H.T.T. Application Fuzzy Multi-Attribute Decision Analysis Method to Prioritize Project Success Criteria, AIP Conference Proceedings, 2017; AIP Publishing LLC: Melville, NY, USA, 2017; p. 070011. [Google Scholar]

- Lam, E.W.; Chan, A.P.; Chan, D.W. Determinants of successful design-build projects. J. Constr. Eng. Manag. 2008, 134, 333–341. [Google Scholar] [CrossRef]

- Li, B.; Akintoye, A.; Edwards, P.J.; Hardcastle, C. Critical success factors for PPP/PFI projects in the UK construction industry. Constr. Manag. Econ. 2005, 23, 459–471. [Google Scholar] [CrossRef]

- Zhang, X. Critical success factors for public–private partnerships in infrastructure development. J. Constr. Eng. Manag. 2005, 131, 3–14. [Google Scholar] [CrossRef]

- Memon, Z.A.; Majid, M.Z.A.; Mustaffar, M. A systematic approach for monitoring and evaluating the construction project progress. J. Inst. Eng. 2006, 67, 26–32. [Google Scholar]

- Dubey, R.; Ali, S.S. Identification of flexible manufacturing system dimensions and their interrelationship using total interpretive structural modelling and fuzzy MICMAC analysis. Glob. J. Flex. Syst. Manag. 2014, 15, 131–143. [Google Scholar] [CrossRef]

- Turner, J.R.; Müller, R. The project manager’s leadership style as a success factor on projects: A literature review. Proj. Manag. J. 2005, 36, 49–61. [Google Scholar] [CrossRef]

- Yang, L.-R.; Wu, K.-S.; Huang, C.-F. Validation of a model measuring the effect of a project manager’s leadership style on project performance. KSCE J. Civ. Eng. 2013, 17, 271–280. [Google Scholar] [CrossRef]

- Wei, Y.; Miraglia, S. Organizational culture and knowledge transfer in project-based organizations: Theoretical insights from a Chinese construction firm. Int. J. Proj. Manag. 2017, 35, 571–585. [Google Scholar] [CrossRef]

- Raziq, M.M.; Borini, F.M.; Malik, O.F.; Ahmad, M.; Shabaz, M. Leadership styles, goal clarity, and project success. Leadersh. Organ. Dev. J. 2018, 39, 309–323. [Google Scholar] [CrossRef]

- Fiol, C.M. Managing culture as a competitive resource: An identity-based view of sustainable competitive advantage. J. Manag. 1991, 17, 191–211. [Google Scholar] [CrossRef]

- Yu, T.; Shi, Q.; Zuo, J.; Chen, R. Critical factors for implementing sustainable construction practice in HOPSCA projects: A case study in China. Sustain. Cities Soc. 2018, 37, 93–103. [Google Scholar] [CrossRef]

- Kivilä, J.; Martinsuo, M.; Vuorinen, L. Sustainable project management through project control in infrastructure projects. Int. J. Proj. Manag. 2017, 35, 1167–1183. [Google Scholar] [CrossRef]

- Demirkesen, S.; Ozorhon, B. Measuring project management performance: Case of construction industry. Eng. Manag. J. 2017, 29, 258–277. [Google Scholar] [CrossRef]

- Bower, D.; Ashby, G.; Gerald, K.; Smyk, W. Incentive mechanisms for project success. J. Manag. Eng. 2002, 18, 37–43. [Google Scholar] [CrossRef]

- Jari, A.J.; Bhangale, P. To study critical factors necessary for a successful construction project. Int. J. Innov. Technol. Explor. Eng. 2013, 2, 331–335. [Google Scholar]

- Mikkelsen, M.F.; Marnewick, C. Investigation of the institutionalizing responsibility of project managers for project benefits realization. J. Mod. Proj. Manag. 2020, 7, 276–294. [Google Scholar]

- Wu, G.; Liu, C.; Zhao, X.; Zuo, J. Investigating the relationship between communication-conflict interaction and project success among construction project teams. Int. J. Proj. Manag. 2017, 35, 1466–1482. [Google Scholar] [CrossRef]

- Meng, X.; Boyd, P. The role of the project manager in relationship management. Int. J. Proj. Manag. 2017, 35, 717–728. [Google Scholar] [CrossRef] [Green Version]

- Nowotna, A.; Pietruszka, B.; Lisowski, P. Eco-Friendly Building Materials. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Prague, Czech Republic, 2–4 July 2019; IOP Publishing: Czech Republic; p. 012024. [Google Scholar]

- Mora, E.P. Life cycle, sustainability and the transcendent quality of building materials. Build. Environ. 2007, 42, 1329–1334. [Google Scholar] [CrossRef]

- Ding, G.K. Life cycle assessment (LCA) of sustainable building materials: An overview. Eco-Effic. Constr. Build. Mater. 2014, 38–62. [Google Scholar]

- Wang, Z. Research on Prevention and Control of Environmental Pollution in Building Construction. J. Archit. Res. Dev. 2019, 3, 2. [Google Scholar] [CrossRef]

- Reddy, B.V. Sustainable building technologies. Curr. Sci. 2004, 87, 899–907. [Google Scholar]

- Wang, N.; Adeli, H. Sustainable building design. J. Civ. Eng. Manag. 2014, 20, 1–10. [Google Scholar] [CrossRef]

- Sandanayake, M.; Lokuge, W.; Zhang, G.; Setunge, S.; Thushar, Q. Greenhouse gas emissions during timber and concrete building construction—A scenario based comparative case study. Sustain. Cities Soc. 2018, 38, 91–97. [Google Scholar] [CrossRef] [Green Version]

| Code (i) | Critical Success Factor | Source of Data |

|---|---|---|

| 1 | Professionalism of partners | [46,93,95] |

| 2 | Partnering experience | [22,24,94] |

| 3 | High credibility of partners | [94,96] |

| 4 | Effective and open internal and external communication and collaboration | [22,24,97] |

| 5 | Mutual trust | [22,23,24,61,97,98] |

| 6 | Clear definition of responsibilities | [22,99,100] |

| 7 | Conflict resolution | [24,70,97] |

| 8 | Effective risk management | [13,23,24,101,102] |

| 9 | Systematically process monitoring | [94,103] |

| 10 | Responsiveness to external environmental changes | [14,98] |

| 11 | Planning and implementation of sustainable strategies | [14,32,66] |

| 12 | Policy support on the protection of local ecological environment | [14,24,89] |

| 13 | Facilitator | [24,46,67] |

| 14 | Organizational project culture | [24,60,90,98] |

| 15 | Resources of water | [97] |

| 16 | Creativity | [97,98,100] |

| 17 | The project manager’s leadership style | [67,71,72,73,98] |

| 18 | Economic viability | [101,102] |

| CSFs (i/j) | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | |||||||||||||||

| 2 | 1 | 1 | ||||||||||||||||

| 3 | 1 | 1 | 1 | |||||||||||||||

| 4 | 1 | 1 | ||||||||||||||||

| 5 | 1 | 1 | 1 | |||||||||||||||

| 6 | 1 | 1 | ||||||||||||||||

| 7 | 1 | |||||||||||||||||

| 8 | 1 | 1 | 1 | |||||||||||||||

| 9 | 1 | 1 | 1 | |||||||||||||||

| 10 | 1 | 1 | ||||||||||||||||

| 11 | 1 | |||||||||||||||||

| 12 | 1 | 1 | ||||||||||||||||

| 13 | 1 | 1 | ||||||||||||||||

| 14 | 1 | 1 | 1 | |||||||||||||||

| 15 | 1 | |||||||||||||||||

| 16 | 1 | 1 | 1 | 1 | ||||||||||||||

| 17 | 1 | 1 | ||||||||||||||||

| 18 | 1 | 1 | 1 |

| CSFs (i/j) | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | Driver Power |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 7 | |||||||||||

| 2 | 1 | 1 | 1 | 3 | |||||||||||||||

| 3 | 1 | 1 | 1 | 1 | 4 | ||||||||||||||

| 4 | 1 | 1 | 2 | ||||||||||||||||

| 5 | 1 | 1 | 1 | 3 | |||||||||||||||

| 6 | 1 | 1 | 2 | ||||||||||||||||

| 7 | 1 | 1 | |||||||||||||||||

| 8 | 1 | 1 | 1 | 3 | |||||||||||||||

| 9 | 1 | 1 | 1 | 1 | 4 | ||||||||||||||

| 10 | 1 | 1 | 2 | ||||||||||||||||

| 11 | 1 | 1 | |||||||||||||||||

| 12 | 1 | 1 | 2 | ||||||||||||||||

| 13 | 1 | 1 | 1 | 1 | 1 | 5 | |||||||||||||

| 14 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 7 | |||||||||||

| 15 | 1 | 1 | |||||||||||||||||

| 16 | 1 | 1 | 1 | 1 | 4 | ||||||||||||||

| 17 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 8 | ||||||||||

| 18 | 1 | 1 | 1 | 1 | 1 | 1 | 6 | ||||||||||||

| Dependence power | 1 | 1 | 1 | 5 | 2 | 3 | 9 | 2 | 1 | 9 | 11 | 1 | 2 | 2 | 7 | 6 | 1 | 1 |

| CSF (i) | R(Si) | A(Si) | C(Si) | Li |

|---|---|---|---|---|

| 1 | 1,6,7,10,11,15,16, | 1 | 1 | |

| 2 | 2,6,7 | 2 | 2 | |

| 3 | 3,4,5,7 | 3 | 3 | |

| 4 | 4,7 | 3,4,5,14,17 | 4 | |

| 5 | 4,5,7 | 3,5 | 5 | |

| 6 | 6,7 | 1,2,6 | 6 | |

| 7 | 7 | 1~7,14,17 | 7 | 7 |

| 8 | 8,10,11 | 8,9 | 8 | |

| 9 | 8,9,10,11 | 9 | 9 | |

| 10 | 10,11 | 1,8,9,10,13,14,16,17,18 | 10 | |

| 11 | 11 | 1,8~14,16,17,18 | 11 | 11 |

| 12 | 11,12 | 12 | 12 | |

| 13 | 10,11,13,15,16 | 13,18 | 13 | |

| 14 | 4,7,10,11,14,15,16 | 14,17 | 14 | |

| 15 | 15 | 1,13~18 | 15 | 15 |

| 16 | 10,11,15,16 | 1,13,14,16,17,18 | 16 | |

| 17 | 4,7,10,11,14,15,16,17 | 17 | 17 | |

| 18 | 10,11,13,15,16,18 | 18 | 18 | |

| 1 | 1,6,10,16, | 1 | 1 | |

| 2 | 2,6 | 2 | 2 | |

| 3 | 3,4,5 | 3 | 3 | |

| 4 | 4 | 3,4,5,14,17 | 4 | 4 |

| 5 | 4,5 | 3,5 | 5 | |

| 6 | 6 | 1,2,6 | 6 | 6 |

| 8 | 8,10 | 8,9 | 8 | |

| 9 | 8,9,10 | 9 | 9 | |

| 10 | 10 | 1,8,9,10,13,14,16,17,18 | 10 | 10 |

| 12 | 12 | 12 | 12 | 12 |

| 13 | 10,13,16 | 13,18 | 13 | |

| 14 | 4,10,14,16 | 14,17 | 14 | |

| 16 | 10,16 | 1,13,14,16,17,18 | 16 | |

| 17 | 4,10,14,16,17 | 17 | 17 | |

| 18 | 10,13,16,18 | 18 | 18 | |

| 1 | 1,16, | 1 | 1 | |

| 2 | 2 | 2 | 2 | 2 |

| 3 | 3,5 | 3 | 3 | |

| 5 | 5 | 3,5 | 5 | 5 |

| 8 | 8 | 8,9 | 8 | 8 |

| 9 | 8,9 | 9 | 9 | |

| 13 | 13,16 | 13,18 | 13 | |

| 14 | 4,14,16 | 14,17 | 14 | |

| 16 | 16 | 1,13,14,16,17,18 | 16 | 16 |

| 17 | 14,16,17 | 17 | 17 | |

| 18 | 13,16,18 | 18 | 18 | |

| 1 | 1 | 1 | 1 | 1 |

| 3 | 3 | 3 | 3 | 3 |

| 9 | 9 | 9 | 9 | 9 |

| 13 | 13 | 13,18 | 13 | 13 |

| 14 | 14 | 14,17 | 14 | 14 |

| 17 | 14,17 | 17 | 17 | |

| 18 | 13,18 | 18 | 18 | |

| 17 | 17 | 17 | 17 | 17 |

| 18 | 18 | 18 | 18 | 18 |

| CSF (i/j) | 7 | 11 | 15 | 4 | 6 | 10 | 12 | 2 | 5 | 8 | 16 | 1 | 3 | 9 | 13 | 14 | 17 | 18 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L1 | 7 | ||||||||||||||||||

| 11 | |||||||||||||||||||

| 15 | |||||||||||||||||||

| L2 | 4 | 1 | |||||||||||||||||

| 6 | 1 | ||||||||||||||||||

| 10 | 1 | ||||||||||||||||||

| 12 | 1 | ||||||||||||||||||

| L3 | 2 | 1 | |||||||||||||||||

| 5 | 1 | ||||||||||||||||||

| 8 | 1 | ||||||||||||||||||

| 16 | 1 | 1 | |||||||||||||||||

| L4 | 1 | 1 | 1 | ||||||||||||||||

| 3 | 1 | ||||||||||||||||||

| 9 | 1 | ||||||||||||||||||

| 13 | 1 | ||||||||||||||||||

| 14 | 1 | 1 | |||||||||||||||||

| L5 | 17 | 1 | |||||||||||||||||

| 18 | 1 | ||||||||||||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Z.; Chen, H. An ISM-Based Methodology for Interrelationships of Critical Success Factors for Construction Projects in Ecologically Fragile Regions: Take Korla, China as an Example. Appl. Sci. 2021, 11, 4668. https://doi.org/10.3390/app11104668

He Z, Chen H. An ISM-Based Methodology for Interrelationships of Critical Success Factors for Construction Projects in Ecologically Fragile Regions: Take Korla, China as an Example. Applied Sciences. 2021; 11(10):4668. https://doi.org/10.3390/app11104668

Chicago/Turabian StyleHe, Zheng, and Huihua Chen. 2021. "An ISM-Based Methodology for Interrelationships of Critical Success Factors for Construction Projects in Ecologically Fragile Regions: Take Korla, China as an Example" Applied Sciences 11, no. 10: 4668. https://doi.org/10.3390/app11104668

APA StyleHe, Z., & Chen, H. (2021). An ISM-Based Methodology for Interrelationships of Critical Success Factors for Construction Projects in Ecologically Fragile Regions: Take Korla, China as an Example. Applied Sciences, 11(10), 4668. https://doi.org/10.3390/app11104668