1. Introduction

Over the past decades, multilegged robots have gained more and more attention for their ability to traverse nonstructural environments and uneven terrains like mammals or insects. Furthermore, they not only can play an important role in transporting materials on flat or rough terrain but also can execute many dangerous missions alone or in cooperation with humans, such as outdoor exploration, disaster rescue, and dangerous substance detection [

1]. Compared with the electric actuators, hydraulic actuation can provide extremely high power density, fast dynamic response, large force output, and strong robustness to impacts [

2], which are widely used in hydraulic robotic manipulators [

3]. Thus, hydraulic legged robots apply to more and more heavy load occasions [

4]. Boston Dynamics developed hydraulic quadruped or humanoid robot series, including BigDog [

5], LS3, Cheetah, Wildcat, Petman [

6], Handle, Atlas [

7], which brought the topic into a hotspot. Italian Institute of Technology (IIT) constructed a series of high-performance hydraulic quadruped robots, such as HyQ [

8], miniHyQ [

9], HyQ2Max [

10], HyQReal. Korea Institute of Industrial Technology (KITECH) proposed hydraulic quadruped robots qRT-1, qRT-2 [

11], p2 [

12], and JINPOONG [

13]. Meanwhile, Shandong University’s (SDU) quadruped robots SCalf-I [

14], SCalf-II [

15], and SCalf-III [

16], Shanghai Jiao Tong University’s (SJTU) Baby elephant [

17] and Octopus [

18], Harbin Institute of Technology’s (HIT) MBBOT [

19], National University of Defense Technology’s (NUDT) quadruped robot [

20] and Beijing Institute of Technology’s (BIT) bionic quadruped robot [

21] also continued to obtain advances in the fields of dynamic locomotion and control in recent years.

Since legged robots usually need to implement multiple tasks at the same time, such as data collection, posture calculation, gait planning, actuation control, they often adopt a hierarchical control system, where the embedded controller often plays an important role. BigDog is controlled by a layered onboard computer that contains a PC104 Pentium processor (Intel Corporation, Santa Clara, California, U.S.) running a multi-rate real-time operating system under QNX as well as I/O cards and I/O interfaces. The high-level control system coordinates the behavior of the legs to regulate the velocity, attitude, and altitude of the body during locomotion in 200 Hz while the lower-level control system servos positions and forces at the joints in 1 kHz [

22]. HyQ’s control system architecture consists of a CPU board and five multifunction I/O boards. The CPU board is a Kontron MOPSPM104 board (Kontron S&T AG, Augsburg, Germany) running a real-time patched version of Linux (Linux kernel patched with real-time Xenomai), while five multifunction I/O boards are responsible for four legs and other sensors in a 1 kHz control frequency [

23]. qRT-2 has a control architecture composed of the task level controller, the function level controller, the local controller, and the power controller [

11]. The MIT Cheetah, whose control system is comprised of four layers: the motor drivers, the parallel UART emulators, the real-time multicore controller, and the monitoring PC, uses an i7 dual-core 1.33 GHz CPU as the real-time controller running two 4 kHz high priority loops [

24]. ANYmal has three Intel NUC PCs (Intel Corporation, Santa Clara, California, U.S.) running the robot operating system (ROS) with a 400 Hz actuator control frequency, including inspection PC, navigation PC, and locomotion PC [

25]. SCalf has a control system comprised of an industrial personal computer and a TMS320f28335 digital signal processor (DSP) (Texas Instruments Incorporated, Dallas, Texas, U.S.) with a 5 kHz sampling frequency and 1 kHz servo rate [

26]. MBBOT owns a PC104 main controller and four leg servo controllers with a 1 kHz joint control frequency [

27]. Chapuis et al. developed a low-cost FPGA-based decentralized control system for a MEMS-based distributed air-flow micromanipulator [

28].

Dynamic motions of the legged robots have been studied for years, and many control methods have been proposed. HyQ uses dynamic torque control to be actively compliant, with an inner PID torque loop and an outer PID position loop [

29]. It also proposes a position control combined with an admittance block to handle the environmental interaction efficiently while the robot is trot-walking [

30]. MIT Cheetah I is controlled by the proprioceptive impedance controller to achieve a stable gallop at 3.2 m/s which can allow reflex responses to external forces according to the predefined compliance [

31]. ANYmal develops a cascaded joint torque, position, and impedance control to realize the joint tracking very accurately [

32]. JINPOONG uses a PD plus feed-forward controller to walk stably on uneven terrain [

33]. Chen et al. utilized a virtual model control (VMC) in SCalf-II to reduce the contact force by 35.7% [

15]. Zhang et al. designed a position/force control law on the base of the operation space dynamic equation and the maximum sinusoid tracking error was less than 8 mm [

34]. Zhang et al. acquired a foot contact estimation method in the impedance control and proposed a compensation scheme using neural network in the real quadruped robot system [

35]. Xie et al. presented a VMC for quadrupedal dynamic locomotion, which consisted of a stance phase virtual model control for full control of the robot body and a swing phase virtual model control for control of swing legs [

36]. Chen et al. proposed an impedance controller to solve the ball-on-plate (BoP) problem for six-parallel-legged robots walking on irregular terrains based on seven six-dimensional(6D) force/torque(F/T) sensors [

37]. Wirekoh et al. implemented a real-time position and force feedback control for the artificial muscle with microfluidic sensors [

38]. Cairone et al. presented a PDMS micro-optofluidic chip [

39] and identified a class of models representing the two-phase microfluidic flow in different experimental conditions [

40].

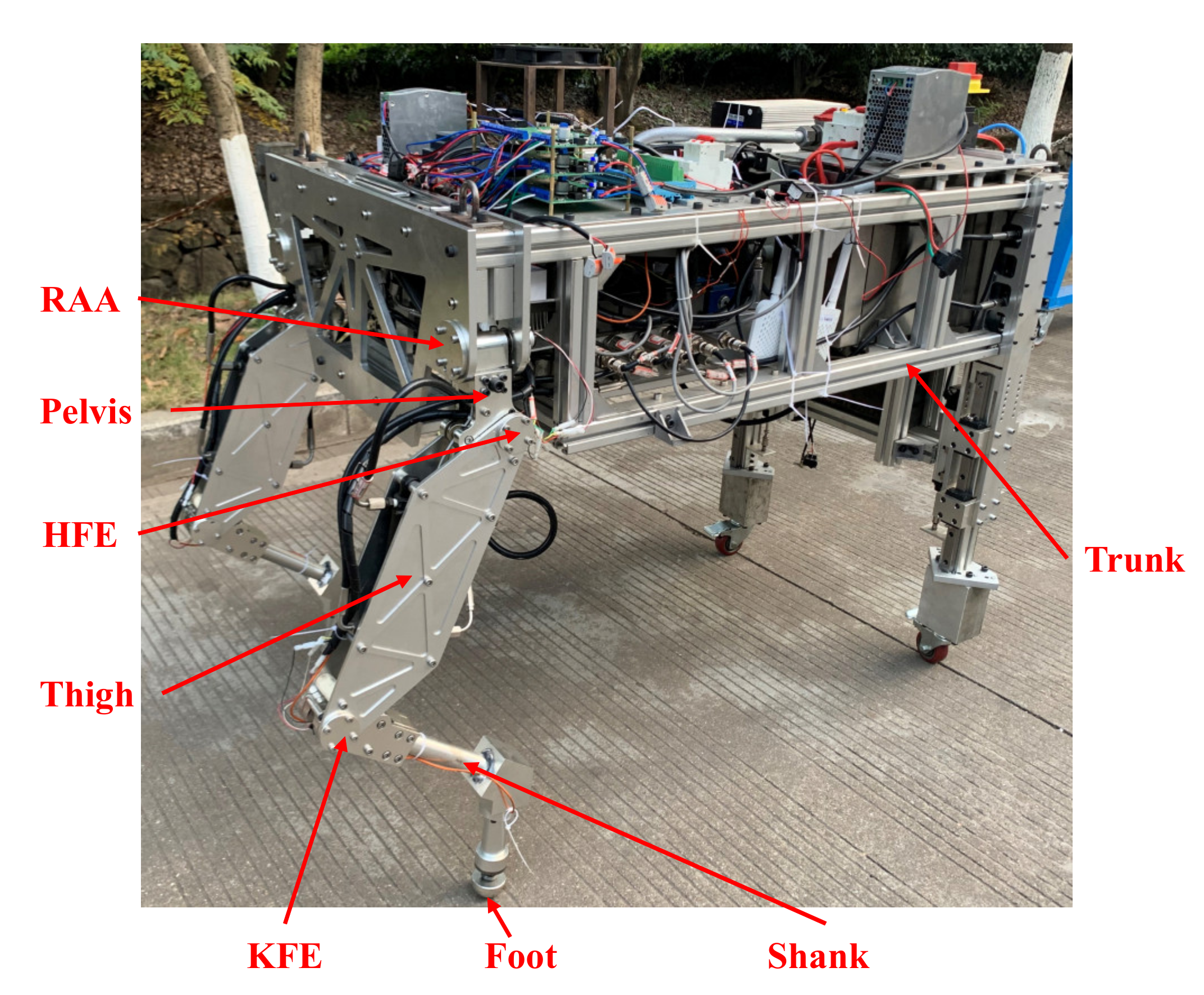

This paper gives an introduction of the quadruped hydraulic wheeled-legged robot WLBOT, including its structure, hydraulic system, and control system. It concentrates on the embedded controller, including the hardware, software design, and control strategy. Both the joint position control and joint force control are introduced respectively. In joint position control, a PID controller with velocity feedforward compensation (VFC) is proposed and the Chebyshev filtering algorithm is utilized to reduce the impact of joint jitter. What’s more, an impedance controller is designed to realize better locomotion behavior in joint force control. Finally, the test platform is constructed, where the feasibility of the design and the validity of the control algorithm is verified. This paper makes the following contributions:

The relationship between ADC-DMA interrupt cycle, data volume, and the sampling rate is researched and a 2 kHz high-speed control loop for the embedded controller is proposed to realize better control performance;

A proportional-integral-derivative (PID) velocity feedforward compensation (VFC) controller is designed to realize the joint position control. Compared with the general PID, VFC can reduce the maximum joint tracking error by 39.13% and 71.31%;

The Chebyshev filtering algorithm is utilized to reduce the vibration noise of joint signals;

An impedance controller in the joint space is proposed to get the better locomotion behavior and compliant effect in the walking experiments.

4. Embedded Controller Software Design

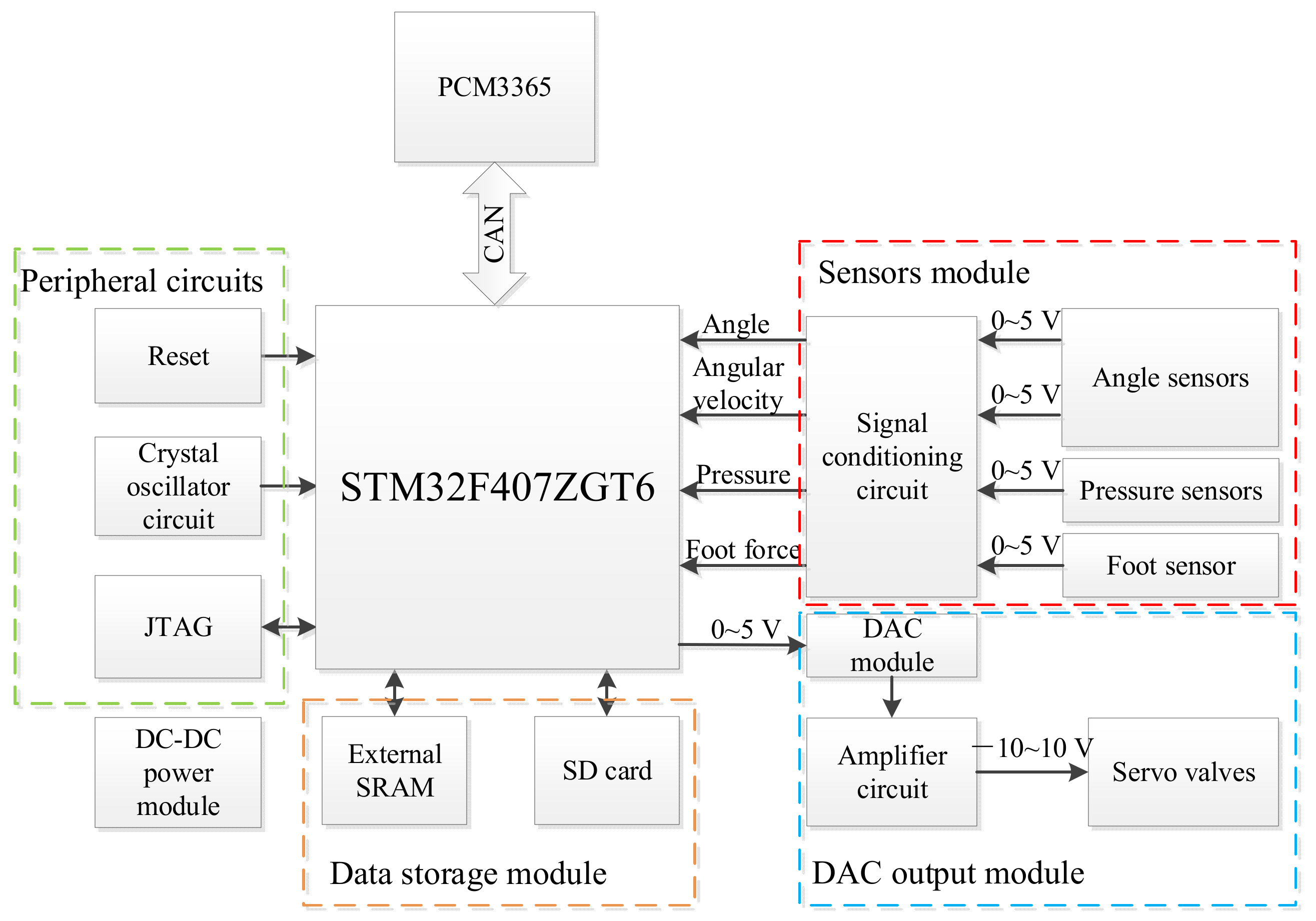

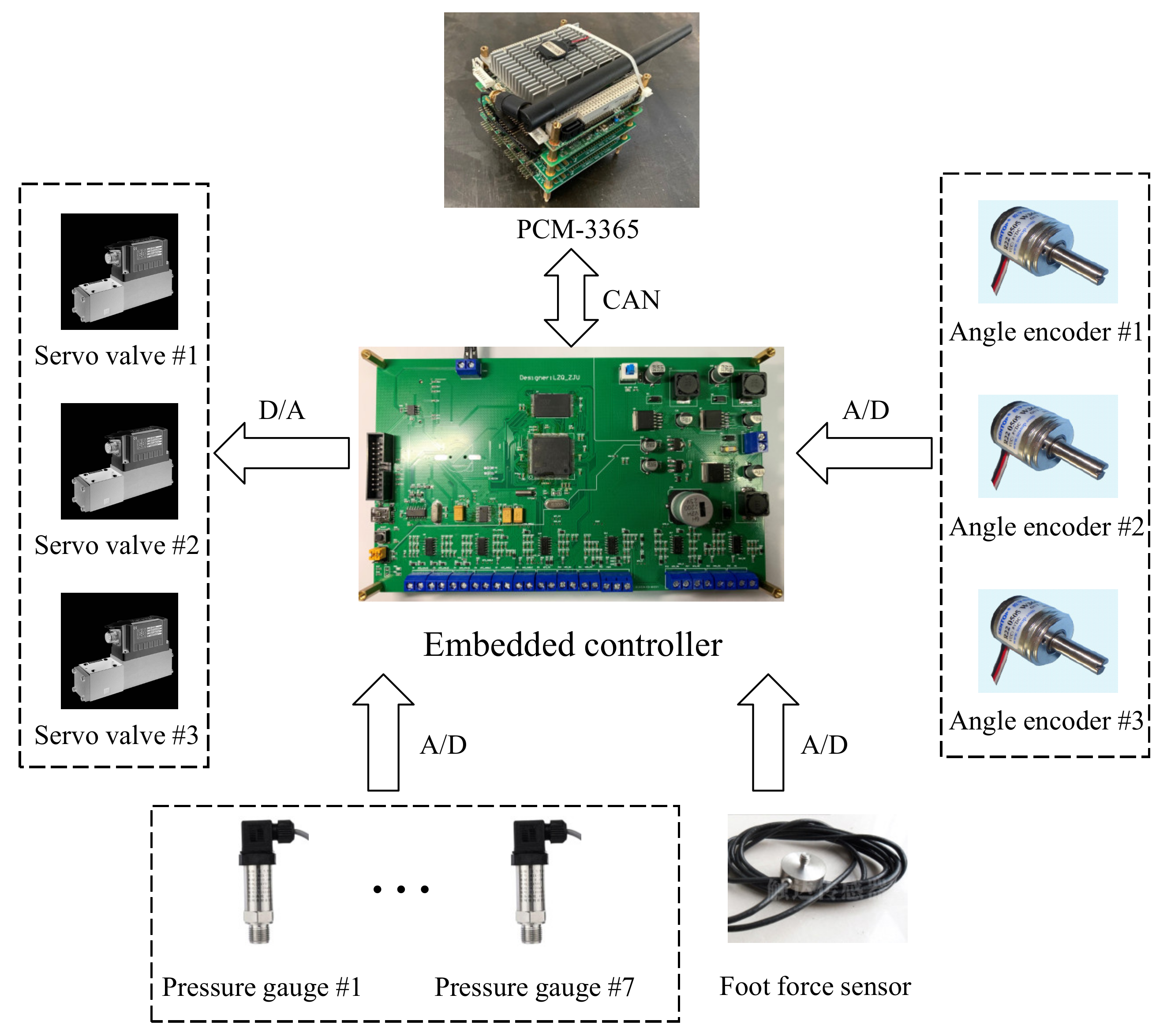

4.1. Software Architecture

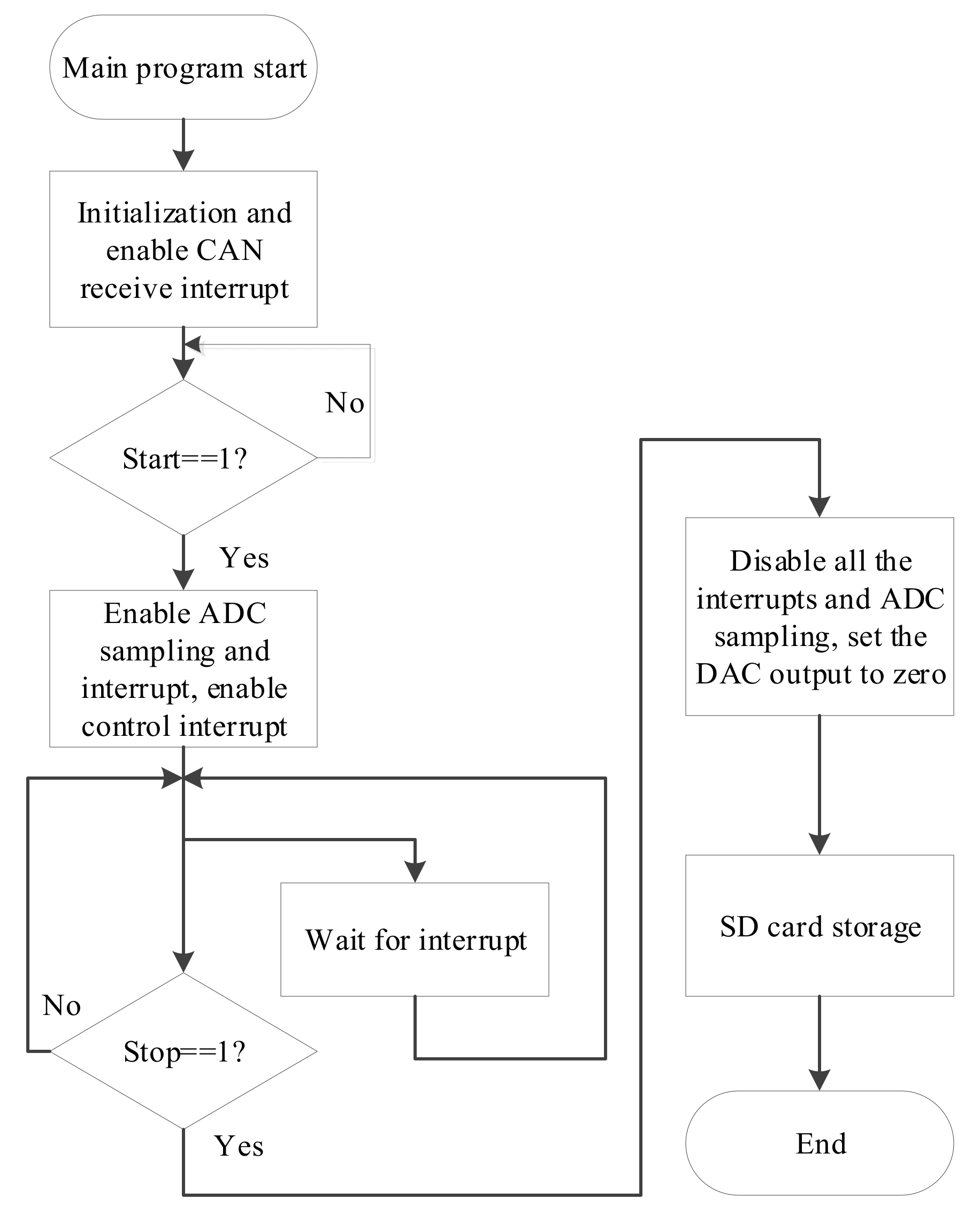

As the essential part of the control system, the software component is supposed to take responsibility for the reasonable arrangement of multiple tasks. The control frequency of the embedded controller affects the accuracy and stability of the robot control. It’s vital to utilize the CPU resources effectively, select the interrupt cycle and configure the priority reasonably. The software program consists of the main program module and four interrupts, which are shown in

Figure 6 and

Figure 7. The interrupt priority is configured in

Table 1 and makes the interrupt service routine (ISR) run properly.

The flow chart of the main program is shown in

Figure 6. When the embedded controller is powered on, the main program will start. The initialization will be implemented firstly and CAN receive interrupt will also be enabled to wait for a command from PCM–3365. When the controller gets a start command, it will set the flag ‘Start’. After that, both ADC1 and ADC3 sampling and interrupt will be enabled as well as the control interrupt. Then the main program will be waiting for the interrupt until the stop command comes. When it comes to the stop command, all the interrupts and ADC sampling will be disabled and the DAC output will be set to zero to avoid servo valves’ misoperation. Before the end, all the test data will be copied from the external SRAM to the SD card for further study.

There are four interrupts as

Table 1 shows and the flow chart of ISR is illustrated in

Figure 7. When the CAN receive interrupt comes, the controller reads data from PCM–3365 and makes different responses according to different commands. Especially, when it gets a start command, the control strategy will be stored. In ADC1–DMA and ADC3–DMA interrupt, the sampling data will be processed in the median and mean filtering. After that, the processed data will be stored in the temporary arrays for the control algorithm to use. As for the control interrupt, the control algorithm will be calculated and all the processed data will be stored in external SRAM for further use.

4.2. Research on the Relationship Between ADC-DMA Interrupt Cycle, Sampling Data Volume, and ADC Sampling Rate

As we need to sample 14 sensor signals, we select both ADC1 and ADC3 controllers while each controller can offer seven sampling channels. ADC1 selects DMA2 stream0 and ADC3 selects DMA2 stream1. When it comes to a start command from PCM–3365, the embedded controller starts continuous sampling. When the data buffer of each DMA is full, an interrupt will be triggered. For the configuration of DMA in ADC sampling, we can reduce the burden of CPU, which greatly improves the embedded controller’s efficiency.

For STM32F4 series chips, the total ADC conversion time

is calculated as follows:

The shortest sampling time can be configured as three cycles. Though the extension of the sampling time will improve the accuracy of sampling, it reduces the AD conversion rate. Since the maximum frequency of STM32F407ZGT6 is 168 MHz, to ensure the accuracy of sampling, ADCCLK prescaler is configured to a division factor of 4, and thus the maximum sampling clock frequency is 21 MHz.

The ADC–DMA interrupt cycle

can be calculated as follows:

where

is the number of ADC sampling channels,

is the sampling data volume of each channel when the data buffer of DMA is full, and

is the actual sampling rate.

Our primary selection is

. With the online debugging function of Keil uVision 5, we can estimate that the third-order median and mean filtering in DMA interrupt costs about

. Thus, the average processing time for each data is about

. If each DMA channel stores

data, it will cost

as follows:

Besides filtering, other programs in DMA interrupt only cost about

. So the ADC–DMA interrupt service routine cost about

as:

Since the running time of the DMA interrupt service routine must be less than or equal to the ADC–DMA interrupt cycle:

Combine Equations (2), (3) and (5), we can easily get the maximum ADC sampling rate

and the minimum ADC–DMA interrupt cycle

:

According to Equation (6), we can plot the relationship between the minimum ADC–DMA interrupt cycle

, the maximum ADC sampling rate

, and the sampling data volume

in

Figure 8.

In the ADC–DMA interrupt, the sampling data will be processed in the median and mean filtering. It has been tested that the filtering algorithm time occupies most of the DMA interrupt service routine time. When

is nearly unchanged,

will be shorter as

gets smaller. However, when

is too small, it will worsen the filtering effect and reduce

. As a result, after coordinating the relationship between

,

and

, we choose an appropriate ADC–DMA interrupt cycle and obtain better sampling results. The final parameters

, actual sampling rate

, and actual ADC–DMA interrupt cycle

are shown in Equation (7). By using the oscilloscope, we can observe that both ADC1–DMA and ADC3–DMA interrupt cycles are about

, which is consistent with the theoretical analysis.

4.3. Realization of High-Speed Control Frequency

PCM–3365 can only send 200 Hz commands via CAN bus, which is far from meeting the requirement of the motion control. Thus, we need to use the previous and the current commands sent by PCM–3365 to perform Lagrangian interpolation in the CAN receive interrupt. The Lagrangian polynomial is obtained and converted into the form required by the embedded controller, as shown in Equation (8).

where

is the interpolated joint angle command,

and

is the previous and current joint angle command,

.

With the help of Lagrangian interpolation, nine values are inserted between the two commands sent by the PCM–3365, and the interval between the new interpolated commands is , which is consistent with the 2 kHz control frequency. The embedded controller utilizes to perform control algorithm calculation during the control interrupt to achieve high-speed control frequency.

With the configuration of interrupt priority, it is ensured that the control interrupt has the highest priority, and the control interrupt and CAN receive interrupt can interrupt the ADC1–DMA and ADC3–DMA ISRs. Since DMA interrupt cycle is shorter than control interrupt cycle, the latest data is continuously written in the CAN send array in ADC–DMA ISRs. As a result, in the control interrupt, we make sure that the control algorithm can always utilize the latest information obtained by the sensors, which is vital to the real-time control of the robot.

Due to the existence of interrupt nesting, we introduce a temporary storage array in ADC–DMA ISRs to reduce the impact of data loss if the filtering program is interrupted. Take ADC1–DMA interrupt as an example. When it comes to the ADC1–DMA ISR, we firstly perform median and mean filtering on the 20 data collected by each channel. Then the processed data for one channel will be temporarily stored in the temporary storage array. Finally, after all the data in seven channels is processed, we transfer all the data in a temporary storage array to the CAN send array for the control algorithm to use. In this case, the data in the CAN send array will be sent to PCM–3365 in the next CAN receive interrupt. The calculation of the control algorithm utilizes the interpolated commands and data in the CAN send array. Even if the executing filtering ISR is interrupted, we can’t get the current complete ADC sampling data, we can still use the last ADC sampling data stored in the CAN send array to implement the control algorithm. Considering the current data and the last data just has a difference of about , the influence can be omitted.

The running time of four ISRs is tested through an oscilloscope, as shown in

Table 2. It’s obvious that the control interrupt ISR is much shorter than the interrupt interval, which will reserve enough space for more complex control algorithms in the future.

4.4. Joint Control Algorithm

4.4.1. PID Control with Velocity Feedforward Compensation (VFC)

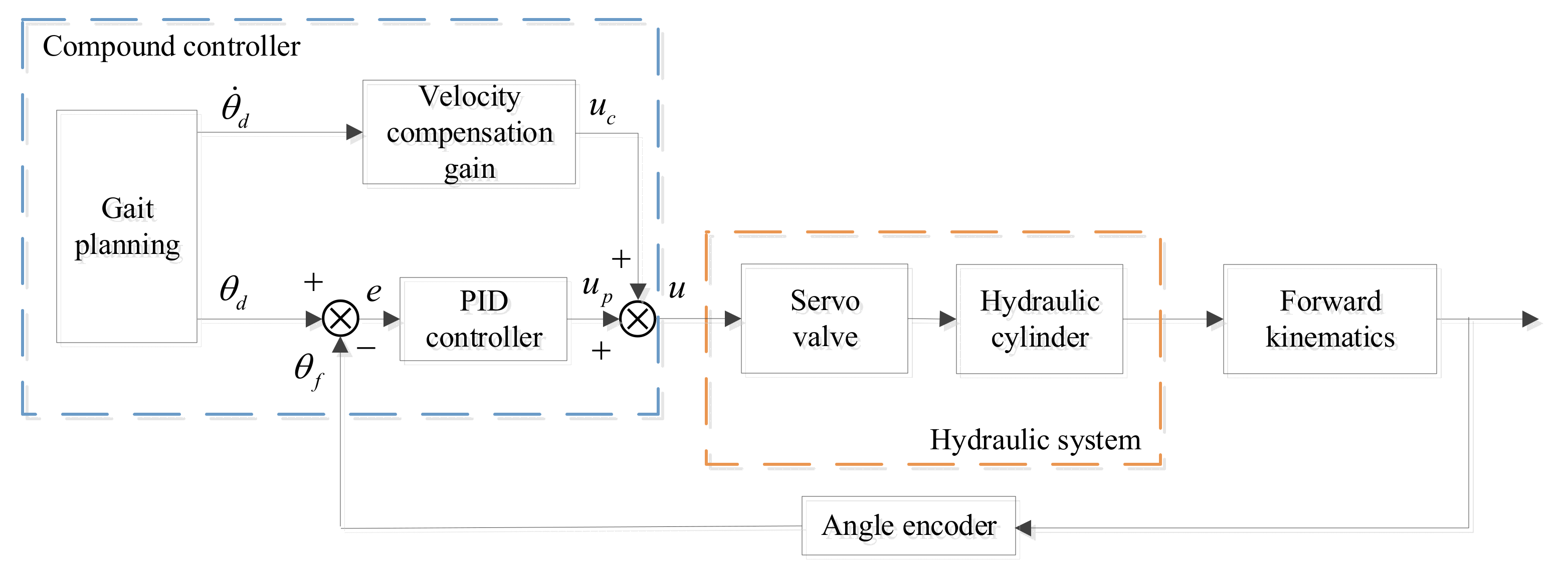

In order to realize joint position control, we develop a PID (proportional-integral-derivative) compound controller with velocity feedforward compensation (VFC) as

Figure 9 illustrates.

The compound controller consists of a conventional PID controller and velocity feedforward compensation (VFC). The control law is shown in Equation (9).

where

is the tracking error;

is the desired angle;

is the feedback angle;

,

,

are the proportional gain, integral gain, and derivative gain;

is the desired angular velocity;

is the velocity compensation gain.

4.4.2. Design of Chebyshev Digital Filtering Algorithm

In the double-joint step response experiment, it is found that the joint jitter is greater in the steady state. Analyzing the experimental data, it is the large fluctuation of the derivative term of the PID output which causes the phenomenon. Although we can use a smaller PID coefficient to reduce the influence of joint jitter, it will bring about the longer settling time. Thus, we consider using the digital low-pass filtering of the derivative term in the PID controller to increase the stability of the robot in the steady state without reducing its response speed. Chebyshev I Filter is introduced in Equation (10).

where

is a positive number less than 1,

is the passband boundary frequency.

We can design a Chebyshev I Filter as Equation (11) shows, with a 70 Hz cut-off frequency. When we convert the Z transfer function into a difference equation, we can implement it in the embedded controller.

4.4.3. Impedance Control

Since hydraulic walking robots are typically modeled as rigid body systems, they have forces or torques as input to their dynamics, and therefore being able to apply precise joint torques to a robot has many advantages. Contrary to the position control, impedance control, as one of the force controls, can significantly increase the versatility and compliance of the robot, which will have outstanding advantages in the interaction with the environment, especially in the walking experiment. The general concept of impedance control was introduced by Hogan in the seminal work [

41,

42] and can nowadays be considered as a classical control approach in robotics. Thus, we design a joint impedance controller in the joint space as

Figure 10 shows. The force inner loop PID controller adopts the same form of the first row of Equation (9). The impedance control can be described as a virtual spring-damper system or a PD controller, which acts as the position outer loop. The control law and the feedback are shown in Equation (12).

where

and

are the stiffness and damping of the virtual joint spring;

and

are the error of angle and angular velocity;

and

are the acting area of piston and rod chamber;

and

are the pressure of piston and rod chamber;

is the force arm of output force of the joint hydraulic cylinder.

6. Conclusions and Future Work

This paper focuses on the design and control strategy of an embedded controller for the hydraulic quadruped robot WLBOT. First, an overview of the WLBOT is given, including its mechanical structure, onboard hydraulic system, and hierarchical control system. Then an embedded controller for WLBOT is designed in detail. The embedded controller’s hardware consists of a CAN bus module, a sensors module, a DAC output module, a data storage module, a DC–DC power module, and other peripheral circuits. In the software design, the main program and four interrupts are introduced as well as their flow charts. CAN receive interrupt will finish the information communication with PCM–3365, while ADC–DMA interrupt can sample and process 14 sensor signals and control interrupt will realize the complex control algorithm. By studying the relationship between ADC–DMA interrupt cycle, data volume, and sampling rate, we select an appropriate interrupt cycle to achieve the controller’s 2 kHz high-speed control frequency. Then the joint position control PID VFC is proposed, combined with the Chebyshev filtering algorithm to reduce the impact of joint jitter. Furthermore, an impedance controller in the joint space is designed to realize better locomotion behavior in the walking experiment. Finally, the experiments show that PID VFC control can have better joint position control accuracy, which can reduce the maximum tracking error by 39.13% and 71.31%. In the walking experiment, the impedance control can achieve a good compliant effect and reduce the SD of foot force by 36.06% and 72.79%, compared with the position control.

Future work will concentrate on improving the motion ability of the robot as well as other complex control strategies for the position, force, and hydraulic system.