Time–Frequency Envelope Analysis for Fault Detection of Rotating Machinery Signals with Impulsive Noise

Abstract

:1. Introduction

2. Envelope Analysis to Detect Defects in Rotating Machinery

2.1. Hilbert Transform

2.2. Signal Modeling for Simulation

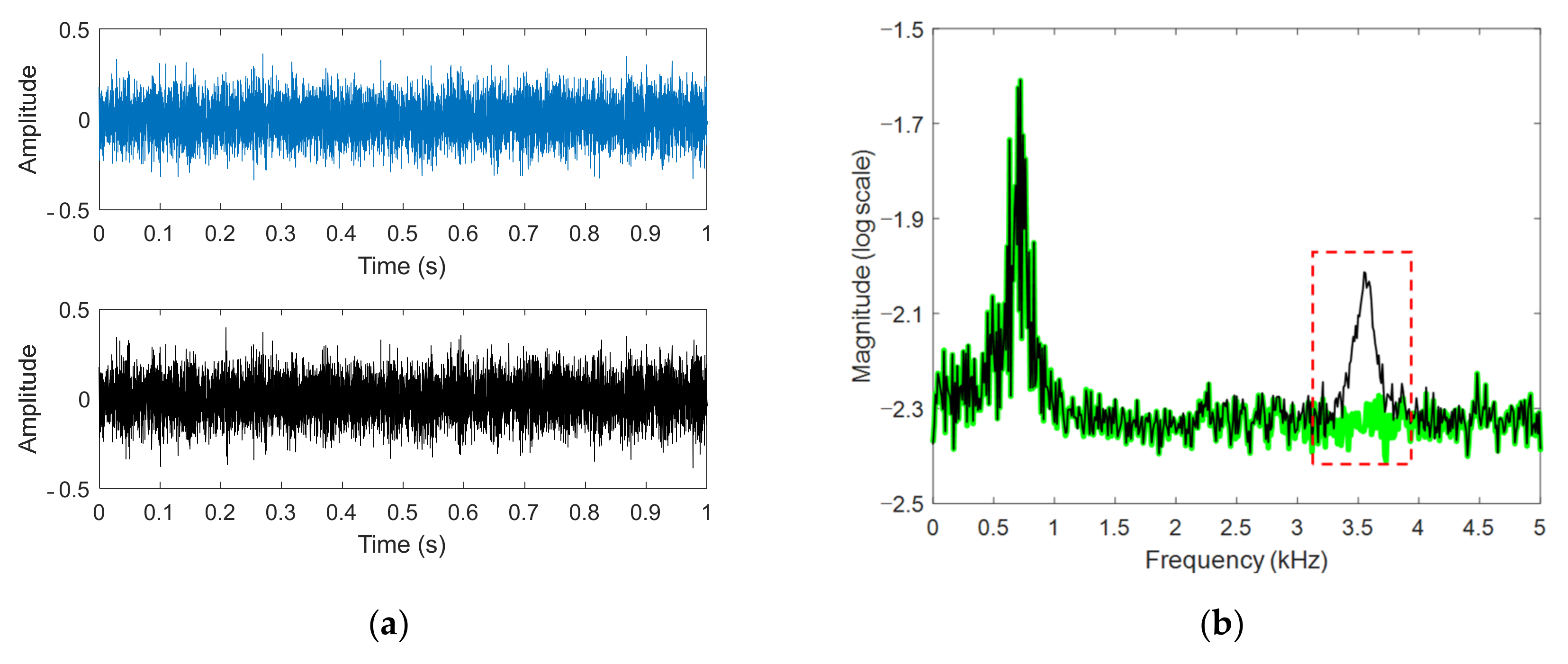

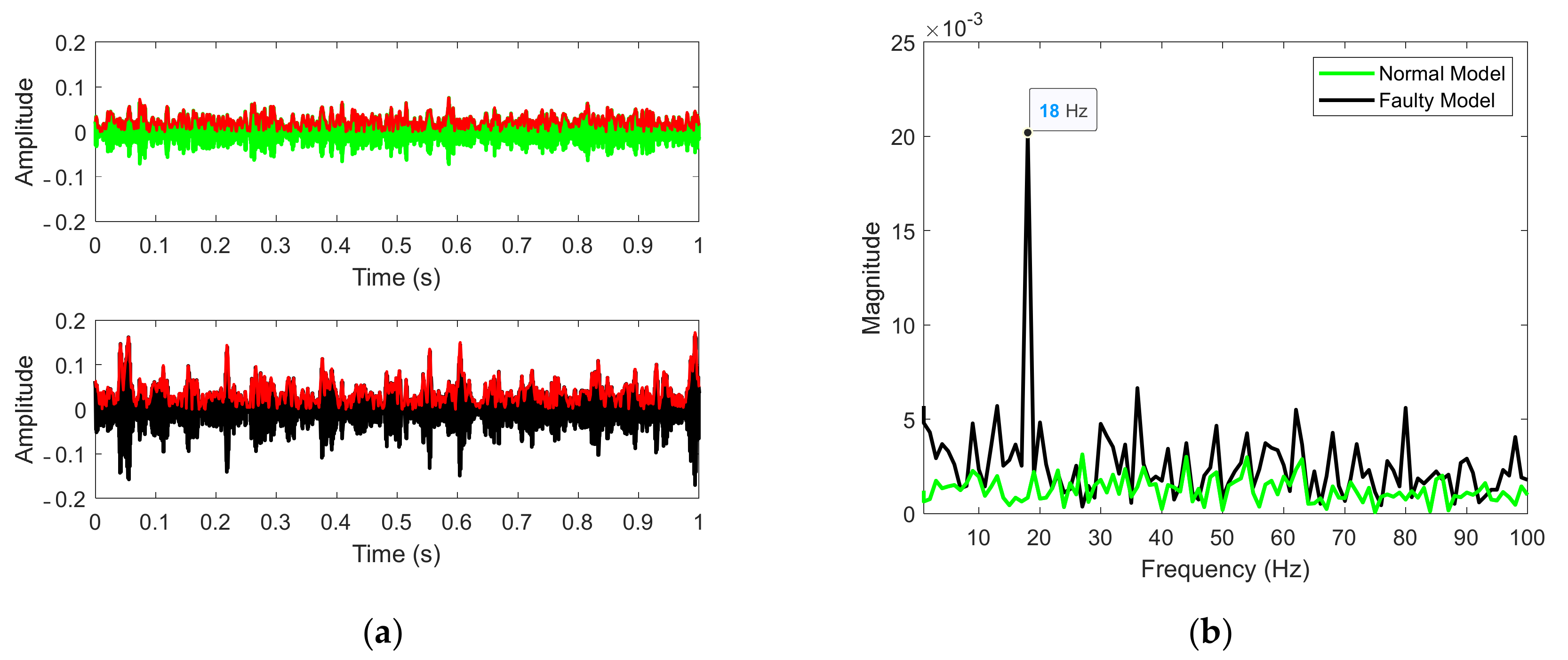

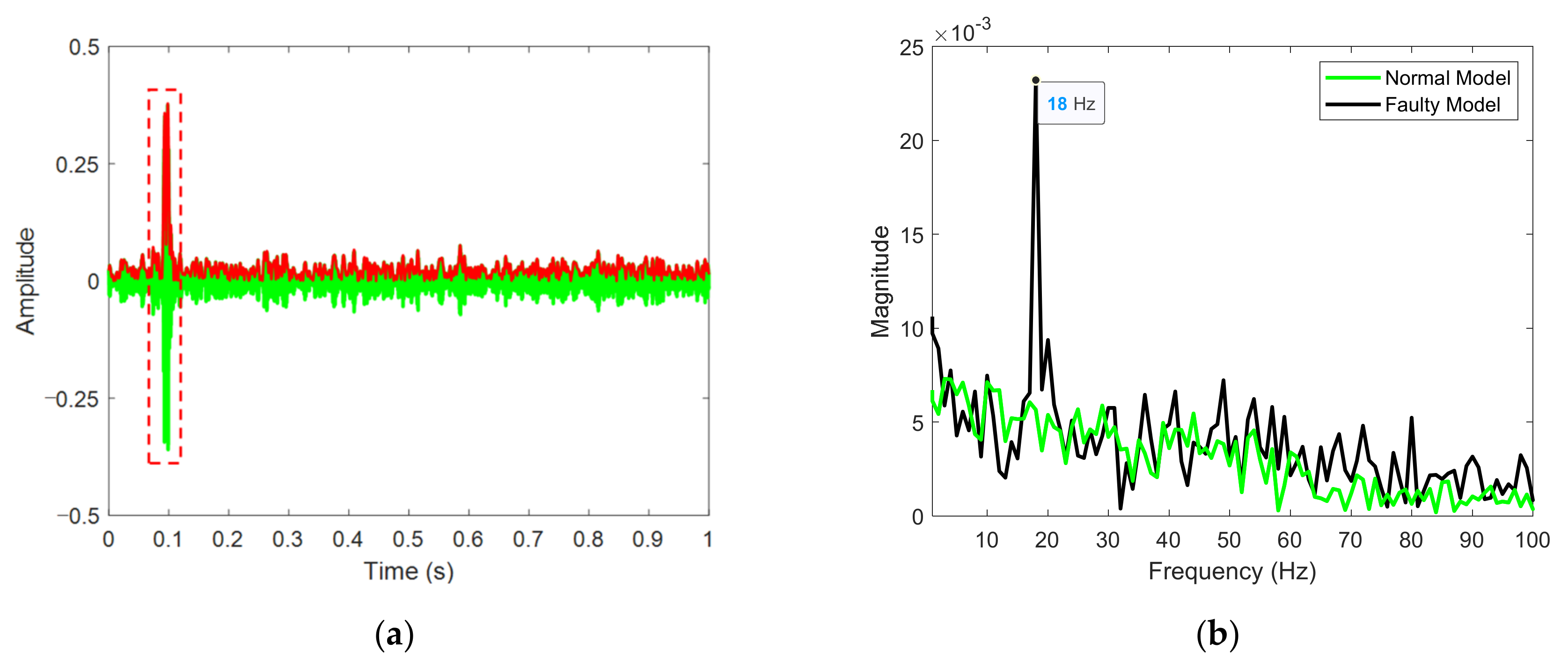

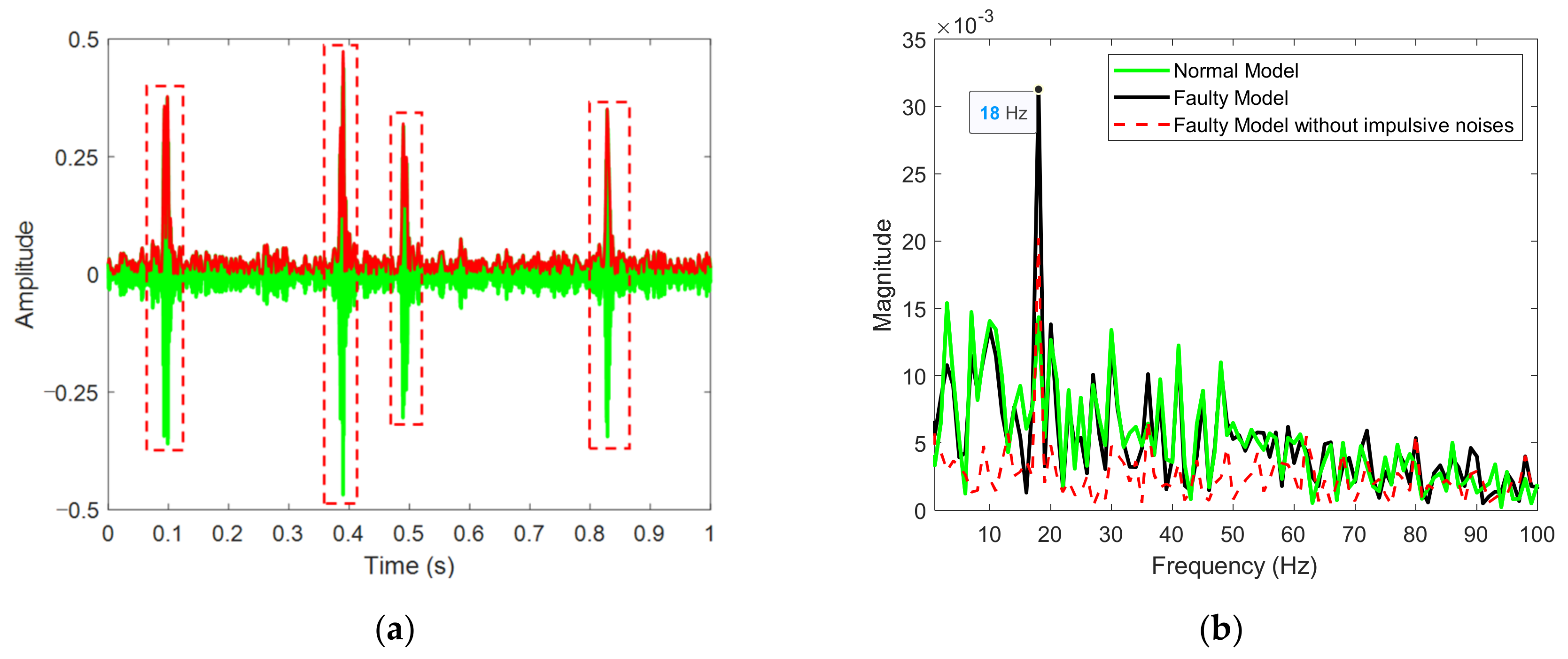

2.3. Degraded Detection Performance by Impulsive Noise

3. Improvement of Envelope Analysis

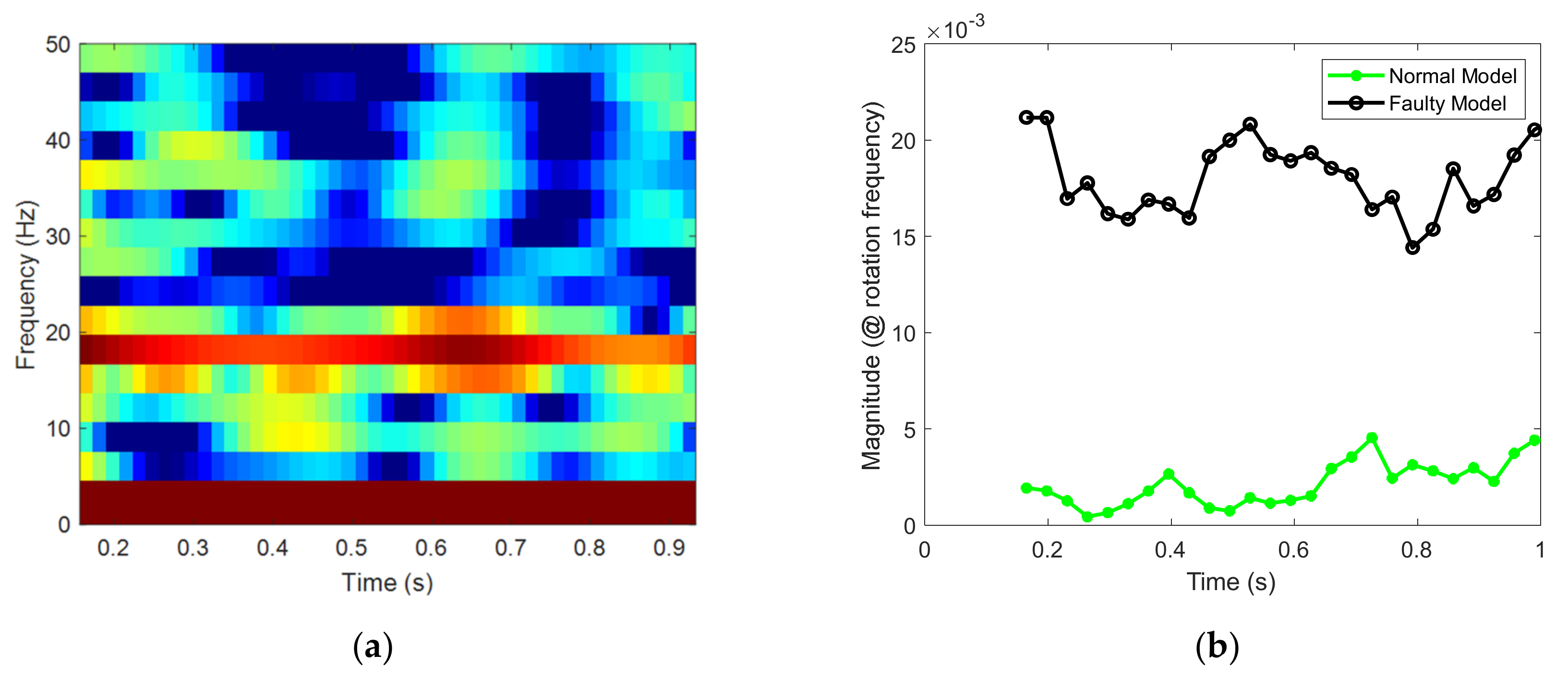

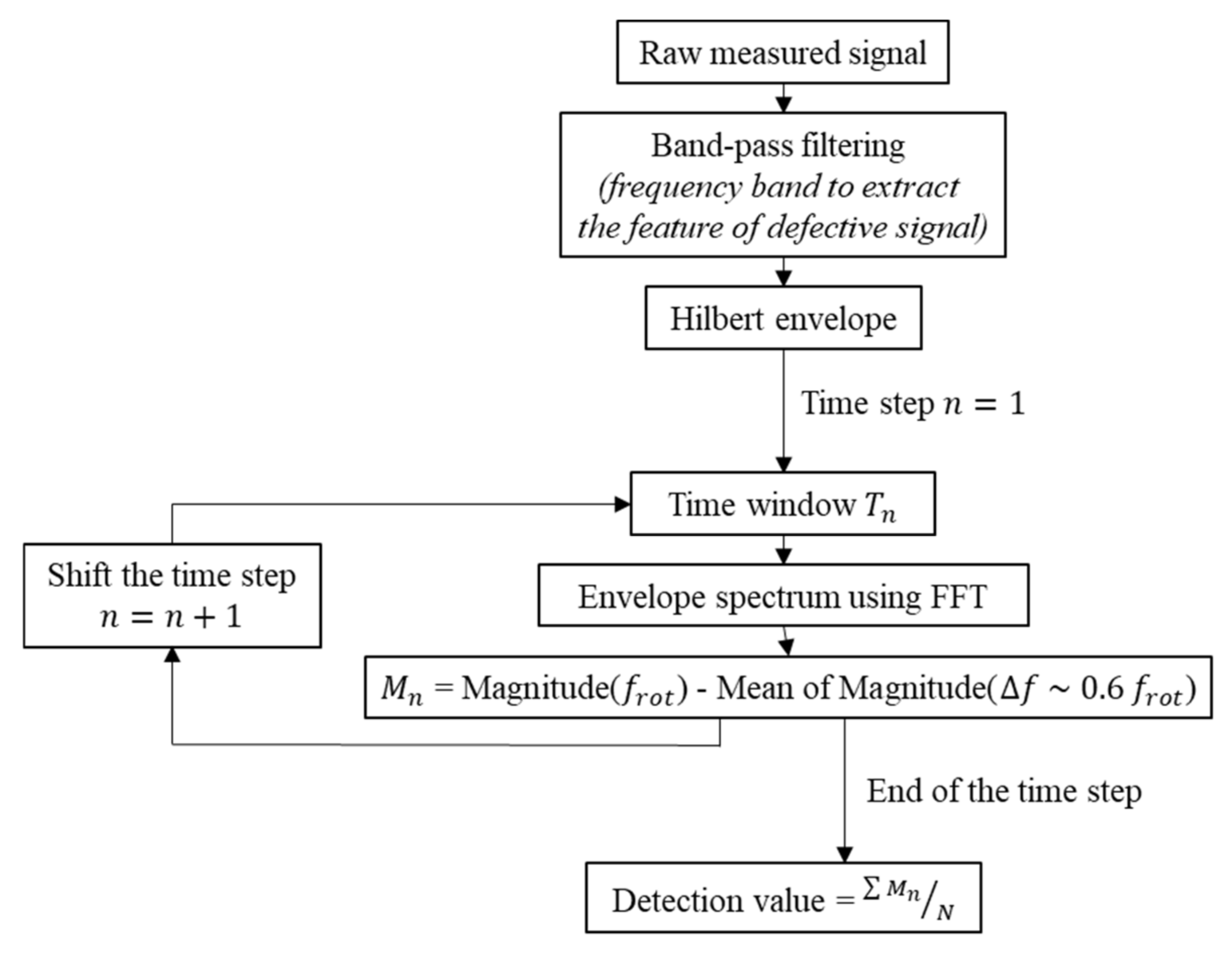

3.1. Time–Frequency Domain Approach for Envelope Analysis

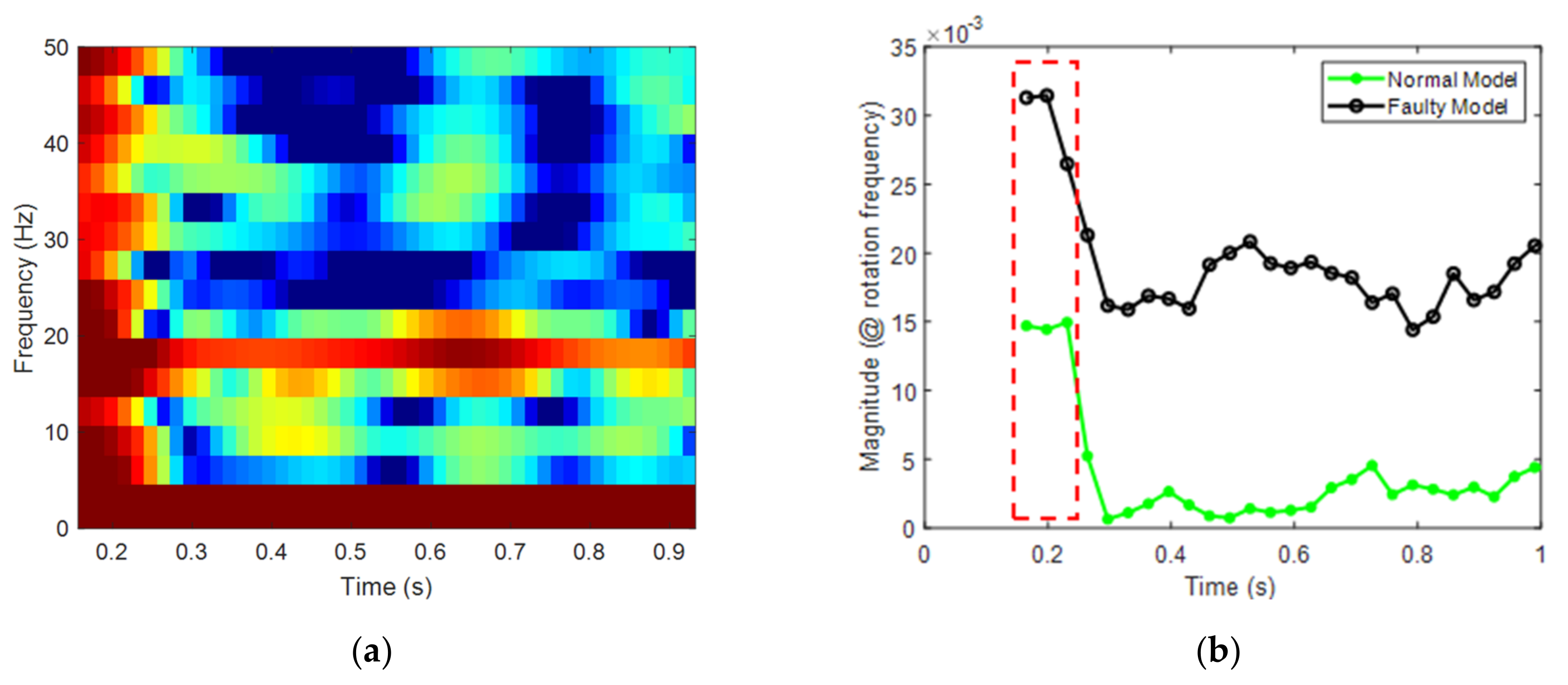

3.2. Methods for Overcoming Impulsive Noises

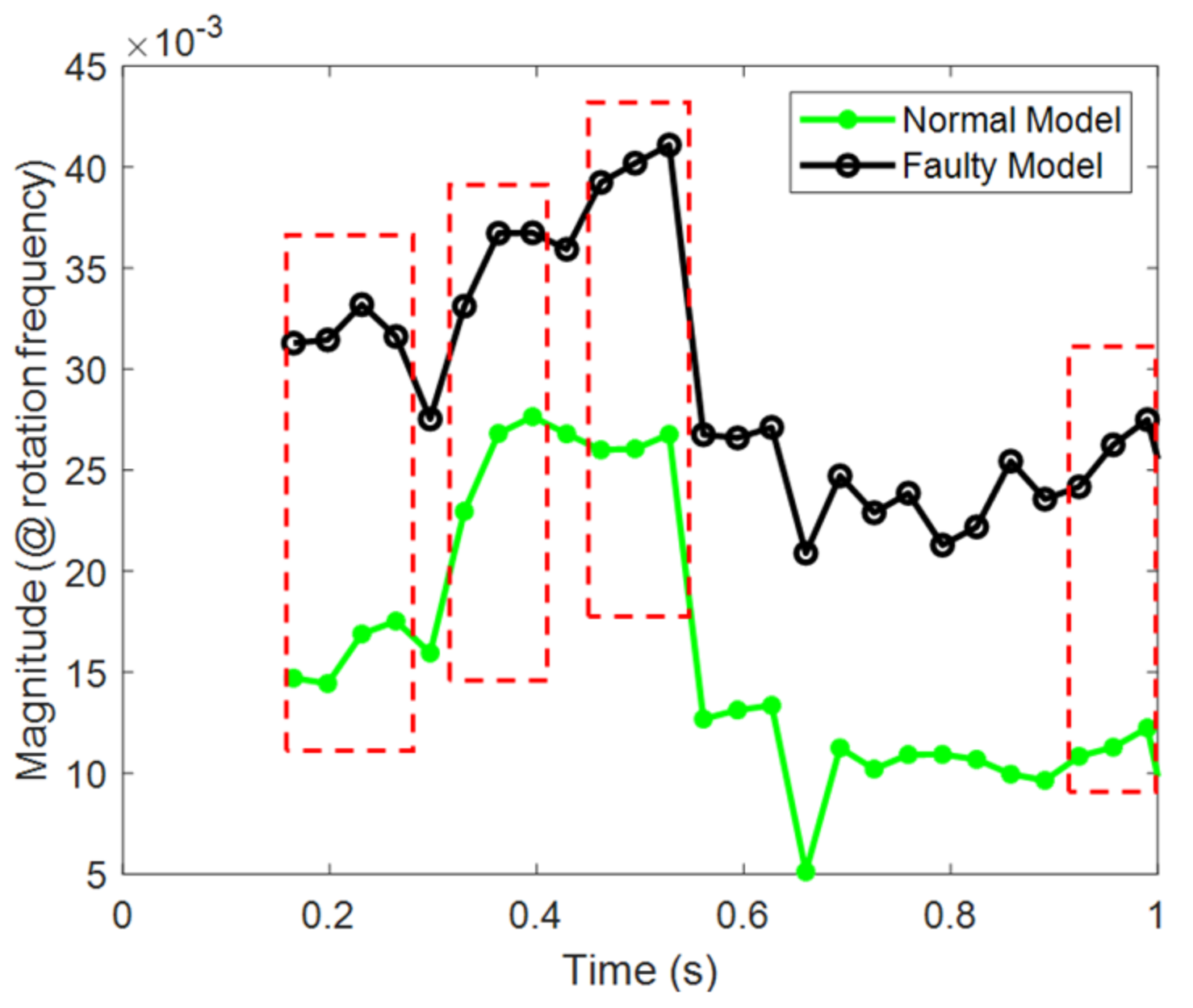

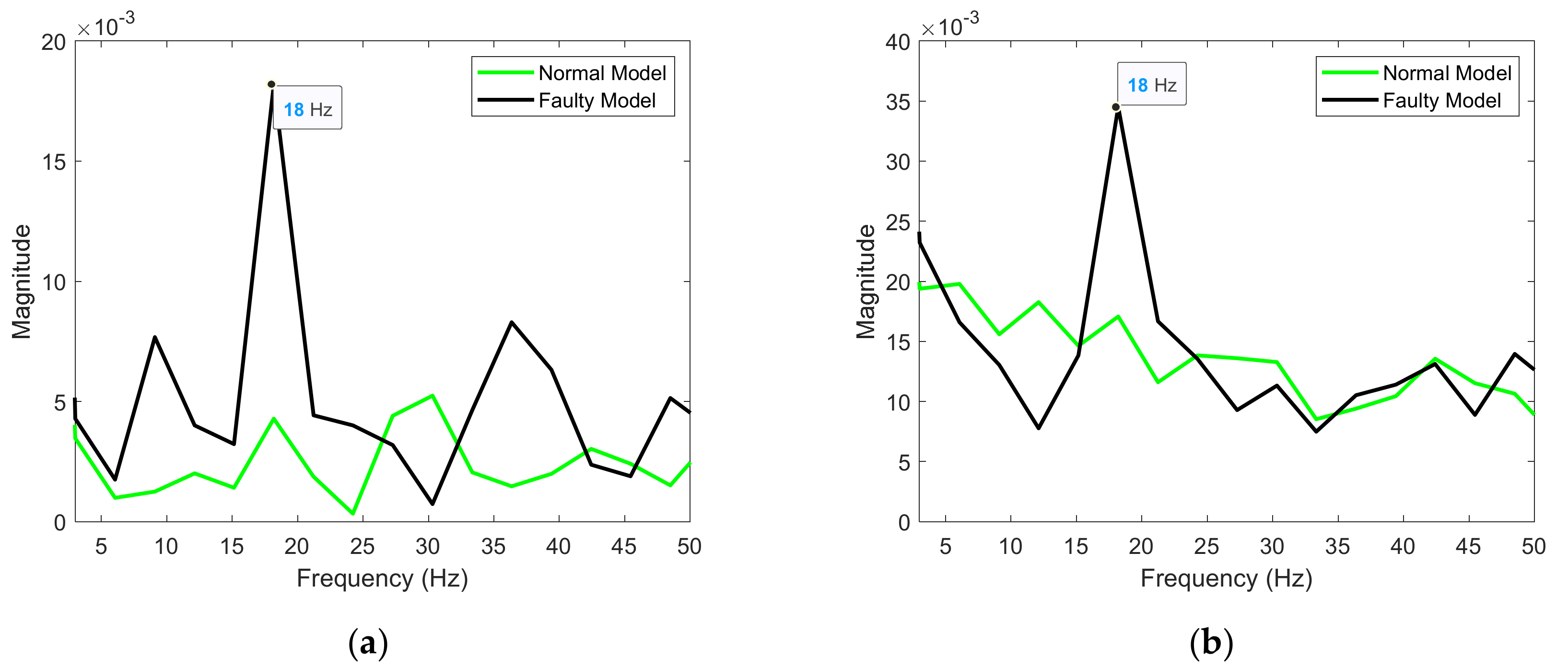

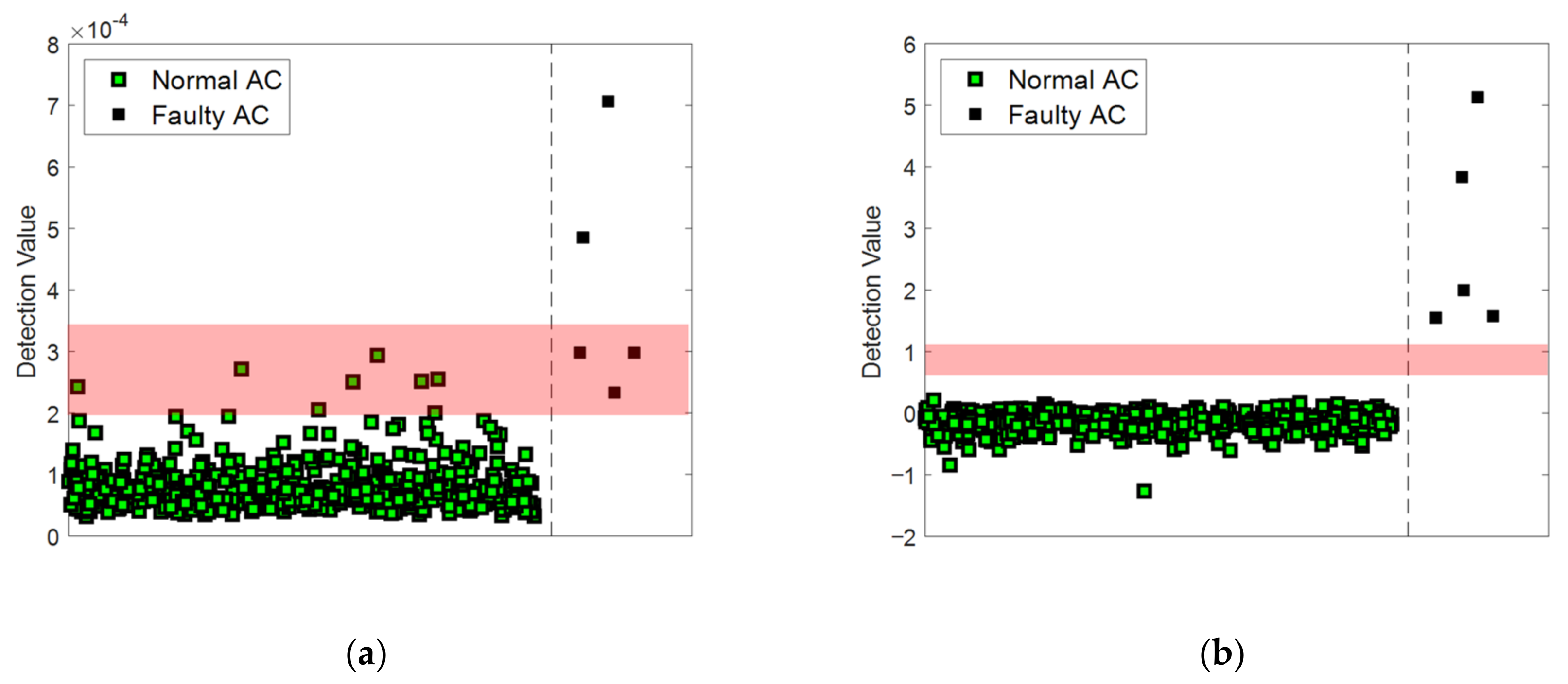

4. Practical Example of the Proposed Method

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Venkatasubramanian, V.; Rengaswamy, R.; Yin, K.; Kavuri, S.N. A review of process fault detection and diagnosis part I: Quantitative model-based methods. Comput. Chem. Eng. 2003, 27, 293–311. [Google Scholar] [CrossRef]

- Sharma, S.; Tiwari, S.K. Sukhjeet Singh Integrated approach based on flexible analytical wavelet transform and permutation entropy for fault detection in rotary machines. Measurement 2021, 169, 108389. [Google Scholar] [CrossRef]

- Kim, J.H. Fault detection for manufacturing home air conditioners using wavelet transform. Int. J. Precis. Eng. Manuf. 2016, 17, 1299–1303. [Google Scholar] [CrossRef]

- Kim, J.H. Time Frequency Image and Artificial Neural Network Based Classification of Impact Noise for Machine Fault Diagnosis. Int. J. Precis. Eng. Manuf. 2018, 19, 821–827. [Google Scholar] [CrossRef]

- Henriquez, P.; Alonso, J.B.; Ferrer, M.A.; Travieso, C.M. Review of Automatic Fault Diagnosis Systems Using Audio and Vibration Signals. IEEE Trans. Syst. Man Cybern. Syst. 2014, 44, 642–652. [Google Scholar] [CrossRef]

- Bin, G.F.; Gao, J.J.; Li, X.J.; Dhillon, B.S. Early fault diagnosis of rotating machinery based on wavelet packets-Empirical mode decomposition feature extraction and neural network. Mech. Syst. Signal Process. 2012, 27, 696–711. [Google Scholar] [CrossRef]

- Antoni, J.; Bonnardot, F.; Raad, A.; El Badaoui, M. Cyclostationary modelling of rotating machine vibration signals. Mech. Syst. Signal Process. 2004, 18, 1285–1314. [Google Scholar] [CrossRef]

- Tang, G.; Pang, B.; Tian, T.; Zhou, C. Fault diagnosis of rolling bearings based on improved fast spectral correlation and optimized random forest. Appl. Sci. 2018, 8, 1859. [Google Scholar] [CrossRef] [Green Version]

- Klausen, A.; Robbersmyr, K.G.; Karimi, H.R. Autonomous Bearing Fault Diagnosis Method based on Envelope Spectrum. IFAC-PapersOnLine 2017, 50, 13378–13383. [Google Scholar] [CrossRef]

- Vicuña, C.M.; Acuña, D.Q. Cyclostationary Processing of Vibration and Acoustic Emissions for Machine Failure Diagnosis. In Cyclostationarity: Theory and Methods; Chaari, F., Leśkow, J., Napolitano, A., Sanchez-Ramirez, A., Eds.; Lecture Notes in Mechanical Engineering; Springer International Publishing: Cham, Germany, 2014; pp. 141–156. ISBN 978-3-319-04186-5. [Google Scholar]

- Abboud, D.; Antoni, J.; Sieg-Zieba, S.; Eltabach, M. Envelope analysis of rotating machine vibrations in variable speed conditions: A comprehensive treatment. Mech. Syst. Signal Process. 2017, 84, 200–226. [Google Scholar] [CrossRef]

- Barszcz, T.; Jabłoński, A. A novel method for the optimal band selection for vibration signal demodulation and comparison with the Kurtogram. Mech. Syst. Signal Process. 2011, 25, 431–451. [Google Scholar] [CrossRef]

- Zhao, X.; Qin, Y.; He, C.; Jia, L.; Kou, L. Rolling element bearing fault diagnosis under impulsive noise environment based on cyclic correntropy spectrum. Entropy 2019, 21, 50. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Antoni, J. The infogram: Entropic evidence of the signature of repetitive transients. Mech. Syst. Signal Process. 2016, 74, 73–94. [Google Scholar] [CrossRef]

- Mosleh, A.; Montenegro, P.A.; Costa, P.A.; Calçada, R. Railway Vehicle Wheel Flat Detection with Multiple Records Using Spectral Kurtosis Analysis. Appl. Sci. 2021, 11, 4002. [Google Scholar] [CrossRef]

- Mosleh, A.; Montenegro, P.; Alves Costa, P.; Calçada, R. An approach for wheel flat detection of railway train wheels using envelope spectrum analysis. Struct. Infrastruct. Eng. 2020, 1–20. [Google Scholar] [CrossRef]

- Smith, W.A.; Fan, Z.; Peng, Z.; Li, H.; Randall, R.B. Optimised Spectral Kurtosis for bearing diagnostics under electromagnetic interference. Mech. Syst. Signal Process. 2016, 75, 371–394. [Google Scholar] [CrossRef] [Green Version]

- Miao, Y.; Zhao, M.; Lin, J. Improvement of kurtosis-guided-grams via Gini index for bearing fault feature identification. Meas. Sci. Technol. 2017, 28. [Google Scholar] [CrossRef]

- Tyagi, S.; Panigrahi, S.K. An improved envelope detection method using particle swarm optimisation for rolling element bearing fault diagnosis. J. Comput. Des. Eng. 2017, 4, 305–317. [Google Scholar] [CrossRef]

- Elasha, F.; Greaves, M.; Mba, D. Planetary bearing defect detection in a commercial helicopter main gearbox with vibration and acoustic emission. Struct. Health Monit. 2018, 17, 1192–1212. [Google Scholar] [CrossRef]

- Peeters, C.; Guillaume, P.; Helsen, J. Vibration-based bearing fault detection for operations and maintenance cost reduction in wind energy. Renew. Energy 2018, 116, 74–87. [Google Scholar] [CrossRef]

- Randall, R.B.; Antoni, J. Rolling element bearing diagnostics—A tutorial. Mech. Syst. Signal Process. 2011, 25, 485–520. [Google Scholar] [CrossRef]

- Maiz, S.; El Badaoui, M.; Bonnardot, F.; Dudek, A.; Leskow, J. Deterministic/cyclostationary signal separation using bootstrap. IFAC Proc. Vol. 2013, 46, 641–646. [Google Scholar] [CrossRef]

- Abboud, D.; Antoni, J.; Sieg-Zieba, S.; Eltabach, M. Deterministic-random separation in nonstationary regime. J. Sound Vib. 2016, 362, 305–326. [Google Scholar] [CrossRef]

- Wodecki, J.; Michalak, A.; Zimroz, R. Local damage detection based on vibration data analysis in the presence of Gaussian and heavy-tailed impulsive noise. Meas. J. Int. Meas. Confed. 2021, 169, 108400. [Google Scholar] [CrossRef]

- Vilela, R.M.; Metrôlho, J.C.; Cardoso, J.C. Machine and industrial monitorization system by analysis of acoustic signatures. In Proceedings of the 12th IEEE Mediterranean Electrotechnical Conference (IEEE Cat. No.04CH37521), Dubrovnik, Croatia, 12–15 May 2004; Volume 1, pp. 277–279. [Google Scholar]

- Liu, T.; Qiu, T.; Luan, S. Cyclic Correntropy: Foundations and Theories. IEEE Access 2018, 6, 34659–34669. [Google Scholar] [CrossRef]

- Luan, S.; Qiu, T.; Zhu, Y.; Yu, L. Cyclic correntropy and its spectrum in frequency estimation in the presence of impulsive noise. Signal Process. 2016, 120, 503–508. [Google Scholar] [CrossRef]

- Baek, W.; Kim, D.Y. In-Process Noise Detection System for Product Inspection by Using Acoustic Data. IFIP Adv. Inf. Commun. Technol. 2019, 567, 413–420. [Google Scholar] [CrossRef] [Green Version]

- Saucedo-Espinosa, M.A.; Escalante, H.J.; Berrones, A. Detection of defective embedded bearings by sound analysis: A machine learning approach. J. Intell. Manuf. 2017, 28, 489–500. [Google Scholar] [CrossRef]

- Leclère, Q.; Pruvost, L.; Parizet, E. Angular and temporal determinism of rotating machine signals: The diesel engine case. Mech. Syst. Signal Process. 2010, 24, 2012–2020. [Google Scholar] [CrossRef] [Green Version]

- He, Q.; Ding, X. Structural Health Monitoring; Yan, R., Chen, X., Mukhopadhyay, S.C., Eds.; Smart Sensors, Measurement and Instrumentation; Springer International Publishing: Cham, Germany, 2017; Volume 26, ISBN 978-3-319-56125-7. [Google Scholar]

- He, Q.; Wang, X.; Zhou, Q. Vibration sensor data denoising using a time-frequency manifold for machinery fault diagnosis. Sensors 2013, 14, 382–402. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Amini, A.; Entezami, M.; Huang, Z.; Rowshandel, H.; Papaelias, M. Wayside detection of faults in railway axle bearings using time spectral kurtosis analysis on high-frequency acoustic emission signals. Adv. Mech. Eng. 2016, 8, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Islam, M.M.M.; Kim, J.M. Time–frequency envelope analysis-based sub-band selection and probabilistic support vector machines for multi-fault diagnosis of low-speed bearings. J. Ambient Intell. Humaniz. Comput. 2017, 1–16. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, R. Time-frequency analysis and support vector machine in automatic detection of defect from vibration signal of centrifugal pump. Meas. J. Int. Meas. Confed. 2017, 108, 119–133. [Google Scholar] [CrossRef]

- Petrillo, A.; Picariello, A.; Santini, S.; Scarciello, B.; Sperlí, G. Model-based vehicular prognostics framework using Big Data architecture. Comput. Ind. 2020, 115. [Google Scholar] [CrossRef]

- Manco, G.; Ritacco, E.; Rullo, P.; Gallucci, L.; Astill, W.; Kimber, D.; Antonelli, M. Fault detection and explanation through big data analysis on sensor streams. Expert Syst. Appl. 2017, 87, 141–156. [Google Scholar] [CrossRef]

- Jing, L.; Zhao, M.; Li, P.; Xu, X. A convolutional neural network based feature learning and fault diagnosis method for the condition monitoring of gearbox. Meas. J. Int. Meas. Confed. 2017, 111, 1–10. [Google Scholar] [CrossRef]

- De santo, A.; Galli, A.; Gravina, M.; Moscato, V.; Sperli, G. Deep Learning for HDD health assessment: An application based on LSTM. IEEE Trans. Comput. 2020, 1–12. [Google Scholar] [CrossRef]

- Feldman, M. Hilbert transform in vibration analysis. Mech. Syst. Signal Process. 2011, 25, 735–802. [Google Scholar] [CrossRef]

- Antoni, J. Cyclostationarity by examples. Mech. Syst. Signal Process. 2009, 23, 987–1036. [Google Scholar] [CrossRef]

- Gardner, W.; Franks, L. Characterization of cyclostationary random signal processes. IEEE Trans. Inf. Theory 1975, 21, 4–14. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, D.-H.; Hong, C.; Jeong, W.-B.; Ahn, S. Time–Frequency Envelope Analysis for Fault Detection of Rotating Machinery Signals with Impulsive Noise. Appl. Sci. 2021, 11, 5373. https://doi.org/10.3390/app11125373

Lee D-H, Hong C, Jeong W-B, Ahn S. Time–Frequency Envelope Analysis for Fault Detection of Rotating Machinery Signals with Impulsive Noise. Applied Sciences. 2021; 11(12):5373. https://doi.org/10.3390/app11125373

Chicago/Turabian StyleLee, Dong-Hyeon, Chinsuk Hong, Weui-Bong Jeong, and Sejin Ahn. 2021. "Time–Frequency Envelope Analysis for Fault Detection of Rotating Machinery Signals with Impulsive Noise" Applied Sciences 11, no. 12: 5373. https://doi.org/10.3390/app11125373

APA StyleLee, D.-H., Hong, C., Jeong, W.-B., & Ahn, S. (2021). Time–Frequency Envelope Analysis for Fault Detection of Rotating Machinery Signals with Impulsive Noise. Applied Sciences, 11(12), 5373. https://doi.org/10.3390/app11125373