Impact of Temperature on the Moisture Buffering Performance of Palm and Sunflower Concretes

Abstract

:1. Introduction

2. Numerical Model

2.1. Mass Transfer Model in Single-Layer Wall

2.2. Effective Capacitance Model

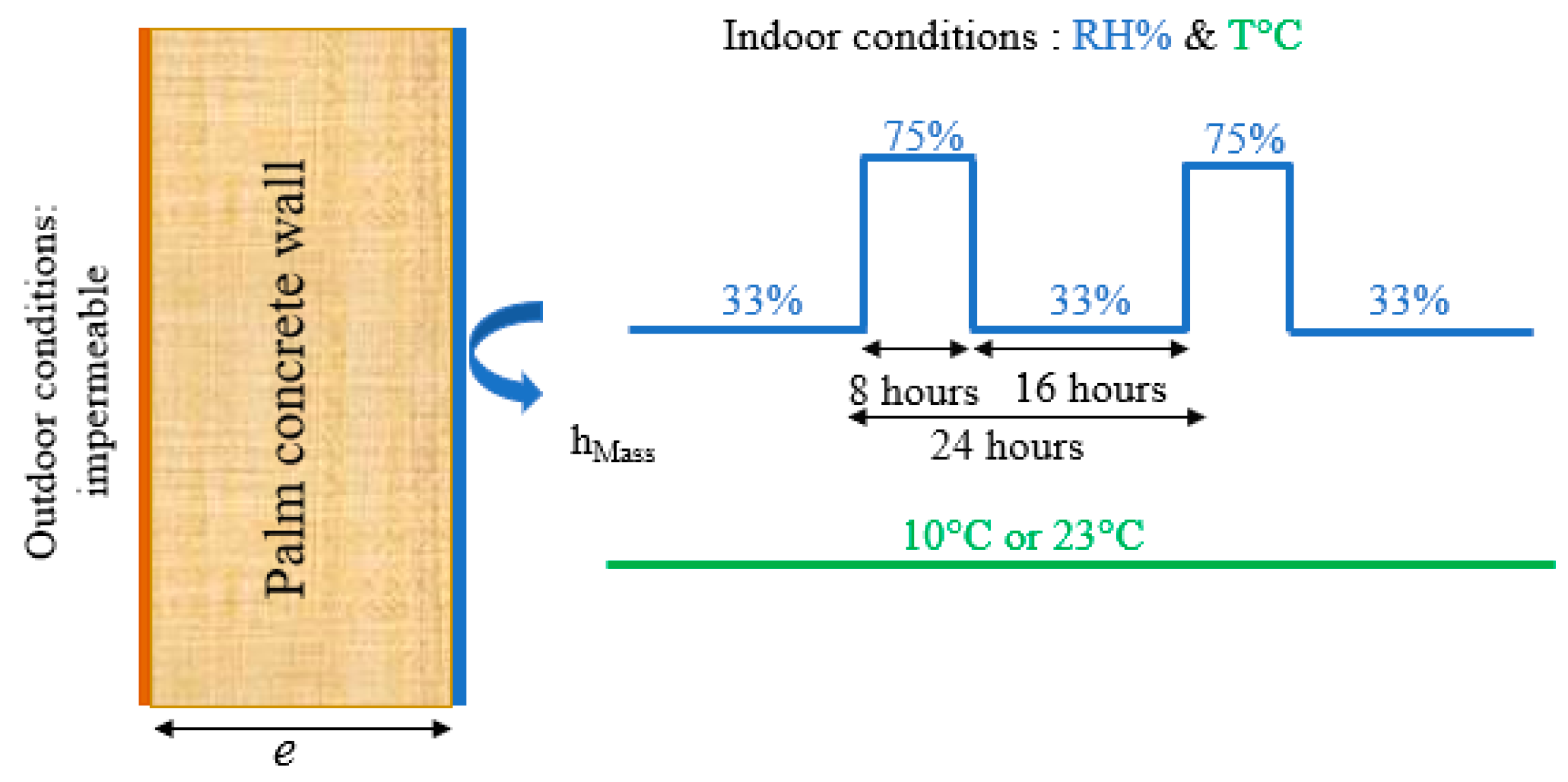

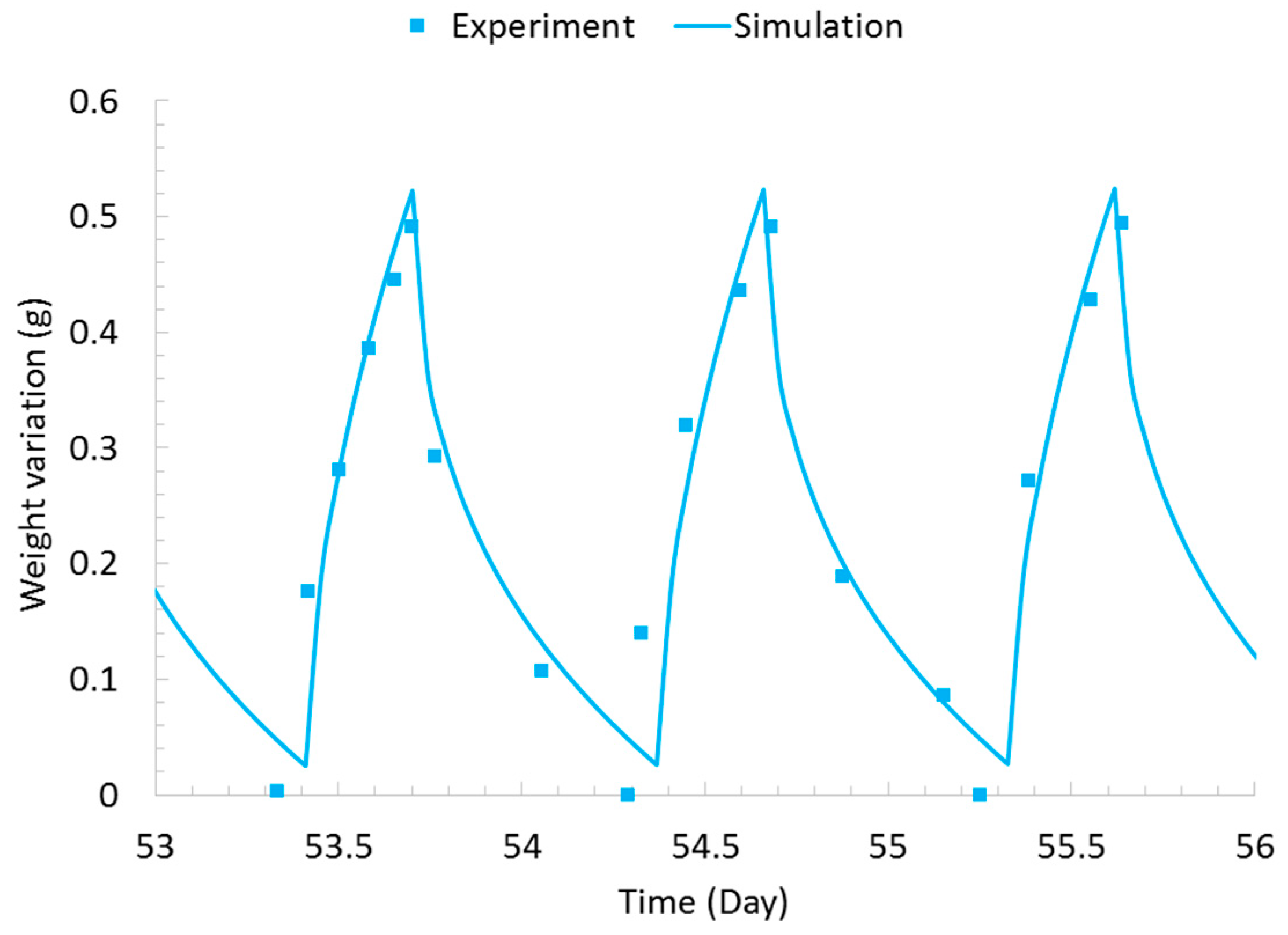

3. Model Validation

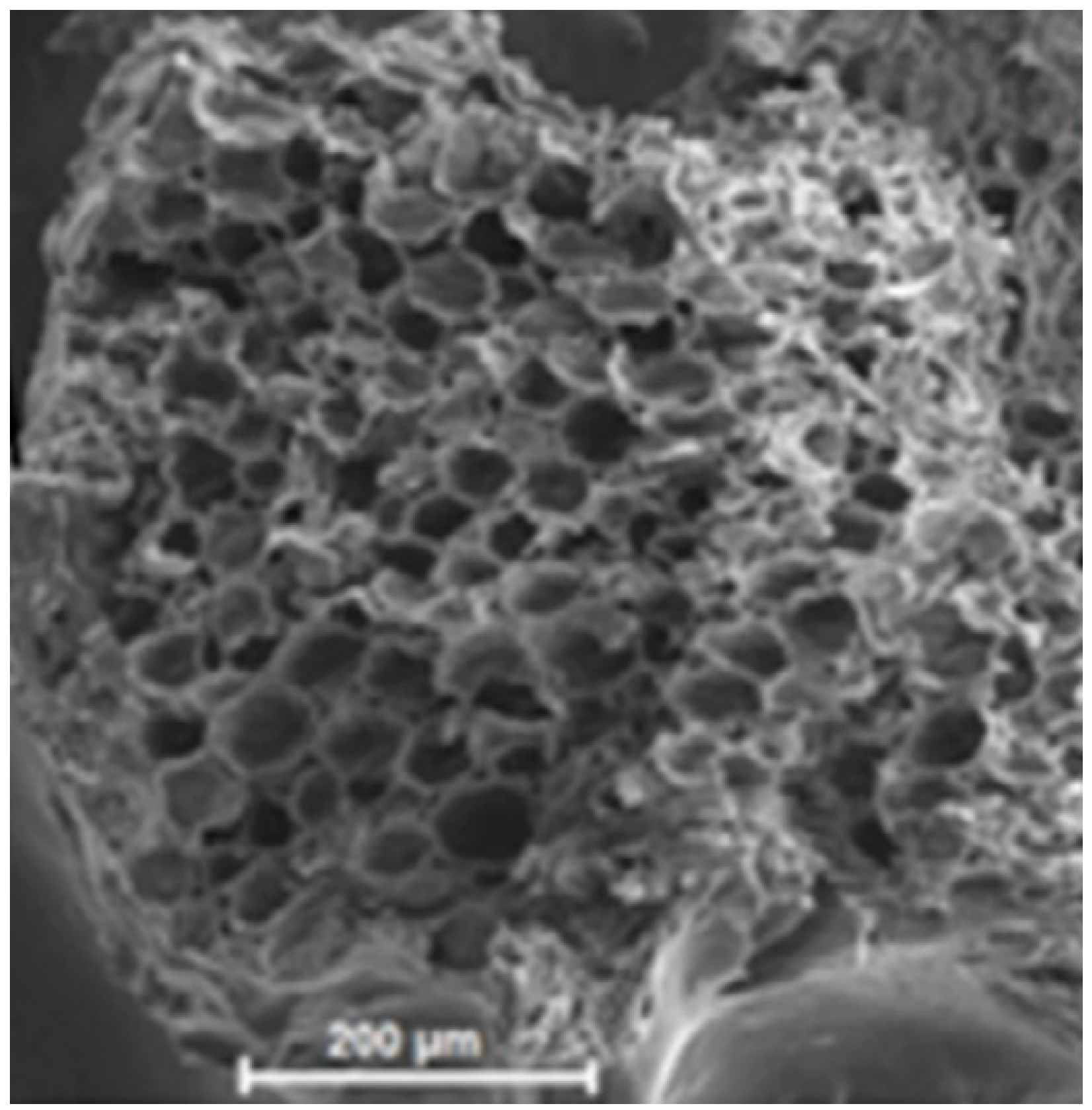

3.1. Material Properties Used for Model Validation

3.2. Model Validation

4. Numerical Study and Discussions

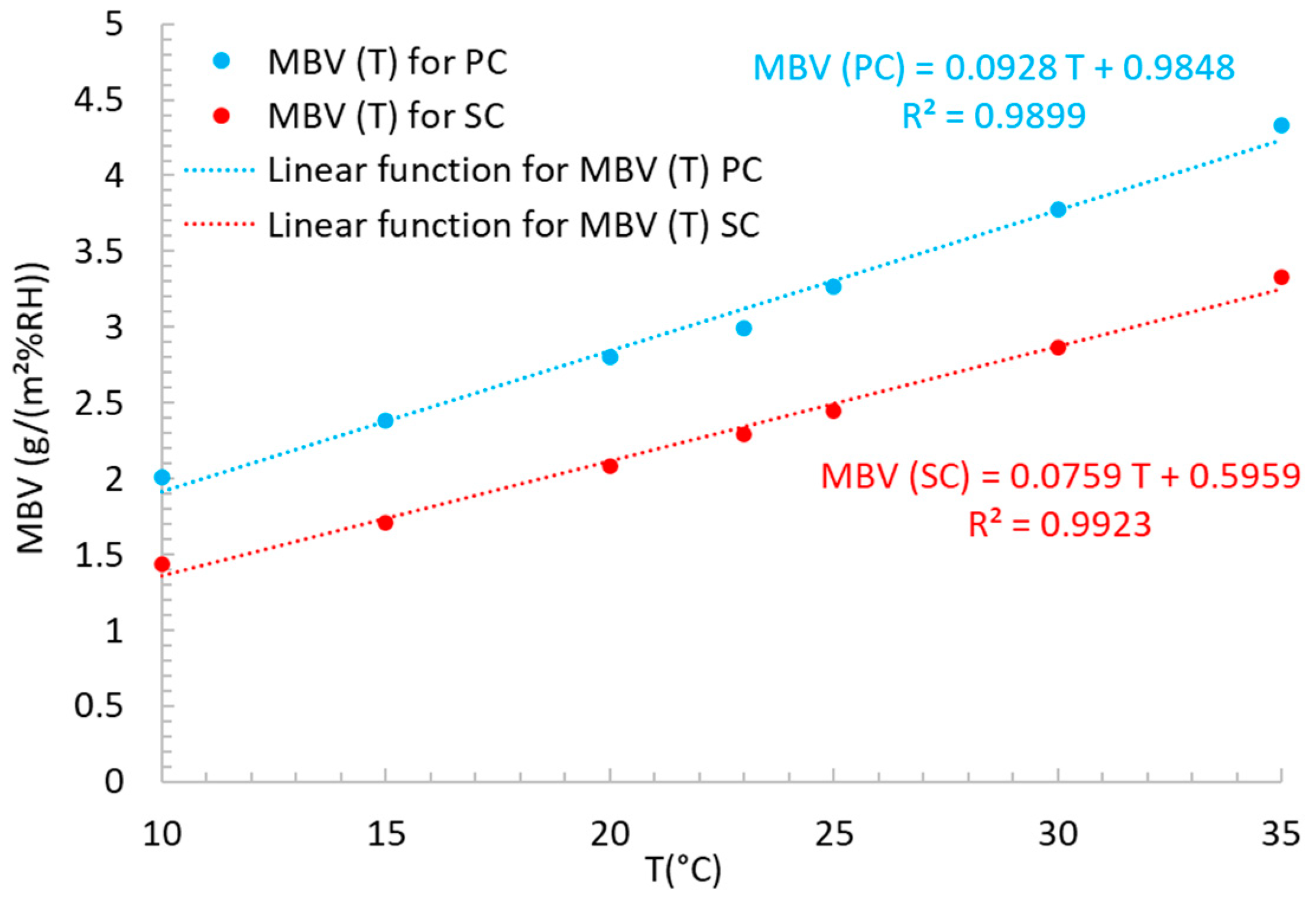

4.1. Influence of Temperature on the Moisture Buffering Capacity and Classification of Bio-Based Materials

4.2. Impact of the Moisture Buffering Capacity on Indoor Relative Humidity of an Office Room

4.2.1. Description of Studied Case and Simulation Conditions

4.2.2. Impact of Moisture Buffering Capacity Classification on Indoor RH

4.2.3. Impact of Temperature on the Performance of PC and SC

4.2.4. Impact of Exposed Surface Area on Indoor RH Variation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| C | Energy constant of GAB model | |

| Cp | Specific heat at constant pressure | J·kg−1·K−1 |

| Dθ | Mass (vapor and liquid) transport coefficient associated with a moisture content gradient | m2·s−1 |

| Dθ. l | Liquid transport coefficient associated with a moisture content gradient | m2·s−1 |

| Dθ. v | Vapor transport coefficient associated with a moisture content gradient | m2·s−1 |

| hM | Convective mass transfer coefficient | m·s−1 |

| K | Energy constant of GAB model | |

| MBV | Moisture buffer value | g/(m2%RH) |

| T | Temperature | K |

| w | Moisture content | kg·kg−1 |

| wm | Monolayer moisture content | kg·kg−1 |

| φ | Relative humidity | % |

| π | Water vapor permeability | kg·m−1·s−1 Pa−1 |

| θ | Moisture volumetric content | m3·m−3 |

| µ | Water vapor diffusion resistance factor |

References

- Arundel, A.V.; Sterling, E.M.; Biggin, J.H.; Sterling, T.D. Indirect health effects of relative humidity in indoor environments. Environ. Health Perspect. 1986, 65, 351–361. [Google Scholar] [PubMed] [Green Version]

- Bergen, J. House air. Science 1911, 34, 407–408. [Google Scholar] [CrossRef]

- Djongyang, N.; Tchinda, R.; Njomo, D. Thermal comfort: A review paper. Renew. Sustain. Energy Rev. 2010, 149, 2626–2640. [Google Scholar] [CrossRef]

- Kent, W.; Crowell, W.J.; Jones, L.C. The air we breathe. Science 1911, 33, 486–491. [Google Scholar] [CrossRef]

- Padfield, T.; Jensen, L.A. Humidity buffering by absorbent materials. In Proceedings of the 9th Nordic Symposium on Building Physics, Tampere University of Technology, Tampere, Finland, 29 May–2 June 2011; pp. 475–482. [Google Scholar]

- Japanese Industrial Standard. JIS A1470-2: Test Method of Adsorption/Desorption Efficiency for Building Materials to Regulate an Indoor Humidity—Part 1: Response Method of Humidity; Japanese Industrial Standard: Tokyo, Japan, 2002. [Google Scholar]

- Rode, C.; Peuhkuri, R.H.; Hansen, K.K.; Time, B.; Svennberg, K.; Arfvidsson, J.; Ojanen, T. NORDTEST project on moisture buffer value of materials. In Proceedings of the AIVC Conference ‘Energy Performance Regulation’: Ventilation in Relation to the Energy Performance of Buildings, Brussels, Belgium, 21–23 September 2005; INIVE EEIG: Brussels, Belgium, 2005; pp. 47–52. [Google Scholar]

- International Standards Organization. ISO 24353: Hygrothermal Performance of Building Materials and Products: Determination of Hygroscopic Sorption Properties; ISO: Geneva, Switzerland, 2013. [Google Scholar]

- Tran Le, A.D.; Maalouf, C.; Mai, T.H.; Wurtz, E.; Collet, F. Transient hygrothermal behaviour of a hemp concrete building envelope. Energy Build. 2010, 42, 1797–1806. [Google Scholar] [CrossRef]

- Xie, H.; Gong, G.; Wu, Y.; Liu, Y.; Wang, Y. Research on the hygroscopicity of a composite hygroscopic material and its influence on indoor thermal and humidity environment. Appl. Sci. 2018, 8, 430. [Google Scholar] [CrossRef] [Green Version]

- Osanyintola, O.F.; Simonson, C.J. Moisture buffering capacity of hygroscopic building materials: Experimental facilities and energy impact. Energy Build. 2006, 38, 1270–1282. [Google Scholar] [CrossRef]

- Svennberg, K.; Lengsfeld, K.; Harderup, L.-E.; Holm, A. Previous Experimental Studies and Field Measurements on Moisture Buffering by Indoor Surface Materials. J. Build. 2007, 30, 261–274. [Google Scholar] [CrossRef]

- Chennouf, N.; Agoudjil, B.; Boudenne, A.; Benzarti, K.; Bouras, F. Hygrothermal characterization of a new bio-based construction material: Concrete reinforced with date palm fibers. Constr. Build. Mater. 2018, 192, 348–356. [Google Scholar] [CrossRef]

- Lagouin, M.; Magniont, C.; Sénéchal, P.; Moonen, P.; Aubert, J.-E.; Laborel-Préneron, A. Influence of types of binder and plant aggregates on hygrothermal and mechanical properties of vegetal concretes. Constr. Build. Mater. 2019, 222, 852–871. [Google Scholar] [CrossRef]

- Colinart, T.; Lelièvre, D.; Glouannec, P. Experimental and numerical analysis of the transient hygrothermal behavior of multilayered hemp concrete wall. Energy Build. 2016, 112, 1–11. [Google Scholar] [CrossRef]

- Collet, F.; Chamoin, J.; Pretot, S.; Lanos, C. Comparison of the hygric behaviour of three hemp concretes. Energy Build. 2013, 62, 294–303. [Google Scholar] [CrossRef]

- Nguyen, D.M.; Grillet, A.-C.; Diep, T.M.H.; Thuc, C.N.H.; Woloszyn, M. Hygrothermal properties of bio-insulation building materials based on bamboo fibers and bio-glues. Constr. Build. Mater. 2017, 155, 852–866. [Google Scholar] [CrossRef]

- Palumbo, M.; McGregor, F.; Heath, A.; Walker, P. The influence of two crop by-products on the hygrothermal properties of earth plasters. Build. Environ. 2016, 105, 245–252. [Google Scholar] [CrossRef] [Green Version]

- Promis, G.; Douzane, O.; Le, A.T.; Langlet, T. Moisture hysteresis influence on mass transfer through bio-based building materials in dynamic state. Energy Build. 2018, 166, 450–459. [Google Scholar] [CrossRef]

- Rahim, M.; Douzane, O.; Le, A.T.; Promis, G.; Langlet, T. Characterization and comparison of hygric properties of rape straw concrete and hemp concrete. Constr. Build. Mater. 2016, 102, 679–687. [Google Scholar] [CrossRef]

- Ramos, N.; Delgado, J.; de Freitas, V.P. Influence of finishing coatings on hygroscopic moisture buffering in building elements. Constr. Build. Mater. 2010, 24, 2590–2597. [Google Scholar] [CrossRef]

- Ahmad, M.R.; Chen, B.; Haque, M.A.; Shah, S.F.A. Development of a sustainable and innovant hygrothermal bio-composite featuring the enhanced mechanical properties. J. Clean. Prod. 2019, 229, 128–143. [Google Scholar] [CrossRef]

- Kreiger, B.K.; Srubar, W.V., III. Moisture buffering in buildings: A review of experimental and numerical methods. Energy Build. 2019, 202, 109394. [Google Scholar] [CrossRef]

- Maskell, D.; Thomson, A.; Walker, P.; Lemke, M. Determination of optimal plaster thickness for moisture buffering of indoor air. Build. Environ. 2018, 130, 143–150. [Google Scholar] [CrossRef]

- Daïan, J.-F. Equilibre et Transferts en Milieux Poreux. Hal-00452876v3. Ph.D. Thesis, Joseph-Fourier University, Grenoble, France, 2013. [Google Scholar]

- Cérézo, V. Propriétés Mécaniques, Thermiques et Acoustiques d’un Matériau à Base de Particules Végétales: Approche Expérimentale et Modélisation Théorique. Ph.D. Thesis, INSA Lyon, Lyon, France, 2005. [Google Scholar]

- Collet-Foucault, F. Caractérisation Hydrique et Thermique de Matériaux de Génie Civil à Faibles Impacts Environnementaux. Ph.D. Thesis, INSA Rennes, Rennes, France, 2004. [Google Scholar]

- Brandt, A.M. Fibre reinforced cement-based (FRC) composites after over 40 years of development in building and civil engineering. Compos. Struct. 2008, 86, 3–9. [Google Scholar] [CrossRef]

- Nozahic, V.; Amziane, S.; Torrent, G.; Saïdi, K.; De Baynast, H. Design of green concrete made of plant-derived aggregates and a pumice–lime binder. Cem. Concr. Compos. 2012, 342, 231–241. [Google Scholar] [CrossRef]

- Liuzzi, S.; Rubino, C.; Stefanizzi, P.; Petrella, A.; Boghetich, A.; Casavola, C.; Pappalettera, G. Hygrothermal properties of clayey plasters with olive fibers. Constr. Build. Mater. 2018, 158, 24–32. [Google Scholar] [CrossRef]

- Marques, B.; Tadeu, A.; Almeida, J.; Antonio, J.; de Brito, J. Characterisation of sustainable building walls made from rice straw bales. J. Build. Eng. 2020, 28, 101041. [Google Scholar] [CrossRef]

- Tran Le, A.D.; Zhang, J.S.; Liu, Z.; Samri, D.; Langlet, T. Modeling the similarity and the potential of toluene and moisture buffering capacities of hemp concrete on IAQ and thermal comfort. Build. Environ. 2021, 188, 107455. [Google Scholar] [CrossRef]

- Cascione, V.; Hagentoft, C.-E.; Maskell, D.; Shea, A.; Walker, P. Moisture buffering in surface materials due to simultaneous varying relative humidity and temperatures: Experimental validation of new analytical formulas. Appl. Sci. 2020, 10, 7665. [Google Scholar] [CrossRef]

- Cascione, V.; Maskell, D.; Shea, A.; Walker, P. The moisture buffering performance of plasters when exposed to simultaneous sinusoidal temperature and RH variations. J. Build. Eng. 2021, 34, 101890. [Google Scholar] [CrossRef]

- Philip, J.; De Vries, D. Moisture movement in porous materials under temperature gradients. Eos Trans. Am. Geophys. Union 1957, 382, 222–232. [Google Scholar] [CrossRef]

- Crausse, P.; Laurent, J.; Perrin, B. Influence des phénomènes d’hystérésis sur les propriétés hydriques de matériaux poreux: Comparaison de deux modèles de simulation du comportement thermohydrique de parois de bâtiment. Rev. Gén. Therm. 1996, 35, 95–106. [Google Scholar] [CrossRef]

- Langmuir, I. The adsorption of gases on plane surfaces of glass, mica and platinum. J. Am. Chem. Soc. 1918, 409, 1361–1403. [Google Scholar] [CrossRef] [Green Version]

- Brunauer, S.; Emmett, P.H.; Teller, E. Adsorption of gases in multimolecular layers. J. Am. Chem. Soc. 1938, 602, 309–319. [Google Scholar] [CrossRef]

- Merouani, L. Phénomènes de Sorption et de Transfert d’Humidité dans des Matériaux du Bâtiment: Étude Expérimentale Comparative d’un Mortier de Ciment et d’un Enduit de Façade. Ph.D. Thesis, INP Grenoble, Grenoble, France, 1987. [Google Scholar]

- Timmermann, E.O. Multilayer sorption parameters: BET or GAB values? Colloids Surf. A Physicochem. Eng. Asp. 2003, 220, 235–260. [Google Scholar] [CrossRef] [Green Version]

- Prothon, F.; Ahrné, L.l.M. Application of the Guggenheim, Anderson and De Boer model to correlate water activity and moisture content during osmotic dehydration of apples. J. Food Eng. 2004, 613, 467–470. [Google Scholar] [CrossRef]

- Andrade, I.; Pires, A.; de Carvalho, G.; Veloso, C.M.; Bonomo, P. Protein and carbohydrate fractioning in elephantgrass silage with agricultural by-products. Rev. Bras. Zootec. 2010, 39, 2342–2348. [Google Scholar] [CrossRef] [Green Version]

- Colinart, T.; Glouannec, P. Temperature dependence of sorption isotherm of hygroscopic building materials. Part 1: Experimental evidence and modeling. Energy Build. 2017, 139, 360–370. [Google Scholar] [CrossRef]

- Janssen, H.; Roels, S. Qualitative and quantitative assessment of interior moisture buffering by enclosures. Energy Build. 2009, 414, 382–394. [Google Scholar] [CrossRef] [Green Version]

- Mendonça, K.; Inard, C.; Wurtz, E.; Winkelmann, F.; Allard, F. A zonal model for predicting simultaneous heat and moisture transfer in buildings. In Proceedings of the INDOOR AIR 2002—The 9th International Conference on Indoor Air Quality and Climate, Monterey, CA, USA, 30 June–5 July 2002; p. 135. [Google Scholar]

- Sowell, E.F.; Haves, P. Efficient solution strategies for building energy system simulation. Energy Build. 2001, 334, 309–317. [Google Scholar] [CrossRef] [Green Version]

- Wurtz, E.; Haghighat, F.; Mora, L.; Mendonca, K.; Zhao, H.; Maalouf, C.; Bourdoukan, P. An integrated zonal model to predict transient indoor humidity distribution. ASHRAE Trans. 2006, 112, 175–186. [Google Scholar]

- Haba, B.; Agoudjil, B.; Boudenne, A.; Benzarti, K. Hygric properties and thermal conductivity of a new insulation material for building based on date palm concrete. Constr. Build. Mater. 2017, 154, 963–971. [Google Scholar] [CrossRef]

- Brouard, Y.; Belayachi, N.; Hoxha, D.; Ranganathan, N.; Méo, S. Mechanical and hygrothermal behavior of clay–Sunflower (Helianthus annuus) and rape straw (Brassica napus) plaster bio-composites for building insulation. Constr. Build. Mater. 2018, 161, 196–207. [Google Scholar] [CrossRef]

- Baughman, A.; Arens, E.A. Indoor humidity and human health--Part I: Literature review of health effects of humidity-influenced indoor pollutants. ASHRAE Trans. 1996, 102, 192–211. [Google Scholar]

- Shea, A.; Lawrence, M.; Walker, P. Hygrothermal performance of an experimental hemp–lime building. Constr. Build. Mater. 2012, 36, 270–275. [Google Scholar] [CrossRef] [Green Version]

| Materials | PC | SC |

|---|---|---|

| wm | 0.019 | 0.0171 |

| C | 1 | 27 |

| K | 0.86 | 0.76 |

| R−2 | 0.98 | 0.99 |

| Hygrothermal Properties | PC | SC |

|---|---|---|

| Density ρ (kg/m3) | 954 | 539.64 |

| Total porosity | 64% | 70% |

| Open porosity | 58% | 68.6% |

| Thermal conductivity λ (W/(m·K)) | 0.185 | 0.127 |

| Specific heat capacity Cp (J/(kg·K)) | 1500 | - |

| Water vapor diffusion resistance factor μ | 5.57 | 2.62 |

| MBV measured at 23 °C (g/(m2%RH)) | 2.96 | 2.26 |

| MBV measured at 10 °C (g/m2%RH)) | 2.03 | - |

| Materials | Experimental MBV (g/(m2%RH)) [13,14] | Numerical MBV (g/(m2%RH)) |

|---|---|---|

| PC | 2.03 at 10 °C and 2.96 at 23 °C | 2.01 at 10 °C and 2.99 at 23 °C |

| SC | 2.26 at 23 °C | 2.29 at 23 °C |

| T (°C) | Pv,sat (Pa) | ρv,e (g/m3) at 33% | Pv (Pa) at 33% | ρv,e (g/m3) at 75% | Pv (Pa) at 75% |

|---|---|---|---|---|---|

| 10 | 1241.2 | 3.13 | 409.6 | 7.1 | 930.9 |

| 15 | 1724.2 | 4.3 | 569 | 9.7 | 1293.1 |

| 20 | 2364.9 | 5.8 | 780.4 | 13.1 | 1773.7 |

| 23 | 2842.1 | 6.9 | 937.9 | 15.6 | 2131.6 |

| 25 | 3205.2 | 7.7 | 1057.7 | 17.5 | 2403.9 |

| 30 | 4295 | 10.1 | 1417.7 | 23 | 3221.3 |

| 35 | 5693.8 | 13.2 | 1879 | 30 | 4270.4 |

| MBV (g/(m2%RH)) | RHi,max | RHi,min | A (Amplitude) | f = A/A0 |

|---|---|---|---|---|

| 0 | 0.73 | 0.50 | A0 = 0.23 | 1 |

| 0.5 | 0.7 | 0.51 | 0.19 | 0.83 |

| 1 | 0.67 | 0.52 | 0.15 | 0.65 |

| 1.5 | 0.65 | 0.54 | 0.11 | 0.48 |

| 2 | 0.63 | 0.54 | 0.09 | 0.39 |

| 2.5 | 0.62 | 0.55 | 0.07 | 0.32 |

| 3 | 0.62 | 0.56 | 0.06 | 0.27 |

| 3.5 | 0.61 | 0.56 | 0.05 | 0.22 |

| 4 | 0.61 | 0.56 | 0.05 | 0.22 |

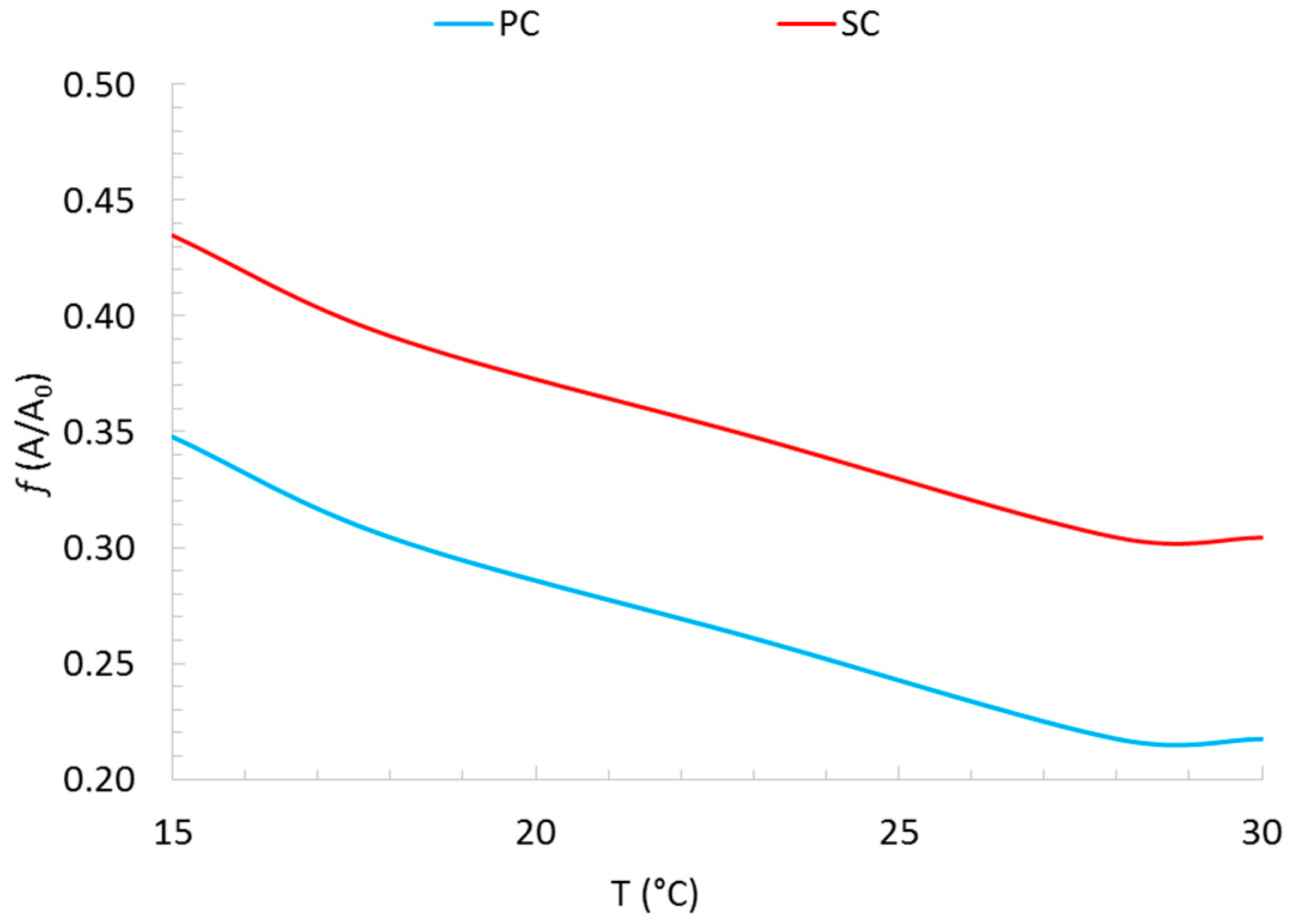

| Table A0 | f (A/A0) for PC | f (A/A0) for SC |

|---|---|---|

| 15 | 0.35 | 0.43 |

| 18 | 0.30 | 0.39 |

| 23 | 0.26 | 0.35 |

| 28 | 0.22 | 0.30 |

| 30 | 0.22 | 0.30 |

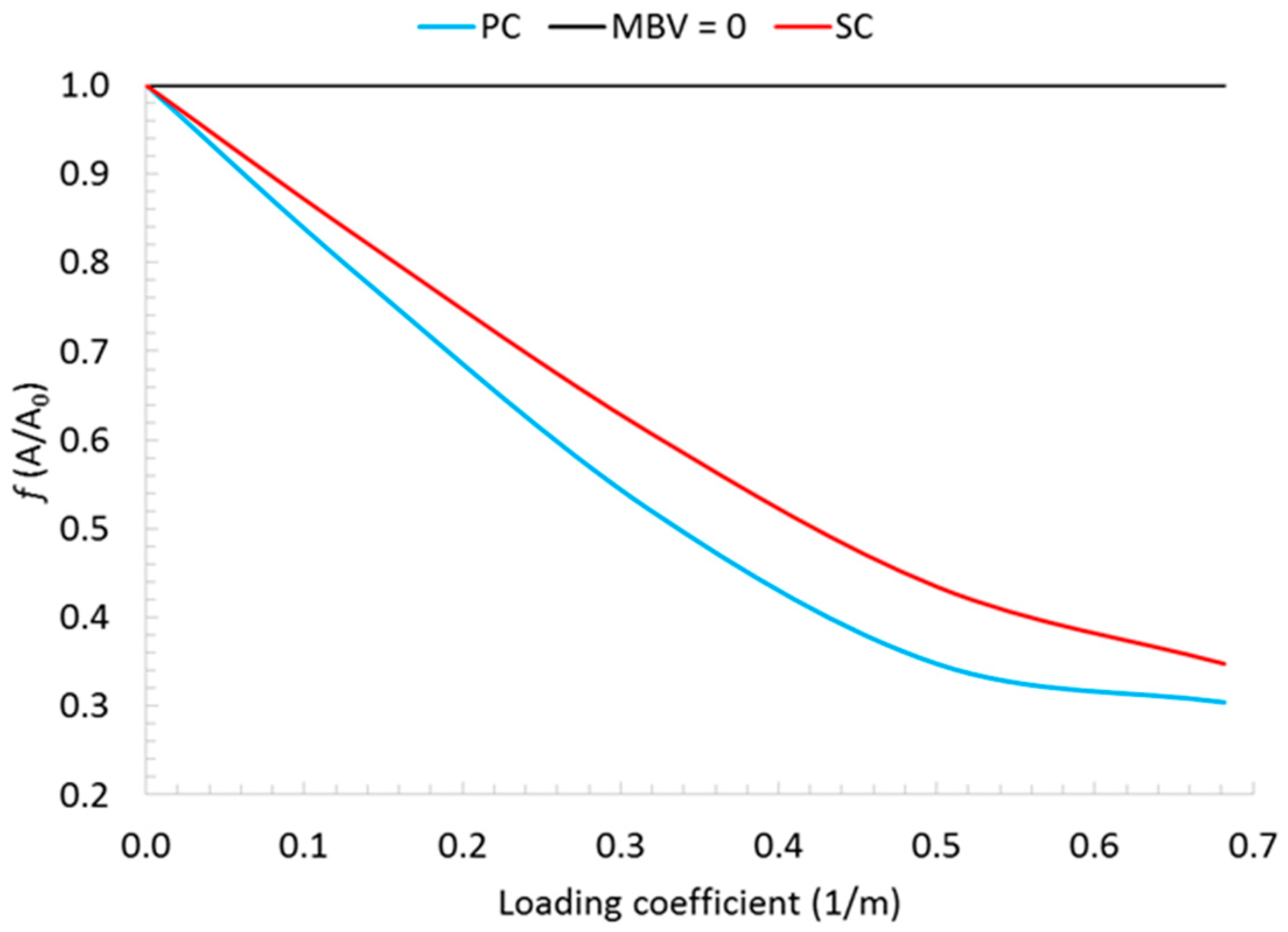

| MBV (g/(m2%RH)) at 23 °C of PC | |||||

|---|---|---|---|---|---|

| Air Effective (Aef) | Loading Coefficient (Aef/V) | RHmax | RHmin | ΔRH | f (A/A0) |

| 0 | 0.00 | 0.73 | 0.5 | 0.23 | 1.00 |

| 7.5 | 0.14 | 0.69 | 0.51 | 0.18 | 0.78 |

| 17.5 | 0.32 | 0.65 | 0.53 | 0.12 | 0.52 |

| 27.5 | 0.50 | 0.63 | 0.55 | 0.08 | 0.35 |

| 37.5 | 0.68 | 0.62 | 0.55 | 0.07 | 0.30 |

| MBV (g/(m2%RH)) at 23 °C of SC | |||||

|---|---|---|---|---|---|

| Air Effective (Aef) | Loading Coefficient (Aef/V) | RHmax | RHmin | ΔRH | f (A/A0) |

| 0 | 0.00 | 0.73 | 0.5 | 0.23 | 1.00 |

| 7.5 | 0.14 | 0.7 | 0.51 | 0.19 | 0.83 |

| 17.5 | 0.32 | 0.66 | 0.52 | 0.14 | 0.61 |

| 27.5 | 0.50 | 0.64 | 0.54 | 0.1 | 0.43 |

| 37.5 | 0.68 | 0.63 | 0.55 | 0.08 | 0.35 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Igue, F.D.; Tran Le, A.D.; Bourdot, A.; Promis, G.; Nguyen, S.T.; Douzane, O.; Lahoche, L.; Langlet, T. Impact of Temperature on the Moisture Buffering Performance of Palm and Sunflower Concretes. Appl. Sci. 2021, 11, 5420. https://doi.org/10.3390/app11125420

Igue FD, Tran Le AD, Bourdot A, Promis G, Nguyen ST, Douzane O, Lahoche L, Langlet T. Impact of Temperature on the Moisture Buffering Performance of Palm and Sunflower Concretes. Applied Sciences. 2021; 11(12):5420. https://doi.org/10.3390/app11125420

Chicago/Turabian StyleIgue, Fathia Dahir, Anh Dung Tran Le, Alexandra Bourdot, Geoffrey Promis, Sy Tuan Nguyen, Omar Douzane, Laurent Lahoche, and Thierry Langlet. 2021. "Impact of Temperature on the Moisture Buffering Performance of Palm and Sunflower Concretes" Applied Sciences 11, no. 12: 5420. https://doi.org/10.3390/app11125420

APA StyleIgue, F. D., Tran Le, A. D., Bourdot, A., Promis, G., Nguyen, S. T., Douzane, O., Lahoche, L., & Langlet, T. (2021). Impact of Temperature on the Moisture Buffering Performance of Palm and Sunflower Concretes. Applied Sciences, 11(12), 5420. https://doi.org/10.3390/app11125420