Use of Bioceramics Enhanced with Effective Microorganisms as an Additive for Construction. Study of Physical and Mechanical Properties in Cement Mortars and Gypsum Plasters

Abstract

:1. Introduction

2. Materials and Methods

2.1. Bioceramics

2.2. Gypsum Plasters

- Water. In order to obtain an appropriate workability for the plasters, and to favor the comparison of results, the quantity of water used was the same for all the mixtures.

- Dry State Density. Measuring the weight and dimensions of each sample, their dry state density was obtained following the procedure defined by UNE-EN 13279-2 standard [30];

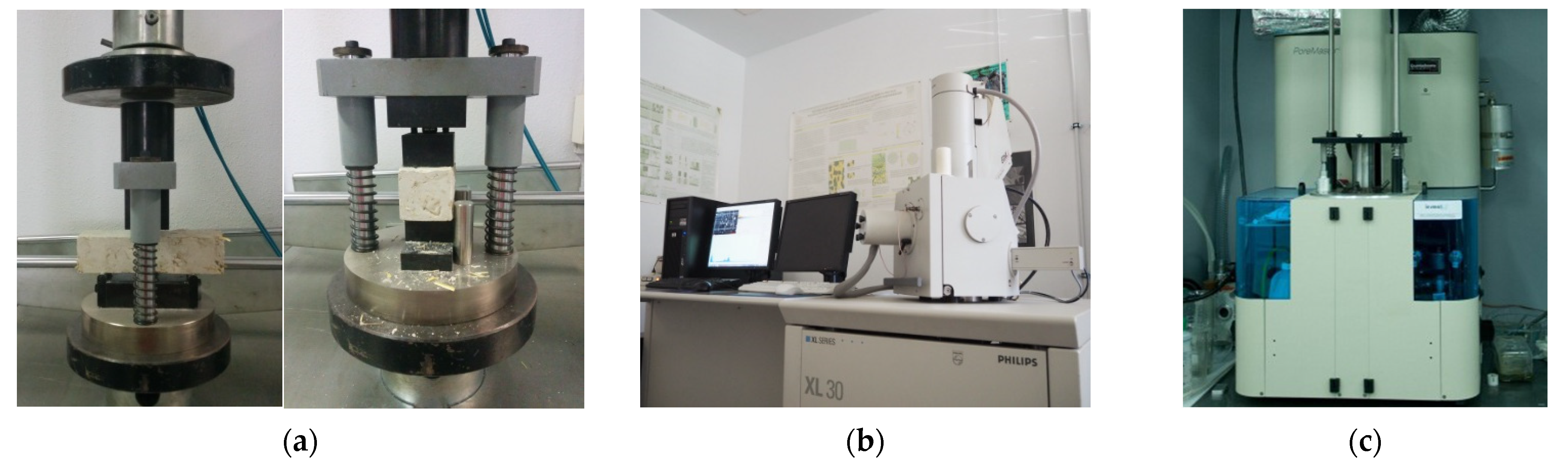

- Mechanical Properties. To calculate the mechanical behavior of the samples, flexural and compressive strength tests were carried out, in accordance with the procedure described in the UNE-EN 13279-2 standard [30]. A universal Suzpecar multi-test press was used. This press has a load capacity of 20 tons and its precision depends on the type of control. In the control per round, the precision is 0.01 mm/min, whereas in the load control the precision is 0.1 Kg/s (Figure 3a);

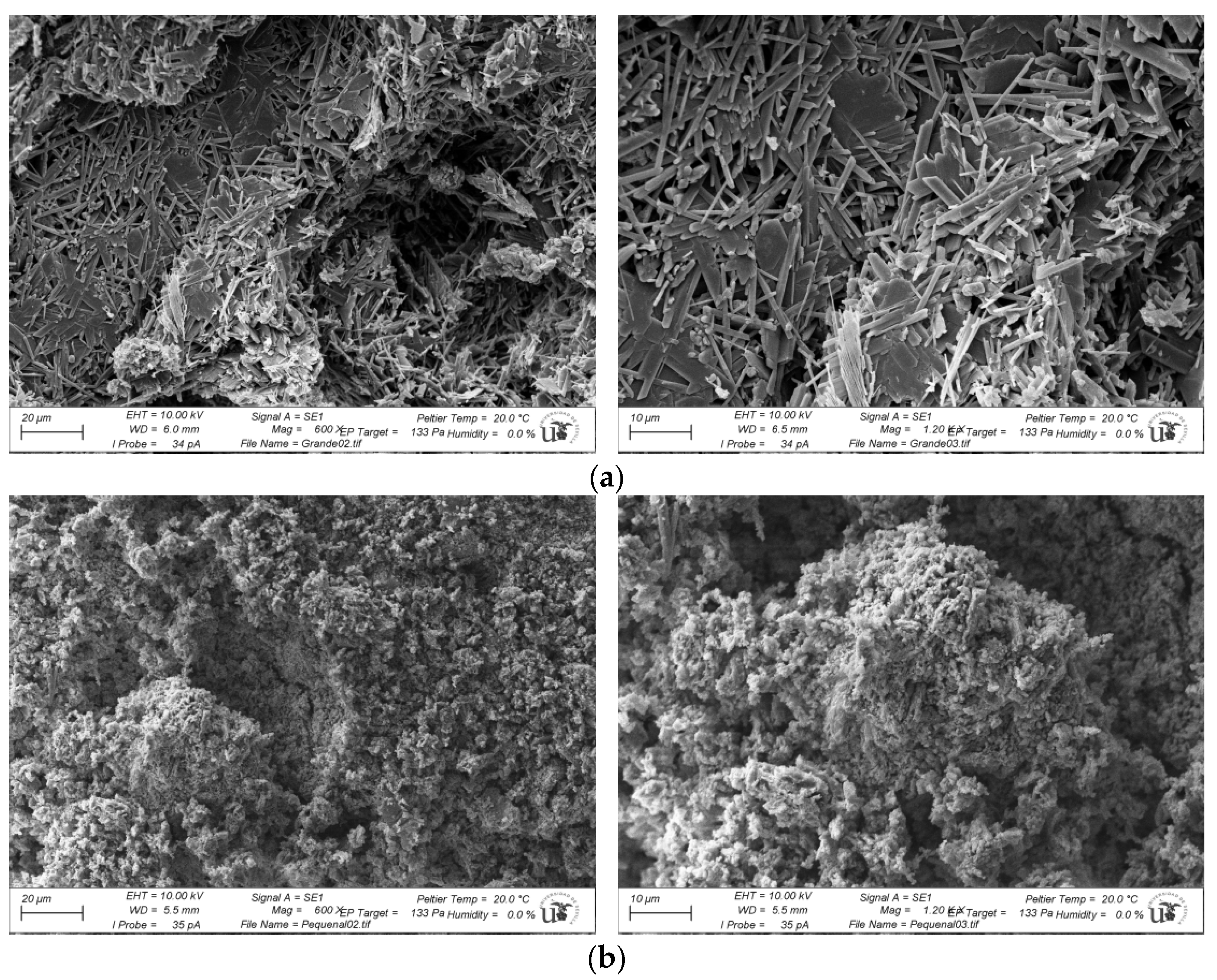

- Scanning Electron Microscopy (SEM). To identify the alterations that the bioceramics caused in the microstructure of the plasters, SEM was employed for examining the microstructures of two samples, R and GBC-1 (mixture including 1% of bioceramics additives). The microscope used was a Phillips XL-30 Scanning Electron Microscope (Figure 3b). The SEM is equipped with an Energy Dispersive Spectrometrer (EDS) and has both back-scattered electron and secondary electron detectos for imaging. The state is nonmotorized. The SEM is operated through a PC-based system. The equipment has a resolution of 3.5 mm at 30 kV and 25 nm at 1 kV, and an acceleration range between 0.2 and 30 kV. To achieve adequate sample conductivity, the EDWARDS sputter six scancoat metallizer was applied to a superficial pattering of gold. The micrographs were recorded for two magnifications, x600 and x1200, for in-depth details.

2.3. Cement Mortars

- Sand. The aggregate used for the mixture’s preparation was natural and had a maximum size (MAS) of 4 mm (Figure 2). This parameter was determined according to the UNE-EN 933:1 standard [32]. The bulk density and the porosity presented values of 1600 kg/m3 and 37.8%, respectively. Finally, the apparent particle density and water absorption presented values of 2600 kg/m3 and 0.47%, respectively. All these magnitudes were determined according to the UNE-EN 1097:6 standard [33];

- Water. In order to obtain an appropriate workability for the mortars, and to favor the comparison of results, the quantity of water used was the same for all the mixtures.

- Fresh State Bulk Density: It was determined by dividing its mass by the volume it occupies when it is introduced into a measuring vessel with a known capacity, following the specifications detailed in the UNE-EN 1015-6 standard [35];

- Dry State Density: Once the mortar hardened, the values of the dry state density were estimated. It was calculated after the curing process described above for 28 days and determined by obtaining the mass in the dry state of a specimen and dividing it by its volume when it is immersed in water in a saturated state, as is specified in the European Standard UNE-EN 1015-10 [36];

- Water Absorption by Capillarity: It was determined using three specimens. They were dried until they reached their constant mass. They were then split and the coefficient of water absorption was determined by measuring the increase in mass after immersing the fractured surface of the dried specimen in 5–10 mm of water for a period of time, following the experimental procedure described in UNE-EN 1015-18 [37];

- Mechanical Properties: All samples were characterized by flexural and compressive strength tests after 28 days, according to the European Standard UNE-EN 1015-11 [34]. Flexural strength was determined using the prismatic samples of 160 × 40 × 40 mm3 and applying a load until failure. After the bending test, the two resulting pieces were tested to compressive strength. These mechanical tests were carried out using the electromechanical Suzpecar press, already described above (Figure 3a);

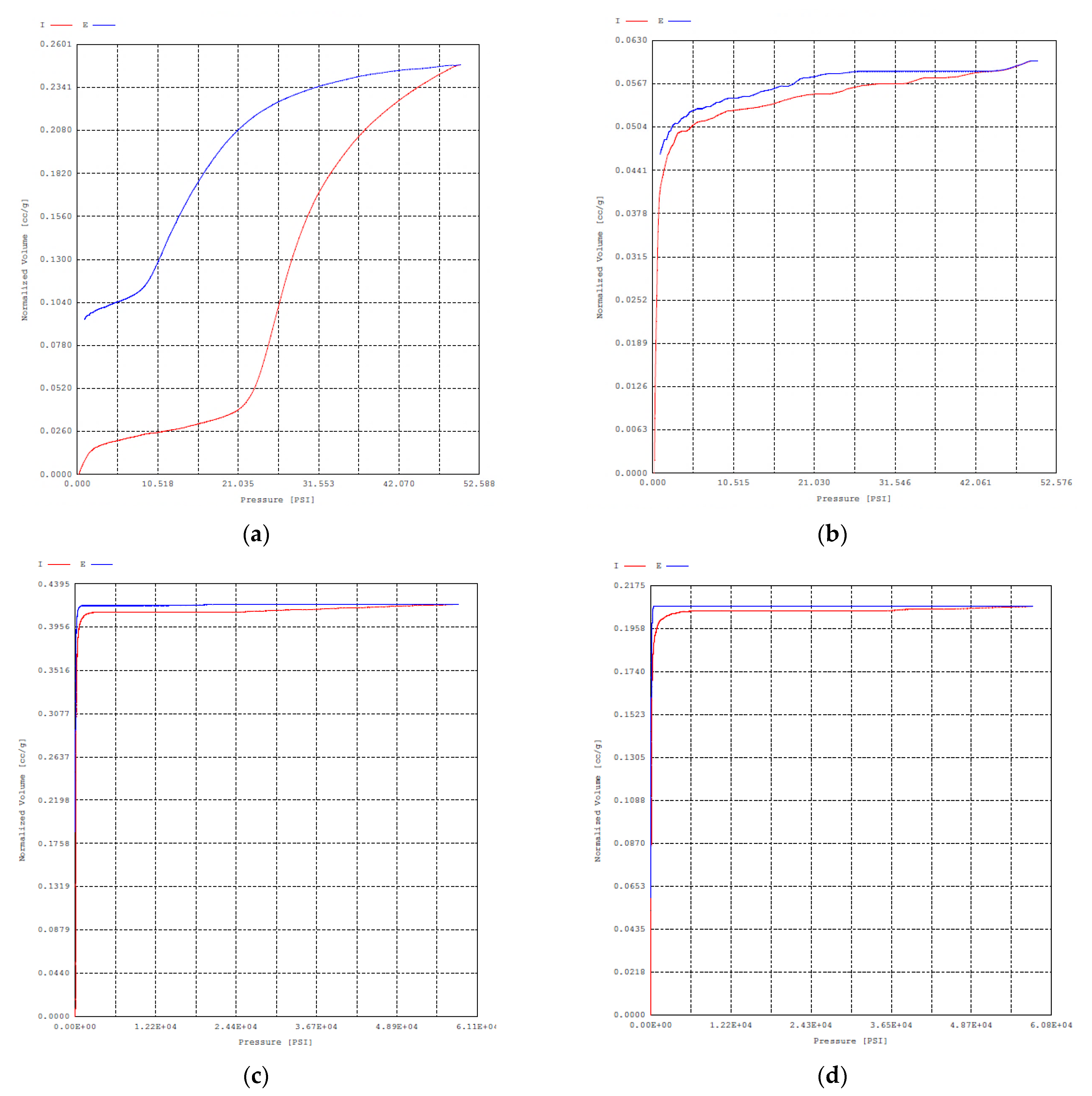

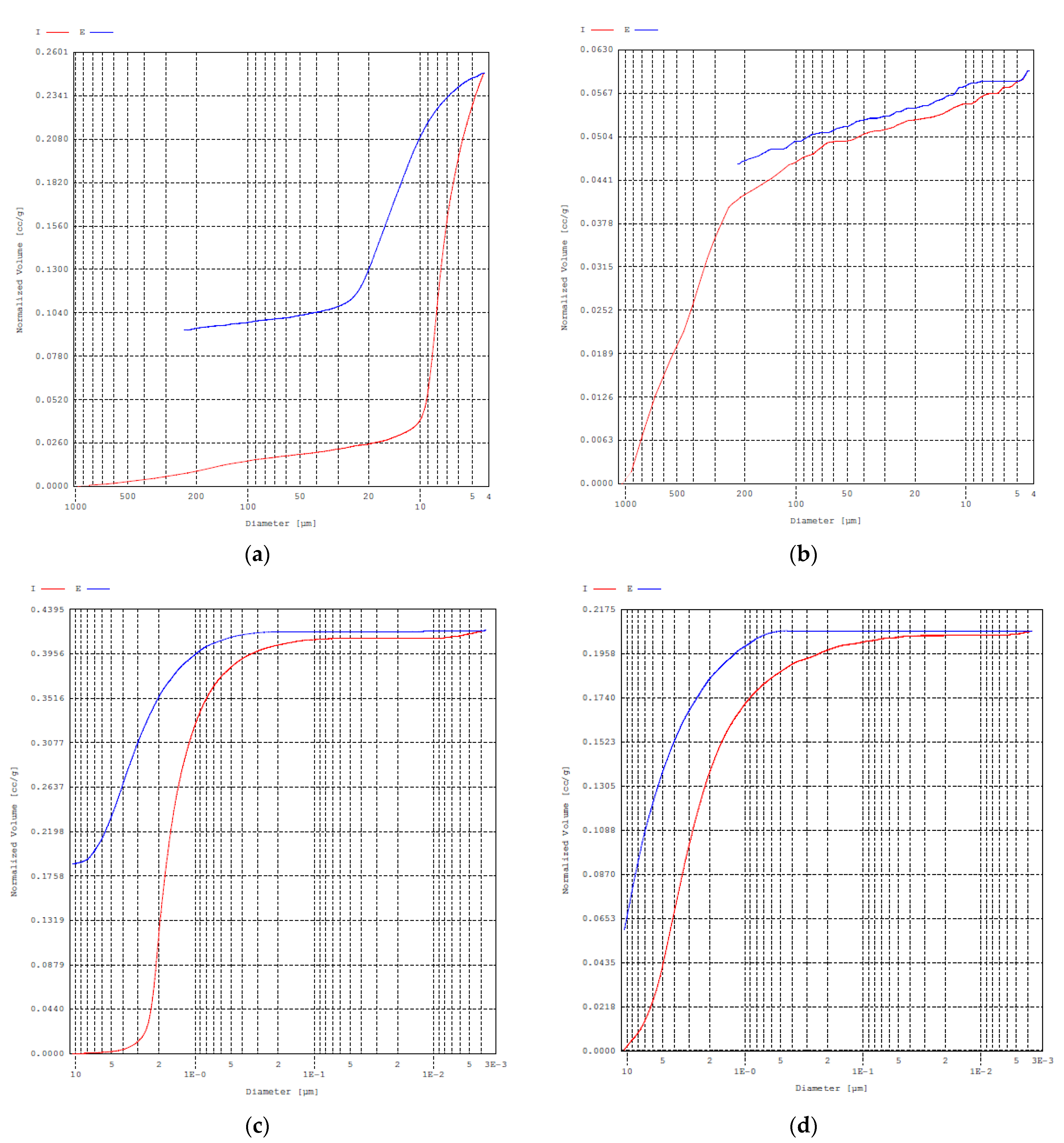

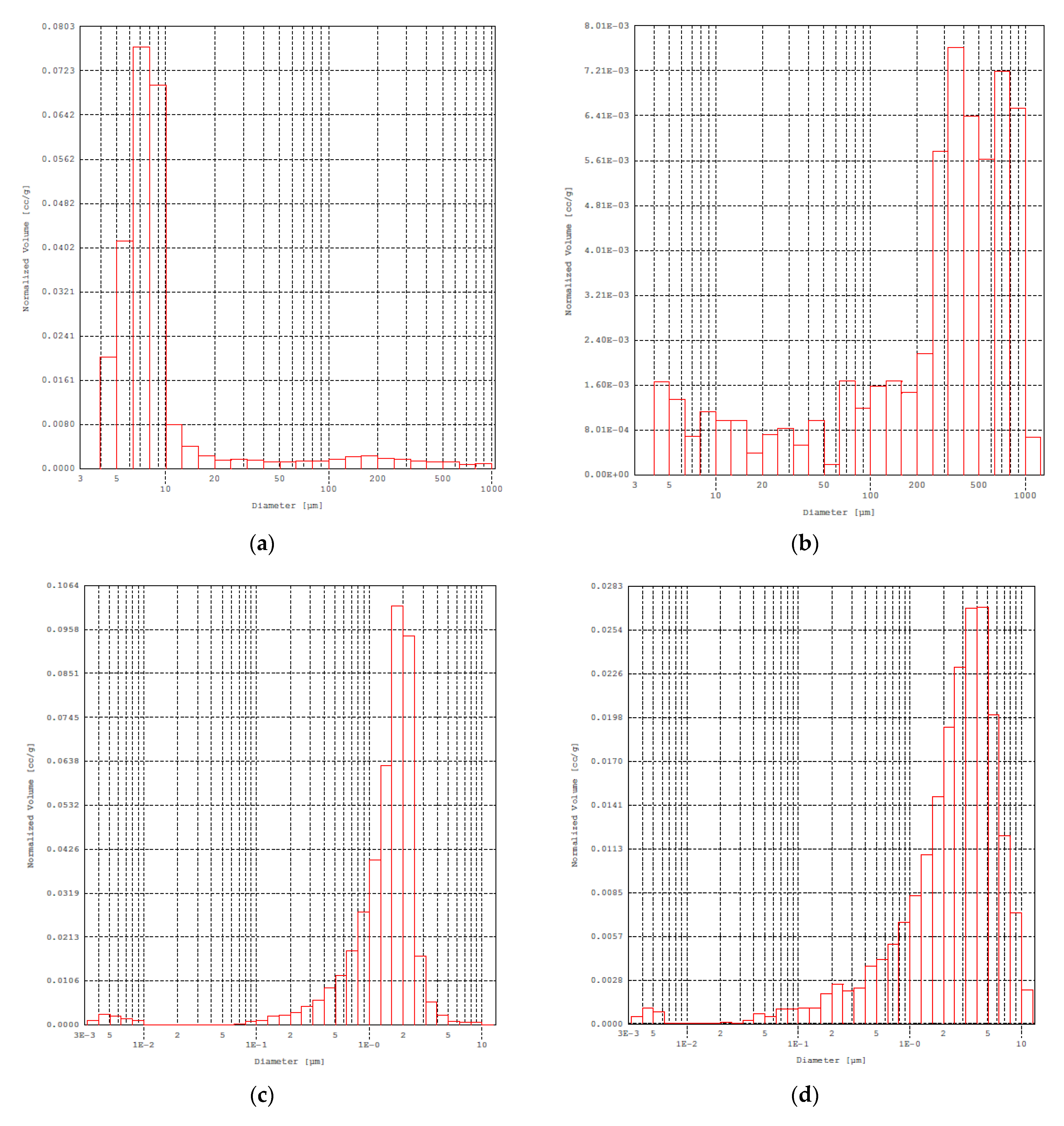

- Mercury Intrusion Porosimetry (MIP): It is a technique where applying pressure forces mercury to enter the pores of the solid. The value of the volume of intruded mercury allows the calculation of area, pore size distribution, percentage of material porosity, and real and apparent densities. The relationship that describes the pressure required to force liquid mercury into the pores of a specific diameter is the called Washburn Equation. The tests can be run at low and high pressure. The low-pressure porosimetry technique was used to characterize pores from 900 micros down to approximately 7 microns. The high-pressure porosimetry was used in the characterization from 7 microns up to the mesopore range. Both tests, at low and high pressure, determined the total porosity of the specimens, as well as the interparticle and intraparticle porosities. The equipment used was a Poremaster 60 GT (Figure 3c). The tests were carried out in samples with a weight of 1 ± 0.01 g stabilized at a temperature of 20 °C.

3. Results and Discussion

3.1. Gypsum Plasters

3.1.1. Dry State Density

3.1.2. Mechanical Properties

3.1.3. Scanning Electron Microscopy (SEM)

3.2. Cement Mortars

3.2.1. Fresh State Bulk Density

3.2.2. Dry State Density

3.2.3. Water Absorption by Capillarity

3.2.4. Mechanical Properties

3.2.5. Mercury Intrusion Porosimetry (MIP)

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Tathe, A.; Ghodke, M.; Nikalje, A.P. A brief review: Biomaterials and their application. Int. J. Pharm. Pharm. Sci. 2010, 2, 19–23. [Google Scholar]

- Coatanlem, P.; Jauberthie, R.; Rendell, F. Lightweight wood chipping concrete durability. Constr. Build. Mater. 2006, 20, 776–781. [Google Scholar] [CrossRef]

- Bederina, M.; Laidoudi, B.; Goullieux, A.; Khenfer, M.M.; Bali, A.; Quéneudec, M. Effect of the treatment of wood shavings on the physico-mechanical characteristics of wood sand concretes. Constr. Build. Mater. 2009, 23, 1311–1315. [Google Scholar] [CrossRef]

- Mohammed, B.S.; Abdullahi, M.; Hoong, C.K. Statistical models for concrete containing wood chipping as partial replacement to fine aggregate. Constr. Build. Mater. 2014, 55, 13–19. [Google Scholar] [CrossRef]

- Elinwa, A.U.; Mahmood, Y.A. Ash from timber waste as cement replacement material. Cem. Concr. Compos. 2002, 24, 219–222. [Google Scholar] [CrossRef]

- Cheah, C.B.; Ramli, M. The implementation of wood waste ash as a partial cement replacement material in the production of structural grade concrete and mortar: An overview. Resour. Conserv. Recycl. 2011, 55, 669–685. [Google Scholar] [CrossRef]

- Siddique, R. Utilization of wood ash in concrete manufacturing. Resour. Conserv. Recycl. 2012, 67, 27–33. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Mazzoli, A.; Siddique, R. Characterization of lightweight mortars containing wood processing by-products waste. Constr. Build. Mater. 2016, 123, 281–289. [Google Scholar] [CrossRef]

- Morales-Conde, M.J.; Rubio-de-Hita, P.; Pérez-Gálvez, F. Composite mortars produced with wood waste from demolition: Assessment of new compounds with enhanced thermal properties. J. Mater. Civ. Eng. 2018, 30, 04017273. [Google Scholar] [CrossRef]

- Dai, D.; Fan, M. Preparation of bio-composite from wood sawdust and gypsum. Ind. Crop. Prod. 2015, 74, 417–424. [Google Scholar] [CrossRef]

- Morales-Conde, M.J.; Rodríguez-Liñán, C.; Pedreño-Rojas, M.A. Physical and mechanical properties of wood-gypsum composites from demolition material in rehabilitation works. Constr. Build. Mater. 2016, 114, 6–14. [Google Scholar] [CrossRef]

- Pedreño-Rojas, M.A.; Morales-Conde, M.J.; Rubio-de-Hita, P.; Pérez-Gálvez, F. Impact of Wetting–Drying Cycles on the Mechanical Properties and Microstructure of Wood Waste–Gypsum Composites. Materials 2019, 12, 1829. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pedreño-Rojas, M.A.; Morales-Conde, M.J.; Pérez-Gálvez, F.; Rodríguez-Liñán, C. Eco-efficient acoustic and thermal conditioning using false ceiling plates made from plaster and wood waste. J. Clean. Prod. 2017, 166, 690–705. [Google Scholar] [CrossRef]

- Del Río-Merino, M.; Santa Cruz-Astorqui, J.; Hernández-Olivares, F. New prefabricated elements of lightened plaster used for partitions and extrados. Constr. Build. Mater. 2005, 19, 487–492. [Google Scholar] [CrossRef]

- Siddique, R.; Singh, K.; Singh, M.; Corinaldesi, V.; Rajor, A. Properties of bacterial rice husk ash concrete. Constr. Build. Mater. 2016, 121, 112–119. [Google Scholar] [CrossRef]

- Mehta, P.K. Properties of blended cements made from rice husk ash. J. Proc. 1977, 74, 440–442. [Google Scholar]

- Jauberthie, R.; Rendell, F.; Tamba, S.; Cissé, I.K. Properties of cement—Rice husk mixture. Constr. Build. Mater. 2003, 17, 239–243. [Google Scholar] [CrossRef]

- Wei, J.; Meyer, C. Utilization of rice husk ash in green natural fiber-reinforced cement composites: Mitigating degradation of sisal fiber. Cem. Concr. Res. 2016, 81, 94–111. [Google Scholar] [CrossRef]

- Selamat, M.E.; Hashim, R.; Sulaiman, O.; Kassim, M.H.M.; Saharudin, N.I.; Taiwo, O.F.A. Comparative study of oil palm trunk and rice husk as fillers in gypsum composite for building material. Constr. Build. Mater. 2019, 197, 526–532. [Google Scholar] [CrossRef]

- Kesikidou, F.; Stefanidou, M. Natural fiber-reinforced mortars. J. Build. Eng. 2019, 25, 100786. [Google Scholar] [CrossRef]

- Lertwattanaruk, P.; Suntijitto, A. Properties of natural fiber cement materials containing coconut coir and oil palm fibers for residential building applications. Constr. Build. Mater. 2015, 94, 664–669. [Google Scholar] [CrossRef]

- Rodríguez-Liñán, C.; Morales-Conde, M.J.; Rubio-de-Hita, P.; Pérez-Gálvez, F.; Pedreño-Rojas, M.A. The influence of natural and synthetic fibre reinforcement on wood-gypsum composites. Open Constr. Build. Technol. J. 2017, 11, 350–362. [Google Scholar]

- Sormunen, P.; Kärki, T. Recycled construction and demolition waste as a possible source of materials for composite manufacturing. J. Build. Eng. 2019, 24, 100742. [Google Scholar] [CrossRef]

- Zhang, L.W.; Sojobi, A.O.; Kodur, V.K.R.; Liew, K.M. Effective utilization and recycling of mixed recycled aggregates for a greener environment. J. Clean. Prod. 2019, 236, 117600. [Google Scholar] [CrossRef]

- Coppola, L.; Bellezze, T.; Belli, A.; Bignozzi, M.C.; Bolzoni, F.; Brenna, A.; Cabrini, M.; Candamano, S.; Cappai, M.; Caputo, D.; et al. Binders alternative to Portland cement and waste management for sustainable construction—Part 1. J. Appl. Biomater. Funct. Mater. 2018, 16, 186–202. [Google Scholar]

- Leung, T.K.; Huang, P.J.; Chen, Y.C.; Lee, C.M. Physical-chemical Test Platform for Room Temperature, Far-infrared Ray Emitting Ceramic Materials (cFIR). J. Chin. Chem. Soc. 2011, 58, 653–658. [Google Scholar] [CrossRef]

- Shigezo, S.; Tetsuro, Y.; Tadahiko, M.; Hiroki, T.; Tomoki, E.; Tsunehisa, A. Effect of Far-Infrared Light Irradiation on Water as Observed by X-Ray Diffraction Measurements. Jpn. J. Appl. Phys. 2004, 43, L545. [Google Scholar]

- Leung, T.; Lin, S.; Yang, T.; Yang, J.; Lin, Y. The Influence of Ceramic Far-Infrared Ray (cFIR) Irradiation on Water Hydrogen Bonding and its Related Chemo-physical Properties. Hydrol. Curr. Res. 2014, 5. [Google Scholar] [CrossRef] [Green Version]

- AENOR. UNE-EN 13279–1: Gypsum Binders and Gypsum Plasters. Part 1: Definitions and Requirements; AENOR: Madrid, Spain, 2006. [Google Scholar]

- AENOR. UNE-EN 13279–2: Gypsum Binders and Gypsum Plasters. Part 2: Test Methods; AENOR: Madrid, Spain, 2006. [Google Scholar]

- Ministerio de la Presidencia. RC-16. Instrucción Para la Recepción de Cementos; Ministerio de la Presidencia: Madrid, Spain, 2016. [Google Scholar]

- AENOR. UNE-EN 933-1: Tests for Geometrical Properties of Aggregates. Part 1: Determination of Particle Size Distribution. Sieving Method; AENOR: Madrid, Spain, 2012. [Google Scholar]

- AENOR. UNE-EN 1097-6: 2001/A1. Tests for Mechanical and Physical Properties of Aggregates. Part 6: Determination of Particle Density and Water Absorption; AENOR: Madrid, Spain, 2006. [Google Scholar]

- AENOR. UNE-EN 1015-11:2000/A1. Methods of Test for Mortar for Masonry. Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar; AENOR: Madrid, Spain, 2007. [Google Scholar]

- AENOR. UNE-EN 1015-6: Methods of Test for Mortar for Masonry. Part 6: Determination of Bulk Density of Fresh Mortar; AENOR: Madrid, Spain, 2000. [Google Scholar]

- AENOR. UNE-EN 1015-10: Methods of Test for Mortar for Masonry. Part 10: Determination of Dry Bulk Density of Hardened Mortar; AENOR: Madrid, Spain, 2000. [Google Scholar]

- AENOR. UNE-EN 1015-18: Methods of Test for Mortar for Masonry. Part 18: Determination of Water Absorption Coefficient Due to Capillary Action of Hardened Mortar; AENOR: Madrid, Spain, 2003. [Google Scholar]

- Lanzón, M.; García-Ruiz, P.A. Effect of citric acid on setting inhibition and mechanical properties of gypsum building plasters. Constr. Build. Mater. 2012, 28, 506–511. [Google Scholar] [CrossRef]

| Composition | [%] |

|---|---|

| Silica (SiO2) | 62.72 |

| Alumina (Al2O3) | 25.88 |

| Sodium oxide (Na2O) | 2.30 |

| Ferric oxide (Fe2O3) | 0.47 |

| Potassium oxide (K2O) | 1.16 |

| Calcium oxide (CaO) | 0.42 |

| Purity [%] | Particle Size [mm] | Surface Hardness (Shore C) | Performance [kg/m2/cm Thickness] | Flexural Strength [N/mm2] | Compressive Strength [N/mm2] | Adherence [N/mm2] | Ph |

|---|---|---|---|---|---|---|---|

| >75 | 0–1 | >45 | 10–12 | >2 | >2 | >0.1 | >6 |

| Samples | Gypsum [g] | Water [g] or [mL] | W/G Ratio | Bioceramics [g] |

|---|---|---|---|---|

| Reference (R) | 1000 | 550 | 0.55 | - |

| GBC-0.3 | 1000 | 550 | 0.55 | 3 |

| GBC-0.65 | 1000 | 550 | 0.55 | 6.5 |

| GBC-1 | 1000 | 550 | 0.55 | 10 |

| Composition | [%] |

|---|---|

| Calcium oxide (CaO) | 62.01 |

| Silica (SiO2) | 18.33 |

| Alumina (Al2O3) | 4.81 |

| Ferric oxide (Fe2O3) | 3.22 |

| Sulfuric anhydride (SO3) | 3.15 |

| Magnesium oxide (MgO) | 0.83 |

| Potassium oxide (K2O) | 0.69 |

| Sodium oxide (Na2O) | 0.18 |

| Titanium oxide (TiO2) | 0.01 |

| Samples | Cement [g] | Aggregate [g] | C/A Ratio | Water [g] or [mL] | W/C Ratio | Bioceramics [g] |

|---|---|---|---|---|---|---|

| Reference (R) | 1000 | 3333 | 0.3 | 600 | 0.6 | - |

| CBC-0.1 | 1000 | 3333 | 0.3 | 600 | 0.6 | 3.3 |

| CBC-0.25 | 1000 | 3333 | 0.3 | 600 | 0.6 | 8.3 |

| CBC-0.4 | 1000 | 3333 | 0.3 | 600 | 0.6 | 13.3 |

| Samples | Dry State Density [kg/m3] (CoV [%]) | Flexural Strength [MPa] (CoV [%]) | Compressive Strength [MPa] (CoV [%]) |

|---|---|---|---|

| Reference (R) | 1209.56 (0.26) | 3.84 (4.55) | 9.02 (21.16) |

| GBC-0.3 | 1206.65 (1.49) | 3.81 (7.87) | 9.36 (18.76) |

| GBC-0.65 | 1209.61 (1.85) | 3.89 (6.06) | 9.58 (33.26) |

| GBC-1 | 1220.22 (1.24) | 3.96 (6.49) | 10.96 (20.49) |

| Samples | Fresh State Density [kg/m3] (CoV [%]) | Dry State Density [kg/m3] (CoV [%]) | Water Absorption [kg/m2·min0.5] | Flexural Strength [MPa] (CoV [%]) | Compressive Strength [MPa] (CoV [%]) |

|---|---|---|---|---|---|

| Reference (R) | 2096.74 (0.26) | 1989.82 (0.18) | 0.42 | 4.68 (5.26) | 23.66 (10.23) |

| CBC-0.1 | 2040.12 (0.74) | 1937.97 (0.15) | 0.29 | 5.38 (7.00) | 24.59 (22.73) |

| CBC-0.25 | 2066.01 (1.33) | 1876.31 (0.23) | 0.41 | 4.92 (10.70) | 20.21 (26.22) |

| CBC-0.4 | 2074.38 (1.16) | 1956.00 (0.05) | 0.32 | 5.68 (13.52) | 27.71 (25.03) |

| Samples | Porosity Type | Reference (R) | CBC-0.4 |

|---|---|---|---|

| Low Pressure | Total [%] | 31.60 | 7.04 |

| Interparticle [%] | 31.60 | 7.04 | |

| Intraparticle [%] | 0.00 | 0.00 | |

| High Pressure | Total [%] | 59.08 | 26.43 |

| Interparticle [%] | 0.73 | 7.72 | |

| Intraparticle [%] | 58.35 | 18.71 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pérez-Gálvez, F.; Morales-Conde, M.J.; Pedreño-Rojas, M.A. Use of Bioceramics Enhanced with Effective Microorganisms as an Additive for Construction. Study of Physical and Mechanical Properties in Cement Mortars and Gypsum Plasters. Appl. Sci. 2021, 11, 3519. https://doi.org/10.3390/app11083519

Pérez-Gálvez F, Morales-Conde MJ, Pedreño-Rojas MA. Use of Bioceramics Enhanced with Effective Microorganisms as an Additive for Construction. Study of Physical and Mechanical Properties in Cement Mortars and Gypsum Plasters. Applied Sciences. 2021; 11(8):3519. https://doi.org/10.3390/app11083519

Chicago/Turabian StylePérez-Gálvez, Filomena, María Jesús Morales-Conde, and Manuel Alejandro Pedreño-Rojas. 2021. "Use of Bioceramics Enhanced with Effective Microorganisms as an Additive for Construction. Study of Physical and Mechanical Properties in Cement Mortars and Gypsum Plasters" Applied Sciences 11, no. 8: 3519. https://doi.org/10.3390/app11083519

APA StylePérez-Gálvez, F., Morales-Conde, M. J., & Pedreño-Rojas, M. A. (2021). Use of Bioceramics Enhanced with Effective Microorganisms as an Additive for Construction. Study of Physical and Mechanical Properties in Cement Mortars and Gypsum Plasters. Applied Sciences, 11(8), 3519. https://doi.org/10.3390/app11083519