Industry 4.0 Technologies for Manufacturing Sustainability: A Systematic Review and Future Research Directions

Abstract

1. Introduction

2. Basic Concepts and Terminology

2.1. Concept and Definitions of Sustainable Manufacturing

Main Definitions of Sustainable Manufacturing (SM)

2.2. Industry 4.0

2.3. Relationship and Link between Industry 4.0 and Sustainable Manufacturing

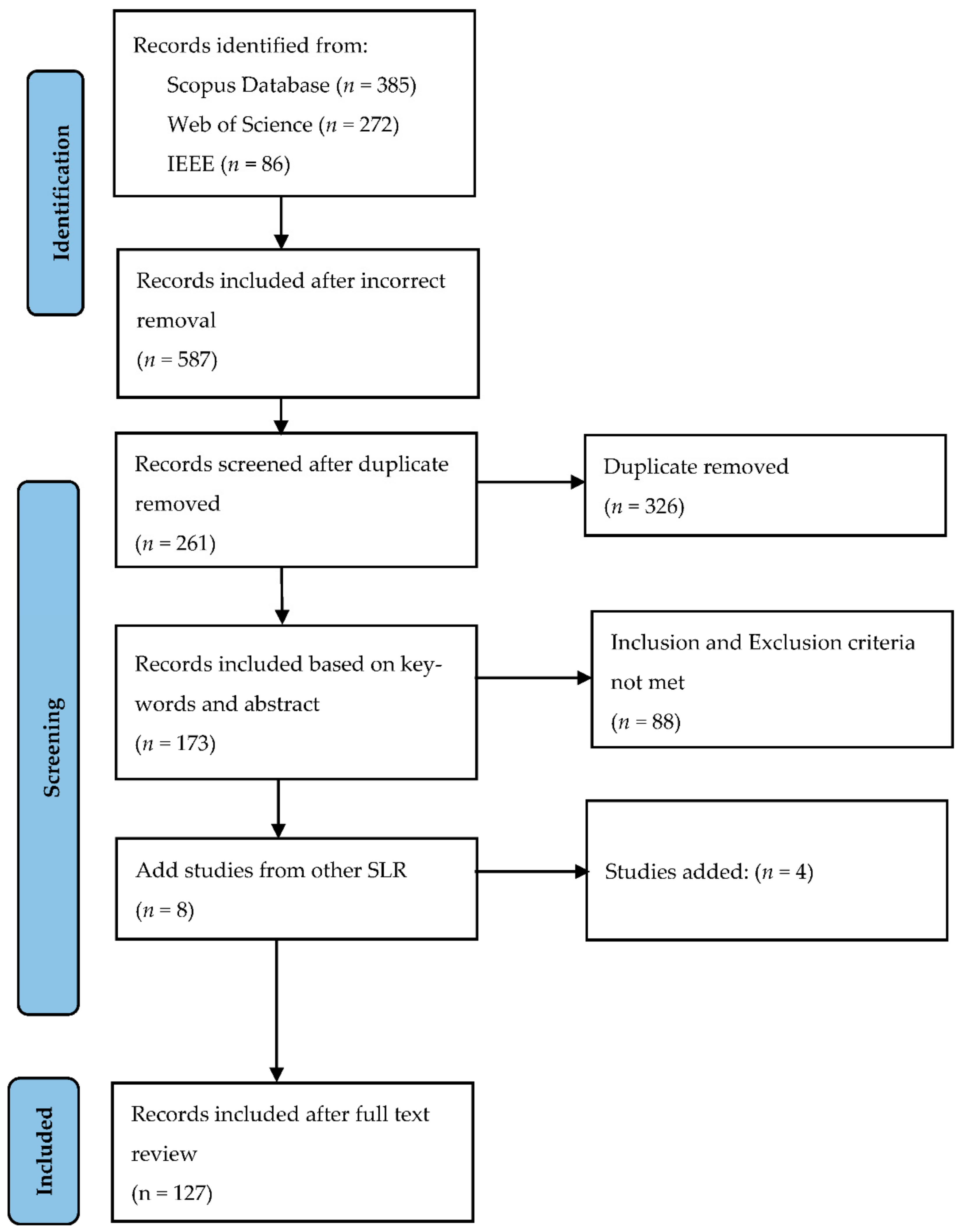

3. Materials and Methods

“An efficient technique for hypothesis testing, for summarizing the results of existing studies, and for assessing consistency among previous studies; these tasks are clearly unique to medicine.”

3.1. Research Questions

3.2. Search Strategy

- Articles published in the English language;

- Articles published before May 2021;

- Articles should be from peer reviewed journals or conference proceedings;

- Articles focused in the area of Industry 4.0 technologies and manufacturing sustainability;

- Articles must be in short or full version (not an editorial or abstract).

4. Results

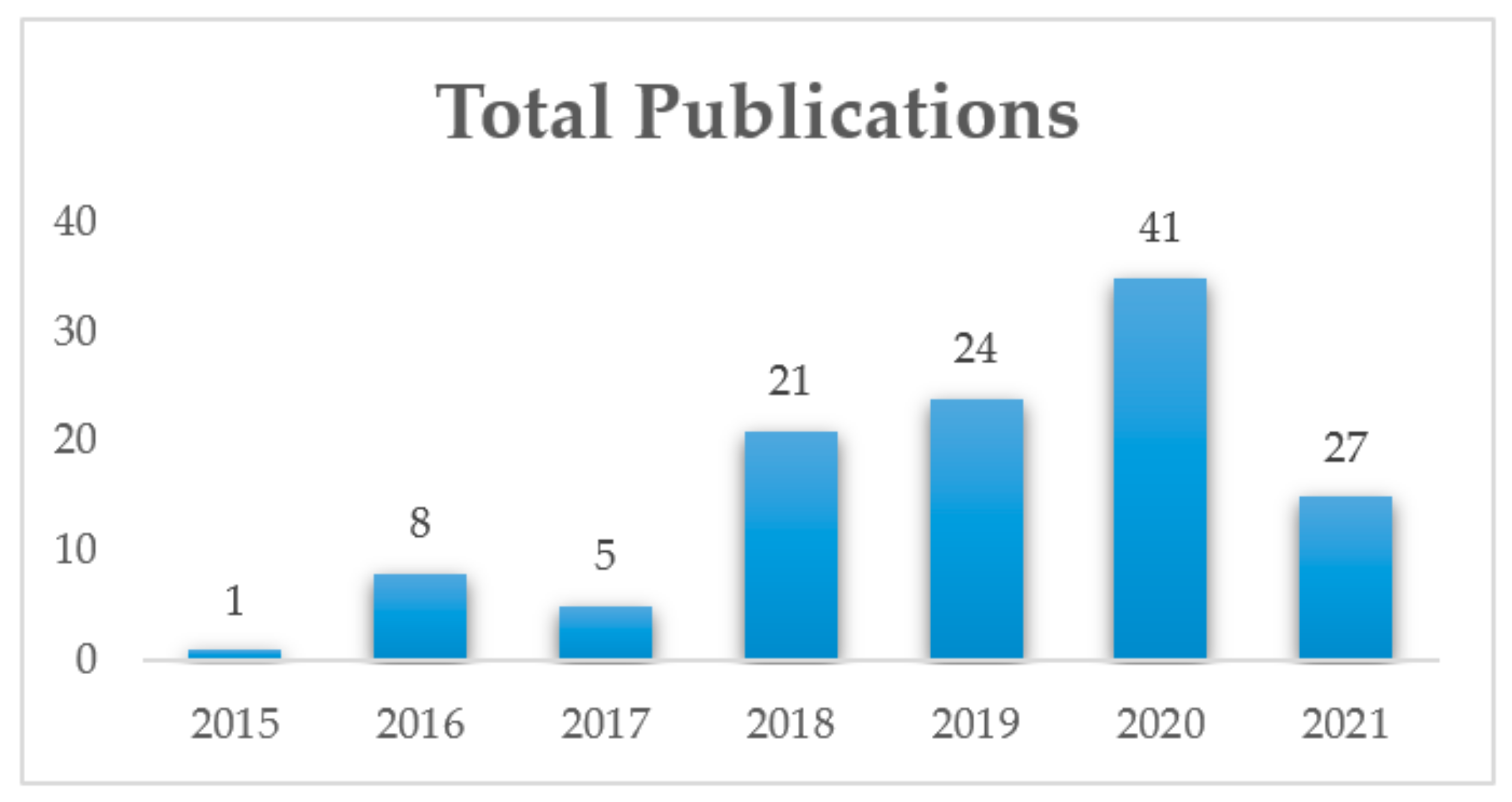

4.1. Year-Wise Publication Progress

4.2. Highly Cited Papers (Global Citations)

4.3. Most Productive Journals

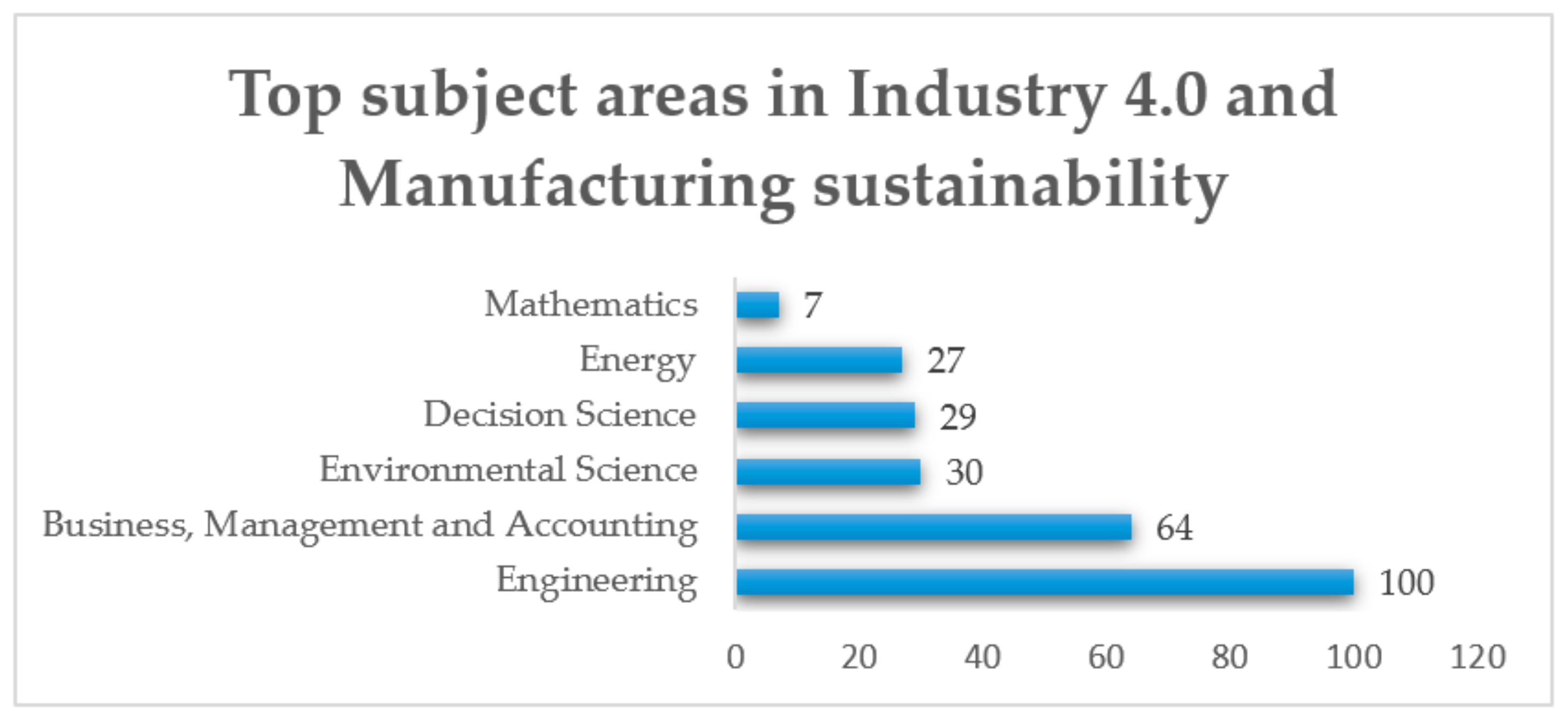

4.4. Top Subject Areas

4.5. Most Used Keywords

5. Discussion on Review Results

5.1. Concepts and Theories Related to Manufacturing in Industry 4.0

Shop-Floor Activities

5.2. Main Technologies of Industry 4.0 for Achieving Sustainability

5.2.1. Additive Manufacturing

5.2.2. Role of Big Data Analytics and Digital Twin

5.2.3. Artificial Intelligence and Machine Learning

5.2.4. Internet of Things (IoT)

5.2.5. Cloud Computing and Manufacturing

5.2.6. Augmented and Virtual Reality

5.2.7. Blockchain Technology

5.2.8. Flexible and Reconfigurable Manufacturing Systems

5.2.9. Robotics

5.2.10. Cyber Security

6. Manufacturing Sustainability in Industry 4.0

6.1. Economic Sustainability

6.2. Social Sustainability

6.3. Environmental Sustainability

7. Future Research Directions

7.1. Lean Production Systems for Environment Management in Industry 4.0

7.2. Establish Relationship between Sustainability and Industry 4.0 Factors

7.3. Impact of Sustainable Supply Chain in Industry 4.0

7.4. Big Data Analytics and Sustainability

7.5. Impact of Machine Learning and Artificial Intelligence (AI) Approaches on Sustainability

7.6. Integrated Process Planning and Scheduling for Sustainability on the Shop Floor

7.7. Non-Destructive Quality Control for Manufacturing Sustainability

- What are the main challenges and requirements for non-destructive testing in the Industry 4.0 scenario?

- Standardization of digital connections for non-destructive testing methods in Industry 4.0.

- Skill development and cost-related issues for non-destructive testing in the Industry 4.0 context.

8. Conclusions

- This study discusses the role and opportunities for Industry 4.0 technologies for various manufacturing operations in industries. The previous published studies were limited to the general concepts related to Industry 4.0 theories and concepts. The role and opportunities for shop floor management in Industry 4.0 are discussed. Furthermore, this study provides the impact of various Industry 4.0 technologies on each sustainability dimension which will be helpful for future studies.

- Secondly, this study uses the three major scientific databases i.e., IEEE explore, Scopus and Web of science, for the literature collection which was the limitation in previously published studies. This study followed the PRISMA approach for a systematic literature review and, on the basis of final articles, different opportunities for the manufacturing sustainability with Industry 4.0 technologies are discussed.

- Finally, from the literature review various research issues and challenges in Industry 4.0 were identified which can be explored in the future studies.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Aiello, G.; Giallanza, A.; Vacante, S.; Fasoli, S.; Mascarella, G. Propulsion Monitoring System for Digitized Ship Management: Preliminary Results from a Case Study. Procedia Manuf. 2020, 42, 16–23. [Google Scholar] [CrossRef]

- Oztemel, E.; Gursev, S. Literature Review of Industry 4.0 and Related Technologies. J. Intell. Manuf. 2020, 31, 127–182. [Google Scholar] [CrossRef]

- Stock, T.; Seliger, G. Opportunities of Sustainable Manufacturing in Industry 4.0. In Procedia CIRP, Proceedings of the 13th Global Conference on Sustainable Manufacturing—Decoupling Growth from Resource Use, Binh Duong, Vietnam, 16–18 September 2016; Seliger, G., Malon, J., Kohl, H., Eds.; Elsevier B.V.: Amsterdam, The Netherlands, 2016; Volume 40, pp. 536–541. [Google Scholar]

- Machado, C.G.; Winroth, M.P.; Ribeiro da Silva, E.H.D. Sustainable Manufacturing in Industry 4.0: An Emerging Research Agenda. Int. J. Prod. Res. 2020, 58, 1462–1484. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent Manufacturing in the Context of Industry 4.0: A Review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Kim, J.H. A Review of Cyber-Physical System Research Relevant to the Emerging IT Trends: Industry 4.0, IoT, Big Data, and Cloud Computing. J. Ind. Integr. Manag. 2017, 2, 1750011. [Google Scholar] [CrossRef]

- Ejsmont, K.; Gladysz, B.; Kluczek, A. Impact of Industry 4.0 on Sustainability-Bibliometric Literature Review. Sustainability 2020, 12, 5650. [Google Scholar] [CrossRef]

- Sharma, R.; Jabbour, C.J.C.; Lopes de Sousa Jabbour, A.B. Sustainable Manufacturing and Industry 4.0: What We Know and What We Don’t. J. Enterp. Inf. Manag. 2020. [Google Scholar] [CrossRef]

- De Sousa Jabbour, A.B.L.; Jabbour, C.J.C.; Foropon, C.; Filho, M.G. When Titans Meet—Can Industry 4.0 Revolutionise the Environmentally-Sustainable Manufacturing Wave? The Role of Critical Success Factors. Technol. Forecast. Soc. Change 2018, 132, 18–25. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A. Sustainable Industry 4.0 Framework: A Systematic Literature Review Identifying the Current Trends and Future Perspectives. Process. Saf. Environ. Prot. 2018, 117, 408–425. [Google Scholar] [CrossRef]

- Bag, S.; Pretorius, J.H.C. Relationships between Industry 4.0, Sustainable Manufacturing and Circular Economy: Proposal of a Research Framework. Int. J. Organ. Anal. 2020. [Google Scholar] [CrossRef]

- Haapala, K.R.; Zhao, F.; Camelio, J.; Sutherland, J.W.; Skerlos, S.J.; Dornfeld, D.A.; Jawahir, I.S.; Clarens, A.F.; Rickli, J.L. A Review of Engineering Research in Sustainable Manufacturing. J. Manuf. Sci. Eng. Trans. ASME 2013, 135. [Google Scholar] [CrossRef]

- Garetti, M.; Taisch, M. Sustainable Manufacturing: Trends and Research Challenges. Prod. Plan. Control. 2012, 23, 83–104. [Google Scholar] [CrossRef]

- Jayal, A.D.; Badurdeen, F.; Dillon, O.W., Jr.; Jawahir, I.S. Sustainable Manufacturing: Modeling and Optimization Challenges at the Product, Process and System Levels. CIRP J. Manuf. Sci. Technol. 2010, 2, 144–152. [Google Scholar] [CrossRef]

- ITA, U. How Does Commerce Define Sustainable Manufacturing? 2012. Available online: https://oneill.indiana.edu/doc/research/sustainability-2014.pdf (accessed on 17 May 2021).

- Sartal, A.; Bellas, R.; Mejías, A.M.; García-Collado, A. The Sustainable Manufacturing Concept, Evolution and Opportunities within Industry 4.0: A Literature Review. Adv. Mech. Eng. 2020, 12. [Google Scholar] [CrossRef]

- McElnea, W.K. Sustainable Manufacturing Initiative: U.S. Department of Commerce. Int. J. Powder Metall. Princet. N. J. 2011, 47, 12–16. [Google Scholar]

- Giallanza, A.; Aiello, G.; Marannano, G.; Nigrelli, V. Industry 4.0: Smart Test Bench for Shipbuilding Industry. Int. J. Interact. Des. Manuf. IJIDeM 2020, 14, 1525–1533. [Google Scholar] [CrossRef]

- Borregan-Alvarado, J.; Alvarez-Meaza, I.; Cilleruelo-Carrasco, E.; Garechana-Anacabe, G. A Bibliometric Analysis in Industry 4.0 and Advanced Manufacturing: What about the Sustainable Supply Chain? Sustainability 2020, 12, 7840. [Google Scholar] [CrossRef]

- Giallanza, A.; Aiello, G.; Marannano, G. Industry 4.0: Advanced Digital Solutions Implemented on a Close Power Loop Test Bench. Procedia Comput. Sci. 2021, 180, 93–101. [Google Scholar] [CrossRef]

- Lee, J.; Azamfar, M.; Singh, J. A Blockchain Enabled Cyber-Physical System Architecture for Industry 4.0 Manufacturing Systems. Manuf. Lett. 2019, 20, 34–39. [Google Scholar] [CrossRef]

- Thramboulidis, K.; Vachtsevanou, D.C.; Kontou, I. CPuS-IoT: A Cyber-Physical Microservice and IoT-Based Framework for Manufacturing Assembly Systems. Annu. Rev. Control 2019, 47, 237–248. [Google Scholar] [CrossRef]

- Abdirad, M.; Krishnan, K. Industry 4.0 in Logistics and Supply Chain Management: A Systematic Literature Review. EMJ Eng. Manag. J. 2020, 1–15. [Google Scholar] [CrossRef]

- Chalmeta, R.; Santos-deLeón, N.J. Sustainable Supply Chain in the Era of Industry 4.0 and Big Data: A Systematic Analysis of Literature and Research. Sustainability 2020, 12, 4108. [Google Scholar] [CrossRef]

- Moher, D.; Shamseer, L.; Clarke, M.; Ghersi, D.; Liberati, A.; Petticrew, M.; Shekelle, P.; Stewart, L.A. Preferred Reporting Items for Systematic Review and Meta-Analysis Protocols (PRISMA-P) 2015 Statement. Syst. Rev. 2015, 4, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Petticrew, M. Systematic Reviews from Astronomy to Zoology: Myths and Misconceptions. BMJ 2001, 322, 98–101. [Google Scholar] [CrossRef] [PubMed]

- Korner, M.E.H.; Lambán, M.P.; Albajez, J.A.; Santolaria, J.; Corrales, L.C.N.; Royo, J. Systematic Literature Review: Integration of Additive Manufacturing and Industry 4.0. Metals 2020, 10, 1061. [Google Scholar] [CrossRef]

- Samala, T.; Manupati, V.K.; Varela, M.L.R.; Putnik, G. Investigation of Degradation and Upgradation Models for Flexible Unit Systems: A Systematic Literature Review. Future Internet 2021, 13, 57. [Google Scholar] [CrossRef]

- Antony, J.; Psomas, E.; Garza-Reyes, J.A.; Hines, P. Practical Implications and Future Research Agenda of Lean Manufacturing: A Systematic Literature Review. Prod. Plan. Control 2020, 1–37. [Google Scholar] [CrossRef]

- Müller, J.M.; Kiel, D.; Voigt, K.-I. What Drives the Implementation of Industry 4.0? The Role of Opportunities and Challenges in the Context of Sustainability. Sustainability 2018, 10, 247. [Google Scholar] [CrossRef]

- Kiel, D.; Müller, J.M.; Arnold, C.; Voigt, K.-I. Sustainable Industrial Value Creation: Benefits and Challenges of Industry 4.0. Int. J. Innov. Manag. 2017, 21. [Google Scholar] [CrossRef]

- Luthra, S.; Mangla, S.K. Evaluating Challenges to Industry 4.0 Initiatives for Supply Chain Sustainability in Emerging Economies. Process Saf. Environ. Prot. 2018, 117, 168–179. [Google Scholar] [CrossRef]

- Manavalan, E.; Jayakrishna, K. A Review of Internet of Things (IoT) Embedded Sustainable Supply Chain for Industry 4.0 Requirements. Comput. Ind. Eng. 2019, 127, 925–953. [Google Scholar] [CrossRef]

- Aiello, G.; Giallanza, A.; Mascarella, G. Towards Shipping 4.0. A Preliminary Gap Analysis. Procedia Manuf. 2020, 42, 24–29. [Google Scholar] [CrossRef]

- Cica, D.; Sredanovic, B.; Tesic, S.; Kramar, D. Predictive Modeling of Turning Operations under Different Cooling/Lubricating Conditions for Sustainable Manufacturing with Machine Learning Techniques. Appl. Comput. Inform. 2020. [Google Scholar] [CrossRef]

- Pickard, M.; Grecu, I.; Grecu, G. Sustainable Smart Manufacturing in Industry 4.0: Real-Time Resource Planning, Process Monitoring, and Production Control. Econ. Manag. Financ. Mark. 2019, 14, 30–36. [Google Scholar] [CrossRef][Green Version]

- Varela, L.; Araújo, A.; Ávila, P.; Castro, H.; Putnik, G. Evaluation of the Relation between Lean Manufacturing, Industry 4.0, and Sustainability. Sustainability 2019, 11, 1439. [Google Scholar] [CrossRef]

- Yang, W.; Takakuwa, S. Simulation-Based Dynamic Shop Floor Scheduling for a Flexible Manufacturing System in the Industry 4.0 Environment. In Proceedings of the 2017 Winter Simulation Conference, Las Vegas, NV, USA, 3–6 December 2017; IEEE: New York, NY, USA, 2017; pp. 3908–3916. [Google Scholar]

- Jamwal, A.; Agrawal, R.; Sharma, M.; Kumar, A.; Kumar, V.; Garza-Reyes, J.A.A. Machine Learning Applications for Sustainable Manufacturing: A Bibliometric-Based Review for Future Research. J. Enterp. Inf. Manag. 2021. [Google Scholar] [CrossRef]

- Moica, S.; Ganzarain, J.; Ibarra, D.; Ferencz, P. Change Made in Shop Floor Management to Transform a Conventional Production System into an “Industry 4.0”: Case Studies in SME Automotive Production Manufacturing. In Proceedings of the 7th International Conference on Industrial Technology and Management (ICITM 2018), Oxford, UK, 7–9 March 2018; IEEE: New York, NY, USA, 2018; pp. 51–56. [Google Scholar]

- Mittal, S.; Romero, D.; Wuest, T. Towards a Smart Manufacturing Toolkit for SMEs. Prod. Lifecycle Manag. Support. Ind. 4.0. 2018, 476–487. [Google Scholar] [CrossRef]

- Schmidt, D.; Villalba Diez, J.; Ordieres-Meré, J.; Gevers, R.; Schwiep, J.; Molina, M. Industry 4.0 Lean Shopfloor Management Characterization Using EEG Sensors and Deep Learning. Sensors 2020, 20, 2860. [Google Scholar] [CrossRef]

- Godina, R.; Ribeiro, I.; Matos, F.; Ferreira, B.T.; Carvalho, H.; Peças, P. Impact Assessment of Additive Manufacturing on Sustainable Business Models in Industry 4.0 Context. Sustainability 2020, 12, 66. [Google Scholar] [CrossRef]

- Haleem, A.; Javaid, M. Additive Manufacturing Applications in Industry 4.0: A Review. J. Ind. Integr. Manag. 2019, 4, 1930001. [Google Scholar] [CrossRef]

- Ford, S.; Despeisse, M. Additive Manufacturing and Sustainability: An Exploratory Study of the Advantages and Challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- Jamwal, A.; Agrawal, R.; Sharma, M.; Kumar, V.; Kumar, S. Developing A Sustainability Framework for Industry 4.0. Procedia CIRP 2021, 98, 430–435. [Google Scholar] [CrossRef]

- Yadav, G.; Kumar, A.; Luthra, S.; Garza-Reyes, J.A.; Kumar, V.; Batista, L. A Framework to Achieve Sustainability in Manufacturing Organisations of Developing Economies Using Industry 4.0 Technologies’ Enablers. Comput. Ind. 2020, 122. [Google Scholar] [CrossRef]

- Mittal, S.; Khan, M.A.; Romero, D.; Wuest, T. A Critical Review of Smart Manufacturing & Industry 4.0 Maturity Models: Implications for Small and Medium-Sized Enterprises (SMEs). J. Manuf. Syst. 2018, 49, 194–214. [Google Scholar]

- Wang, L.; Wang, G. Big Data in Cyber-Physical Systems, Digital Manufacturing and Industry 4.0. Int. J. Eng. Manuf. IJEM 2016, 6, 1–8. [Google Scholar]

- Addo-Tenkorang, R.; Helo, P.T. Big Data Applications in Operations/Supply-Chain Management: A Literature Review. Comput. Ind. Eng. 2016, 101, 528–543. [Google Scholar] [CrossRef]

- Castelo-Branco, I.; Cruz-Jesus, F.; Oliveira, T. Assessing Industry 4.0 Readiness in Manufacturing: Evidence for the European Union. Comput. Ind. 2019, 107, 22–32. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 Technologies: Implementation Patterns in Manufacturing Companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Papadopoulos, T.; Singh, S.P.; Spanaki, K.; Gunasekaran, A.; Dubey, R. Towards the next Generation of Manufacturing: Implications of Big Data and Digitalization in the Context of Industry 4.0. Prod. Plan. Control. 2021. [Google Scholar] [CrossRef]

- Li, D.; Tang, H.; Wang, S.; Liu, C. A Big Data Enabled Load-Balancing Control for Smart Manufacturing of Industry 4.0. Clust. Comput. 2017, 20, 1855–1864. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q.; Wang, L.; Nee, A.Y.C. Digital Twins and Cyber–Physical Systems toward Smart Manufacturing and Industry 4.0: Correlation and Comparison. Engineering 2019, 5, 653–661. [Google Scholar] [CrossRef]

- Ke, S.; Xiang, F.; Zhang, Z.; Zuo, Y. A Enhanced Interaction Framework Based on VR, AR and MR in Digital Twin. Procedia Cirp 2019, 83, 753–758. [Google Scholar] [CrossRef]

- Wang, X.V.; Wang, L. Digital Twin-Based WEEE Recycling, Recovery and Remanufacturing in the Background of Industry 4.0. Int. J. Prod. Res. 2019, 57, 3892–3902. [Google Scholar] [CrossRef]

- Lee, J.; Davari, H.; Singh, J.; Pandhare, V. Industrial Artificial Intelligence for Industry 4.0-Based Manufacturing Systems. Manuf. Lett. 2018, 18, 20–23. [Google Scholar] [CrossRef]

- Ayvaz, S.; Alpay, K. Predictive maintenance system for production lines in manufacturing: A machine learning approach using IoT data in real-time. Expert Syst. Appl. 2021, 173, 114598. [Google Scholar] [CrossRef]

- Yao, X.; Zhou, J.; Zhang, J.; Boër, C.R. From Intelligent Manufacturing to Smart Manufacturing for Industry 4.0 Driven by next Generation Artificial Intelligence and Further On. In Proceedings of the 2017 5th International Conference on Enterprise Systems (ES), Beijing, China, 22–24 September 2017; IEEE: New York, NY, USA, 2017; pp. 311–318. [Google Scholar]

- Bajic, B.; Cosic, I.; Lazarevic, M.; Sremcev, N.; Rikalovic, A. Machine Learning Techniques for Smart Manufacturing: Applications and Challenges in Industry 4.0. In Proceedings of the 9th International Scientific and Expert Conference, Novi Sad, Serbia, 10-12 October 2018; p. 29. [Google Scholar]

- Cioffi, R.; Travaglioni, M.; Piscitelli, G.; Petrillo, A.; De Felice, F. Artificial Intelligence and Machine Learning Applications in Smart Production: Progress, Trends, and Directions. Sustainability 2020, 12, 492. [Google Scholar] [CrossRef]

- Angelopoulos, A.; Michailidis, E.T.; Nomikos, N.; Trakadas, P.; Hatziefremidis, A.; Voliotis, S.; Zahariadis, T. Tackling Faults in the Industry 4.0 Era—a Survey of Machine-Learning Solutions and Key Aspects. Sensors 2020, 20, 109. [Google Scholar] [CrossRef]

- Çınar, Z.M.; Abdussalam Nuhu, A.; Zeeshan, Q.; Korhan, O.; Asmael, M.; Safaei, B. Machine Learning in Predictive Maintenance towards Sustainable Smart Manufacturing in Industry 4.0. Sustainability 2020, 12, 8211. [Google Scholar] [CrossRef]

- Candanedo, I.S.; Nieves, E.H.; González, S.R.; Martín, M.T.S.; Briones, A.G. Machine Learning Predictive Model for Industry 4.0; Springer: Berlin/Heidelberg, Germany, 2018; pp. 501–510. [Google Scholar]

- Psarommatis, F.; May, G.; Dreyfus, P.-A.; Kiritsis, D. Zero Defect Manufacturing: State-of-the-Art Review, Shortcomings and Future Directions in Research. Int. J. Prod. Res. 2020, 58, 1–17. [Google Scholar] [CrossRef]

- Huang, Z.; Angadi, V.C.; Danishvar, M.; Mousavi, A.; Li, M. Zero Defect Manufacturing of Microsemiconductors—An Application of Machine Learning and Artificial Intelligence. In Proceedings of the 2018 5th International Conference on Systems and Informatics (ICSAI), Nanjing, China, 10–18 November 2018; IEEE: New York, NY, USA, 2018; pp. 449–454. [Google Scholar]

- Lindström, J.; Kyösti, P.; Birk, W.; Lejon, E. An Initial Model for Zero Defect Manufacturing. Appl. Sci. 2020, 10, 4570. [Google Scholar] [CrossRef]

- Eger, F.; Coupek, D.; Caputo, D.; Colledani, M.; Penalva, M.; Ortiz, J.A.; Freiberger, H.; Kollegger, G. Zero Defect Manufacturing Strategies for Reduction of Scrap and Inspection Effort in Multi-Stage Production Systems. Procedia CIRP 2018, 67, 368–373. [Google Scholar] [CrossRef]

- Psarommatis, F.; Vuichard, M.; Kiritsis, D. Improved Heuristics Algorithms for Re-Scheduling Flexible Job Shops in the Era of Zero Defect Manufacturing. Procedia Manuf. 2020, 51, 1485–1490. [Google Scholar] [CrossRef]

- Saqlain, M.; Piao, M.; Shim, Y.; Lee, J.Y. Framework of an IoT-Based Industrial Data Management for Smart Manufacturing. J. Sens. Actuator Netw. 2019, 8, 25. [Google Scholar] [CrossRef]

- Islam, M.M.; AlGeddawy, T. The Industrial Internet of Things Models, Challenges and Opportunities in Sustainable Manufacturing. In Proceedings of the 39th International Annual Conference of the American Society for Engineering Management, ASEM 2018: Bridging the Gap Between Engineering and Business, Coeur D’Alene, ID, USA, 17–20 October 2018; American Society for Engineering Management: Huntsville, AL, USA, 2018; pp. 122–131. [Google Scholar]

- Belli, L.; Davoli, L.; Medioli, A.; Marchini, P.L.; Ferrari, G. Toward Industry 4.0 with IoT: Optimizing Business Processes in an Evolving Manufacturing Factory. Front. ICT 2019, 6, 17. [Google Scholar] [CrossRef]

- Wan, J.; Chen, B.; Imran, M.; Tao, F.; Li, D.; Liu, C.; Ahmad, S. Toward Dynamic Resources Management for IoT-Based Manufacturing. IEEE Commun. Mag. 2018, 56, 52–59. [Google Scholar] [CrossRef]

- Gerrikagoitia, J.K.; Unamuno, G.; Urkia, E.; Serna, A. Digital Manufacturing Platforms in the Industry 4.0 from Private and Public Perspectives. Appl. Sci. 2019, 9, 2934. [Google Scholar] [CrossRef]

- Xu, L.D.; Xu, E.L.; Li, L. Industry 4.0: State of the Art and Future Trends. Int. J. Prod. Res. 2018, 56, 2941–2962. [Google Scholar] [CrossRef]

- Beier, G.; Ullrich, A.; Niehoff, S.; Reißig, M.; Habich, M. Industry 4.0: How It Is Defined from a Sociotechnical Perspective and How Much Sustainability It Includes—A Literature Review. J. Clean. Prod. 2020, 259. [Google Scholar] [CrossRef]

- Singh, R.; Bhanot, N. An Integrated DEMATEL-MMDE-ISM Based Approach for Analysing the Barriers of IoT Implementation in the Manufacturing Industry. Int. J. Prod. Res. 2020, 58, 2454–2476. [Google Scholar] [CrossRef]

- Xu, X. From Cloud Computing to Cloud Manufacturing. Robot. Comput. Integr. Manuf. 2012, 28, 75–86. [Google Scholar] [CrossRef]

- Caggiano, A. Cloud-Based Manufacturing Process Monitoring for Smart Diagnosis Services. Int. J. Comput. Integr. Manuf. 2018, 31, 612–623. [Google Scholar] [CrossRef]

- Li, B.-H.; Zhang, L.; Ren, L.; Chai, X.-D.; Tao, F.; Wang, Y.-Z.; Yin, C.; Huang, P.; Zhao, X.-P.; Zhou, Z.-D. Typical Characteristics, Technologies and Applications of Cloud Manufacturing. Comput. Integr. Manuf. Syst. 2012, 18, 1345–1356. [Google Scholar]

- Adamson, G.; Wang, L.; Holm, M.; Moore, P. Cloud Manufacturing–a Critical Review of Recent Development and Future Trends. Int. J. Comput. Integr. Manuf. 2017, 30, 347–380. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, L.; Wang, X.V.; Xu, X.; Zhang, L. Scheduling in Cloud Manufacturing: State-of-the-Art and Research Challenges. Int. J. Prod. Res. 2019, 57, 4854–4879. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, L.; Venkatesh, V.; Luo, Y.; Cheng, Y. Cloud Manufacturing: A Computing and Service-Oriented Manufacturing Model. Proc. Inst. Mech. Eng. Part. B J. Eng. Manuf. 2011, 225, 1969–1976. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, L.; Wang, X.V.; Xu, X.; Jiang, P. Cloud Manufacturing: Key Issues and Future Perspectives. Int. J. Comput. Integr. Manuf. 2019, 32, 858–874. [Google Scholar] [CrossRef]

- Wu, D.; Greer, M.J.; Rosen, D.W.; Schaefer, D. Cloud Manufacturing: Strategic Vision and State-of-the-Art. J. Manuf. Syst. 2013, 32, 564–579. [Google Scholar] [CrossRef]

- Coronado, P.D.U.; Lynn, R.; Louhichi, W.; Parto, M.; Wescoat, E.; Kurfess, T. Part Data Integration in the Shop Floor Digital Twin: Mobile and Cloud Technologies to Enable a Manufacturing Execution System. J. Manuf. Syst. 2018, 48, 25–33. [Google Scholar] [CrossRef]

- Varela, M.L.; Putnik, G.D.; Manupati, V.K.; Rajyalakshmi, G.; Trojanowska, J.; Machado, J. Collaborative Manufacturing Based on Cloud, and on Other I4. 0 Oriented Principles and Technologies: A Systematic Literature Review and Reflections. Manag. Prod. Eng. Rev. 2018, 9, 90–99. [Google Scholar]

- Lu, Y.; Xu, X. Cloud-Based Manufacturing Equipment and Big Data Analytics to Enable on-Demand Manufacturing Services. Robot. Comput. Integr. Manuf. 2019, 57, 92–102. [Google Scholar] [CrossRef]

- Mubarok, K.; Xu, X.; Ye, X.; Zhong, R.Y.; Lu, Y. Manufacturing Service Reliability Assessment in Cloud Manufacturing. Procedia CIRP 2018, 72, 940–946. [Google Scholar] [CrossRef]

- Fisher, O.; Watson, N.; Porcu, L.; Bacon, D.; Rigley, M.; Gomes, R.L. Cloud Manufacturing as a Sustainable Process Manufacturing Route. J. Manuf. Syst. 2018, 47, 53–68. [Google Scholar] [CrossRef]

- Bottani, E.; Vignali, G. Augmented Reality Technology in the Manufacturing Industry: A Review of the Last Decade. IISE Trans. 2019, 51, 284–310. [Google Scholar] [CrossRef]

- Damiani, L.; Revetria, R.; Morra, E. Safety in Industry 4.0: The Multi-Purpose Applications of Augmented Reality in Digital Factories. Adv. Sci. Technol. Eng. Syst. 2020, 5, 248–253. [Google Scholar] [CrossRef]

- Lai, Z.-H.; Tao, W.; Leu, M.C.; Yin, Z. Smart Augmented Reality Instructional System for Mechanical Assembly towards Worker-Centered Intelligent Manufacturing. J. Manuf. Syst. 2020, 55, 69–81. [Google Scholar] [CrossRef]

- Nabati, E.; Nieto, M.A.; Decker, A.; Thoben, K.-D. Application of Virtual Reality Technologies for Achieving Energy Efficient Manufacturing: Literature Analysis and Findings; Springer: Berlin/Heidelberg, Germany, 2020; pp. 479–486. [Google Scholar]

- Shiba, Y.; Imai, S. Development of Engineering Educational Support System for Manufacturing Using Augmented Reality; IEEE: New York, NY, USA, 2020; pp. 198–202. [Google Scholar]

- Lee, H. Real-Time Manufacturing Modeling and Simulation Framework Using Augmented Reality and Stochastic Network Analysis. Virtual Real. 2019, 23, 85–99. [Google Scholar] [CrossRef]

- Rumsey, A.; Le Dantec, C.A. Manufacturing Change: The Impact of Virtual Environments on Real Organizations. In Proceedings of the CHI ’20: CHI Conference on Human Factors in Computing Systems, Honolulu, HI, USA, 25–30 April 2020; pp. 1–12. [Google Scholar]

- Mittal, S.; Khan, M.A.; Romero, D.; Wuest, T. Smart Manufacturing: Characteristics, Technologies and Enabling Factors. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2019, 233, 1342–1361. [Google Scholar] [CrossRef]

- Malik, A.A.; Masood, T.; Bilberg, A. Virtual Reality in Manufacturing: Immersive and Collaborative Artificial-Reality in Design of Human-Robot Workspace. Int. J. Comput. Integr. Manuf. 2020, 33, 22–37. [Google Scholar] [CrossRef]

- Mandic, V. Model-Based Manufacturing System Supported by Virtual Technologies in an Industry 4.0 Context; Springer: Berlin/Heidelberg, Germany, 2020; pp. 215–226. [Google Scholar]

- Leng, J.; Ruan, G.; Jiang, P.; Xu, K.; Liu, Q.; Zhou, X.; Liu, C. Blockchain-Empowered Sustainable Manufacturing and Product Lifecycle Management in Industry 4.0: A Survey. Renew. Sustain. Energy Rev. 2020, 132. [Google Scholar] [CrossRef]

- Li, Z.; Barenji, A.V.; Huang, G.Q. Toward a Blockchain Cloud Manufacturing System as a Peer to Peer Distributed Network Platform. Robot. Comput. Integr. Manuf. 2018, 54, 133–144. [Google Scholar] [CrossRef]

- Westerkamp, M.; Victor, F.; Küpper, A. Tracing Manufacturing Processes Using Blockchain-Based Token Compositions. Digit. Commun. Netw. 2020, 6, 167–176. [Google Scholar] [CrossRef]

- Lohmer, J.; Lasch, R. Blockchain in Operations Management and Manufacturing: Potential and Barriers. Comput. Ind. Eng. 2020, 149, 106789. [Google Scholar] [CrossRef]

- Ko, T.; Lee, J.; Ryu, D. Blockchain Technology and Manufacturing Industry: Real-Time Transparency and Cost Savings. Sustainability 2018, 10, 4274. [Google Scholar] [CrossRef]

- Yu, C.; Zhang, L.; Zhao, W.; Zhang, S. A Blockchain-Based Service Composition Architecture in Cloud Manufacturing. Int. J. Comput. Integr. Manuf. 2020, 33, 701–715. [Google Scholar] [CrossRef]

- Aghamohammadzadeh, E.; Fatahi Valilai, O. A Novel Cloud Manufacturing Service Composition Platform Enabled by Blockchain Technology. Int. J. Prod. Res. 2020, 58, 5280–5298. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, X.; Liu, A.; Lu, Q.; Xu, L.; Tao, F. Blockchain-Based Trust Mechanism for IoT-Based Smart Manufacturing System. IEEE Trans. Comput. Soc. Syst. 2019, 6, 1386–1394. [Google Scholar] [CrossRef]

- Yu, C.; Jiang, X.; Yu, S.; Yang, C. Blockchain-Based Shared Manufacturing in Support of Cyber Physical Systems: Concept, Framework, and Operation. Robot. Comput. Integr. Manuf. 2020, 64, 101931. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, Y.; Cheng, Y.; Ren, J.; Wang, D.; Qi, Q.; Li, P. Digital Twin and Blockchain Enhanced Smart Manufacturing Service Collaboration and Management. J. Manuf. Syst. 2020. [Google Scholar] [CrossRef]

- Barenji, A.V.; Li, Z.; Wang, W.M. Blockchain Cloud Manufacturing: Shop Floor and Machine Level. In Proceedings of the Smart SysTech 2018; European Conference on Smart Objects, Systems and Technologies, Dresden, Germany, 12–13 June 2018; VDE: Berlin, Germany, 2018; pp. 1–6. [Google Scholar]

- Ouyang, L.; Yuan, Y.; Wang, F.-Y. A Blockchain-Based Framework for Collaborative Production in Distributed and Social Manufacturing. In Proceedings of the IEEE International Conference on Service Operations and Logistics, and Informatics, SOLI, Zhengzhou, China, 11–13 October 2019; IEEE: New York, NY, USA, 2019; pp. 76–81. [Google Scholar]

- Touzout, F.A.; Benyoucef, L. Multi-Objective Sustainable Process Plan Generation in a Reconfigurable Manufacturing Environment: Exact and Adapted Evolutionary Approaches. Int. J. Prod. Res. 2019, 57, 2531–2547. [Google Scholar] [CrossRef]

- Khezri, A.; Benderbal, H.H.; Benyoucef, L. A Sustainable Reconfigurable Manufacturing System Designing with Focus on Environmental Hazardous Wastes. In Proceedings of the IEEE International Conference on Emerging Technologies and Factory Automation, ETFA, Zaragoza, Spain, 10–13 September 2019; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2019; Volume 2019-Septe, pp. 317–324. [Google Scholar]

- Alcácer, V.; Cruz-Machado, V. Scanning the Industry 4.0: A Literature Review on Technologies for Manufacturing Systems. Eng. Sci. Technol. Int. J. 2019, 22, 899–919. [Google Scholar] [CrossRef]

- Vaidya, S.; Ambad, P.; Bhosle, S. Industry 4.0—A Glimpse. Procedia Manuf. 2018, 20, 233–238. [Google Scholar] [CrossRef]

- Long, F.; Zeiler, P.; Bertsche, B. Modelling the Flexibility of Production Systems in Industry 4.0 for Analysing Their Productivity and Availability with High-Level Petri Nets. IFAC Pap. 2017, 50, 5680–5687. [Google Scholar] [CrossRef]

- Suzić, N.; Forza, C.; Trentin, A.; Anišić, Z. Implementation Guidelines for Mass Customization: Current Characteristics and Suggestions for Improvement. Prod. Plan. Control 2018, 29, 856–871. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, H.-S.; Yang, J.-H.; Wang, K.-S. Industry 4.0: A Way from Mass Customization to Mass Personalization Production. Adv. Manuf. 2017, 5, 311–320. [Google Scholar] [CrossRef]

- Khalil, T.; Olivia, P.; Thierno, M.D.; Romdhane, B.K.; Noureddine, B.Y.; Jean-Yves, C. Model Based Systems Engineering Approach for the Improvement of Manufacturing System Flexibility. In Proceedings of the International Workshop on Research and Education in Mechatronics (REM), Cracow, Poland, 10 December 2020; IEEE: New York, NY, USA, 2020; pp. 1–6. [Google Scholar]

- Florescu, A.; Barabas, S.A. Modeling and Simulation of a Flexible Manufacturing System—A Basic Component of Industry 4.0. Appl. Sci. 2020, 10, 8300. [Google Scholar] [CrossRef]

- Luscinski, S.; Ivanov, V. A Simulation Study of Industry 4.0 Factories Based on the Ontology on Flexibility with Using FlexSimr Software. Manag. Prod. Eng. Rev. 2020, 11, 74–83. [Google Scholar]

- Sang, G.M.; Xu, L.; de Vrieze, P.; Bai, Y. Towards Predictive Maintenance for Flexible Manufacturing Using FIWARE; Springer: Berlin/Heidelberg, Germany, 2020; pp. 17–28. [Google Scholar]

- Goel, R.; Gupta, P. Robotics and industry 4.0. In A Roadmap to Industry 4.0: Smart Production, Sharp Business and Sustainable Development; Nayyar, A., Kumar, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2020; pp. 157–169. [Google Scholar]

- Krueger, V.; Rovida, F.; Grossmann, B.; Petrick, R.; Crosby, M.; Charzoule, A.; Martin Garcia, G.; Behnke, S.; Toscano, C.; Veiga, G. Testing the Vertical and Cyber-Physical Integration of Cognitive Robots in Manufacturing. Robot. Comput. Integr. Manuf. 2019, 57, 213–229. [Google Scholar] [CrossRef]

- Dhanabalan, T.; Sathish, A. Transforming Indian Industries through Artificial Intelligence and Robotics in Industry 4.0. Int. J. Mech. Eng. Technol. 2018, 9, 835–845. [Google Scholar]

- Bragança, S.; Costa, E.; Castellucci, I.; Arezes, P.M. A Brief Overview of the Use of Collaborative Robots in Industry 4.0: Human Role and Safety. In Occupational and Environmental Safety and Health; Arezes, P.M., Baptista, J.S., Barroso, M.P., Carneiro, P., Cordeiro, P., Costa, N., Melo, R.B., Miguel, A.S., Perestrelo, G., Eds.; Springer: Berlin/Heidelberg, Germany, 2019; pp. 641–650. [Google Scholar]

- Karabegović, I.; Karabegović, E.; Mahmić, M.; Husak, E. Implementation of Industry 4.0 and Industrial Robots in the Manufacturing Processes; Springer: Berlin/Heidelberg, Germany, 2019; pp. 3–14. [Google Scholar]

- Fragapane, G.; Ivanov, D.; Peron, M.; Sgarbossa, F.; Strandhagen, J.O. Increasing Flexibility and Productivity in Industry 4.0 Production Networks with Autonomous Mobile Robots and Smart Intralogistics. Ann. Oper. Res. 2020, 1–19. [Google Scholar] [CrossRef]

- Karabegović, I. The Role of Industrial and Service Robots in the 4th Industrial Revolution—“Industry 4.0”. Acta Tech. Corviniensis Bull. Eng. 2018, 11, 11–16. [Google Scholar]

- Wan, J.; Tang, S.; Hua, Q.; Li, D.; Liu, C.; Lloret, J. Context-Aware Cloud Robotics for Material Handling in Cognitive Industrial Internet of Things. IEEE Internet Things J. 2017, 5, 2272–2281. [Google Scholar] [CrossRef]

- Culot, G.; Fattori, F.; Podrecca, M.; Sartor, M. Addressing Industry 4.0 Cybersecurity Challenges. IEEE Eng. Manag. Rev. 2019, 47, 79–86. [Google Scholar] [CrossRef]

- Ervural, B.C.; Ervural, B. Overview of cyber security in the industry 4.0 era. In Industry 4.0: Managing the Digital Transformation; Ustundag, A., Cevikcan, E., Eds.; Springer: Berlin/Heidelberg, Germany, 2018; pp. 267–284. [Google Scholar]

- Rubio, J.E.; Roman, R.; Lopez, J. Analysis of Cybersecurity Threats in Industry 4.0: The Case of Intrusion Detection; Springer: Berlin/Heidelberg, Germany, 2017; pp. 119–130. [Google Scholar]

- Elmamy, S.B.; Mrabet, H.; Gharbi, H.; Jemai, A.; Trentesaux, D. A Survey on the Usage of Blockchain Technology for Cyber-Threats in the Context of Industry 4.0. Sustainability 2020, 12, 9179. [Google Scholar] [CrossRef]

- Lezzi, M.; Lazoi, M.; Corallo, A. Cybersecurity for Industry 4.0 in the Current Literature: A Reference Framework. Comput. Ind. 2018, 103, 97–110. [Google Scholar] [CrossRef]

- Ghobakhloo, M. The Future of Manufacturing Industry: A Strategic Roadmap toward Industry 4.0. J. Manuf. Technol. Manag. 2018. [Google Scholar] [CrossRef]

- Wegner, A.; Graham, J.; Ribble, E. A new approach to cyberphysical security in industry 4.0. In Cybersecurity for Industry 4.0; Thames, L., Schaefer, D., Eds.; Springer: Berlin/Heidelberg, Germany, 2017; pp. 59–72. [Google Scholar]

- Jamwal, A.; Agrawal, R.; Sharma, M.; Kumar, V. Review on Multi-Criteria Decision Analysis in Sustainable Manufacturing Decision Making. Int. J. Sustain. Eng. 2021. [Google Scholar] [CrossRef]

- Vinuesa, R.; Azizpour, H.; Leite, I.; Balaam, M.; Dignum, V.; Domisch, S.; Felländer, A.; Langhans, S.D.; Tegmark, M.; Nerini, F.F. The Role of Artificial Intelligence in Achieving the Sustainable Development Goals. Nat. Commun. 2020, 11, 1–10. [Google Scholar] [CrossRef]

- Ghobakhloo, M. Industry 4.0, Digitization, and Opportunities for Sustainability. J. Clean. Prod. 2020, 252. [Google Scholar] [CrossRef]

- Braccini, A.M.; Margherita, E.G. Exploring Organizational Sustainability of Industry 4.0 under the Triple Bottom Line: The Case of a Manufacturing Company. Sustainability 2018, 11, 36. [Google Scholar] [CrossRef]

- Brozzi, R.; Forti, D.; Rauch, E.; Matt, D.T. The Advantages of Industry 4.0 Applications for Sustainability: Results from a Sample of Manufacturing Companies. Sustainability 2020, 12, 3647. [Google Scholar] [CrossRef]

- Müller, J.M.; Voigt, K.-I. Sustainable Industrial Value Creation in SMEs: A Comparison between Industry 4.0 and Made in China 2025. Int. J. Precis. Eng. Manuf. Green Technol. 2018, 5, 659–670. [Google Scholar] [CrossRef]

- Luthra, S.; Kumar, A.; Zavadskas, E.K.; Mangla, S.K.; Garza-Reyes, J.A. Industry 4.0 as an Enabler of Sustainability Diffusion in Supply Chain: An Analysis of Influential Strength of Drivers in an Emerging Economy. Int. J. Prod. Res. 2020, 58, 1505–1521. [Google Scholar] [CrossRef]

- Vrchota, J.; Pech, M.; Rolínek, L.; Bednář, J. Sustainability Outcomes of Green Processes in Relation to Industry 4.0 in Manufacturing: Systematic Review. Sustainability 2020, 12, 5968. [Google Scholar] [CrossRef]

- Tayal, A.; Solanki, A.; Singh, S.P. Integrated Frame Work for Identifying Sustainable Manufacturing Layouts Based on Big Data, Machine Learning, Meta-Heuristic and Data Envelopment Analysis. Sustain. Cities Soc. 2020, 62. [Google Scholar] [CrossRef]

- Waibel, M.W.; Oosthuizen, G.A.; Du Toit, D.W. Investigating Current Smart Production Innovations in the Machine Building Industry on Sustainability Aspects. In Procedia Manufacturing, Proceedings of the 15th Global Conference on Sustainable Manufacturing, Haifa, Israel, 25–27 September 2018; Shpitalni, M., Kagermann, H., Seliger, G., Wertheim, R., Fischer, A., Eds.; Elsevier B.V.: Amsterdam, The Netherlands, 2018; Volume 21, pp. 774–781. [Google Scholar]

- Ghobakhloo, M.; Fathi, M. Corporate Survival in Industry 4.0 Era: The Enabling Role of Lean-Digitized Manufacturing. J. Manuf. Technol. Manag. 2020, 31, 1–30. [Google Scholar] [CrossRef]

- Bhanot, N.; Rao, P.V.; Deshmukh, S.G. Enablers and Barriers of Sustainable Manufacturing: Results from a Survey of Researchers and Industry Professionals. In Procedia CIRP, Proceedings of the 22nd CIRP Conference on Life Cycle Engineering, Sydney, Australia, 7–9 April 2015; Kara, S., Ed.; Elsevier B.V.: Amsterdam, The Netherlands, 2015; Volume 29, pp. 562–567. [Google Scholar]

- Manupati, V.K.; Schoenherr, T.; Ramkumar, M.; Wagner, S.M.; Pabba, S.K.; Inder Raj Singh, R. A Blockchain-Based Approach for a Multi-Echelon Sustainable Supply Chain. Int. J. Prod. Res. 2020, 58, 2222–2241. [Google Scholar] [CrossRef]

- Afshari, H.; Searcy, C.; Jaber, M.Y. The Role of Eco-Innovation Drivers in Promoting Additive Manufacturing in Supply Chains. Int. J. Prod. Econ. 2020, 223. [Google Scholar] [CrossRef]

- Bag, S.; Telukdarie, A.; Pretorius, J.H.C.; Gupta, S. Industry 4.0 and Supply Chain Sustainability: Framework and Future Research Directions. Benchmarking 2018. [Google Scholar] [CrossRef]

- Belaud, J.-P.; Prioux, N.; Vialle, C.; Sablayrolles, C. Big Data for Agri-Food 4.0: Application to Sustainability Management for by-Products Supply Chain. Comput. Ind. 2019, 111, 41–50. [Google Scholar] [CrossRef]

- Laney, D. 3D Data Management: Controlling Data Volume, Velocity and Variety. META Group Res. Note 2001, 6, 1. [Google Scholar]

- Ren, S.; Zhang, Y.; Liu, Y.; Sakao, T.; Huisingh, D.; Almeida, C.M.V.B. A Comprehensive Review of Big Data Analytics throughout Product Lifecycle to Support Sustainable Smart Manufacturing: A Framework, Challenges and Future Research Directions. J. Clean. Prod. 2019, 210, 1343–1365. [Google Scholar] [CrossRef]

- Kumar, A.; Shankar, R.; Thakur, L.S. A Big Data Driven Sustainable Manufacturing Framework for Condition-Based Maintenance Prediction. J. Comput. Sci. 2018, 27, 428–439. [Google Scholar] [CrossRef]

- Collins, K. Cyber-Physical Production Networks, Real-Time Big Data Analytics, and Cognitive Automation in Sustainable Smart Manufacturing. J. Self-Gov. Manag. Econ. 2020, 8, 21–27. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Wamba, S.F.; Papadopoulos, T. The Impact of Big Data on World-Class Sustainable Manufacturing. Int. J. Adv. Manuf. Technol. 2016, 84, 631–645. [Google Scholar] [CrossRef]

- Hack-Polay, D.; Rahman, M.; Billah, M.M.; Al-Sabbahy, H.Z. Big Data Analytics and Sustainable Textile Manufacturing: Decision-Making about the Applications of Biotechnologies in Developing Countries. Manag. Decis. 2020. [Google Scholar] [CrossRef]

- Plumpton, D. Cyber-Physical Systems, Internet of Things, and Big Data in Industry 4.0: Digital Manufacturing Technologies, Business Process Optimization, and Sustainable Organizational Performance. Econ. Manag. Financ. Mark. 2019, 14, 23–29. [Google Scholar] [CrossRef]

- Ali, S.S.; Kaur, R.; Persis, D.J.; Saha, R.; Pattusamy, M.; Sreedharan, V.R. Developing a Hybrid Evaluation Approach for the Low Carbon Performance on Sustainable Manufacturing Environment. Ann. Oper. Res. 2020. [Google Scholar] [CrossRef]

- Hayhoe, T.; Podhorska, I.; Siekelova, A.; Stehel, V. Sustainable Manufacturing in Industry 4.0: Cross-Sector Networks of Multiple Supply Chains, Cyber-Physical Production Systems, and Ai-Driven Decision-Making. J. Self-Gov. Manag. Econ. 2019, 7, 31–36. [Google Scholar] [CrossRef]

- Jung, H.; Jeon, J.; Choi, D.; Park, J.-Y. Application of Machine Learning Techniques in Injection Molding Quality Prediction: Implications on Sustainable Manufacturing Industry. Sustainability 2021, 13, 4120. [Google Scholar] [CrossRef]

- Schorr, S.; Möller, M.; Heib, J.; Fang, S.; Bähre, D. Quality Prediction of Reamed Bores Based on Process Data and Machine Learning Algorithm: A Contribution to a More Sustainable Manufacturing. In Procedia Manufacturing, Proceedings of the 17th Global Conference on Sustainable Manufacturing, Shanghai, China, 9–11 October 2020; Seliger, G., Kagermann, H., Ganiyusufoglu, O.S., Zhang, W., Eds.; Elsevier B.V.: Amsterdam, The Netherlands, 2020; Volume 43, pp. 519–526. [Google Scholar]

| Author | Contribution | Total Global Citations |

|---|---|---|

| [3] | Highlighted opportunities for SM in Industry 4.0 | 1305 |

| [10] | Developed a sustainability framework for Industry 4.0 | 387 |

| [30] | Empirical investigation on German manufacturing industries in five sectors | 348 |

| [31] | Empirical investigation on 46 German manufacturing industries | 348 |

| [9] | Identified critical success factors for SM practices in Industry 4.0 | 304 |

| [32] | Challenges for Sustainable supply chain for manufacturing sustainability in Industry 4.0 | 278 |

| [33] | Opportunities for IoT in sustainable supply chain for manufacturing sustainability | 225 |

| Sustainability Dimension in I4.0 | Main Influence from I4.0 | References |

|---|---|---|

| Economic | Sustainable value creation, efficiency and profits | [3,8,10,11,37] |

| Reduction in operational costs | [4,8] | |

| Impact on market share, supply chain, security | [9,46,47,146] | |

| New business model opportunities, turnover | [3,4,8,48] |

| Sustainability Dimension in I4.0 | Main Influence from I4.0 | References |

|---|---|---|

| Social | Employment | [48] |

| Better collaboration among stakeholders | [4,8] | |

| Reduction in accidents | [37,128] | |

| Improved living conditions for societies | [9,10,48] | |

| Improved working conditions | [3,9] |

| Sustainability Dimension in I4.0 | Main Influence from I4.0 | References |

|---|---|---|

| Environmental | Industrial waste reduction | [3,47,149] |

| Promote circular economy | [9,11] | |

| Use and production of renewable sources | [46,47,102] | |

| Reduction in use of non-renewable sources and energy consumption | [4,8,9] | |

| Reduction in global warming, resource consumption, energy consumption | [8,147] |

| Category | Research Issue | References |

|---|---|---|

| Supply chain strategies for Industry 4.0 | How digital transformation is forcing manufacturing industries to rethink their business models? What is the relationship between Industry 4.0 technologies and supply chain strategies? What is the effect of supply chain digitalization on network value? | [23,24,50] |

| Supply chain orientation in Industry 4.0 | Role and benefits of sustainable supply chain management (SSCM) in Industry 4.0? What are the benefits and drawbacks of technological infrastructure manufacturing industries required for SSCM practices? | [4,8,23,50] |

| Customer value creation | What are the effects of data driven SSCM practices in Industry 4.0? How Industry 4.0 technologies will help to implement SSCM in manufacturing industries? | [3,50,154] |

| Human centric issues in SSCM | What is role of human in digitalized supply chain network and practices? How machine learning and AI based approaches can help to achieve sustainability in SCM (supply chain management)? | [9,153,155] |

| Future Research Challenge | References |

|---|---|

| Architecture development for sustainable smart manufacturing (SSM) practices | [6,89] |

| Data acquisition issues for SSM | [24,50] |

| Data aggregation and integration issues | [49,54] |

| Algorithms and model development for BDA enabled SSM practices | [49,54,159] |

| Data quality management issues for SSM | [160,161] |

| Role of cloud-based technologies for SSM | [89] |

| Issues related to energy consumption and optimization | [162] |

| Future Research Challenge | References |

|---|---|

| Development of integrated SM layouts by machine learning approaches | [148] |

| What is impact of AI and machine learning approaches in Industry 4.0 from sustainability perspective | [39] |

| Prediction modelling and condition-based monitoring issues | [35,158] |

| AI and Machine learning based intelligent decision making | [163,164] |

| Quality prediction issues | [165,166] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jamwal, A.; Agrawal, R.; Sharma, M.; Giallanza, A. Industry 4.0 Technologies for Manufacturing Sustainability: A Systematic Review and Future Research Directions. Appl. Sci. 2021, 11, 5725. https://doi.org/10.3390/app11125725

Jamwal A, Agrawal R, Sharma M, Giallanza A. Industry 4.0 Technologies for Manufacturing Sustainability: A Systematic Review and Future Research Directions. Applied Sciences. 2021; 11(12):5725. https://doi.org/10.3390/app11125725

Chicago/Turabian StyleJamwal, Anbesh, Rajeev Agrawal, Monica Sharma, and Antonio Giallanza. 2021. "Industry 4.0 Technologies for Manufacturing Sustainability: A Systematic Review and Future Research Directions" Applied Sciences 11, no. 12: 5725. https://doi.org/10.3390/app11125725

APA StyleJamwal, A., Agrawal, R., Sharma, M., & Giallanza, A. (2021). Industry 4.0 Technologies for Manufacturing Sustainability: A Systematic Review and Future Research Directions. Applied Sciences, 11(12), 5725. https://doi.org/10.3390/app11125725