Abstract

The primary purpose of this article is to present a maturity model dealing with environmental manufacturing processes in a company. According to some authors, Industry 4.0 is based on characteristics that have already been the focus of “lean and green” concepts. The goal of the article was to move from resource consumption, pollutant emissions, and more extensive manufacturing towards environmentally responsible manufacturing (ERM). Using environmental materials and methods reduces energy consumption, which generates cost savings and higher profits. Here, value stream mapping (VSM) was applied to identify core processes with environmental potential. This paper provides an understanding of the role of environmental manufacturing in the era of the Fourth Industrial Revolution.

1. Introduction

Industrial revolutions were characterised by innovations in mechanics (the First Industrial Revolution), electronics (the Second Industrial Revolution), and information technologies (the Third Industrial Revolution) [1]. The Fourth Industrial Revolution combines several key technologies and enables the realisation of production in which individual machines and products communicate with each other. The concept is based on the German government’s high-tech strategy, which was presented at the Cebit 2013 trade fair in Hanover [2]. It is characterised by information technologies and intelligent cyber–physical systems (CPSs) leading to automation of production processes, gradually replacing the human workforce, and creating the need for establishing modern workplaces. Cameras, transmitters, sensors, code readers, and other higher generation technological devices will help to achieve this, taking over both repetitive, simple tasks and dangerous activities, as well as the intelligent decision-making processes that people currently carry out [3]. According to experts [4], this should lead to an increase in production productivity by up to one-third, compared to the current situation.

Industry 4.0 has arrived just in time for the most critical decade for climate action. The environmental economy concept is widely discussed in many circles due to its qualitative and quantitative aspects. The environmental economy is defined as an economy that aims at reducing environmental risks and ecological scarcities, as well as contributing to sustainable development without degrading the environment [5]. It is closely related to ecological economics, but for our purposes, the environmental aspect is presented in smart factory processes with a focus on environmental production.

The environmental aspect is critical here since it intends to reduce environmental impacts and risks and, at the same time, achieve organisational profit and market share objectives [6]. The environmental paradigm has its roots in environmental management [7]. Environmental supply chain management adopts environmentally friendly initiatives that can be deployed to decrease the environmental impact [8]. This can be through the reduction of waste such as energy, water, air emissions, solid and hazardous waste. According to [9], environmental initiatives should be considered in the initial phase of product design and raw material acquisition and continue throughout the various manufacturing stages, the delivery and distribution of the product to the customer, and the disposal of the end product. The scope of the environmental supply chain ranges from initiatives implemented through reduce, reuse and recycle, rework, return, remanufacturing, and reverse logistics [10].

According to [11], there are options for environmental production chain management, for example, reducing the quantity of material used by reducing the quantity of material needed to produce. Additionally, alternative materials are essential because by implementing them, we can use them to replace the original material with ones with less environmental impact. Recycling materials that make up the product and searching for alternative products which perform the same function is also a way of “going environmental”. Product recycling and reuse and eliminating excessive functions such as stopping production of unused or less used product features are other ways of implementing “environmental” standards into production. Digital technologies, as one of the Industry 4.0. pillars, can accelerate the reduction of global emissions by up to 15 per cent by 2030 while being responsible for only 1.4% of global emissions [12].

The objective of the article is to support the move from resource consumption, pollutant emissions, and more extensive manufacturing towards environmentally responsible manufacturing (ERM). The objective is intended to be fulfilled by the proposed Industry 4.0 maturity model dealing with the environmental attributes of a manufacturing company. The creation of the model and its application using a case study is the content of the next sections of the article.

2. Literature Review

Essential topics, such as environmental manufacturing, carbon footprint, costs aspects, industrial engineering methods, and maturity models assessing the readiness of companies for Industry 4.0 are included in the proposed maturity model, with environmental aspects evaluating the production and nonproduction processes. Therefore, these key areas are subject to a literature review in which also an overview and knowledge of each area play an important role.

2.1. Environmental Manufacturing and Carbon Footprint

Environmental manufacturing is primarily about changing business and manufacturing practices, as well as the mindset of stakeholders, to mitigate the industrial impact on climate change and other environmental concerns. The Fourth Industrial Revolution and industrial Internet of Things (IoT) present new opportunities to unlock process innovations to develop sustainable, environmentally friendly materials, decarbonise energy, i.e., use digital innovations to accomplish more with less, and extend goods life cycle within a “zero waste to landfill” framework [13]. Environmental manufacturing offers revolutionary advances in productivity and efficiency without the downsides of waste or pollution. Its proper implementation into the entire industry would thus accelerate the realisation of a low-carbon production [14]. One of the most effective ways to “calculate” the impact of environmental manufacturing is by determining the carbon footprint.

The carbon footprint is calculated by estimating the amount of carbon dioxide and other greenhouse gases (methane, nitrous oxide, and some fluorocarbons) produced during operation and by adding waste streams from manufacturing processes themselves [15]. Corporate carbon footprint (CCF) [16] can be calculated with three scopes: (1) direct emissions, (2) indirect emissions from electricity production and other services, and (3) indirect emissions upstream and/or downstream on the production chain. However, it is possible to calculate the carbon footprint of each part of the manufacturing process. Product carbon footprint (PCF) can be calculated for specific products over their lifecycle and specific applications, using paths to determine the effect products have on emissions and the environment [17].

2.2. Environmental Manufacturing and Industrial Engineering

Environmental manufacturing accents the environmental philosophy in manufacturing. Environmental manufacturing refers to production processes that pollute less and create less overall production waste. Within this definition, the scope ranges from changing processes to using fewer resources, e.g., finding ways to use less water in specific production techniques or producing a more durable product with replaceable parts, i.e., a product that fits into a circular economy [18].

Manufacturing, in general, (without special environmental regulations) concentrates on all relevant customer needs with legislative regulations taken into account and with a target to minimise production costs. Environmental manufacturing itself, even if it represents a positive approach for the environment, leads to higher costs of manufacturing [19].

For example, European Union (EU) states are trying to accent and support the environmental philosophy with manifestos, on the one hand [20], and with regulations and subsidies, on the other. The second factor can change the situation in costs of manufacturing in order to apply the environmental ones. It has a significant influence on the internal market, where instruments include, for example, a system of emission allowance (European Union) or electromobility subsidies. There are also ideas to apply individual taxes to suppliers from external markets who will not comply with environmental aspects [21].

Environmental issues play a role in industrial engineering. Industrial engineering concentrates on the optimisation of production and its accompanying processes with a target of cost reduction. This cost reduction is standardly the primary target, but targets can also differ depending on specific needs [22]. The main subject of this paper is environmental manufacturing, thus focusing on the variety of options that industrial engineering offers. The issue of increased costs is considered to be solved at the governmental level, in which all companies will have the same environmental supporting conditions mentioned above.

Industrial engineering is linked with the lean concept, using a variety of principles and methods (Just in Time, 5S, Kaizen, TPM, etc.). The purpose of the methods differs based on specific needs [23]. For the purpose of this paper, we first need to analyse the process to obtain the specific information needed to determine green status. To analyse the process, methods such as theory of constraints (TOC), force field analysis (FFA), value stream mapping (VSM), critical path method (CPM), Ishikawa diagram, failure mode, and effect analysis (FMEA) are used. Each one differs in the specific target of the method. VSM provides the relevant information about the production and logistics, with links to maintenance and IT. Other methods provide specific information that is mostly not relevant or not sufficient for the purpose of identifying the environmental status. This is the reason for choosing VSM as the source of information to identify the green status by the proposed maturity model [24].

3. Materials and Methods

The concept of Industry 4.0 is at the heart of many futuristic visions of business executives, economists, and politicians. We need even more information about the current state of preparation in industry and especially in engineering which is an important industry for the implementation of the concept of Industry 4.0. This section looks at maturity models, which are run as a tool for conceptualising and measuring the maturity of an organisation or process related to a specific target state. In principle, these are models that make it possible to identify the current state and prepare for the concept of Industry 4.0 comprehensively throughout a company or in various business areas, or to look for the potential to estimate the state of readiness for the future.

The capability maturity model (CMM) is a crucial concept from which individual maturity models can be selected. The capability maturity model integration (CMMI) model has been prepared [25]. CMMI is a model that aims to help an organisation plan, define, implement, develop, evaluate, and improve processes. It is not a methodology but determines the goals that an entrepreneur has and does not have as well as precise prescribed procedures [26].

CMMI models come in various modifications. However, they have the same internal organisational and evaluation principles, which define five levels of maturities. The model is proposed for companies naturally developing the quality of possible processes according to levels. The levels are from the lowest (first level) initial, through managed, defined, quantitatively managed levels, to the highest fifth level, which is optimisation [27].

The individual models of maturity for Industry 4.0 are primarily based on the same, albeit main principles, such as CMMI models; therefore, it is important to mention them. The analysed areas (dimensions) are always defined. For large models, dimensions are further extended to subdimensions. Additionally, the method of evaluation is important. The similarity of models in an extensive evaluation is given by a high degree of maturity in given areas (dimensions). There are four to six levels of readiness. They are arranged logically from lowest to highest. They have names and custom characteristics that relate to meeting the scale within the area (dimension). The maturity of a company is expressed in various samples quantitatively in the form of a maturity index.

3.1. Division of Maturity Models and Their Main Attributes

The primary division of models for evaluation is according to the level of scope. The models are at the macro level, where evaluations are performed concerning countries and show preconditions for the development and digitisation of the industry in the monitored country. The priority is to improve the country’s competitiveness by increasing its innovation capacity and digitisation [28]. We primarily focus on micro-level models that assess a company’s maturity. At the micro level, it is not necessary to compare a large number of companies and dozens of indicators [29]. This research focuses on micro-level models for which there are many modifications and methodologies. The aim is to analyse individual models and their main attributes.

The scientific method in the form of analysis and comparison was used to search for these models. They are academic, but they are also models from practical associations or consulting companies. Of course, the scope and quality of the models were different. In addition to the analysis, the method of abstraction was also performed, where the potential for evaluation of green (environmental) aspects in some of the dimensions was sought.

The models were analysed according to the following main attributes:

- Source name and origin—Models that were from foreign universities, engineering associations, and consulting companies, often combining academia and industry;

- Analysed dimensions—There were different numbers and characters of dimensions, ranging from a minimum of three dimensions to nine. Some models still used partial subdimensions;

- Evaluation method—Levels for evaluation were very similar for the models. Models with several levels, often from four to six levels, were used for final evaluation, and these levels were characterised;

- Potential for evaluation of environmental aspects—Searching for a dimension for the evaluation of green (environmental) aspects or perspectives in one of the dimensions;

- In addition to these critical attributes, of course, other attributes were analysed, such as model intent, which can be descriptive, comparative, or prescriptive.

The availability was also essential—the model may be publicly available with an online self-assessment questionnaire or in the form of a practical study or research article with guidance on how to carry out the evaluation. The models were also categorised into groups according to design. The main categories of model implementation are roadmaps, readiness models, maturity models, or a framework for assessment.

The difference between maturity and readiness models is that readiness models are used to assess readiness before involvement in the process and to check whether all necessary prerequisites and preparations for the use of technology have been met. Measuring technological maturity (readiness) is especially crucial for an organisation with respect to its process and proposed goals. Maturity models were used to describe and capture the state of processes, systems, corporate culture, and other attributes during the maturation process. Roadmaps were mainly used in technology planning and development. A specific area of technology was precisely represented, and information was provided on technical requirements or key numbers of technological performance [30].

3.2. Evaluation of Maturity Models

The evaluation of relevant maturity models focused on the area of Industry 4.0 maturity models that reflected the scope of the article. Overall, 35 models were found and analysed, and after selection in terms of quality and suitability, only 19 models were used. Some were very complex; some were more concise. Table 1 shows all the analysed models, including the key attributes surveyed. The models’ name and the appropriate source are listed. Furthermore, the type of resource is indicated as academic (Acad.), practical association (Pract. Assoc.), and consulting companies (Cons. Co.). For the analysed dimensions, the focus of the models played a role. Some models were designed for production areas, and some for logistics or possibly in the field of information security. The number of levels with the names of the lowest and highest level had a role in the rating method to evaluate needed attributes. Here, it is important to note that models used a similar number of levels (usually six levels) with similar names and characteristics.

Table 1.

The main attributes of maturity models.

3.3. Findings

The first part of this article deals with a thorough search of the available literature on the main topics—environmental manufacturing and carbon footprint, cost aspects and industrial engineering methods, and maturity models assessing the readiness of companies for Industry 4.0. Based on the review, the following summary of findings was established:

- By implementing environmental “factors” into production (processes), we can achieve sustainable development without degrading the environment;

- Materials recycling or substitution by alternative products (with the same function) is a way of green production;

- Using digital technologies can accelerate the reduction of global emissions;

- Carbon footprint is one of the most effective ways to calculate the impact of green manufacturing;

- Product carbon footprint is used to determine the effect products have on emissions and the environment;

- Environmental manufacturing, even if it represents a positive approach for the environment, leads to higher costs, leading to the need for governmental support;

- Maturity models assess a company’s readiness for Industry 4.0 in several dimensions, which they classify into several defined levels;

- Environmental aspects are not assessed in maturity models, and they do not occur in dimensions, subdimensions, or even in criteria.

Specifying the general objective mentioned at the end of the Introduction Section follows. The results from the state-of-the-art review clearly show [50] (which is also summarised in Table 1) that models for the maturity of companies for Industry 4.0 do not include environmental aspects of production, nor the interconnection of carbon footprint (as the main indicator of environmentally friendly production). Thus, it is essential to implement this into a maturity model. Since none of the existing models meet our criteria, a proposal for a new maturity model is presented here.

4. Theory—Proposal of a Maturity Model Evaluating Environmental Aspects

The proposed maturity model evaluating environmental aspects is mainly based on the opinion that models evaluating the readiness of companies for Industry 4.0 do not have an integrated assessment of environmental aspects in combination with Industry 4.0. This is the main result of a detailed literature search of a large number of maturity models, which have been analysed and compared, and the main reason why such a model is being newly developed. There are maturity models that assess environmental aspects across companies and use similar principles, but they are not in the context of Industry 4.0. These are, for example, models by [51,52,53]. Within the literature search, resources for Industry 4.0, main technologies, principles, etc. were also examined, which were also described in individual models. Theoretical background was an important aspect for the design of a new model and was therefore composed of maturity models and the concept of Industry 4.0.

Another suitable aspect influencing model design and form was the focus of the authors who specialise in the field of industrial engineering. In addition to the academic area, the industrial area was also important, where professional interviews took place within the framework of cooperation and workshops.

With regard to these aspects, a maturity model with environmental aspects was gradually developed and designed in the following three main phases working with the main parameters for determining the model structure:

- Determining main dimensions, levels, and indicators for evaluation;

- Application within VSM tool and evaluation;

- Final level evaluation in given dimensions.

4.1. Phase 1—Determining Main Dimensions, Levels, and Indicators for Evaluation

This phase contained the main steps, such as defining the main model dimensions, setting levels for evaluation, and setting the percentage of CO2 reduction indicator with a link to the related level. This phase basically determined the model scope and structure. Individual dimensions were at intersections with levels, and they were characterised. In addition, the main indicators of given dimensions were incorporated into dimensions for greater detail and coverage. Without these indicators, dimensions would be rather general, and the evaluation would not be detailed. Within the characteristics, our model also worked with principles of Industry 4.0 in relation to environmental aspects since carbon footprint decreases with increasing levels of assessment.

The main dimensions were the following:

- Production;

- Logistics;

- Maintenance;

- IT.

There were six levels for process evaluation in dimensions from the point of view of Industry 4.0 on the basis of analysis and synthesis. Thus, six levels of maturity were set for modelling the evaluation of all dimensions, including level 0, with the integration of the percentage of CO2 reduction indicator.

The levels with a brief description are as follows:

- Level 0: 0% carbon footprint reduction—No implementations in production processes;

- Level 1: −10% carbon footprint reduction—Very limited implementations in production processes;

- Level 2: −30% carbon footprint reduction—Partly implemented in production processes;

- Level 3: −60% carbon footprint reduction—Mostly implemented in production processes;

- Level 4: −80 carbon footprint reduction—Nearly completely implemented in production processes;

- Level 5: carbon neutral company—Totally implemented in production processes.

The set levels have an upward development, and from their short definition, it is clear what each level means. Levels are defined numerically as well as verbally and technologically. To this description of levels are added qualitative data in the form of CO2 indicators. No processes for reducing the CO2 indicator are defined for the lowest level 0; therefore, there is zero reduction, and the company does not work with any procedures and functions for reduction.

Other levels work with the gradual reduction of the CO2 indicator up to the highest fifth level. Their gradual difference was determined by estimation after consultation with environmental engineering experts and after test calculations so that the reduction is gradual and realistic in an industrial environment. However, for evaluation within the model, the levels were characterised in even more detail for each of the dimensions.

Production dimension’s environmental aspect indicators:

The level of automation (I 4.0 implementation, utilisation) indicator corresponds to the modern technologies used in production. It enables the production to be more effective with less waste (and fewer resources needed), which also leads to improving the environmental characteristics of production.

The energy sources–production equipment indicator is linked with energy sources used by the production equipment. The important factor is the level of the environmental status of the energy sources; this leads to the use of alternative energy sources.

Environmental aspects of a production system represent environmental aspects in production other than the energy sources and modern technologies, for example, adaptability of the site equipment in the production system or preference of local suppliers of production equipment.

Maintenance dimension’s environmental aspect indicators:

MRO processes are the main indicator when dealing with the environmental aspects of maintenance in a company. Implementation of CMMS systems, hand in hand with paperless systems and Industry 4.0 technologies, are the main catalysts of environmentally friendly maintenance here.

The second very important aspect is energy consumption and time efficiency. This can be mainly influenced through equipment design (reduction of maintenance steps), pollution prevention, and efforts to bring resource consumption to a minimal level. At higher levels, environmentally responsible manufacturing (ERM) and environmentally conscious manufacturing (ECM) are implemented.

Lubricants and cleaning agents are the third main indicator in our model—from not using any (or not caring for or maintaining machinery) at all to biodegradable lubricants, to the most modern synthetic lubricants derived from renewable resources. Tribology is also important here; energy-efficient bearings and lubricants can effectively reduce wear, as well as consumption, and extend lubrication frequencies.

Logistics dimension’s environmental aspect indicators:

Manipulation processes and the level of automation within internal logistics play a significant role. In internal logistics, where the material input point is a warehouse and the output is, for example, a production line, the goal is to transport goods, material, or in-progress work with minimal human intervention. Manipulation processes can be controlled by a person using transport technology, automated with the participation of a person in different areas of the company (warehouse, production), or it is possible to fully interconnect and integrate individual technologies, processes, and people into one unit. This achieves complete automation of intralogistics processes and a fully autonomous solution. Transport vehicles use different types of propulsion, while efforts towards environmental solutions include replacing diesel engines, hybrid propulsion, electric propulsion, and alternative propulsion that reduces CO2, NOx, and airborne particles and reduces the carbon footprint.

Packaging should be designed to allow efficient storage, followed by handling technology used by the company to make efficient use of storage and cargo space. Packaging, therefore, plays an important role and has important factors that influence the environmental aspects. Businesses strive for packaging with maximum service life, enabling long-lasting packaging cycles and high cyclicality and recyclability, which reduces their costs and are less harmful to the environment, unlike one-way or non-returnable packaging. The packaging is made from plant sources and can be composted at the end of its life cycle. Part of the ecological and labelled packaging is product synergy, to which robotic packaging adapts and creates an autonomous system.

Environmental aspects of a warehouse system apply to logistics and warehousing facilities where the intention is to build energy-efficient buildings, including environmental friendliness. Thus, the main goal is economic profit as well as environmental aspects. The indicator addresses energy intensity, intelligent lighting, water and waste management, use of environmentally friendly materials, energy-efficient building elements (double facade cladding, windows, doors), or a building’s internal environment quality (or in the best-case scenario, the synergy of all aspects). Warehouses corresponding to Industry 4.0 with regard to the environment have economic and ecological technologies, such as modern heating, cooling, and ventilation systems, increased thermal insulation, etc. The highest levels are represented by warehouses built of materials such as wood or special concrete without CO2.

IT dimension’s environmental aspect indicators:

Material and human resources reduction is achieved here by implementing IT. From basic (paper) reduction to more complex forms, in which complex systems are digitised and monitored by IT technicians through full automatisation of company processes and services (which are automatised or remotely driven). The highest level is represented by the complete integration of IT systems, production, logistics, and maintenance through a comprehensive exchange of data and information.

Energy consumption (efficient energy use) is very important when dealing with environmental manufacturing. The more environmentally friendly production processes there are, the more energy-measurement software is used. Energy consumption is also optimised, and later, process automation is implemented (RPA). The most advanced form of energy management is represented by the use of alternative energy sources. As a bonus, factories can support ecology by forest creation in empty areas of the plant.

The use and function of IT equipment in the company varies from simple HW and SW which are not interconnected and not used for data exchange to advanced IT equipment with partial IS implementation. More sophisticated systems represent the transfer of information across all company levels, wider use of cloud services, and data sharing. Process automation (RPA) also plays a role here. The most advanced use of IT systems is driven by artificial intelligence, which is used to support or control all company functions (“lights-out factories”).

4.2. Phase 2—Application within VSM Tool and Evaluation

The second phase focused on the use of a maturity model for the evaluation of processes in the main dimensions. The key issue of the whole model and its usability was the application of the model within the VSM tool.

VSM is a tool for identifying waste and shortcomings across business processes (production, logistics processes, etc.). VSM focuses on the efficiency of processes, evaluating them in terms of the ratio between their added and non-added value. VSM serves either as a descriptive tool, where it works with the total time sum of activities that add or do not add value, or as an improvement tool, where we propose a new procedure for implementing activities and eliminating shortcomings in any area and any process [54].

Within VSM, main production, logistics processes, and their main attributes were mapped. The information flow was linked to them and the IT area was therefore covered. Maintenance processes were captured as part of production processes mapping. A questionnaire and a structured interview with company employees were created for the mapping and the model. This is a very important part since evaluation results depend, to a large extent, on the quality of the implementation of connectivity with the VSM tool and the combining of the evaluators.

4.3. Phase 3—Final-Level Evaluation in Given Dimensions

The third phase is the final evaluation of levels in individual dimensions using a combination of the VSM tool and maturity model. The result of the VSM application is a map of the current state, as well as a capture of the key attributes and VA index. However, based on the model application, it is possible to determine further levels in individual dimensions and the characteristics of the main indicators of the dimension. The company will find the areas where the level of maturity should be improved and increased.

5. Case Study

In this part, a case study will be presented to illustrate the use of the application of the proposed maturity model evaluating the environmental aspects of a company. The case study mainly contains an analytical phase, which is divided into several main steps.

The analytical phase maps the current state of processes in the company, and the proposed maturity model is used in combination with the VSM tool.

Mapping the current situation in manufacturing and non-manufacturing sectors reveals possible losses, bottlenecks, shortcomings, and reasons for inefficient flows in workplace processes, in the production system, or warehouses. The next part of the analytical phase is the evaluation of the current state. The state of environmental aspects in individual dimensions will also be evaluated using the model. The result of the analytical phase is the input for the implementation phase, which deals with the design of corrective measures aimed at improving the situation in identified areas. Finally, the evaluation and outputs of the case study are performed.

It is important to mention that the proposed readiness model is mainly of a diagnostic nature and thus is only presented in principle in this case study. The main task is the analytical phase and evaluation of the current state of company maturity.

Aim of the case study:

Mapping the current state of processes in the company concerning green (environmental) aspects and finding potential in production, non-production, and logistics areas. Application of the newly designed maturity model is a crucial issue in combination with the VSM tool.

5.1. Analytical Phase—Mapping the Current State

The analysis of the current state was performed in a company that focuses on the development, design, manufacture, and installation of electromechanical components for the automotive industry. The company selected one product—an electronic aesthetic facet made of polycarbonate—because the company was interested in finding out the particular state of production and non-production processes. The main attributes of the company are listed in Table 2.

Table 2.

Main attributes of the company.

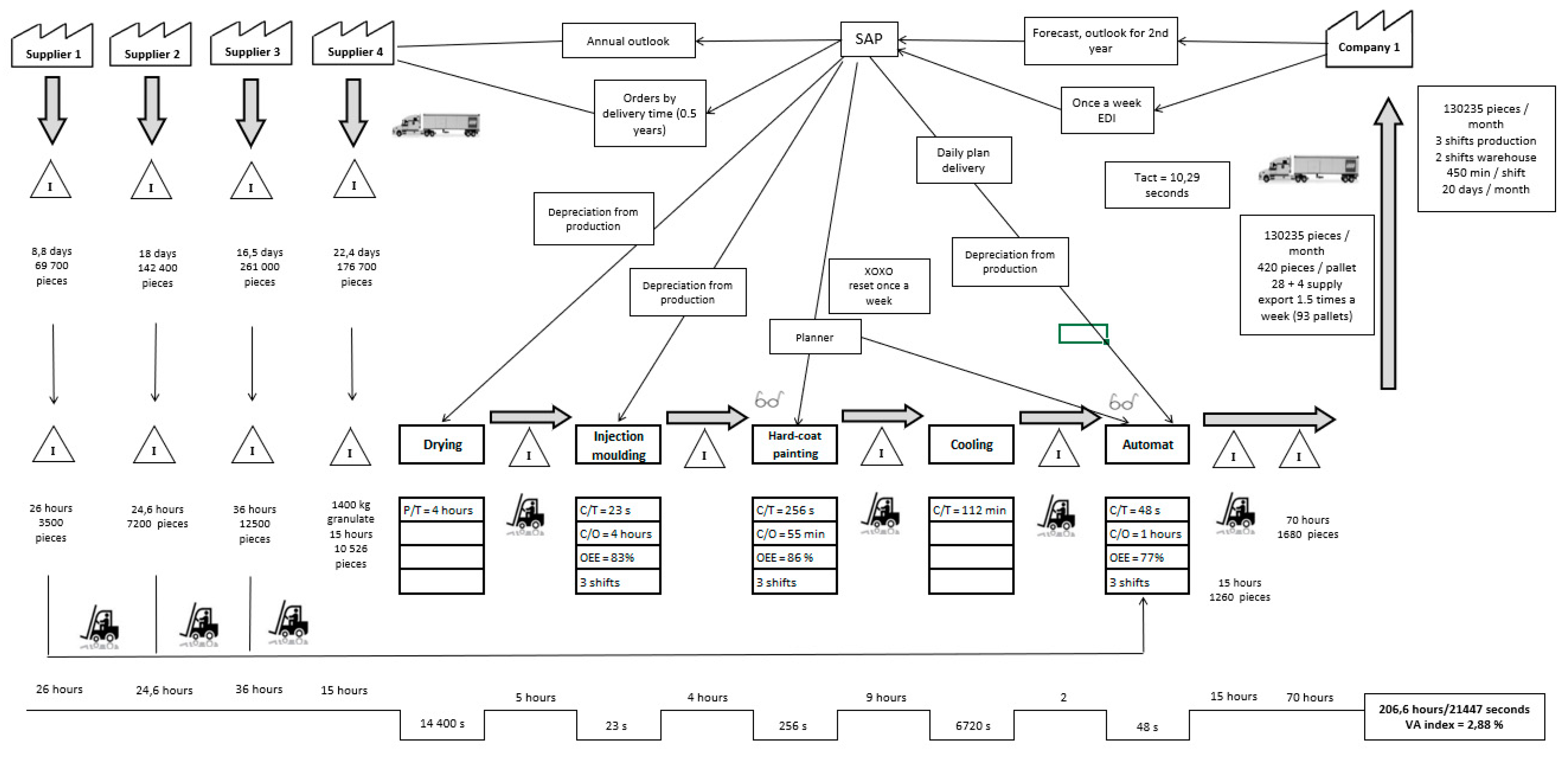

In this analytical phase, a value stream mapping (VSM) tool was applied. In the maturity model, we worked with four main dimensions—production, logistics, maintenance, and information technology. By using this tool, we were also able to obtain detailed information about environmental aspects with corresponding dimensions. The maturity model is incorporated into the mapping. The versatility of the VSM tool is therefore essential.

We used this tool to map production processes and gather information about them in detail. We identified machine attributes, the principle of production, machine controllability, production times, conversion times, tools and accessories, the number of manufactured pieces, availability, and workplace ergonomics.

VSM has a wide range of applications in the field of internal logistics processes, such as handling, packaging, supply, or storage. On this basis, we obtained information about material flows of a given product, which were later carried out throughout the company. The main parameters of material flows are the distances between workplaces, transport time, type of transport equipment, controllability of equipment, fleet equipment, handling units, types of packaging.

The use of VSM is marginal in maintenance management. However, it can be used to describe, for example, maintenance processes on monitored machines and this is the basis for describing (standardising) the required condition. This can be helped by reports on machine maintenance, set plans for check-ups, maintenance tools used, etc.

We also used the tool to evaluate information flow. Information flows in the manufacturing plant were recorded. These include manual information transfer, electronic information transfer, material recalls, weekly scheduling, etc.

Figure 1 shows a map of the current state according to the principles of VSM in the company. The production processes with the main measured parameters are shown graphically. The main processes include drying, injection moulding, hard-coat painting, cooling, and automat. Logistic processes were also recorded for manipulation between production processes with the main parameters, i.e., how long the material is stored in “intermediate warehouses” and in what quantity. The ratio of times adding the value to times not adding creates the resulting VA index.

Figure 1.

Map of the current state according to VSM.

During the mapping of the current state according to the VSM tool, structured interviews and a questionnaire were used to assess readiness according to the maturity model. The questions were designed so that the answers correspond to given levels. They always applied to each dimension and the relevant indicator, which are presented in Table 3.

Table 3.

Maturity model–environmental aspect indicators.

After obtaining the relevant information about the initial conditions and the levels of particular dimensions in the maturity model, the green aspects had to be determined. To determine the levels, the current situation of the plant had to be evaluated. To evaluate the situation of the plant, specific “environmental” aspect indicators relevant to the maturity model were used.

5.2. Analytical Phase—Evaluation

The results of individual dimensions were further characterised according to the maturity model. The following steps were completed during the previous part of the analytical phase: current state mapping, the questionnaire, and structured interviews with relevant plant employees (mainly specialists, different levels of management) of the departments related to the dimensions of the maturity model. Based on the results from the questionnaire and structured interviews, the individual dimensions of the maturity model were evaluated, and the current levels of the dimensions were determined. Examples of the questions in the questionnaire are given in Appendix A. Together with the VSM, the questionnaire was the basic tool for maturity model evaluation.

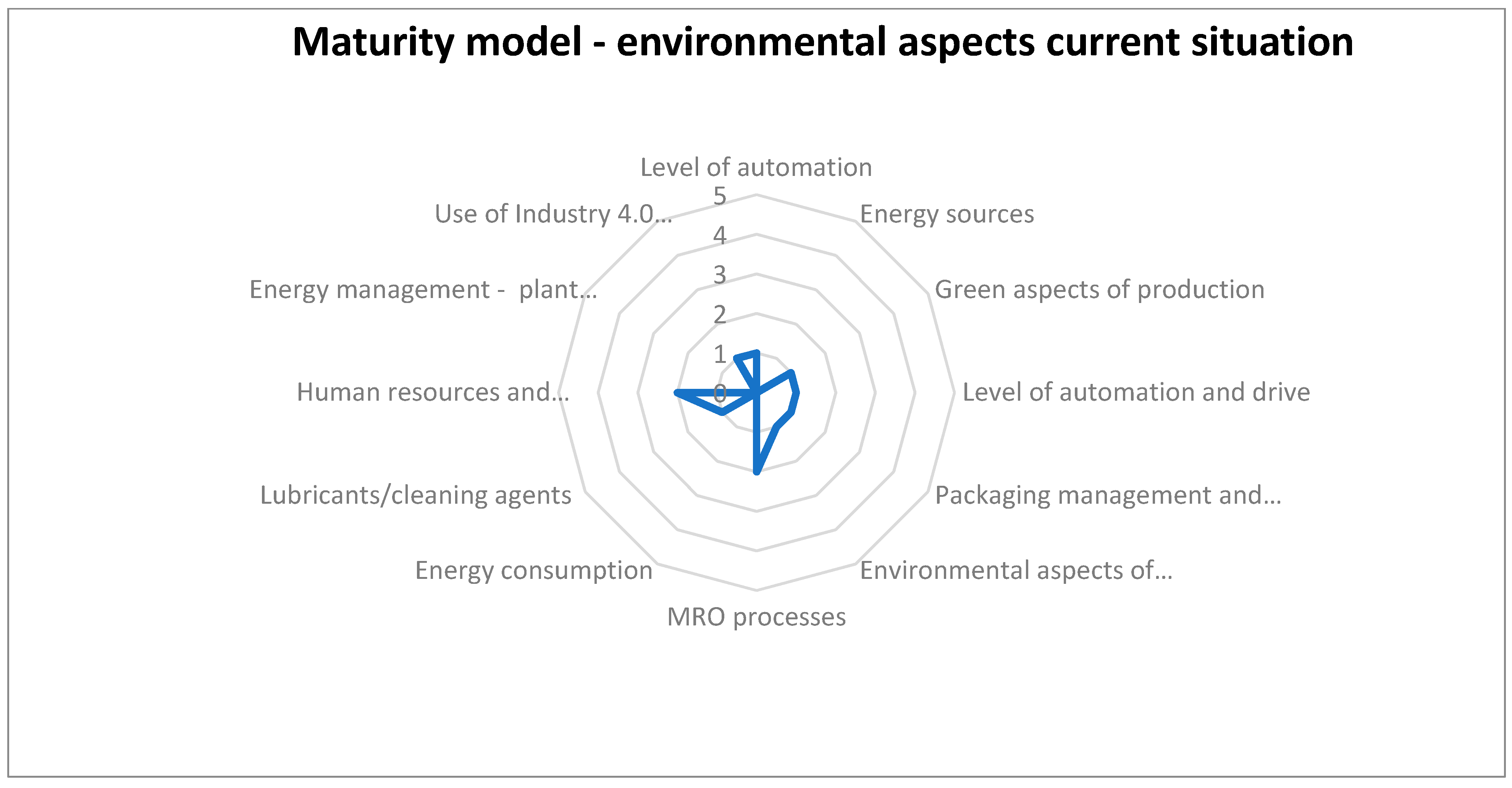

The current situation of the “environmental” aspects in the production company is shown in the maturity model classification in Table 4 below (spider diagram).

Table 4.

Evaluation and classification of dimensions into levels.

The table consists of four main dimensions in the manufacturing company—production, logistics, maintenance, and IT. Each area has three main indicators described in Table 5, Table 6, Table 7 and Table 8. Based on the questionnaires, we determined levels for each indicator resulting in the final spider diagram below. The environmental aspects current situation is represented on Figure 2.

Table 5.

Production dimension.

Table 6.

Maintenance dimension.

Table 7.

Logistics dimension.

Table 8.

IT dimension.

Figure 2.

Maturity model–environmental aspects current situation.

6. Results

The overall level of each selected dimension depends on the evaluation of the specific indicators defined in Table 2. The evaluation was based on the questionnaire (see example questions in Table 5, Table 6, Table 7 and Table 8). There were conducted structured interviews with a team of experts. A total of four meetings were planned, with each dimension (Section 6.1, Section 6.2, Section 6.3 and Section 6.4) inspected. For each dimension, three indicators were set.

6.1. Production Dimension

- The level of automation (Industry 4.0 implementation, utilisation) is the main environmental indicator when dealing with production. Many technologies offer the potential to reduce emissions. Implementing can reduce the need for factory floor space. Using (collaborative) robots in the factory raises the level of efficiency, in addition to reducing the number of human workers and costs for heating and lighting (transition to “lights-out factories”), which is considered as the highest form of an autonomous manufacturing company.

- The energy sources–production equipment indicator is, in this case, related to the previous one. Adjusting energy loads on machines can reduce energy use hand in hand with reducing carbon footprint. Another form of energy reduction is lowering heating requirements. Lowering cycle times also tends to result in lower final energy output. Electric motors drain the greatest amount of power. Manufacturers use these motors in factories to act as generators and provide mechanical or hydraulic capabilities. Consumption and production increase the total demand for electricity and can easily raise greenhouse gas emissions, depending on the carbon footprints of the power sources used.

- The environmental aspects of the production system indicator are mainly linked to factory pollution. These are mainly related to air pollution, emissions, toxic waste disposal, or contamination of water. Consumption of non-recyclable resources and rapid population growth is also important here. Environmental impacts can be divided into local, regional, or global. The bigger the impact is, the bigger threat it represents.

6.2. Logistics Dimension

- d.

- The indicator (level of automation and drive) relates to handling technology used in internal logistics. Internal logistics was an extended area in the company, so a team solution was used in a structured interview. The main factor was that the evaluation of the maturity model was objective, and in a large industrial enterprise, the team evaluation proved to be successful, which unifies both the knowledge and opinion differences of experts. Consultations took place with experts in warehouse management, as well as with the department for packaging processes. Based on a structured interview and visual inspection and observation of the use of handling equipment, the company uses forklifts, low lift trucks, picking trucks, pallet trucks, and conventional trucks. This technology uses several types of power units. Basic diesel engines are gradually being replaced by LPG engines. The company is also using and testing electric trucks in the warehouse for picking goods. Warehouse technology is connected to the information system and material flow is optimised according to material call actions. All technology is human controlled. Traffic routes and their reduction are optimised.

- e.

- There is basic packaging management in the company, which deals with individual packaging and subsequent recycling (ecological use). There are several types of packaging of different sizes. The minimum packaging is disposable. Reusable packaging has multiple circulation options (up to 20, 20–50, and over 50 circuits). Most packaging is recyclable (plastic packaging) and is environmentally friendly. The company sorts waste, possibly using packaging secondarily for other products, and has a set percentage of packaging waste.

- f.

- The indicator (environmental aspects of warehouse system) emphasises the energy aspects of storage space for material storage and works in progress. There is a minimum of economic and ecological technologies in the storage space. Some rooms are designed so that only part of a room where the movement of people and machines is detected is illuminated. It is possible to light up the storage space completely independently. No modern heating or ventilation systems, thermal insulation, thermally insulated bridges are used here. The warehouse has a vertical elevator warehouse stacker for storing and picking materials. This corresponds with the first indicator (level of automation) and technology; however, the stacker is static in nature.

6.3. Maintenance Dimension

It Must Be Said That the Environmental Aspect Plays Only a Small Role in Maintenance, Repairs, and Operations (MRO) Dimensions; However, We still Succeeded in Defining Three Main Indicators Here

- g.

- MRO processes are very important. Machinery maintenance itself has a long history beginning after World War II. Since then, all forms of maintenance from “no maintenance” (in which operators did not care at all; once machinery was broken, it was just changed) to preventive and predictive maintenance, to most advanced types of maintenance using Industry 4.0 technologies (implementation of artificial intelligence (AI), use of online sensors, dashboards, etc. in order to reduce the number of physical workers in MRO). Additionally, computerised maintenance management systems (CMMS) are a step in the right direction towards environmentally responsible manufacturing (ERM). Right (also use of natural) lighting and ventilation combined with paperless maintenance management systems also support this system.

- h.

- Energy consumption is directly related to environmentally oriented maintenance. You can reduce the amount of paper by implementing easy IS for maintenance (CMMS mentioned above). Additionally, with proper equipment design (which is reflected in the decline of resource consumption and transportation requirements), you can reduce maintenance steps. Pollution prevention (also eliminating waste streams) and environmentally compatible plant layout and design are also related to proper energy management.

- i.

- By using biodegradable lubricants and cleaning agents, you can effectively reduce wear, extend lubrication intervals and reduce lubrication consumption. The use of environmentally compatible lubricants or cleaning agents, such as synthetic lubricants derived from renewable resources, is in accordance with environmentally responsible manufacturing (ERM) and environmentally conscious manufacturing (ECM) principles.

6.4. IT Dimension

- j.

- Human resources and material reduction by IT (mostly achieved by implementing RPA). Digitisation in a company can fulfil the basic function (e.g., paper reduction) from zero implementation in business processes to more complex systems, in which data and information across various functions are largely managed by humans, to complete integration of IT systems (and other dimensions of production, logistics, and maintenance) through a comprehensive exchange of data and information.

- k.

- Energy management does not play such a big role as, for example, in the production or maintenance dimensions, but it is necessary to mention it. Basic software measurement of energy consumption for IT products and services is often optimised for less energy consumption. Additionally, alternative energy sources are used for IT energy supply (solar, wind, etc.). The highest level is represented by enterprise-wide IT process automation systems, such as robotic process automation (RPA), implemented with green-oriented cloud computing and services. Empty company areas are used for forest creation.

- l.

- IT equipment is directly linked to the transfer of information across all company levels, the use of cloud services and data sharing, and IT robotic process automation (RPA) systems. Artificial intelligence systems are implemented and have a supporting function in implementing environmental principles in all company functions.

The subsequent implementation is structured into three basic phases. The first phase is focused on processing outputs from the analytical part, evaluation, and classification of individual dimensions into levels and determination of the most critical areas (indicators). The second phase begins with the decision of whether it is necessary to optimise the whole dimension or only a partial indicator, which is then selected, and partial measures are determined for it. The third phase is defining ways to achieve improvements in each of the key areas. The procedures are processed, including the determination of the necessary methods and tools.

7. Discussion

Industry 4.0 presents challenges and opportunities for environmental protection. This paper argues that integration among concepts and technologies of Industry 4.0 would unlock the potential for environmentally responsible manufacturing (ERM) and environmentally conscious manufacturing (ECM). Four main dimensions (production, logistics, maintenance, and IT) were presented. The importance of the model is shown in improving production factors, as well as the involvement of other important parts (logistics, maintenance, and IT). These implementations need to be conducted in order to increase the level of potential for environmental production. We proposed a few solutions described in more detail in Section 4.3.

Every level of each specific model dimension is connected to an approximation of carbon footprint reduction that represents a measure of the environmental level related to a particular sector (industry, companies, automobiles, etc.). Aspect levels were created with a focus on the practical examples of what technology (equipment, etc.) has to be implemented to reach the specific level, and this made the evaluation part performed with the model easier. This also simplified the proposals about what (technologies) to concentrate on to reach a better level (and carbon footprint reduction) in specific aspects.

Further developments assume adding more dimensions to the existing maturity model. In the proposed model, we calculated only with four main dimensions (production, logistics, maintenance, and IT) in order to increase their environmental potential. These dimensions were selected as the “most important”. Further research will add other new dimensions (controlling, quality management, etc.) or subdimensions of the existing ones (divide logistics into internal and external logistics, divide maintenance into corrective, preventive, predictive, etc.).

Since globalisation and internationalisation is an ongoing trend, adding PEST (external) factors to the model seems a viable option. Additionally, questionnaires and structured interviews created for mapping the model (Section 4.2) can be modified (as more experience is gained with the model) in order to achieve better-structured results. Finally, our initial model was operating with only three indicators for each dimension. Future work assumes implementation of more indicators for each factor to obtain a more detailed maturity model of the environmental aspects in all levels of company production processes.

8. Conclusions

The ongoing Fourth Industrial Revolution is now a major trend in production systems, merging modern technologies in order to achieve the highest possible level of automation with very few or no workers at all (lights-out factories). A comprehensive literature review of models from universities, engineering associations, and consulting companies was made. The results clearly show that almost none of the available Industry 4.0 related models include environmental aspects of manufacturing (or related processes) in the company, nor their interconnection with the carbon footprint (as the main indicator of environmentally friendly production). This was the main reason for creating the environmentally related maturity model in the context of Industry 4.0 technologies used in companies. The addition of “environment aspect” to the maturity model respecting Industry 4.0 technologies is, in general, the most significant result of the work.

Created maturity model contains main four evaluated dimensions important for manufacturing company—production, logistics, maintenance, and IT. The main indicators of given dimensions were determined and incorporated into dimensions for greater detail and coverage. Evaluation in dimensions is based on defined six levels of the percentage of CO2 reduction. The use of a maturity model for the evaluation of processes in the main dimensions is based on the application of the model within the VSM tool. A questionnaire and a structured interview with company employees were created for the mapping and the model. The result of the VSM application is a map of the current state, as well as a capture of the key attributes and VA index. Based on the information, the company will find the areas where the level of maturity should be improved and increased.

The proposed maturity model can be used in two ways, i.e., either as a diagnostic tool (only analytical parts of the model) or it is possible to use part of a phase of implementation, in which proposed measures are applied as a part of a comprehensive methodology.

Within the case study presented in the article, the analytical part and evaluation of the current state are described. The potential for using the maturity model is in combination with the VSM tool, as shown in the case study. Results of this part of the article serve as input data for the execution part (Section 5 onwards). The implementation phase deals with the design of corrective measures aimed at improving specified dimensions (production, manufacturing, logistics, and information technologies) in a way to reduce carbon footprint according to the maturity model. The potential for using the maturity model is in combination with the VSM tool.

The future research proposal is based on the validation of the model in a variety of manufacturing companies. The companies are proposed to cover a wide range of industries and be large in number to validate the proposed model properly.

Author Contributions

Conceptualization, M.Z., P.P., T.B. and J.B.; methodology, M.Z., P.P., T.B. and J.B.; software, T.B.; validation, M.Z., P.P. and T.B.; formal analysis, M.Z. and P.P.; investigation, M.Z., P.P. and T.B.; resources, M.Z., P.P. and T.B.; data curation, P.P.; writing—original draft preparation, M.Z., P.P. and T.B.; writing—review and editing, M.Z., P.P. and T.B.; visualization, M.Z., P.P. and T.B.; supervision, M.Z. and P.P.; project administration, M.Z., P.P. and M.S.; funding acquisition, M.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was created by the support of the project SGS-2021-028 ‘Developmental and training tools for the interaction of man and the cyber-physical production system’ under the Internal Grant Agency of the University of West Bohemia.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A. Questionnaires for Evaluating Dimensions of Proposed Model

Table A1.

An example of a question for evaluating the production dimension.

Table A1.

An example of a question for evaluating the production dimension.

| Production Dimension | ||

|---|---|---|

| Indicator: Energy Sources–Production Equipment | ||

| Question: To what extent does your production equipment uses energy sources in relation to an environmental approach? | ||

| Level 0 | No usage in relation to environmental aspects | ☐ |

| Level 1 | Measurement of energy consumption, basic waste (water) management in production | ☐ |

| Level 2 | Advanced waste management in production | ☐ |

| Level 3 | Alternative energy sources used in production (solar, wind, etc.) | ☐ |

| Level 4 | Green production building using energy recovery. CO2 emissions report for installations. | ☐ |

| Level 5 | Wide support of negative emissions technologies (Ocean fertilisation, enhanced weathering, etc.) | ☐ |

Table A2.

An example of a question for evaluating the maintenance dimension.

Table A2.

An example of a question for evaluating the maintenance dimension.

| Maintenance Dimension | ||

|---|---|---|

| Indicator: Use of Lubricants and Cleaning Agents | ||

| Question: What type of lubricants/cleaning agents are used when dealing with machinery maintenance? | ||

| Level 0 | No special attention paid to the use of lubricants in the company, not monitored | ☐ |

| Level 1 | Tribo-materials, energy-efficient bearings, and long-life lubricants | ☐ |

| Level 2 | Use of degradable, and less eco-toxic lubricants | ☐ |

| Level 3 | Synthetic lubricants, particularly synthetic ether lubricants, derived from renewable resources | ☐ |

| Level 4 | Tribo-compatible materials with self-lubricating property | ☐ |

| Level 5 | No lubricants are needed (for example because of no leakage through joints and seals; no groundwater contamination)/nor used in the company | ☐ |

Table A3.

An example of a question for evaluating the logistics dimension.

Table A3.

An example of a question for evaluating the logistics dimension.

| Logistics Dimension | ||

|---|---|---|

| Indicator: Degree of Automation and Controllability | ||

| Question: What manipulation technology is used in the company in terms of controllability and automation? | ||

| Level 0 | Mechanised manipulation equipment (diesel engines) only human controlled | ☐ |

| Level 1 | Manipulation technology for hybrid propulsion units replacing human-controlled diesel engines (CNGs) and shortening routes by using, for example, picking systems in the warehouse | ☐ |

| Level 2 | Manipulation technology is driven by electric units and their partial automation, human-controlled, routes reduction and shortening with connection to partial automation of warehouse systems | ☐ |

| Level 3 | Manipulation technology driven by electric units and their majority automated with collaborative human cooperation. Optimised transport routes and mainly connected to automated warehousing systems | ☐ |

| Level 4 | Implemented fully autonomous and robotic handling equipment driven by electricity (AGV, drones) adaptable to products. Optimised transport routes and full connection to automated warehousing systems | ☐ |

| Level 5 | Manipulation technology fuelled by alternative energy sources fully adaptable to products and full connection to complex autonomous storage systems | ☐ |

Table A4.

An example of a question for evaluating the IT dimension.

Table A4.

An example of a question for evaluating the IT dimension.

| IT Dimension | ||

|---|---|---|

| Indicator: Use of Process Automation | ||

| Question: What level of process automation is used in your company? | ||

| Level 0 | Zero digitisation (paper reduction), no implementation in business processes. | ☐ |

| Level 1 | More complex digitisation (paper reduction). Minimal cloud use. | ☐ |

| Level 2 | Advanced digitalisation, data, and information largely managed by humans. Optimisation of energy consumption for IT products and services. | ☐ |

| Level 3 | More improved digitalisation. Alternative energy sources used for IT. Implemented IS across the company with basic automation (RPA). | ☐ |

| Level 4 | Minimal human participation. Most of the processes automatised or remotely driven.) Environmentally oriented cloud computing and services. | ☐ |

| Level 5 | Complete integration of IT systems through all company sectors, comprehensive exchange of data and information. Artificial intelligence systems are widely implemented. | ☐ |

References

- Yin, Y.; Stecke, K.E.; Li, D. The evolution of production systems from Industry 2.0 through Industry 4.0. Int. J. Prod. Res. 2018, 56, 848–861. [Google Scholar] [CrossRef]

- Hofmann, E.; Rüsch, M. Industry 4.0 and the current status as well as future prospects on logistics. Comput. Ind. 2017, 89, 23–34. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 technologies: Implementation patterns in manufac-turing companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A. Sustainable Industry 4.0 framework: A systematic literature review identifying the current trends and future perspectives. Process Saf. Environ. Prot. 2018, 117, 408–425. [Google Scholar] [CrossRef]

- Omer, A.M. Energy, environment and sustainable development. Renew. Sustain. Energy Rev. 2008, 12, 2265–2300. [Google Scholar] [CrossRef]

- Shrivastava, P. The Role of Corporations in Achieving Ecological Sustainability. Acad. Manag. Rev. 1995, 20, 936–960. [Google Scholar] [CrossRef]

- Levy, D.L. Environmental Management as Political Sustainability. Organ. Environ. 1997, 10, 126–147. [Google Scholar] [CrossRef]

- Laosirihongthong, T.; Adebanjo, D.; Choon Tan, K. Green supply chain management practices and perfor-mance. Ind. Manag. Data Syst. 2013, 113, 1088–1109. [Google Scholar] [CrossRef]

- Jaggernath, R.; Khan, Z. Green supply chain management. World J. Entrep. Manag. Sustain. Dev. 2015, 11, 37–47. [Google Scholar] [CrossRef]

- Srivastava, S.K. Green supply-chain management: A state-of-the-art literature review. Int. J. Manag. Rev. 2007, 9, 53–80. [Google Scholar] [CrossRef]

- Boons, F. Greening products: A framework for product chain management. J. Clean. Prod. 2002, 10, 495–505. [Google Scholar] [CrossRef]

- Nejat, P.; Jomehzadeh, F.; Taheri, M.M.; Gohari, M.; Majid, M.Z.A. A global review of energy consumption, CO 2 emissions and policy in the residential sector (with an overview of the top ten CO 2 emitting countries). Renew. Sustain. Energy Rev. 2015, 43, 843–862. [Google Scholar] [CrossRef]

- Curran, T.; Williams, I. A zero waste vision for industrial networks in Europe. J. Hazard. Mater. 2012, 207–208, 3–7. [Google Scholar] [CrossRef] [PubMed]

- Ockwell, D.G.; Mallett, A. Low-Carbon Technology Transfer: From Rhetoric to Reality; Routledge: London, UK; New York, NY, USA, 2012. [Google Scholar]

- Halmann, M.M.; Steinberg, M. Greenhouse Gas Carbon Dioxide Mitigation: Science and Technology; Lewis Publishers: Boca Raton, FL, USA, 1999. [Google Scholar]

- Navarro, A.; Puig, R.; Fullana-i-Palmer, P. Product vs corporate carbon footprint: Some methodological is-sues. A case study and review on the wine sector. Sci. Total Environ. 2017, 581–582, 722–733. [Google Scholar] [CrossRef]

- Dada, A.; Staake, T. Carbon Footprints from Enterprises to Product Instances: The Potential of the EPC Network. In INFORMATIK 2008. Beherrschbare Systeme-dank Informatik. Band 2; Hegering, H.-G., Lehmann, A., Ohlbach, H.J., Scheideler, C., Eds.; Gesellschaft für Informatik: Bonn, Germany, 2008; pp. 873–878. [Google Scholar]

- WATIFY. Green Manufacturing—The Solution for Reducing Production Waste—Boosting Technological Trans-formation. 2019. Available online: https://ec.europa.eu/growth/tools-databases/dem/watify/boosting/news/green-manufacturing-%E2%80%93-solution-reducing-production-waste (accessed on 11 October 2020).

- Mao, Y.; Wang, J. Is green manufacturing expensive? Empirical evidence from China. Int. J. Prod. Res. 2018, 57, 7235–7247. [Google Scholar] [CrossRef]

- Green New Deal for Europe. Available online: https://www.gndforeurope.com/ (accessed on 1 May 2021).

- Ft.com. Davos 2020: Ursula Von Der Leyen Warns China to Price Carbon or Face Tax. 2020. Available online: https://www.ft.com/content/c93694c8-3d15-11ea-a01a-bae547046735 (accessed on 1 May 2021).

- Domanski, C. Cost Engineering: A Practical Method for Sustainable Profit Generation in Manufacturing; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar]

- Groover, M.P. Fundamentals of Modern Manufacturing: Materials, Processes, and Systems; John Wiley: Hoboken, NJ, USA, 2020. [Google Scholar]

- Faulkner, W.; Badurdeen, F. Sustainable Value Stream Mapping (Sus-VSM): Methodology to visualize and assess manufacturing sustainability performance. J. Clean. Prod. 2014, 85, 8–18. [Google Scholar] [CrossRef]

- CMMI® for Services, Version 1.3 CMMI-SVC, V1.3 CMMI Product Team Improving Processes for Providing Better Services. 2010. Available online: http://cmmi.kondakov.ru/library/SDocs/CMMI_SVC_1_3.pdf (accessed on 1 May 2021).

- Mutafelija, B.; Stromberg, H. Process Improvement with CMMI® v1.2 and ISO Standards; ISO: Geneva, Switzerland, 2008. [Google Scholar]

- Paulk, M.C.; Curtis, B.; Chrissis, M.B.; Weber, C.V. Capability maturity model, version 1.1. IEEE Softw. 1993, 10, 18–27. [Google Scholar] [CrossRef]

- Viharos, Z.J.; Soós, S.; Nick, G.A.; Várgedő, T.; Beregi, R.J. Non-comparative, Industry 4.0 readiness evaluation for manufacturing enterprises. In Proceedings of the 15th IMEKO TC10 Workshop on Technical Diagnostics, Budapest, Hungary, 6–7 June 2017. [Google Scholar]

- Basl, J. Companies on the way to industry 4.0 and their readiness. J. Syst. Integr. 2018, 9, 3–6. [Google Scholar]

- Schmitt, P.; Schmitt, J.; Engelmann, B. Evaluation of proceedings for SMEs to conduct I4.0 projects. Procedia CIRP 2019, 86, 257–263. [Google Scholar] [CrossRef]

- Lichtblau, K. Industrie 4.0-Readiness; Impuls-Stiftung: Aachen, Germany, 2015. [Google Scholar]

- Leyh, C.; Schäffer, T.; Bley, K.; Forstenhäusler, S. SIMMI 4.0—A Maturity Model for Classifying the Enter-prise-wide IT and Software Landscape Focusing on Industry 4.0. In Proceedings of the 2016 Federated Conference on Computer Science and Information Systems, Gdansk, Poland, 11–14 September 2016; pp. 1297–1302. [Google Scholar]

- Iggins, J.P. Cochrane Handbook for Systematic Reviews of Interventions; Version 5.0.1; The Cochrane Collaboration: London, UK, 2008. [Google Scholar]

- Schumacher, A.; Erol, S.; Sihn, W. A Maturity Model for Assessing Industry 4.0 Readiness and Maturity of Manufacturing Enterprises. Procedia CIRP 2016, 52, 161–166. [Google Scholar] [CrossRef]

- De Carolis, A.; Macchi, M.; Kulvatunyou, B.; Brundage, M.P.; Terzi, S. Maturity Models and Tools for Ena-bling Smart Manufacturing Systems: Comparison and Reflections for Future Developments. In Product Lifecycle Management and the Industry of the Future; Springer: Cham, Switzerland, 2017; pp. 23–35. [Google Scholar]

- Gökalp, E.; Şener, U.; Eren, P.E. Development of an Assessment Model for Industry 4.0: Industry 4.0-MM. In Communications in Computer and Information Science; Springer Science and Business Media LLC: Cham, Switzerland, 2017; pp. 128–142. [Google Scholar]

- Agca, O.; Gibson, J.; Godsell, J.; Ignatius, J.; Davies, C.W.; Xu, O. An Industry 4 Readiness Assessment Tool; WMG-The University of Warwick: Coventry, UK, 2017. [Google Scholar]

- Weber, C.; Königsberger, J.; Kassner, L.; Mitschang, B. M2DDM—A Maturity Model for Data-Driven Manufacturing. Procedia CIRP 2017, 63, 173–178. [Google Scholar] [CrossRef]

- Singapore, E.D.B. The Singapore smart industry readiness index. In Catalysing the Transformation of Manufacturing; Singapore Economic Development Board: Singapore, 2018. [Google Scholar]

- Dennis, M.; Ramaswamy, C.; Ameen, M.N.; Jayaram, V. Asset Performance Management Maturity Model; BCG Perspective, Capgemini: Paris, France, 2017. [Google Scholar]

- Mittal, S.; Romero, D.; Wuest, T. Towards a Smart Manufacturing Maturity Model for SMEs (SM3E). Advances in Production Management Systems. Smart Manuf. Ind. 2018, 4, 155–163. Available online: https://link.springer.com/chapter/10.1007/978-3-319-99707-0_20 (accessed on 10 October 2020).

- Sjödin, D.R.; Parida, V.; Leksell, M.; Petrovic, A. Smart Factory Implementation and Process Innovation. Res. Manag. 2018, 61, 22–31. [Google Scholar] [CrossRef]

- Oleśków-Szłapka, J.; Stachowiak, A. The Framework of Logistics 4.0 Maturity Model. Advances in Intelligent Systems and Computing. 2018. Available online: https://link.springer.com/chapter/10.1007%2F978-3-319-97490-3_73 (accessed on 20 October 2020).

- Pacchini, A.P.T.; Lucato, W.C.; Facchini, F.; Mummolo, G. The degree of readiness for the implementation of Industry 4.0. Comput. Ind. 2019, 113, 103125. [Google Scholar] [CrossRef]

- Zeller, V.; Hocken, C.; Stich, V. acatech Industrie 4.0 Maturity Index—A Multidimensional Maturity Model. Secur. Educ. Crit. Infrastruct. 2018, 4, 105–113. [Google Scholar] [CrossRef]

- Jung, K.; Kulvatunyou, B.; Choi, S.; Brundage, M.P. An Overview of a Smart Manufacturing System Readi-ness Assessment. IFIP Advances in Information and Communication Technology. 2016. Available online: https://link.springer.com/chapter/10.1007%2F978-3-319-51133-7_83 (accessed on 9 October 2020).

- Akdil, K.Y.; Ustundag, A.; Cevikcan, E. Maturity and Readiness Model for Industry 4.0 Strategy. Springer Series in Advanced Manufacturing. 2017. Available online: https://link.springer.com/chapter/10.1007%2F978-3-319-57870-5_4 (accessed on 13 October 2020).

- Lee, J.; Jun, S.; Chang, T.-W.; Park, J. A Smartness Assessment Framework for Smart Factories Using Analytic Network Process. Sustainability 2017, 9, 794. [Google Scholar] [CrossRef]

- Sternad, M.; Lerher, T.; Gajsek, B. Maturity Levels for Logistics 4.0 Based on Nrw’s Industry 4.0 Maturity Model. Bus. Logist. Mod. Manag. 2018, 18, 695–708. [Google Scholar]

- Shukla, G.P.; Adil, G.K. A conceptual four-stage maturity model of a firm’s green manufacturing technology alternatives and performance measures. J. Manuf. Technol. Manag. 2021. [Google Scholar] [CrossRef]

- Ormazabal, M.; Sarriegi, J.M.; Viles, E. Environmental management maturity model for industrial companies. Manag. Environ. Qual. Int. J. 2017, 28, 632–650. [Google Scholar] [CrossRef]

- Moutchnik, D.A. The maturity model for corporate environmental management. Umwelt Wirtschafts Forum 2015, 23, 161–170. [Google Scholar] [CrossRef]

- Verrier, B.; Rose, B.; Caillaud, E. Lean and Green strategy: The Lean and Green House and maturity deployment model. J. Clean. Prod. 2016, 116, 150–156. [Google Scholar] [CrossRef]

- Jeffrey, K. The Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer; McGraw-Hill: New York, NY, USA, 2004. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).