Experimental Investigation of Traditional Clay Brick and Lime Mortar Intended for Restoration of Cultural Heritage Sites

Abstract

:1. Introduction

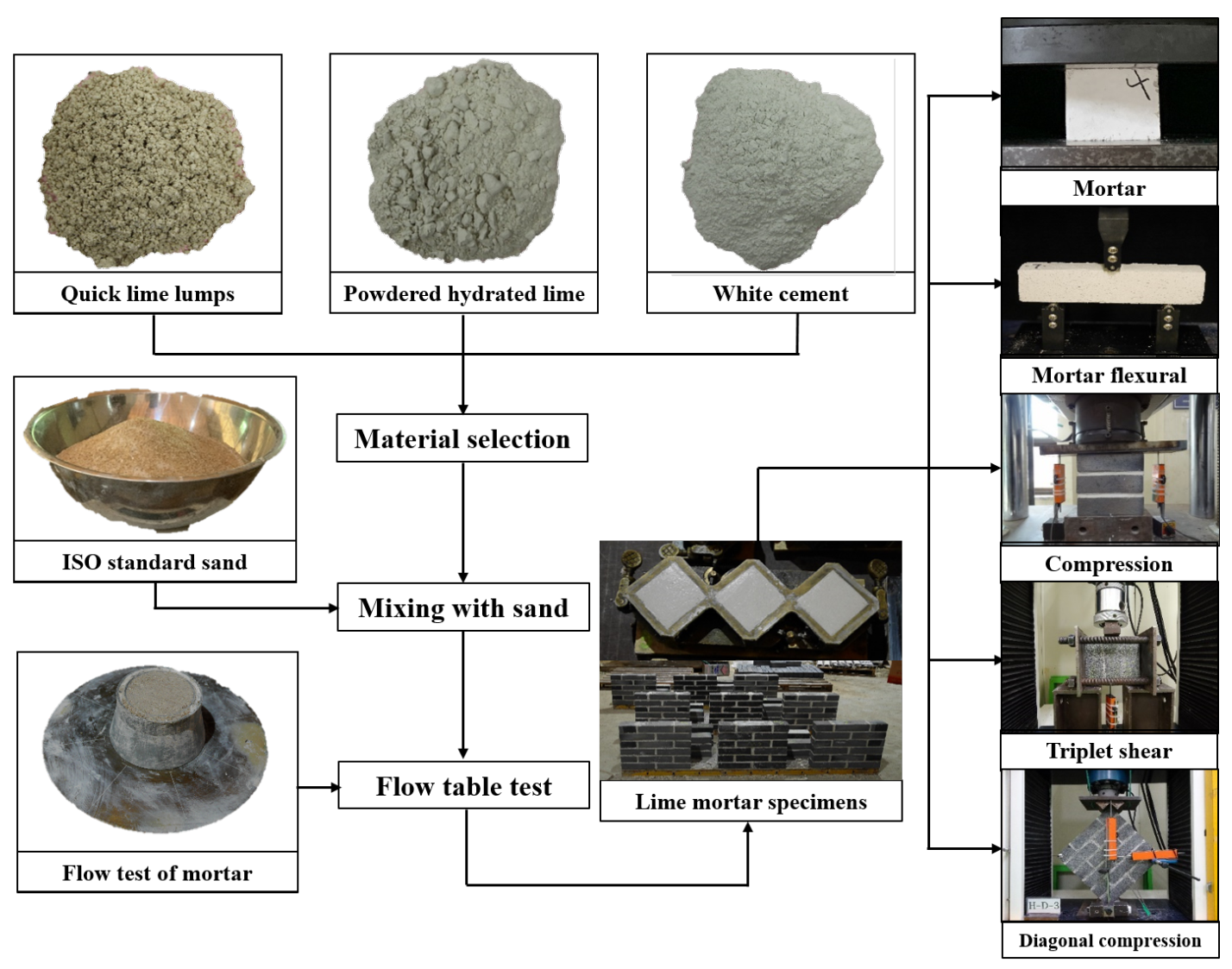

2. Material and Method

2.1. Lime Mortar Mixture

2.2. Traditional Handmade Brick Test

2.3. Compressive Strength of Mortar Cubes Test

2.4. Flexural Strength of the Mortar Test

2.5. Compressive Strength of the Masonry Prism Test

2.6. Shear Strength of Masonry Triplets Test

2.7. Diagonal Compressive Strength of Masonry Panels Test

3. Results and Discussion

3.1. Traditional Handmade Brick Compressive Strength

3.2. Compressive Strength of Mortar

3.3. Flexural Strength of Mortar

3.4. Compressive Strength of the Masonry Prism

3.5. Shear Strength of Masonry Triplets

3.6. Diagonal Compressive Strength of Masonry Panels

4. Conclusions

- 1.

- In the material tests, the addition of white cement resulted in almost no noticeable enhancement of mortar strength. However, in the masonry specimens, this effect was more pronounced. This can be interpreted to mean that the bonding between mortar and bricks, which is a critical factor affecting the masonry’s behavior, was stronger with additional cement in the mixing ratio.

- 2.

- For each type of mortar (LL and PL), mixtures with white cement exhibited superior behavior in terms of compressive strength and diagonal shear strength compared to non-cement mixtures. However, this effect was barely observed in triplet shear tests, where the change in shear strength of most of the masonry specimens was minor (below 0.11 MPa), which led to prompt failure by detachment of either the mortar layer or the mortar bed joint and bricks.

- 3.

- The results also implied that the white cement had a greater effect on PL mortar than LL mortar.The compressive strengths of the LL-3 and PL-3 masonry prisms were 11.38 MPa and 15.39 MPa, respectively, and the PL-3 compressive strength was 35.2% greater than that of LL-3, while the diagonal shear strength of the masonry panels were 0.242 MPa and 0.284 MPa, respectively. Therefore, the mixing ratio of PL-3, which provided the most favorable performance among all ratios, can be considered for the repair and maintenance of masonry cultural heritage sites. Future research can investigate further effects of different ratios of added cement.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- David Kingery, W.; Vandiver, P.B.; Prickett, M. The Beginnings of Pyrotechnology, Part II: Production and Use of Lime and Gypsum Plaster in the Pre-Pottery Neolithic Near East. J. Abbr. 1988, 15, 219–243. [Google Scholar] [CrossRef]

- Carran, D.; Hughes, J.; Leslie, A.; Kennedy, C. A Short History of the Use of Lime as a Building Material beyond Europe and North America. Int. J. Archit. Herit. 2012, 6, 117–146. [Google Scholar] [CrossRef]

- Elert, K.; Rodriguez-Navarro, C.; Pardo, E.S.; Hansen, E.; Cazalla, O. Lime Mortars for the Conservation of Historic Buildings. Stud. Conserv. 2002, 47, 62–75. [Google Scholar]

- Kim, S.H.; Lee, C.H.; Jo, Y.H. Behavioral Characteristics and Structural Stability of the Walls in the Ancient Korean Royal Tombs from the Sixth Century Baekje Kingdom. Environ. Earth Sci. 2020, 79, 1–13. [Google Scholar] [CrossRef]

- Park, H.J.; Ha, J.G.; Kim, S.H.; Jo, S.S. Seismic Performance of Ancient Masonry Structures in Korea Rediscovered in 2016 M 5.8 Gyeongju Earthquake. Sustainability 2019, 11, 1565. [Google Scholar] [CrossRef] [Green Version]

- Pham, K.V.A.; Hong, S.G.; Lee, S.M.; Park, H.J.; Lee, K. Assessment of Seismic Performance of Three-Story Masonry Stone Pagoda by Dynamic Centrifuge Test and Simulation Analysis. Int. J. Archit. Herit. 2019, 1–14. [Google Scholar] [CrossRef]

- Messali, F.; Metelli, G.; Plizzari, G. Experimental Results on the Retrofitting of Hollow Brick Masonry Walls with Reinforced High Performance Mortar Coatings. Constr. Build. Mater. 2017, 141, 619–630. [Google Scholar] [CrossRef]

- Gattesco, N.; Macorini, L. In-Plane Stiffening Techniques with Nail Plates or CFRP Strips for Timber Floors in Historical Masonry Buildings. Constr. Build. Mater. 2014, 58, 64–76. [Google Scholar] [CrossRef]

- Lawrence, R.M.H. A Study of Carbonation in Non-Hydraulic Lime Mortars; University of Bath: Bath, UK, 2006. [Google Scholar]

- Kang, S.H.; Lee, S.O.; Hong, S.G.; Kwon, Y.H. Historical and Scientific Investigations into the Use of Hydraulic Lime in Korea and Preventive Conservation of Historic Masonry Structures. Sustainability 2019, 11, 5169. [Google Scholar] [CrossRef] [Green Version]

- Ince, C.; Derogar, S.; Tiryakiolu, N.Y.; Toklu, Y.C. The Influence of Zeolite and Powdered Bayburt Stones on the Water Transport Kinetics and Mechanical Properties of Hydrated Lime Mortars. Constr. Build. Mater. 2015, 98, 345–352. [Google Scholar] [CrossRef]

- van Hees, R.P.; Binda, L.; Papayianni, I.; Toumbakari, E. Damage Analysis as a Step Towards Compatible Repair Mortars. Rilem Rep. 2015, 28, 107–152. [Google Scholar]

- Nguyen, K.T.; Ahn, N.; Le, T.A.; Lee, K. Theoretical and Experimental Study on Mechanical Properties and Flexural Strength of Fly Ash-Geopolymer Concrete. Constr. Build. Mater. 2016, 106, 65–77. [Google Scholar] [CrossRef]

- Nguyen, K.T.; Le, T.A.; Lee, J.; Lee, D.; Lee, K. Investigation on Properties of Geopolymer Mortar Using Preheated Materials and Thermogenetic Admixtures. Constr. Build. Mater. 2017, 130, 146–155. [Google Scholar] [CrossRef]

- Nguyen, K.T.; Le, T.A.; Lee, K. Evaluation of the Mechanical Properties of Sea Sand-Based Geopolymer Concrete and the Corrosion of Embedded Steel Bar. Constr. Build. Mater. 2018, 169, 462–472. [Google Scholar] [CrossRef]

- Pham, K.V.A.; Nguyen, T.K.; Le, T.A.; Han, S.W.; Lee, G.; Lee, K. Assessment of Performance of Fiber Reinforced Geopolymer Composites by Experiment and Simulation Analysis. Appl. Sci. 2019, 9, 3424. [Google Scholar] [CrossRef] [Green Version]

- Mosquera, M.J.; Silva, B.; Prieto, B.; Ruiz-Herrera, E. Addition of Cement to Lime-Based Mortars: Effect on Pore Structure and Vapor Transport. Cem. Concr. Res. 2006, 36, 1635–1642. [Google Scholar] [CrossRef]

- Sala, E.; Zanotti, C.; Passoni, C.; Marini, A. Lightweight Natural Lime Composites for Rehabilitation of Historical Heritage. Constr. Build. Mater. 2016, 125, 81–93. [Google Scholar] [CrossRef]

- Collepardi, M. Degradation and Restoration of Masonry Walls of Historical Buildings. Mater. Struct. 1990, 23, 81–102. [Google Scholar] [CrossRef]

- Zhang, D.; Zhao, J.; Wang, D.; Xu, C.; Zhai, M.; Ma, X. Comparative Study on the Properties of Three Hydraulic Lime Mortar Systems: Natural Hydraulic Lime Mortar, Cement-Aerial Lime-Based Mortar and Slag-Aerial Lime-Based Mortar. Constr. Build. Mater. 2018, 186, 45–52. [Google Scholar] [CrossRef]

- Maravelaki-Kalaitzaki, P.; Bakolas, A.; Karatasios, I.; Kilikoglou, V. Hydraulic Lime Mortars for the Restoration of Historic Masonry in Crete. Cem. Concr. Res. 2005, 35, 1577–1586. [Google Scholar] [CrossRef]

- Silva, B.A.; Ferreira Pinto, A.P.; Gomes, A. Natural Hydraulic Lime versus Cement for Blended Lime Mortars for Restoration Works. Constr. Build. Mater. 2015, 94, 346–360. [Google Scholar] [CrossRef]

- BS EN 459-1:2010. Building Lime-Part 1: Definition, Specifications and Conformity Criteria; BSI: London, UK, 2010. [Google Scholar]

- Faria, P.; Henriques, F.; Rato, V. Comparative Evaluation of Lime Mortars for Architectural Conservation. J. Cult. Herit. 2008, 9, 338–346. [Google Scholar] [CrossRef]

- American Society of Testing and Materials. ASTM C5, Standard Specification for Quicklime for Structural Purposes; ASTM: West Conshohocken, PA, USA, 2018. [Google Scholar]

- American Society of Testing and Materials. ASTM C25, Standard Test Methods for Chemical Analysis of Limestone, Quicklime, and Hydrated Lime; ASTM: West Conshohocken, PA, USA, 2019. [Google Scholar]

- Strength and Stress-Strain Characteristics of Traditional Adobe Block and Masonry. Mater. Struct. Mater. Constr. 2013, 46, 1449–1457. [CrossRef]

- Lee, J.H. Seismic Capacity and Seismic Retrofitting of Low Rise Buildings. Ph.D. Thesis, Kwangwoon University, Seoul, Korea, 2004. [Google Scholar]

- Corinaldesi, V. Environmentally-Friendly Bedding Mortars for Repair of Historical Buildings. Constr. Build. Mater. 2012, 35, 778–784. [Google Scholar] [CrossRef]

- Alecci, V.; Fagone, M.; Rotunno, T.; De Stefano, M. Shear Strength of Brick Masonry Walls Assembled with Different Types of Mortar. Constr. Build. Mater. 2013, 40, 1038–1045. [Google Scholar] [CrossRef]

- Noh, J.H.; Oh, S.J.; Kim, K.J. Applied-Mineralogical Study on the Mineral Facies and Characteristics of Domestic High-Ca Limestone. J. Mineral. Soc. Korea 2004, 17, 339–355. [Google Scholar]

- American Society of Testing and Materials. ASTM C109/C109M REV A, Standard Test Method for Compressive Strength of Hydraulic Cement Mortars; ASTM: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Korea Standard Association. KS L 5105, Testing Method for Compressive Strength of Hydraulic Cement Mortar; Korean Standards Association: Seoul, Korea, 2017. [Google Scholar]

- Kim, J.H.; Kim, C.D.; Kim, T.N.; Kim, T.W. A Study on the Analysis of Lime Mortar Composition for the Preservation of Myung Dong Cathedral Church-Focused on the East Brick Wall. J. Archit. Hist. 2005, 14, 89–101. [Google Scholar]

- Cultural Heritage Repair Standard Product Count; Cultural Heritage Administration: Seoul, Korea, 2019.

- Nam, B.J.; Noh, S.K.; Kim, E.K.; Ahn, S.A.; Kang, S.Y. Initial Behavior and Shrinkage Properties of Lime Mortars for Restoration of Cultural Heritage According to the Mixing Ratio. J. Conserv. Sci. 2020, 36, 456–474. [Google Scholar] [CrossRef]

- Kang, S.H.; Kwon, Y.H.; Moon, J. Quantitative Analysis of CO2 Uptake and Mechanical Properties of Air Lime-Based Materials. Energies 2019, 12, 2903. [Google Scholar] [CrossRef] [Green Version]

- Kwon, K.-H.; Yu, H.-R. An Experimental Study on the Physical Property of Lime Mortar in the Building’Masonry. J. Korea Inst. Struct. Maint. Insp. 2009, 13, 133–141. [Google Scholar]

- American Society of Testing and Materials. ASTM C348-20, Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars; ASTM: West Conshohocken, PA, USA, 2019. [Google Scholar]

- American Society of Testing and Materials. ASTM C1314M REV A, Standard Test Method for Compressive Strength of Masonry Prisms; ASTM: West Conshohocken, PA, USA, 2018; pp. 1–9. [Google Scholar]

- BS EN 1052-3:2002. Methods of Test for Masonry-Part 3: Determination or Initial Shear Strength; BSI: London, UK, 2002. [Google Scholar]

- American Society of Testing and Materials. ASTM E 519, Standard Test Method for Diagonal Tension (Shear) in Masonry Assemblages; ASTM: West Conshohocken, PA, USA, 2010. [Google Scholar]

- Fódi, A. Effects Influencing the Compressive Strength of a Solid, Fired Clay Brick. Period. Polytech. Civ. Eng. 2011, 55, 117–128. [Google Scholar] [CrossRef]

- Suciu, O.; Cruciat, R.; Ghindea, C.L. Experimental Case Studies on Clay Fired Bricks Compressive Strength. Key Eng. Mater. 2014, 601, 215–218. [Google Scholar] [CrossRef]

- Cultural Heritage Repair Standard Specification; Cultural Heritage Administration: Seoul, Korea, 2020.

- Atkinson, R.H.; Noland, J.L. A Proposed Failure Theory for Brick Masonry in Compression. In Proceedings of the 3rd Canadian Masonry Symposium, Edmonton, AB, Canada, 6–8 June 1983; pp. 5.1–5.17. [Google Scholar]

- Gumaste, K.S.; Rao, K.S.N.; Reddy, B.V.V.; Jagadish, K.S. Strength and Elasticity of Brick Masonry Prisms and Wallettes under Compression. J. Mater. Struct. Constr. 2007, 40, 241–253. [Google Scholar] [CrossRef]

- Pelà, L.; Kasioumi, K.; Roca, P. Experimental Evaluation of the Shear Strength of Aerial Lime Mortar Brickwork by Standard Tests on Triplets and Non-Standard Tests on Core Samples. J. Mater. Struct. Constr. 2017, 136, 441–453. [Google Scholar] [CrossRef]

- Rahgozar, A.; Hosseini, A. Experimental and Numerical Assessment of In-Plane Monotonic Response of Ancient Mortar Brick Masonry. J. Mater. Struct. Constr. 2017, 155, 892–909. [Google Scholar] [CrossRef]

- Bompa, D.V.; Elghazouli, A.Y. Experimental and Numerical Assessment of the Shear Behaviour of Lime Mortar Clay Brick Masonry Triplets. Constr. Build. Mater. 2020, 262, 120571. [Google Scholar] [CrossRef]

| SiO | AlO | TiO | FeO | MnO | MgO | CaO | NaO | KO | LOI | Total |

|---|---|---|---|---|---|---|---|---|---|---|

| 1.94 | 0.39 | 0.00 | 0.01 | 0.00 | 0.56 | 52.91 | 0.00 | 0.03 | 44.16 | 100 |

| No | Sample Name | Hydrated Lime | Mixing Ratio (by Mass) | |||

|---|---|---|---|---|---|---|

| Preparations | Binder | Aggregate | Water (%) | |||

| Lime | Cement | Sand | ||||

| 1 | LL-1 | Quick lime lumps | 1 | - | 1 | 10 |

| 2 | LL-2 | 1 | - | 3 | 10 | |

| 3 | LL-3 | 1 | 0.2 | 4.9 | 14 | |

| 4 | LL-4 | 1.2 | - | 4.9 | 10 | |

| 5 | PL-1 | Powdered hydrated lime | 1 | - | 1 | 28 |

| 6 | PL-2 | 1 | - | 3 | 17 | |

| 7 | PL-3 | 1 | 0.2 | 4.9 | 11 | |

| 8 | PL-4 | 1.2 | - | 4.9 | 11 | |

| No | Maximum Load (kN) | Compressive Strength (MPa) |

|---|---|---|

| 1 | 1024 | 60.97 |

| 2 | 766 | 44.81 |

| 3 | 1001 | 62.19 |

| 4 | 1063 | 65.96 |

| 5 | 1128 | 58.49 |

| Average | 1000 | 60.56 |

| Deviation | 137 | 7.25 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, G.; Park, J.H.; Pham, K.V.A.; Lee, C.H.; Lee, K. Experimental Investigation of Traditional Clay Brick and Lime Mortar Intended for Restoration of Cultural Heritage Sites. Appl. Sci. 2021, 11, 6228. https://doi.org/10.3390/app11136228

Lee G, Park JH, Pham KVA, Lee CH, Lee K. Experimental Investigation of Traditional Clay Brick and Lime Mortar Intended for Restoration of Cultural Heritage Sites. Applied Sciences. 2021; 11(13):6228. https://doi.org/10.3390/app11136228

Chicago/Turabian StyleLee, Gayoon, Jun Hyoung Park, Khoa V. A. Pham, Chan Hee Lee, and Kihak Lee. 2021. "Experimental Investigation of Traditional Clay Brick and Lime Mortar Intended for Restoration of Cultural Heritage Sites" Applied Sciences 11, no. 13: 6228. https://doi.org/10.3390/app11136228

APA StyleLee, G., Park, J. H., Pham, K. V. A., Lee, C. H., & Lee, K. (2021). Experimental Investigation of Traditional Clay Brick and Lime Mortar Intended for Restoration of Cultural Heritage Sites. Applied Sciences, 11(13), 6228. https://doi.org/10.3390/app11136228