Structural Performance of R-Type Steel Damper Used in Reinforced Concrete Members

Abstract

:1. Introduction

2. Experimental Program

2.1. Phase I Test Program

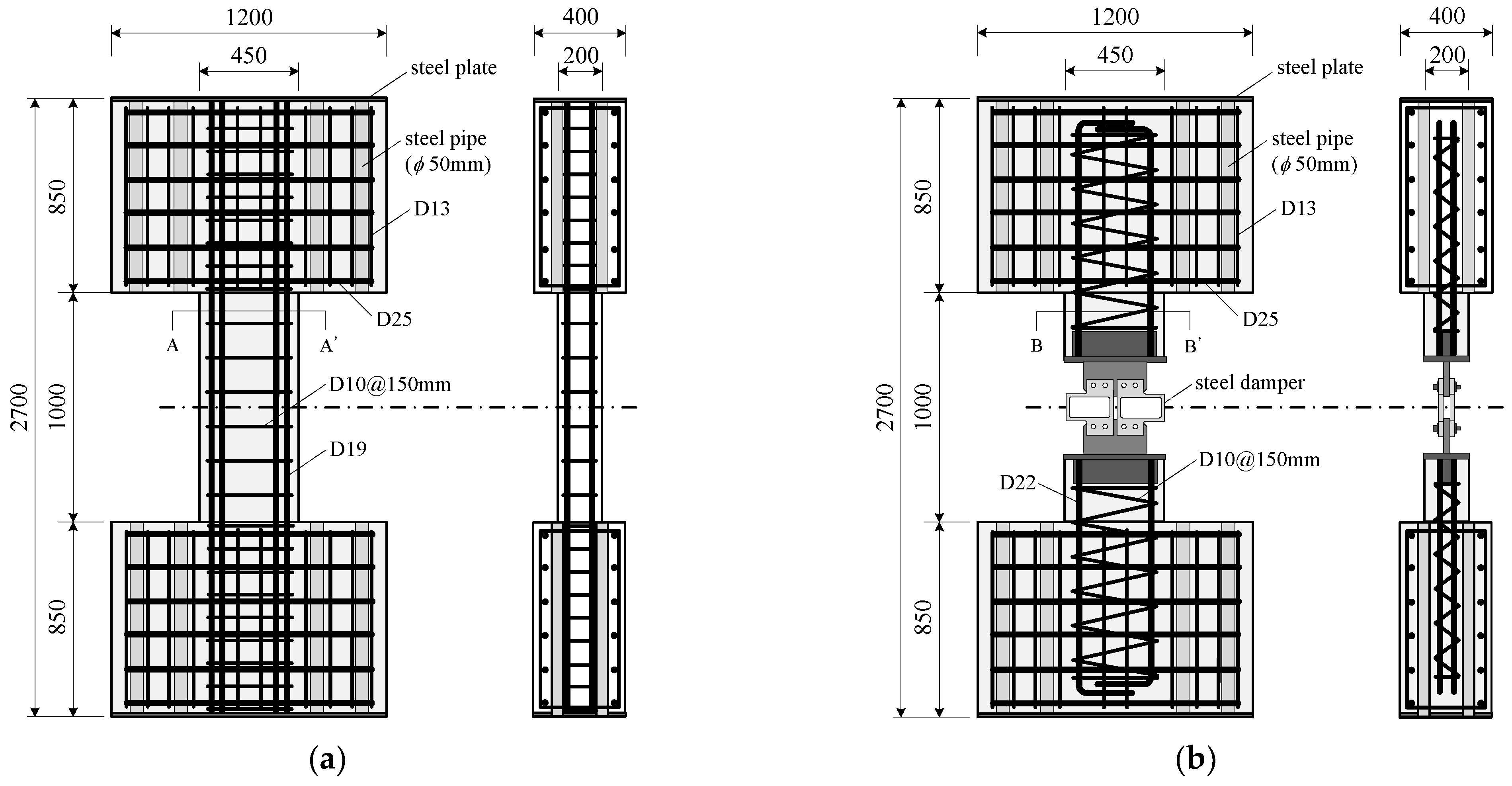

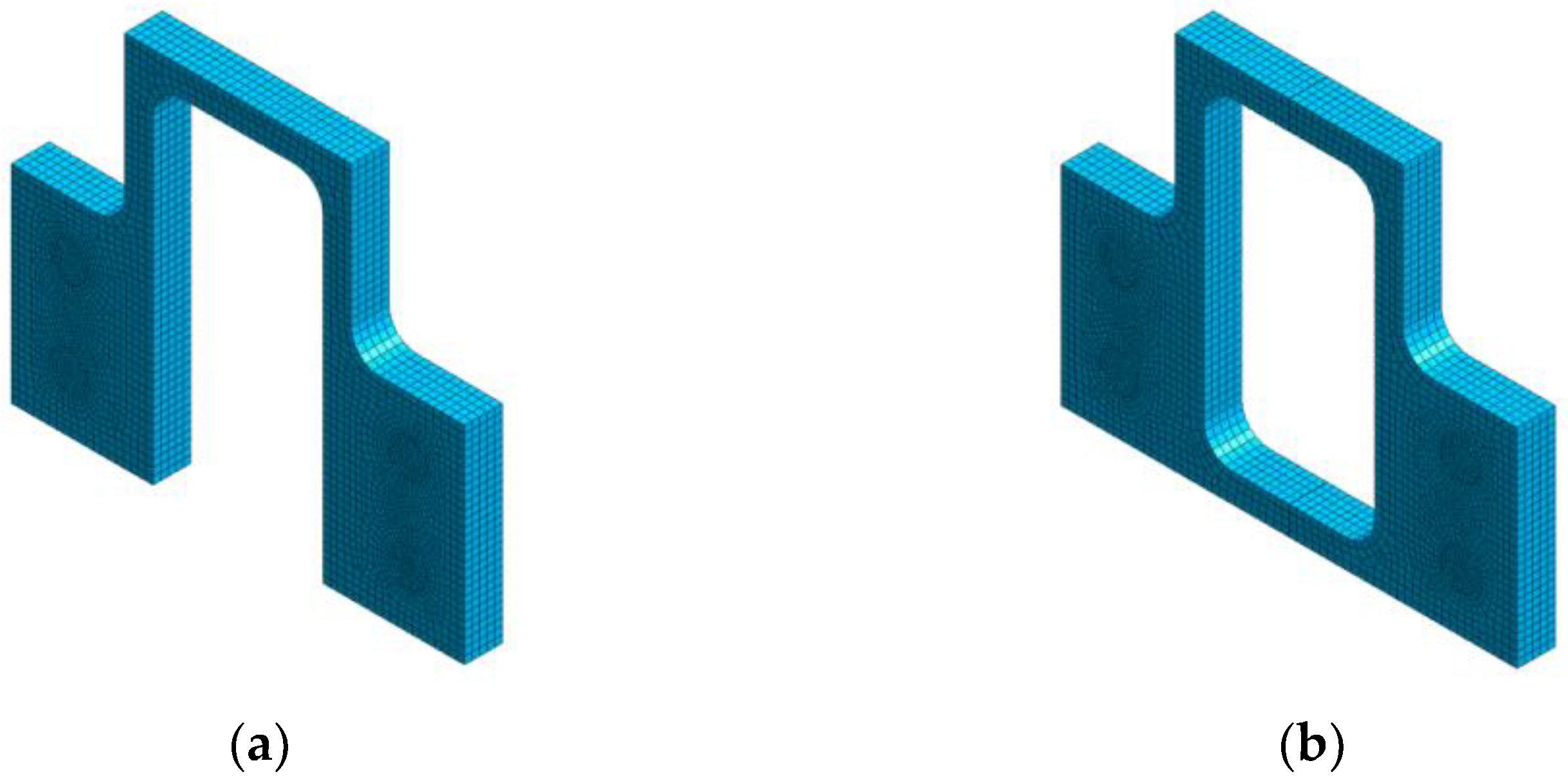

2.1.1. Design of Phase I Test Specimens

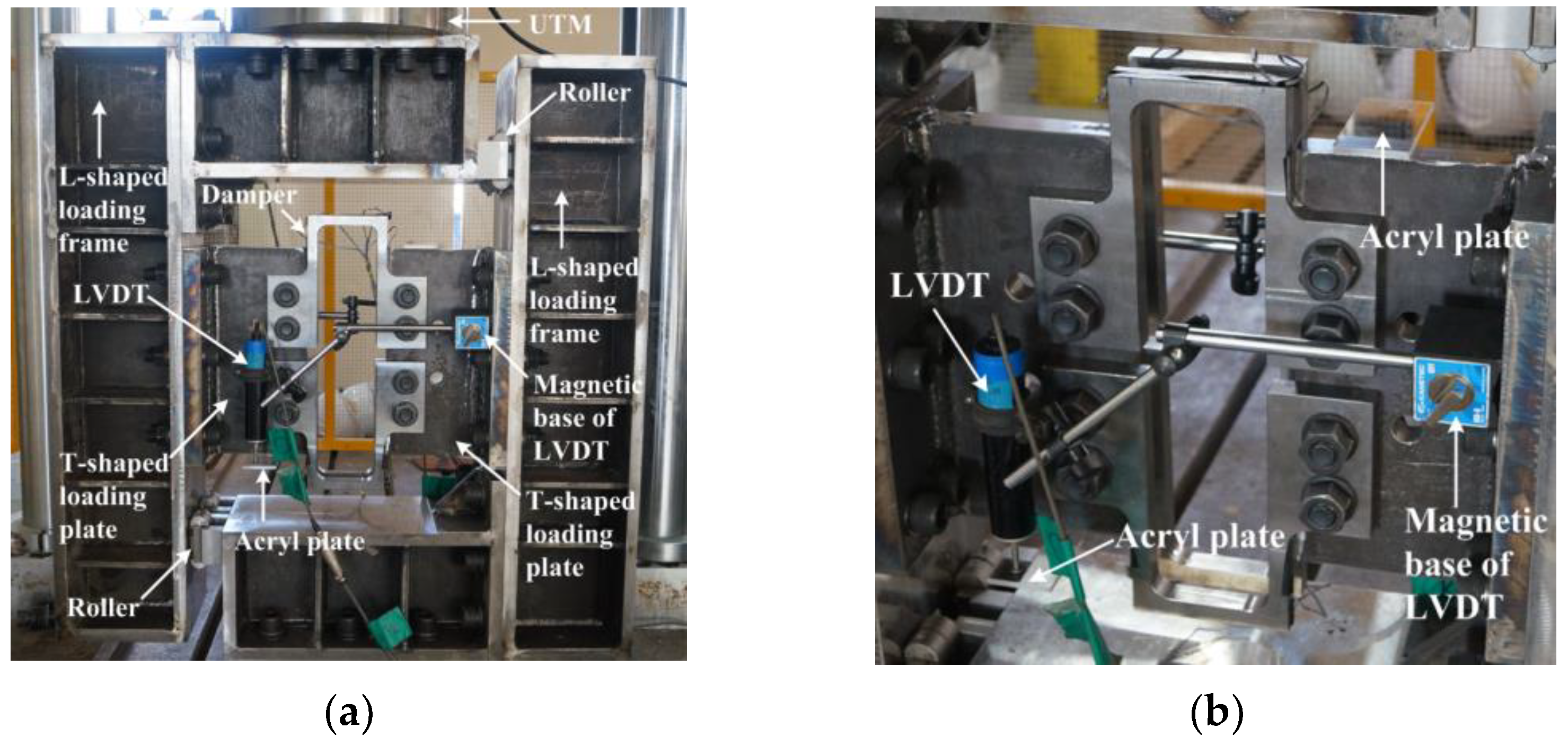

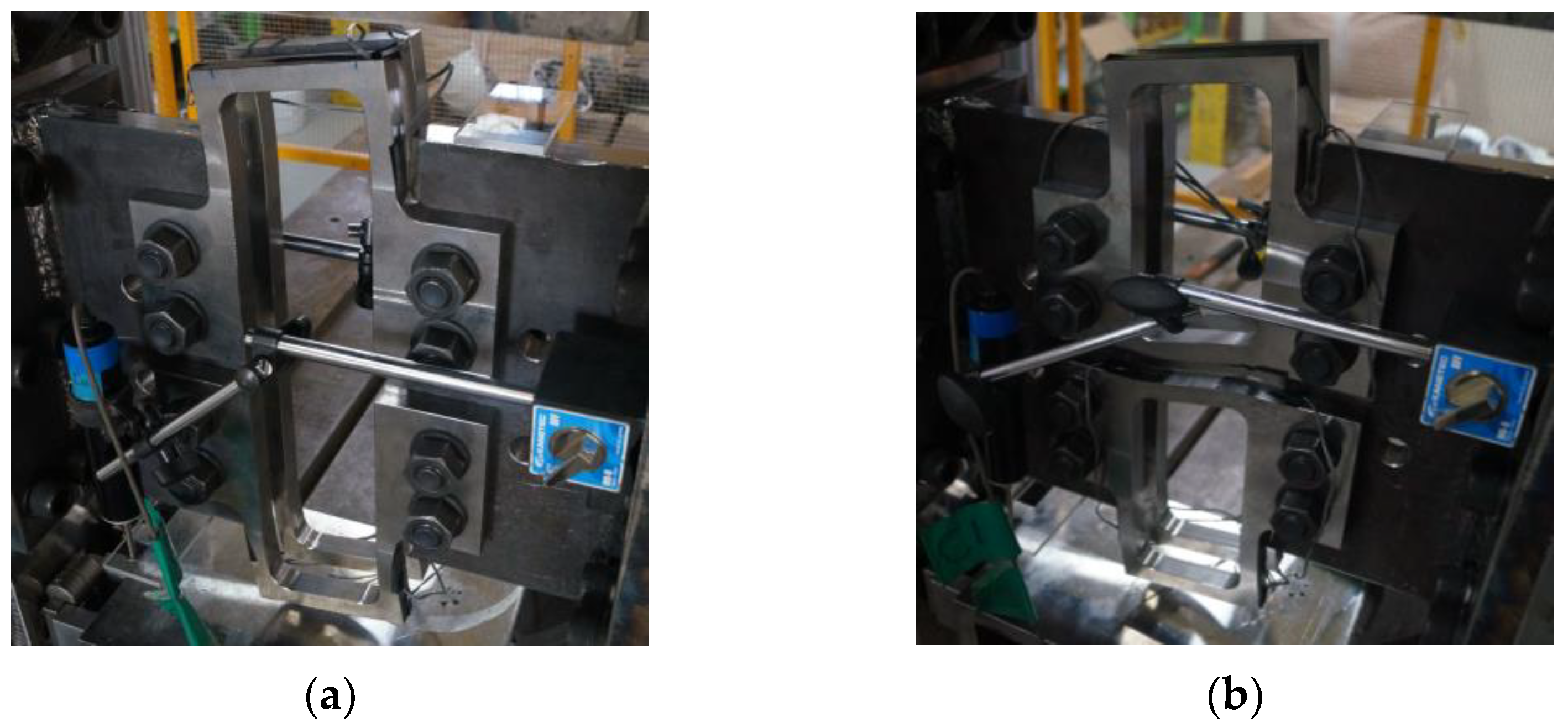

2.1.2. Test Setup and Loading Procedure

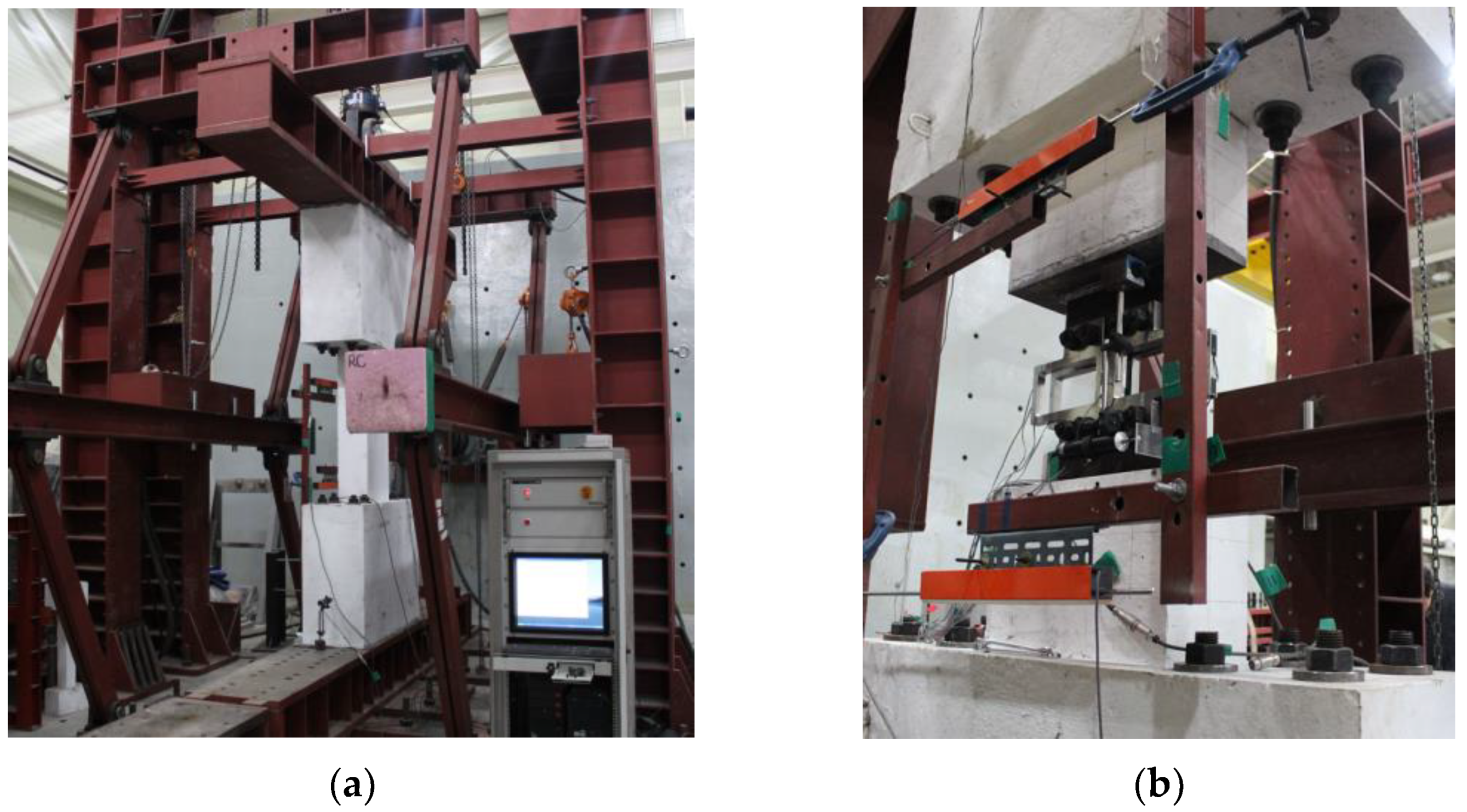

2.2. Phase II Test Program

2.2.1. Design of Phase II Specimens

2.2.2. Test Setup and Loading Procedure

3. Phase I Test Results

3.1. Behavior of Specimens

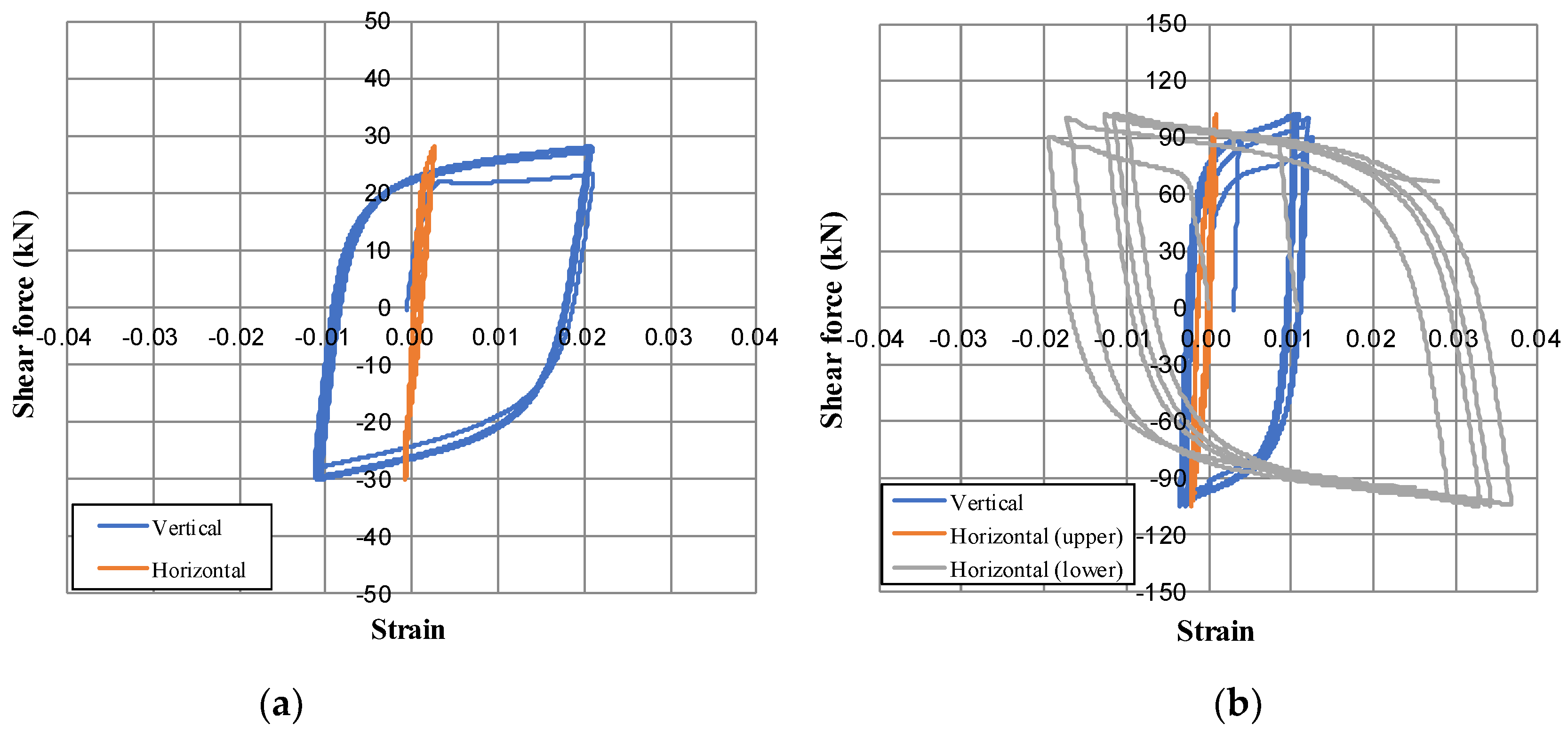

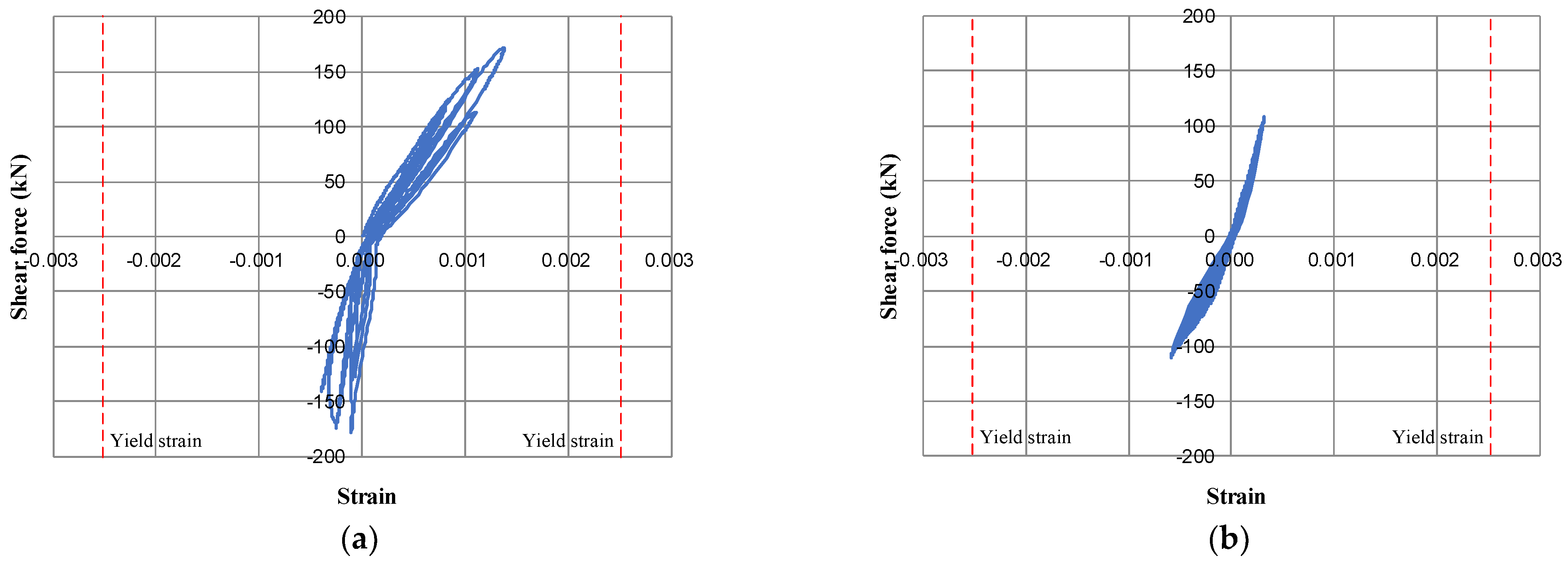

3.2. Strain Distribution

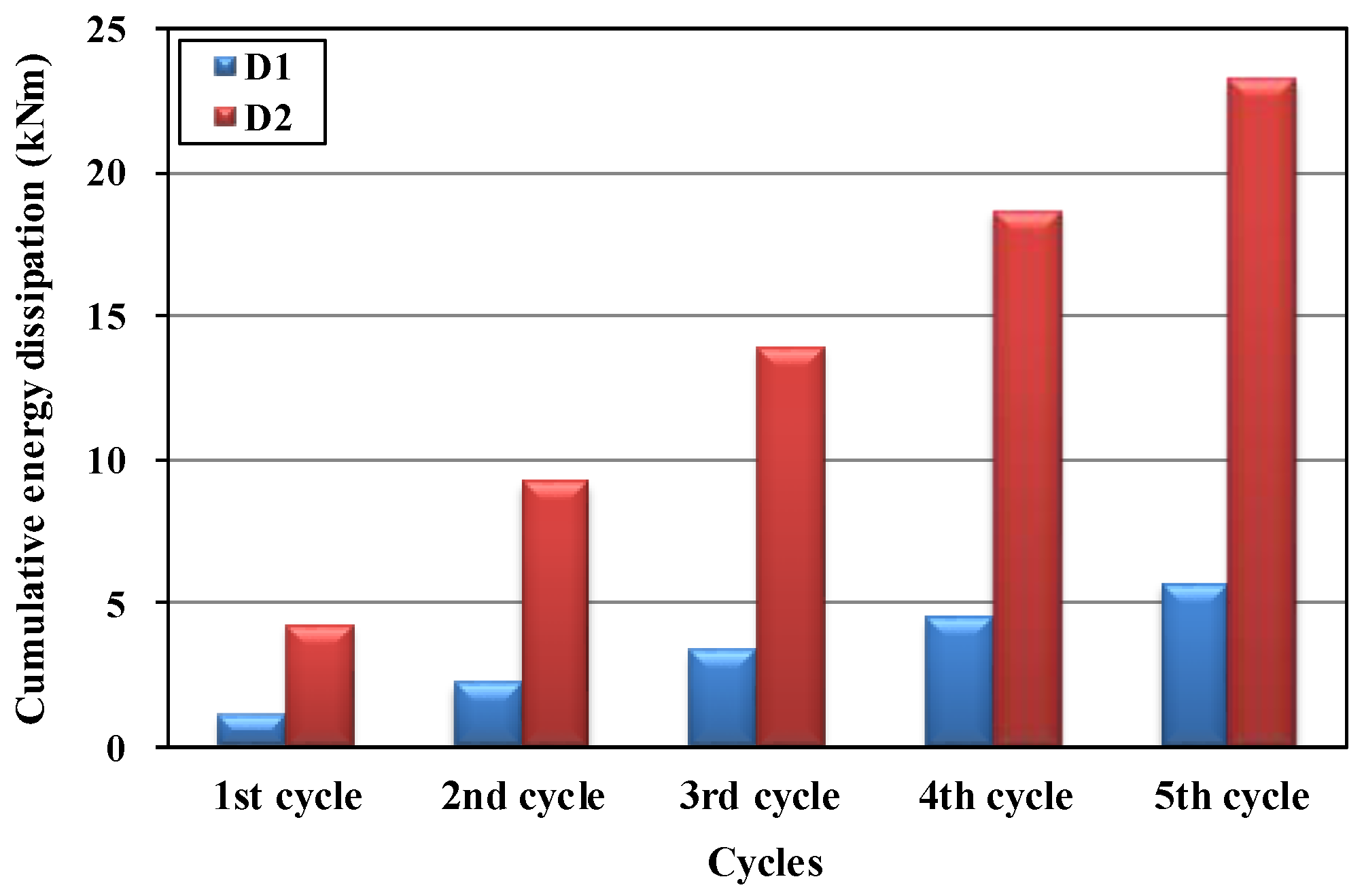

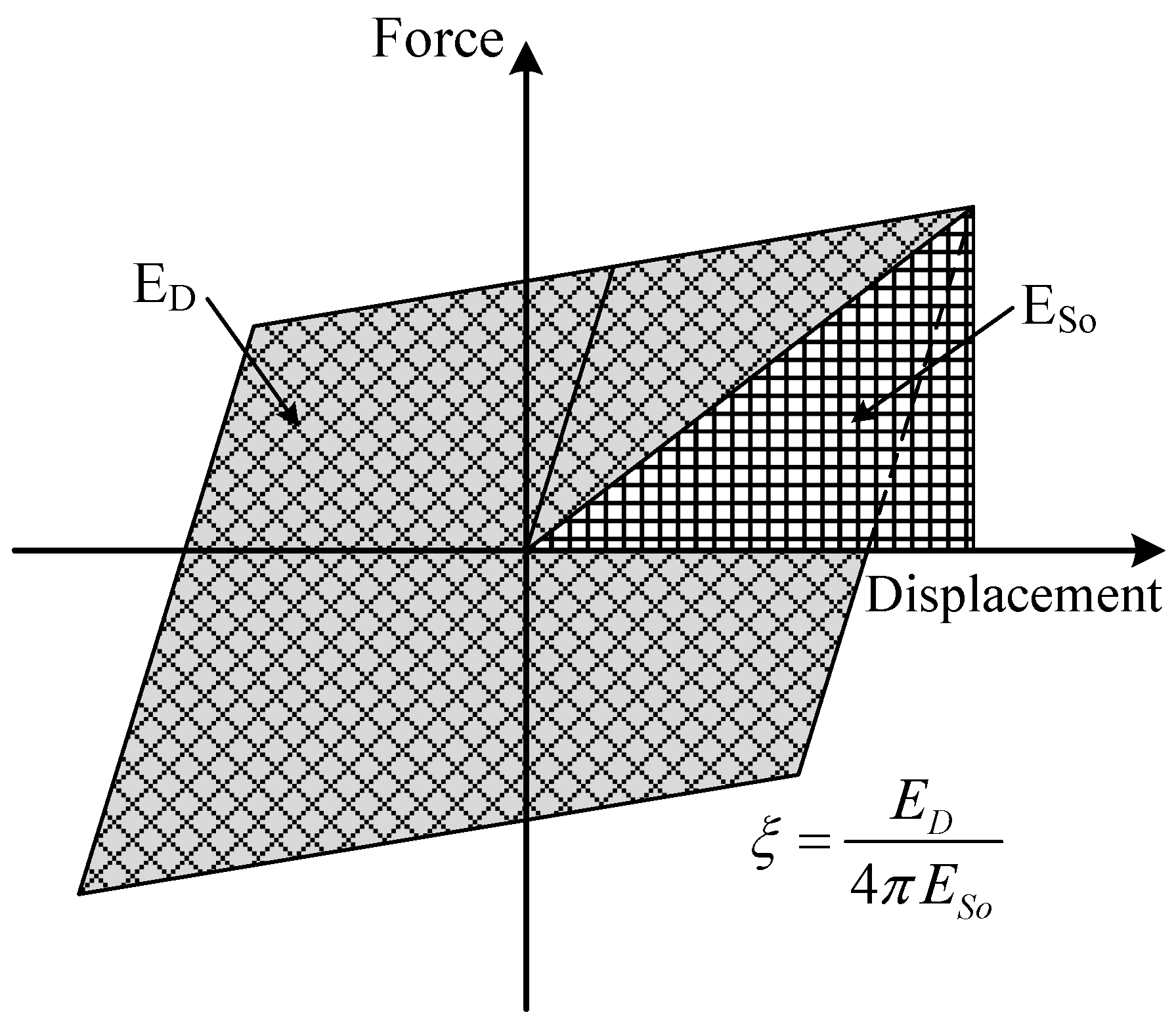

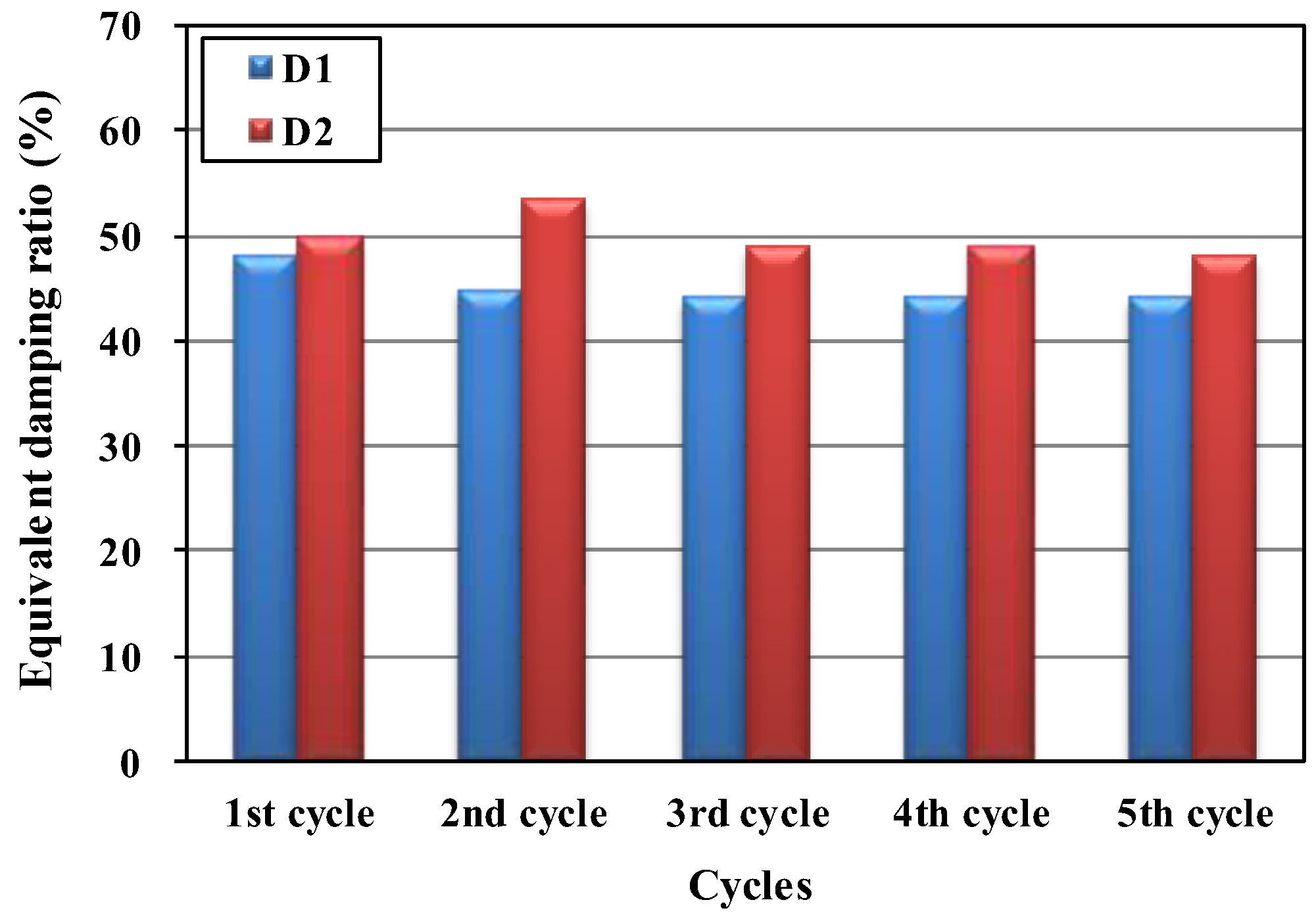

3.3. Energy Dissipation and Damping Capacities

3.4. Stress Distribution by FE Analysis at Target Displacement

4. Phase II Test Results

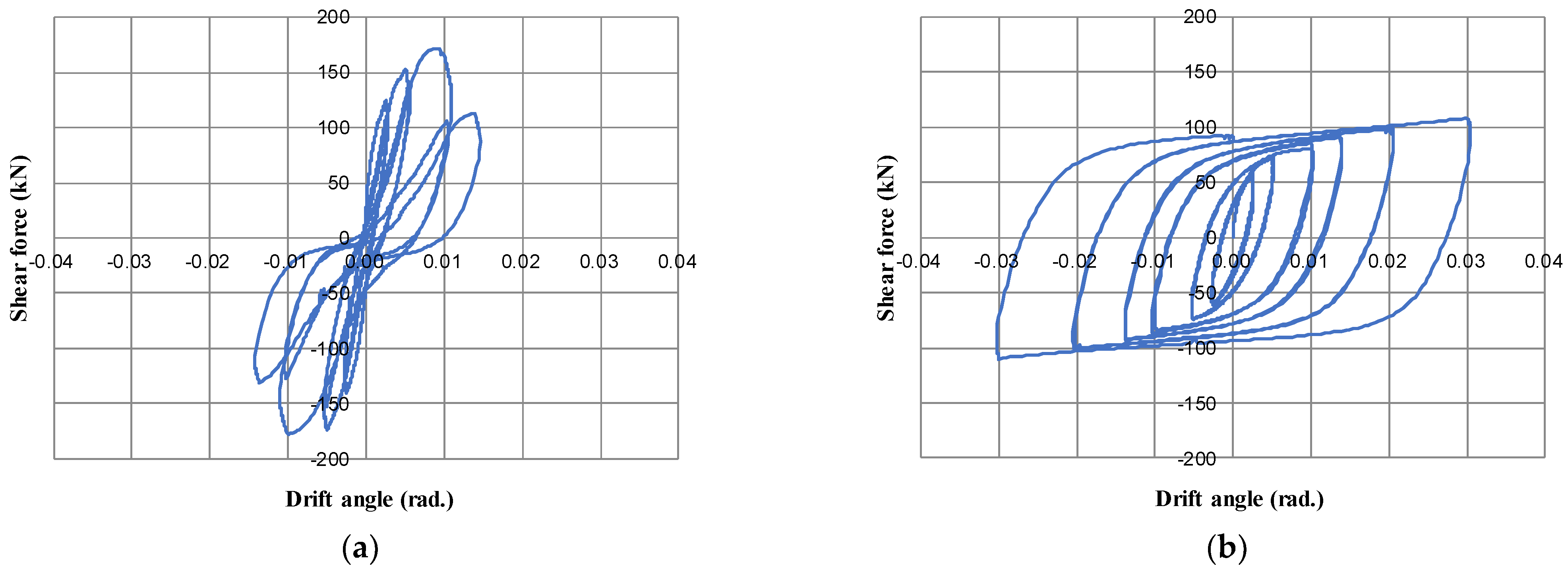

4.1. Shear vs. Drift Angle Relationships

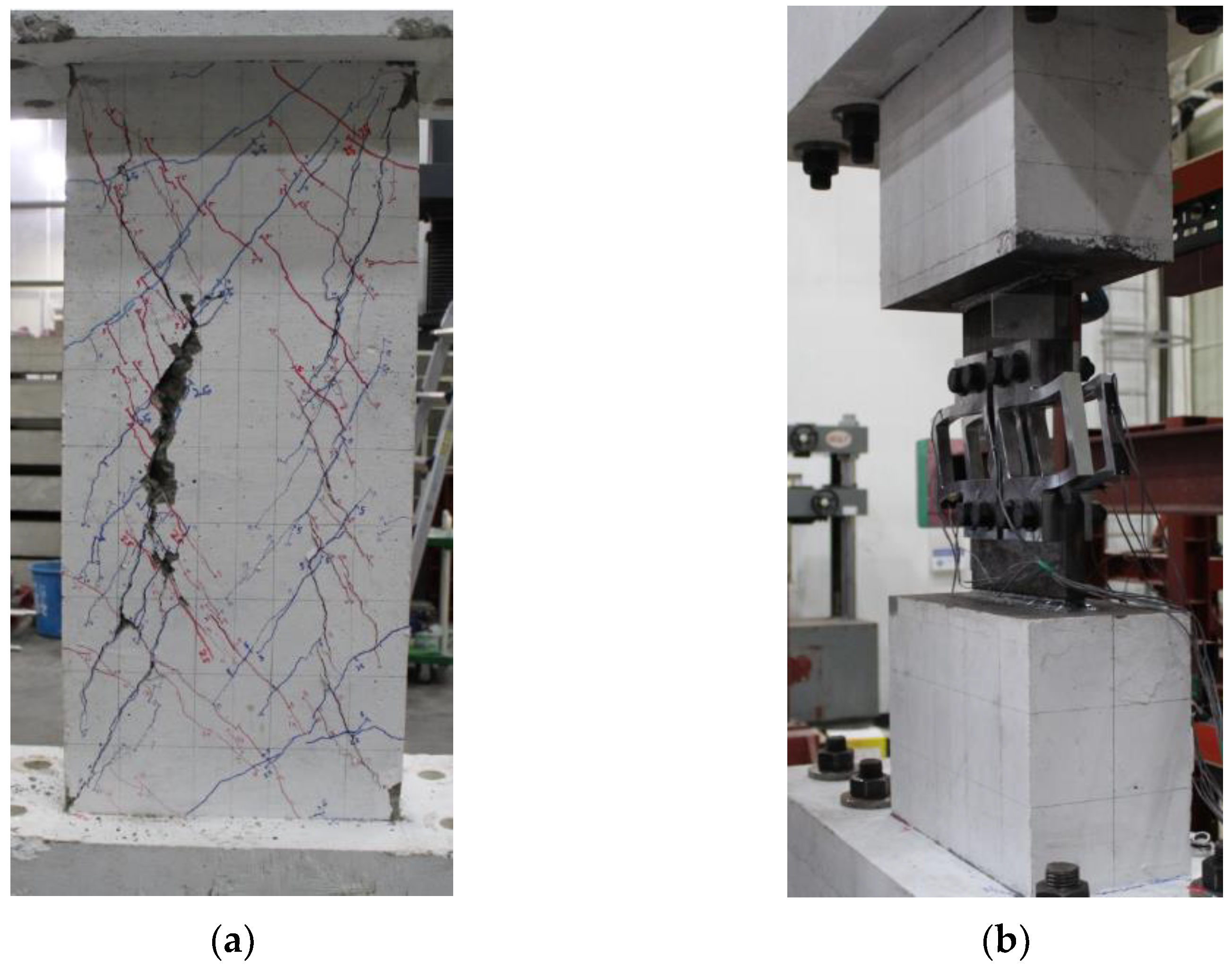

4.2. Crack Patterns and Failure Modes

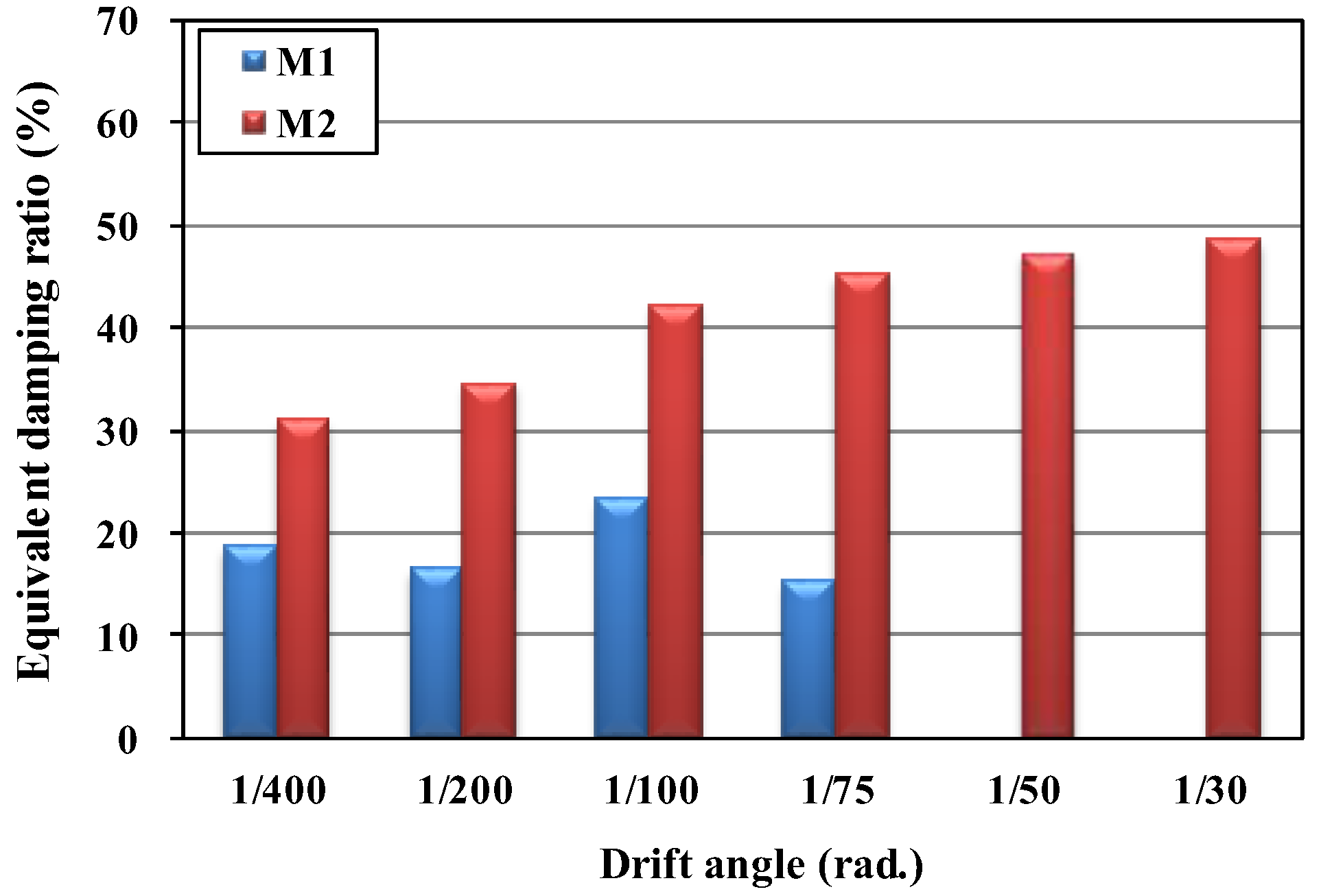

4.3. Energy Dissipation and Damping Capacities

5. Conclusions

- (1)

- The shape of the proposed damper is easy to manufacture and the number and cross-sectional dimensions of the dampers can be changed freely according to the required structural performance. Tests of the structural performance of the proposed damper showed that the strength and stiffness were maintained without decreasing while a repeated load was applied five times up to the target displacement. In addition, no buckling was observed until the end of the experiment.

- (2)

- In the proposed damper, the vertical and upper horizontal members are involved in the ductile behavior and energy dissipation and the lower horizontal member is involved in strength enhancement and energy dissipation. The experimental results of the angled U-shaped steel damper showed that the strength and initial rigidity of the proposed R-type steel damper were increased by around 3.5 and 6.4 times, respectively.

- (3)

- In the Phase I test, the energy dissipation capacity of the proposed damper did not decrease during five repeated loads. In addition, the proposed damper showed an equivalent damping ratio of up to 53.4%, indicating high damping capacity. Similar characteristics were observed in the Phase II test. The Specimen M2 with the proposed damper showed an equivalent damping ratio of up to 48.6%, indicating excellent damping ability.

- (4)

- The region in which energy is dissipated in the damper was similar in the FE analytical and experimental results. Most vertical and lower horizontal members of the proposed damper yielded and showed high strain in the experiment. On the other hand, the upper horizontal member yielded in some areas but contributed to the stable and ductile behavior of the damper.

- (5)

- In the Phase II test, an excellent energy dissipation capacity was measured. In the M1 specimen without the damper, excessive cracking and damage occurred because the RC member resisted the external lateral load. By contrast, the M2 specimen with the proposed R-type steel dampers showed ductile behavior without strength deterioration for a drift angle of up to 3% because the damper effectively dissipated the energy of the external lateral load. Furthermore, hardly any cracks or damage were observed in the M2 specimen. Based on the experimental results, the proposed steel damper can be applied excellently to structures as an energy dissipating device.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Elnashai, A.S.; Disarno, L. Fundamentals of Earthquake Engineering; Wiley and Sons: Chichester, UK, 2008. [Google Scholar]

- Whittaker, A.S.; Bertero, V.V.; Thompson, C.L.; Alonso, L.J. Seismic testing of steel plate energy dissipation devices. Earthq. Spectra 1991, 7, 563–604. [Google Scholar] [CrossRef]

- Shih, M.H.; Sung, W.P. A model for hysteretic behavior of rhombic low yield strength steel added damping and stiffness. Comput. Struct. 2005, 83, 895–908. [Google Scholar] [CrossRef]

- Tsai, K.-C.; Chen, H.-W.; Hong, C.-P.; Su, Y.-F. Design of Steel Triangular Plate Energy Absorbers for Seismic-Resistant Construction. Earthq. Spectra 1993, 9, 505–528. [Google Scholar] [CrossRef]

- Lee, M.; Lee, J.; Kim, J. Seismic retrofit of structures using steel honeycomb dampers. Int. J. Steel Struct. 2017, 17, 215–229. [Google Scholar] [CrossRef]

- Nakashima, M. Strain-Hardening Behavior of Shear Panels Made of Low-Yield Steel. I: Test. J. Struct. Eng. 1995, 121, 1742–1749. [Google Scholar] [CrossRef]

- Foti, D.; Diaferio, M.; Nobile, R. Optimal design of a new seismic passive protection device made in aluminium and steel. Struct. Eng. Mech. 2010, 35, 119–122. [Google Scholar] [CrossRef]

- Choi, J.; Abebe, D.Y. Hysteresis Characteristics of Shear Panel Damper Using SLY120. APCBEE Procedia 2014, 9, 370–375. [Google Scholar] [CrossRef]

- Di Sarno, L.; Manfredi, G. Experimental tests on full-scale RC unretrofitted frame and retrofitted with buckling-restrained braces. Earthq. Eng. Struct. Dyn. 2012, 41, 315–333. [Google Scholar] [CrossRef] [Green Version]

- Teruna, D.R.; Majid, T.A.; Budiono, B. The use of steel damper for enhancing the seismic performance of R/C frame with soft first story. J. Civ. Eng. Res. 2014, 4, 191–202. [Google Scholar]

- Teruna, D.R.; Majid, T.A.; Budiono, B. Experimental Study of Hysteretic Steel Damper for Energy Dissipation Capacity. Adv. Civ. Eng. 2015, 2015, 631726. [Google Scholar] [CrossRef] [Green Version]

- Bagheri, S.; Barghian, M.; Saieri, F.; Farzinfar, A. U-shaped metallic-yielding damper in building structures: Seismic behavior and comparison with a friction damper. Structures 2015, 3, 163–171. [Google Scholar] [CrossRef]

- Jamkhaneh, M.E.; Ebrahimi, A.H.; Amiri, M.S. Experimental and Numerical Investigation of Steel Moment Resisting Frame with U-Shaped Metallic Yielding Damper. Int. J. Steel Struct. 2018, 19, 806–818. [Google Scholar] [CrossRef]

- Sravya, J.S.; Manchalwar, A. Seismic isolation system using U-shaped steel damper. Int. J. Recent Technol. Eng. 2019, 8, 12336–12339. [Google Scholar]

- Lee, J.; Kim, J. Development of box-shaped steel slit dampers for seismic retrofit of building structures. Eng. Struct. 2017, 150, 934–946. [Google Scholar] [CrossRef]

- Shen, X.; Wang, X.; Ye, Q.; Ye, A. Seismic performance of Transverse Steel Damper seismic system for long span bridges. Eng. Struct. 2017, 141, 14–28. [Google Scholar] [CrossRef]

- Abebe, D.Y.; Kim, J.W.; Gwak, G.; Choi, J.H. Low-Cycled Hysteresis Characteristics of Circular Hollow Steel Damper Subjected to Inelastic Behavior. Int. J. Steel Struct. 2018, 19, 157–167. [Google Scholar] [CrossRef] [Green Version]

- Naeem, A.; Kim, J. Seismic performance evaluation of a multi-slit damper. Eng. Struct. 2019, 189, 332–346. [Google Scholar] [CrossRef]

- Qiu, C.; Wang, H.; Liu, J.; Qi, J.; Wang, Y. Experimental tests and finite element simulations of a new SMA-steel damper. Smart Mater. Struct. 2020, 29, 035016. [Google Scholar] [CrossRef]

- Standard Test Methods for Tension Testing of Metallic Materials; ASTM E8/E8M-21; ASTM International: West Conshohocken, PA, USA, 2021.

- Chopra, A.K. Dynamics of Structures, Theory and Applications to Earthquake Engineering, 5th ed.; Pearson Education: London, UK, 2017; 960p. [Google Scholar]

- Web Address of MIDAS-NFX. 2020. Available online: https://kor.midasuser.com/nfx/ (accessed on 11 July 2021).

| Steels | Yield Strength (MPa) | Tensile Strength (MPa) | Yield Strain | Elastic Modulus (×105 MPa) |

|---|---|---|---|---|

| Steel damper | 245 | 420 | 0.00147 | 1.67 |

| D10 (stirrup) | 461 | 600 | 0.00242 | 1.90 |

| D10 (spiral) | 554 | 607 | 0.00275 | 2.01 |

| D19 | 520 | 662 | 0.00260 | 2.00 |

| D22 | 518 | 672 | 0.00258 | 2.01 |

| Specimens | At First Yield | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Cycle | (kN) | Disp. (mm) | Directions | 1st | 2nd | 3rd | 4th | 5th | ||

| D1 | +1st | +18.1 | +1.85 | Positive Negative | 1.28 −1.56 | 1.50 −1.65 | 1.54 −1.66 | 1.55 −1.66 | 1.55 −1.66 | |

| D2 | +1st | +36.0 | +0.57 | Positive Negative | 2.51 −2.77 | 2.79 −2.93 | 2.84 −2.91 | 2.84 −2.90 | 2.84 −2.88 | |

| Speci-mens | Directions | Peak Load and Drift Angle at First Loading of Each Cycle | |||||

|---|---|---|---|---|---|---|---|

| 1/400 | 1/200 | 1/100 | 1/75 | 1/50 | 1/30 | ||

| M1 | Positive | 124.7 (0.0025) | 153.0 (0.005) | 171.4 (0.0088) | 112.8 (0.0139) | - | - |

| Negative | −140.3 (−0.0025) | −174.4 (−0.005) | −177.8 (−0.010) | −131.4 (−0.0137) | - | - | |

| M2 | Positive | 55.3 (0.0025) | 71.2 (0.005) | 81.0 (0.010) | 90.6 (0.0135) | 98.4 (0.02) | 108.0 (0.03) |

| Negative | −60.9 (−0.0026) | −73.2 (−0.0051) | −83.2 (−0.010) | −91.9 (−0.0134) | −100.5 (−0.02) | −110.1 (−0.03) | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.-W.; Kim, K.-H. Structural Performance of R-Type Steel Damper Used in Reinforced Concrete Members. Appl. Sci. 2021, 11, 6404. https://doi.org/10.3390/app11146404

Kim S-W, Kim K-H. Structural Performance of R-Type Steel Damper Used in Reinforced Concrete Members. Applied Sciences. 2021; 11(14):6404. https://doi.org/10.3390/app11146404

Chicago/Turabian StyleKim, Sang-Woo, and Kil-Hee Kim. 2021. "Structural Performance of R-Type Steel Damper Used in Reinforced Concrete Members" Applied Sciences 11, no. 14: 6404. https://doi.org/10.3390/app11146404