2.1. Dataset of the Transformer’s Working Condition and Oil Temperature

The oil temperature working condition dataset of the oil-immersed transformer recorded the parameters related to the operation of the oil-immersed transformer. These parameters included the timestamp of working condition data (OCCUR_TIME); active power of the high-voltage side, medium-voltage side, and low-voltage side (YG_YC_G/Z/D); reactive power of the high-voltage, medium-voltage, and low-voltage side (WG_YC_G/Z/D); power factor of the high-voltage, medium-voltage, and low-voltage side (COS_G/Z/D); AC current RMS value of the high-voltage, medium-voltage, and low-voltage side (I_YC_G); winding temperature of the A/B/C phase (RZWDA/B/C_YC); and the oil temperature of the A/B/C phase (YWA/B/C_YC). The sample period was 5 min. The specific explanation of the above parameters related to the transformer is shown in

Table 1:

The external environment of the transformer can conspicuously influence the heat radiation of the transformer, such as the rise of the transform’s restraining temperature due to cold and windy weather. Therefore, in this paper, the weather data at the location of the transformer were also taken into consideration as important parameters, including the timestamp of weather data (OCCUR_TIME), local temperature (TEMPERATURE), highest temperature of the day (HIGH_TEMPERATURE), lowest temperature of the day (LOW_TEMPERATURETEM), rainfall capacity (RAIN), wind direction (WIND_DIRECTION), wind velocity (WIND_VELOCITY), pressure (PRESSURE), and humidity (HUMIDITY). The sample period was 5 min. The specific explanation of the above parameters related to the weather data is shown in

Table 2:

The formal expression of the dataset for the abnormal oil temperature abnormal diagnosis of transformer in information system is , where X are the attributes of working conditions with weather data and Y are the decision attributes, which are oil temperature from the sensors measurement at 1 phase of the transformer.

2.2. Abnormal Detection of Oil Temperature Based on Bagging Ensemble Learning

Based on background knowledge about the strong correlation between transformer working conditions and oil temperature, this paper proposes an abnormal detection approach of the transformer oil temperature based on bagging ensemble learning. According to bagging ensemble learning, the oil temperature prediction model is organized with a set of base classifiers and their power weights, which are trained in parallel by random sampling from historical working condition datasets and oil temperature datasets with replacements.

The steps of Algorithm 1 are described as follows:

| Algorithm 1. Oil Temperature Prediction Based on Bagging Ensemble Learning. |

| Input: Training dataset , which includes the historical working condition dataset of transformer , historical oil temperature dataset Y, and initial base classifiers . |

| Output: Trained base classifiers and their power weights . |

| The Steps of Algorithm 1: |

| Step 1. Sample k training datasets from independently from with corresponding , where and . |

| Step 2. Train base classifier from training set . Therefore, training datasets from can independently construct base classifiers . |

| Step 3. The expected value of predicted oil temperature can be calculated as from k prediction results of , according to , and , where and . |

| Step 4. Algorithm ends. |

According to trained base classifiers and their power weights from Algorithm 1, the present oil temperature can be predicted from the present working condition data.

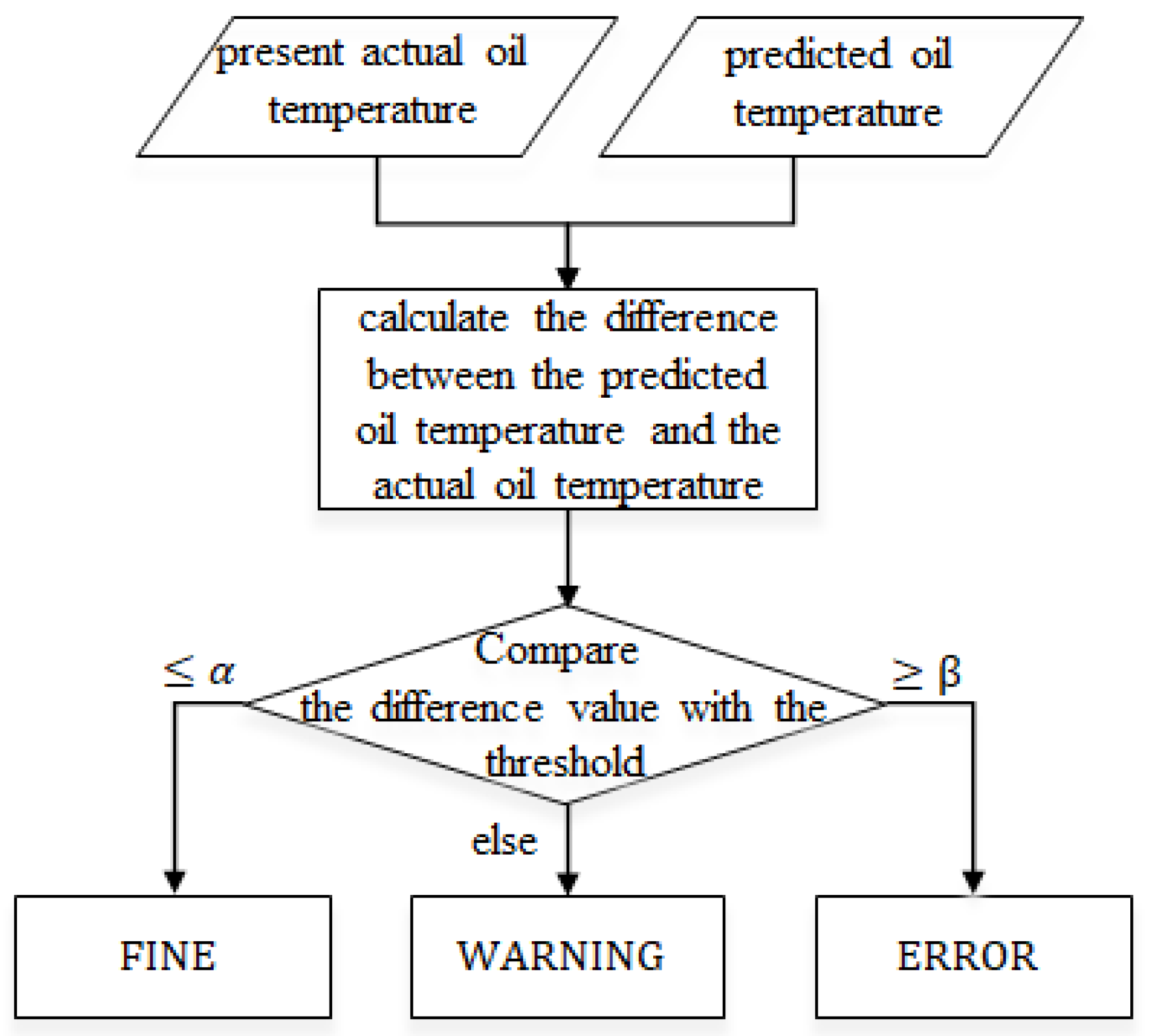

Furthermore, through 2 preset thresholds

, the deviation rates between the predicted oil temperature and actual oil temperature can be used to judge the present working state of the transformer using the 3-way decision-making rule. The flowchart of the 3-way decision-making rule is shown in

Figure 1.

The detailed steps of Algorithm 2 are described as follows:

| Algorithm 2. Abnormal Detection of the Transformer’s Working State. |

| Input: Present working condition data , present actual oil temperature , k base classifiers and their power weights , and 2 preset thresholds and . |

| Output: k base classifiers and their power weights , working state of transformer . |

| The Steps of Algorithm 2: |

| Step 1. Input the present transformer’s working condition data into trained base classifiers , respectively, and obtain k values of prediction . |

| Step 2. Calculate the expected value of k prediction results as the present predicted oil temperature. |

| The steps of Algorithm 2 are described as follows: |

| Step 2.1. If , then the working state of transformer , and the algorithm ends. Otherwise, it goes to the next step. |

| Step 2.2. If , then the working state of transformer , which means the transformer has potential problems but can still work, and the algorithm ends. Otherwise, go to the next step. |

| Step 2.3. If , then the working state of transformer , which means the transformer has serious problems and should stop to overhaul. |

| Step 3. Algorithm ends and outputs , , and . |

The above oil temperature prediction and abnormal detection model based on bagging ensemble learning is the foundation of the oil temperature abnormal diagnosis method in this paper. However, if concept drift occurs in the working condition dataset of the transformer, then the prediction and abnormal detection model will have obvious bias and inevitably lead to the incorrect diagnosis result.

2.3. Concept Drift Solution of Oil Temperature Prediction and Abnormal Detection Model

Given that the specified factors, such as the aging of the transformer’s components, cause the fluctuation of the transformer’s working condition feature, concept drift always influences the result of oil temperature prediction. Therefore, in this paper, a concept drift solution based on performance testing is proposed to reduce the influence of concept drift.

Suppose that, during timeseries , there is transformer’s working condition data series and the actual oil temperature data series , where represents the working condition data at time, and represents the oil temperature data at time. According to the transformer’s working condition data series , the predicted oil temperature results can be obtained from the oil temperature prediction model.

Definition 1. Relative Error Rate of Oil Temperature Prediction.

The relative error rate is the quotient of the absolute difference between the predicted oil temperature and actual oil temperature divided by actual oil temperature. The formal equation of relative error rate

at time

is as follows:

Hence, the set of relative error rate during all time is .

The preset threshold of relative error rate is defined as the warning trigger. If the relative error rate is greater than threshold , then the prediction result considers that concept drift occurred. Otherwise, the prediction is considered without influence from concept drift.

Definition 2. Three-Way Decision-Making Rule of Conceptual Drift Whether Influences Oil Temperature Predictionor not.

The thresholds of the 3-way decision-making rule were preset as and . Suppose that the set of relative error rate exists k elements which are less than the warning threshold defined in definition 1. If k is greater than or equal to the threshold , then concept drift influences prediction model, and the detection result will be = ‘With Influence of Concept Drift’. If k is less than or equal to the threshold , then there is no influence of concept drift on prediction model, and detection result will be = ‘Without Influence of Concept Drift’. If k is less than the threshold but greater than the threshold , then the decision will be delayed, and detection result will be = ‘Delay to Make Decision’.

According to Definition 2, the formal expression of 3-way decision-making rule is:

Note: k is the number of .

Based on definition 2, a concept drift detection algorithm is proposed in this paper. When the relative error rates of a specified number of base classifiers are higher than the preset thresholds, the decision can be made that concept drift has occurred and has obviously influenced the result of the prediction model.

Moreover, to reduce the influence of concept drift on the prediction model, we designed a concept drift detection algorithm. The flowchart of concept drift adaptation is shown in

Figure 2.

First, use the concept drift detection algorithm (see Algorithm 3 for details) to detect whether the current concept drift occurs. The process is to calculates the relative error rate on the prediction data using the oil temperature prediction algorithm, and then obtain the detection result through Definition 2. If the result is that the concept drift did not happen, the algorithm ends. If the result requires a delayed decision, then update the prediction data and redetect the concept drift. If the result is that the concept drift happens, the oil temperature prediction model must be adjusted (see Algorithm 4 below for details). The following is a detailed description of Algorithm 3, the detection algorithm of concept drift.

| Algorithm 3. Concept Drift Detection Algorithm. |

| Input: The present transformer’s working condition data series , k base classifiers and their power weights , and the present actual oil temperature data series . |

| Output: The prediction result matrix of all base classifiers and the decision of concept drift detection result . |

| The Steps of Algorithm 3: |

| Step 1. Initialize the delay decision threshold and the count number of delay decision . |

| Step 2. Input the transformer’s working condition data series into k base classifiers , and, respectively, obtain the prediction results:. |

| Note: and |

| Step 3. Calculate the expected value of prediction based on , where , and . |

| Step 4. According to Definition 1, calculate relative error rate and . |

| Step 5. According to the 3-way decision-making rule in Definition 2, the decision , whether to use the concept drift influence prediction model or not, will be made by the count number of relative error rate set , which are less than the warning threshold . |

| Step 5.1. If the decision = ‘With Influence of Concept Drift’, then go to Step 6 and output the decision and the prediction result matrix . |

| Step 5.2. If the decision = ‘Without Influence of Concept Drift’, then go to Step 6 and output the decision . |

| Step 5.3. If the decision = ‘Delay to Make Decision’, then update the count number of delay decision to and compare with the delayed decision threshold as following: |

| Step 5.3.1. If , then return to Step 5.1. |

| Step 5.3.2. if , then update the transformer working condition data series and oil temperature data series and return to Step 2. |

| Step 6. Algorithm ends. |

According to the decision from Algorithm 3, the update of prediction model will be executed only when the decision is ‘With Influence of Concept Drift’.

Based on the decision of the concept drift detection result and the prediction result matrix of all base classifiers, the adaptive update algorithm of base classifiers tends to update each base classifier and their power weight to reduce the influence of concept drift the following Adaboost ensemble learning approach if the decision of concept drift = ‘With Influence of Concept Drift’.

The Adaptive Update Algorithm of Base Classifiers is described as follows:

| Algorithm 4. Adaptive Update Algorithm of Base Classifiers Based on Adaboost Ensemble Learning. |

| Input: Prediction result matrix , present transformer’s working condition data series , k base classifiers and their power weights , present actual oil temperature data series , and historical training data set . |

| Output: Updated base classifiers and their updated power weights . |

| The Steps of Algorithm 4: |

| Step 1. Initialize the sample weight , where , and , and . |

| Step 2. Update the base classifiers and their power weights . |

| Step 2.1. Sample M data from to obtain training dataset |

| Step 2.2. Train base classifier based on , and calculate total error rate , where is the predicted oil temperature. |

| Step 2.3. Update the power weight of base classifier . |

| (3) |

| Step 2.4. Update all sample weights , and . |

| (4) |

| Step 2.5. Normalize the sample weights to make . |

| Step 2.6. Set , and return to Step 2.1 until . |

| Step 2.7. Normalize the power weights to make . |

| Step 3. Expected value of predicted oil temperature can be calculated as: |

| (5) |

| where , and . |

| Step 4. Algorithm ends. |

In summary, Algorithm 1 (Oil Temperature Prediction Based on Bagging Ensemble Learning) was first utilized to construct k base classifiers and their power weights. Then, Algorithm 2 (Abnormal detection of the transformer’s working state) was utilized for the transformer’s abnormal oil temperature diagnosis. After a period of time, Algorithm 3 (Concept Drift Detection Algorithm) was used to evaluate the influence of concept drift. If the concept drift did not influence the prediction result of model such that = ‘Without Influence of Concept Drift’, then the working state S of the transformer from Algorithm 2 was the final decision of diagnosis. If the concept drift happened and influenced the prediction of model such that = ‘With Influence of Concept Drift’, then Algorithm 4 (Adaptive Update Algorithm of Base classifiers Based on Adaboost ensemble learning) was used to update the base classifiers and their power weight. Then, we returned to Algorithm 2 again to obtain the final working state S of the transformer.