Hydrothermal Carbonization of Spent Coffee Grounds

Abstract

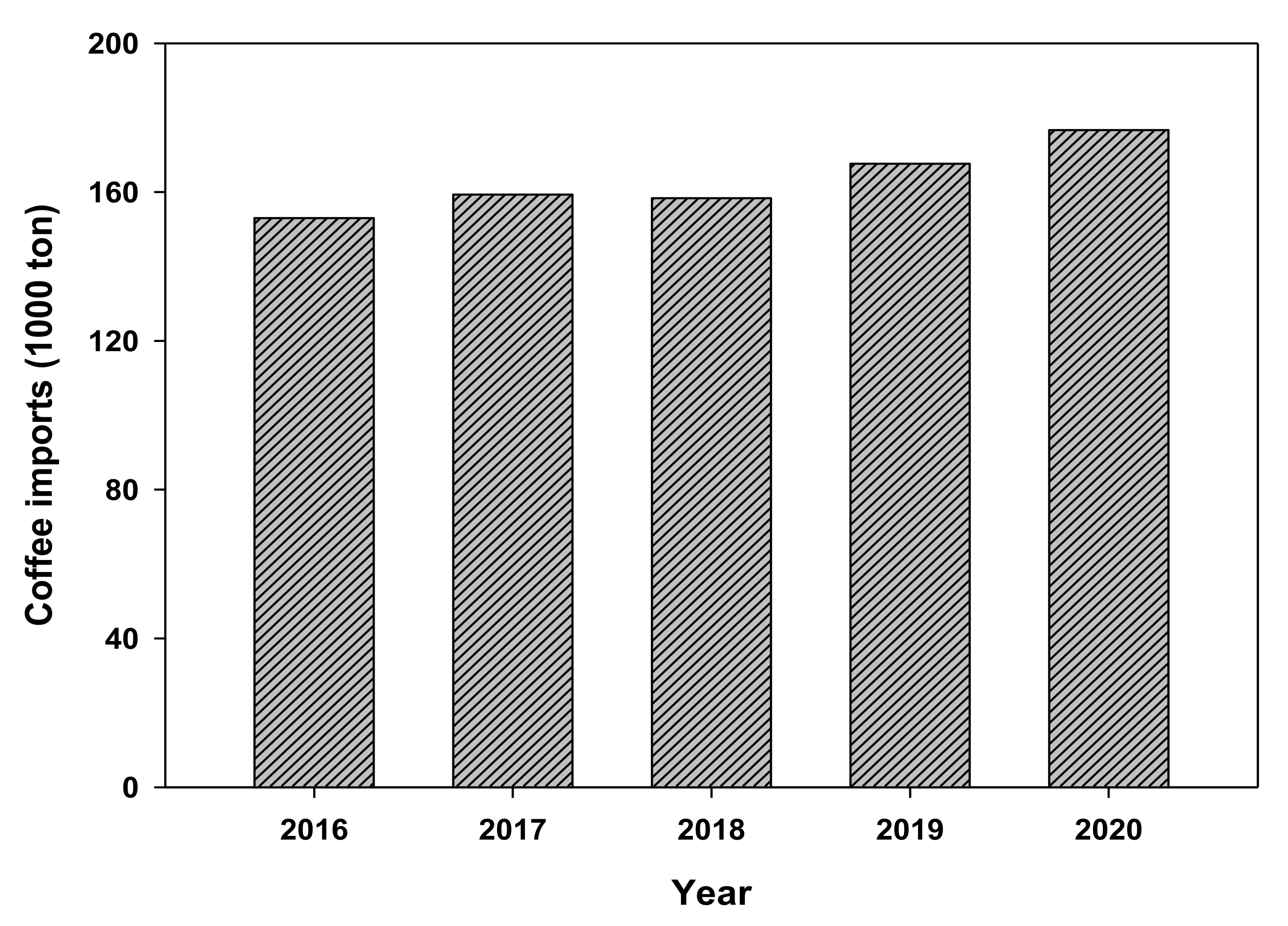

:1. Introduction

2. Materials and Methods

2.1. Experimental Apparatus

2.2. Materials

2.3. Experimental Methods

3. Results and Discussion

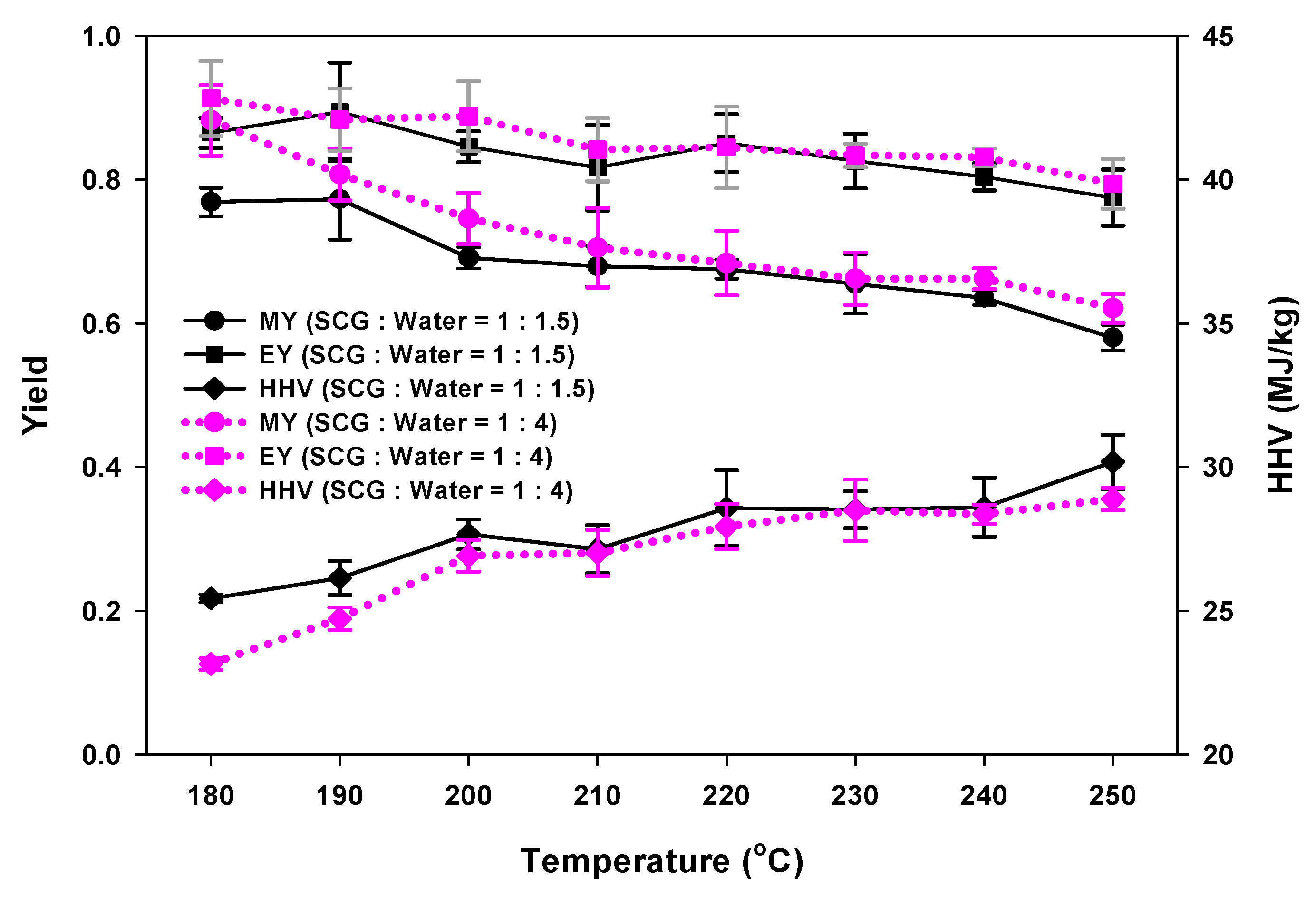

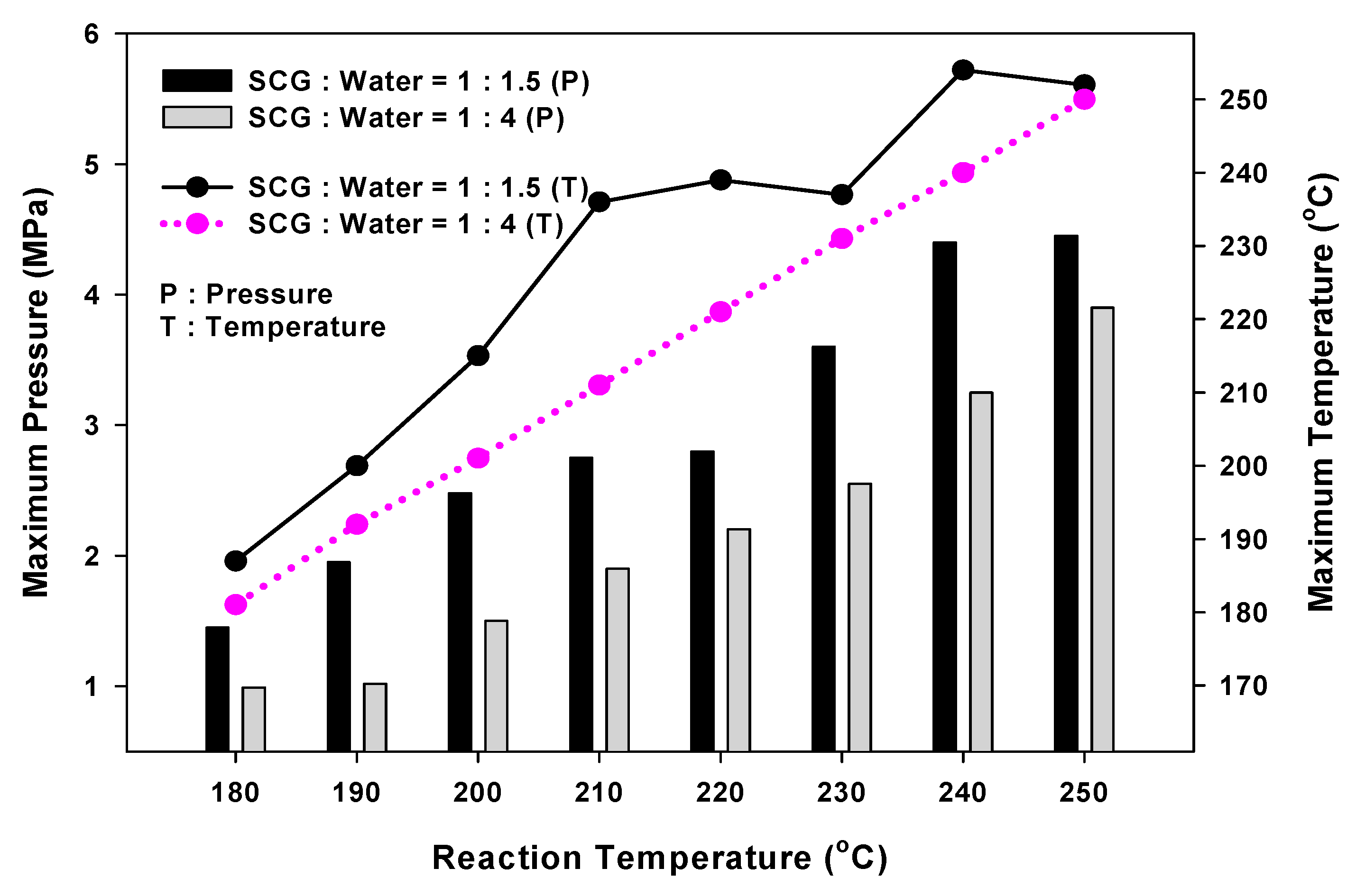

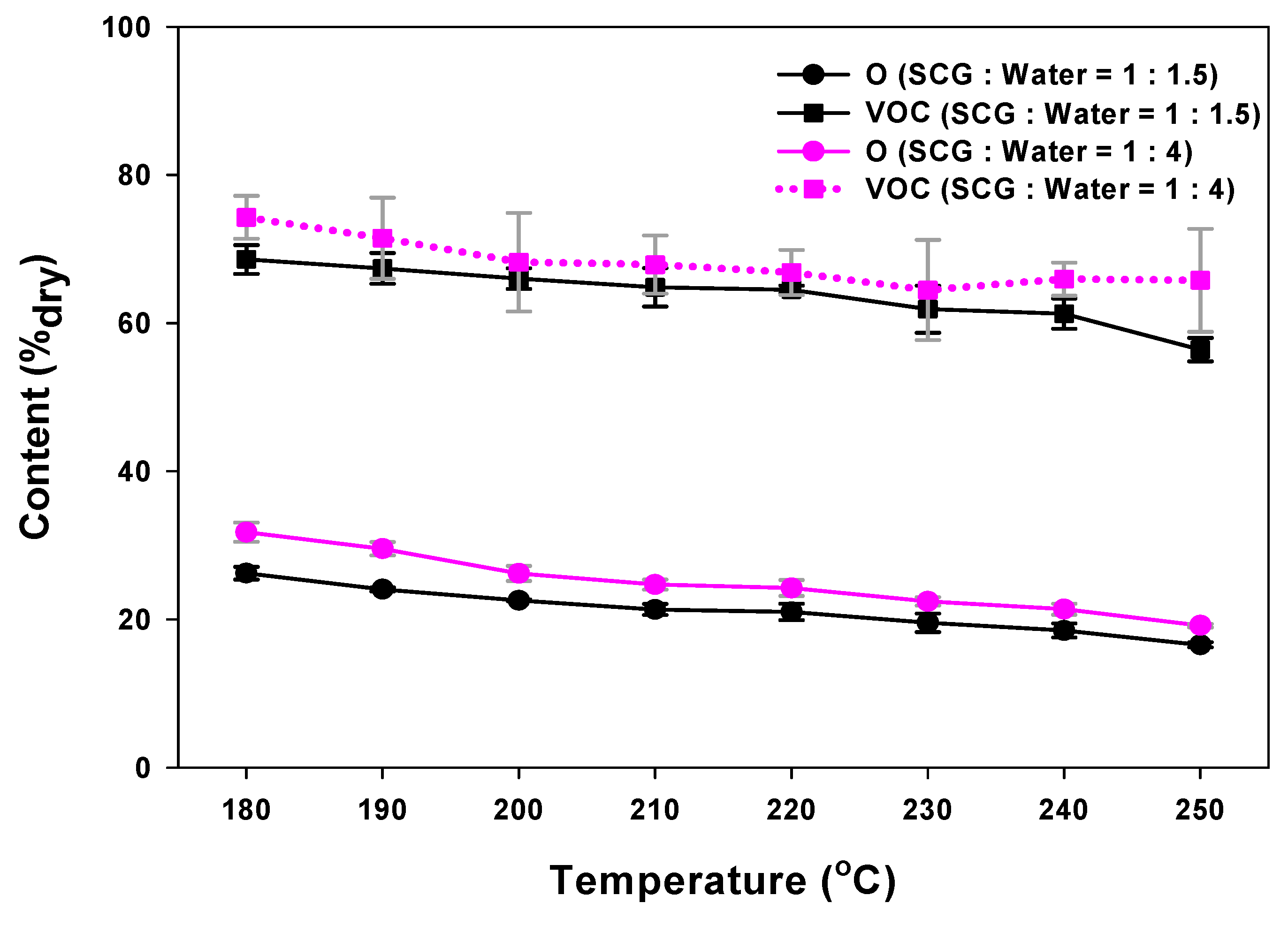

3.1. Mass and Energy Yields

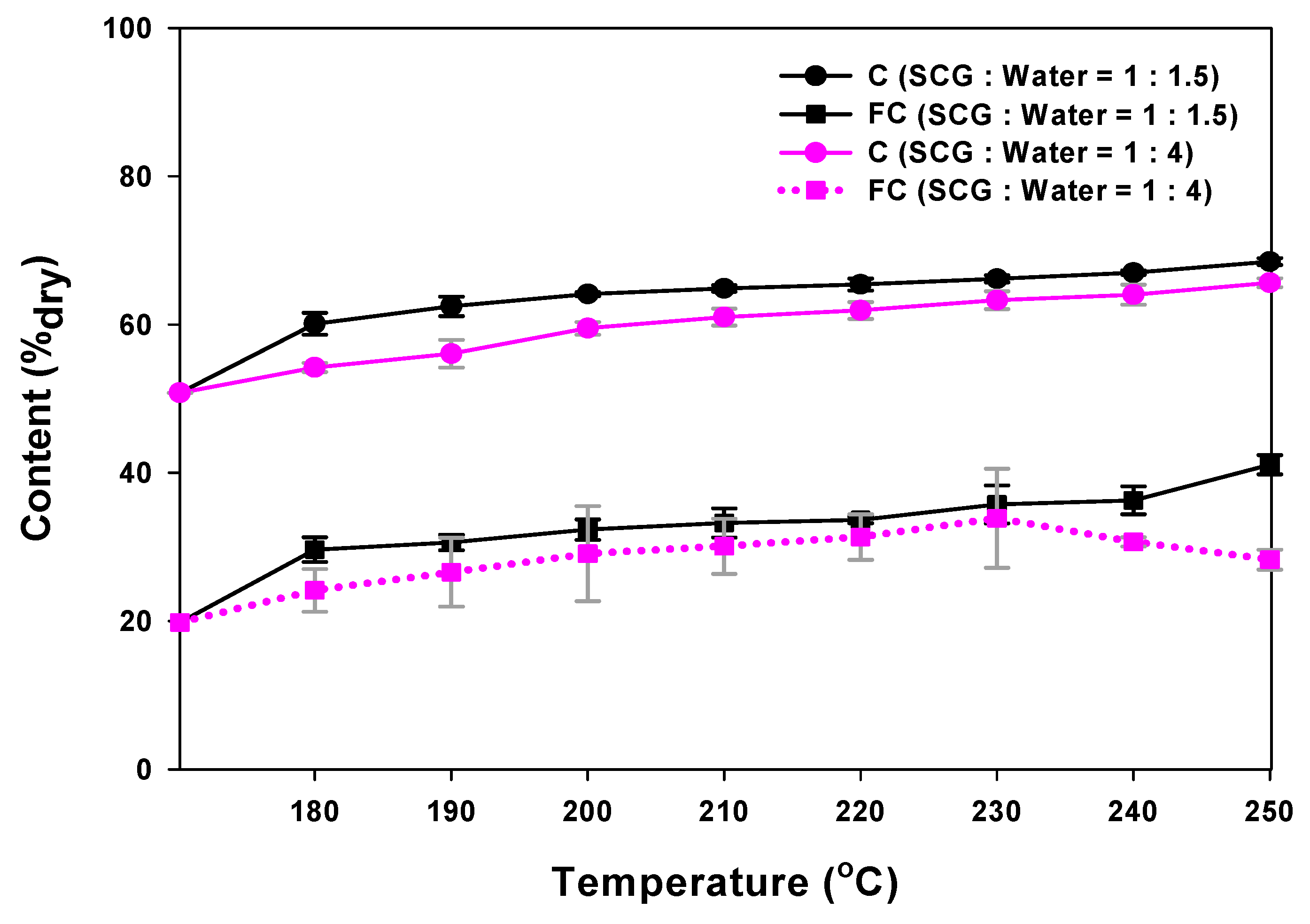

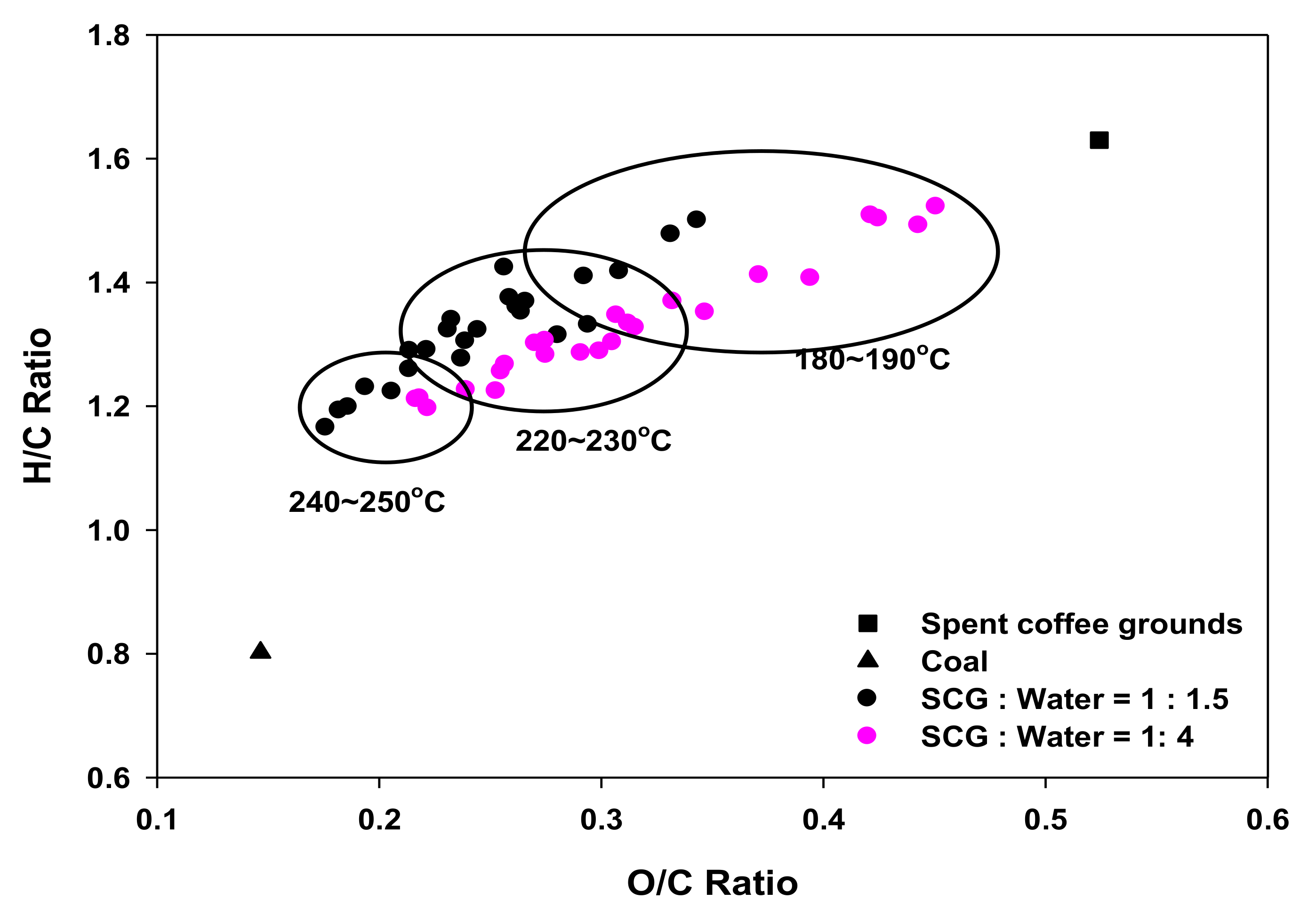

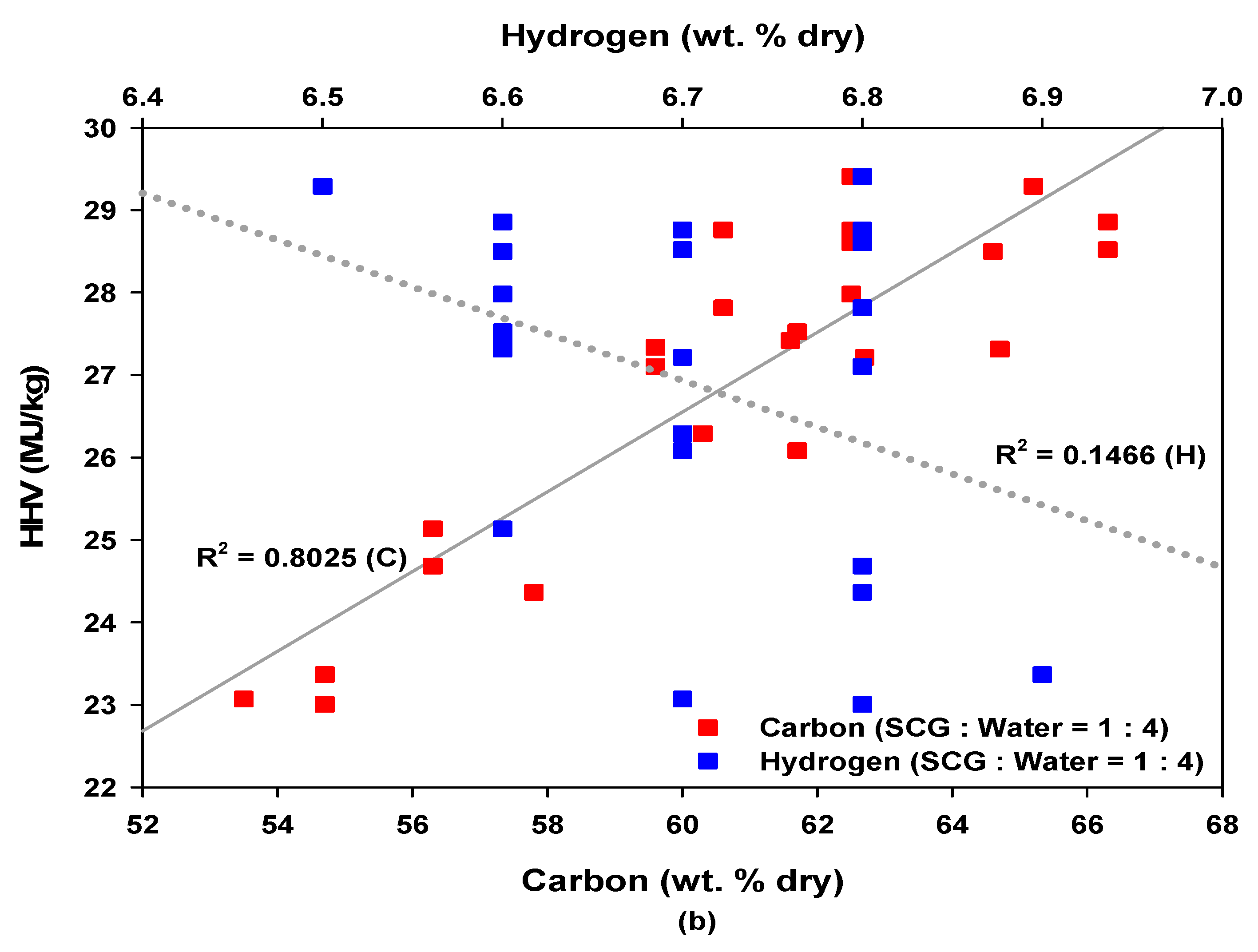

3.2. Fuel Characteristics

3.3. TGA/DTG, FT-IR, and COD Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| SCGs | Spent coffee grounds |

| TGA | Thermogravimetric analysis |

| DTG | Derivative thermogravimetry |

| FT-IR | Fourier transform infrared spectroscopy |

| HHV | Higher heating value |

| VM | Volatile matter |

| FC | Fixed carbon |

| COD | Chemical oxygen demand |

References

- Korea Customs Service. Coffee Market in South Korea with Coffee Trade; Korea Customs Service: Daejeon, Korea, 2021.

- Bok, J.P.; Choi, H.S.; Choi, Y.S.; Park, H.C.; Kim, S.J. Fast Pyrolysis of Coffee Grounds: Characteristics of Product Yields and Biocrude Oil Quality. Energy 2012, 47, 17–24. [Google Scholar] [CrossRef]

- Campos-Vega, R.; Loarca-Piña, G.; Vergara-Castañeda, H.A.; Oomah, B.D. Spent Coffee Grounds: A Review on Current Research and Future Prospects. Trends Food Sci. Technol. 2015, 45, 24–36. [Google Scholar] [CrossRef]

- Kondamudi, N.; Mohapatra, S.K.; Misra, M. Spent Coffee Grounds as a Versatile Source of Green Energy. J. Agric. Food Chem. 2008, 56, 11757–11760. [Google Scholar] [CrossRef] [PubMed]

- Vakalis, S.; Moustakas, K.; Benedetti, V.; Cordioli, E.; Patuzzi, F.; Loizidou, M.; Baratieri, M. The “COFFEE BIN” Concept: Centralized Collection and Torrefaction of Spent Coffee Grounds. Environ. Sci. Pollut. Res. Int. 2019, 26, 35473–35481. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Strezov, V.; Kan, T. Energy Recovery Potential Analysis of Spent Coffee Grounds Pyrolysis Products. J. Anal. Appl. Pyrol. 2014, 110, 79–87. [Google Scholar] [CrossRef]

- Afolabi, O.O.D.; Sohail, M.; Cheng, Y.L. Optimisation and Characterisation of Hydrochar Production from Spent Coffee Grounds by Hydrothermal Carbonisation. Renew. Energy 2020, 147, 1380–1391. [Google Scholar] [CrossRef]

- Funke, A.; Ziegler, F. Hydrothermal Carbonization of Biomass: A Summary and Discussion of Chemical Mechanisms for Process Engineering. Biofuels Bioprod. Bioref. 2010, 4, 160–177. [Google Scholar] [CrossRef]

- Wang, Y.; Qiu, L.; Zhu, M.; Sun, G.; Zhang, T.; Kang, K. Comparative Evaluation of Hydrothermal Carbonization and Low Temperature Pyrolysis of Eucommia Ulmoides Oliver for the Production of Solid Biofuel. Sci. Rep. 2019, 9, 5535. [Google Scholar] [CrossRef] [Green Version]

- Yang, T.; Liu, X.; Li, R.; Li, B.; Kai, X. Hydrothermal Liquefaction of Sewage Sludge to Produce Bio-Oil: Effect of Co-Pretreatment with Subcritical Water and Mixed Surfactants. J. Supercrit. Fluids 2019, 144, 28–38. [Google Scholar] [CrossRef]

- Lynam, J.G.; Coronella, C.J.; Yan, W.; Reza, M.T.; Vasquez, V.R. Acetic Acid and Lithium Chloride Effects on Hydrothermal Carbonization of Lignocellulosic Biomass. Bioresour. Technol. 2011, 102, 6192–6199. [Google Scholar] [CrossRef]

- Toor, S.S.; Rosendahl, L.; Rudolf, A. Hydrothermal Liquefaction of Biomass: A Review of Subcritical Water Technologies. Energy 2011, 36, 2328–2342. [Google Scholar] [CrossRef]

- Siskin, M.; Katritzky, A.R. Reactivity of Organic Compounds in Hot Water: Geochemical and Technological Implications. Science 1991, 254, 231–237. [Google Scholar] [CrossRef]

- Henge, M.H.; Macko, S.A. (Eds.) Organic. Geochemistry; Plenum Press: New York, NY, USA, 1993; Volume 23, pp. 72–419. [Google Scholar]

- Bobleter, O. Hydrothermal Degradation of Polymers Derived from Plants. Prog. Polym. Sci. 1994, 19, 797–841. [Google Scholar] [CrossRef]

- Mok, W.S.L.; Antal, M.J.; Szabo, P.; Varhegyi, G.; Zelei, B. Formation of Charcoal from Biomass in a Sealed Reactor. Ind. Eng. Chem. Res. 1992, 31, 1162–1166. [Google Scholar] [CrossRef]

- Kim, H.J.; Park, C.; Nepal, R.; Oh, S.C. Hydrothermal Treatment of Empty Fruit Bunches to Enhance Fuel Characteristics. Energies 2021, 14, 1467. [Google Scholar] [CrossRef]

- Parikh, J.; Channiwala, S.A.; Ghosal, G.K. A Correlation for Calculating Elemental Composition from Proximate Analysis of Biomass Materials. Fuel 2007, 86, 1710–1719. [Google Scholar] [CrossRef]

- Kim, D.; Lee, K.; Park, K. Hydrothermal Carbonization of Sewage Sludge for Solid Recovered Fuel and Energy Recovery. J. Korean Soc. Water Wastewater 2015, 29, 57–63. [Google Scholar] [CrossRef]

- Kabakcı, S.B.; Baran, S.S. Hydrothermal Carbonization of Various Lignocellulosics: Fuel Characteristics of Hydrochars and Surface Characteristics of Activated Hydrochars. Waste Manag. 2019, 100, 259–268. [Google Scholar] [CrossRef]

- Park, D.K.; Song, E. Pressurized Pyrolysis Characteristics of Two Ranks of Coal in a Thermogravimetric Analyzer. J. Energy Eng. 2017, 143, 04017017. [Google Scholar] [CrossRef]

- Uemura, Y.; Matsumoto, R.; Saadon, S.; Matsumura, Y. A Study on Torrefaction of Laminaria Japonica. Fuel Process. Technol. 2015, 138, 133–138. [Google Scholar] [CrossRef]

- Yang, H.; Yan, R.; Chen, H.; Zheng, C.; Lee, D.H.; Liang, D.T. In-Depth Investigation of Biomass Pyrolysis Based on Three Major Components: Hemicellulose, Cellulose and Lignin. Energy Fuels 2006, 20, 388–393. [Google Scholar] [CrossRef]

- Gan, M.J.; Lim, W.S.; Ng, H.X.; Ong, M.H.; Gan, S.; Lee, L.Y.; Thangalazhy-Gopakumar, S. Enhancement of Palm Kernel Shell Fuel Properties via Wet Torrefaction: Response Surface, Optimization, and Combustion Studies. Energy Fuels 2019, 33, 11009–11020. [Google Scholar] [CrossRef]

- Stevanic, J.S.; Salmén, L. Characterizing Wood Polymers in the Primary Cell Wall of Norway Spruce (Picea abies (L.) Karst.) Using Dynamic FT-IR Spectroscopy. Cellulose 2008, 15, 285–295. [Google Scholar] [CrossRef]

- Wang, P.; Zhang, J.; Shao, Q.; Wang, G. Physicochemical Properties Evolution of Chars from Palm Kernel Shell Pyrolysis. J. Therm. Anal. Calorim. 2018, 133, 1271–1280. [Google Scholar] [CrossRef]

- Park, J.; Meng, J.; Lim, K.H.; Rojas, O.J.; Park, S. Transformation of Lignocellulosic Biomass During Torrefaction. J. Anal. Appl. Pyrol. 2013, 100, 199–206. [Google Scholar] [CrossRef]

- Xu, X.; Jiang, E. Treatment of urban sludge by hydrothermal carbonization. Bioresour. Technol. 2017, 238, 182–187.26. [Google Scholar] [CrossRef]

| Element Analysis [wt.%] | Proximate Analysis [wt.%] | Higher Heating Value [MJ/kg] | |||||||

|---|---|---|---|---|---|---|---|---|---|

| C | H | N | O | S | Others | VM | FC | Ash | |

| 50.8 (0.35) | 6.9 (0.06) | 2.5 (0.07) | 35.5 (0.30) | - | 4.3 (0.33) | 80.4 (1.86) | 18.1 (1.71) | 1.5 (0.13) | 22.6 (0.22) |

| Temperature | Elemental Analysis (wt.%, dry) | Proximate Analysis (wt.%, dry) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| C | H | O | N | S | Others | VM | FC | Ash | |

| 180 °C | 60.1 ± 1.7 | 7.3 ± 0.1 | 26.2 ± 0.9 | 2.7 ± 0.2 | 0 | 3.6 ± 1.0 | 68.6 ± 2.2 | 29.6 ± 1.8 | 1.8 ± 0.4 |

| 190 °C | 62.5 ± 1.4 | 7. ± 0.2 | 24.1 ± 0.3 | 3.2 ± 0.3 | 0 | 3.3 ± 1.4 | 67.4 ± 2.3 | 30.6 ± 1.2 | 1.7 ± 0.8 |

| 200 °C | 64.1 ± 0.3 | 7.3 ± 0.1 | 22.6 ± 0.1 | 3.0 ± 0.1 | 0 | 3.1 ± 0.4 | 66.0 ± 1.6 | 32.3 ± 1.6 | 1.7 ± 0.2 |

| 210 °C | 64.9 ± 0.5 | 7.3 ± 0.4 | 21.3 ± 0.9 | 3.0 ± 0.4 | 0 | 3.5 ± 1.0 | 64.8 ± 2.9 | 33.2 ± 2.1 | 1.9 ± 0.8 |

| 220 °C | 65.4 ± 0.8 | 7.3 ± 0.1 | 21.0 ± 1.3 | 3.2 ± 0.5 | 0 | 3.1 ± 0.7 | 64.5 ± 0.6 | 33.7 ± 0.5 | 1.8 ± 0.3 |

| 230 °C | 66.2 ± 0.5 | 7.0 ± 0.1 | 19.5 ± 1.3 | 3.3 ± 0.4 | 0 | 4.0 ± 0.7 | 61.9 ± 3.7 | 35.7 ± 3.0 | 2.4 ± 0.7 |

| 240 °C | 67.0 ± 0.3 | 7.0 ± 0.2 | 18.5 ± 1.1 | 3.5 ± 0.2 | 0 | 4.0 ± 0.9 | 61.3 ± 2.1 | 36.3 ± 1.9 | 2.4 ± 0.2 |

| 250 °C | 68.5 ± 0.5 | 6.8 ± 0.1 | 16.6 ± 0.4 | 3.7 ± 0.0 | 0 | 4.5 ± 0.1 | 56.4 ± 1.7 | 41.1 ± 1.4 | 2.5 ± 0.3 |

| Temperature | Elemental Analysis (wt.%, dry) | Proximate Analysis (wt.%, dry) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| C | H | O | N | S | Others | VM | FC | Ash | |

| 180 °C | 54.2 ± 0.7 | 6.8 ± 0.1 | 31.8 ± 1.5 | 2.6 ± 0.1 | 0 | 4.7 ± 2.3 | 75.2 ± 1.4 | 23.3 ± 1.5 | 1.5 ± 0.1 |

| 190 °C | 56.1 ± 2.0 | 6.7 ± 0.1 | 29.5 ± 0.9 | 2.7 ± 0.2 | 0 | 4.9 ± 1.3 | 73.4 ± 3.3 | 24.9 ± 2.7 | 1.7 ± 0.6 |

| 200 °C | 59.5 ± 0.9 | 6.7 ± 0.1 | 26.2 ± 1.1 | 3.0 ± 0.1 | 0 | 4.6 ± 0.4 | 70.9 ± 3.0 | 27.0 ± 3.6 | 2.2 ± 0.6 |

| 210 °C | 61.0 ± 1.3 | 6.6 ± 0.1 | 24.7 ± 0.8 | 3.0 ± 0.2 | 0 | 4.7 ± 1.3 | 69.1 ± 3.0 | 29.1 ± 3.1 | 1.8 ± 0.1 |

| 220 °C | 61.9 ± 1.3 | 6.7 ± 0.1 | 24.2 ± 1.2 | 3.1 ± 0.1 | 0 | 4.1 ± 1.1 | 68.3 ± 1.7 | 29.9 ± 1.7 | 1.8 ± 0.1 |

| 230 °C | 63.3 ± 1.4 | 6.7 ± 0.1 | 22.4 ± 0.6 | 3.2 ± 0.1 | 0 | 4.4 ± 0.7 | 67.2 ± 4.5 | 31.0 ± 4.2 | 1.7 ± 0.3 |

| 240 °C | 64.0 ± 1.5 | 6.7 ± 0.1 | 21.4 ± 0.8 | 3.4 ± 0.1 | 0 | 4.5 ± 1.9 | 67.5 ± 0.7 | 30.4 ± 0.8 | 1.9 ± 0.1 |

| 250 °C | 65.6 ± 0.7 | 6.6 ± 0.1 | 19.2 ± 0.3 | 3.6 ± 0.1 | 0 | 5.0 ± 1.0 | 69.8 ± 1.4 | 28.3 ± 1.3 | 1.9 ± 0.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.-J.; Oh, S.-C. Hydrothermal Carbonization of Spent Coffee Grounds. Appl. Sci. 2021, 11, 6542. https://doi.org/10.3390/app11146542

Kim H-J, Oh S-C. Hydrothermal Carbonization of Spent Coffee Grounds. Applied Sciences. 2021; 11(14):6542. https://doi.org/10.3390/app11146542

Chicago/Turabian StyleKim, Hyeok-Jin, and Sea-Cheon Oh. 2021. "Hydrothermal Carbonization of Spent Coffee Grounds" Applied Sciences 11, no. 14: 6542. https://doi.org/10.3390/app11146542