Dehumidified Air-Assisted Spray-Drying of Cloudy Beetroot Juice at Low Temperature

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Juice and Feed Solutions

2.3. Spray-Drying

2.4. Powder Characterization

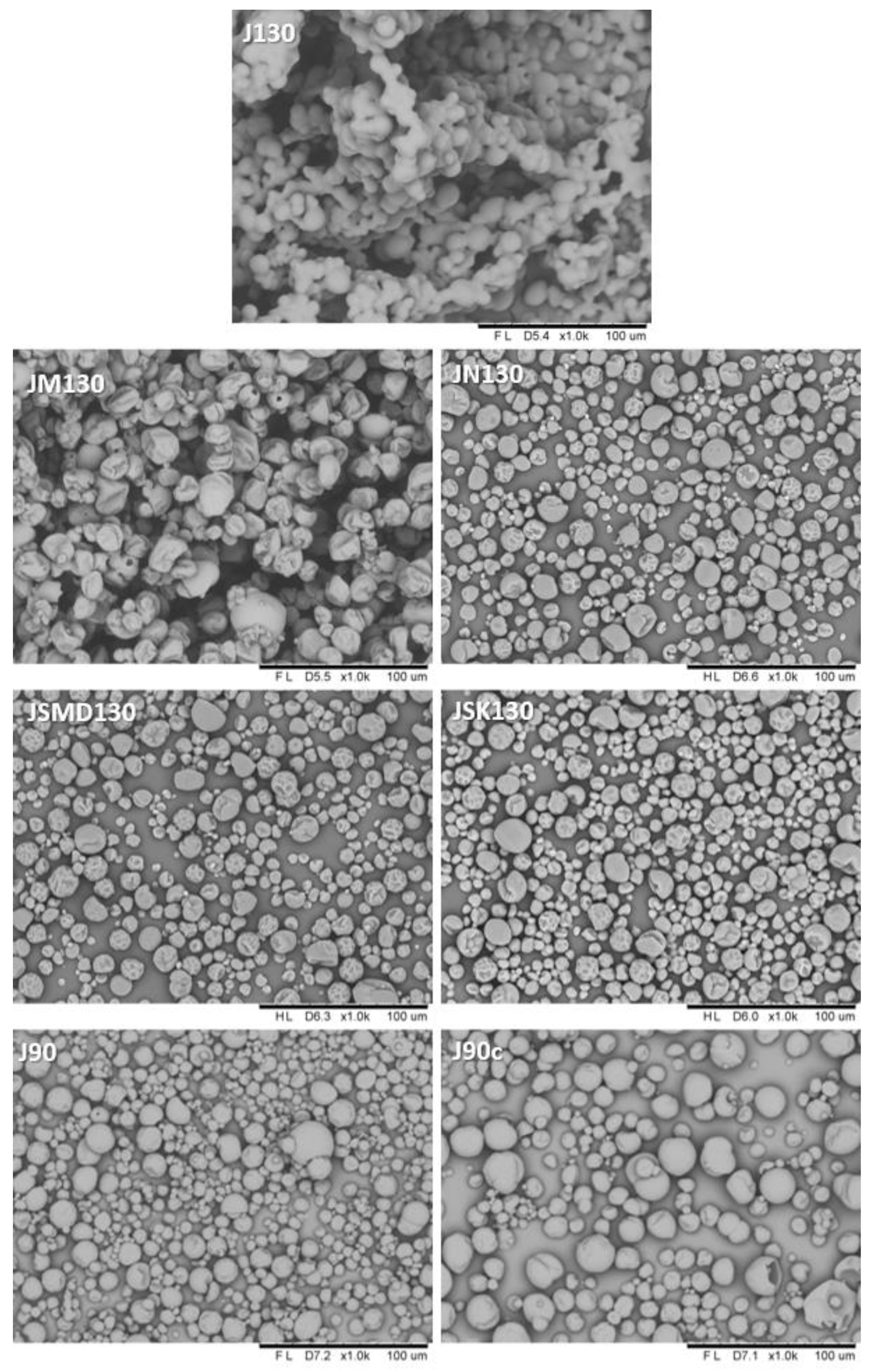

2.4.1. Morphologies of the Particles

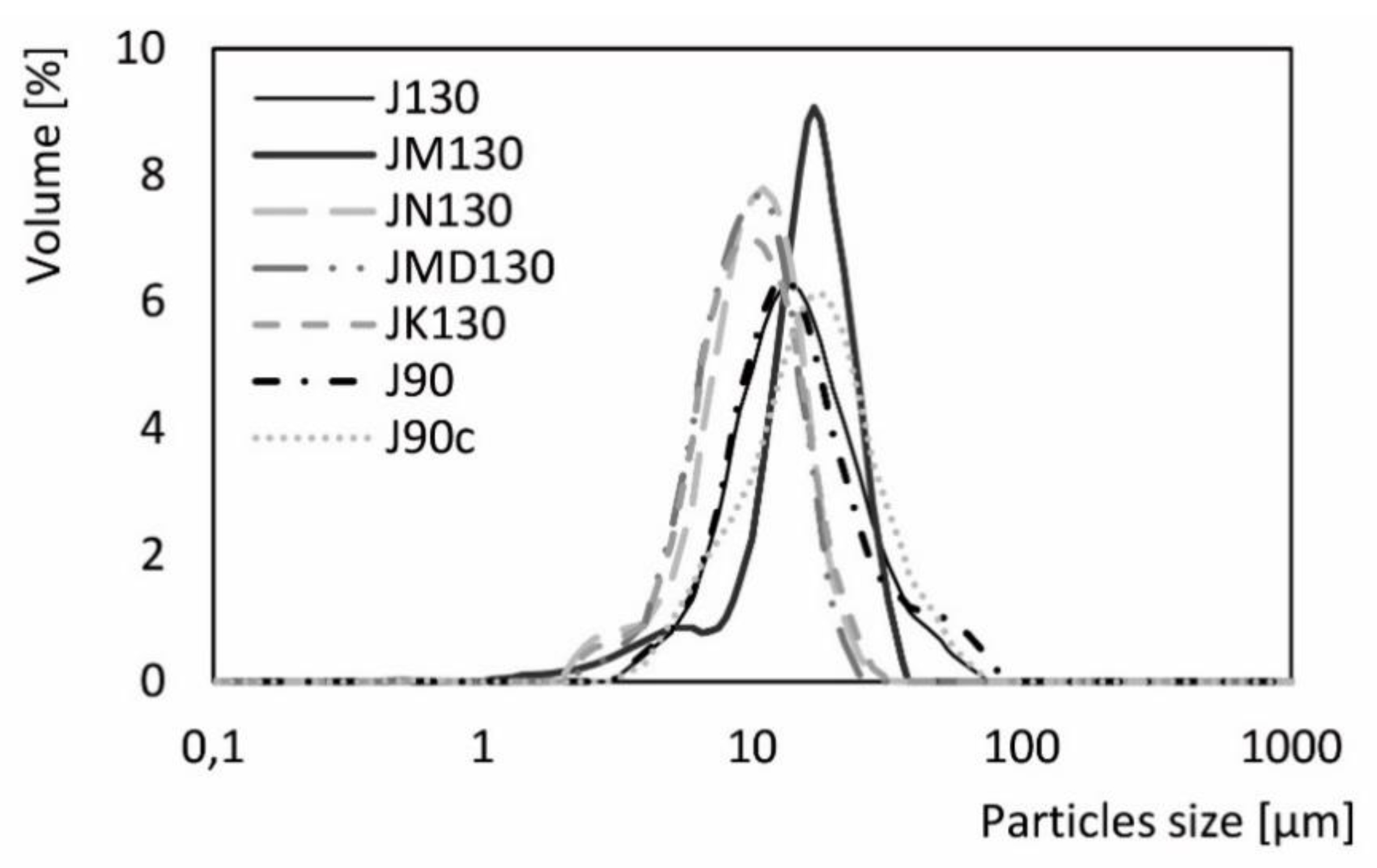

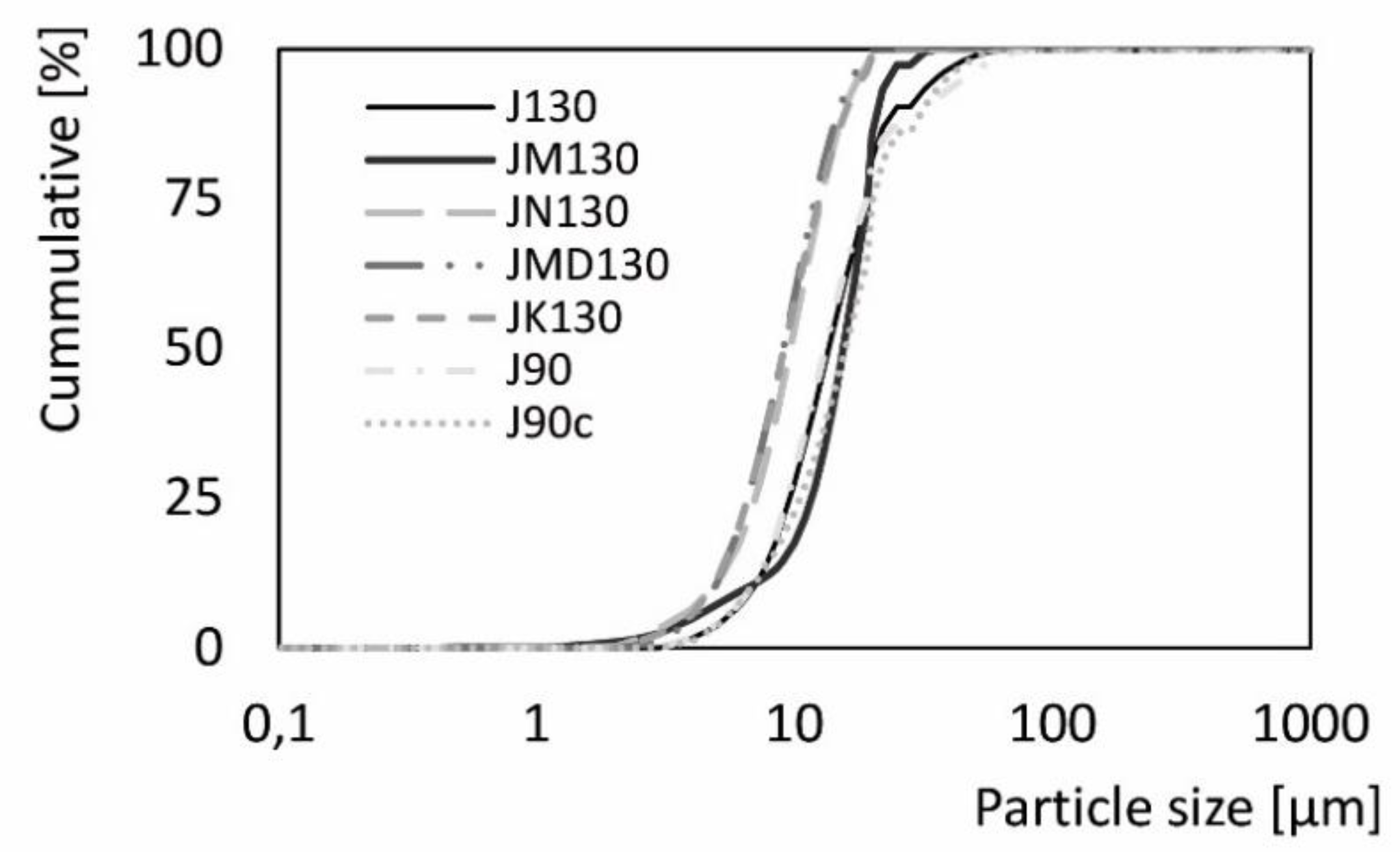

2.4.2. Particle Size Distribution

2.4.3. Water Content and Water Activity

2.4.4. Glass Transition Temperature

2.4.5. Hygroscopicity

2.4.6. Loose Bulk Density and Tapped Density

2.4.7. Apparent Density

2.4.8. Bulk Porosity and Flowability

2.4.9. Color

2.4.10. Betalains

2.5. Statistical Methods

3. Results and Discussion

3.1. Powder Recovery

3.2. Morphologies of Particles

3.3. Particles Size Distribution

3.4. Water Content and Activity

3.5. Glass Transition Temperature

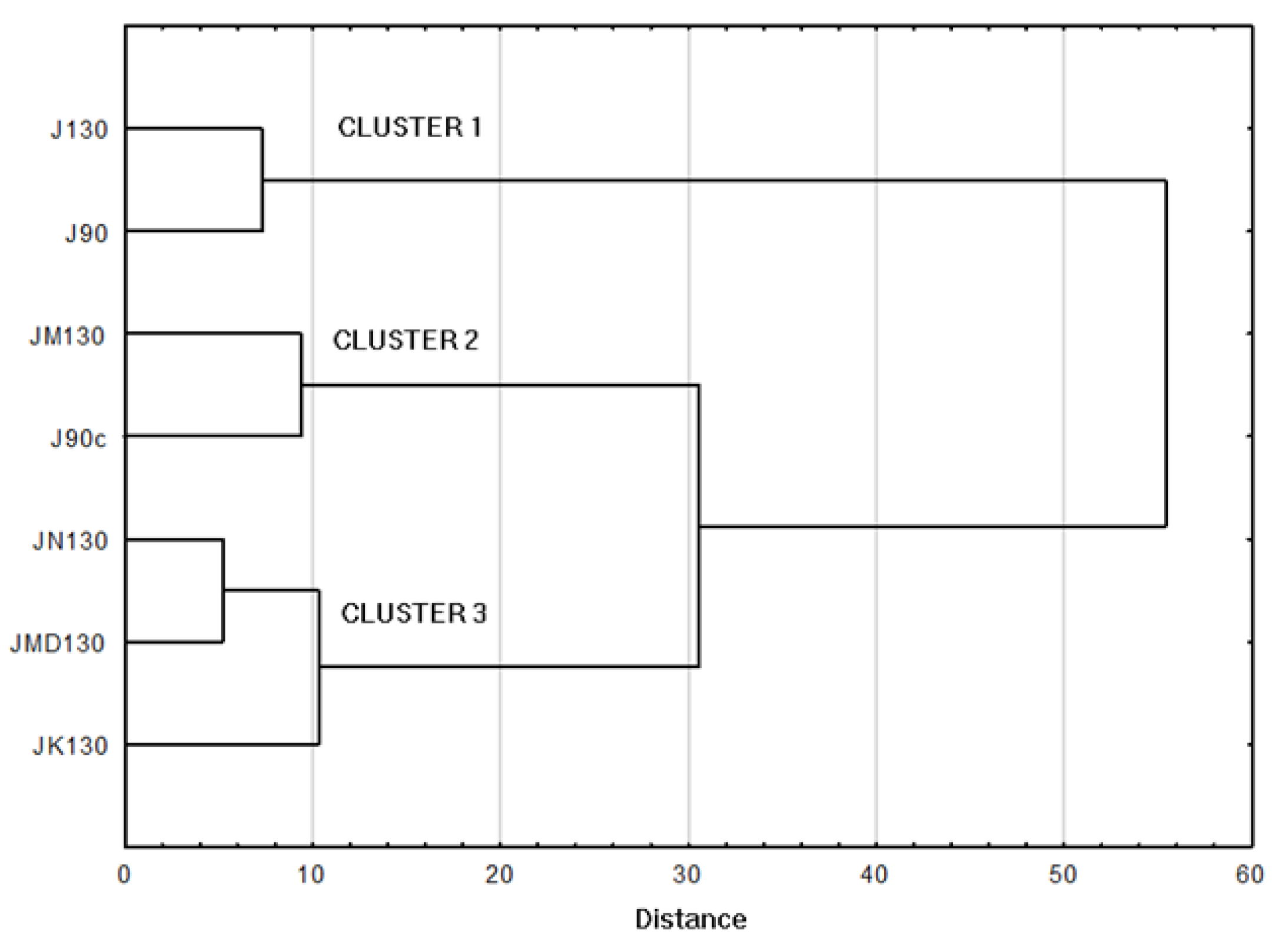

3.6. Hygroscopicity

3.7. Apparent Density

3.8. Bulk Density

3.9. Bulk Porosity

3.10. Flowability

3.11. Color

3.12. Betalains

Retention

3.13. HCA

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chhikara, N.; Kushwaha, K.; Sharma, P.; Gat, Y.; Panghal, A. Bioactive compounds of beetroot and utilization in food processing industry: A critical review. Food Chem. 2019, 272, 192–200. [Google Scholar] [CrossRef]

- Janiszewska-Turak, E. Microencapsulated beetroot juice as a potential source of betalain. Powder Technol. 2014, 264, 190–196. [Google Scholar] [CrossRef]

- Chawla, H.; Parle, M.; Sharma, K.; Yadav, M. Beetroot: A health promoting functional food. Inven. Rapid Nutraceuticals 2016, 1, 0976–3872. [Google Scholar]

- Gościnna, K.; Czapski, J.; Mikołajczyk-Bator, K.; Kidoń, M. Zawartość barwników betalainowych, azotanów i zdolność przeciwutleniająca soków z buraka ćwikłowego w zależności od odmiany i wielkości korzenia. Apar. Badaw. I Dydakt. 2012, 17, 85–90. [Google Scholar]

- Klewicka, E. Betacyjaniny–Biodostępność i biologiczna aktywność. Żywność Nauka Technologia Jakość 2012, 81, 5–21. [Google Scholar]

- Polturak, G.; Aharoni, A. “La Vie en Rose”: Biosynthesis, Sources, and Applications of Betalain Pigments. Mol. Plant 2018, 11, 7–22. [Google Scholar] [CrossRef] [Green Version]

- Tontul, I.; Topuz, A. Spray-drying of fruit and vegetable juices: Effect of drying conditions on the product yield and physical properties. Trends Food Sci. Technol. 2017, 63, 91–102. [Google Scholar] [CrossRef]

- Phisut, N. Spray drying technique of fruit juice powder: Some factors influencing the properties of product. Int. Food Res. J. 2012, 19, 1297–1306. [Google Scholar]

- Jedlińska, A.; Samborska, K.; Wieczorek, A.; Wiktor, A.; Ostrowska-Ligęza, E.; Jamróz, W.; Skwarczyńska-Maj, K.; Kiełczewski, D.; Błażowski, Ł.; Tułodziecki, M.; et al. The application of dehumidified air in rapeseed and honeydew honey spray drying—Process performance and powders properties considerations. J. Food Eng. 2019, 245, 80–87. [Google Scholar] [CrossRef]

- Chasekioglou, A.N.; Goula, A.; Adamopoulos, K.G.; Lazarides, H.N. An approach to turn olive mill wastewater into a valuable food by-product based on spray drying in dehumidified air using drying aids. Powder Technol. 2017, 311, 376–389. [Google Scholar] [CrossRef]

- Shishir, M.R.I.; Chen, W. Trends of spray drying: A critical review on drying of fruit and vegetable juices. Trends Food Sci. Technol. 2017, 65, 49–67. [Google Scholar] [CrossRef]

- Samborska, K.; Wiktor, A.; Jedlińska, A.; Matwijczuk, A.; Jamróz, W.; Skwarczyńska-Maj, K.; Kiełczewski, D.; Tułodziecki, M.; Błażowski, Ł.; Witrowa-Rajchert, D. Development and characterization of physical properties of honey-rich powder. Food Bioprod. Process. 2019, 115, 78–86. [Google Scholar] [CrossRef]

- Goula, A.; Adamopoulos, K.G. Spray drying of tomato pulp in dehumidified air: I. The effect on product recovery. J. Food Eng. 2005, 66, 25–34. [Google Scholar] [CrossRef]

- Singh, B.; Hathan, B.S. Process optimization of spray drying of beetroot Juice. J. Food Sci. Technol. 2017, 54, 2241–2250. [Google Scholar] [CrossRef]

- Bhusari, S.; Muzaffar, K.; Kumar, P. Effect of carrier agents on physical and microstructural properties of spray dried tamarind pulp powder. Powder Technol. 2014, 266, 354–364. [Google Scholar] [CrossRef]

- Muzaffar, K.; Kumar, P. Effect of Soya Protein Isolate as a Complementary Drying Aid of Maltodextrin on Spray Drying of Tamarind Pulp. Dry. Technol. 2015, 34, 142–148. [Google Scholar] [CrossRef]

- Jayasundera, M.; Adhikari, B.; Adhikari, R.; Aldred, P. The effects of proteins and low molecular weight surfactants on spray drying of model sugar-rich foods: Powder production and characterisation. J. Food Eng. 2011, 104, 259–271. [Google Scholar] [CrossRef]

- Flores-Mancha, M.A.; Ruíz-Gutiérrez, M.G.; Sánchez-Vega, R.; Santellano-Estrada, E.; Chávez-Martínez, A. Characterization of Betabel Extract (Beta vulgaris) Encapsulated with Maltodextrin and Inulin. Molecules 2020, 25, 5498. [Google Scholar] [CrossRef]

- Roos, Y.; Karel, M.; Kokini, J. Glass transitions in low moisture and foods: Effects on shelf life and quality. Food Technol. Chic. 1996, 50, 95–108. [Google Scholar]

- Sobulska, M.; Zbicinski, I. Advances in spray drying of sugar-rich products. Dry. Technol. 2020, 1–26. [Google Scholar] [CrossRef]

- Jouppila, K.; Roos, Y. Glass Transitions and Crystallization in Milk Powders. J. Dairy Sci. 1994, 77, 2907–2915. [Google Scholar] [CrossRef]

- Shrestha, A.K.; Howes, T.; Adhikari, B.; Bhandari, B. Water sorption and glass transition properties of spray dried lactose hydrolysed skim milk powder. LWT Food Sci. Technol. 2007, 40, 1593–1600. [Google Scholar] [CrossRef]

- Bhandari, B.; Howes, T. Implication of glass transition for the drying and stability of dried foods. J. Food Eng. 1999, 40, 71–79. [Google Scholar] [CrossRef]

- Balasubramanian, S.; Devi, A.; Singh, K.K.; Bosco, S.J.D.; Mohite, A. Application of Glass Transition in Food Processing. Crit. Rev. Food Sci. Nutr. 2016, 56, 919–936. [Google Scholar] [CrossRef]

- Fan, F.; Roos, Y.H. Glass Transition-Associated Structural Relaxations and Applications of Relaxation Times in Amorphous Food Solids: A Review. Food Eng. Rev. 2017, 9, 257–270. [Google Scholar] [CrossRef]

- Bhandari, B.; Senoussi, A.; Dumoulin, E.; Lebert, A. Spray Drying of Concentrated Fruit Juices. Dry. Technol. 1993, 11, 1081–1092. [Google Scholar] [CrossRef]

- Goula, A.M.; Adamopoulos, K.G. Effect of Maltodextrin Addition during Spray Drying of Tomato Pulp in Dehumidified Air: I. Drying Kinetics and Product Recovery. Dry. Technol. 2008, 26, 714–725. [Google Scholar] [CrossRef]

- Nurhadi, B.; Roos, Y. Influence of anti-caking agent on the water sorption isotherm and flow-ability properties of vacuum dried honey powder. J. Food Eng. 2017, 210, 76–82. [Google Scholar] [CrossRef]

- Bazaria, B.; Kumar, P. Effect of whey protein concentrate as drying aid and drying parameters on physicochemical and functional properties of spray dried beetroot juice concentrate. Food Biosci. 2016, 14, 21–27. [Google Scholar] [CrossRef]

- Tonon, R.V.; Brabet, C.; Pallet, D.; Brat, P.; Hubinger, M. Physicochemical and morphological characterisation of açai (Euterpe oleraceaeMart.) powder produced with different carrier agents. Int. J. Food Sci. Technol. 2009, 44, 1950–1958. [Google Scholar] [CrossRef]

- Janiszewska, E.; Witrowa-Rajchert, D. Mikrokapsulacja aromatu rozmarynowego podczas suszenia rozpyłowego. Postępy Techniki Przetwórstwa Spożywczego 2007, 2, 33–36. [Google Scholar]

- Kwapinska, M.; Zbicinski, I. Prediction of Final Product Properties After Cocurrent Spray Drying. Dry. Technol. 2005, 23, 1653–1665. [Google Scholar] [CrossRef]

- Suhag, Y.; Nanda, V. Optimisation of process parameters to develop nutritionally rich spray-dried honey powder with vitamin C content and antioxidant properties. Int. J. Food Sci. Technol. 2015, 50, 1771–1777. [Google Scholar] [CrossRef]

- Grabowski, J.A.; Truong, V.-D.; Daubert, C.R. Spray-Drying of Amylase Hydrolyzed Sweetpotato Puree and Physicochemical Properties of Powder. J. Food Sci. 2006, 71, E209–E217. [Google Scholar] [CrossRef]

- Santhalakshmy, S.; Bosco, S.J.D.; Francis, S.; Sabeena, M. Effect of inlet temperature on physicochemical properties of spray-dried jamun fruit juice powder. Powder Technol. 2015, 274, 37–43. [Google Scholar] [CrossRef]

- Caparino, O.A.; Tang, J.; Nindo, C.I.; Sablani, S.S.; Powers, J.R.; Fellman, J.K. Effect of drying methods on the physical properties and microstructures of mango (Philippine ‘Carabao’ var.) powder. J. Food Eng. 2012, 111, 135–148. [Google Scholar] [CrossRef]

- Premi, M.; Sharma, H. Effect of different combinations of maltodextrin, gum arabic and whey protein concentrate on the encapsulation behavior and oxidative stability of spray dried drumstick (Moringa oleifera) oil. Int. J. Biol. Macromol. 2017, 105, 1232–1240. [Google Scholar] [CrossRef]

- Sahni, P.; Shere, D.M. Comparative evaluation of physico-chemical and functional properties of apple, carrot and beetroot pomace powders. Int. J. Food Ferment. Technol. 2017, 7, 317–323. [Google Scholar] [CrossRef]

- Tze, N.L.; Han, C.P.; Yusof, Y.A.; Ling, C.N.; Talib, R.A.; Taip, F.S.; Aziz, M.G. Physicochemical and nutritional properties of spray-dried pitaya fruit powder as natural colorant. Food Sci. Biotechnol. 2012, 21, 675–682. [Google Scholar] [CrossRef]

- Samborska, K.; Langa, E.; Kamińska-Dwórznicka, A.; Witrowa-Rajchert, D. The influence of sodium caseinate on the physical properties of spray-dried honey. Int. J. Food Sci. Technol. 2014, 50, 256–262. [Google Scholar] [CrossRef]

- Landillon, V.; Cassan, D.; Morel, M.-H.; Cuq, B. Flowability, cohesive, and granulation properties of wheat powders. J. Food Eng. 2008, 86, 178–193. [Google Scholar] [CrossRef]

- Do Carmo, E.L.; Teodoro, R.A.R.; Campelo, P.H.; Figueiredo, J.D.A.; Botrel, D.A.; Fernandes, R.V.D.B.; Borges, S.V. The use of different temperatures and inulin:whey protein isolate ratios in the spray drying of beetroot juice. J. Food Process. Preserv. 2019, 43, 14113. [Google Scholar] [CrossRef]

- Delia, S.-C.; Chávez, G.M.; Frank, M.L.-M.; Aracelib, S.-G.P.; Irais, A.-L.; Franco, A.-A. Spray drying microencapsulation of betalain rich extracts from Escontria chiotilla and Stenocereus queretaroensis fruits using cactus mucilage. Food Chem. 2019, 272, 715–722. [Google Scholar] [CrossRef] [PubMed]

- Janiszewska, E.; Włodarczyk, J. Influence of spray drying conditions on beetroot pigments retention after microencapsulation process. Acta Agrophysica 2013, 20, 2. [Google Scholar]

| Variant | Carrier | Inlet/Outlet Air Temperature (°C) |

|---|---|---|

| J130 | No carrier added | 130/80 |

| JM130 | Milk powder | 130/80 |

| JN130 | Nutriose | 130/80 |

| JMD130 | Maltodextrin | 130/80 |

| JK130 | Kleptose | 130/80 |

| J90 | No carrier added | 90/55 |

| J90c | No carrier added | 90/55 |

| Variant | Rp (%) | Tg (°C) | WC (%) | aw | D50 (μm) | DL (g/cm3) | DT (g/cm3) | HR | Dap (g/cm3) | εL (%) |

|---|---|---|---|---|---|---|---|---|---|---|

| J130 | 90.0 ± 9.4 b | 58.4 ± 0.1 a | 4.0 ± 0.6 a | 0.169 ± 0.004 c | 13.2 ± 0.3 b | 0.44 ± 0.05 a,b | 0.61 ± 0.06 b | 1.37 ± 0.03 cd | 1.57 ± 0.04 b,c | 71.7 ± 3.1 b,c |

| JM130 | 55.2 ± 3.6 a | 65.6 ± 1.6 a,b | 6.9 ± 1.0 b | 0.142 ± 0.013 b | 17.1 ± 0.7 b | 0.41 ± 0.04 a | 0.50 ± 0.05 a | 1.21 ± 0.05 a | 1.49 ± 0.02 a | 72.1 ± 2.4 b,c |

| JN130 | 71.6 ± 3.0 a,b | 68.5 ± 2.7 b,c | 4.1 ± 0.6 a | 0.107 ± 0.004 a | 9.3 ± 0.3 a | 0.61 ± 0.03 c | 0.78 ± 0.01 c | 1.27 ± 0.05 a,b | 1.55 ± 0.01 b | 60.3 ± 1.6 a |

| JMD130 | 76.1 ± 1.7 a,b | 70.0 ± 0.3 c | 3.7 ± 0.6 a | 0.113 ± 0.005 a | 9.1 ± 0.1 a | 0.58 ± 0.02 c | 0.73 ± 0.01 c | 1.26 ± 0.04 a,b | 1.54 ± 0.00 b | 62.5 ± 1.1 a |

| JK130 | 65.3 ± 11.9 a,b | 69.2 ± 1.4 b,c | 3.6 ± 0.3 a | 0.148 ± 0.005 b | 9.2 ± 0.1 a | 0.57 ± 0.03 c | 0.74 ± 0.01 c | 1.31 ± 0.06 b,c | 1.56 ± 0.01 b,c | 63.8 ± 1.7 a |

| J90 | 89.8 ± 2.3 b | 65.3 ± 2.0 b,c | 3.5 ± 0.6 a | 0.179 ± 0.008 c | 14.1 ± 1.3 b | 0.42 ± 0.01 a | 0.60 ± 0.01 b | 1.44 ± 0.03 d | 1.60 ± 0.04 c | 73.9 ± 1.1 c |

| J90c | 63.5 ± 13.5 a,b | 63.7 ± 0.6 a,b | 3.9 ± 0.6 a | 0.202 ± 0.010 d | 15.6 ± 1.0 b | 0.49 ± 0.03 b | 0.64 ± 0.05 b | 1.29 ± 0.05 a,b,c | 1.65 ± 0.01 d | 70.1 ± 2.0 b |

| Tg | WC | aw | D50 | DL | DT | HR | Dap | εL | |

|---|---|---|---|---|---|---|---|---|---|

| RP | −0.400 | −0.604 | 0.152 | −0.201 | −0.168 | 0.078 | 0.838 * | 0.298 | 0.220 |

| Tg | −0.089 | −0.649 | −0.594 | 0.697 | 0.579 | −0.415 | −0.313 | −0.718 | |

| WC | −0.152 | 0.597 | −0.446 | −0.667 | −0.617 | −0.662 | 0.303 | ||

| aw | 0.657 | −0.643 | −0.507 | 0.522 | 0.743 | 0.765 * | |||

| D50 | −0.884 * | −0.926 * | 0.017 | 0.127 | 0.874 * | ||||

| DL | 0.956 * | −0.344 | −0.048 | −0.982 * | |||||

| DT | −0.061 | 0.136 | −0.905 * | ||||||

| HR | 0.547 | 0.447 | |||||||

| Dap | 0.226 |

| Variant | L* | a* | b* | C* | H* | Color* |

|---|---|---|---|---|---|---|

| J130 | 32.3 ± 0.4 b | 46.6 ± 0.6 c | 9.8 ± 0.3 b | 47.6 ± 0.7 d | 0.2 ± 0.0 c | |

| JM130 | 36.4 ± 0.5 c | 44.7 ± 0.5 b | 5.4 ± 0.4 a | 45.0 ± 0.6 b,c | 0.1 ± 0.0 a | |

| JN130 | 38.0 ± 0.1 c | 44.2 ± 0.2 b | 6.2 ± 0.1 a | 44.6 ± 0.2 b | 0.1 ± 0.0 a,b | |

| JMD130 | 37.1 ± 0.8 c | 44.2 ± 0.7 b | 6.3 ± 0.5 a | 44.7 ± 0.8 b | 0.1 ± 0.0 a,b | |

| JK130 | 37.5 ± 0.8 c | 44.3 ± 0.8 b | 6.5 ± 0.6 a | 44.8 ± 0.9 b,c | 0.1 ± 0.0 a,b | |

| J90 | 24.4 ± 0.9 a | 45.6 ± 0.5 b,c | 9.1 ± 0.4 b | 46.5 ± 0.5 c,d | 0.2 ± 0.0 c | |

| J90c | 25.7 ± 1.6 a | 39.4 ± 0.2 a | 6.9 ± 1.2 a | 40.0 ± 0.4 a | 0.2 ± 0.0 b,c |

| Variant | BL (mg/100 g Solids) | BN (mg/100 g Solids) | V (mg/100 g Solids) | Betalain Retention (%) | Betanin Retention (%) | Vulgaxanthin Retention (%) |

|---|---|---|---|---|---|---|

| Juice | 1141.26 ± 3.82 | 651.56 ± 1.68 | 489.70 ± 3.82 | - | - | - |

| J130 | 819.1 ± 13.0 d | 465.4 ± 6.8 d | 345.0 ± 13.1 d | 71.8 ± 0.6 b | 71.4 ± 1.3 b | 70.5 ± 2.7 b |

| JM130 | 527.1 ± 9.4 a | 311.9 ± 6.5 a | 215.3 ± 3.1 a | 77.0 ± 1.4 c | 79.8 ± 1.2 c | 73.3 ± 1.4 b,c |

| JN130 | 576.7 ± 11.7 b | 329.8 ± 3.6 a,b | 246.9 ± 7.9 b | 84.2 ± 0.3 d | 84.4 ± 0.5 d | 84.0 ± 0.2 d |

| JMD130 | 546.1 ± 25.2 a,b | 314.4 ± 13.7 a | 231.8 ± 11.7 a,b | 79.8 ± 1.6 c | 80.4 ± 0.9 c | 78.9 ± 2.6 c |

| JK130 | 581.1 ± 4.9 b | 342.1 ± 16.0 b | 238.9 ± 11.2 a,b | 84.9 ± 0.7 d | 87.5 ± 3.8 d | 81.3 ± 2.6 d |

| J90 | 691.3 ± 11.1 c | 384.6 ± 8.2 c | 306.8 ± 2.9 b | 60.6 ± 0.8 a | 59.0 ± 2.3 a | 62.7 ± 1.3 a |

| J90c | 824.6 ± 9.4 d | 416.0 ± 4.5 c | 408.7 ± 5.6 e | 72.3 ± 1.2 b | 63.9 ± 1.8 a,b | 83.5 ± 0.8 d |

| a* | b* | C* | BL | BT | V | |

|---|---|---|---|---|---|---|

| L* | 0.297 | −0.597 | 0.215 | −0.740 | −0.634 | −0.799 * |

| a* | 0.420 | 0.994 * | −0.255 | −0.005 | −0.470 | |

| b* | 0.510 | 0.725 | 0.836 * | 0.577 | ||

| C* | −0.161 | 0.086 | −0.382 | |||

| BL | 0.963 * | 0.967 * | ||||

| BN | 0.866 * |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jedlińska, A.; Barańska, A.; Witrowa-Rajchert, D.; Ostrowska-Ligęza, E.; Samborska, K. Dehumidified Air-Assisted Spray-Drying of Cloudy Beetroot Juice at Low Temperature. Appl. Sci. 2021, 11, 6578. https://doi.org/10.3390/app11146578

Jedlińska A, Barańska A, Witrowa-Rajchert D, Ostrowska-Ligęza E, Samborska K. Dehumidified Air-Assisted Spray-Drying of Cloudy Beetroot Juice at Low Temperature. Applied Sciences. 2021; 11(14):6578. https://doi.org/10.3390/app11146578

Chicago/Turabian StyleJedlińska, Aleksandra, Alicja Barańska, Dorota Witrowa-Rajchert, Ewa Ostrowska-Ligęza, and Katarzyna Samborska. 2021. "Dehumidified Air-Assisted Spray-Drying of Cloudy Beetroot Juice at Low Temperature" Applied Sciences 11, no. 14: 6578. https://doi.org/10.3390/app11146578