Experimental Investigation on Integrated Subsurface Monitoring of Soil Slope Using Acoustic Emission and Mechanical Measurement

Abstract

:1. Introduction

2. Experimental System and Test Procedure

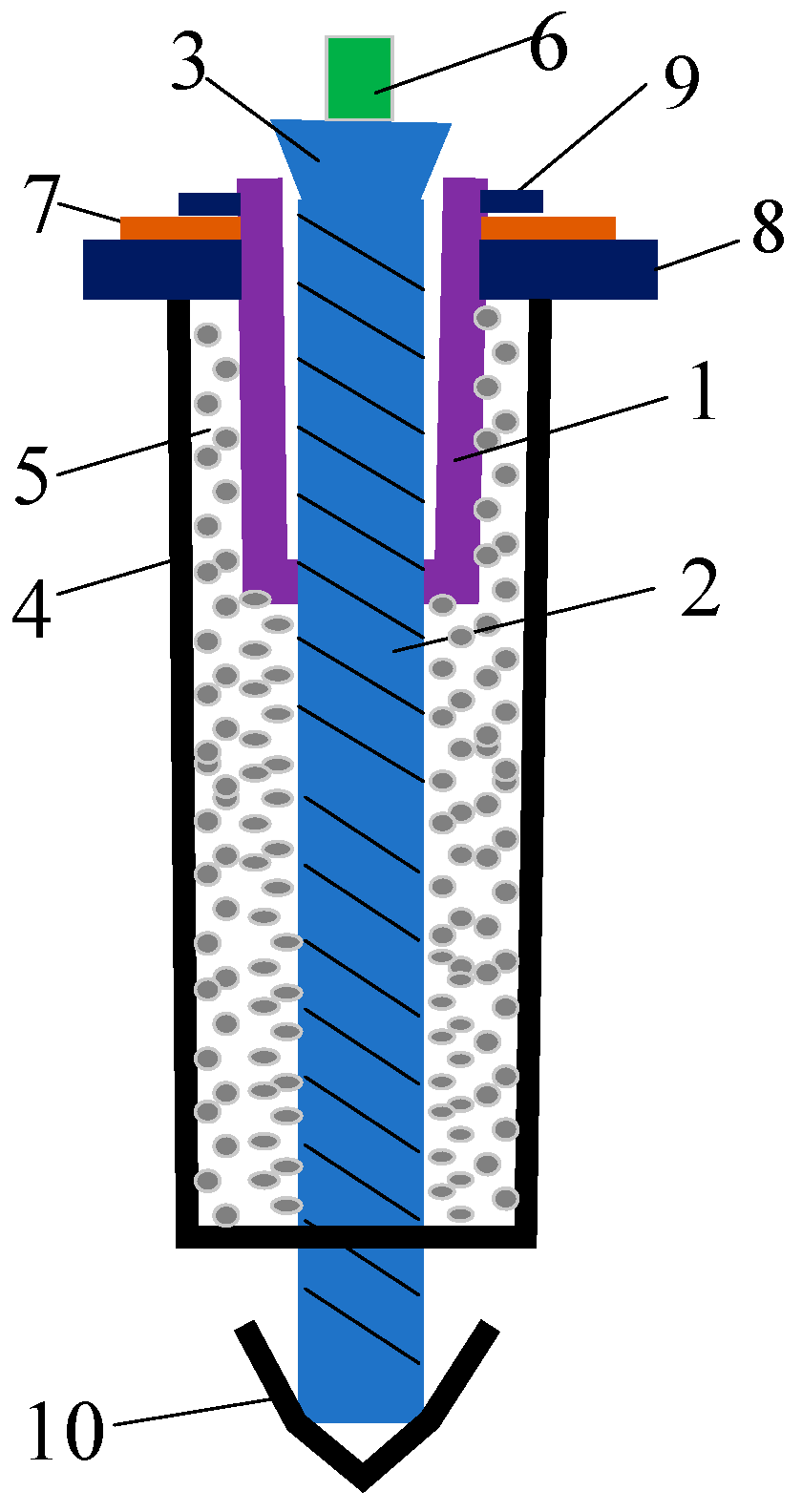

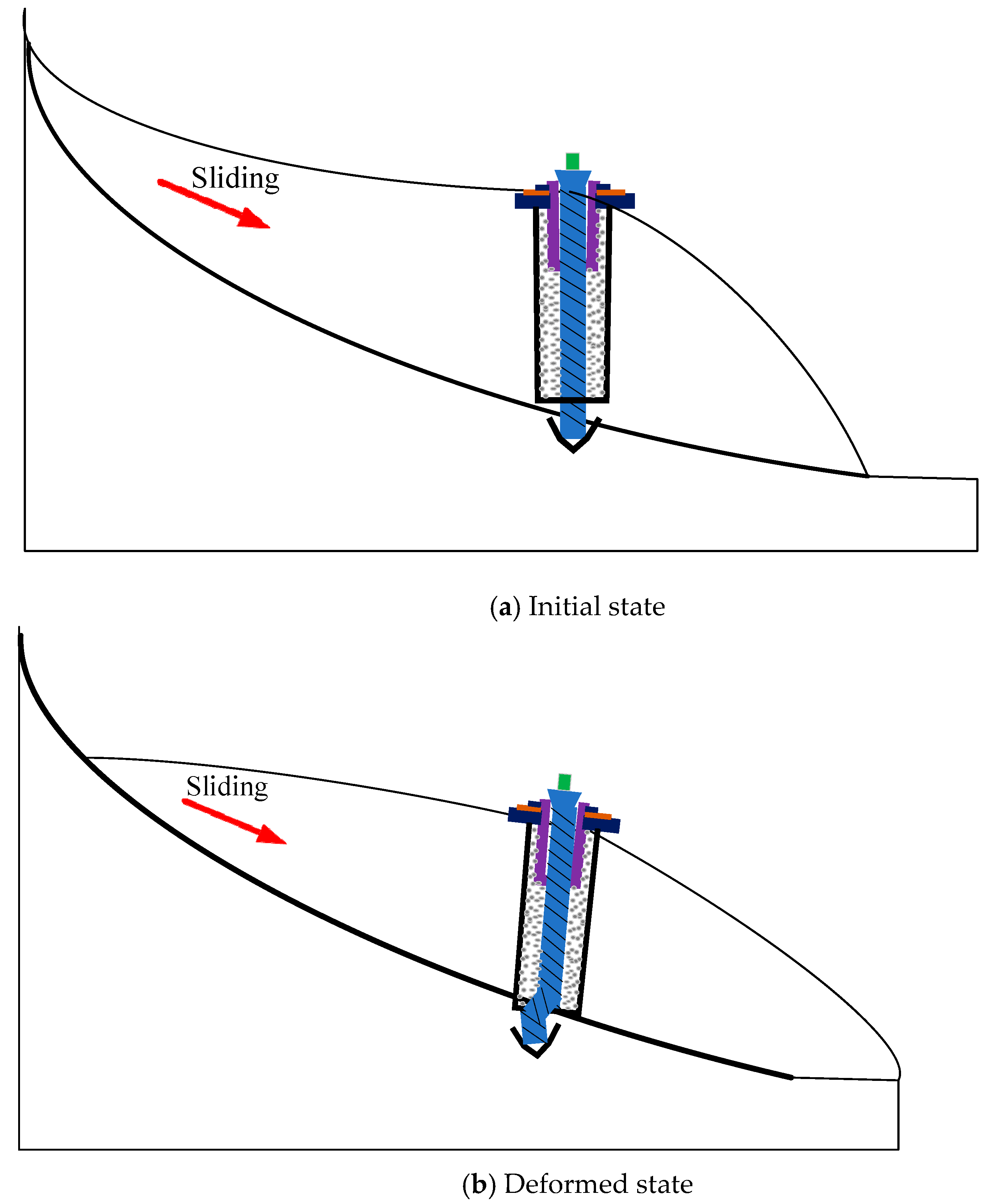

2.1. Design of Flexible Device for Slope Subsurface Monitoring

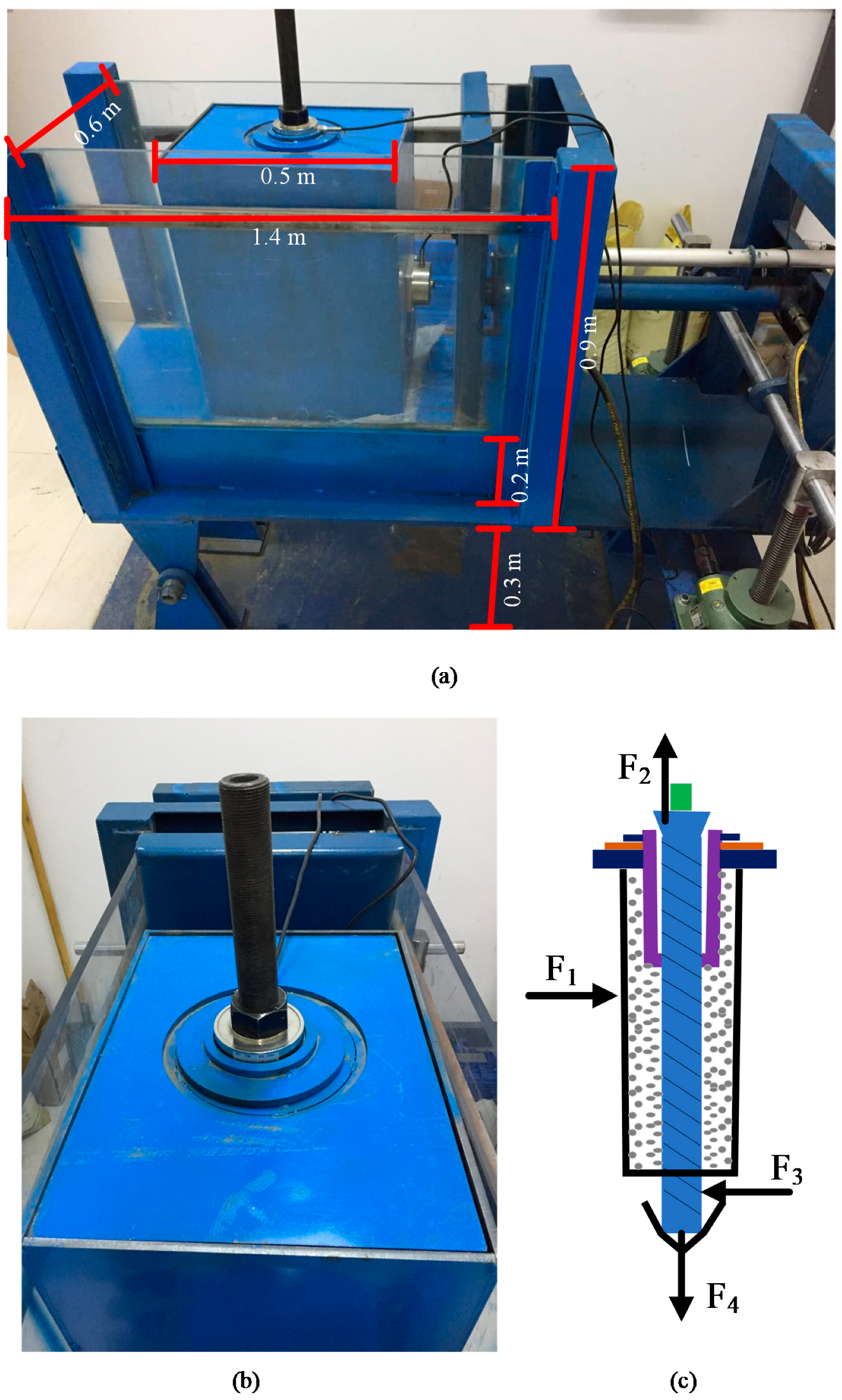

2.2. Experimental System and Method

3. Results and Analysis

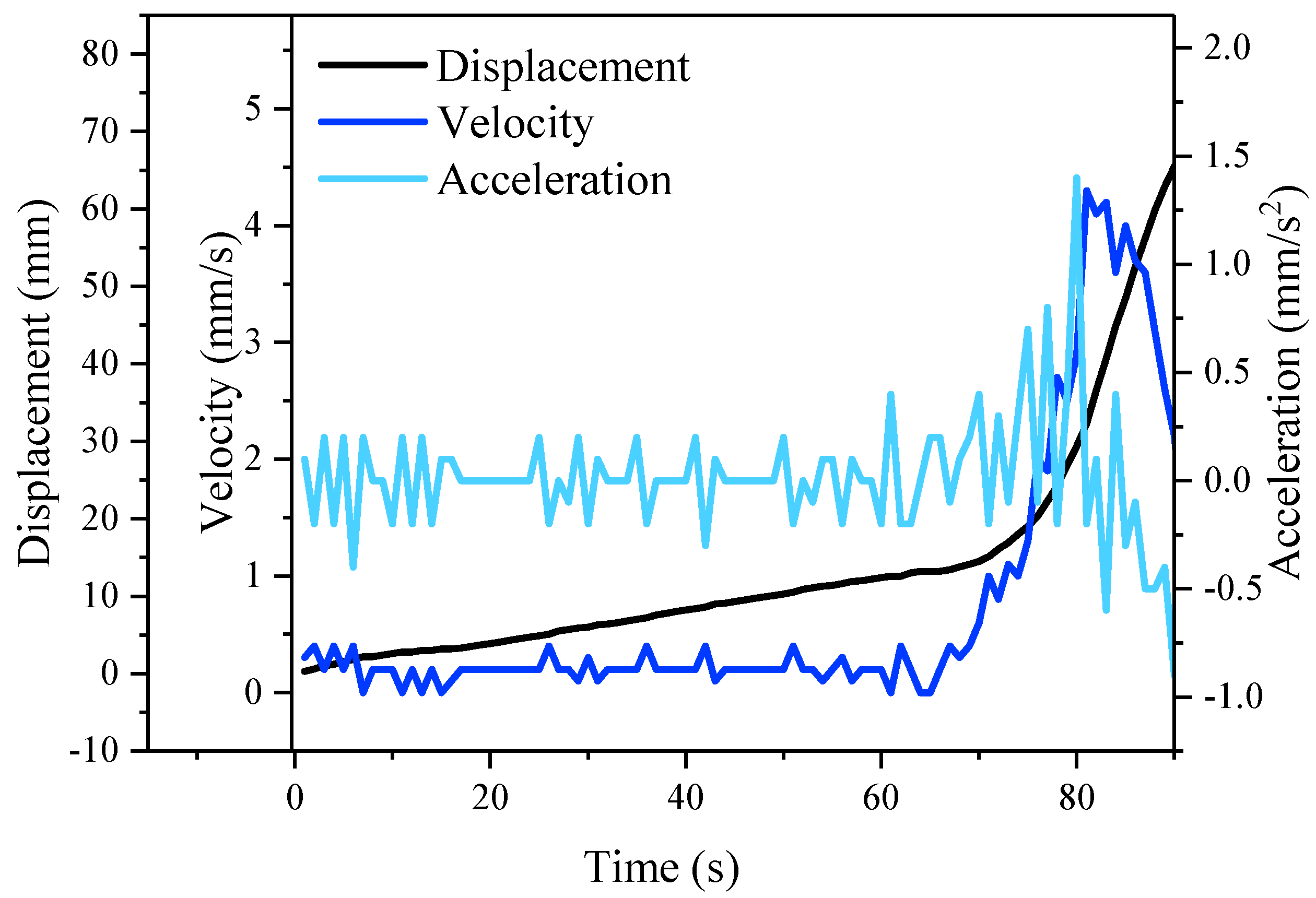

3.1. Kinematic Parameters

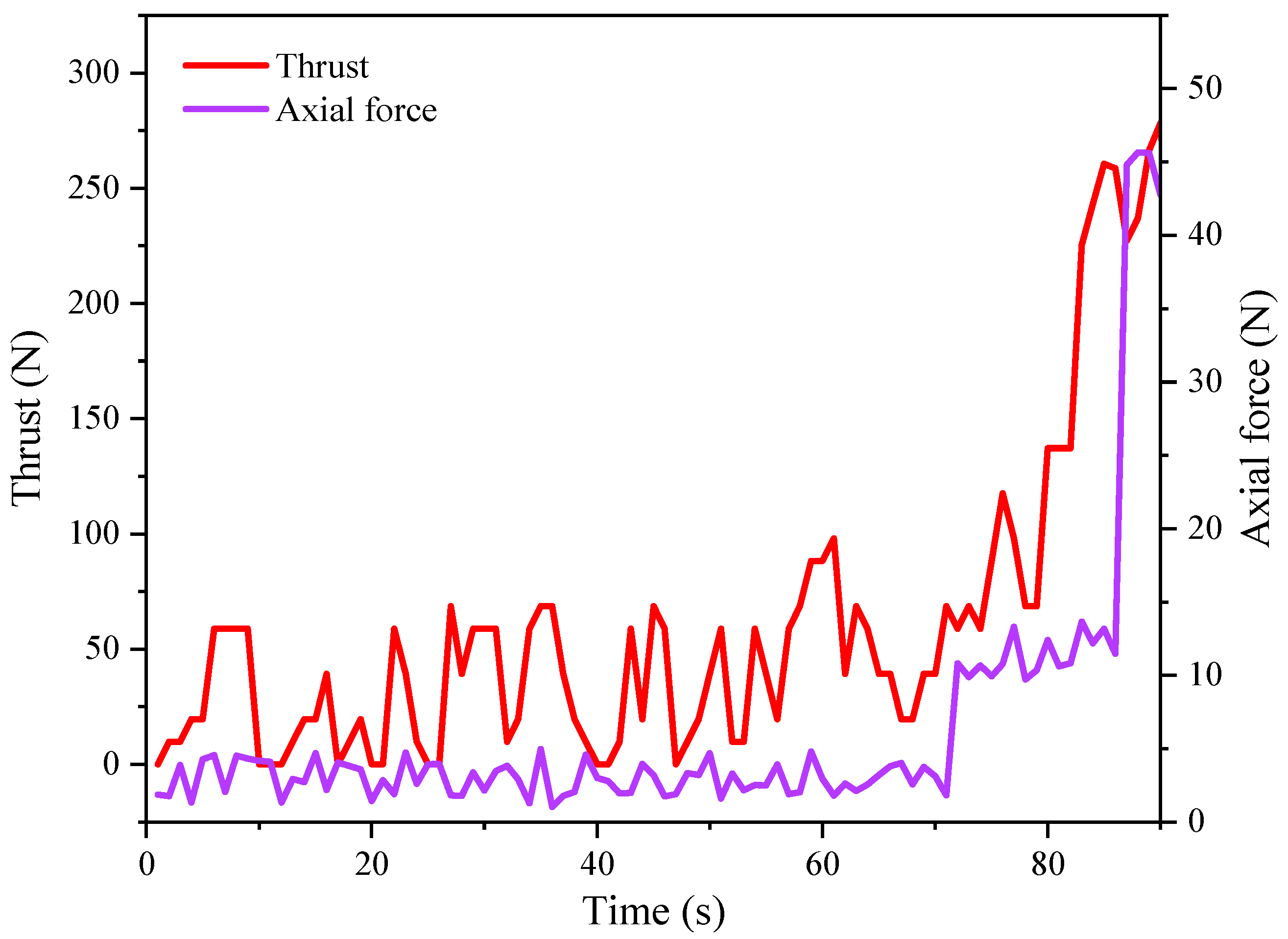

3.2. Mechanical Parameters

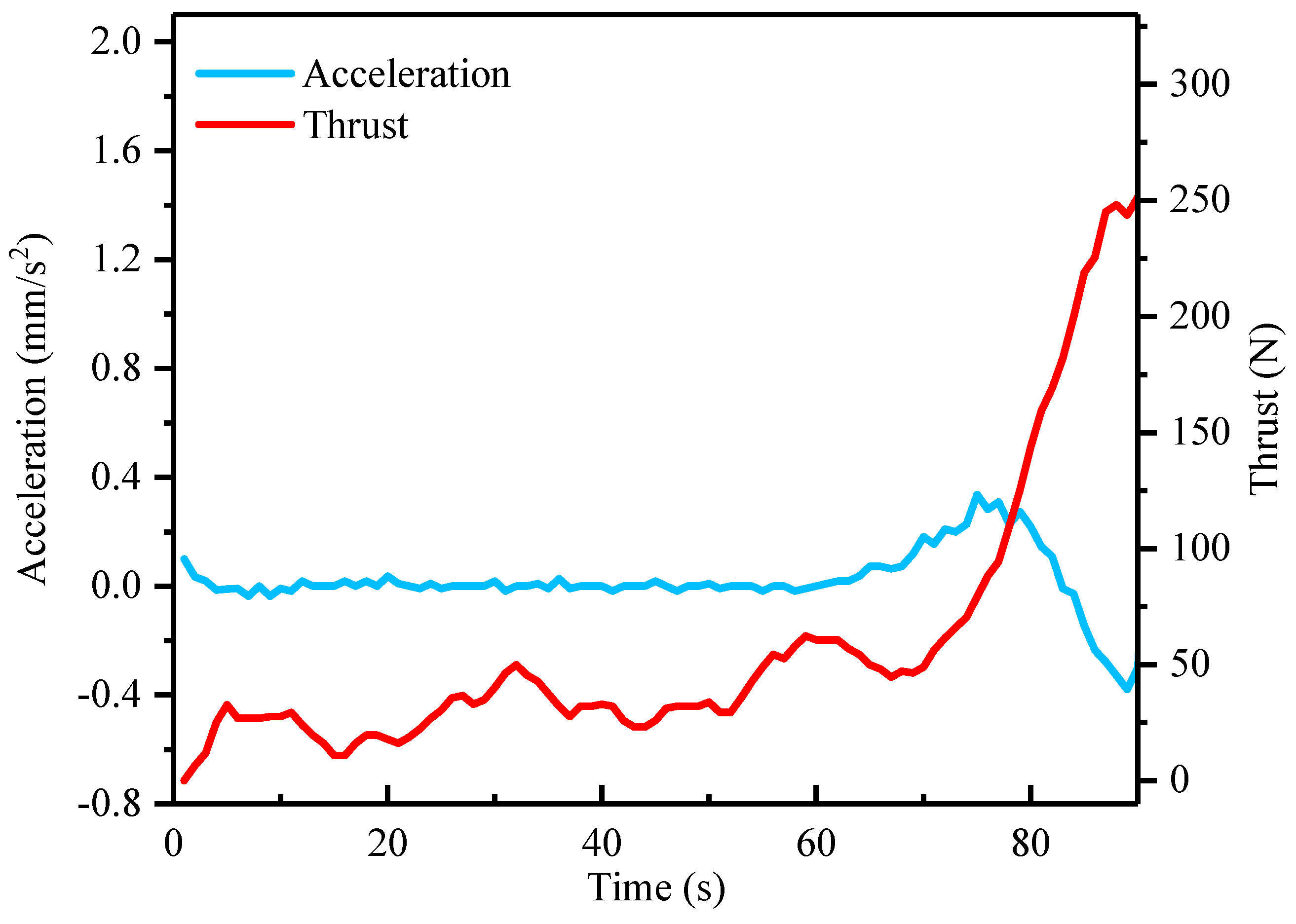

3.3. Thrust and Acceleration

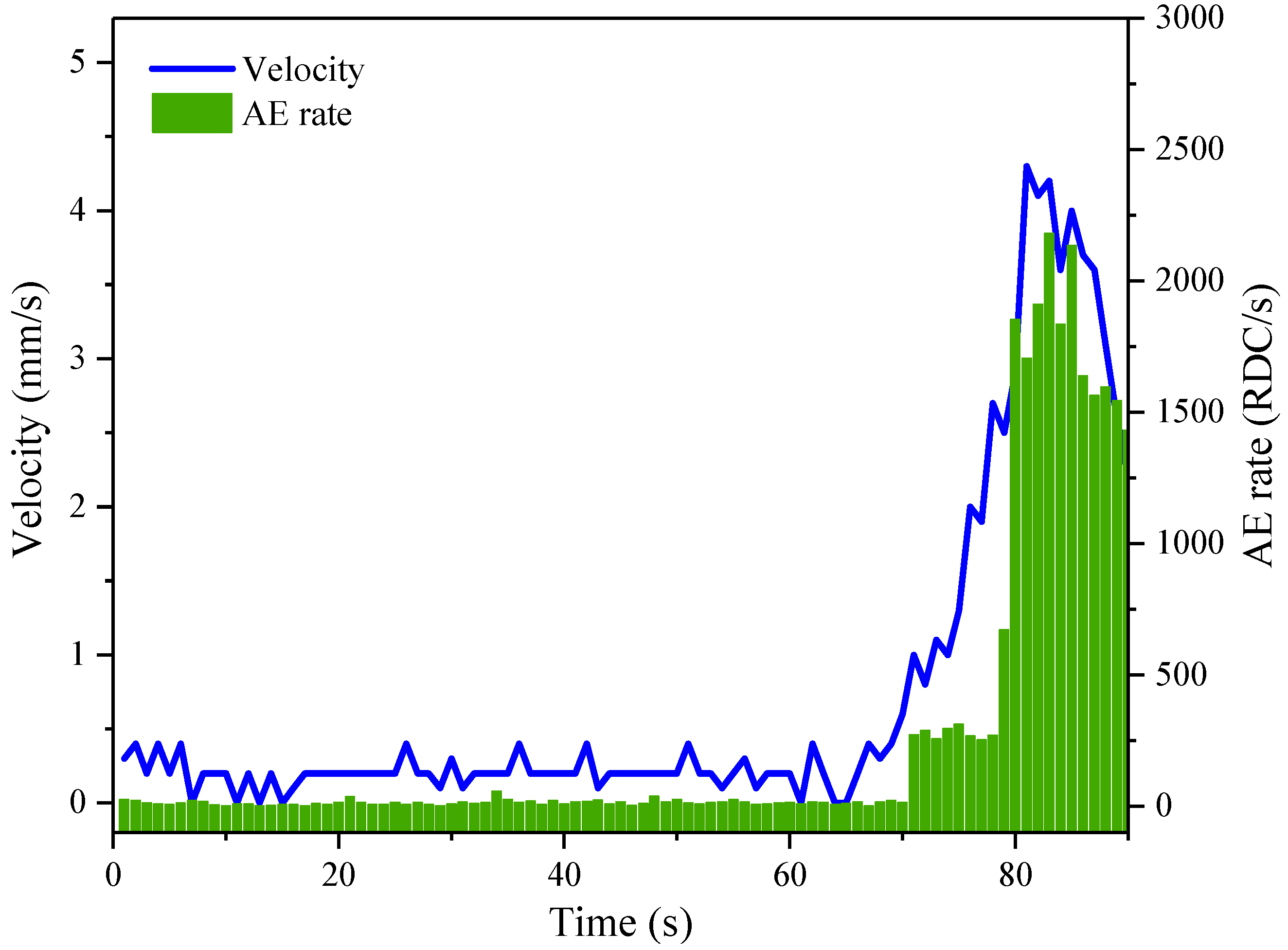

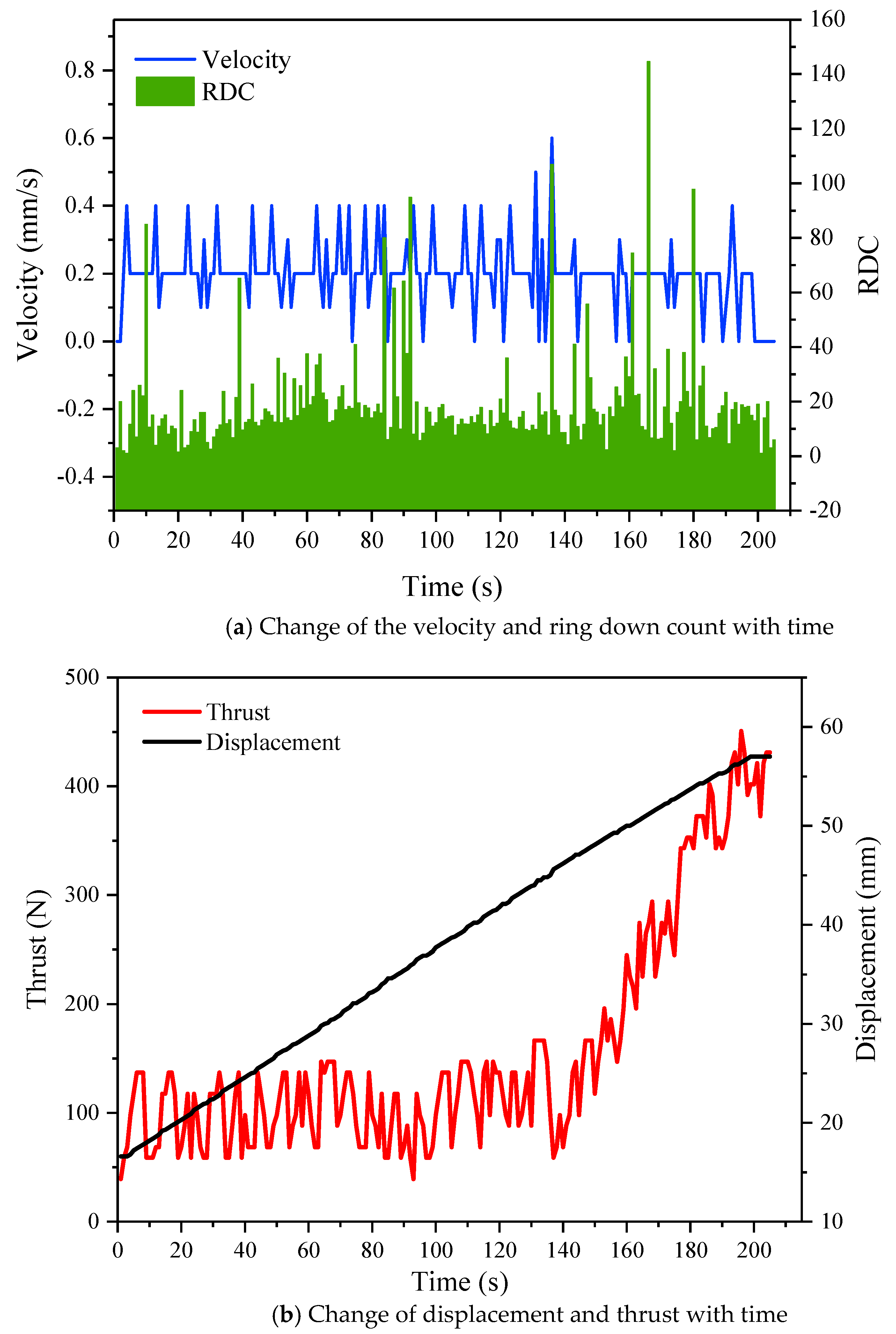

3.4. Sliding Velocity and Ring down Count

3.5. Sliding Displacement and Cumulative Ring down Count

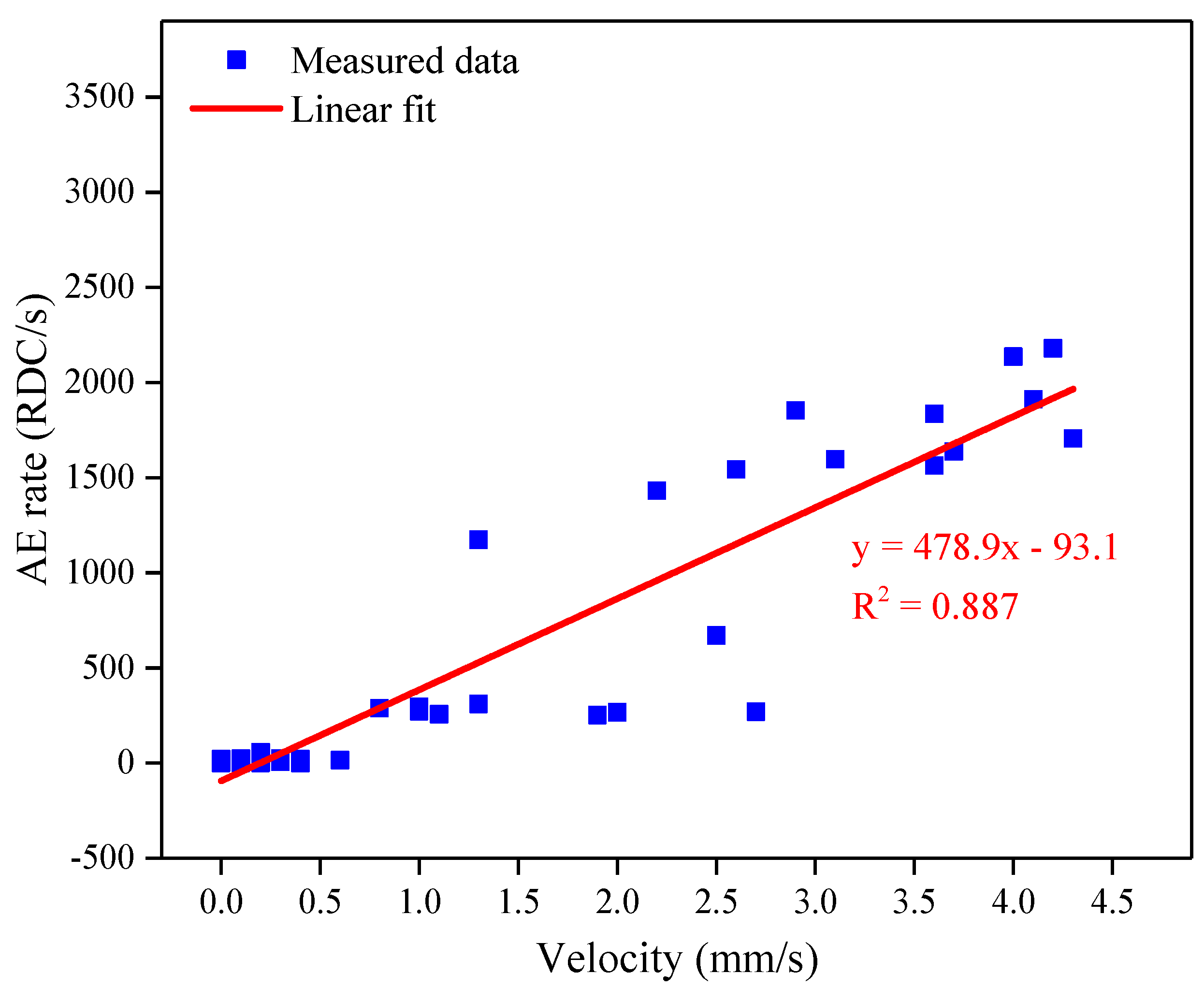

3.6. Performance of Deformation Quantification by Acoustic Emission

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Palmer, J. Creeping Catastrophes. Nature 2017, 548, 384–386. [Google Scholar] [CrossRef] [PubMed]

- AghaKouchak, A.; Huning, L.S.; Mazdiyasni, O.; Mallakpour, I.; Chiang, F.; Sadegh, M.; Vahedifard, F.; Moftakhari, H. How do natural hazards cascade to cause disasters? Nature 2018, 561, 458–460. [Google Scholar] [CrossRef] [Green Version]

- Chuang, Y.-C.; Shiu, Y.-S. Relationship between landslides and mountain development—Integrating geospatial statistics and a new long-term database. Sci. Total Environ. 2018, 622–623, 1265–1276. [Google Scholar] [CrossRef]

- Froude, M.J.; Petley, D.N. Global fatal landslide occurrence from 2004 to 2016. Nat. Hazards Earth Syst. Sci. 2018, 18, 2161–2181. [Google Scholar] [CrossRef] [Green Version]

- Reichenbach, P.; Rossi, M.; Malamud, B.D.; Mihir, M.; Guzzetti, F. A review of statistically-based landslide susceptibility models. Earth-Sci. Rev. 2018, 180, 60–91. [Google Scholar] [CrossRef]

- Hu, X.-D.; Hu, K.-H.; Zhang, X.-P.; Wei, L.; Tang, J.-B. Quantitative assessment of the impact of earthquake-induced geohazards on natural landscapes in Jiuzhaigou Valley. J. Mt. Sci. 2019, 16, 441–452. [Google Scholar] [CrossRef]

- Zhang, X.; Song, J.; Peng, J.; Wu, J. Landslides-oriented urban disaster resilience assessment—A case study in ShenZhen, China. Sci. Total Environ. 2019, 661, 95–106. [Google Scholar] [CrossRef] [PubMed]

- Smith, A.; Dixon, N. Quantification of landslide velocity from active waveguide–generated acoustic emission. Can. Geotech. J. 2015, 52, 413–425. [Google Scholar] [CrossRef] [Green Version]

- Smethurst, J.A.; Smith, A.; Uhlemann, S.; Wooff, C.; Chambers, J.; Hughes, P.; Lenart, S.; Saroglou, H.; Springman, S.M.; Löfroth, H.; et al. Current and future role of instrumentation and monitoring in the performance of transport infrastructure slopes. Q. J. Eng. Geol. Hydrogeol. 2017, 50, 271–286. [Google Scholar] [CrossRef] [Green Version]

- Wasowski, J.; Bovenga, F. Investigating landslides and unstable slopes with satellite Multi Temporal Interferometry: Current issues and future perspectives. Eng. Geol. 2014, 174, 103–138. [Google Scholar] [CrossRef]

- Frattini, P.; Crosta, G.B.; Rossini, M.; Allievi, J. Activity and kinematic behaviour of deep-seated landslides from PS-InSAR displacement rate measurements. Landslides 2018, 15, 1053–1070. [Google Scholar] [CrossRef]

- Wasowski, J.; Pisano, L. Long-term InSAR, borehole inclinometer, and rainfall records provide insight into the mechanism and activity patterns of an extremely slow urbanized landslide. Landslides 2019, 17, 445–457. [Google Scholar] [CrossRef]

- Li, Y.; Huang, J.; Jiang, S.-H.; Huang, F.; Chang, Z. A web-based GPS system for displacement monitoring and failure mechanism analysis of reservoir landslide. Sci. Rep. 2017, 7, 17171. [Google Scholar] [CrossRef] [Green Version]

- Syahmi, M.Z.; Aziz, W.W.; Zulkarnaini, M.A.; Anuar, A.; Othman, Z. The movement detection on the landslide surface by using Terrestrial Laser Scanning. In Proceedings of the 2011 IEEE Control and System Graduate Research Colloquium, Shah Alam, Malaysia, 27–28 June 2011; pp. 175–180. [Google Scholar]

- Smith, A. Quantification of Slope Deformation Behaviour Using Acoustic Emission Monitoring; Loughborough University: Loughborough, UK, 2015. [Google Scholar]

- Zheng, Y.; Zhu, Z.-W.; Li, W.-J.; Gu, D.-M.; Xiao, W. Experimental research on a novel optic fiber sensor based on OTDR for landslide monitoring. Measurement 2019, 148, 106926. [Google Scholar] [CrossRef]

- Uhlemann, S.; Smith, A.; Chambers, J.; Dixon, N.; Dijkstra, T.; Haslam, E.; Meldrum, P.; Merritt, A.; Gunn, D.; Mackay, J. Assessment of ground-based monitoring techniques applied to landslide investigations. Geomorphology 2016, 253, 438–451. [Google Scholar] [CrossRef] [Green Version]

- Pei, H.; Jing, J.; Zhang, S. Experimental study on a new FBG-based and Terfenol-D inclinometer for slope displacement monitoring. Measurement 2020, 151, 107172. [Google Scholar] [CrossRef]

- Zhou, Y.; Dongjian, Z.; Zhuoyan, C.; Yongtao, L. Research on a novel inclinometer based on distributed optical fiber strain and conjugate beam method. Measurement 2020, 153, 107404. [Google Scholar] [CrossRef]

- Stark, T.D.; Choi, H. Slope inclinometers for landslides. Landslides 2008, 5, 339–350. [Google Scholar] [CrossRef]

- Green, G.; Mikkelsen, P. Measurement of ground movement with inclinometers. In Proceedings of the Fourth International Geotechnical Seminar on Field Instrumentation and In-Situ Measurement, Singapore, 25–27 November 1986; pp. 235–246. [Google Scholar]

- Dasenbrock, D. Performance observations of MEMS ShapeAccelArray (SAA) deformation sensors. Geotech. Instrum. News 2014, 32, 23–26. [Google Scholar]

- Dixon, N.; Smith, A.; Spriggs, M.; Ridley, A.; Meldrum, P.; Haslam, E. Stability monitoring of a rail slope using acoustic emission. Proc. Inst. Civ. Eng. Geotech. Eng. 2015, 168, 373–384. [Google Scholar] [CrossRef] [Green Version]

- Koerner, R.M.; McCabe, W.M.; Lord, A.E. Acoustic Emission Behavior and Monitoring of Soils; ASTM Special Technical Publications: West Conshohocken, PA, USA, 1981; Volume 49. [Google Scholar]

- Dixon, N.; Smith, A.; Flint, J.A.; Khanna, R.; Clark, B.; Andjelkovic, M. An acoustic emission landslide early warning system for communities in low-income and middle-income countries. Landslides 2018, 15, 1631–1644. [Google Scholar] [CrossRef] [Green Version]

- Matsuura, S.; Asano, S.; Okamoto, T. Relationship between rain and/or meltwater, pore-water pressure and displacement of a reactivated landslide. Eng. Geol. 2008, 101, 49–59. [Google Scholar] [CrossRef]

- Berg, N.; Smith, A.; Russell, S.; Dixon, N.; Proudfoot, D.; Take, W.A. Correlation of acoustic emissions with patterns of movement in an extremely slow-moving landslide at Peace River, Alberta, Canada. Can. Geotech. J. 2018, 55, 1475–1488. [Google Scholar] [CrossRef] [Green Version]

- Smith, A.; Dixon, N.; Meldrum, P.; Haslam, E.; Chambers, J. Acoustic emission monitoring of a soil slope: Comparisons with continuous deformation measurements. Géotech. Lett. 2014, 4, 255–261. [Google Scholar] [CrossRef] [Green Version]

- Smith, A.; Dixon, N.; Fowmes, G.J. Early detection of first-time slope failures using acoustic emission measurements: Large-scale physical modelling. Géotechnique 2017, 67, 138–152. [Google Scholar] [CrossRef] [Green Version]

- Abdoun, T.; Bennett, V.; Desrosiers, T.; Simm, J.; Barendse, M. Asset Management and Safety Assessment of Levees and Earthen Dams Through Comprehensive Real-Time Field Monitoring. Geotech. Geol. Eng. 2013, 31, 833–843. [Google Scholar] [CrossRef]

- Smith, A.; Moore, I.D.; Dixon, N. Acoustic Emission Sensing of Pipe–Soil Interaction: Full-Scale Pipelines Subjected to Differential Ground Movements. J. Geotech. Geoenviron. Eng. 2019, 145, 04019113. [Google Scholar] [CrossRef] [Green Version]

- Dixon, N.; Spriggs, M. Quantification of slope displacement rates using acoustic emission monitoring. Can. Geotech. J. 2007, 44, 966–976. [Google Scholar] [CrossRef] [Green Version]

- Dixon, N.; Spriggs, M.P.; Smith, A.; Meldrum, P.; Haslam, E. Quantification of reactivated landslide behaviour using acoustic emission monitoring. Landslides 2014, 12, 549–560. [Google Scholar] [CrossRef] [Green Version]

- Codeglia, D.; Dixon, N.; Fowmes, G.J.; Marcato, G. Analysis of acoustic emission patterns for monitoring of rock slope deformation mechanisms. Eng. Geol. 2017, 219, 21–31. [Google Scholar] [CrossRef] [Green Version]

- Codeglia, D.; Dixon, N.; Fowmes, G.J.; Marcato, G. Strategies for rock slope failure early warning using acoustic emission monitoring. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2015; Volume 26, p. 012028. [Google Scholar] [CrossRef]

- Smith, A.; Dixon, N.; Fowmes, G. Monitoring buried pipe deformation using acoustic emission: Quantification of attenuation. Int. J. Geotech. Eng. 2017, 11, 418–430. [Google Scholar] [CrossRef] [Green Version]

- Deng, L.; Yuan, H.; Chen, J.; Sun, Z.; Fu, M.; Zhou, Y.; Yan, S.; Zhang, Z.; Chen, T. Experimental investigation on progressive deformation of soil slope using acoustic emission monitoring. Eng. Geol. 2019, 261, 105295. [Google Scholar] [CrossRef]

- He, M.; Gong, W.; Wang, J.; Qi, P.; Tao, Z.; Du, S.; Peng, Y. Development of a novel energy-absorbing bolt with extraordinarily large elongation and constant resistance. Int. J. Rock Mech. Min. Sci. 2014, 67, 29–42. [Google Scholar] [CrossRef]

- He, M.; Xia, H.; Jia, X.; Gong, W.; Zhao, F.; Liang, K. Studies on classification, criteria and control of rockbursts. J. Rock Mech. Geotech. Eng. 2012, 4, 97–114. [Google Scholar] [CrossRef] [Green Version]

- Smith, A.; Dixon, N. Acoustic emission behaviour of dense sands. Géotechnique 2019, 69, 1107–1122. [Google Scholar] [CrossRef]

- Smith, A.; Dixon, N.; Moore, R.; Meldrum, P. Photographic feature: Acoustic emission monitoring of coastal slopes in NE England, UK. Q. J. Eng. Geol. Hydrogeol. 2017, 50, 239–244. [Google Scholar] [CrossRef] [Green Version]

- Cruden, D.M.; Varnes, D.J. Landslide Types and Processes. In Landslides: Investigation and Mitigation, Special Report 247-Transportation Research Board; Turner, A.K., Schuster, R.L., Eds.; National Research Council; National Academy Press: Washington, DC, USA, 1996; pp. 36–75. [Google Scholar]

| Range | Precision | Cost | |

|---|---|---|---|

| ShapeAccelArray (SAA) | hundreds of millimetres [23] | ±1.5 mm per 30 m [30] | very high |

| Inclinometer | <50 mm [23] | ±0.01 mm per 500 mm | high |

| Acoustic emission (AE) | >400 mm [23] | 0.0001 mm/h to more than 400 mm/h [31] | low |

| Description | Particle Size | Packing | |||

| Size Range (mm) | Coefficient of Uniformity | Particle Density (mg·m−3) | Dry Density (mg·m−3) | Void Ratio | |

| Granite gravel | 4.1–7.4 | 1.81 | 2.67 | 1.63 | 0.72 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, L.; Yuan, H.; Chen, J.; Fu, M.; Chen, Y.; Li, K.; Yu, M.; Chen, T. Experimental Investigation on Integrated Subsurface Monitoring of Soil Slope Using Acoustic Emission and Mechanical Measurement. Appl. Sci. 2021, 11, 7173. https://doi.org/10.3390/app11167173

Deng L, Yuan H, Chen J, Fu M, Chen Y, Li K, Yu M, Chen T. Experimental Investigation on Integrated Subsurface Monitoring of Soil Slope Using Acoustic Emission and Mechanical Measurement. Applied Sciences. 2021; 11(16):7173. https://doi.org/10.3390/app11167173

Chicago/Turabian StyleDeng, Lizheng, Hongyong Yuan, Jianguo Chen, Ming Fu, Yang Chen, Kaiyuan Li, Miaomiao Yu, and Tao Chen. 2021. "Experimental Investigation on Integrated Subsurface Monitoring of Soil Slope Using Acoustic Emission and Mechanical Measurement" Applied Sciences 11, no. 16: 7173. https://doi.org/10.3390/app11167173

APA StyleDeng, L., Yuan, H., Chen, J., Fu, M., Chen, Y., Li, K., Yu, M., & Chen, T. (2021). Experimental Investigation on Integrated Subsurface Monitoring of Soil Slope Using Acoustic Emission and Mechanical Measurement. Applied Sciences, 11(16), 7173. https://doi.org/10.3390/app11167173