Design and Experimental Study of the General Mechanical Pneumatic Combined Seed Metering Device

Abstract

:1. Introduction

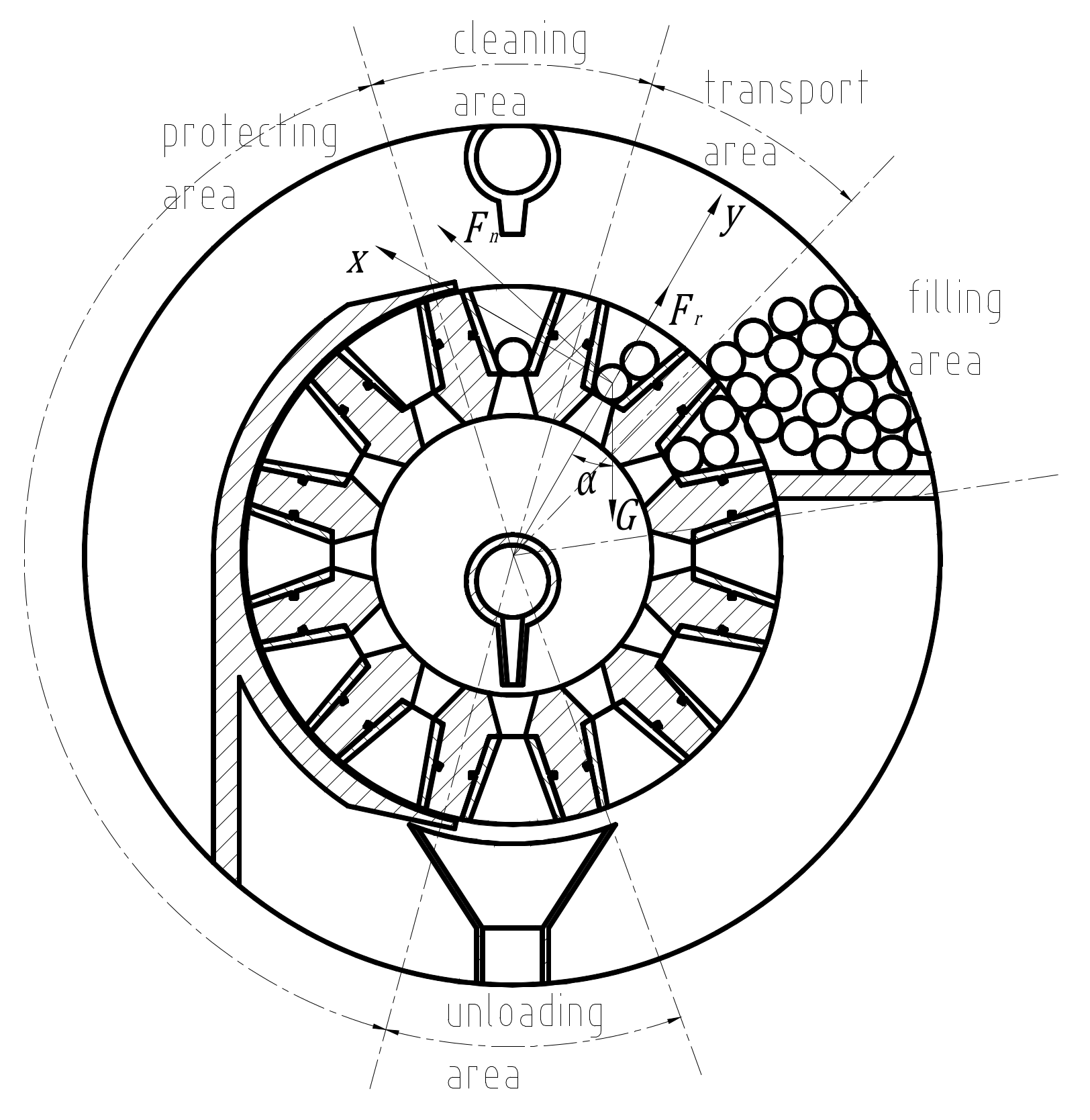

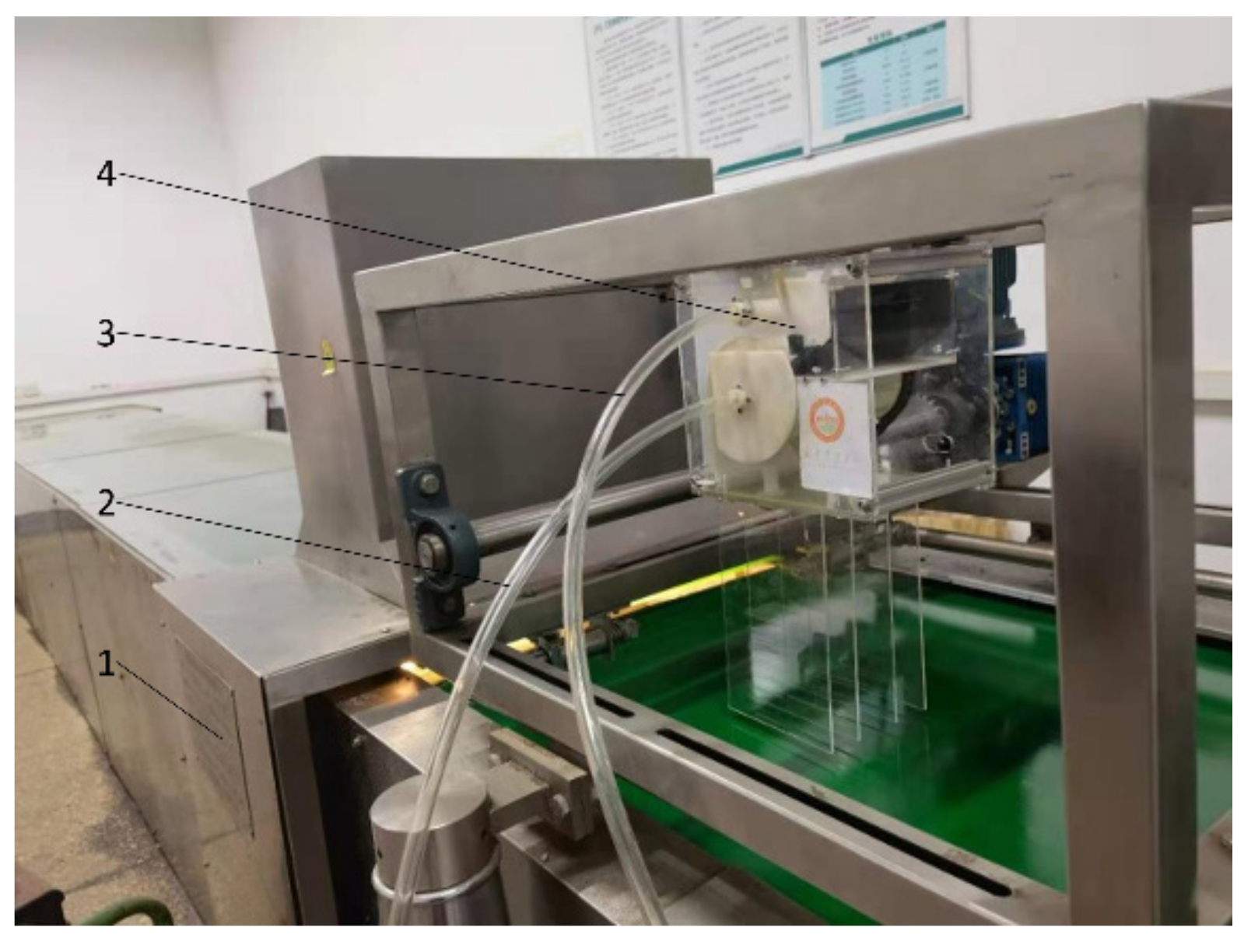

2. Structure and Working Principle

3. Key Component Parameter Design and Analysis

3.1. Structure Design of Feeding Drum

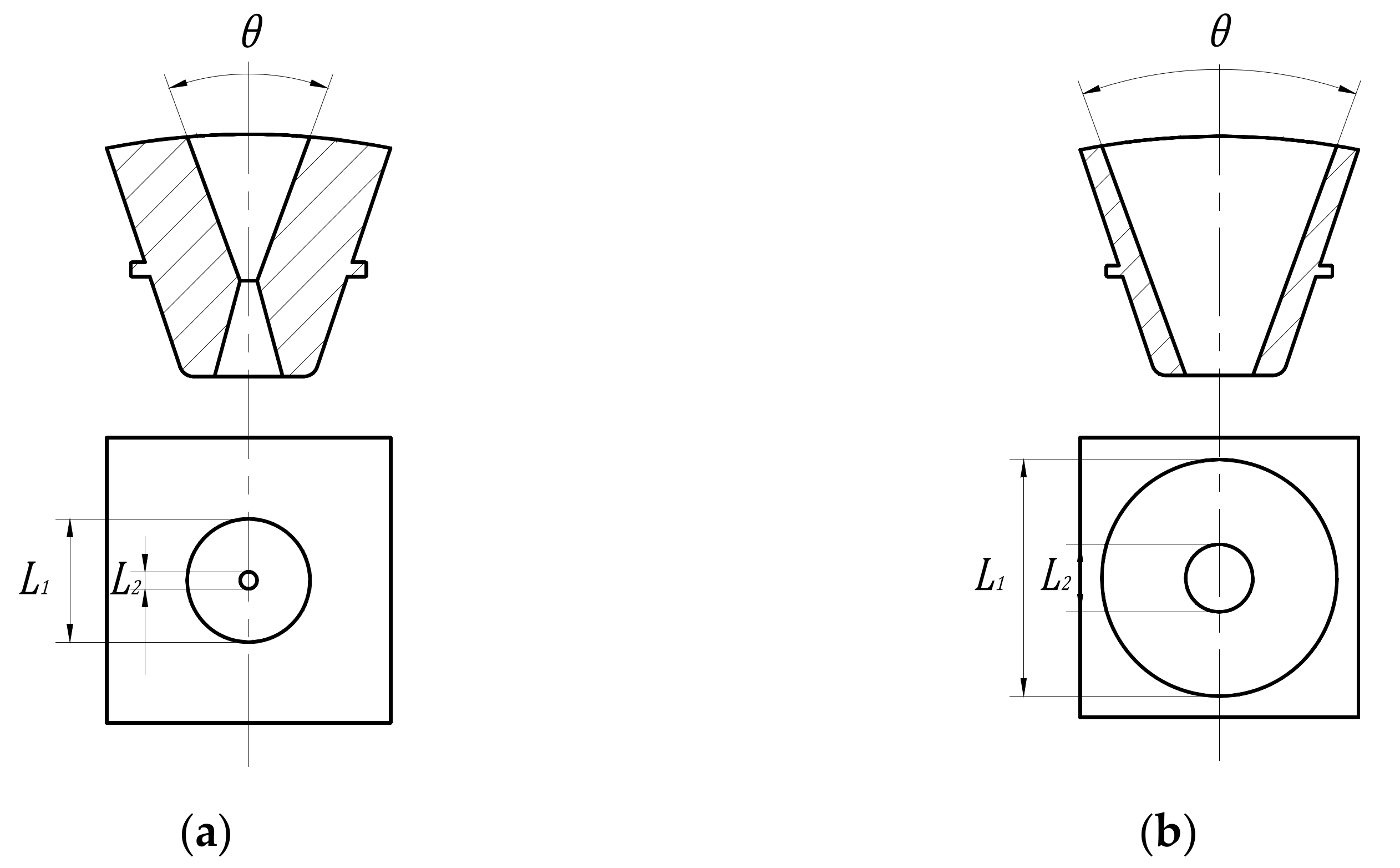

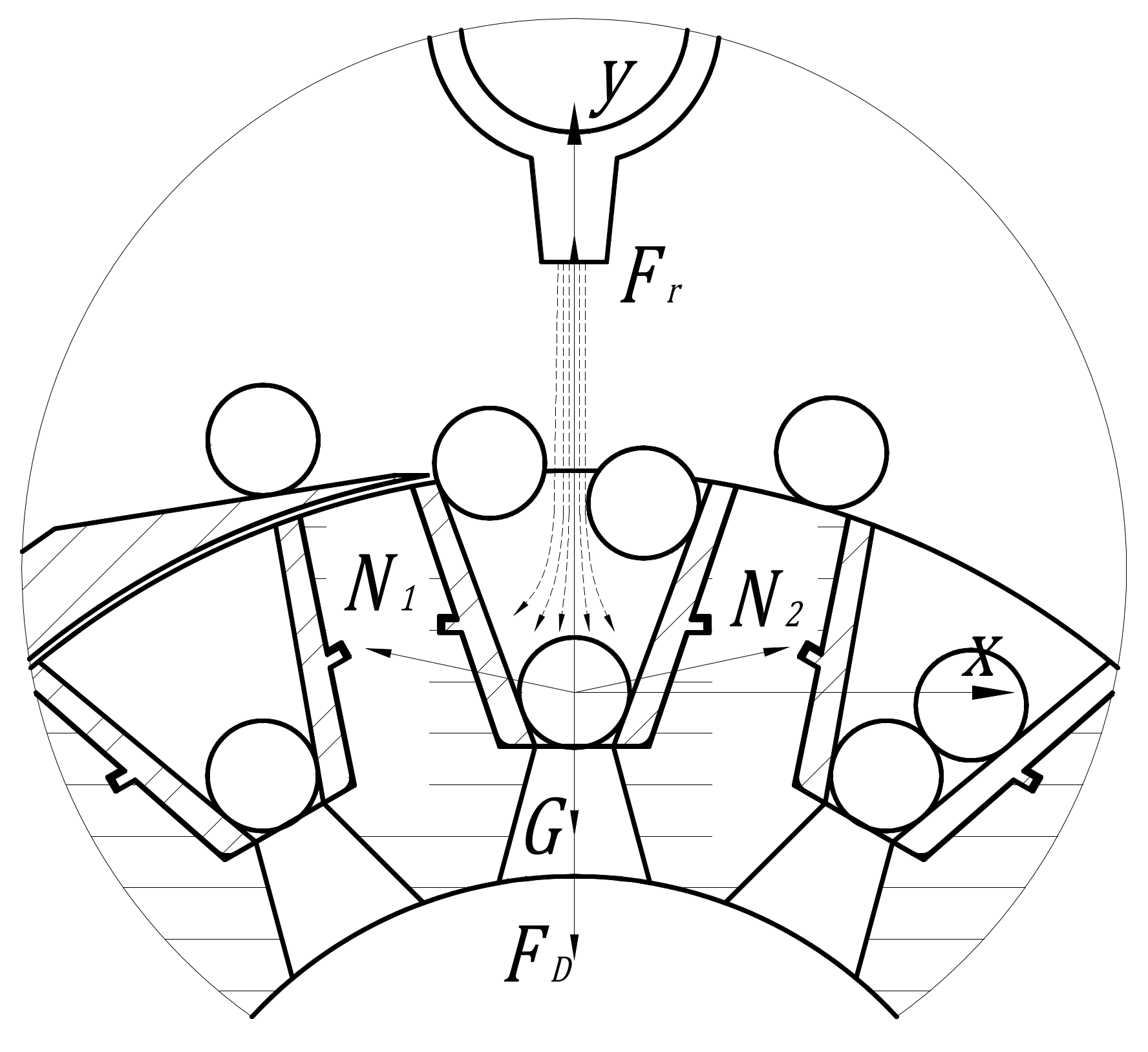

3.2. Structure Design of Type Hole and Seeding Strip

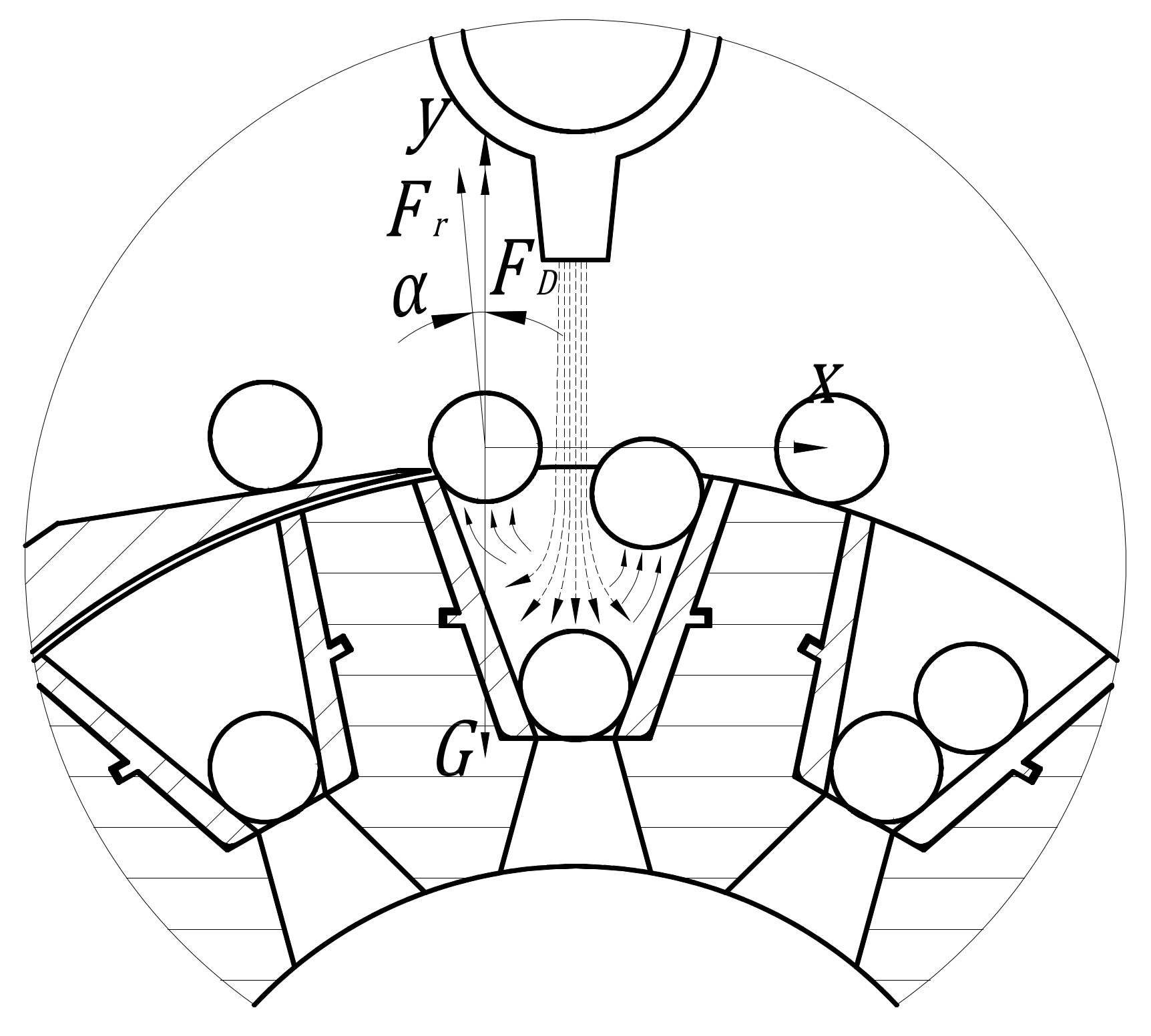

3.3. Seed Cleaning Process Analysis

4. Seed Performance Test

4.1. Test Materials and Equipment

4.2. Evaluation Index

4.3. Single-Factor Test

4.3.1. Test Method

4.3.2. Airflow Velocity of Cleaning Seed

4.3.3. Unloading Air Flow Velocity

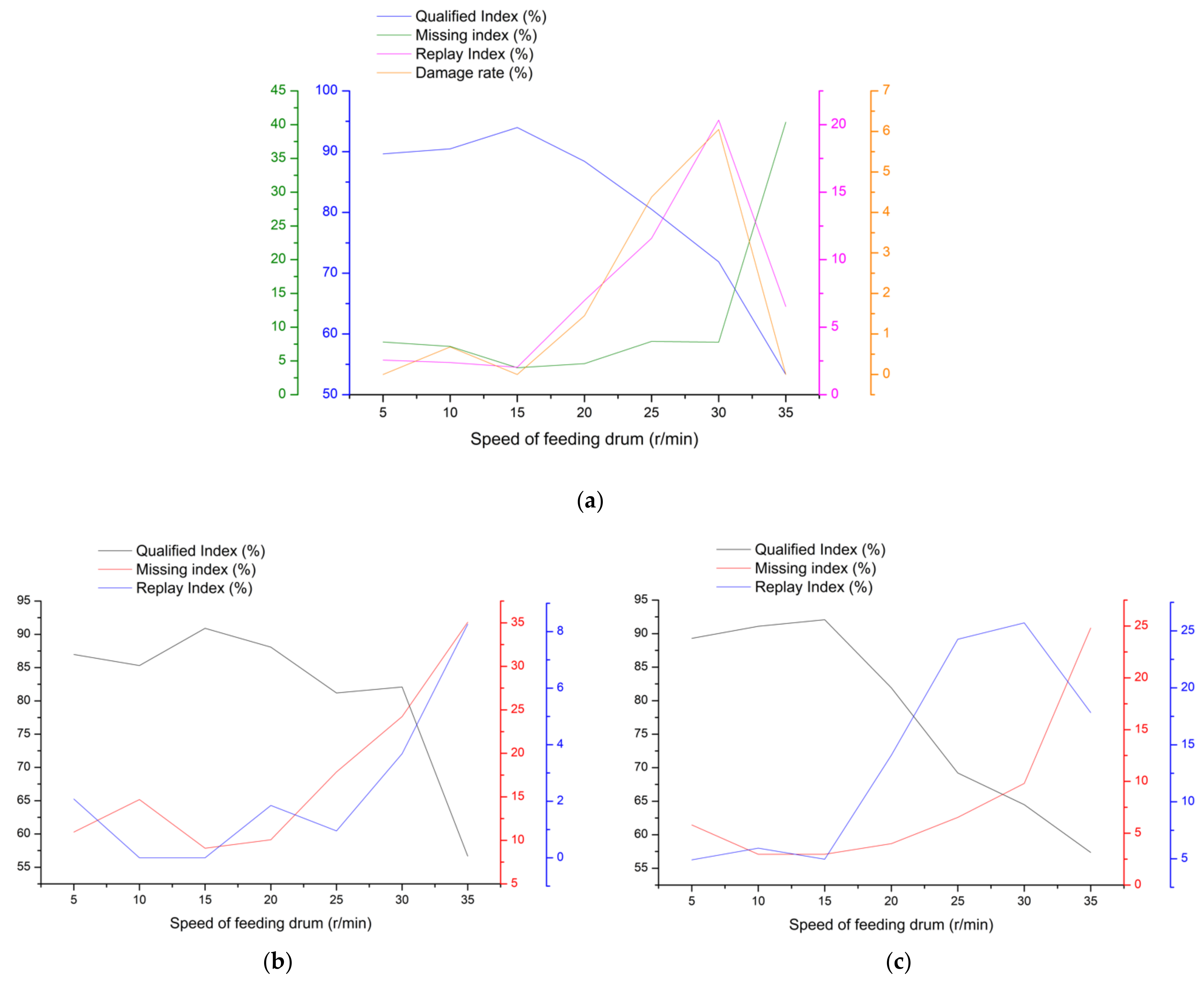

4.3.4. Rotation Speed of Feeding Drum

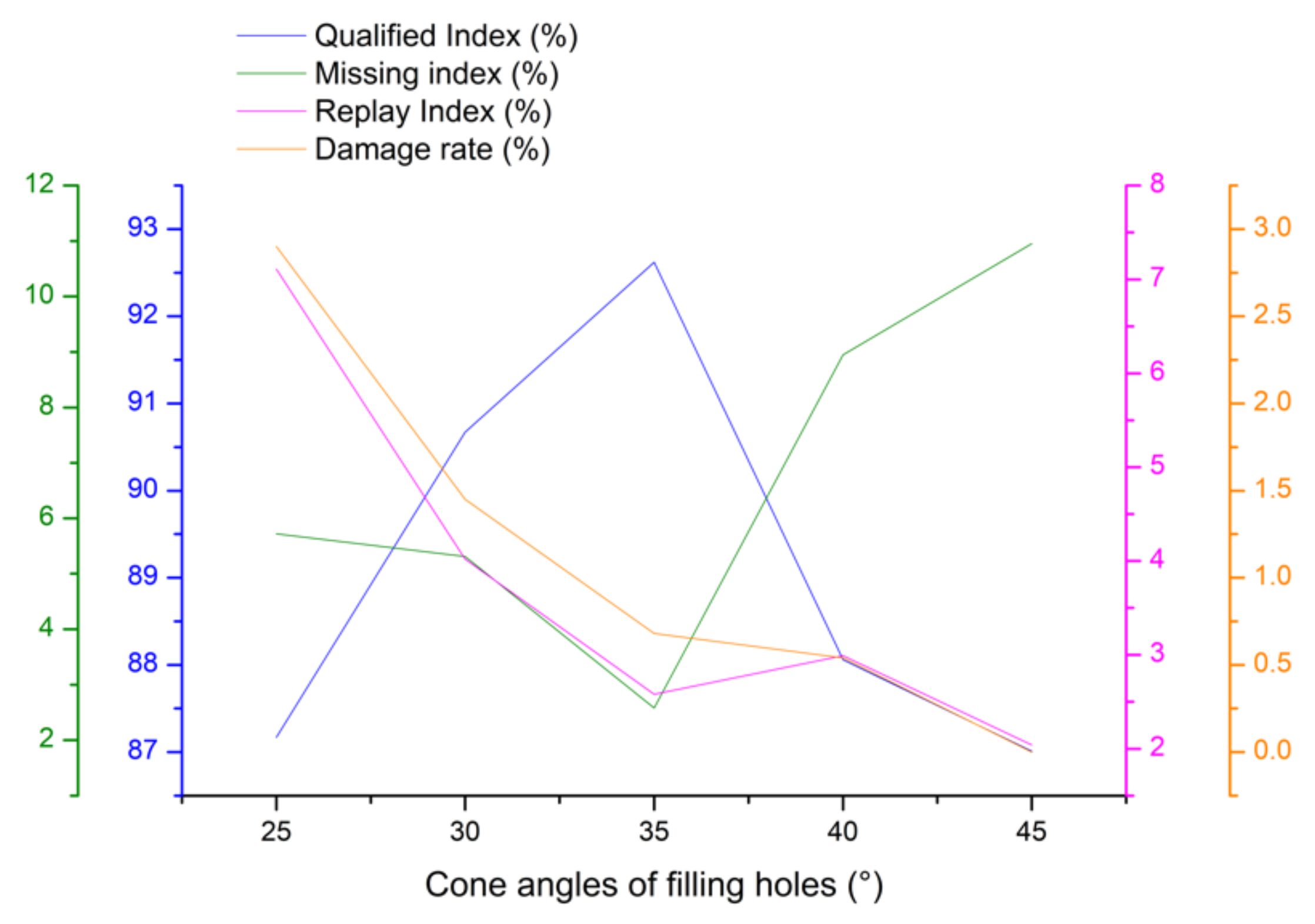

4.3.5. Cone Angle of Seed Filling Hole

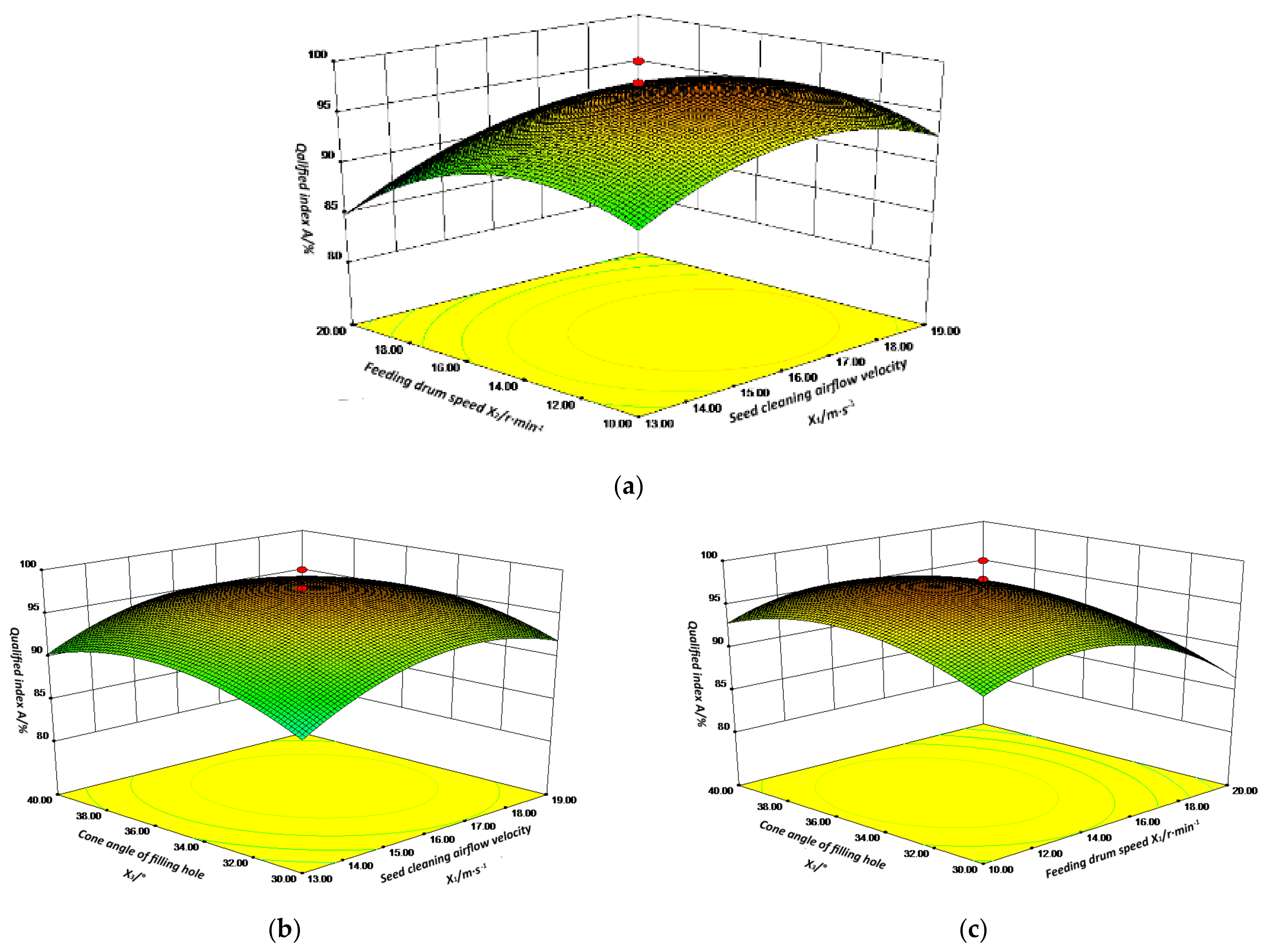

4.4. Multivariate Test

4.4.1. Test Method

4.4.2. Test Results and Establishment of Regression Model

4.4.3. Parameter Optimization

5. Conclusions

- (1)

- Under suitable working parameters, the qualified index of different sizes and shapes (e.g., soybeans, corns and rapes) reached over 85%, the reseeding index was less than 5%, the missing sowing index was less than 10%, and the damage rate was meet the requirements. As revealed from the results, the metering exhibited high performance and versatility

- (2)

- The CCD test show that the cleaning air velocity, the rotation speed of the feeding drum and the cone angle of the filling hole significantly impacted the seeding performance. The best combination of parameter levels for the seeding performance effect was the cleaning air velocity 16.7 m/s, the feeding drum speed 13.7 r/min, the filling hole cone angle 35.6°. The verification test was conducted, and the results showed that the seeding performance complied with the optimization results.

- (3)

- The future development of this research will focus on the versatility of the seed metering device for more crop seeds, and conduct field trials to verify the performance of the seed metering device in different field environments.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yitao, L.; Lei, W.; Qingxi, L. Design and test of an inside-filling pneumatic precision centralized seed-metering device for rapeseed. Int. J. Agric. Biol. Eng. 2017, 10, 56–62. [Google Scholar]

- Liu, H.; Liu, J.; Tang, S.; Xu, X. Design on opposed inclined-plate high-speed precision seed-metering device and its working mechanism analysis. Trans. Chin. Soc. Agric. Eng. 2016, 32, 24–31. [Google Scholar]

- Kamgar, S.; Noei-Khodabadi, F.; Shafaei, S.M. Design, development and field assessment of a controlled seed metering unit to be used in grain drills for direct seeding of wheat. Inf. Process. Agric. 2015, 2, 169–176. [Google Scholar] [CrossRef] [Green Version]

- Jianbo, Z.; Junfang, X.; Yong, Z.; Shun, Z. Design and experimental study of the control system for precision seed-metering device. Int. J. Agric. Biol. Eng. 2014, 7, 13–18. [Google Scholar]

- Yang, R.; Zhai, P.; Liao, Q. Recent Advances on Rapeseed Metering Devices. Recent Pat. Mech. Eng. 2017, 10, 12–17. [Google Scholar] [CrossRef]

- Lei, X.; Liao, Y.; Zhang, Q.; Wang, L.; Liao, Q. Numerical simulation of seed motion characteristics of distribution head for rapeseed and wheat. Comput. Electron. Agric. 2018, 150, 98–109. [Google Scholar] [CrossRef]

- Liao, Q.; Lei, X.; Liao, Y.; Ding, Y.; Zhang, Q.; Wang, L. Research progress of precision seeding for rapeseed. Trans. Chin. Soc. Agric. Mach. 2017, 48, 1–16. [Google Scholar]

- Cujbescu, D.; Găgeanu, I.; Persu, C.; Matache, M.; Vlăduț, V.; Voicea, I.; Paraschiv, G.; Biriș, S.Ș.; Ungureanu, N.; Voicu, G.; et al. Simulation of Sowing Precision in Laboratory Conditions. Appl. Sci. 2021, 11, 6264. [Google Scholar] [CrossRef]

- Huang, X.; Zhang, S.; Luo, C.; Li, W.; Liao, Y. Design and Experimentation of an Aerial Seeding System for Rapeseed Based on an Air-Assisted Centralized Metering Device and a Multi-Rotor Crop Protection UAV. Appl. Sci. 2020, 10, 8854. [Google Scholar] [CrossRef]

- Lü, J.; Yang, Y.; Li, Z.; Tian, Z.; Shang, Q.; Wu, J. Design and experiment of cup-belt type potato seed-metering device. Trans. Chin. Soc. Agric. Eng. 2016, 32, 17–25. [Google Scholar]

- Cong, J.; Yu, J.; Cao, X.; Liao, Y.; Liao, Q. Design of dual-purpose pneumatic precision metering device for rape and wheat. Trans. Chin. Soc. Agric. Mach. 2014, 45, 46–52. [Google Scholar]

- Singh, R.C.; Singh, G.; Saraswat, D.C. Optimisation of Design and Operational Parameters of a Pneumatic Seed Metering Device for Planting Cottonseeds. Biosyst. Eng. 2005, 92, 429–438. [Google Scholar] [CrossRef]

- Maleki, M.R.; Jafari, J.F.; Raufat, M.H.; Mouazen, A.M.; Baerdemaeker, J.D. Evaluation of Seed Distribution Uniformity of a Multi-flight Auger as a Grain Drill Metering Device. Biosyst. Eng. 2006, 94, 535–543. [Google Scholar] [CrossRef]

- Jack, D.S.; Hesterman, D.C.; Guzzomi, A.L. Precision metering of Santalum spicatum (Australian Sandalwood) seeds. Biosyst. Eng. 2013, 115, 171–183. [Google Scholar] [CrossRef]

- Yazgi, A.; Degirmencioglu, A. Measurement of seed spacing uniformity performance of a precision metering unit as function of the number of holes on vacuum plate. Measurement 2014, 56, 128–135. [Google Scholar] [CrossRef]

- Gao, X.; Zhou, J.; Lai, Q. Design and experiment of pneumatic cylinder precision seed-metering device for panax notoginseng. Trans. Chin. Soc. Agric. Eng. 2016, 32, 20–28. [Google Scholar]

- Cui, Q.; Hou, H.; Zheng, D.; Wu, Z. Design and test of tilt dise-type fine and small-amount seed metering device for foxtail millet. Trans. Chin. Soc. Agric. Eng. 2016, 32, 17–23. [Google Scholar]

- Xiaolong, L.; Hongji, H.; Wencheng, W.; Hongnan, L.; Liyang, L.; Wenhao, Y.; Zhonglin, Z.; Wanjun, R. Seed motion characteristics and seeding performance of a centralised seed metering system for rapeseed investigated by DEM simulation and bench testing. Biosyst. Eng. 2021, 203, 22–33. [Google Scholar]

- Li, Z.; Li, S.; Cao, X.; Lei, X.; Liao, Y.; Wei, Y.; Liao, Q. Seeding performance experiment of pneumatic-typed precision centralized metering device. Trans. Chin. Soc. Agric. Eng. 2015, 31, 17–25. [Google Scholar]

- Wu, M.; Guan, C.; Gao, X.; Luo, H.; Tang, C. Test on limit turning speed of eccentric round hole-wheel seedmeter for rape. Trans. Chin. Soc. Agric. Eng. 2010, 26, 119–123. [Google Scholar]

- Li, Z.; Lei, X.; Cao, X.; Liao, Y.; Liao, Q.; Li, S. Design and experiment of pneumatic-typed precision centralized metering device for rapeseed. Trans. Chin. Soc. Agric. Eng. 2015, 31, 9–17. [Google Scholar]

- Wang, Y. Design and Experiment of Precision Seed-Metering Device. Ph.D. Thesis, Shenyang Agricultural University, Shenyang, China, 2012. [Google Scholar]

- Ma, C.; Wang, S.; Zhang, S.; He, D.; Hu, S. The study and design of pneumatic wheel-type seed-metering device. Trans. Chin. Soc. Agric. Mach. 1990, 21, 28–34. [Google Scholar]

- Zhang, S.; Xia, J.; Zhou, Y.; Wu, D.; Cao, C.; Xia, P. Field experiment and seeding performance analysis of pneumatic cylinder-type precision direct seed-metering device for rice. Trans. Chin. Soc. Agric. Eng. 2017, 33, 14–23. [Google Scholar]

- Huang, J. Design on Centralized Slot Wheeled Precision Metering Device for Rapeseed and Experiment on Its Damaged Rate. Master’s Thesis, Huazhong Agricultural University, Wuhan, China, 2010. [Google Scholar]

- Hu, S.; Ma, C.; Li, H.; Li, S. Effects of conical hold design parameters on seed-metering performance a study on the pneumatic seed-metering device. Trans. Chin. Soc. Agric. Mach. 1981, 3, 21–31. [Google Scholar]

- Standardization Administration of the P.R.C. Testing Methods of Single Seed Drills. GB/T 6973-2005, 24; Standardization Administration of the P.R.C.: Beijing, China, 2005. [Google Scholar]

| Levels | Factor | ||

|---|---|---|---|

| Clearing Airflow Velocity X1/m/s | Speed of Feeding Drum X2/r·min−1 | Cone Angles of Filling Holes X3/° | |

| 1.682 | 21 | 23.4 | 43.4 |

| 1 | 19 | 20 | 40 |

| 0 | 16 | 15 | 35 |

| −1 | 13 | 10 | 30 |

| −1.682 | 11 | 6.6 | 26.6 |

| Experimental Number | Experimental Factor | Experimental Index | ||||

|---|---|---|---|---|---|---|

| Clearing Airflow Velocity X1/m/s | Speed of Feeding Drum X2/r·min−1 | Cone Angles of Filling Holes X3/° | Qualified Index A/% | Replay Index D/% | Missing Index M/% | |

| 1 | −1 | 1 | 1 | 82.51 | 7.89 | 9.6 |

| 2 | 0 | 1.682 | 0 | 82.03 | 6.01 | 11.96 |

| 3 | 0 | 0 | 1.682 | 92.88 | 1.11 | 6.01 |

| 4 | 1 | −1 | 1 | 88.08 | 4.51 | 7.41 |

| 5 | −1 | −1 | 1 | 88.36 | 5.2 | 6.44 |

| 6 | 1 | 1 | 1 | 82.9 | 1.65 | 15.45 |

| 7 | 0 | 0 | 0 | 96.96 | 0 | 3.04 |

| 8 | 0 | 0 | 0 | 95.84 | 0 | 4.16 |

| 9 | 1 | −1 | −1 | 89 | 3.7 | 7.3 |

| 10 | 0 | 0 | 0 | 97.92 | 2.08 | 0 |

| 11 | 1 | 1 | −1 | 84.76 | 4.07 | 11.17 |

| 12 | −1 | −1 | −1 | 88.43 | 5.13 | 6.44 |

| 13 | 0 | 0 | 0 | 100 | 0 | 0 |

| 14 | 0 | 0 | 0 | 96.84 | 1.04 | 2.12 |

| 15 | −1 | 1 | −1 | 81.25 | 8.75 | 10 |

| 16 | 0 | 0 | 0 | 96.88 | 0 | 3.12 |

| 17 | 0 | 0 | −1.682 | 85.8 | 5.62 | 8.58 |

| 18 | 1.682 | 0 | 0 | 92.77 | 0 | 7.23 |

| 19 | 0 | −1.682 | 0 | 88.52 | 1.04 | 10.44 |

| 20 | −1.682 | 0 | 0 | 82.92 | 5.71 | 11.37 |

| Variance Source | Qualified Index A/% | Replay Index D/% | Missing Index M/% | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sum of Square | Degree of Freedom | Mean Square | F Value | p Value | Sum of Square | Degree of Freedom | Mean Square | F Value | p Value | Sum of Square | Degree of Freedom | Mean Square | F Value | p Value | |

| Model | 652.82 | 9 | 72.54 | 13.20 | 0.0002 | 131.26 | 9 | 14.58 | 7.09 | 0.0026 | 271.57 | 9 | 30.17 | 5.65 | 0.0061 |

| X1 | 31.54 | 1 | 31.54 | 5.74 | 0.0376 | 37.54 | 1 | 37.54 | 18.24 | 0.0016 | 0.26 | 1 | 0.26 | 0.049 | 0.8295 |

| X2 | 81.51 | 1 | 81.51 | 14.83 | 0.0032 | 10.86 | 1 | 10.86 | 5.28 | 0.0445 | 32.87 | 1 | 32.87 | 6.16 | 0.0325 |

| X3 | 7.79 | 1 | 7.79 | 1.42 | 0.2612 | 7.30 | 1 | 7.30 | 3.55 | 0.0890 | 8.081 × 10−3 | 1 | 8.081 × 10−3 | 1.514 × 10−3 | 0.9697 |

| X1X2 | 1.63 | 1 | 1.63 | 0.30 | 0.5981 | 9.68 | 1 | 9.68 | 4.70 | 0.0553 | 3.37 | 1 | 3.37 | 0.63 | 0.4455 |

| X1X3 | 1.97 | 1 | 1.97 | 0.36 | 0.5627 | 0.084 | 1 | 0.084 | 0.041 | 0.8439 | 2.87 | 1 | 2.87 | 0.54 | 0.4804 |

| X2X3 | 0.019 | 1 | 0.019 | 3.459 × 10−3 | 0.9543 | 2.16 | 1 | 2.16 | 1.05 | 0.3294 | 1.78 | 1 | 1.78 | 0.33 | 0.5767 |

| X12 | 190.82 | 1 | 190.82 | 34.72 | 0.0002 | 20.20 | 1 | 20.20 | 9.82 | 0.0106 | 86.84 | 1 | 86.84 | 16.27 | 0.0024 |

| X22 | 298.01 | 1 | 298.01 | 54.22 | <0.0001 | 29.10 | 1 | 29.10 | 14.14 | 0.0037 | 140.87 | 1 | 140.87 | 26.39 | 0.0004 |

| X32 | 139.41 | 1 | 139.41 | 25.36 | 0.0005 | 26.82 | 1 | 26.82 | 13.03 | 0.0048 | 43.93 | 1 | 43.93 | 8.23 | 0.0167 |

| Residual | 54.96 | 10 | 5.50 | 20.58 | 10 | 2.06 | 53.37 | 10 | 5.34 | ||||||

| Lack of Fit | 44.72 | 5 | 8.94 | 4.37 | 0.0658 | 16.80 | 5 | 3.36 | 4.44 | 0.0639 | 38.39 | 5 | 7.68 | 2.56 | 0.1625 |

| Pure Error | 10.24 | 5 | 2.05 | 3.79 | 5 | 0.76 | 14.98 | 5 | 3.00 | ||||||

| Cor Total | 707.78 | 19 | 151.84 | 19 | 324.94 | 19 | |||||||||

| Levels | Qualified Index A/% | Replay Index D/% | Missing Index M/% |

|---|---|---|---|

| 1 | 99.07 | 0 | 0.93 |

| 2 | 98.15 | 0 | 1.85 |

| 3 | 99.07 | 0 | 0.93 |

| 4 | 97.00 | 0 | 3.00 |

| 5 | 97.20 | 0 | 2.80 |

| Average | 98.10 | 0 | 1.90 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, D.; Wu, M.; Xie, W.; Liu, R.; Luo, H. Design and Experimental Study of the General Mechanical Pneumatic Combined Seed Metering Device. Appl. Sci. 2021, 11, 7223. https://doi.org/10.3390/app11167223

Xiong D, Wu M, Xie W, Liu R, Luo H. Design and Experimental Study of the General Mechanical Pneumatic Combined Seed Metering Device. Applied Sciences. 2021; 11(16):7223. https://doi.org/10.3390/app11167223

Chicago/Turabian StyleXiong, Dengyu, Mingliang Wu, Wei Xie, Rong Liu, and Haifeng Luo. 2021. "Design and Experimental Study of the General Mechanical Pneumatic Combined Seed Metering Device" Applied Sciences 11, no. 16: 7223. https://doi.org/10.3390/app11167223

APA StyleXiong, D., Wu, M., Xie, W., Liu, R., & Luo, H. (2021). Design and Experimental Study of the General Mechanical Pneumatic Combined Seed Metering Device. Applied Sciences, 11(16), 7223. https://doi.org/10.3390/app11167223