IFC-Based 4D Construction Management Information Model of Prefabricated Buildings and Its Application in Graph Database

Abstract

1. Introduction

2. Literature Review

2.1. 4D BIM and Construction Management

2.2. Delay Analysis of Construction Management

2.3. IFC Extension

2.4. Conclusion

3. Methodology

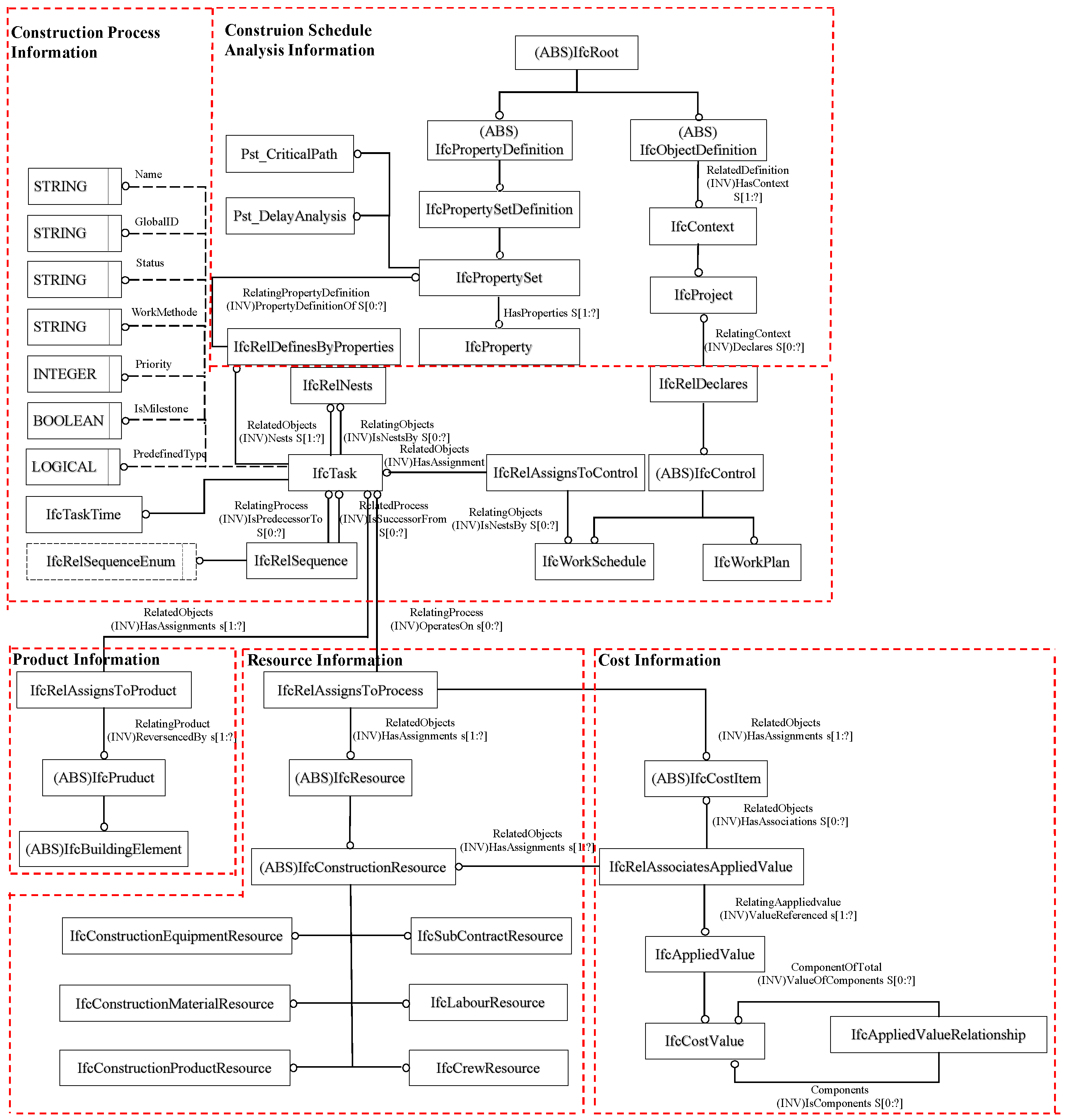

4. Realization of IFC-Based 4D Construction Information Model of Prefabricated Buildings

4.1. IFC Standard and Its Extension Mechanism

4.2. Realizing the Extension of IFC-Based 4D Construction Management Information Model of Prefabricated Buildings

4.2.1. Realizing Process Information’s Extension Based on IFC Standard

4.2.2. Realizing Resource Information’s Extension Based on IFC Standard

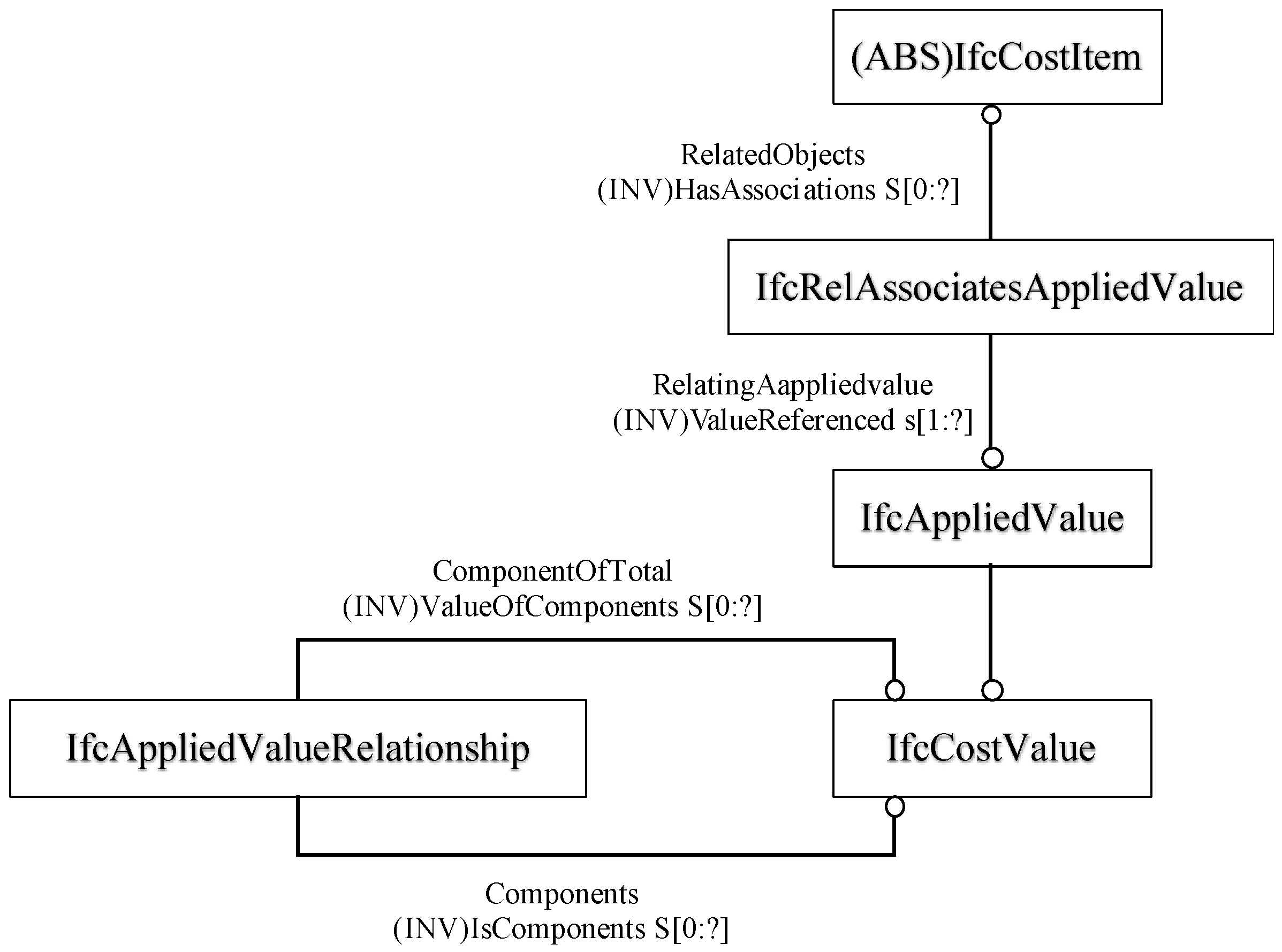

4.2.3. Realizing Cost Information’s Extension Based on IFC Standard

4.2.4. Realizing Construction Schedule Analysis Information’s Extension Based on IFC Standard

4.2.5. Realizing Information Extension Based on IFC Standard

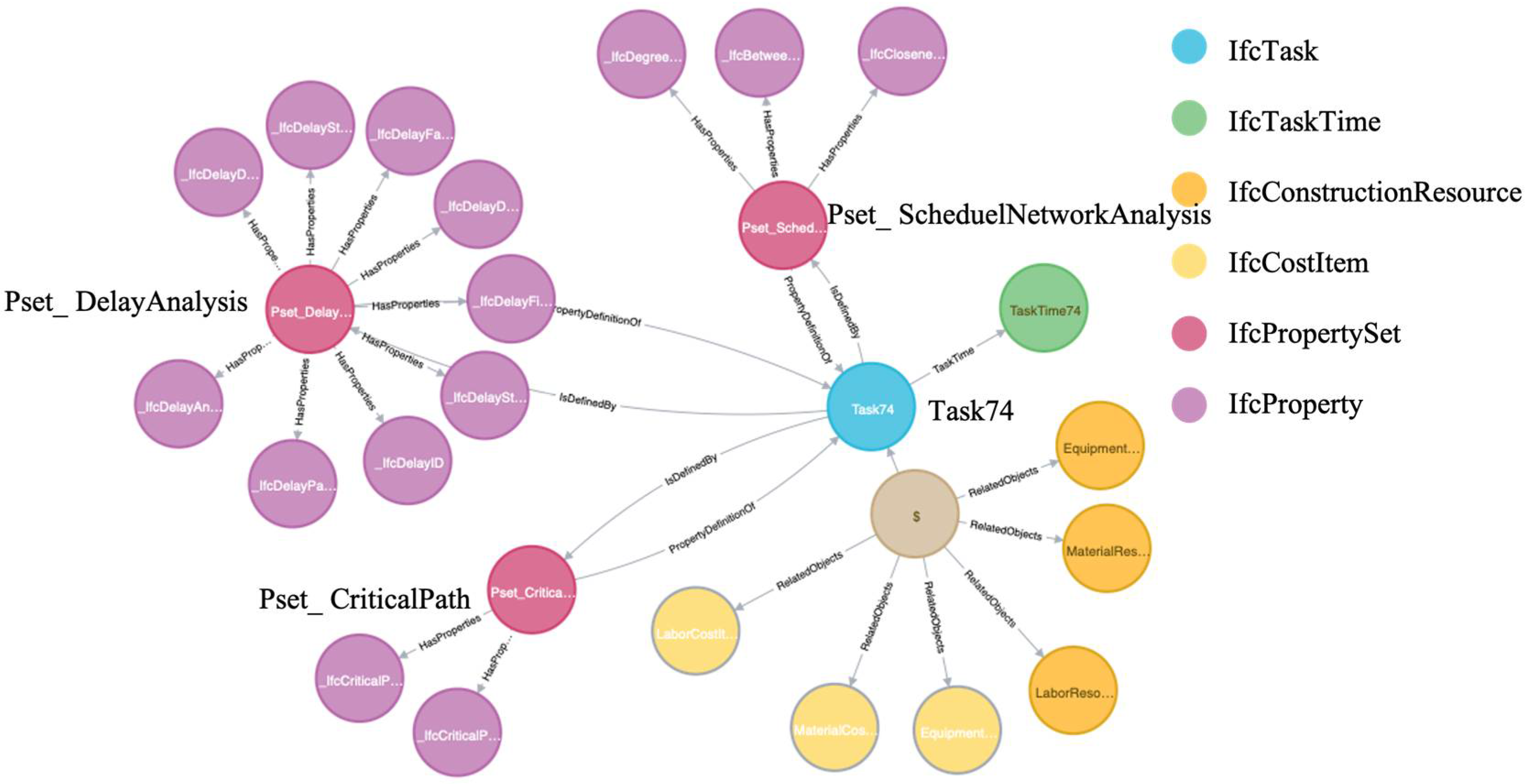

4.3. Instantiating the IFC-Based 4D Construction Management Information Model of Prefabricated Buildings

5. Twinning the IFC-Based 4D Construction Management Information Model into Graph Database

6. Analyzing the Graph Database-Based and IFC-Based Construction Management Information Model

6.1. Data Update

6.2. Schedule Network Analysis

6.3. Delay Analysis

6.4. 4D Visualization

7. Case Study

7.1. Realizing the IFC-Based 4D Construction Management Information Model of Engineering Case’s Prefabricated Building

7.2. Twinning the IFC-Based 4D Construction Management Information Model of Engineering Case’s Prefabricated Building to Graph Database

7.3. Analyzing the Graph Database-Based and IFC-Based 4D Construction Management Information Model of Engineering Case’s Prefabricated Building

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wang, H.; Zhang, Y.; Gao, W.; Kuroki, S. Life Cycle Environmental and Cost Performance of Prefabricated Buildings. Sustainability 2020, 12, 2609. [Google Scholar] [CrossRef]

- Wang, Q.; Guo, Z.; Mei, T.; Li, Q.; Li, P. Labor Crew Workspace Analysis for Prefabricated Assemblies’ Installation: A 4D-BIM-Based Approach. Eng. Constr. Archit. Manag. 2018, 25, 374–411. [Google Scholar] [CrossRef]

- Ji, Y.; Qi, K.; Qi, Y.; Li, Y.; Li, H.X.; Lei, Z.; Liu, Y. BIM-Based Life-Cycle Environmental Assessment of Prefabricated Buildings. Eng. Constr. Archit. Manag. 2020. [Google Scholar] [CrossRef]

- Xue, H.; Zhang, S.; Su, Y.; Wu, Z. Factors Affecting the Capital Cost of Prefabrication-A Case Study of China. Sustainability 2017, 9, 1512. [Google Scholar] [CrossRef]

- Baglivo, C.; Congedo, P.M. High Performance Precast External Walls for Cold Climate by a Multi-Criteria Methodology. Energy 2016, 115, 561–576. [Google Scholar] [CrossRef]

- Yu, S.; Liu, Y.; Wang, D.; Bahaj, A.S.; Wu, Y.; Liu, J. Review of Thermal and Environmental Performance of Prefabricated Buildings: Implications to Emission Reductions in China. Renew. Sustain. Energy Rev. 2021, 137, 110472. [Google Scholar] [CrossRef]

- Richard, R.B. Industrialised Building Systems: Reproduction before Automation and Robotics. Autom. Constr. 2005, 14, 442–451. [Google Scholar] [CrossRef]

- Eastman, C.M.; Eastman, C.; Teicholz, P.; Sacks, R.; Liston, K. BIM Handbook: A Guide to Building Information Modeling for Owners, Managers, Designers, Engineers and Contractors; John Wiley & Sons: Hoboken, NJ, USA, 2011; ISBN 978-0-470-54137-1. [Google Scholar]

- De Gaetani, C.I.; Mert, M.; Migliaccio, F. Interoperability Analyses of BIM Platforms for Construction Management. Appl. Sci. 2020, 10, 4437. [Google Scholar] [CrossRef]

- Chen, Q.; Hall, D.M.; Adey, B.T.; Haas, C.T. Identifying Enablers for Coordination across Construction Supply Chain Processes: A Systematic Literature Review. Eng. Constr. Archit. Manag. 2020, 28, 1083–1113. [Google Scholar] [CrossRef]

- Volk, R.; Stengel, J.; Schultmann, F. Building Information Modeling (BIM) for Existing Buildings—Literature Review and Future Needs. Autom. Constr. 2014, 38, 109–127. [Google Scholar] [CrossRef]

- buildingSmart ISO 16739-1:2018. Available online: https://www.iso.org/cms/render/live/en/sites/isoorg/contents/data/standard/07/03/70303.html (accessed on 15 March 2021).

- Xue, W.; Wang, Y.; Man, Q. Research on Information Models for the Construction Schedule Management Based on the IFC Standard. J. Ind. Eng. Manag. 2015, 8, 615–635. [Google Scholar] [CrossRef]

- Muller, M.F.; Garbers, A.; Esmanioto, F.; Huber, N.; Loures, E.R.; Canciglieri Junior, O. Data interoperability assessment though IFC for BIM in structural design—A five-year gap analysis. J. Civ. Eng. Manag. 2017, 23, 943–954. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, L. A BIM-Data Mining Integrated Digital Twin Framework for Advanced Project Management. Autom. Constr. 2021, 124, 103564. [Google Scholar] [CrossRef]

- Hamledari, H.; McCabe, B.; Davari, S.; Shahi, A. Automated Schedule and Progress Updating of IFC-Based 4D BIMs. J. Comput. Civ. Eng. 2017, 31, 04017012. [Google Scholar] [CrossRef]

- Mckinney, K.; Kim, J.; Fischer, M.; Howard, C. Interactive 4D-CAD. In Proceedings of the ASCE Third Congress on Computing in Civil Engineering, Anaheim, CA, USA, 17–19 June 1996; pp. 381–389. [Google Scholar]

- Wang, H.J.; Zhang, J.P.; Chau, K.W.; Anson, M. 4D Dynamic Management for Construction Planning and Resource Utilization. Autom. Constr. 2004, 13, 575–589. [Google Scholar] [CrossRef]

- Zhang, J.-P.; Anson, M.; Wang, Q. A New 4D Management Approach to Construction Planning and Site Space Utilization. In Proceedings of the Eighth International Conference on Computing in Civil and Building Engineering (ICCCBE-VIII), Moscow, Russia, 27–29 June 2012; pp. 15–22. [Google Scholar] [CrossRef]

- Chen, L.; Luo, H. A BIM-Based Construction Quality Management Model and Its Applications. Autom. Constr. 2014, 46, 64–73. [Google Scholar] [CrossRef]

- De Soto, B.G.; Rosarius, A.; Rieger, J.; Chen, Q.; Adey, B.T. Using a Tabu-search Algorithm and 4D Models to Improve Construction Project Schedules. In Creative Construction Conference 2017, Ccc 2017; Hajdu, M., Skibniewski, M.E., Eds.; Elsevier Science Bv: Amsterdam, The Netherlands, 2017; Volume 196, pp. 698–705. [Google Scholar]

- Li, C.Z.; Xue, F.; Li, X.; Hong, J.; Shen, G.Q. An Internet of Things-Enabled BIM Platform for on-Site Assembly Services in Prefabricated Construction. Autom. Constr. 2018, 89, 146–161. [Google Scholar] [CrossRef]

- Valluru, P.; Shetty, S. An Approach to Open-BIM Based Construction Project Management; Universitätsverlag der TU Berlin: Berlin, Germany, 2019; ISBN 978-3-7983-3104-4. [Google Scholar]

- Deng, Y.; Gan, V.J.L.; Das, M.; Cheng, J.C.P.; Anumba, C. Integrating 4D BIM and GIS for Construction Supply Chain Management. J. Constr. Eng. Manag. 2019, 145, 04019016. [Google Scholar] [CrossRef]

- Vieira, R.; Carreira, P.; Domingues, P.; Costa, A.A. Supporting Building Automation Systems in BIM/IFC: Reviewing the Existing Information Gap. Eng. Constr. Archit. Manag. 2020, 27, 1357–1375. [Google Scholar] [CrossRef]

- Ji, Y.; Qi, L.; Liu, Y.; Liu, X.; Li, H.X.; Li, Y. Assessing and Prioritising Delay Factors of Prefabricated Concrete Building Projects in China. Appl. Sci. 2018, 8, 2324. [Google Scholar] [CrossRef]

- Li, Z.; Shen, G.Q.; Xue, X. Critical Review of the Research on the Management of Prefabricated Construction. Habitat Int. 2014, 43, 240–249. [Google Scholar] [CrossRef]

- Bektas, S.; Talat Birgonul, M.; Dikmen, I. Integrated Probabilistic Delay Analysis Method to Estimate Expected Outcome of Construction Delay Disputes. J. Leg. Aff. Dispute Resolut. Eng. Constr. 2021, 13, 04520037. [Google Scholar] [CrossRef]

- Dallasega, P.; Marengo, E.; Revolti, A. Strengths and Shortcomings of Methodologies for Production Planning and Control of Construction Projects: A Systematic Literature Review and Future Perspectives. Prod. Plan. Control 2021, 32, 257–282. [Google Scholar] [CrossRef]

- Bokor, O.; Hajdu, M. Investigation of Critical Activities in a Network with Point-to-Point Relations. Procedia Eng. 2015, 123, 198–207. [Google Scholar] [CrossRef][Green Version]

- Lo, W.; Kuo, M.-E. Cost Impact of Float Loss on a Project with Adjustable Activity Durations. J. Oper. Res. Soc. 2013, 64, 1147–1156. [Google Scholar] [CrossRef]

- Seppänen, O.; Evinger, J.; Mouflard, C. Effects of the Location-Based Management System on Production Rates and Productivity. Constr. Manag. Econ. 2014, 32, 608–624. [Google Scholar] [CrossRef]

- Turkakin, O.H.; Manisali, E.; Arditi, D. Delay Analysis in Construction Projects with No Updated Work Schedules. Eng. Constr. Archit. Manag. 2020. [Google Scholar] [CrossRef]

- Yang, J.B.; Kao, C.K. Critical Path Effect Based Delay Analysis Method for Construction Projects. Int. J. Proj. Manag. 2012, 30, 385–397. [Google Scholar] [CrossRef]

- Menesi, W.; Hegazy, T. Why CPS Is Better than CPM? In Proceedings of the Annual Conference-Canadian Society for Civil Engineering, Ottawa, ON, Canada, 14–17 June 2011; Volume 3.

- Yu, K.; Froese, T.; Grobler, F. A Development Framework for Data Models for Computer-Integrated Facilities Management. Autom. Constr. 2000, 9, 145–167. [Google Scholar] [CrossRef]

- Lam, K.P.; Wong, N.H.; Shen, L.J.; Mahdavi, A.; Leong, E.; Solihin, W.; Au, K.S.; Kang, Z. Mapping of Industry Building Product Model for Detailed Thermal Simulation and Analysis. Adv. Eng. Softw. 2006, 37, 133–145. [Google Scholar] [CrossRef]

- Zhang, J.; Guo, J.; Wang, S.; Xu, Z. Intelligent Facilities Management System Based on IFC Standard and Building Equipment Integration. J. Tsinghua Univ. Sci. Technol. 2008, 48, 940–942, 946. [Google Scholar]

- Zhang, J.; Yu, F.; Li, D.; Hu, Z. Development and Implementation of an Industry Foundation Classes-Based Graphic Information Model for Virtual Construction. Comput. Aided Civ. Infrastruct. Eng. 2014, 29, 60–74. [Google Scholar] [CrossRef]

- Ma, Z.; Teng, M.; Ren, Y. Method of Extracting Static Data of Building Energy Consumption Monitoring from BIM Model. J. Harbin Inst. Technol. 2019, 51, 187–193. [Google Scholar]

- Xu, Z.; Wang, X.; Xiao, Y.; Yuan, J. Modeling and Performance Evaluation of PPP Projects Utilizing IFC Extension and Enhanced Matter-Element Method. Eng. Constr. Archit. Manag. 2020, 27, 1763–1794. [Google Scholar] [CrossRef]

- Akinci, B.; Boukamp, F. Representation and Integration of As-Built Information to IFC Based Product and Process Models for Automated Assessment of As-Built Conditions. ISARC Proc. 2002, 543–548. [Google Scholar]

- Seo, J.; Kim, I. Industry Foundation Classes-Based Approach for Managing and Using the Design Model and Planning Information in the Architectural Design. J. Asian Archit. Build. Eng. 2009, 8, 431–438. [Google Scholar] [CrossRef][Green Version]

- Park, J.; Cai, H.; Dunston, P.S.; Ghasemkhani, H. Database-Supported and Web-Based Visualization for Daily 4D BIM. J. Constr. Eng. Manag. 2017, 143, 04017078. [Google Scholar] [CrossRef]

- Gui, N.; Wang, C.; Qiu, Z.; Gui, W.; Deconinck, G. IFC-Based Partial Data Model Retrieval for Distributed Collaborative Design. J. Comput. Civ. Eng. 2019, 33, 04019016. [Google Scholar] [CrossRef]

- Weise, M.; Liebich, T.; Wix, J. Integrating Use Case Definitions for IFC Developments; Zarli, A., Scherer, R., Eds.; CRC Press-Taylor & Francis Group: Boca Raton, FL, USA, 2009; pp. 637–645. ISBN 978-0-415-48245-5. [Google Scholar]

- Lee, S.-H.; Kim, B.-G. IFC Extension for Road Structures and Digital Modeling. In Proceedings of the Twelfth East Asia-Pacific Conference on Structural Engineering and Construction (easec12); Fai, L.H., Ed.; Elsevier Science Bv: Amsterdam, The Netherlands, 2011; Volume 14, pp. 1037–1042. [Google Scholar]

- Chen, L.; Lai, H.; Deng, X.; Lv, Z. Research on Methods of Entity Extension in IFC Standard Domain Layer. J. Graph. 2015, 36, 282–288. [Google Scholar]

- xbim Ltd. Xbim Toolkit. Available online: https://docs.xbim.net/ (accessed on 15 December 2020).

- Solihin, W.; Eastman, C.; Lee, Y.-C. Multiple Representation Approach to Achieve High-Performance Spatial Queries of 3D BIM Data Using a Relational Database. Autom. Constr. 2017, 81, 369–388. [Google Scholar] [CrossRef]

- Marmo, R.; Polverino, F.; Nicolella, M.; Tibaut, A. Building Performance and Maintenance Information Model Based on IFC Schema. Autom. Constr. 2020, 118, 103275. [Google Scholar] [CrossRef]

- Beetz, J.; van Berlo, L.; de Laat, R. Bimserver.org—An open source IFC model server. In Proceedings of the CIP W78 Conference, Cairo, Egypt, 16–19 November 2010; p. 9. [Google Scholar]

- Lin, Y.-H.; Liu, Y.-S.; Gao, G.; Han, X.-G.; Lai, C.-Y.; Gu, M. The IFC-Based Path Planning for 3D Indoor Spaces. Adv. Eng. Inform. 2013, 27, 189–205. [Google Scholar] [CrossRef]

- Ma, L.; Sacks, R. A Cloud-Based BIM Platform for Information Collaboration.; IAARC (The International Association for Automation and Robotics in Construction): Auburn, AL, USA, 1 October 2016; Volume 33, pp. 581–589. [Google Scholar]

- Chen, Z.; Pu, Y.; Shelden, D.R. A Graph Database and Query Approach to IFC Data Management. Future Inf. Exch. Interoperability 2019, 28–36. [Google Scholar]

- Neo4j Inc. Graph Database Use Cases: Neo4j for Graph Data Science and AI. Available online: https://neo4j.com/use-cases/graph-data-science-artificial-intelligence/ (accessed on 15 December 2020).

- Huang, H.; Dong, Z. Research on Architecture and Query Performance Based on Distributed Graph Database Neo4j; IEEE: New York, NY, USA, 2013; pp. 533–536. ISBN 978-1-4799-2860-6. [Google Scholar]

- Avelar, P.; Lemos, H.; Prates, M.; Lamb, L. Multitask Learning on Graph Neural Networks: Learning Multiple Graph Centrality Measures with a Unified Network. In Artificial Neural Networks and Machine Learning—ICANN 2019: Workshop and Special Sessions; Tetko, I.V., Kůrková, V., Karpov, P., Theis, F., Eds.; Lecture Notes in Computer Science; Springer International Publishing: Cham, Switzerland, 2019; Volume 11731, pp. 701–715. ISBN 978-3-030-30492-8. [Google Scholar]

- Bavelas, A. Communication Patterns in Task-Oriented Groups. J. Acoust. Soc. Am. 1950, 22, 725–730. [Google Scholar] [CrossRef]

- Freeman, L.C. A Set of Measures of Centrality Based on Betweenness. Sociometry 1977, 40, 35. [Google Scholar] [CrossRef]

| Functions | Software | Features |

|---|---|---|

| IFC files parsing | xBIM | It can generate IFC files. |

| IFC-gen | It can automatically generate syntax trees based on the input IFC files. | |

| IfcEditor | Simple text parsing. It can generate syntax trees. | |

| IFC File Analyzer | It can generate xls files. | |

| IfcOpenShell | It supports Python to compile IFC 2X3 and IFC4 files. | |

| IFC models display | BIM Vision | 1. Can display 3D models 2. Does not support visualize time-related entities, such as IfcTask, IfcTaskTime. |

| Solibri Anywhere | ||

| XBIMXplore | ||

| IFC++ |

| Extension Methods | Usability | Compatibility | Time Consumption | Operational Efficiency |

|---|---|---|---|---|

| Based on increasing entity types. | Difficult | Cannot be guaranteed | Long | High |

| Based on IfcProxy, IfcBuildingElementryProxy, and existing entities. | Easy | Good | Short | Low |

| Based on property sets. | Easy | Somewhere in between | Somewhere in between | Somewhere in between |

| Property Sets’ Names | Application Entities | Description |

|---|---|---|

| Pset_ScheduleNetworkAnalysis | IfcTask | Property set to store parameters’ value of schedule network. |

| Pset_CriticalPath | IfcTask | Property set to store information of critical path. |

| Pset_DelayAnalysis | IfcTask | Property set to store information of delay analysis. |

| Attributes | Property Type | Entity Data Type | Description |

|---|---|---|---|

| _IfcDegreeCentrality | IfcPropertySingleValue | IfcReal | A real value to express the degree centrality of construction tasks. |

| _IfcClosenessCentrality | IfcPropertySingleValue | IfcReal | A real value to express the closeness centrality of construction tasks. |

| _IfcBetweennessCentrality | IfcPropertySingleValue | IfcReal | A real value to express the betweenness centrality of construction tasks. |

| Attributes | Property Type | Entity Data Type | Description |

|---|---|---|---|

| _IfcCriticalPath | IfcPropertySingleValue | IfcBoolean | A Boolean representing whether the activity resides on the critical path of the project. |

| _IfcCriticalPathDate | IfcPropertySingleValue | IfcDateTime | The date when the critical path is made. |

| Attributes | Property Type | Entity Data Type | Description |

|---|---|---|---|

| _IfcDelayID | IfcPropertySingleValue | IfcInteger | The ID number of delay events. |

| _IfcDelayStartTime | IfcPropertySingleValue | IfcDateTime | The time at which the delay events start. |

| _IfcDelayFinishTime | IfcPropertySingleValue | IfcDateTime | The time at which the delay events finish. |

| _IfcDelayDuration | IfcPropertySingleValue | IfcDuration | The duration of the delay. |

| _IfcDelayStage | IfcPropertySingleValue | IfcLabel | The stage at which the delay events occur, such as fabrication stage, transportation stage, installation stage, etc. |

| _IfcDelayFactor | IfcPropertySingleValue | IfcLabel | The factors of delay events. |

| _IfcDelayDescription | IfcPropertySingleValue | IfcText | The description of delay events. |

| _IfcDelayParticipant | IfcPropertySingleValue | IfcLabel | The responsible participants of delay events. |

| _IfcDelayAndCriticalPath | IfcPropertySingleValue | IfcBoolean | A Boolean representing whether the delay events reside on the critical path of the project; in other words, whether the delay events will influent the project’s duration. |

| No. | IFC-Based 4D Construction Management Information Model’s Selected Content |

|---|---|

| 1 | #1=IFCPROJECT(‘12bxz3uTDC4wb_jB5gE948′,‘OwnerHistory’,$,$,$,’I:\\Revit\\House1.ifc’,$,$,$); |

| 2 | #1036=IFCTASK(‘1zkqn2e7LFhg2St02HQTwu’,#1027,‘TaskGroundLevel’,$,$,$,$,$,$,.F.,$,#1035,$); |

| 3 | #1039=IFCTASK(‘0NP1O_S$r8$eViUO4glyKt’,#1027,’TaskGroundLevel1’,$,$,$,$,$,$,.F.,$,#1038,$); |

| 4 | #1065=IFCTASK(‘011WcvxnbD8AZVZ2Q7dd8W’,#1027,‘TaskFabricateSummary’,$,$,$,$,$,$,.F.,$,#1064,$); |

| 5 | #1067=IFCTASK(‘3MOUWoiRz2NuBJwJ2nJfbV’,#1027,‘TaskFabricateSlabSummary’,$,$,$,$,$,$,.F.,$,#1066,$); |

| 6 | #1069=IFCTASK(‘0nOmrtxyj2VBWkHO5P4SnH’,#1027,‘TaskFabricateSlab1’,$,$,$,$,$,$,.F.,$,#1068,$); |

| 7 | #1091=IFCTASK(‘0huWK9JJr4rfdG4_i4MQap’,#1027,‘TaskTransportSummary’,$,$,$,$,$,$,.F.,$,#1090,$); |

| 8 | #1117=IFCTASK(‘1Ys2i9e8nBYvzKk8O1wo7s’,#1027,‘TaskHoistSummary’,$,$,$,$,$,$,.F.,$,#1116,$); |

| 9 | #1143=IFCTASK(‘3RNsuY0gH56g4d3ZNj65hy’,#1027,‘TaskInstallSummary’,$,$,$,$,$,$,.F.,$,#1142,$); |

| 10 | #1168=IFCRELNESTS(‘2FNkC4Z8bEmPoiDAwKYBkT’,#1027,$,$,#1036,(#1039)); |

| 11 | #1240=IFCRELSEQUENCE(‘3uhXQNRNb9sAZ8jEi5vq58′,#1027,$,$,#1161,#1166,$,.START_START.,$); |

| 12 | #1247=IFCLABORRESOURCE(‘2ZPqsrMRD0uehic7XAYwTb’,#1027,’LaborResourceHoistSlab1’,$,$,$,$,$,$,$,.CONCRETE.); |

| 13 | #1248=IFCCONSTRUCTIONMATERIALRESOURCE(‘1N5hKWta53cuWxoopADUpr’,#1027,‘MaterialResourceHoistSlab1’,$,$,$,$,$,$,#1243,.CONCRETE.); |

| 14 | #1249=IFCCONSTRUCTIONEQUIPMENTRESOURCE(‘0fUvYJc5jCKPeiVBfqPWIV’,#1027,’EquipmentResourceHoistSlab1’,$,$,$,$,$,$,$,.TRANSPORTING.) |

| 15 | #1253=IFCCOSTITEM(‘1CZAhyPqD3hAzaDo_GSMhV’,#1027,‘LaborCostItemHoistSLab1’,$,$,$,$,(#1250),$); |

| 16 | #1256=IFCRELASSIGNSTOPROCESS(‘0pSmSJ3qD3vOKmPBOgvRTN’,#1027,$,$,(#1247,#1248,#1249,#1253,#1254,#1255),$,#1121,$) |

| Task Name | Degree Centrality | Task Name | Closeness Centrality | Task Name | Betweenness Centrality |

|---|---|---|---|---|---|

| Task 74 | 0.40000000 | Task 74 | 0.479233227 | Task 74 | 2712.615384615384 |

| Task 81 | 0.38888889 | Task 77 | 0.478214670 | Task 84 | 2702.000000000001 |

| Task 67 | 0.33333333 | Task 71 | 0.477200424 | Task 81 | 2668.384615384646 |

| Task 64 | 0.30000000 | Task 81 | 0.475687104 | Task 64 | 2624.153846153846 |

| Task 71 | 0.30000000 | Task 64 | 0.473684211 | Task 91 | 2624.153846153846 |

| Task 84 | 0.30000000 | Task 87 | 0.469728601 | Task 87 | 2613.538461538462 |

| Task 67 | 0.27777778 | Task 67 | 0.465838509 | Task 71 | 2613.538461538461 |

| Task 61 | 0.24444444 | Task 84 | 0.463917526 | Task 77 | 2592.307692307692 |

| Task 77 | 0.24444444 | Task 61 | 0.458248473 | Task 67 | 2561.435478256821 |

| Task 72 | 0.20000000 | Task 72 | 0.443240123 | Task 64 | 2487.346782493274 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, B.; Dong, M.; Wang, C.; Liu, B.; Wang, Z.; Zhang, B. IFC-Based 4D Construction Management Information Model of Prefabricated Buildings and Its Application in Graph Database. Appl. Sci. 2021, 11, 7270. https://doi.org/10.3390/app11167270

Yang B, Dong M, Wang C, Liu B, Wang Z, Zhang B. IFC-Based 4D Construction Management Information Model of Prefabricated Buildings and Its Application in Graph Database. Applied Sciences. 2021; 11(16):7270. https://doi.org/10.3390/app11167270

Chicago/Turabian StyleYang, Bin, Miaosi Dong, Congjun Wang, Boda Liu, Zhichen Wang, and Binghan Zhang. 2021. "IFC-Based 4D Construction Management Information Model of Prefabricated Buildings and Its Application in Graph Database" Applied Sciences 11, no. 16: 7270. https://doi.org/10.3390/app11167270

APA StyleYang, B., Dong, M., Wang, C., Liu, B., Wang, Z., & Zhang, B. (2021). IFC-Based 4D Construction Management Information Model of Prefabricated Buildings and Its Application in Graph Database. Applied Sciences, 11(16), 7270. https://doi.org/10.3390/app11167270