Structure Optimization of Battery Thermal Management Systems Using Sensitivity Analysis and Stud Genetic Algorithms

Abstract

:1. Introduction

2. Battery Pack Cooling Mathematical Model

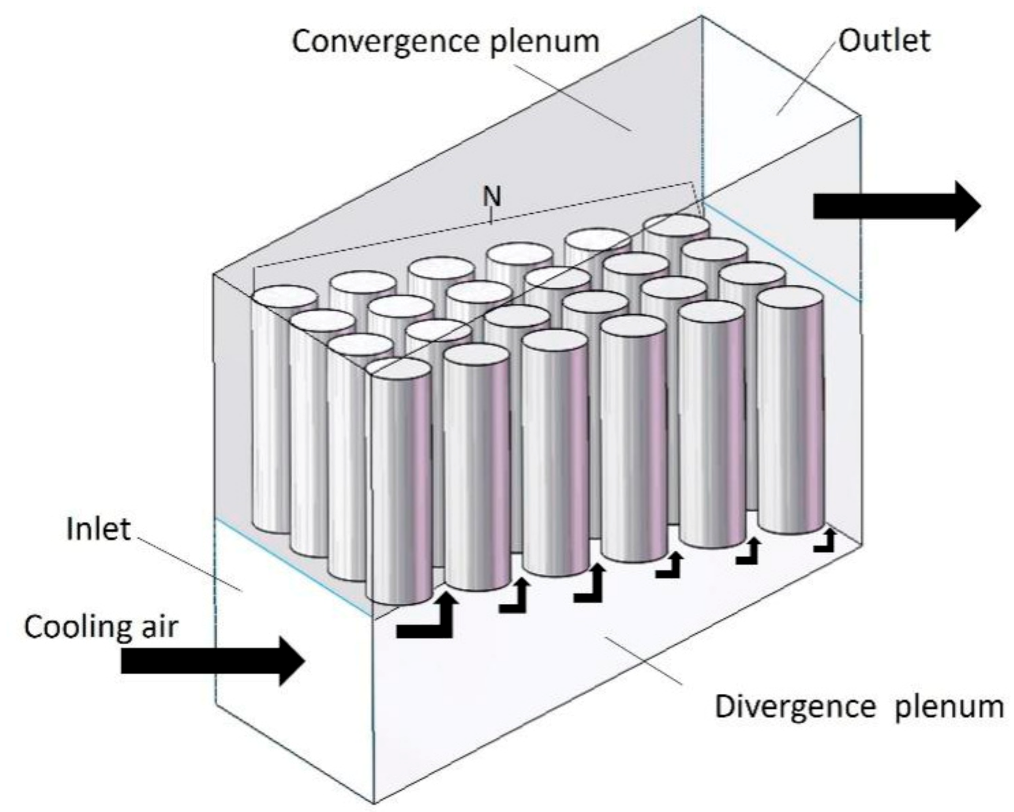

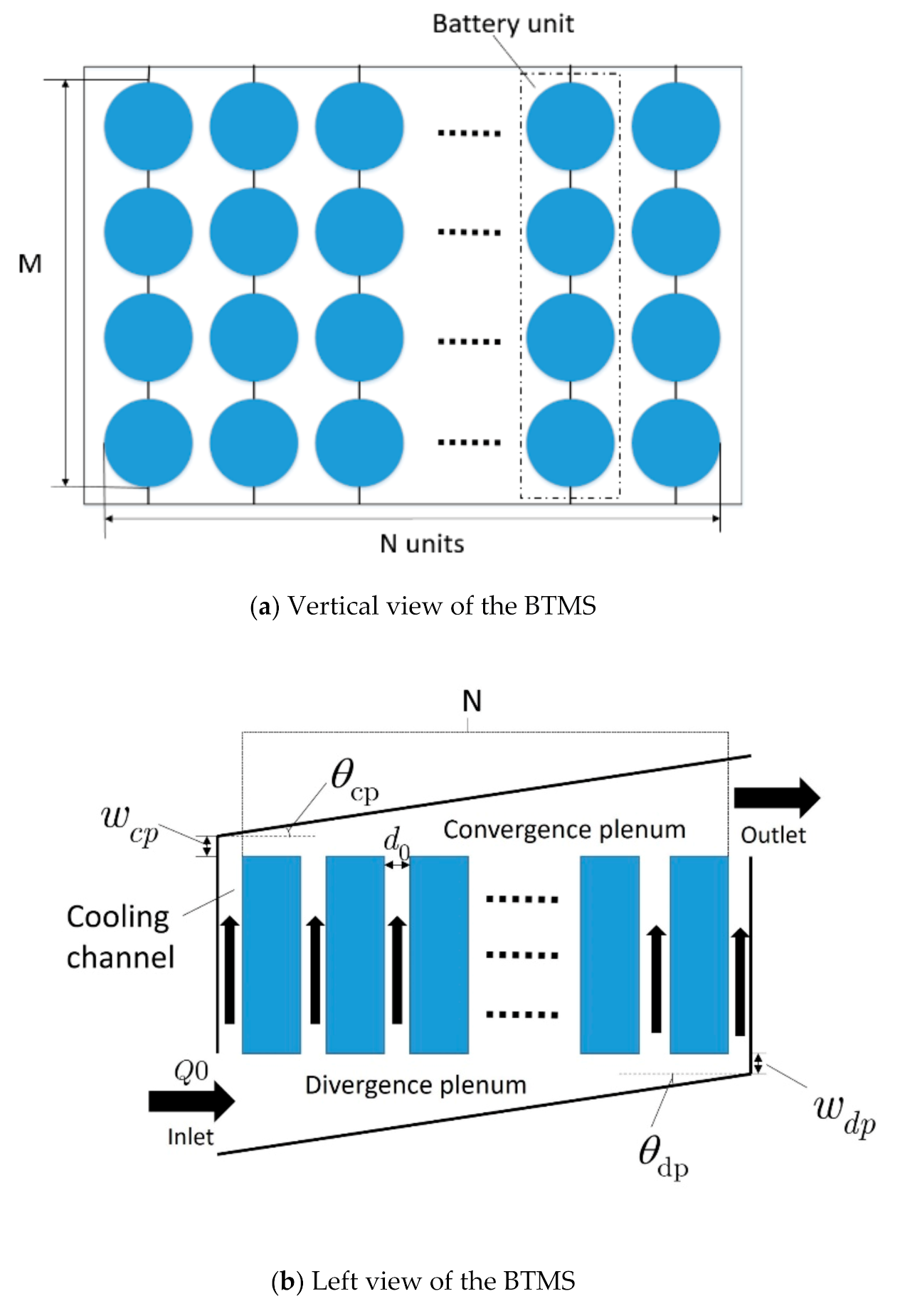

2.1. Air-Cooled Battery Pack Structure Introduction

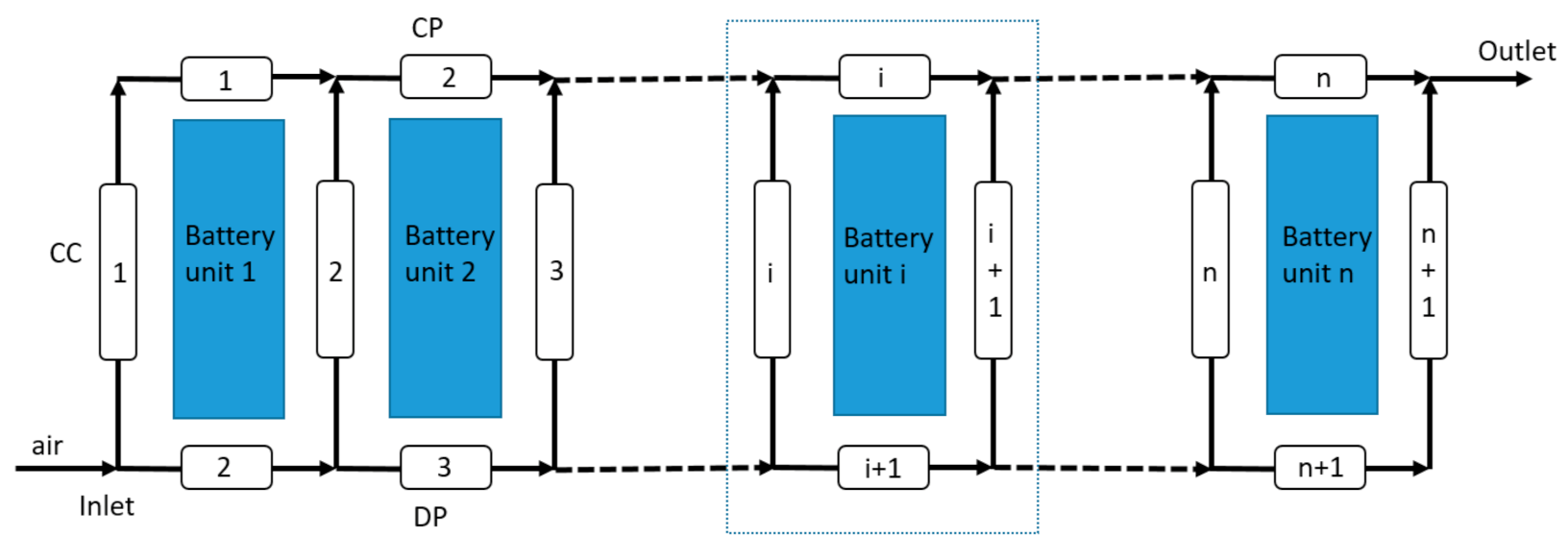

2.2. Flow Resistance Model

2.3. Heat Dissipation Model

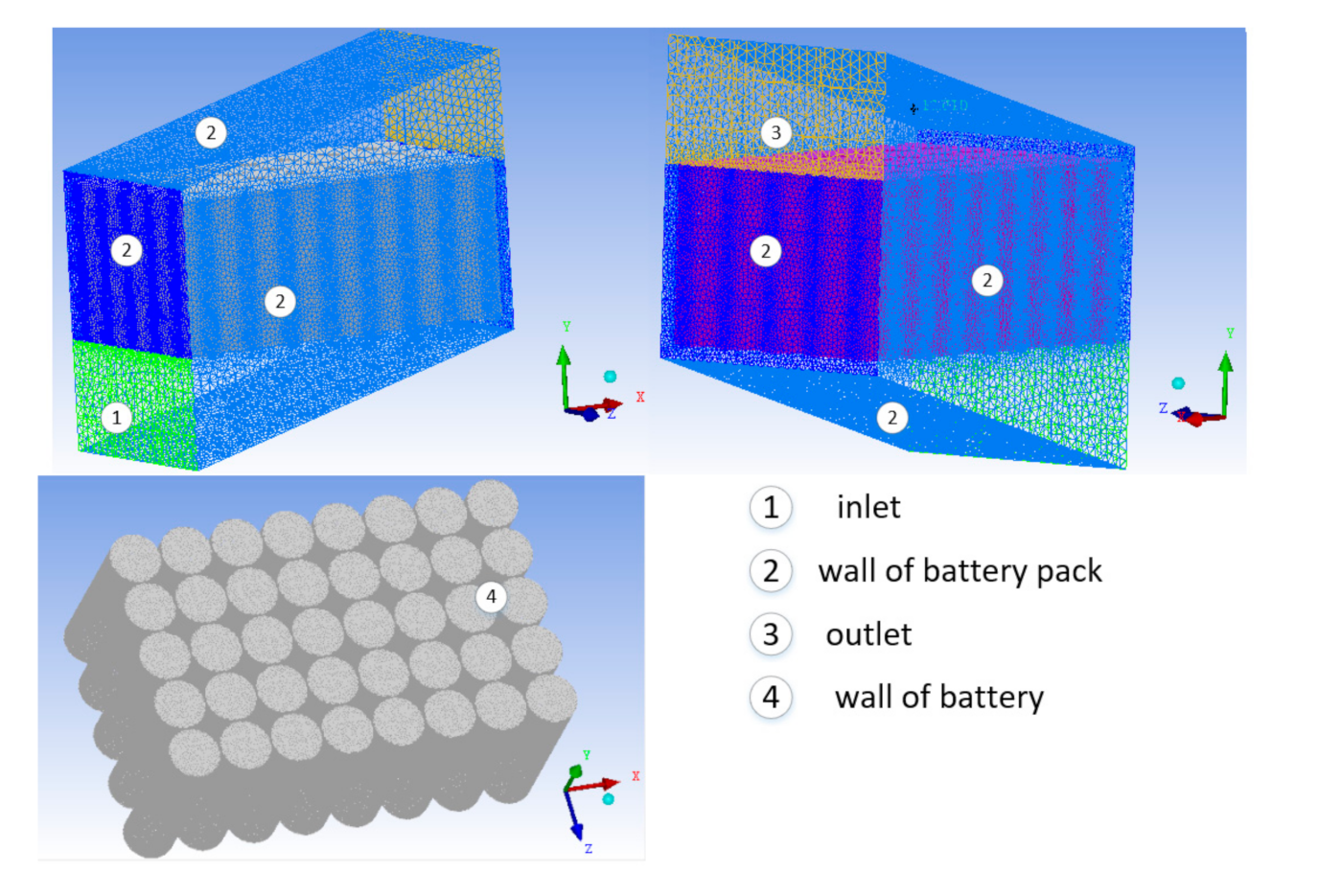

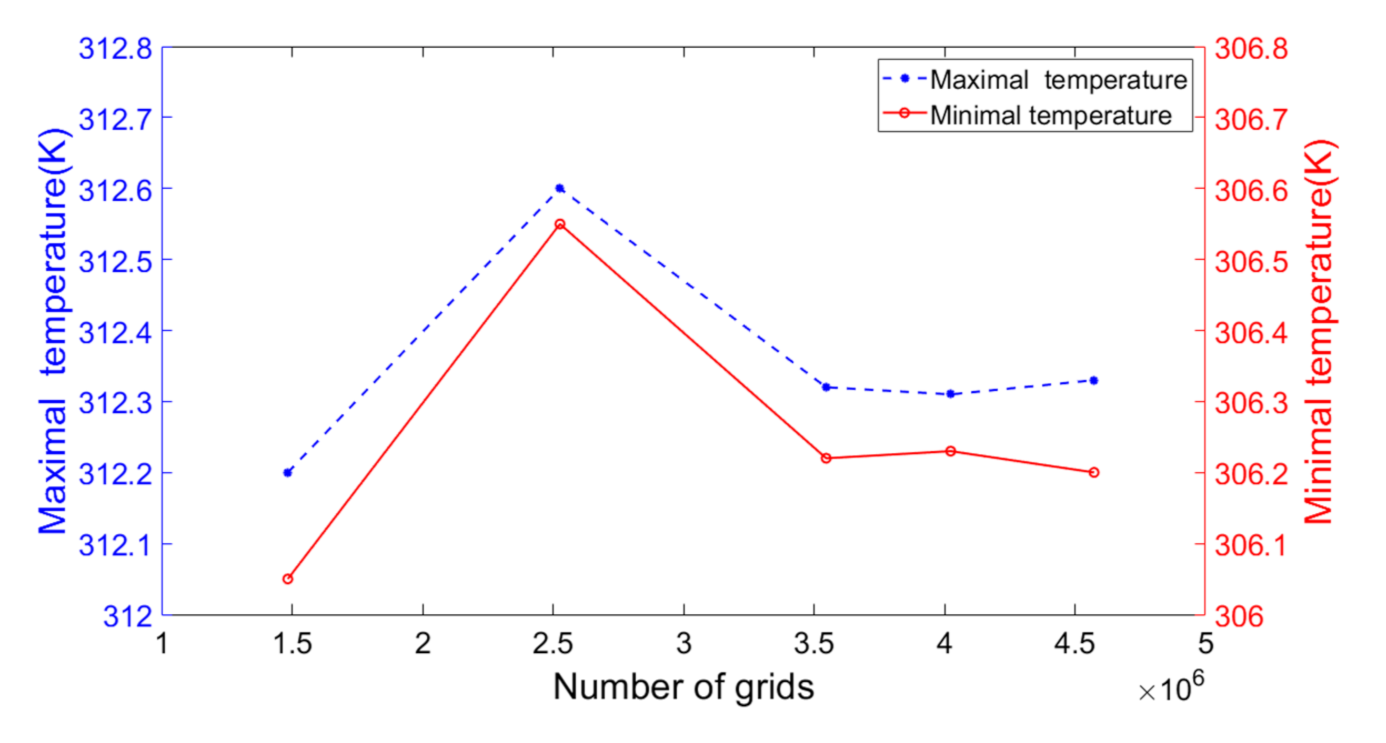

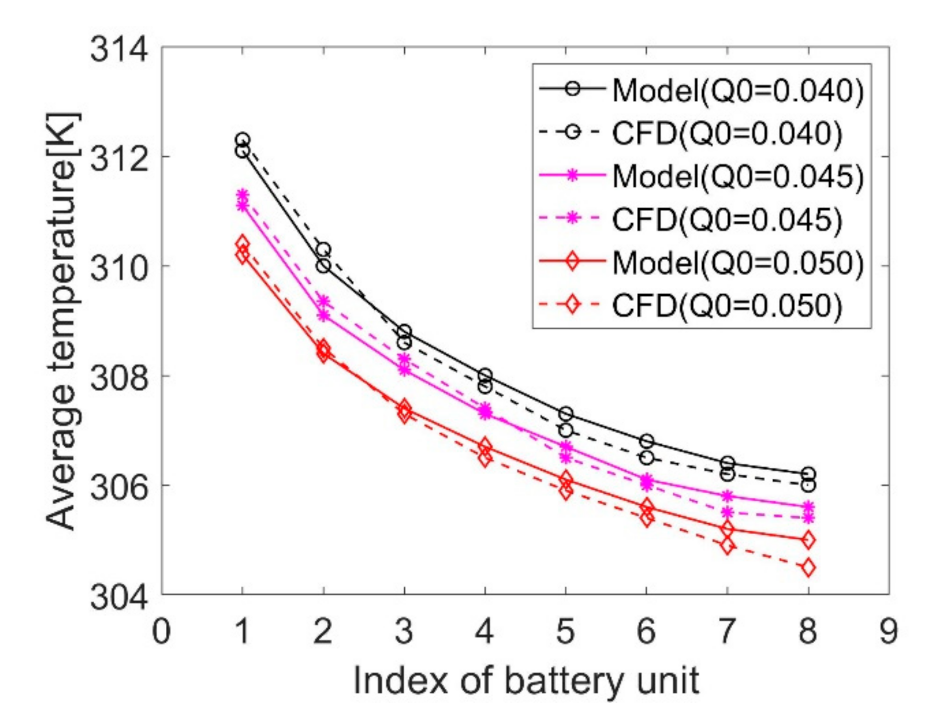

2.4. Validation of the Mathematical Model

3. Single Factor Variable Sensitivity Analysis

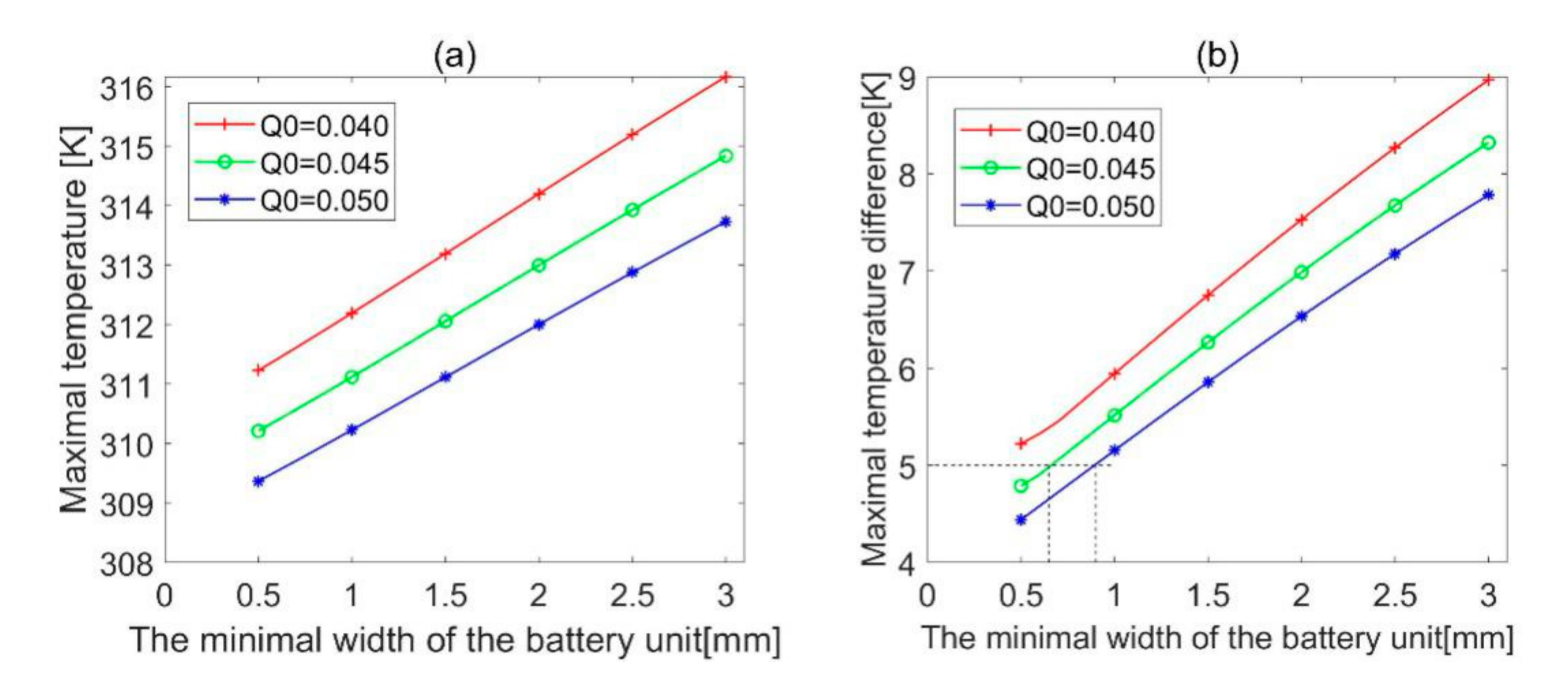

3.1. The Minimal Width of Battery Unit ()

3.2. Plate Angle of the Convergence Plenum ()

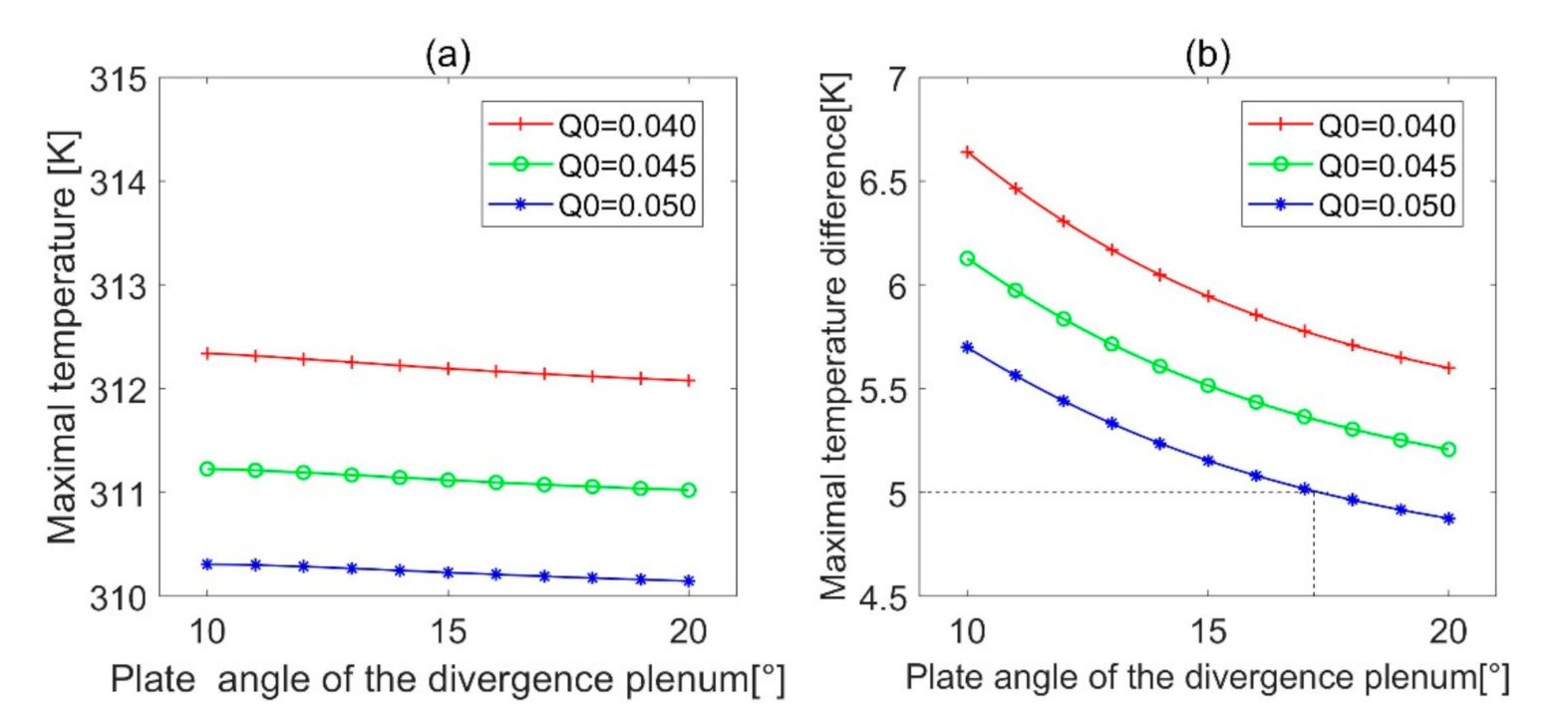

3.3. Plate Angle of the Divergence Plenum ()

3.4. The Minimal Width of the Divergence Plenum ()

3.5. The Minimal Width of the Convergence Plenum ()

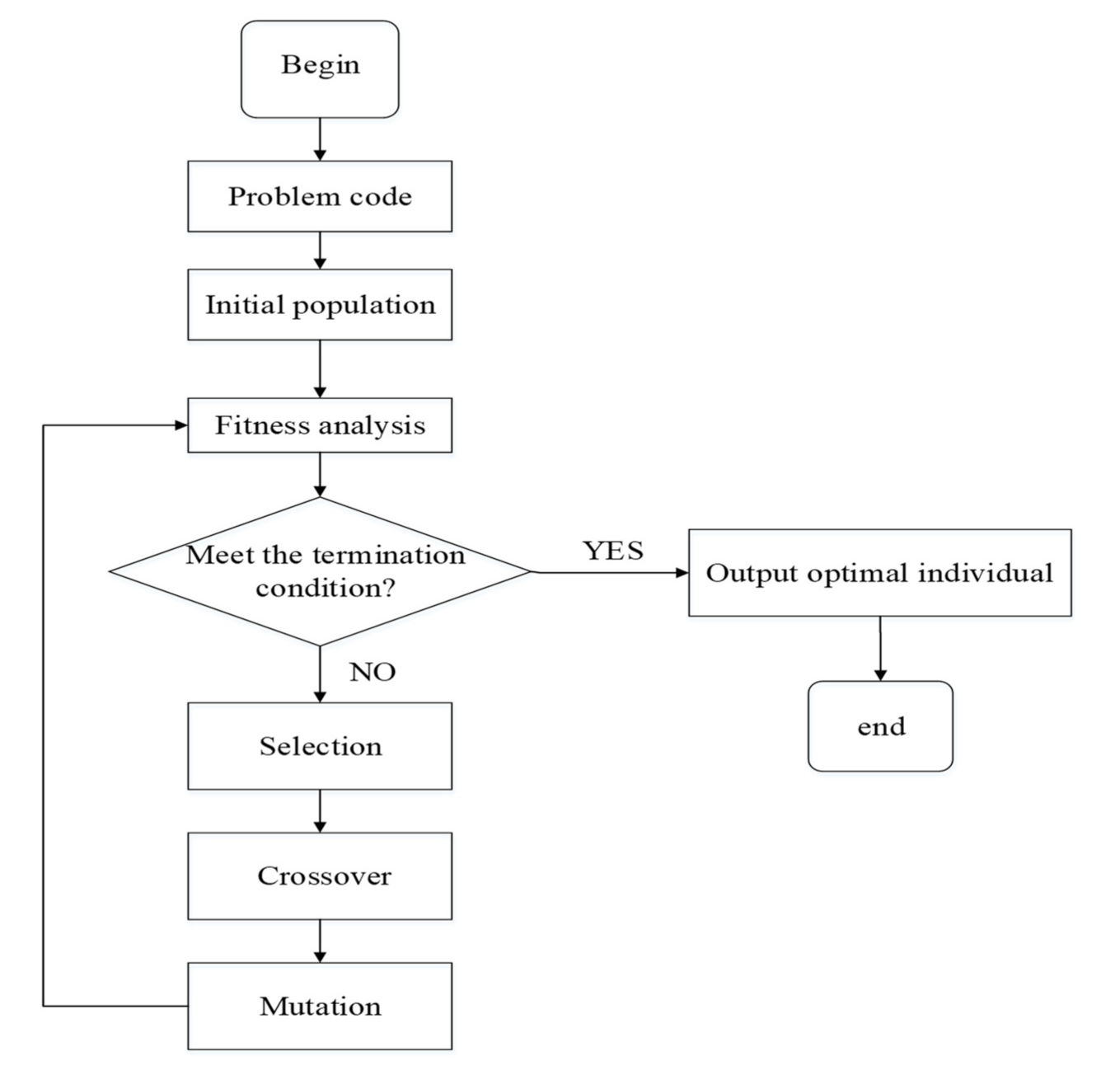

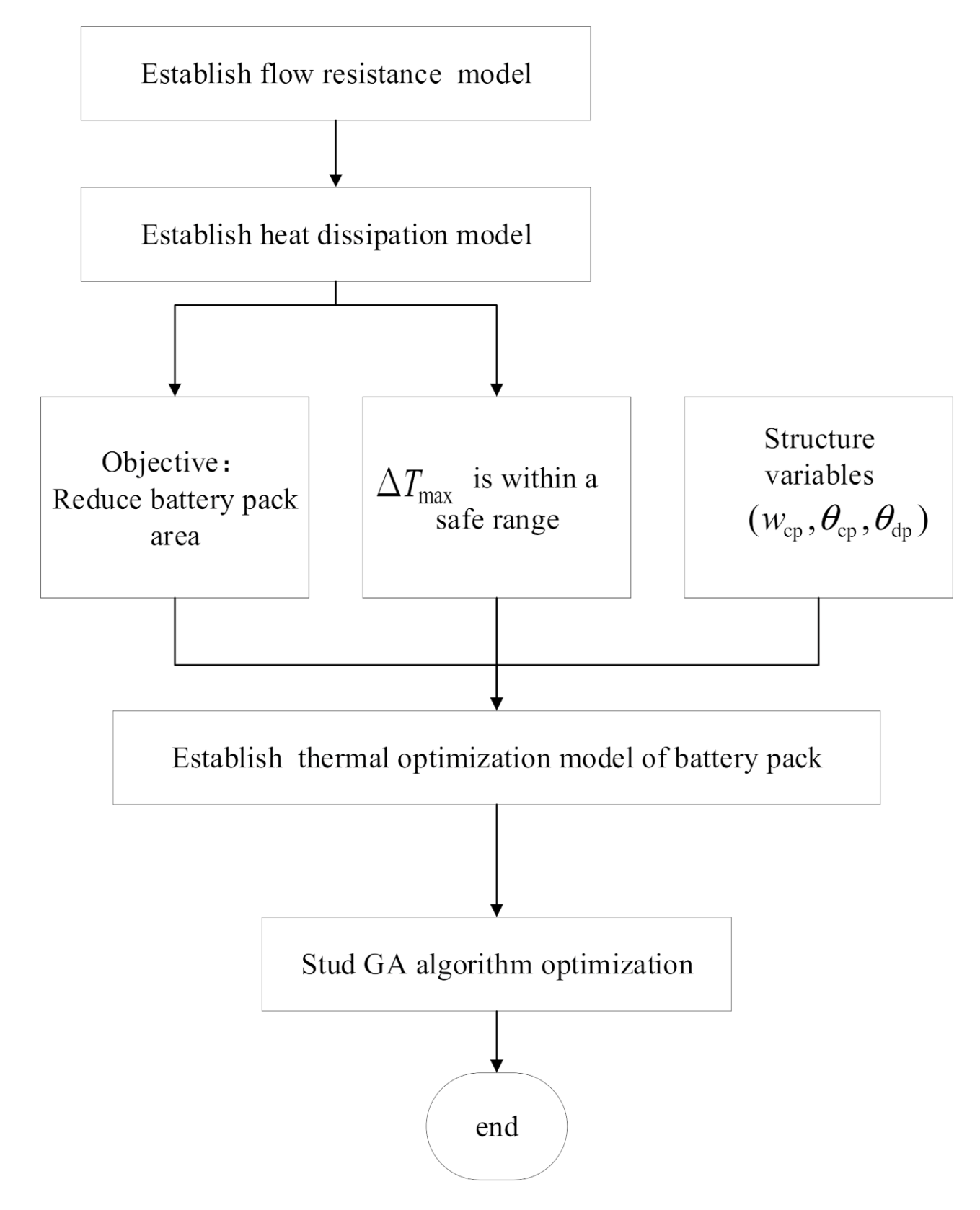

4. Optimization of Battery Pack Area Based on Stud Genetic Algorithm

4.1. Establishment of Objective Function and Constraint

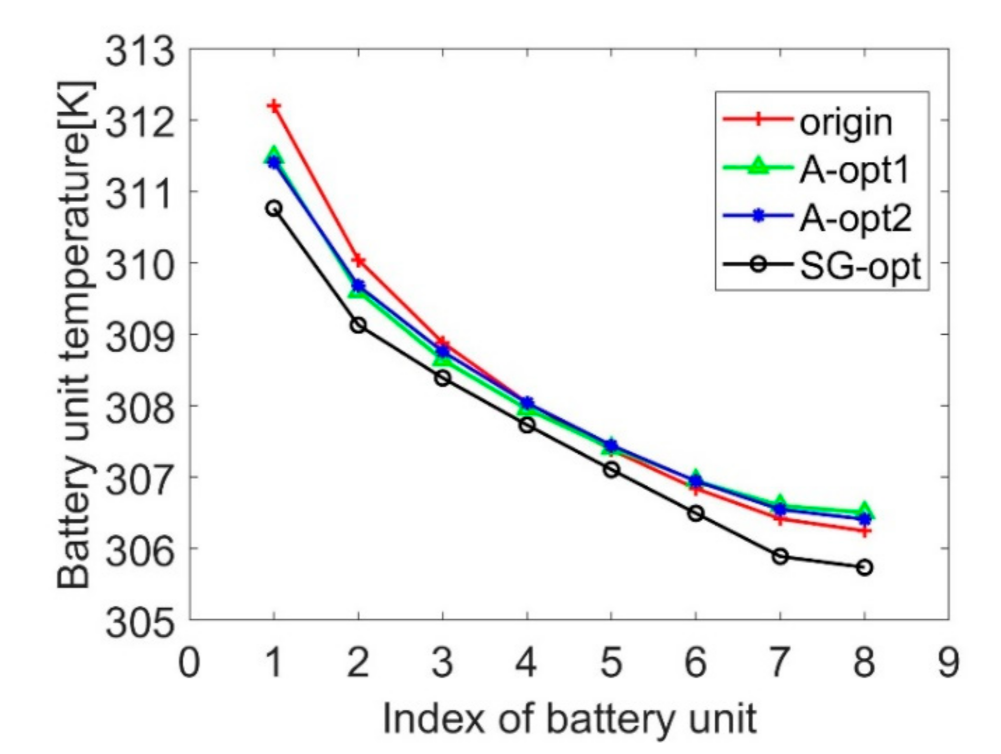

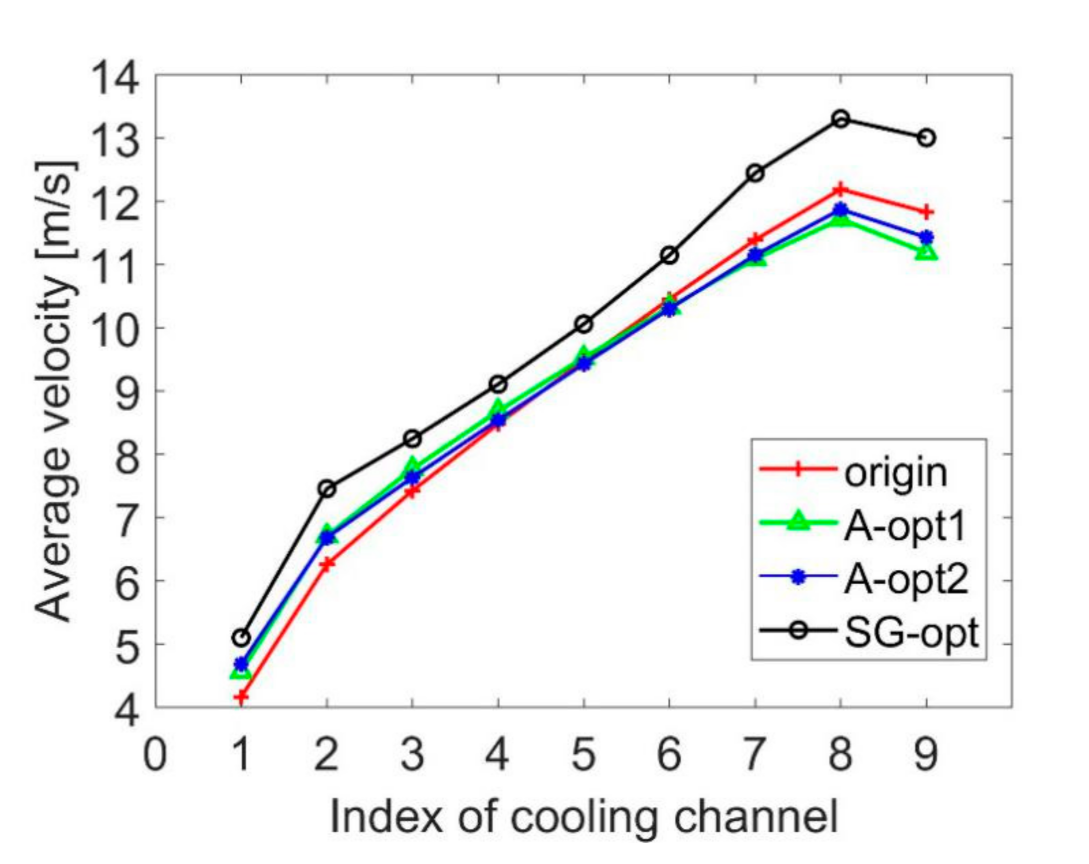

4.2. Result Analysis

5. Conclusions

- Under various inlet airflow rates, comparing the temperature of battery unit calculated by the proposed mathematical model and the CFD method, it was found that the degree of coincidence was very good. Compared to the CFD method, which requires more than a dozen hours of calculation, the flow resistance and heat dissipation model can be calculated in a few seconds, which can save a lot of time.

- Through sensitivity analysis, it was found that the structural variable that had the greatest influence on the maximal temperature difference was , followed by , and finally . These three parameters were positively correlated with the maximum temperature difference. and were minimized to facilitate the heat dissipation and reduce the size of the battery pack.

- In the case of the minimum inlet airflow rate, the minimum area of the battery pack was targeted, and the maximum temperature difference obtained by the heat dissipation model was required to be less than 5K as the constraint function. The stud GA was used to optimize , and . The final results show that compared to the original battery pack structure, the optimized battery pack meets the requirements that the maximal temperature difference be less than 5K and saves 6.24% area. The use of the heat dissipation mathematical model can greatly accelerate the design cycle of the battery industry, and at the same time increase the energy density of the battery pack to ensure that the battery works safely at a suitable temperature.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Williford, R.E.; Viswanathan, V.V.; Zhang, J.G. Effects of entropy changes in anodes and cathodes on the thermal behavior of lithium ion batteries. J. Power Sources 2009, 189, 101–107. [Google Scholar] [CrossRef]

- Tamura, K.; Horiba, T. Large-scale development of lithium batteries for electric vehicles and electric power storage applications. J. Power Sources 1999, 81, 156–161. [Google Scholar] [CrossRef]

- Onda, K.; Ohshima, T.; Nakayama, M.; Fukuda, K.; Araki, T. Thermal behavior of small lithium-ion battery during rapid charge and discharge cycles. J. Power Sources 2006, 158, 535–542. [Google Scholar] [CrossRef]

- Pesaran, A.A. Battery thermal models for hybrid vehicle simulations. J. Power Sources 2002, 110, 377–382. [Google Scholar] [CrossRef]

- Ou, K.; Wang, Y.X.; Li, Z.Z.; Shen, Y.-D.; Xuan, D.-J. Feedforward fuzzy-PID control for air flow regulation of PEM fuel cell system. Int. J. Hydrogen Energy 2015, 40, 11686–11695. [Google Scholar] [CrossRef]

- Mi, C.; Li, B.; Buck, D.; Ota, N. Advanced electro-thermal modeling of lithium-ion battery system for hybrid electric vehicle applications. In Proceedings of the 2007 IEEE Vehicle Power and Propulsion Conference, Arlington, TX, USA, 9–12 September 2007; pp. 107–111. [Google Scholar]

- Chen, K.; Chen, Y.; Li, Z.; Yuan, F.; Wang, S. Design of the cell spacings of battery pack in parallel air-cooled battery thermal management system. Int. J. of Heat Mass Transf. 2018, 127, 393–401. [Google Scholar] [CrossRef]

- Wang, J.; Lu, S.; Wang, Y.; Ni, Y.; Zhang, S. Novel investigation strategy for mini-channel liquid-cooled battery thermal management system. Int. J. Energy Res. 2020, 44, 1971–1985. [Google Scholar] [CrossRef]

- Yang, X.H.; Tan, S.C.; Liu, J. Thermal management of Li-ion battery with liquid metal. Energy Convers Manag. 2016, 117, 577–585. [Google Scholar] [CrossRef]

- Qian, Z.; Li, Y.; Rao, Z. Thermal performance of lithium-ion battery thermal management system by using mini-channel cooling. Energy Convers. Manag. 2016, 126, 622–631. [Google Scholar] [CrossRef]

- Zhu, Y.; Fang, Y.; Su, L.; Fei, Y. Experimental study on thermal performance of a pumped two-phase battery thermal management system. Int. J. Energy Res. 2020, 44, 4664–4676. [Google Scholar] [CrossRef]

- Amalesh, T.; Lakshmi Narasimhan, N. Cooling of a lithium ion battery using phase change material with air/dielectric fluid media: A numerical study. Proc. Inst. Mech. Eng. Part. A J. Power Energy 2020, 234, 722–738. [Google Scholar] [CrossRef]

- Rao, Z.; Huo, Y.; Liu, X.; Zhang, G. Experimental investigation of battery thermal management system for electric vehicle based on paraffin/copper foam. J. Energy Inst. 2015, 88, 241–246. [Google Scholar] [CrossRef]

- Alipanah, M.; Li, X. Numerical studies of lithium-ion battery thermal management systems using phase change materials and metal foams. Int. J. Heat Mass Trandf. 2016, 102, 1159–1168. [Google Scholar] [CrossRef]

- Jiang, Z.Y.; Qu, Z.G. Lithium–ion battery thermal management using heat pipe and phase change material during discharge–charge cycle: A comprehensive numerical study. Appl. Energy 2019, 242, 378–392. [Google Scholar] [CrossRef]

- Pesaran, A.A. Battery thermal management in EVEs and HEVs: Issues and solutions. In Proceedings of the Nevada, Advanced Automotive Battery Conference, Como, Italy, 6–8 February 2001. [Google Scholar]

- Pesaran, A.; Keyser, M.; Burch, S. An Approach for Designing Thermal Management Systems for Electric and Hybrid Vehicle Battery Packs; National Renewable Energy Laboratory: Golden, CO, USA, 1999. [Google Scholar]

- Wang, T.; Tseng, K.J.; Zhao, J.; Wei, Z. Thermal investigation of lithium-ion battery module with different cell arrangement structures and forced air-cooling strategies. Appl. Energy 2014, 134, 229–238. [Google Scholar] [CrossRef]

- Xun, J.; Liu, R.; Jiao, K. Numerical and analytical modeling of lithium ion battery thermal behaviors with different cooling designs. J. Power Sources 2013, 233, 47–61. [Google Scholar] [CrossRef]

- He, F.; Li, X.; Ma, L. Combined experimental and numerical study of thermal management of battery module consisting of multiple Li-ion cells. Int. J. Heat Mass Transf. 2014, 72, 622–629. [Google Scholar] [CrossRef]

- Severino, B.; Gana, F.; Palma-Behnke, R.; Estévez, P.A.; Williams, R.C.-M.; Marcos, E.O.; Jorge, R.; Marcelo, C. Multi-objective optimal design of lithium-ion battery packs based on evolutionary algorithms. J. Power Sources 2014, 267, 288–299. [Google Scholar] [CrossRef]

- Qian, X.; Xuan, D.; Zhao, X.; Shi, Z. Heat dissipation optimization of lithium-ion battery pack based on neural networks. Appl. Therm. Eng. 2019, 162, 114289. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, Y.; Zhang, J.; Liu, Z. Shortcut computation for the thermal management of a large air-cooled battery pack. Appl. Therm. Eng. 2014, 66, 445–452. [Google Scholar] [CrossRef]

- Chen, K.; Song, M.; Wei, W.; Wang, S. Structure optimization of parallel air-cooled battery thermal management system with U-type flow for cooling efficiency improvement. Energy 2018, 145, 603–613. [Google Scholar] [CrossRef]

- Chen, K.; Wang, S.; Song, M.; Chen, L. Configuration optimization of battery pack in parallel air-cooled battery thermal management system using an optimization strategy. Appl. Therm. Eng. 2017, 123, 177–186. [Google Scholar] [CrossRef]

- Chen, K.; Wang, S.; Song, M.; Chen, L. Structure optimization of parallel air-cooled battery thermal management system. Int. J. Heat Mass Transf. 2017, 111, 943–952. [Google Scholar] [CrossRef]

- Fan, L.; Khodadadi, J.M.; Pesaran, A.A. A parametric study on thermal management of an air-cooled lithium-ion battery module for plug-in hybrid electric vehicles. J. Power Sources 2013, 238, 301–312. [Google Scholar] [CrossRef]

- Park, H. A design of air flow configuration for cooling lithium ion battery in hybrid electric vehicles. J. Power Sources 2013, 239, 30–36. [Google Scholar] [CrossRef]

- Chen, K.; Chen, Y.; Song, M.; Wang, S. Multi-parameter structure design of parallel mini-channel cold plate for battery thermal management. Int. J. Energy Res. 2020, 44, 4321–4334. [Google Scholar] [CrossRef]

- Loh, B.G.; Hyun, S.; Ro, P.I.; Kleinstreuer, C. Acoustic streaming induced by ultrasonic flexural vibrations and associated enhancement of convective heat transfer. J. Acoust. Soc. Am. 2002, 111, 875–883. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Perry, R.H.; Green, D.W. Perry’s Chemical Engineers’ Handbook, 7th ed.; McGraw-Hill Professional: New York, NY, USA, 1997. [Google Scholar]

- Bassett, M.D.; Winterbone, D.E.; Pearson, R.J. Calculation of steady flow pressure loss coefficients for pipe junctions. Proc. Inst. Mech. Eng. Part. C 2001, 215, 861–881. [Google Scholar] [CrossRef]

- Shi, Y.; Wang, J.; Yu, G.; Chen, M. Chemical Engineering Handbook, 2nd ed.; Chemical Industry Press: Beijing, China, 1996. [Google Scholar]

- Thomas, P.D.; Lombard, C.K. Geometric conservation law and its application to flow computations on moving grids. AIAA J. 1979, 17, 1030–1037. [Google Scholar] [CrossRef]

- Saw, L.H.; Ye, Y.; Tay, A.A.O. Electrochemical–thermal analysis of 18650 Lithium Iron Phosphate cell. Energy Convers. Manag. 2013, 75, 162–174. [Google Scholar] [CrossRef]

- Jeon, D.H.; Baek, S.M. Thermal modeling of cylindrical lithium ion battery during discharge cycle. Energy Convers. Manag. 2011, 52, 2973–2981. [Google Scholar] [CrossRef]

- Winterton, R.H.S. Newton’s law of cooling. Contemp. Phys. 1999, 40, 205–212. [Google Scholar] [CrossRef]

- Khatib, W.; Fleming, P.J. The stud GA: A mini revolution? In International Conference on Parallel Problem Solving from Nature; Springer: Berlin/Heidelberg, Germany, 1998; pp. 683–691. [Google Scholar]

| Re | Y | y |

|---|---|---|

| 1–4 | 0.989 | 0.330 |

| 4–40 | 0.911 | 0.385 |

| 40–4000 | 0.683 | 0.466 |

| 4000–40,000 | 0.193 | 0.618 |

| 40,000–250,000 | 0.0266 | 0.805 |

| Parameter | Air | Battery |

|---|---|---|

| Density [kg/m3] | 1.1614 | 5400 |

| Intensity of heat generated [W/m3] | - | 264,170 |

| Specific heat capacity [J/(kg K)] | 1007 | 502.35 |

| Thermal conductivity [W/(m K)] | 0.0263 | 1.37 x/17.33 z |

| Dynamic viscosity [kg/(m s)] | 1.85 10−5 | - |

| BTMS | (°) | (°) | (mm) | (K) | Area(m2) |

|---|---|---|---|---|---|

| origin | 15.0 | 15.0 | 5.0 | 5.9 | 1.7747 × 10−2 |

| A-opt1 | 17.1 | 15.0 | 5.0 | 5.0 | 1.8212 × 10−2 |

| A-opt2 | 15.0 | 15.0 | 7.8 | 5.0 | 1.8176 × 10−2 |

| SG-opt | 14.0 | 10.1 | 10.2 | 5.0 | 1.6639 × 10−2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Xuan, D.; Wang, B.; Jiang, R. Structure Optimization of Battery Thermal Management Systems Using Sensitivity Analysis and Stud Genetic Algorithms. Appl. Sci. 2021, 11, 7440. https://doi.org/10.3390/app11167440

Chen J, Xuan D, Wang B, Jiang R. Structure Optimization of Battery Thermal Management Systems Using Sensitivity Analysis and Stud Genetic Algorithms. Applied Sciences. 2021; 11(16):7440. https://doi.org/10.3390/app11167440

Chicago/Turabian StyleChen, Jiahui, Dongji Xuan, Biao Wang, and Rui Jiang. 2021. "Structure Optimization of Battery Thermal Management Systems Using Sensitivity Analysis and Stud Genetic Algorithms" Applied Sciences 11, no. 16: 7440. https://doi.org/10.3390/app11167440

APA StyleChen, J., Xuan, D., Wang, B., & Jiang, R. (2021). Structure Optimization of Battery Thermal Management Systems Using Sensitivity Analysis and Stud Genetic Algorithms. Applied Sciences, 11(16), 7440. https://doi.org/10.3390/app11167440