Complex Maturity Method for Estimating the Concrete Strength Based on Curing Temperature, Ambient Temperature and Relative Humidity

Abstract

:1. Introduction

2. Materials and Methods

- —the temperature-time factor at age t, degree-days or degree-hours;

- —a time interval, days or hours;

- —average concrete temperature during time interval , °C;

- —datum temperature, °C.

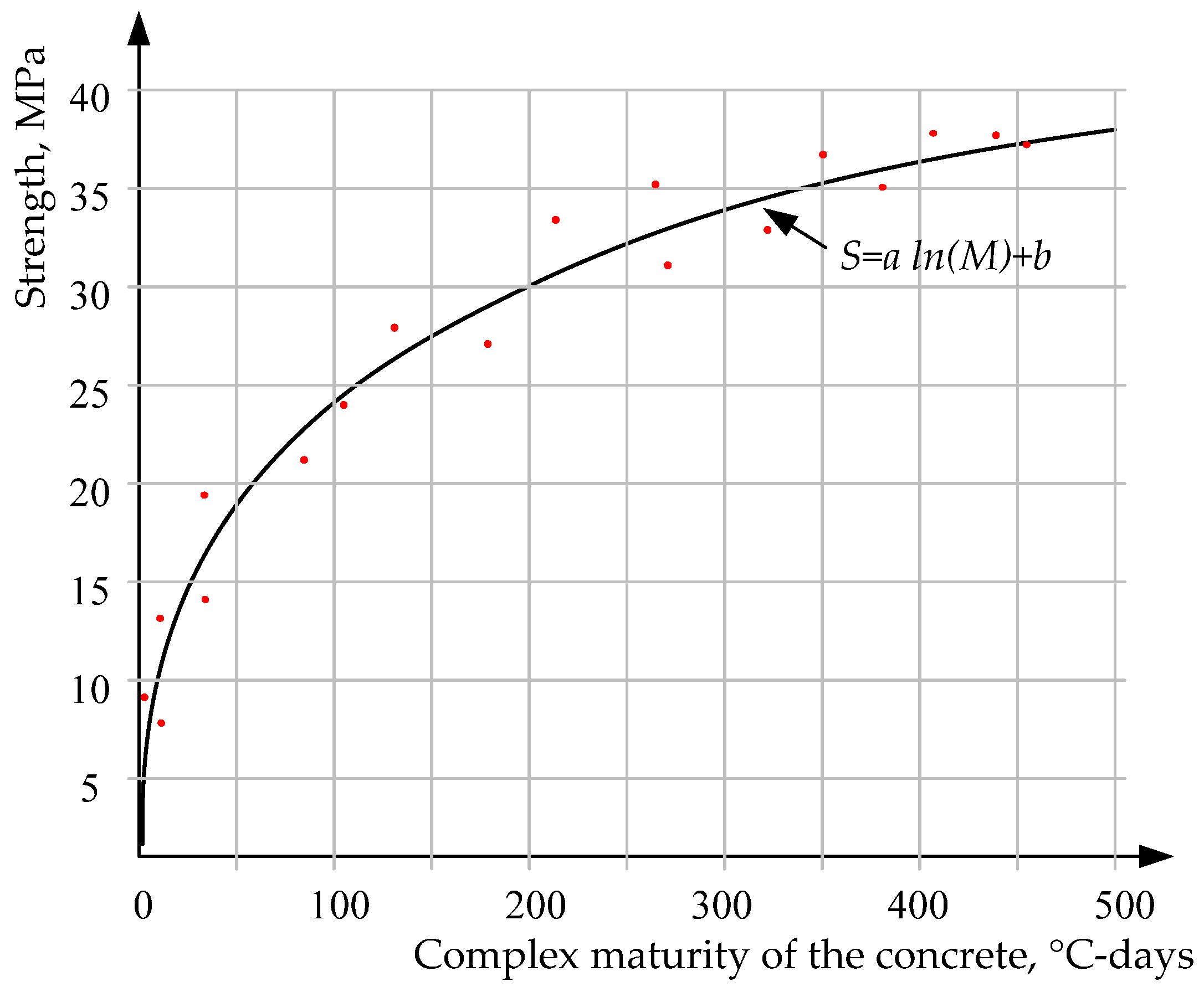

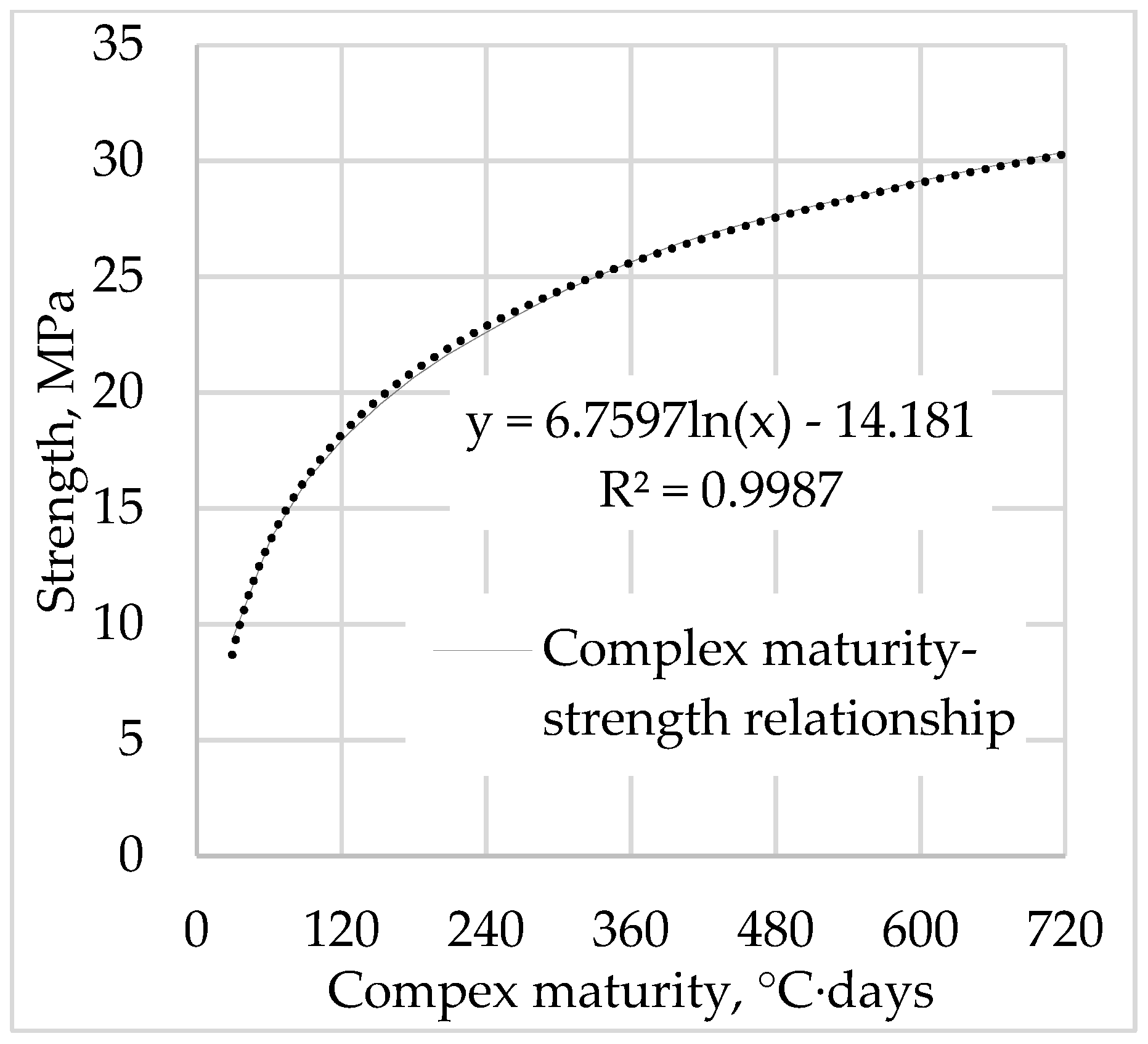

3. Results

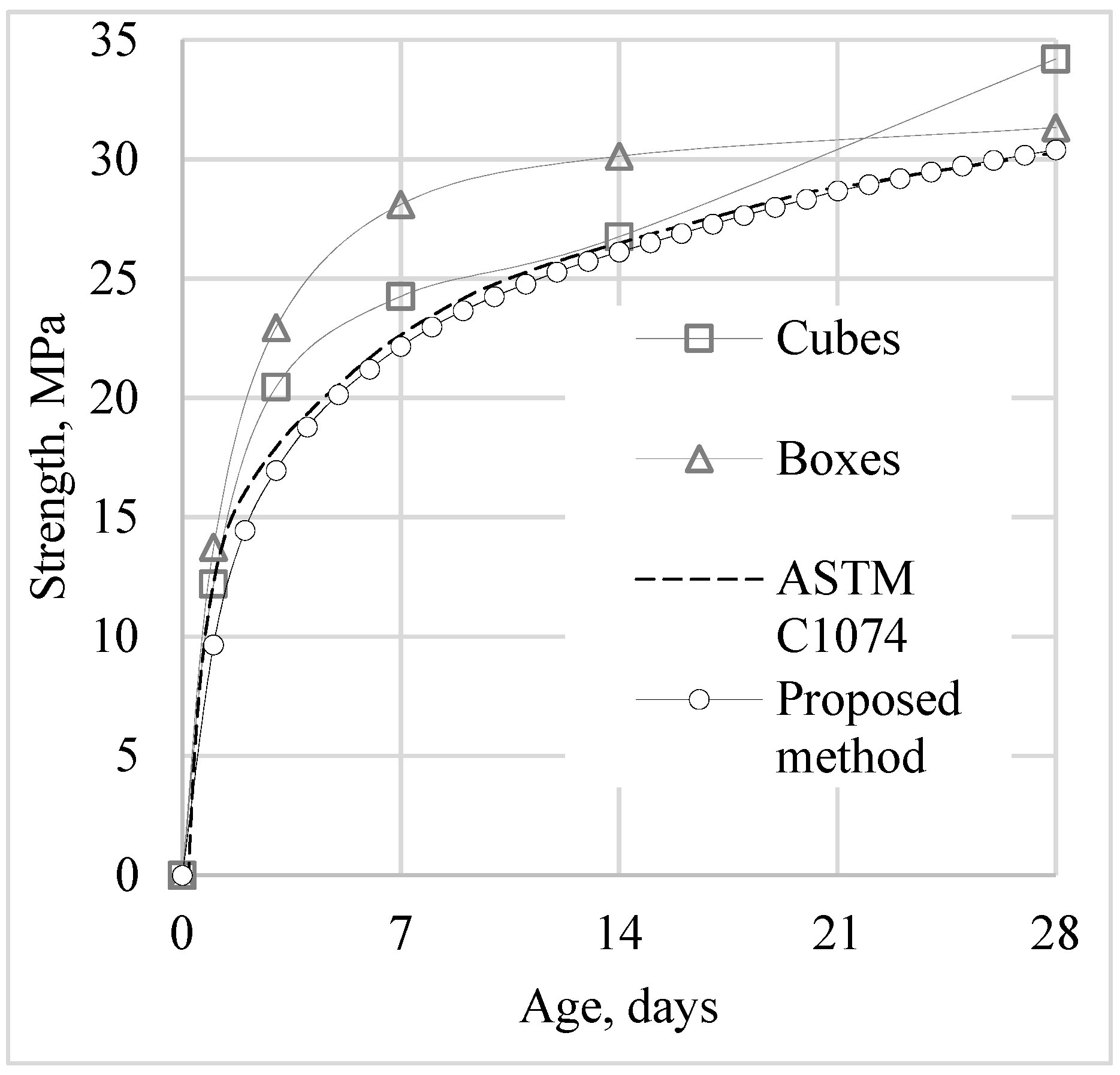

4. Discussion

- -

- The compression testing of the cubes with an edge size of 10 cm by [14] represented by square markers;

- -

- The non-destructive testing of the boxes using the IPS-MG 4.01 sclerometer [22] represented by triangle markers;

- -

- The maturity–strength method by [13] represented by a dashed line;

- -

- The proposed complex maturity method, based on [13] and modified, accounting for additional influencing parameters, such as the ambient temperature and relative humidity represented by the circle markers on the graph.

5. Conclusions

- The laboratory tests for measuring the concrete strength by compression method and non-destructive sclerometer method were performed on concrete samples according to ASTM C109, GOST 10180 and GOST 22690. The estimated current strength values of concrete were obtained by ASTM C1074 (Nurse–Saul) and the proposed complex maturity methods.

- Assessment of concrete strength by the proposed method was based on ASTM C1074 and developed by taking the influence of ambient temperature and relative humidity into account when calculating the complex maturity.

- The estimated and measured by various methods strength were analyzed on the 1st, 3rd, 7th, 14th and 28th days of concrete curing and compared with the strength obtained from the results of compression tests of cubes with an edge size of 10 cm, according to GOST 10180.

- According to the calibration dependence of the existing and proposed methods in relation to the strength gained in cubic samples, the highest coefficient of determination R2 = 0.976 was revealed for the proposed method of strength estimation by complex maturity, which indicates the reliability of the latter.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Saul, A.G.A. Principles underlying the steam curing of concrete at atmospheric pressure. Mag. Concr. Res. 1951, 2, 127–140. [Google Scholar] [CrossRef]

- Hansen, P.F.; Pedersen, E.J. Maturity computer for controlled curing and hardening of concrete. Nord. Betong 1977, 1, 19–34. [Google Scholar]

- CHENGJU, G. Maturity of concrete—Method for predicting early-stage strength. ACI Mater. J. 1989, 86, 341–353. [Google Scholar]

- Carino, N.J.; Lew, H.S. The Maturity Method: From Theory to Application. Struct. Congr. Expo. Am. Soc. Civ. Eng. 2001. [CrossRef]

- Plowman, J.M. Maturity and the strength of concrete. Mag. Concr. Res. 1956, 8, 13–22. [Google Scholar] [CrossRef]

- Tekle, B.H.; Al-Deen, S.; Anwar-Us-Saadat, M.; Willans, N.; Zhang, Y.; Lee, C.K. Use of maturity method to estimate early age compressive strength of slab in cold weather. Struct. Concr. 2021, 1–15. [Google Scholar] [CrossRef]

- Ustabaş, İ.; Deşik, F. Transition coefficients between compressive strengths of samples with different shape and size in mass concrete and use of weight maturity method in dam construction. Struct. Concr. 2021, 22, E696–E709. [Google Scholar] [CrossRef]

- Yikici, T.A.; Chen, H.-L. (Roger) Use of maturity method to estimate compressive strength of mass concrete. Constr. Build. Mater. 2015, 95, 802–812. [Google Scholar] [CrossRef]

- Nandhini, K.; Karthikeyan, J. The early-age prediction of concrete strength using maturity models: A review. J. Build. Pathol. Rehabil. 2021, 6, 7. [Google Scholar] [CrossRef]

- Nixon, J.M. Evaluation of Maturity Method to Estimate Concrete Strength in Field Applications; Auburn University: Auburn, Alabama, 2006. [Google Scholar]

- Sun, B.; Noguchi, T.; Cai, G.; Chen, Q. Prediction of early compressive strength of mortars at different curing temperature and relative humidity by a modified maturity method. Struct. Concr. 2021, 22, E732–E744. [Google Scholar] [CrossRef]

- Barroca, N.; Borges, L.M.; Velez, F.J.; Monteiro, F.; Górski, M.; Castro-Gomes, J. Wireless sensor networks for temperature and humidity monitoring within concrete structures. Constr. Build. Mater. 2013, 40, 1156–1166. [Google Scholar] [CrossRef] [Green Version]

- ASTM C1074. Standard Practice for Estimating Concrete Strength by the Maturity Method; American Society for Testing and Materials: West Conshohocken, PA, USA, 2019. [Google Scholar]

- GOST 10180. Concretes. Methods for Strength Determination Using Reference Specimens; Interstate standardization organization: Moscow, Russia, 2012. [Google Scholar]

- NEN 5970. Determination of Strength of Fresh Concrete with the Method of Weighted Maturity; Delft, Netherlands, 2001. Available online: https://standards.globalspec.com/std/10294720/nen-5970 (accessed on 1 September 2001).

- ST-NP SRO SSK-04. Temperature and Strength Control of Concrete during the Construction of Monolithic Structures in Winter; Chelyabinsk, Russia, 2013. Available online: https://www.russiangost.com/p-169830-st-np-sro-ssk-04-2013.aspx (accessed on 18 July 2013).

- BS EN 13791. Assessment of In-Situ Compressive Strength in Structures and Precast Concrete Components; London, UK. Available online: https://shop.bsigroup.com/products/assessment-of-in-situ-compressive-strength-in-structures-and-precast-concrete-components?pid=000000000030349923 (accessed on 31 January 2020).

- Brooks, A.G.; Schindler, A.K.; Barnes, R.W. Maturity Method Evaluated for Various Cementitious Materials. J. Mater. Civ. Eng. 2007, 19, 1017–1025. [Google Scholar] [CrossRef]

- Soutsos, M.; Hatzitheodorou, A.; Kwasny, J.; Kanavaris, F. Effect of in situ temperature on the early age strength development of concretes with supplementary cementitious materials. Constr. Build. Mater. 2016, 103, 105–116. [Google Scholar] [CrossRef] [Green Version]

- Tada, S.; Watanabe, K. A Dynamic Method Determining Equilibrium Moisture Content of Porous Materials. In Proceedings of the 4th International Symposium on Humidity and Moisture, Taipei, Taiwan, 16–19 September 2002; pp. 318–324. [Google Scholar]

- ASTM C192/C192M. Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory; American Society for Testing and Materials: West Conshohocken, PA, USA, 2019. [Google Scholar] [CrossRef]

- GOST 22690. Concretes. Determination of Strength by Mechanical Methods of Nondestructive Testing; Moscow, Russia, 2015. Available online: https://fresh-deko.ru/en/fruit-trees/ispytanie-betona-gost-22690-opredelenie-prochnosti-mehanicheskimi.html (accessed on 25 September 2015).

- Utepov, Y.B.; Khudaibergenov, O.A.; Kabdush, Y.B.; Kazkeev, A.B. Prototyping an embedded wireless sensor for monitoring reinforced concrete structures. Comput. Concr. 2019, 24, 95–102. [Google Scholar] [CrossRef]

| Age, Hours | i Parameters | Compressive Strength in Cylinders, MPa | ||

|---|---|---|---|---|

| t | IT | AT | ARH | CS |

| 0.5 | 21.44 | 23.9 | 29.7 | 0 |

| 1 | 21.56 | 23.4 | 30.6 | 0 |

| 1.5 | 21.94 | 23.3 | 33.8 | 0 |

| … | … | … | … | … |

| 672 | 11.88 | 13.8 | 40.9 | 30.38 |

| Age, Days | Maturity of i Parameter | Correlation Coefficients between i Parameters and Compressive Strength | Weights of Maturity of i Parameters | Complex Maturity, °C·Days | Compressive Strength in Cylinders, MPa | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| t | MIT | MAT | MARH | Mc | CS | ||||||

| 1 | 30.89 | 39.72 | 20.43 | 0.68 | 0.26 | 0.55 | 0.46 | 0.17 | 0.37 | 29.44 | 9.34 |

| 2 | 55.38 | 107.37 | 36.76 | 0.92 | 0.84 | 0.88 | 0.35 | 0.32 | 0.33 | 61.59 | 13.71 |

| 3 | 78.13 | 174.68 | 51.18 | 0.06 | 0.50 | 0.54 | 0.05 | 0.45 | 0.49 | 92.28 | 16.27 |

| 4 | 99.38 | 245.08 | 64.25 | 0.38 | 0.04 | 0.20 | 0.61 | 0.07 | 0.32 | 122.63 | 18.09 |

| 5 | 123.44 | 302.32 | 80.21 | 0.30 | 0.16 | 0.19 | 0.46 | 0.25 | 0.29 | 151.95 | 19.50 |

| 6 | 150.46 | 345.37 | 98.36 | 0.58 | 0.33 | 0.52 | 0.41 | 0.23 | 0.36 | 179.81 | 20.65 |

| 7 | 175.42 | 394.17 | 114.63 | 0.74 | 0.65 | 0.74 | 0.35 | 0.30 | 0.35 | 207.57 | 21.62 |

| 8 | 199.75 | 444.27 | 130.40 | 0.47 | 0.15 | 0.35 | 0.49 | 0.16 | 0.36 | 235.21 | 22.47 |

| 9 | 224.20 | 485.47 | 146.22 | 0.75 | 0.88 | 0.73 | 0.32 | 0.37 | 0.31 | 260.76 | 23.21 |

| 10 | 245.46 | 530.46 | 158.87 | 0.76 | 0.33 | 0.79 | 0.41 | 0.18 | 0.42 | 284.81 | 23.88 |

| 11 | 265.21 | 577.40 | 169.98 | 0.64 | 0.80 | 0.79 | 0.29 | 0.36 | 0.35 | 308.19 | 24.48 |

| 12 | 284.53 | 629.17 | 180.77 | 0.69 | 0.38 | 0.59 | 0.41 | 0.23 | 0.36 | 332.44 | 25.03 |

| 13 | 302.85 | 678.10 | 190.93 | 0.62 | 0.42 | 0.60 | 0.38 | 0.25 | 0.37 | 355.38 | 25.53 |

| 14 | 320.96 | 724.01 | 200.85 | 0.54 | 0.32 | 0.45 | 0.41 | 0.24 | 0.34 | 377.42 | 26.00 |

| 15 | 341.14 | 767.04 | 212.05 | 0.64 | 0.56 | 0.61 | 0.35 | 0.31 | 0.34 | 400.05 | 26.44 |

| 16 | 360.26 | 818.35 | 222.76 | 0.49 | 0.43 | 0.51 | 0.34 | 0.30 | 0.36 | 424.09 | 26.84 |

| 17 | 381.14 | 872.48 | 234.85 | 0.34 | 0.02 | 0.05 | 0.84 | 0.05 | 0.11 | 450.01 | 27.23 |

| 18 | 403.44 | 922.70 | 248.34 | 0.39 | 0.14 | 0.21 | 0.53 | 0.19 | 0.28 | 476.06 | 27.59 |

| 19 | 426.36 | 968.15 | 262.59 | 0.34 | 0.01 | 0.16 | 0.66 | 0.02 | 0.31 | 501.46 | 27.93 |

| 20 | 448.45 | 1017.85 | 275.83 | 0.96 | 0.74 | 0.97 | 0.36 | 0.28 | 0.36 | 527.20 | 28.25 |

| 21 | 461.33 | 1099.88 | 281.56 | 0.47 | 0.62 | 0.41 | 0.31 | 0.41 | 0.28 | 554.38 | 28.56 |

| 22 | 477.11 | 1156.03 | 289.34 | 0.20 | 0.11 | 0.23 | 0.36 | 0.21 | 0.43 | 577.20 | 28.85 |

| 23 | 495.61 | 1206.61 | 298.97 | 0.72 | 0.36 | 0.81 | 0.38 | 0.19 | 0.43 | 600.43 | 29.13 |

| 24 | 511.93 | 1267.34 | 306.79 | 0.61 | 0.51 | 0.60 | 0.35 | 0.30 | 0.35 | 624.59 | 29.40 |

| 25 | 527.83 | 1329.16 | 314.39 | 0.48 | 0.24 | 0.44 | 0.42 | 0.21 | 0.38 | 648.77 | 29.66 |

| 26 | 544.70 | 1385.29 | 323.04 | 0.14 | 0.06 | 0.07 | 0.51 | 0.21 | 0.28 | 672.33 | 29.91 |

| 27 | 562.47 | 1436.74 | 332.52 | 0.57 | 0.35 | 0.44 | 0.42 | 0.26 | 0.32 | 695.42 | 30.15 |

| 28 | 580.97 | 1489.62 | 342.92 | 0.49 | 0.30 | 0.42 | 0.41 | 0.25 | 0.34 | 719.47 | 30.38 |

| Mean value | 0.42 | 0.24 | 0.34 | ||||||||

| Age, Hours | i Parameters | ||

|---|---|---|---|

| t | IT | AT | ARH |

| 0.5 | 20.9 | 23.9 | 29.7 |

| 1 | 21.2 | 23.4 | 30.6 |

| 1.5 | 21.6 | 23.3 | 33.8 |

| … | … | … | … |

| 672 | 8.3 | 13.8 | 40.9 |

| Age, Days | Maturity of i Parameter | Complex Maturity, °C·Days | Estimated Strength in Boxes, MPa | ||

|---|---|---|---|---|---|

| t | MIT | MAT | MARH | Mc | CS |

| 1 | 41.76 | 39.72 | 20.43 | 33.96 | 9.65 |

| 2 | 73.31 | 107.37 | 36.76 | 69.03 | 14.44 |

| 3 | 97.01 | 174.68 | 51.18 | 100.12 | 16.96 |

| 4 | 119.46 | 245.08 | 64.25 | 130.96 | 18.77 |

| 5 | 143.02 | 302.32 | 80.21 | 160.08 | 20.13 |

| 6 | 169.33 | 345.37 | 98.36 | 187.64 | 21.20 |

| 7 | 195.51 | 394.17 | 114.63 | 215.91 | 22.15 |

| 8 | 220.34 | 444.27 | 130.40 | 243.75 | 22.97 |

| 9 | 245.35 | 485.47 | 146.22 | 269.53 | 23.65 |

| 10 | 268.13 | 530.46 | 158.87 | 294.22 | 24.24 |

| 11 | 288.72 | 577.40 | 169.98 | 317.94 | 24.77 |

| 12 | 308.81 | 629.17 | 180.77 | 342.52 | 25.27 |

| 13 | 327.90 | 678.10 | 190.93 | 365.78 | 25.71 |

| 14 | 346.39 | 724.01 | 200.85 | 387.97 | 26.11 |

| 15 | 366.25 | 767.04 | 212.05 | 410.47 | 26.49 |

| 16 | 385.93 | 818.35 | 222.76 | 434.74 | 26.88 |

| 17 | 406.45 | 872.48 | 234.85 | 460.52 | 27.27 |

| 18 | 428.39 | 922.70 | 248.34 | 486.41 | 27.64 |

| 19 | 451.14 | 968.15 | 262.59 | 511.74 | 27.98 |

| 20 | 474.30 | 1017.85 | 275.83 | 537.93 | 28.32 |

| 21 | 489.89 | 1099.88 | 281.56 | 566.23 | 28.67 |

| 22 | 504.88 | 1156.03 | 289.34 | 588.72 | 28.93 |

| 23 | 522.73 | 1206.61 | 298.97 | 611.68 | 29.19 |

| 24 | 539.95 | 1267.34 | 306.79 | 636.22 | 29.46 |

| 25 | 556.23 | 1329.16 | 314.39 | 660.55 | 29.71 |

| 26 | 572.76 | 1385.29 | 323.04 | 683.97 | 29.95 |

| 27 | 590.62 | 1436.74 | 332.52 | 707.10 | 30.17 |

| 28 | 608.83 | 1489.62 | 342.92 | 731.03 | 30.40 |

| Age, Day | Results of Strength Tests, MPa | Estimated Strength, MPa | |||||

|---|---|---|---|---|---|---|---|

| ASTM C192 | GOST 10180 | GOST 22690 | ASTM C1074 | Proposed | |||

| Cylinders (ꬾ15 × 15 cm) | Cubes (10 × 10 × 10 cm) | Box 1 (50 × 50 × 50 cm) | Box 2 (50 × 50 × 50 cm) | Average in Boxes | |||

| 1 | 9.67 | 12.2 | 13.15 | 14.35 | 13.75 | 12.25 | 9.65 |

| 3 | 16.06 | 20.45 | 24.25 | 21.65 | 22.95 | 17.92 | 16.96 |

| 7 | 22.17 | 24.25 | 27.75 | 28.45 | 28.1 | 22.63 | 22.15 |

| 14 | 23.99 | 26.75 | 30.3 | 29.95 | 30.125 | 26.48 | 26.11 |

| 28 | 31.72 | 34.2 | 31.3 | 31.35 | 31.325 | 30.27 | 30.40 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Utepov, Y.; Aniskin, A.; Tulebekova, A.; Aldungarova, A.; Zharassov, S.; Sarsembayeva, A. Complex Maturity Method for Estimating the Concrete Strength Based on Curing Temperature, Ambient Temperature and Relative Humidity. Appl. Sci. 2021, 11, 7712. https://doi.org/10.3390/app11167712

Utepov Y, Aniskin A, Tulebekova A, Aldungarova A, Zharassov S, Sarsembayeva A. Complex Maturity Method for Estimating the Concrete Strength Based on Curing Temperature, Ambient Temperature and Relative Humidity. Applied Sciences. 2021; 11(16):7712. https://doi.org/10.3390/app11167712

Chicago/Turabian StyleUtepov, Yelbek, Aleksej Aniskin, Assel Tulebekova, Aliya Aldungarova, Shyngys Zharassov, and Assel Sarsembayeva. 2021. "Complex Maturity Method for Estimating the Concrete Strength Based on Curing Temperature, Ambient Temperature and Relative Humidity" Applied Sciences 11, no. 16: 7712. https://doi.org/10.3390/app11167712

APA StyleUtepov, Y., Aniskin, A., Tulebekova, A., Aldungarova, A., Zharassov, S., & Sarsembayeva, A. (2021). Complex Maturity Method for Estimating the Concrete Strength Based on Curing Temperature, Ambient Temperature and Relative Humidity. Applied Sciences, 11(16), 7712. https://doi.org/10.3390/app11167712