Assessing the Energy Efficiency Potential of Recycled Materials with Construction and Demolition Waste: A Spanish Case Study

Abstract

:1. Introduction

2. Methods

- Identification of the most common construction model in Spain;

- Characteristics of the reference building;

- Characteristics of the energy simulation model;

- Selection of recycled materials and building applications.

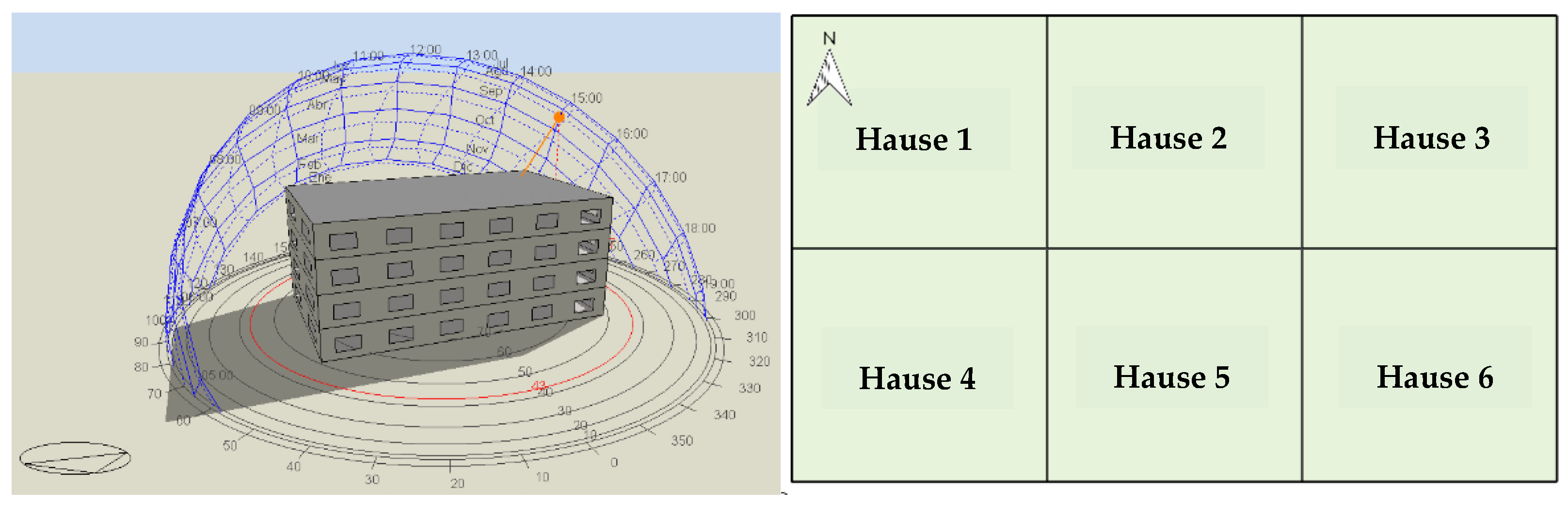

2.1. Identification of the Most Common Construction Model in Spain

- New building for residential use;

- Average surface per home of 110 m2;

- Four floors above ground level and none below ground level;

- Vertical structure of reinforced concrete and horizontal structure with unidirectional slab;

- Flat roof, exterior cladding with continuous cladding, and interior ceramic flooring;

- False ceiling;

- Cooling and heating system.

2.2. Characteristics of the Reference Building (Case 1)

2.3. Characteristics of the Energy Simulation Model

2.4. Selection of Sustainable Materials

2.5. Case Studies

- CASE 4. Roof and façade incorporating recycled materials (Table 5).

3. Results

3.1. Consumption of the Reference Building with Traditional Materials

3.2. Comparative Study of the Different Scenarios Studied

4. Conclusions

- Energy savings can range from 8% in warm climates (e.g., Sevilla) to 13% in colder climates (e.g., Soria), being greater in heating than in cooling;

- Incorporating recycled materials into the roof presents greater energy savings potential (up to 7%) than when placed in the façade;

- Economic savings due to the reduction in the energy consumption of the cooling system can reach up to 14% for heating in colder climates (e.g., Soria) or 4% for cooling in warm climates (e.g., Seville).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Porras-Amores, C.; Viñas-Arrebola, C.; Rodríguez-Sánchez, A.; Villoria-Sáez, P. Assessing the potential use of strategies independent from the architectural design to achieve efficient ventilation: A Spanish case study. Build. Serv. Eng. Res. 2014, 35, 529–542. [Google Scholar] [CrossRef]

- European Commission, Directive 2010/31/UE Regarding Energy Efficiency in Buildings 2010. Available online: https://eur-lex.europa.eu/legal-content/FR/ALL/?uri=celex%3A32010L0031 (accessed on 23 August 2021).

- Spanish Government. Real Decreto 314/2006, de 17 de Marzo, por el que se Aprueba el Código Técnico de la Edificación; Vivienda, M.D., Ed.; Boletın Oficial del Estado: Madrid, Spain, 2006. [Google Scholar]

- Spanish Government. Royal Decree 235/2013, of April 5, Which Approves the Basic Procedure for the Certification of the Energy Efficiency of Buildings (Real Decreto 235/2013, de 5 de abril, por el que se Aprueba el Procedimiento Básico Para la Certificación de la Eficiencia Energética de los Edificios); Boletın Oficial del Estado: Madrid, Spain, 2013. [Google Scholar]

- Cuchí, A.; Sweatman, P. A National Perspective of Spain’s Buildings Sector: A Roadmap for a New Housing Sector; Working Group for Rehabilitation: Madrid, Spain, 2011. [Google Scholar]

- European Commision. Eurostat Statistics for Waste Flow Generation. 2012. Available online: http://epp.eurostat.ec.europa.eu/portal/page/portal/eurostat/home/ (accessed on 23 August 2021).

- Fischer, C.; Werge, M.; Reichel, A. EU as a Recycling Society Present Recycling Levels of Municipal Waste and Construction & Demolition Waste in the EU; European Topic Centre on Resource and Waste Management: Bruselas, Belgium, 2011. [Google Scholar]

- Spanish Government. Real Decreto 105/2008, de 1 de Febrero, por el que se Regula la Producción y Gestión de los Residuos de Construcción y Demolición. Royal Decree 105/2008, of February 1, on the Production and Management of Construction and Demolition Waste; Official State Bulletin (BOE): Madrid, Spain, 2008; pp. 7724–7730. [Google Scholar]

- Haselein, C.R.; Calegari, L.; Alberti, L.F.; Minello, A.L.; Silva, P.A.d.; Pintos, R.G.F. Manufacturing gypsum-bonded-particleboard with recycled paper and pine wood particles. Ciência Florest. 2002, 12, 81–88. [Google Scholar] [CrossRef] [Green Version]

- Sair, S.; Mandili, B.; Taqi, M.; El Bouari, A. Development of a new eco-friendly composite material based on gypsum reinforced with a mixture of cork fibre and cardboard waste for building thermal insulation. Compos. Commun. 2019, 16, 20–24. [Google Scholar] [CrossRef]

- Cherki, A.-B.; Remy, B.; Khabbazi, A.; Jannot, Y.; Baillis, D. Experimental thermal properties characterization of insulating cork–gypsum composite. Constr. Build. Mater. 2014, 54, 202–209. [Google Scholar] [CrossRef]

- Vasconcelos, G.; Lourenço, P.; Camões, A.; Martins, A.; Cunha, S. Evaluation of the performance of recycled textile fibres in the mechanical behaviour of a gypsum and cork composite material. Cem. Concr. Compos. 2015, 58, 29–39. [Google Scholar] [CrossRef]

- Morales-Conde, M.J.; Rodríguez-Liñán, C.; Pedreño-Rojas, M.A. Physical and mechanical properties of wood-gypsum composites from demolition material in rehabilitation works. Constr. Build. Mater. 2016, 114, 6–14. [Google Scholar] [CrossRef]

- Musa, M.N.; Aziz, M.F.A. Thermal Conductivity for Mixture of Rice Husk Fiber and Gypsum. Appl. Mech. Mater. 2016, 819, 69–73. [Google Scholar] [CrossRef]

- Oliveira, C.E.; Oliveira, M.C.; Oliveira, J.L.; Damasceno, F.A.; Alves, N.M.; Bezerra, L.A. Gypsum-based composites with addition of woody endocarp of Barueiro nut residue and sawdust. In Proceedings of the 2016 ASABE Annual International Meeting, ASABE, St. Joseph, MI, USA, 18–20 July 2016; p. 1. [Google Scholar]

- Belayachi, N.; Hoxha, D.; Ismail, B. Impact of fiber treatment on the fire reaction and thermal degradation of building insulation straw composite. Energy Procedia 2017, 139, 544–549. [Google Scholar] [CrossRef]

- Braiek, A.; Karkri, M.; Adili, A.; Ibos, L.; Ben Nasrallah, S. Estimation of the thermophysical properties of date palm fibers/gypsum composite for use as insulating materials in building. Energy Build. 2017, 140, 268–279. [Google Scholar] [CrossRef]

- Iucolano, F.; Liguori, B.; Aprea, P.; Caputo, D. Evaluation of bio-degummed hemp fibers as reinforcement in gypsum plaster. Compos. Part B Eng. 2018, 138, 149–156. [Google Scholar] [CrossRef]

- Medina, N.F.; Barrera, M.D.M.B. Mechanical and physical enhancement of gypsum composites through a synergic work of polypropylene fiber and recycled isostatic graphite filler. Constr. Build. Mater. 2017, 131, 165–177. [Google Scholar] [CrossRef]

- Miño, C.R.B. Estudio de la Conductividad Térmica de Residuos Sólidos Dentro de una Matriz de yeso, Provenientes del Proceso de Rebajado del Cuero en la Empresa Curtiduría Tungurahua SA. Ph.D. Thesis, Universidad Técnica de Ambato, Facultad de Ingeniería Civil y Mecánica, Ambato, Ecuador, 2017. Available online: https://repositorio.uta.edu.ec/handle/123456789/25258 (accessed on 23 August 2021).

- Merino, M.d.; Astorqui, J.S.C.; Sáez, P.V.; Jiménez, R.S.; Cortina, M.G.J.C. Eco plaster mortars with addition of waste for high hardness coatings. Constr. Build. Mater. 2018, 158, 649–656. [Google Scholar] [CrossRef]

- Rodríguez-Orejón, A.; Del Río-Merino, M.; Martinez, F.F. Characterization mixtures of thick gypsum with addition of treated waste from laminated plasterboards. Mater. Construcción 2014, 64, e018. [Google Scholar] [CrossRef]

- Piñeiro, S.R.; Merino, M.D.R.; García, C.P. New Plaster Composite with Mineral Wool Fibres from CDW Recycling. Adv. Mater. Sci. Eng. 2015, 2015, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Vidales-Barriguete, A.; Sanchez, E.A.; del Río-Merino, M.; Ramirez, C.P. Analysis of the improved water-resistant properties of plaster compounds with the addition of plastic waste. Constr. Build. Mater. 2019, 230, 116956. [Google Scholar] [CrossRef]

- Barriguete, A.V.; Merino, M.d.; Sánchez, E.A.; Ramírez, C.P.; Arrebola, C.V.J.C. Analysis of the feasibility of the use of CDW as a low-environmental-impact aggregate in conglomerates. Constr. Build. Mater. 2018, 178, 83–91. [Google Scholar] [CrossRef] [Green Version]

- Morales-Segura, M.; Porras-Amores, C.; Villoria-Sáez, P.; Caballol-Bartolomé, D. Characterization of Gypsum Composites Containing Cigarette Butt Waste for Building Applications. Sustainability 2020, 12, 7022. [Google Scholar] [CrossRef]

- San-Antonio-González, A.; Merino, M.D.R.; Arrebola, C.V.; Villoria-Sáez, P. Lightweight material made with gypsum and extruded polystyrene waste with enhanced thermal behaviour. Constr. Build. Mater. 2015, 93, 57–63. [Google Scholar] [CrossRef]

- San-Antonio-González, A.; Merino, M.D.R.; Arrebola, C.V.; Villoria-Sáez, P. Lightweight Material Made with Gypsum and EPS Waste with Enhanced Mechanical Strength. J. Mater. Civ. Eng. 2016, 28, 04015101. [Google Scholar] [CrossRef]

- Babu, K.; Babu, D. Behaviour of lightweight expanded polystyrene concrete containing silica fume. Cem. Concr. Res. 2003, 33, 755–762. [Google Scholar] [CrossRef]

- Küçük, V.A.; Uğur, M.; Korucu, H.; Şimşek, B.; Uygunoğlu, T.; Kocakerim, M.M. Chemical resistance of dioctyl terephthalate pozzolanic-cement mortar: Comparative study with other waste polymers. Constr. Build. Mater. 2020, 263, 120905. [Google Scholar] [CrossRef]

- Muñoz-Ruiperez, C.; Rodríguez, A.; Gutiérrez-González, S.; Calderón, V.J.C. Lightweight masonry mortars made with expanded clay and recycled aggregates. Constr. Build. Mater. 2016, 118, 139–145. [Google Scholar] [CrossRef]

- Souza, L.D.F.; Mansur, H. Production and characterization of ceramic pieces obtained by slip casting using powder wastes. J. Mater. Process. Technol. 2004, 145, 14–20. [Google Scholar] [CrossRef]

- Silva, J.; De Brito, J.; Veiga, R. Recycled Red-Clay Ceramic Construction and Demolition Waste for Mortars Production. J. Mater. Civ. Eng. 2010, 22, 236–244. [Google Scholar] [CrossRef]

- Cheng, A.; Lin, W.-T.; Huang, R. Application of rock wool waste in cement-based composites. Mater. Des. 2011, 32, 636–642. [Google Scholar] [CrossRef]

- Lin, W.-T.; Cheng, A.; Huang, R.; Wu, Y.-C.; Han, T.-Y. Rock wool wastes as a supplementary cementitious material replacement in cement-based composites. Comput. Concr. 2013, 11, 93–104. [Google Scholar] [CrossRef]

- Ramírez, C.P.; Barriguete, A.V.; Somolinos, R.S.; Merino, M.D.R.; Sánchez, E.A. Analysis of fire resistance of cement mortars with mineral wool from recycling. Constr. Build. Mater. 2020, 265, 120349. [Google Scholar] [CrossRef]

- Ramírez, C.P.; Merino, M.D.R.; Arrebola, C.V.; Barriguete, A.V.; Kosior-Kazberuk, M. Analysis of the mechanical behaviour of the cement mortars with additives of mineral wool fibres from recycling of CDW. Constr. Build. Mater. 2019, 210, 56–62. [Google Scholar] [CrossRef]

- Barrera, M.D.M.B.; Pombo, O.; Navacerrada, M. Textile fibre waste bindered with natural hydraulic lime. Compos. Part B Eng. 2016, 94, 26–33. [Google Scholar] [CrossRef]

- Araya-Letelier, G.; Antico, F.; Carrasco, M.; Rojas, P.; Garcia-Herrera, C. Effectiveness of new natural fibers on damage-mechanical performance of mortar. Constr. Build. Mater. 2017, 152, 672–682. [Google Scholar] [CrossRef]

- Khmiri, A.; Chaabouni, M.; Samet, B. Chemical behaviour of ground waste glass when used as partial cement replacement in mortars. Constr. Build. Mater. 2013, 44, 74–80. [Google Scholar] [CrossRef]

- Ling, T.-C.; Poon, C.-S. Utilization of recycled glass derived from cathode ray tube glass as fine aggregate in cement mortar. J. Hazard. Mater. 2011, 192, 451–456. [Google Scholar] [CrossRef]

- Matos, A.M.; Sousa-Coutinho, J.J.A.i.C.R. Waste glass powder in cement: Macro and micro scale study. Adv. Cem. Res. 2008, 28, 423–432. [Google Scholar] [CrossRef]

- Pourchez, J.; Ruot, B.; Debayle, J.; Grosseau, P. Some aspects of cellulose ethers influence on water transport and porous structure of cement-based materials. Cem. Concr. Res. 2010, 40, 242–252. [Google Scholar] [CrossRef] [Green Version]

- Patural, L.; Marchal, P.; Govin, A.; Grosseau, P.; Ruot, B.; Devès, O. Cellulose ethers influence on water retention and consistency in cement-based mortars. Cem. Concr. Res. 2011, 41, 46–55. [Google Scholar] [CrossRef] [Green Version]

- Roselló, J.; Soriano, L.; Santamarina, M.P.; Akasaki, J.L.; Monzó, J.; Payá, J. Rice straw ash: A potential pozzolanic supplementary material for cementing systems. Ind. Crop. Prod. 2017, 103, 39–50. [Google Scholar] [CrossRef] [Green Version]

- Fantilli, A.P.; Sicardi, S.; Dotti, F. The use of wool as fiber-reinforcement in cement-based mortar. Constr. Build. Mater. 2017, 139, 562–569. [Google Scholar] [CrossRef]

- Botasso, H.; Fensel, E. Proyecto para el uso sistemático de residuos de construcción, demolición y procesos industriales. in Actas del Cuarto Congreso Internacional de Metalurgia y Materiales (Conamet-Sam). 2014. [Google Scholar]

- Ashour, T.; Korjenic, A.; Korjenic, S.; Wu, W. Thermal conductivity of unfired earth bricks reinforced by agricultural wastes with cement and gypsum. Energy Build. 2015, 104, 139–146. [Google Scholar] [CrossRef]

- Gheni, A.; ElGawady, M.A.; Myers, J.J. Thermal characterization of cleaner and eco-efficient masonry units using sustainable aggregates. J. Clean. Prod. 2017, 165, 980–993. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Patnaikuni, I.; Wu, Y.-F.; Fawad, U. Thermal performance enhancement of eco-friendly bricks incorporating agro-wastes. Energy Build. 2018, 158, 1117–1129. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.-F.; Hanif, A.; Patnaikuni, I. Thermal performance evaluation of eco-friendly bricks incorporating waste glass sludge. J. Clean. Prod. 2018, 172, 1867–1880. [Google Scholar] [CrossRef]

- Porras-Amores, C.; Santa-Cruz-Astorqui, J.; Del-Río-Merino, M.; Villoria-Sáez, P.; Viñas-Arrebola, C.J.D.-I.e.I. Comportamiento térmico del yeso tradicional con residuos de construcción y demolición. DYNA-Ing. Ind. 2019, 94, 431–436. [Google Scholar] [CrossRef] [Green Version]

- Astorqui, J.S.C.; Merino, M.D.R.; Sáez, P.V.; Porras-Amores, C. Analysis of the Relationship between Density and Mechanical Strength of Lightened Gypsums: Proposal for a Coefficient of Lightening. Adv. Mater. Sci. Eng. 2017, 2017, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Merino, M.d.; Sáez, P.V.; Longobardi, I.; Astorqui, J.S.C.; Porras-Amores, C. Redesigning lightweight gypsum with mixes of polystyrene waste from construction and demolition waste. J. Clean. Prod. 2019, 220, 144–151. [Google Scholar] [CrossRef]

- Sáez, P.V.; Merino, M.D.R.; Sanchez, E.A.; Astorqui, J.S.C.; Porras-Amores, C. Viability of Gypsum Composites with Addition of Glass Waste for Applications in Construction. J. Mater. Civ. Eng. 2019, 31, 04018403. [Google Scholar] [CrossRef]

- Astorqui, J.S.C.; Merino, M.d.R.; Sáez, P.V.; Amores, C.P. Analysis of the viability of prefabricated elements for partitions manufactured with plaster and EPS from waste recycling. Dyna 2019, 94, 415–420. [Google Scholar]

- Ouakarrouch, M.; El Azhary, K.; Laaroussi, N.; Garoum, M.; Kifani-Sahban, F. Thermal performances and environmental analysis of a new composite building material based on gypsum plaster and chicken feathers waste. Therm. Sci. Eng. Prog. 2020, 19, 100642. [Google Scholar] [CrossRef]

- Sáez, P.V.; Merino, M.D.R.; Sorrentino, M.; Amores, C.P.; Astorqui, J.S.C.; Arrebola, C.V. Mechanical Characterization of Gypsum Composites Containing Inert and Insulation Materials from Construction and Demolition Waste and Further Application as A Gypsum Block. Materials 2020, 13, 193. [Google Scholar] [CrossRef] [Green Version]

- Merabti, S.; Kenai, S.; Belarbi, R.; Khatib, J. Thermo-mechanical and physical properties of waste granular cork composite with slag cement. Constr. Build. Mater. 2020, 272, 121923. [Google Scholar] [CrossRef]

- Instituto Nacional de Estadística, Censo de Población y Viviendas, in Ideas Propias, España. Madrid. 2011. Available online: https://www.ine.es/dyngs/INEbase/es/operacion.htm?c=Estadistica_C&cid=1254736176992&menu=ultiDatos&idp=1254735576757 (accessed on 23 August 2021).

- Gobierno de España, Anuario Estadístico 2015. Ministerio de Fomento. 2015. Available online: http://www.interior.gob.es/web/archivos-y-documentacion/anuario-estadistico-de-2015 (accessed on 23 August 2021).

- Gobierno de España, Construcción de Edificios 2011-Datos Recogidos de las Licencias de obra Concedidas por los Ayuntamientos. Ministerio de Fomento. 2016. Available online: https://www.mitma.gob.es/informacion-para-el-ciudadano/informacion-estadistica/construccion/construccion-de-edificios/construccion-de-edificios-licencias-municipales-de-obra (accessed on 23 August 2021).

- Instituto de Ciencias de la Construcción Eduardo Torroja and Instituto de la Construcción de Castilla y León. CTE WEB. Código técnico de la Edificación Web. 2007. Available online: http://cte-web.iccl.es (accessed on 23 August 2021).

- Crawley, D.B.; Lawrie, L.K.; Winkelmann, F.C.; Buhl, W.; Huang, Y.; Pedersen, C.O.; Strand, R.K.; Liesen, R.J.; Fisher, D.E.; Witte, M.J.; et al. EnergyPlus: Creating a new-generation building energy simulation program. Energy Build. 2001, 33, 319–331. [Google Scholar] [CrossRef]

- Dahanayake, K.K.C.; Chow, C.L. Studying the potential of energy saving through vertical greenery systems: Using EnergyPlus simulation program. Energy Build. 2017, 138, 47–59. [Google Scholar] [CrossRef]

- Zhang, R.; Lam, K.P.; Yao, S.-C.; Zhang, Y.J. Coupled EnergyPlus and computational fluid dynamics simulation for natural ventilation. Build. Environ. 2013, 68, 100–113. [Google Scholar] [CrossRef]

- Mateus, N.M.; da Graça, G.C. Simulated and measured performance of displacement ventilation systems in large rooms. Build. Environ. 2017, 114, 470–482. [Google Scholar] [CrossRef]

- DesignBuilder Software Ltd. Design Builder Simulation and CFD Training Guide; DesignBuilder Software Ltd.: London, UK, 2017. [Google Scholar]

- C-Therm. TCi Thermal Conductivity Analyzer. 2019. Available online: https://ctherm.com/products/tci_thermal_conductivity/ (accessed on 23 August 2021).

- Amores, C.P.; Astorqui, J.S.C.; Merino, M.d.R.; Sáez, P.V.; Arrebola, C.J.D.V. Thermal behavior of traditional lightweight gypsum with construction and demolition waste materials. Dyna 2019, 94. [Google Scholar] [CrossRef] [Green Version]

| Year, Reference | Waste | Binder | Application | Thermal Conductivity [w/mK] (% of Waste Addition) | Compressive Strength [Mpa] (% of Waste Addition) |

|---|---|---|---|---|---|

| 2015, [48] | Wheat and barley straw | Gypsum, cement, soil | Bricks | 0.31 (3% wheat straw) 0.314 (3% barley straw) | - |

| 2017, [49] | Rubber | Cement | Masonry units | 0.8 (20% waste) 0.65 (37% waste) | 15.4 (20% rubber) 6.7 (37% rubber) |

| 2018, [50] | Sugarcane Bagasse Ash Rice Husk Ash | Clay | Bricks | 0.35 (15% SBA) 0.37 (15% RHA) | 5.01 (15% SBA) 5.53 (15% RHA) |

| 2018, [51] | Glass | Clay | Bricks | 0.59 (25% waste) | 12.56 (25% glass) |

| 2018, [52,53] | Expanded polystyrene Extruded polystyrene | Gypsum | Plasters, coatings | 0.23 (2% EPS) 0.29 (2% XPS) | 2.74 (2% EPS) 5.59 (2% XPS) |

| 2019, [54] | Expanded polystyrene Extruded polystyrene | Gypsum | Plasterboard | 0.16 (3% EPS + 1% XPS) 0.15 (2% EPS + 3% XPS) | 3.56 (3% EPS + 1% XPS) 3.28 (2% EPS + 3% XPS) |

| 2019, [55] | Glass | Gypsum | Coatings, prefabricated elements | 0.28 (70% waste) 0.31 (100% waste) | 8.7 (70% waste) 10.2 (100% waste) |

| 2019 [56] | Expanded polystyrene | Gypsum | Plasterboard | 0.3 (2% EPS) | 2.35 (2% EPS) |

| 2020, [57] | Chicken feathers | Gypsum | Plasterboard | 0.309 (5% waste) | - |

| 2020, [58] | Ceramics Expanded polystyrene | Gypsum | Blocks | 0.28 (75% CER + 2/3 EPS) | 0.95 (75% CER + 2/3 EPS) |

| 2021, [59] | Granular cork | Cement | Non-load carrying elements | 0.38 (100% waste, m3) 0.15 (300% waste, m3 + 3% slag) | - |

| SEVILLA U-Value: 0.54 W/m2K | SORIA U-Value: 0.36 W/m2K | ||||

|---|---|---|---|---|---|

| Material | Thickness (m) | Density (kg/m3) | Conductivity (W/m·K) | Density (kg/m3) | Conductivity (W/m·K) |

| Single-layer cement mortar | 0.015 | 1900 | 1.3 | 1900 | 1.3 |

| Perforated ceramic brick | 0.115 | 900 | 0.5 | 900 | 0.5 |

| Cement mortar plastering | 0.01 | 1700 | 1 | 1700 | 1 |

| Non-ventilated air chamber | 0.04 | 1.2 | 0.22 | 1.2 | 0.22 |

| Mineral wool | 0.03/0.05 | 45 | 0.022 | 45 | 0.022 |

| Laminated gypsum board | 0.015 | 900 | 0.25 | 900 | 0.25 |

| SEVILLA U-Value: 0.41 W/m2K | SORIA U-Value: 0.34 W/m2K | ||||

|---|---|---|---|---|---|

| Material | Thickness (m) | Density (kg/m3) | Conductivity (W/m·K) | Density (kg/m3) | Conductivity (W/m·K) |

| Ceramic flooring | 0.01 | 2400 | 1.900 | 2400 | 1.900 |

| Gripping cement mortar | 0.01 | 1700 | 1.000 | 1700 | 1.000 |

| Cement mortar | 0.03 | 1700 | 1.000 | 1700 | 1.000 |

| Extruded polystyrene (XPS) | 0.04/0.055 | 35 | 0.034 | 35 | 0.034 |

| Waterproofing. Bituminous sheet | 0.01 | 2100 | 0.700 | 2100 | 0.700 |

| Lightened slope mortar with expanded clay | 0.12 | 700 | 0.220 | 700 | 0.220 |

| Unidirectional concrete slab | 0.30 | 1110 | 0.9375 | 1110 | 0.9375 |

| Non-ventilated air chamber | 0.15 | 1.2 | 0.560 | 1.2 | 0.560 |

| Laminated gypsum board | 0.015 | 900 | 0.250 | 900 | 0.250 |

| Year, Reference | Waste | Binder | Application | Thermal Conductivity [w/mK] |

|---|---|---|---|---|

| 2018, [50] | Sugarcane bagasse ash (SBA) Rice husk ash (RHA) | Clay | Bricks | 0.35 (15% SBA) 0.37 (15% RHA) |

| 2019, [54] | Expanded polystyrene (EPS) Extruded Polystyrene (XPS) | Gypsum | Plasterboard | 0.15 (2% EPS + 3% XPS) |

| 2020, [58] | Ceramics (CER) Expanded polystyrene (EPS) | Gypsum | Blocks | 0.28 (75% CER + 2/3 EPS) |

| 2021, [59] | Granular cork | Cement | Non-load carrying elements and insulation elements | 0.38 (100% waste, m3) 0.15 (300% waste, m3 + 3% slag) |

| Own testing | Extruded Polystyrene (XPS) | Cement and expanded clay (EC) | Slope mortar | 0.04 (50% EC + 50% XPS) |

| Building System | Application | Recycled Material | Traditional Material | ||

|---|---|---|---|---|---|

| Material | Thermal Resistance [m2K/W] | Material | Thermal Resistance [m2K/W] | ||

| Façade | Outer coating-Monolayer | Cement mortar with granular cork waste and slag | 0.10 | Cement mortar | 0.01 |

| Façade | Exterior Brick Wall | Ceramic brick with sugarcane bagasse ash (SBA) | 0.33 | Perforated ceramic brick | 0.23 |

| Façade | Coating and Plastering | Cement mortar with granular cork waste and slag | 0.07 | Cement mortar | 0.01 |

| Facade | Interior cladding-Plasterboard | Plaster with expanded polystyrene | 0.10 | Laminated gypsum board | 0.06 |

| Roof | Basement | Cement mortar with granular cork waste and slag | 0.20 | Cement mortar | 0.03 |

| Roof | Lightened mortar slope formation | Cement mortar with arlite and extruded polystyrene | 3.00 | Lightened slope mortar with expanded clay | 0.55 |

| Roof | False ceiling-Plasterboard | Plaster with expanded polystyrene | 0.10 | Laminated gypsum board | 0.06 |

| Heat Transfer Type | Heating | Cooling | Heating + Cooling | ||||

|---|---|---|---|---|---|---|---|

| Consumption (kWh) | Savings | Consumption (kWh) | Savings | Consumption (kWh) | Percentage | ||

| SEVILLA | |||||||

| Case 1 | Renovations | 64,328 | 26,291 | 90,619 | |||

| Case 2 | Renovations | 63,825 | 1% | 26,709 | −2% | 90,534 | 0% |

| Case 3 | Renovations | 62,671 | 3% | 26,338 | 0% | 89,009 | 2% |

| Case 4 | Renovations | 61,999 | 4% | 26,696 | −2% | 88,695 | 2% |

| Case 1 | Envelope | 17,076 | 6979 | 24,054 | |||

| Case 2 | Envelope | 16,936 | 1% | 7087 | −2% | 24,023 | 0% |

| Case 3 | Envelope | 15,819 | 7% | 6648 | 5% | 22,467 | 7% |

| Case 4 | Envelope | 15,523 | 9% | 6684 | 4% | 22,207 | 8% |

| SORIA | |||||||

| Case 1 | Renovations | 245,576 | 3189 | 248,765 | |||

| Case 2 | Renovations | 244,595 | 0% | 3533 | −11% | 248,127 | 0% |

| Case 3 | Renovations | 242,994 | 1% | 3460 | −8% | 245,606 | 1% |

| Case 4 | Renovations | 241,768 | 2% | 3838 | −20% | 245,606 | 1% |

| Case 1 | Envelope | 52,772 | 685 | 53,457 | |||

| Case 2 | Envelope | 51,211 | 3% | 740 | −8% | 51,951 | 3% |

| Case 3 | Envelope | 47,659 | 10% | 679 | 1% | 48,337 | 10% |

| Case 4 | Envelope | 45,572 | 14% | 723 | −6% | 46,295 | 13% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Porras-Amores, C.; Martin Garcia, P.; Villoria Sáez, P.; del Rio Merino, M.; Vitielo, V. Assessing the Energy Efficiency Potential of Recycled Materials with Construction and Demolition Waste: A Spanish Case Study. Appl. Sci. 2021, 11, 7809. https://doi.org/10.3390/app11177809

Porras-Amores C, Martin Garcia P, Villoria Sáez P, del Rio Merino M, Vitielo V. Assessing the Energy Efficiency Potential of Recycled Materials with Construction and Demolition Waste: A Spanish Case Study. Applied Sciences. 2021; 11(17):7809. https://doi.org/10.3390/app11177809

Chicago/Turabian StylePorras-Amores, César, Patricia Martin Garcia, Paola Villoria Sáez, Mercedes del Rio Merino, and Veronica Vitielo. 2021. "Assessing the Energy Efficiency Potential of Recycled Materials with Construction and Demolition Waste: A Spanish Case Study" Applied Sciences 11, no. 17: 7809. https://doi.org/10.3390/app11177809

APA StylePorras-Amores, C., Martin Garcia, P., Villoria Sáez, P., del Rio Merino, M., & Vitielo, V. (2021). Assessing the Energy Efficiency Potential of Recycled Materials with Construction and Demolition Waste: A Spanish Case Study. Applied Sciences, 11(17), 7809. https://doi.org/10.3390/app11177809