1. Introduction

Legged robots are always the most popular choice for robotics researchers due to their benefits over traditional wheeled robots or those that follow automated stages in applications such as mobility over irregular terrain [

1,

2,

3]. Bartsch et al. built the “Space-Climber 1”, which is a bio-inspired, six-legged, and vibrancy-effective robot. This robot was planned for use in extraterrestrial surface investigation, especially for portability in lunar pits [

4]. Estremera et al. described the improvement of a hexapod robot, “SILO-6”, using crab and turning gaits. Their robot was designed to move across a characteristic landscape containing uneven ground, and it can be used for humanitarian demining [

5]. Moro et al. proposed an approach of directly mapping a range of horse gaits to a quadruped robot with the intention of generating a more realistic locomotion gait [

6]. Ref. [

6] also used kinematic motion primitives to generate stable and valid walking, trotting, and galloping gaits in a compliant quadruped robot. Refs. [

4,

5,

6] developed robots that were generally effective in mimicking the gait cycles of their biological counterparts; however, they suffered from a high payload-to-machine-load ratio and high energy consumption.

Several approaches to developing energy-efficient walking machines have been reported. Ref. [

7] developed a set of rules to improve energy efficiency in statically-stable walking robots by comparing two-legged mammal and insect configurations on a hexapod robotic platform.Ref. [

8] applied the minimization criterion to optimize energy efficiency in a hexapod robot with respect to each half of a locomotion cycle, especially walking on uneven terrain. Ref. [

9] discussed two significant energy-efficient approaches toward determining optimal foot forces and joint torques for a six-legged robot.

In order to solve this problem, multi-legged robots that can be driven with a small number of actuators have been studied. Jansen [

10], a Dutch kinetic artist, proposed an unconventional closed kinematic-chain-based approach that requires actuation at only a single leg by mapping internal cyclic motion into elliptical motion. Various aspects of the Jansen mechanism have been studied by a number of researchers. In [

11,

12], the authors proposed an extension of Theo Jansen’s mechanism by introducing an additional up–down motion in the linkage center in order to realize new gait cycles, with approximately 10 times the height of the original, for climbing over obstacles. A vector loop and simple geometric methods were used in conjunction with software tools, such as ProEngineer and SAM, to analyze the forward kinematics of Theo Jansen’s mechanism in [

13]. An attempt to optimize the leg geometry of Theo Jansen’s mechanism using the genetic algorithm was presented in [

14]. This work explored the stability limits and tractive abilities while validating the kinematic and kinetic models through experiments with hardware prototypes. In [

15], a preliminary dynamic analysis was performed using the superposition method with the intention of optimizing Theo Jansen’s mechanism. Ref. [

16] developed an eight-legged walking robot that consisted of Theo Jansen’s mechanism and experimentally demonstrated its effectiveness in both flat and stair-climbing environments. In [

17], we presented a dynamic analysis of a four-legged Theo Jansen link mechanism using the projection method, which resulted in constraint force and an equivalent Lagrange equation of motion. In [

18,

19], the design of a novel reconfigurable Theo Jansen linkage was put forward and validated. This design produced a wide variety of gait cycles, opening new possibilities for innovative applications. The suggested mechanism switched from a pin-jointed Grübler kinematic chain to a five-degree-of-freedom mechanism with slider joints during the reconfiguration process. An original design approach was presented in [

20] to develop a trajectory generator that realized a set of stable walking gaits, gait synchronization, and a transition for a reconfigurable Jansen platform.

Another example is 1STAR, a six-legged robot capable of being driven with one degree of freedom [

21,

22,

23]. This robot consists of a rectangular body with six legs attached to both the vertex of the rectangular body and its long sides. The movements of the six legs are synchronized by gears, and the difference in the elasticity of the legs—thanks to the effects of torsion springs—is utilized to achieve forward and turning locomotion. STAR, which was developed by the same team, is a sprawl-tuned hexapod robot driven by three actuators: Two actuators work to drive the left and right legs, and the third actuator is used for the sprawl angle [

24,

25,

26]. SAW is a robot that can be driven by a single actuator and can move forward by generating a wave-like motion [

27,

28]. SAW has a spine that constrains the links from moving around it, producing an advancing wave-like motion. SAW is also able to drive between two flexible surfaces. HIbot is a single-actuated mobile crawling robot inspired by hexapod insects [

29]. It consists of six wheeled-leg mechanisms with four spokes and two bodies connected by passive joints. The six wheeled-leg mechanisms are appropriately synchronized by a belt, and it has been shown to be able to propel itself on stairs and uneven environments.

Another example of an approach to multi-legged robots driven with a lower number of actuators is the bio-inspired approach. Ref. [

30] categorized the morphologies of multi-legged robots into the mammal type, called “M-type,” and the insect type, called “I-type,” and concluded that the I-type is more efficient than the M-type when using a leg mechanism for a walking robot. A lizard possesses the I-type morphology. It improves its walking efficiency through the flexion movement of the trunk instead of through leg locomotion, especially when running quickly. This characteristic enabled us to decrease the number of actuators, and may even lead to a multi-legged robot that is driven by a single actuator, which will help in addressing the issue of the energy efficiency of multi-legged robots. A team at the College of Industrial Technology found that a lizard mainly walks by only twisting its waist [

31]. The same team analyzed the kinematics and then developed and demonstrated a lizard-type robot [

32,

33]. In our previous study, the dynamics of a lizard-type robot were analyzed [

34], and a robot capable of walking with only a single actuator was developed [

35]. The robot in [

31,

32,

33,

34,

35] had the morphology depicted in

Figure 1. This morphology consists of two facing triangles whose vertices are secured by an active pin joint. The vertices other than the active joint work as the legs. The active joints are swung sinusoidally, and the robot walks forward.

Although related studies have shown interesting results, including experiments, these robots cannot walk unless the support legs slip, or they require additional actuators to change their propulsive direction. For example, the Theo Jansen mechanism similarly requires its legs to slip in order to walk. In [

17,

18,

19], kinematic and dynamic analyses were addressed, and the velocity of the leg was shown to vary non-linearly. Hence, when driven synchronously in a certain phase, the legs of the Theo Jansen walking robot have different speeds (i.e., the support legs slip). In [

36], the trajectory generation method was proposed to maintain a constant leg velocity. However, to apply this trajectory generation method to a multi-legged robot, it is necessary to install an actuator on each leg. Thus, it cannot be driven by a single actuator alone. Meanwhile, 1STAR also requires the legs to slip in order to walk because the legs, which are equipped on the rectangular sides, are forced to slip geometrically for continuous leg driving. In fact, their team designed their robot based on a dynamic analysis that included the coefficient of friction with the ground. However, the coefficient of friction with the ground varies from place to place. Hence, a case-by-case analysis is required for a proper analysis of the locomotion of the robot. SAWs and HIbots are also only mechanically capable of moving forward or backward. Therefore, they require an additional actuator to change the propulsive direction.

Similarly, in a lizard-like robot with the morphology shown in

Figure 1, if the support legs depicted in black circles are completely fixed, then the waist (depicted in blue circles) can only exist at an equal point from each of the support legs, which are therefore constrained to one of the two distant points. Thus, when the angle of the waist is moved continuously, the position of the support legs also changes continuously (i.e., they slip). These issues are disadvantages, and they require a complex dynamic analysis, including an analysis of the friction coefficients with the ground, to know the kinematics of the robot. More specifically, it is difficult to achieve accurate motion control because the control system is also required to consider unknown toe slippage.

The purpose of this paper was to implement a lizard-inspired robot that is capable of being driven by a single actuator. Our proposed lizard-inspired robot overcomes these disadvantages because our robot possesses a morphology consisting of a four-bar linkage mechanism, as depicted in

Figure 2. The morphology of the four-bar linkage mechanism is able to regard the fixed link as the support leg and can be driven without the slipping of the support leg. By switching the fixed links of the support legs appropriately, we realized a robot that is theoretically capable of walking without its support legs slipping. This is the biggest difference between our robot and those of the related research, and it is our main novelty. This provides the robot with appropriate walking in which its support legs do not slip. It also allows the robot to formulate proper kinematic characteristics via kinematic analyses, which are much simpler than dynamic analyses. The robot moves forward by setting the fixed link of a four-bar linkage mechanism as support legs, and then switching them. The purpose of this paper was achieved through the following three processes.

The first process was a kinematic analysis. In this paper, a biased sinusoidal input angle function was adopted as the input for the system. The two ideas for the kinematic analysis were to define our own robot model and to formulate the kinematic characteristics based on the period of the input angle function. In particular, the first idea was to set a “robot coordinate” at the center of the front link. The robot coordinate allowed us to represent symmetrically important states, such as a turning angle and related angles between each link. In the second idea, the kinematics were characterized with respect to each half-period of the input angle function. Since the robot consists of a four-bar linkage mechanism, the same kinematic characteristics are maintained unless the support legs are switched. Hence, formulating the kinematic characteristics of the robot at the switching of the support legs can adequately represent the kinematic characteristics of the robot. In this paper, we formulated a turning angle and a stride length. These two characteristics are important for understanding the locomotion of the robot. In the turning locomotion analysis, it was proven that the robot turns with constant curvature by adding a constant bias onto the input angle. In the stride-length analysis, it was proven that the stride length depends on the amplitude and the bias of the input angle, as well as the link length of the robot. The validity of the results of the kinematics analysis was guaranteed via three numerical simulations.

The second process was the design and fabrication of the robot. For the robot’s design, two main issues were addressed. The first was the switching method between the support and swing legs. Since the robot proposed in this paper consists of a four-bar linkage mechanism, a mechanism lifting the legs while avoiding collisions was too difficult to design. Consequently, we propose a shuffle-walking method that uses a claw-shaped leg mechanism. Shuffle-walking is realized by hooking the claw-shaped leg mechanism on a carpeted flat surface. The claw is grippy in the direction of the claw, and is slippery otherwise. This characteristic is utilized to realize shuffle-walking. The second main issue was the equipment location of the actuator. In the proposed robot model, the input angle function is input into the origin of the robot’s coordinates for the robot’s locomotion. This required us to equip the actuator between two points with varying distances. As a solution to the second main issue, a linear sliding rod was adopted to connect the two points. One side was designed as a pin joint to equip the actuator, and the other side was a sliding joint. Finally, the robot was fabricated.

The third process was experimental verification. The effectiveness of the fabricated robot was verified through four experiments. The first experiment was conducted to verify the effectiveness of the claw-shaped leg mechanism. The other three experiments were conducted to verify the mobility of the robot. In particular, forward locomotion, clockwise turning locomotion, and counter-clockwise turning locomotion were performed. In these three experiments, the motion of the robot was captured. The captured results were quantitatively compared with the analytical results of the kinematic analysis.

This remainder of this paper is organized as follows. In

Section 2, the kinematics of the robot are analyzed. In particular, the turning angle and the stride length are formulated. In

Section 3, the mechanism of the robot is designed and fabricated. The effectiveness of the fabricated robot is verified in

Section 4. Finally,

Section 5 concludes this paper.

3. Design and Fabrication of the Lizard-Type Robot

In this section, the lizard-inspired robot with a new morphology consisting of a four-bar linkage mechanism was designed and fabricated. When designing the robot, two main issues were addressed. Solutions to the issues are shown herein, and the robot was then designed and fabricated.

The first main issue was the switching method between the supporting and idling legs. A general multi-legged robot walks by switching the roles of each leg into those of the supporting leg and the idling leg, synchronizing them appropriately. In addition, proper gripping is preferred for the supporting leg, while full slipping with lower load forces (e.g., friction forces) is preferred for the idling leg. A general multi-legged robot switches the supporting and idling legs when the leg contacts the ground. However, the robot proposed in this paper consists of a planar closed-linkage mechanism, and each pin joint works as a leg. Thus, to realize the switching of the supporting and idling legs through the up–down movement of the legs (similarly to a general multi-legged robot), pin joints are required in order to drive them in the axial direction. A mechanism for satisfying this requirement could be designed. However, such a mechanism would easily generate collisions between linkages. Driving the pin joints in the axial direction represents driving the connected links of the joints. Thus, two links in the front and back, as well as another two links crossing one another, move perpendicularly to the plane. Moreover, it is easy to imagine that the movements result in collisions between the links. In order to avoid collisions, it is necessary to design a complex shape for the linkage and pin joints, and such a mechanism design is too difficult to prototype.

As a solution for the first main issue, we propose a shuffle-walking method. The shuffle-walking method allowed us to design a robot consisting of a simple planar linkage mechanism using a claw-shaped leg mechanism. Generally, a claw is grippy in the claw direction, but is otherwise slippery. A textured plane, such as a carpet, was supposed, and the claw was designed so that its tip was pointed in the diagonal direction of the carpet surface; additionally, it was equipped so that the tip was pointed in the backward direction with respect to the robot. The design used a leg mechanism that is grippy in the backward direction and slippery in the forward direction. Each pin joint possesses a claw-shaped leg mechanism. When rotating the driving link on the carpet surface, one pin joint generates a translational force in the backward direction, and the opposite joint generates force in the forward direction. The pin joint generating the force in the backward direction stays on-site because the claw is hooked onto the carpet surface. However, the opposite joint slips on the carpet surface and moves forward, since the force works in the slippery direction for the claw. Thus, shuffle-walking is realized.

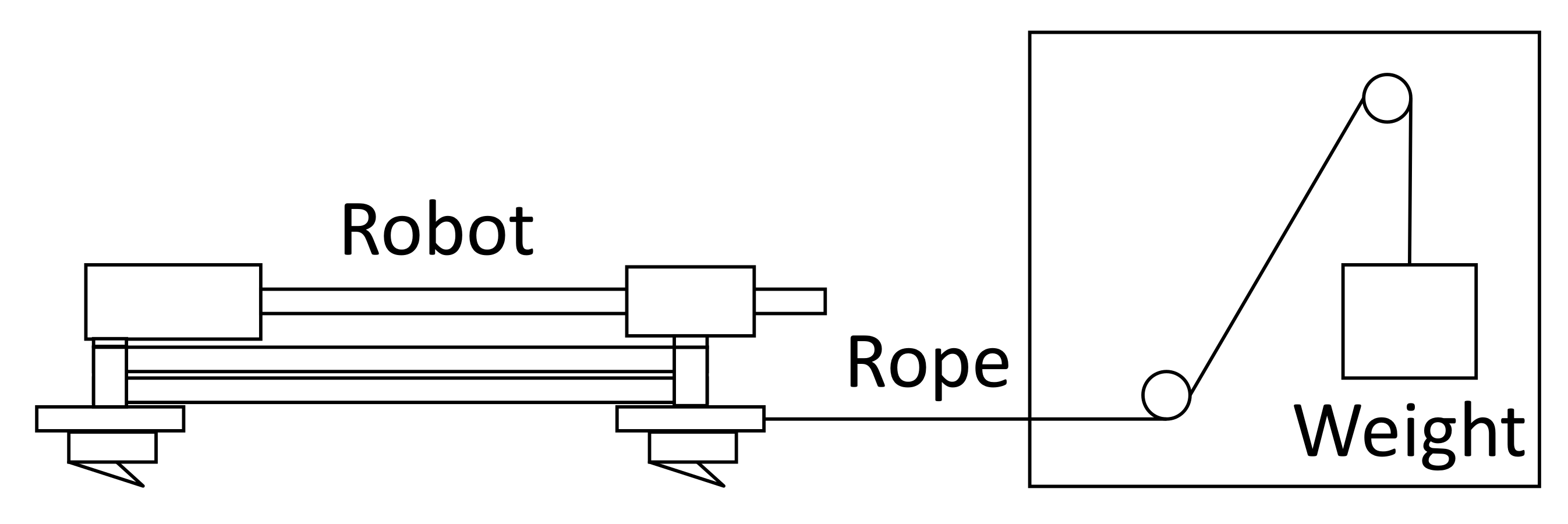

The second main issue was the location for the installment of an actuator. In the proposed robot model, the input angle function was set on the robot coordinates for the robot’s locomotion. Hence, the robot’s actuator in the design also had to be installed on the robot’s coordinate (i.e., on ). To install the actuator on the robot’s coordinate, and have to be physically connected by a link. However, the distance between and varies, corresponding to the angle of the input angle function .

As a solution for the second main issue, a linear sliding rod was adopted to connect the pin joints at and . In particular, was designed as a pin joint to install the actuator, and was designed as a sliding joint. Meanwhile, and were connected by a sliding rod.

Figure 14 shows the CAD designs of the robot.

Figure 15 shows photographs of the developed robot. As shown in

Figure 14 and

Figure 15, the robot possessed the morphology of the four-bar linkage mechanism consisting of one sliding rod, two “S”-shaped links, and two “I”-shaped links, and each link was connected by a linear bush and bearings. The links were fabricated with a 3D printer, and the claw-shaped legs with aluminum were fabricated with a laser cutter. Dynamixel XM430-W350-T, which was developed by ROBOTIS, was installed as the actuator.

Table 2 shows the specifications of Dynamixel XM430-W350-T. OpenCM 9.04-C with an Expansion Board, also developed by ROBOTIS, was adopted as a control board.

Table 3 shows the specifications of OpenCM 9.04-C. An external power supply provided DC12 V for the power source of both the actuator and the control board.

Figure 15c and

Figure 16 are photographs of the claw-shaped leg mechanism, with the right-hand direction in the picture being the direction of travel of the robot. When the leg moves in the direction of motion, it slides easily on the ground because the claw does not grip. In other words, the legs move forward. On the other hand, when the leg moves backward, it does not slide because the claw gets caught on the ground. In other words, the legs do not move backward. The roles of these legs are switched according to the direction of rotation of the actuator.

5. Conclusions

A new type of lizard-inspired robot that is capable of walking with only a single actuator was developed and verified via four experiments. A lizard possesses an I-type morphology. It improves its walking efficiency through the flexion movement of the trunk instead of through leg locomotion, especially when running quickly. This characteristic enabled us to decrease the number of actuators, that is, to allude to the feasibility of a multi-legged robot that is driven by only a single actuator. Realizing this robot can help in resolving the issue of the energy efficiency of multi-legged robots. The novelty of our robot lies in its ability to mimic the morphology of a lizard with a four-bar linkage mechanism. This novelty provides the robot with an appropriate means of walking in which its support legs do not slip. This also allowed us to formulate proper kinematic characteristics via kinematic analyses, which are much simpler than dynamic analyses. The conclusions of this paper were supported by three processes.

The first process was kinematic analysis, where we defined our own robot model and formulated the kinematic characteristics based on the period of the input angle function. Based on these ideas, the turning angle and the stride length of the robot were formulated. In addition, the results of the kinematic analysis were guaranteed through three numerical simulations.

The second process was the design and the fabrication of the robot. For the robot’s design, two main issues were addressed. The first issue was the switching method between the support and swing legs. To solve this issue, we proposed a shuffle-walking method using a claw-shaped leg mechanism. The second issue was the location of the actuator. As a solution to the second main issue, a linear sliding rod was adopted to connect the two points with varying distances. One side was designed as a pin joint for the actuator, and the other side was a sliding joint. The robot was then fabricated according to these solutions.

The third process was experimental verification. The effectiveness of the fabricated robot was verified through four experiments. The first experiment verified the effectiveness of the claw-shaped leg mechanism. The maximum static frictional force in the longitudinal direction was measured, and the experimental results showed that the proposed leg mechanism generated an 85.26 N difference in the static frictional force. The second experiment verified the forward locomotion performance. The trajectories of the markers attached to the robot were measured with a motion-capture system. The experimental results showed that the robot was able to move forward with a 3.51% error compared to the kinematic analysis. The third and fourth experiments verified the clockwise and counter-clockwise turning locomotions, respectively. In the same way as in the second experiment, the trajectories of the markers were measured, and the turning angles of the robot were calculated. The error ratios were 3.16% in clockwise locomotion and 3.53% in counter-clockwise turning locomotion. The results of these experiments proved that the fabricated lizard-inspired robot is capable of achieving its expected performance.

In future work, our next goal is to design a motion control system, such as trajectory tracking control, based on the kinematic analyses formulated in this paper. The bias of the input function can be controlled so that it follows a reference trajectory, such as a straight line or a circle. In addition, we are also working on developing more advanced leg mechanisms. The prototype developed in this paper can walk only on a flat surface. However, since a real environment is uneven, we will develop a new leg mechanism that can cope with the unevenness.