Rotation Accuracy Analysis of Aerostatic Spindle Considering Shaft’s Roundness and Cylindricity

Abstract

:1. Introduction

2. Mathematical Model

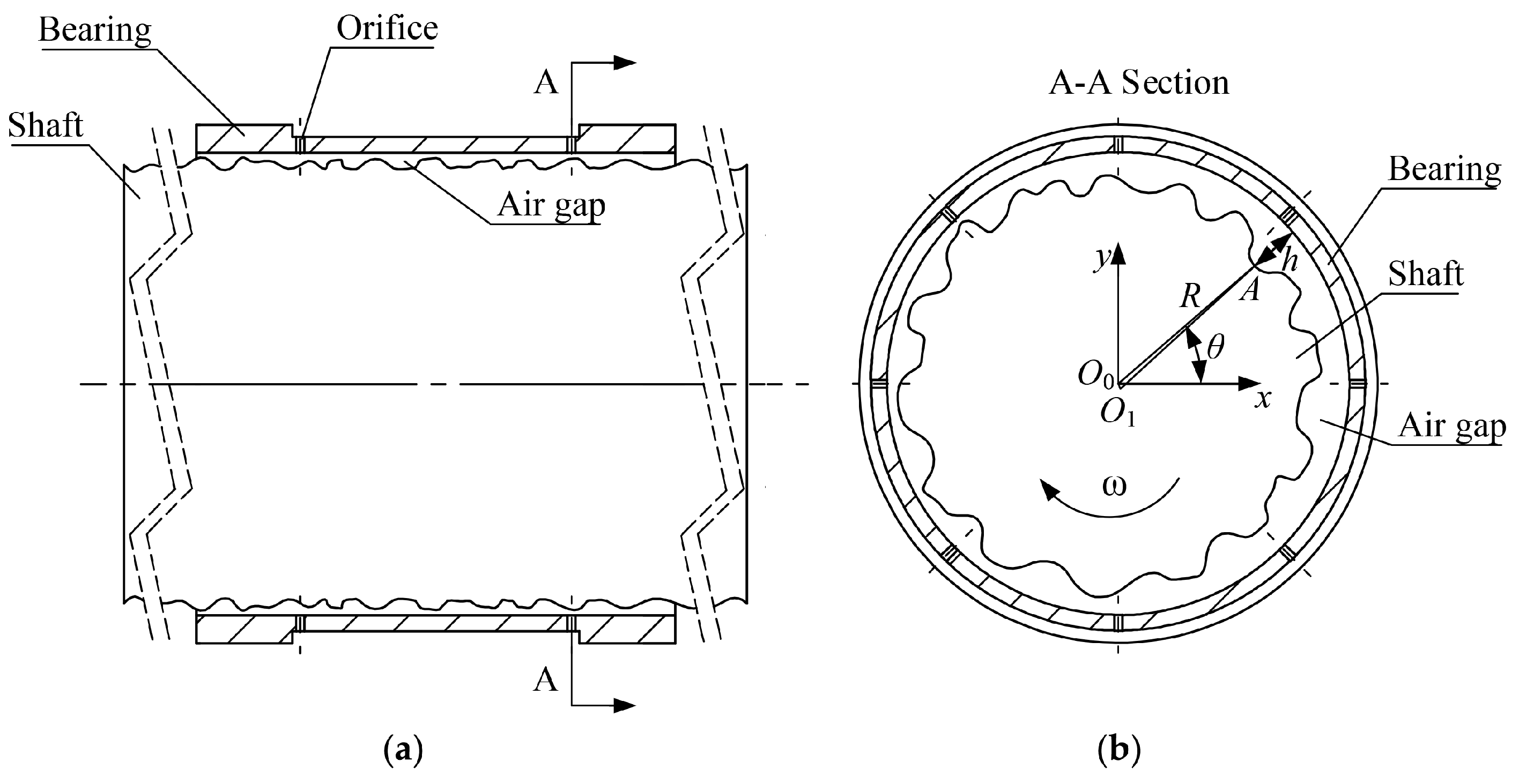

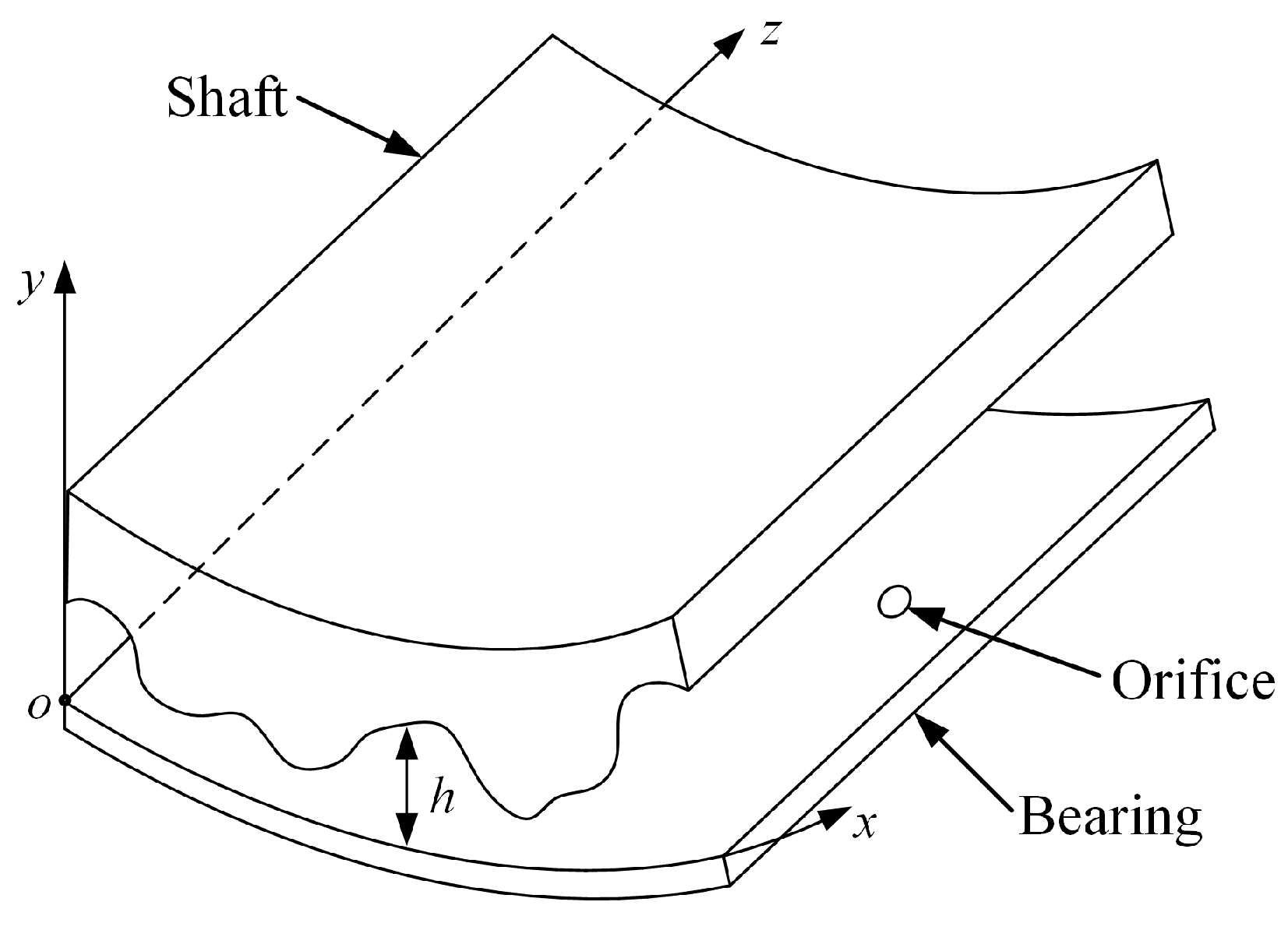

2.1. Modeling of the Aerostatic Spindle

- The spindle is cooled sufficiently—that is, the bearing, shaft and gas film is isothermal;

- There is no axial and angular movement of the shaft;

- The gas flow is laminar.

2.2. Numerical Analysis

3. Data Acquisition and Processing

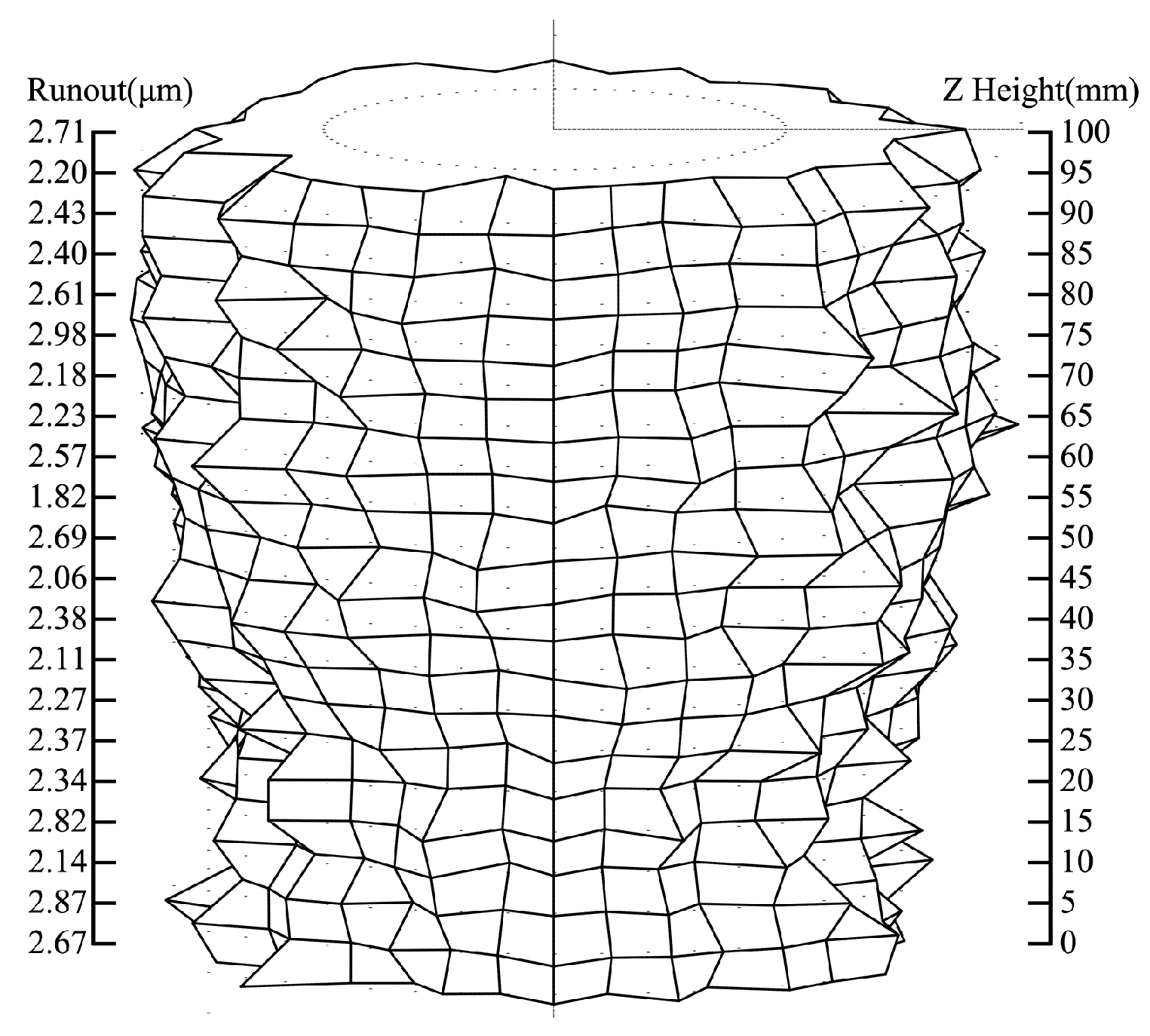

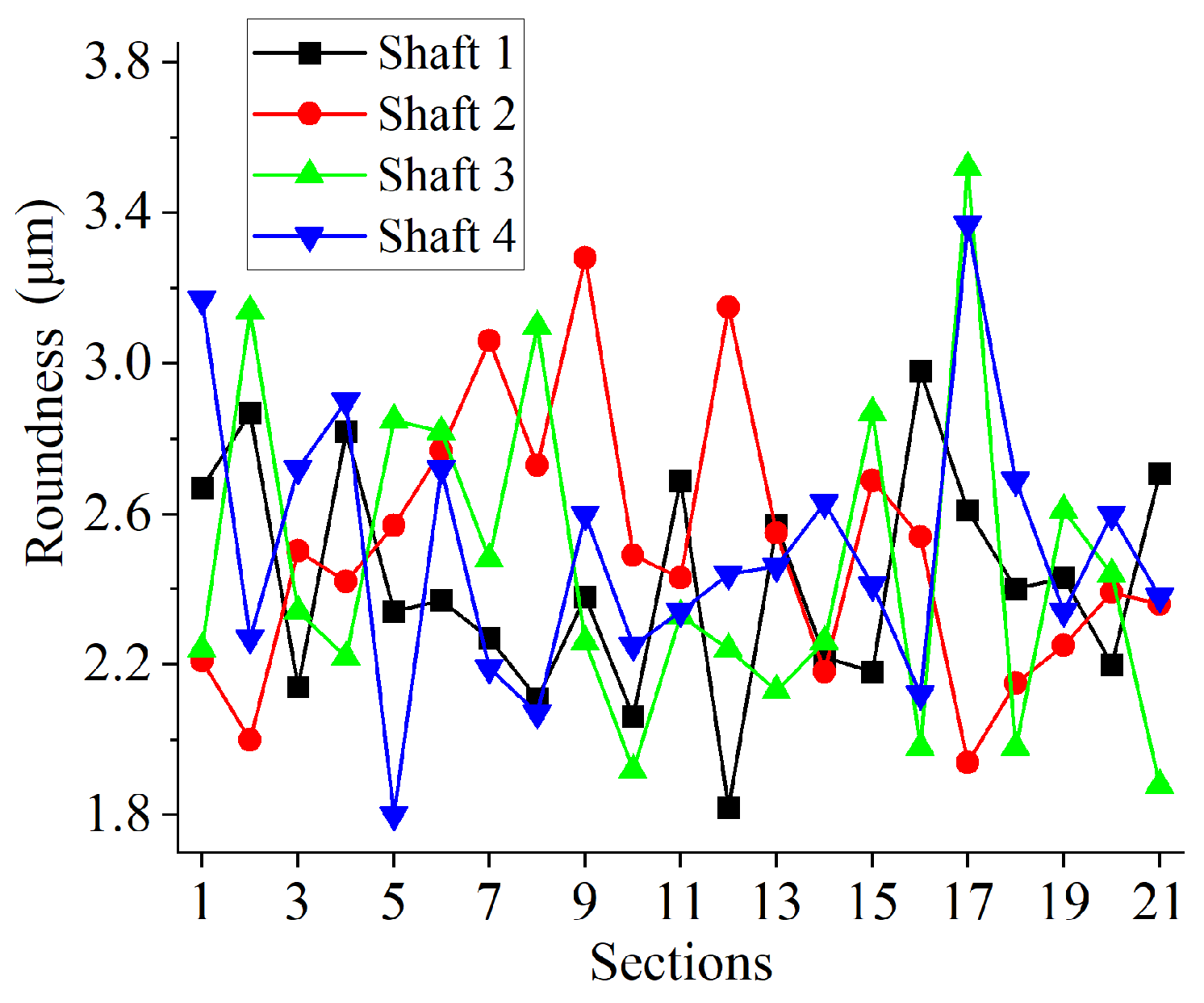

3.1. Roundness and Cylindricity Errors Measurement of Shaft

3.2. Data Processing

3.3. Calculation Settings

4. Results and Discussions

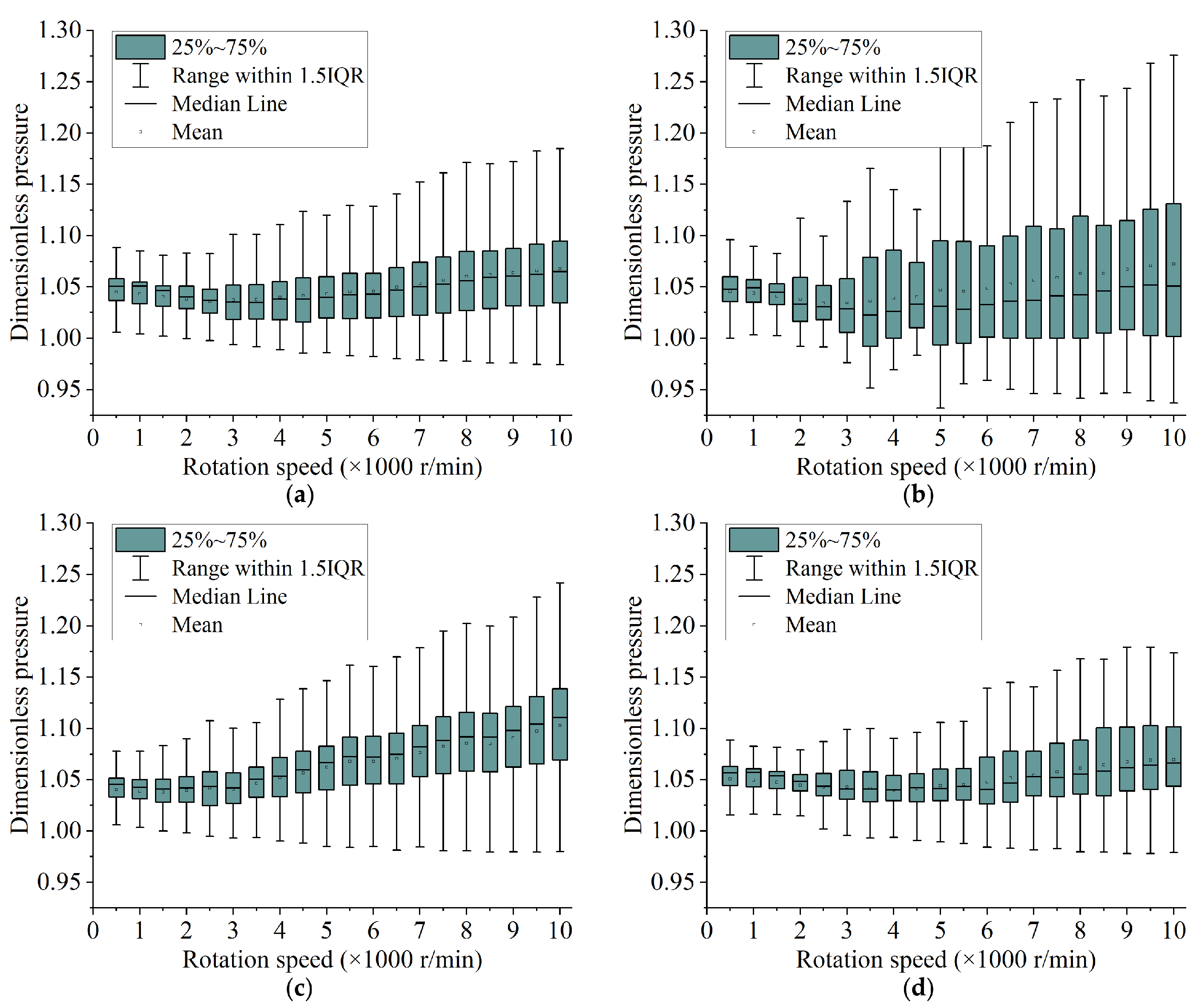

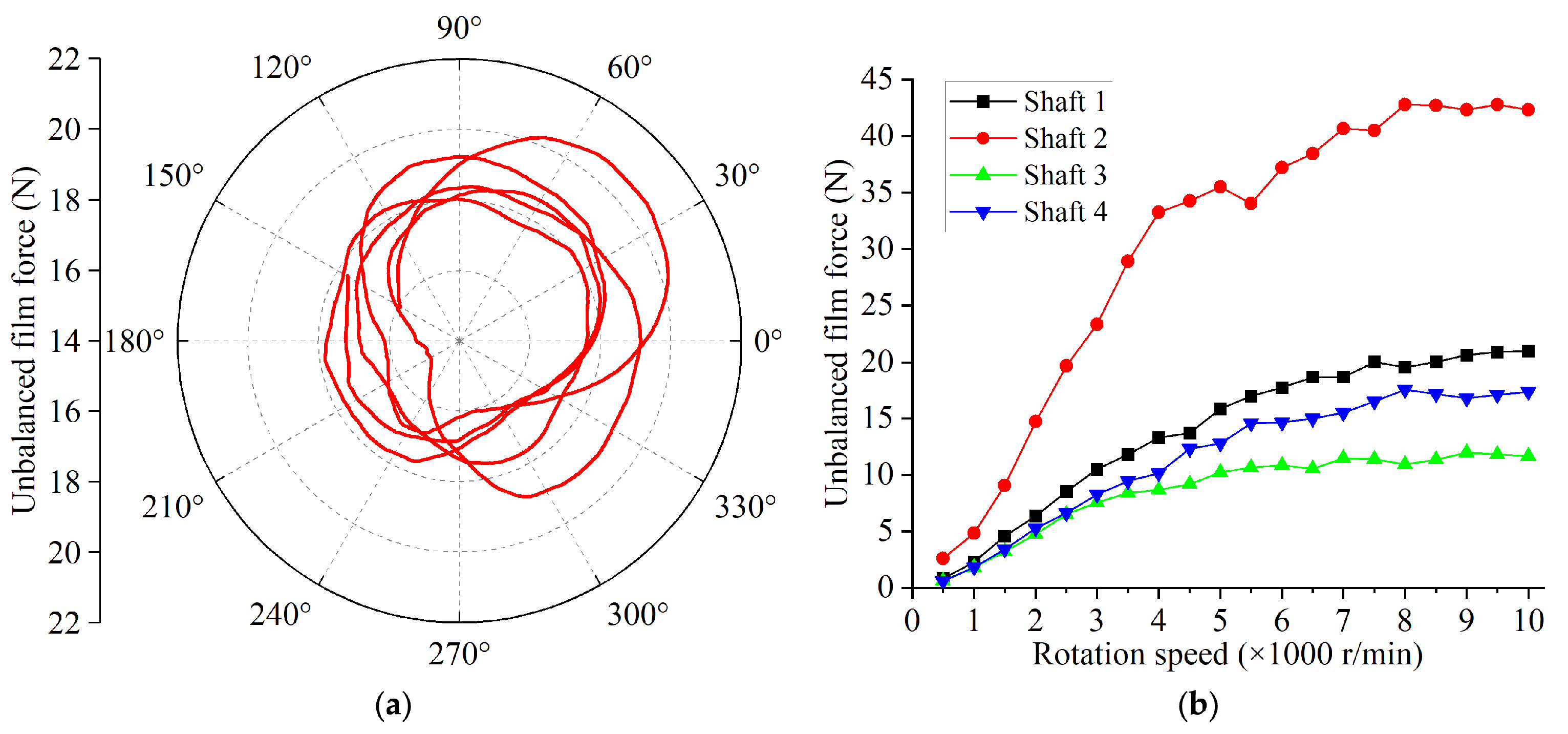

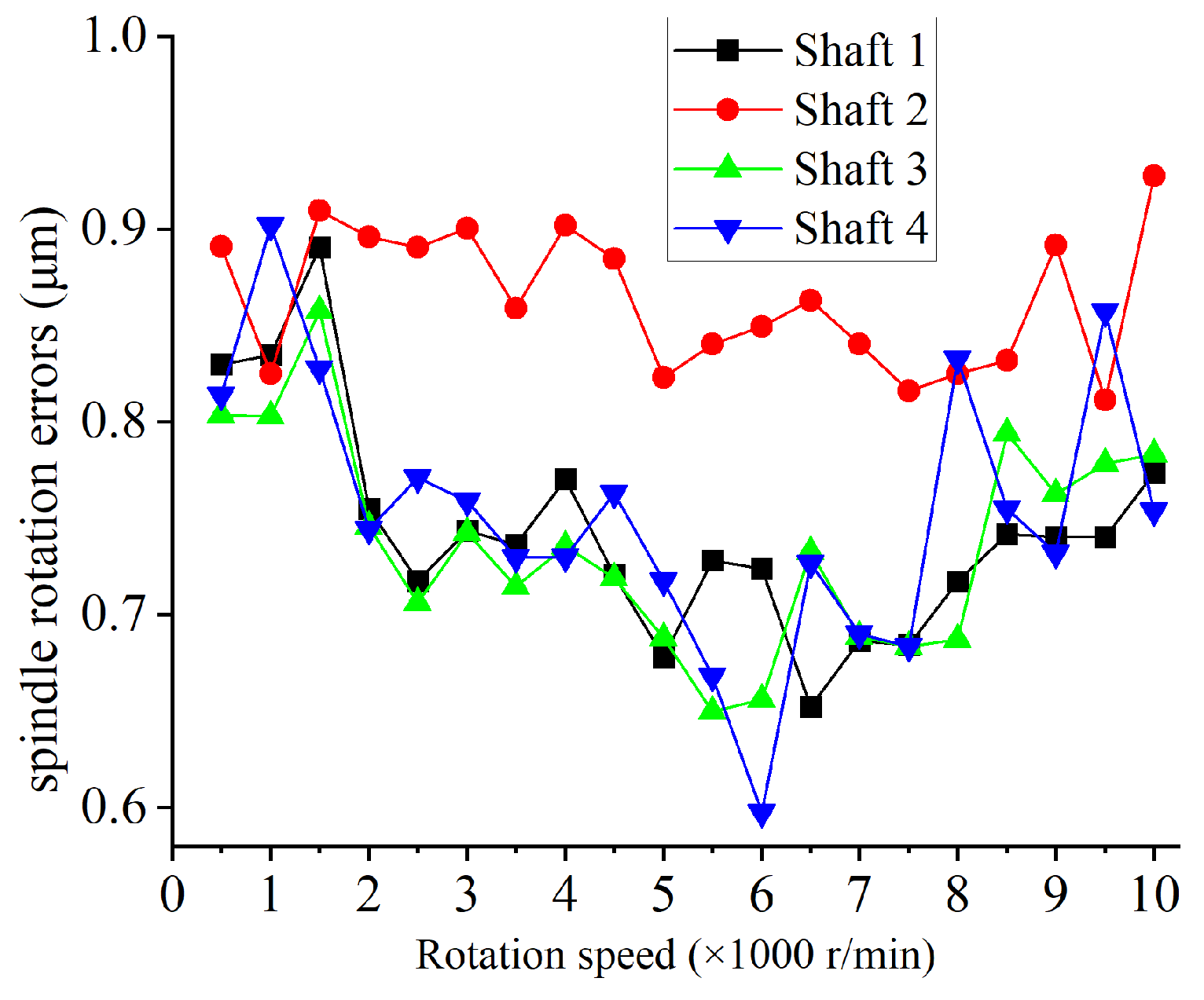

4.1. Simulation Results

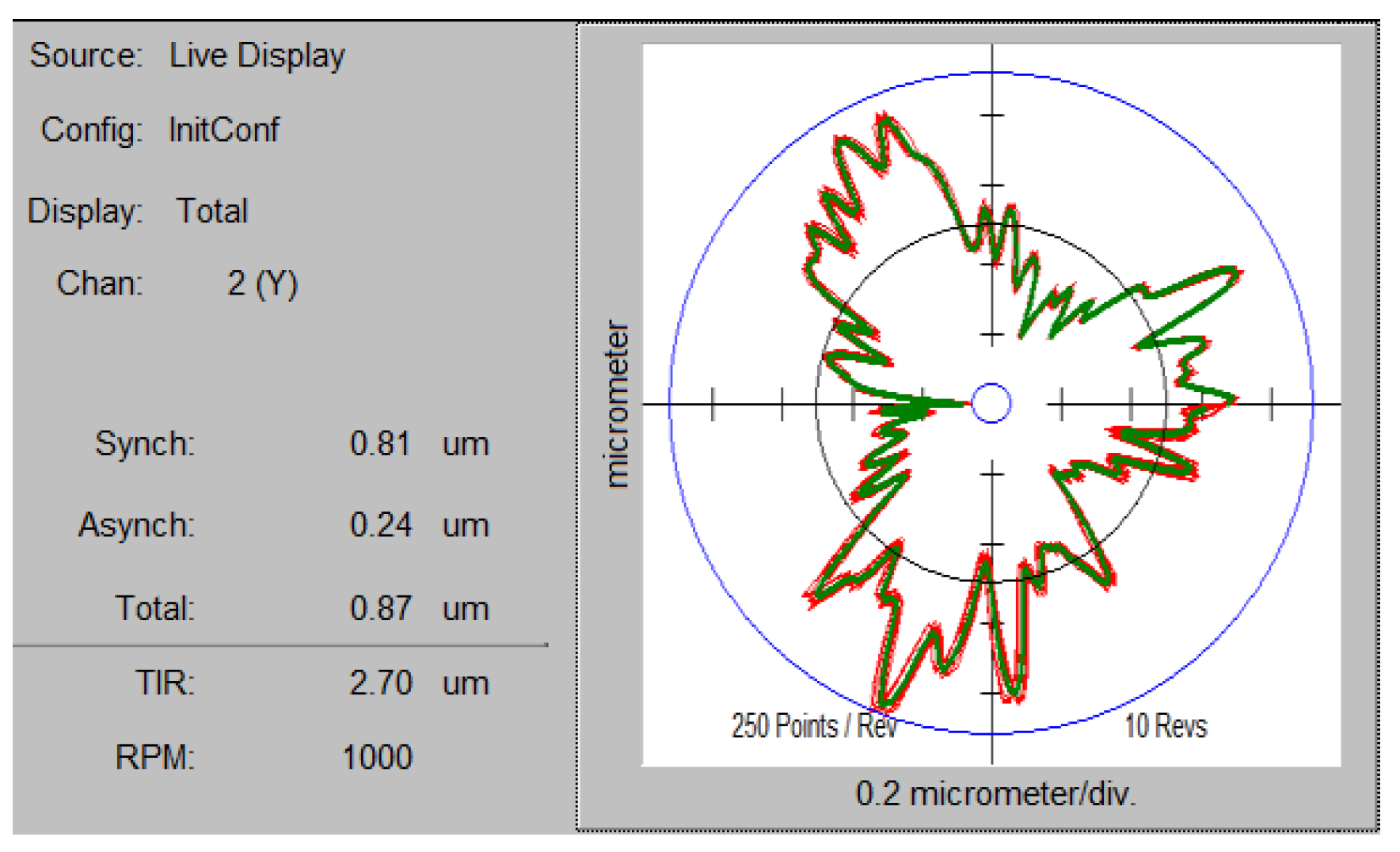

4.2. Comparison with Experimental Results

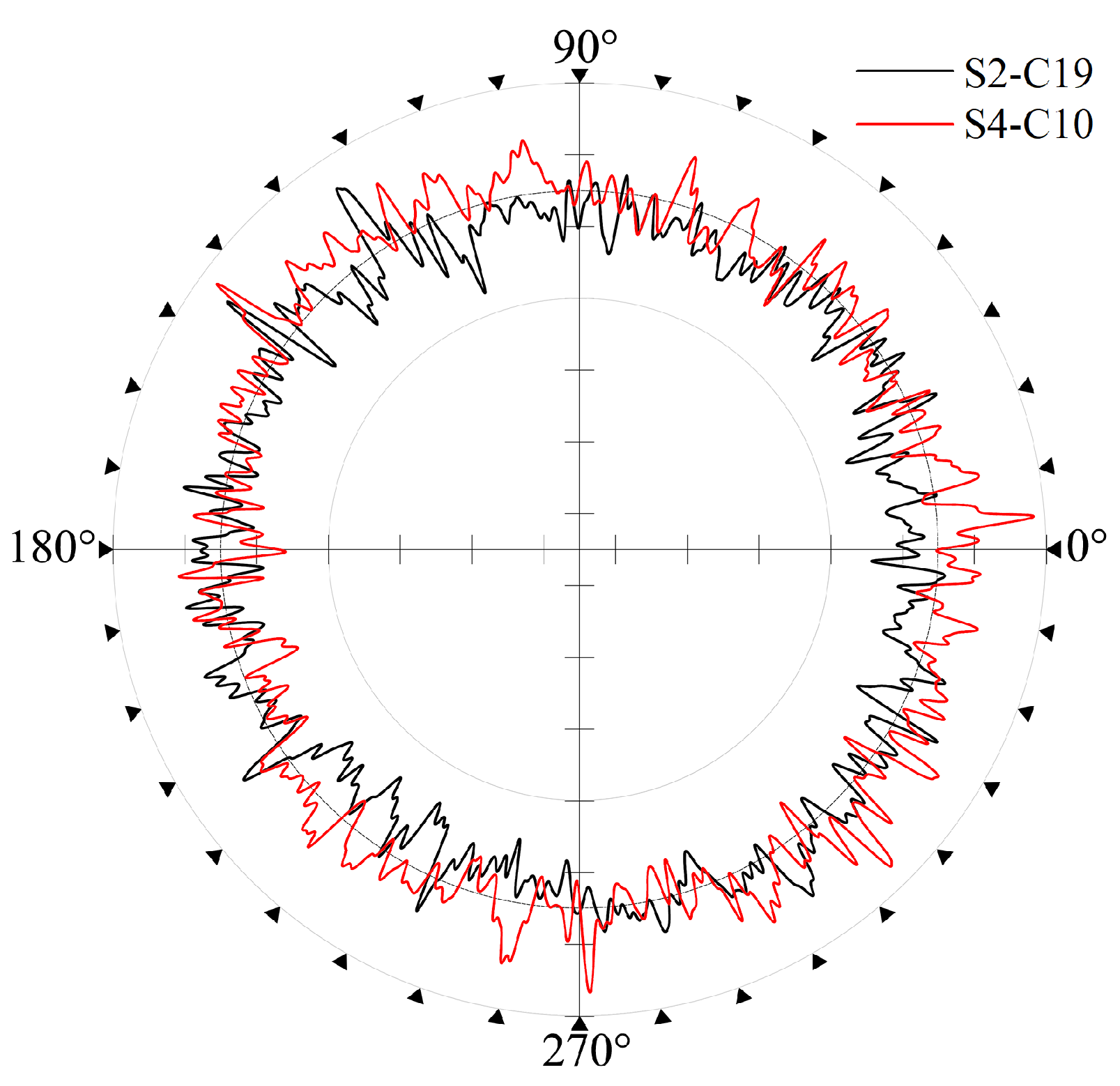

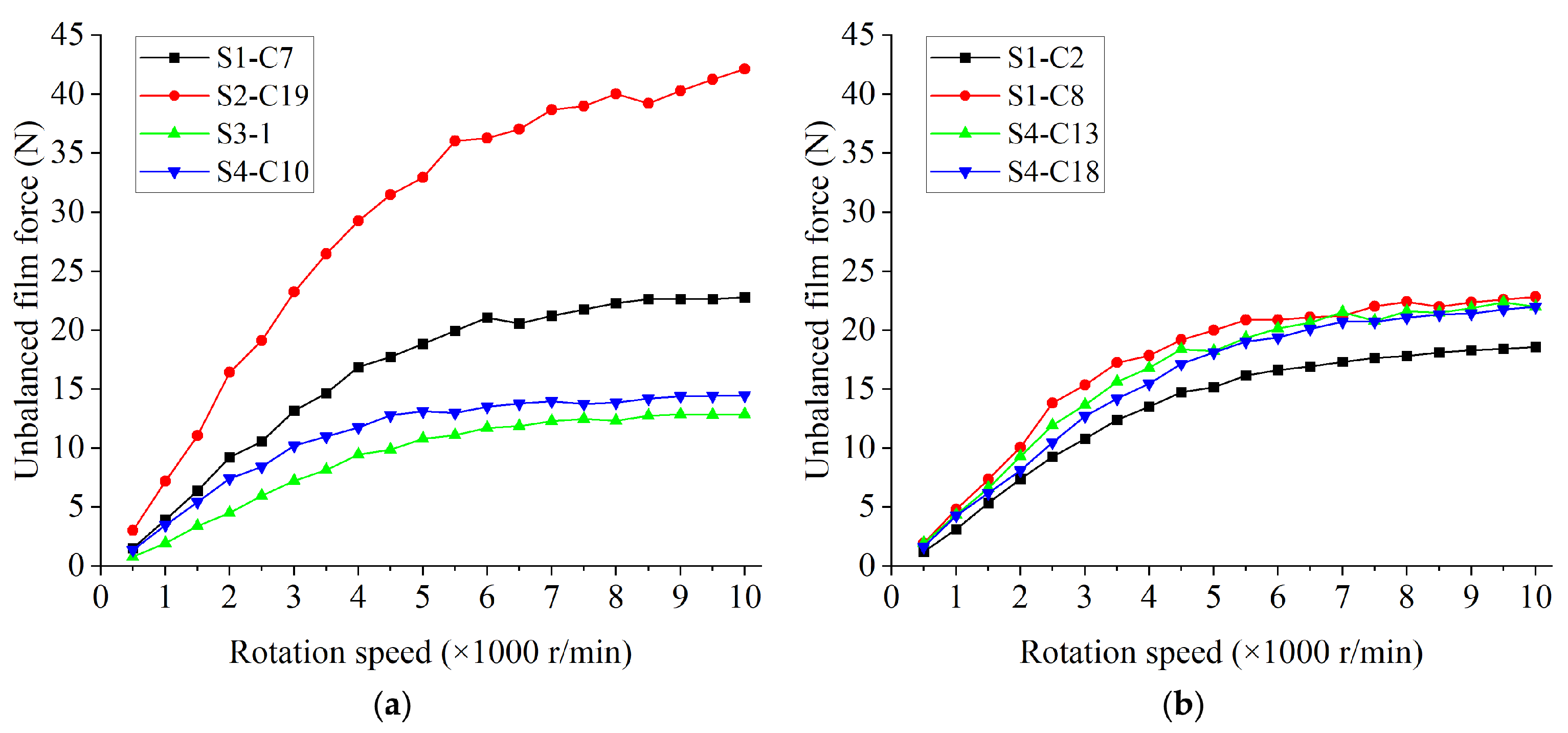

4.3. Evaluation with Dispersion Coefficient

5. Conclusions

- Because of the errors of roundness and cylindricity in the shaft, the film thickness inside the spindle will be different at different places, resulting in an uneven distribution of film pressure. With the rotation of the shaft, the pressure of the gas film will keep changing, resulting in an unbalanced film force, which will affect the stability of the spindle;

- The errors of roundness and cylindricity of the shaft can not adequately reflect the distribution of film thickness inside the spindle. Shafts with similar errors may have large differences in unbalanced film force and rotation errors;

- The dispersion coefficient reflects the fluctuation of the shaft radius. Shafts with similar discrete coefficients will not demonstrate much difference in their roundness error values, and the unbalanced film forces acting on the shaft during rotation are close to each other. Compared with roundness and cylindricity errors, the discrete coefficient is a better index to predict the spindle rotation accuracy. Therefore, during the design and manufacturing process of the spindle, the shaft radius dispersion coefficient should be controlled and measured for better spindle rotation accuracy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gao, Q.; Chen, W.; Lu, L.; Huo, D.; Cheng, K. Aerostatic bearings design and analysis with the application to precision engineering: State-of-the-art and future perspectives. Tribol. Int. 2019, 135, 1–17. [Google Scholar] [CrossRef]

- Pande, S.; Somasundaram, S. Effect of manufacturing errors on the performance of aerostatic journal bearings. Wear 1981, 66, 145–156. [Google Scholar] [CrossRef]

- Song, M.; Azam, S.; Jang, J.; Park, S.S. Effect of shape errors on the stability of externally pressurized air journal bearings using semi-implicit scheme. Tribol. Int. 2017, 115, 580–590. [Google Scholar] [CrossRef]

- Sun, F.; Zhang, X.; Wang, X.; Su, Z.; Wang, D. Effects of Shaft Shape Errors on the Dynamic Characteristics of a Rotor-Bearing System. J. Tribol. 2019, 141. [Google Scholar] [CrossRef]

- Cappa, S.; Reynaerts, D.; Al-Bender, F. Reducing the radial error motion of an aerostatic journal bearing to a nanometre level: Theoretical modelling. Tribol. Lett. 2014, 53, 27–41. [Google Scholar] [CrossRef]

- Cui, H.; Wang, Y.; Yue, X.; Huang, M.; Wang, W.; Jiang, Z. Numerical analysis and experimental investigation into the effects of manufacturing errors on the running accuracy of the aerostatic porous spindle. Tribol. Int. 2018, 118, 20–36. [Google Scholar] [CrossRef]

- Zhang, P.; Chen, Y.; Liu, X. Relationship between roundness errors of shaft and radial error motions of hydrostatic journal bearings under quasi-static condition. Precis. Eng. 2018, 51, 564–576. [Google Scholar] [CrossRef]

- Wang, X.; Xu, Q.; Huang, M.; Zhang, L.; Peng, Z. Effects of journal rotation and surface waviness on the dynamic performance of aerostatic journal bearings. Tribol. Int. 2017, 112, 1–9. [Google Scholar] [CrossRef]

- Lee, S.M.; Lee, D.W.; Ha, Y.H.; Lee, S.J.; Hwang, J.H.; Choi, Y.H. A study on the influence of waviness error to a hydrostatic bearing for a crankshaft pin turner. Tribol. Trans. 2013, 56, 1077–1086. [Google Scholar] [CrossRef]

- Li, B.; Zhou, D.; Xu, W.; Zhang, Y. Effect of Surface Waviness on Stability of Hydrodynamic Journal Bearing Systems. J. Mech. Eng. 2019, 55, 51–59. [Google Scholar] [CrossRef] [Green Version]

- Quiñonez, A.F.; Morales-Espejel, G. Surface roughness effects in hydrodynamic bearings. Tribol. Int. 2016, 98, 212–219. [Google Scholar] [CrossRef]

- Lin, J.R. Surface roughness effect on the dynamic stiffness and damping characteristics of compensated hydrostatic thrust bearings. Int. J. Mach. Tools Manuf. 2000, 40, 1671–1689. [Google Scholar] [CrossRef]

- Kumar, R.; Azam, M.S.; Ghosh, S.K. Influence of stochastic roughness on performance of a Rayleigh step bearing operating under Thermo-elastohydrodynamic lubrication considering shear flow factor. Tribol. Int. 2019, 134, 264–280. [Google Scholar] [CrossRef]

- Zhu, S.; Sun, J.; Li, B.; Zhao, X.; Wang, H.; Teng, Q.; Ren, Y.; Zhu, G. Stochastic models for turbulent lubrication of bearing with rough surfaces. Tribol. Int. 2019, 136, 224–233. [Google Scholar] [CrossRef]

- Kim, M.; Lee, S.M.; Lee, D.W.; Park, S.; Kim, S. Tribological effects of a rough surface bearing using an average flow analysis with a contact model of asperities. Int. J. Precis. Eng. Manuf. 2017, 18, 99–107. [Google Scholar] [CrossRef]

- Maharshi, K.; Mukhopadhyay, T.; Roy, B.; Roy, L.; Dey, S. Stochastic dynamic behaviour of hydrodynamic journal bearings including the effect of surface roughness. Int. J. Mech. Sci. 2018, 142–143, 370–383. [Google Scholar] [CrossRef]

- Rajput, A.K.; Sharma, S.C. Combined influence of geometric imperfections and misalignment of journal on the performance of four pocket hybrid journal bearing. Tribol. Int. 2016, 97, 59–70. [Google Scholar] [CrossRef]

- Pierart, F.G.; Santos, I.F. Active lubrication applied to radial gas journal bearings. Part 2: Modelling improvement and experimental validation. Tribol. Int. 2016, 96, 237–246. [Google Scholar] [CrossRef] [Green Version]

- Morosi, S.; Santos, I.F. On the modelling of hybrid aerostatic-gas journal bearings. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2011, 225, 641–653. [Google Scholar] [CrossRef]

- Wang, X.; Xu, Q.; Wang, B.; Zhang, L.; Yang, H.; Peng, Z. Effect of surface waviness on the static performance of aerostatic journal bearings. Tribol. Int. 2016, 103, 394–405. [Google Scholar] [CrossRef]

- Muralikrishnan, B.; Raja, J. Computational Surface and Roundness Metrology; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Lo, C.Y.; Wang, C.C.; Lee, Y.H. Performance analysis of high-speed spindle aerostatic bearings. Tribol. Int. 2005, 38, 5–14. [Google Scholar] [CrossRef]

- Morosi, S.; Santos, I.F. Active lubrication applied to radial gas journal bearings. Part 1: Modeling. Tribol. Int. 2011, 44, 1949–1958. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Bearing diameter (D/mm) | 32 |

| Bearing length (L/mm) | 100 |

| Nominal radius clearance (/mm) | 0.01 |

| Orifice diameter (d/mm) | 0.16 |

| Orifice length (l/mm) | 2 |

| Column number of feeding orifices | 2 |

| Number of orifices on each column | 8 |

| Atmospheric pressure (/Pa) | 1.013 × |

| Supplied pressure (/) | 4 |

| Gas dynamic viscosity (/Pa·s) | 18.448 × |

| Shaft Material | Ti-6Al-4V |

| Shaft density (/) | 4.51 × |

| Shaft-Cross Section | S1-C7 | S2-C19 | S3-C1 | S4-C10 |

|---|---|---|---|---|

| Roundness (m) | 2.27 | 2.25 | 2.24 | 2.25 |

| Dispersion Coefficient (×) | 3.07 | 4.57 | 2.34 | 2.60 |

| Shaft-Cross Section | S1-C2 | S1-C8 | S4-C13 | S4-C18 |

|---|---|---|---|---|

| Roundness (m) | 2.87 | 2.11 | 2.46 | 2.69 |

| Dispersion Coefficient (×) | 2.96 | 2.99 | 2.97 | 3.01 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, G.; Zheng, J.; Yu, H.; Zhao, R.; Shi, W.; Wang, J. Rotation Accuracy Analysis of Aerostatic Spindle Considering Shaft’s Roundness and Cylindricity. Appl. Sci. 2021, 11, 7912. https://doi.org/10.3390/app11177912

Zhang G, Zheng J, Yu H, Zhao R, Shi W, Wang J. Rotation Accuracy Analysis of Aerostatic Spindle Considering Shaft’s Roundness and Cylindricity. Applied Sciences. 2021; 11(17):7912. https://doi.org/10.3390/app11177912

Chicago/Turabian StyleZhang, Guoqing, Jianming Zheng, Hechun Yu, Renfeng Zhao, Weichao Shi, and Jin Wang. 2021. "Rotation Accuracy Analysis of Aerostatic Spindle Considering Shaft’s Roundness and Cylindricity" Applied Sciences 11, no. 17: 7912. https://doi.org/10.3390/app11177912

APA StyleZhang, G., Zheng, J., Yu, H., Zhao, R., Shi, W., & Wang, J. (2021). Rotation Accuracy Analysis of Aerostatic Spindle Considering Shaft’s Roundness and Cylindricity. Applied Sciences, 11(17), 7912. https://doi.org/10.3390/app11177912