1. Introduction

The increase in speed of the aircraft often leads to an increase in temperature, which are always subjected to an extremely high surface temperature and large temperature gradients, which can seriously affect the modal characteristics of the structure and can affect the aeroelastic and aeroservoelastic stability of the vehicles. Usually, the FE model analysis methods are to be employed to predict structural dynamic properties. Hence, accurately determining the modal characteristics of these structures at elevated temperatures is vital. However, there is a coupling effect between structural vibration and temperature [

1]. On the one hand, the change of structural temperature distribution with time causes structural vibration [

2]; on the other hand, the mechanical energy is converted into thermal energy during structural vibration, which changes the state of structural temperature distribution [

3]. As this coupling effect is very weak, for large complex mechanical systems, especially in high temperature environments, the temperature change caused by structural vibration is negligible. Therefore, when dealing with structural dynamics in a thermal environment, temperature is generally considered as the equivalent load acting on the vibration equation, ignoring the effect of the thermal-elastic coupling effect.

The identification of thermal parameters is an important element of the inverse heat conduction problem and is necessary to obtain accurate temperature distributions, which are widely used in aerospace, power engineering, nuclear physics and other fields. Sawaf and Özisik used Levenberg-Marquardt method to identify the thermal conductivity of anisotropic materials [

4]. A 3–D transient inverse heat conduction problem is solved with the CGM and the general-purpose commercial code CFX4.2-based inverse algorithm to estimate the unknown boundary heat flux in any 3-D irregular domain [

5]. Gosselin summarized the application of genetic algorithms to heat transfer problems, mainly for thermal system design, heat transfer inverse problems and heat transfer correlations [

6]. Sahoo and his colleagues used segment-by-segment linear fit, polynomial fit and a cubic spline approach to investigate the heat transfer inverse problem for hypervelocity vehicle test data, and the results showed that only the polynomial fit and the cubic spline approach obtained results that were consistent with the test data [

7] The joint PPDF of the heat source values at consecutive time points is computed with Bayes’ formula, and the MCMC simulation method is used to compute the MAP and posterior mean estimates of the heat source [

8]. Cui [

9] proposed a complex variable differentiation method to calculate the sensitivity matrix, the thermophysical properties of the material with temperature are identified by the conjugate gradient method, the functional form of the unknown parameters is not required in the calculation, and the computational efficiency and computational accuracy of the algorithm are verified using numerical calculations. Cappelli and his coworkers proposed a MSIS to identify the parameters involved in the elastic, viscoelastic in presence of uncertainty and by considering more general piezo-electric materials at each pertinent scale of the structure [

10,

11]. This means that the MSIS is able not only to identify the parameters involved into the material law at the macroscopic scale but also those parameters involved at the microscopic scale of the constitutive phases of the composite [

12]. But these works based on Genetic Algorithms which cost a significant computational resources and computational time. This problem is largely overcome by the use of a metamodel as a surrogate for the physical model.

The frequently used approaches for identifying thermophysical parameters currently assume that the thermophysical parameters of the material are a constant or are of a known functional form that changes with temperature [

13]. However, in practical engineering, the rules of the thermophysical parameters changing with temperature are usually more complicated. On the basis of the steady-state temperature distribution, this paper proposes an identification approach for thermophysical parameters based on support vector regression. In contrast with the traditional identification approaches, we assume the thermophysical parameters are in a format of the primary function linear combination group, in which the primary function can be expressed through surrogate model. The common construction methods for the surrogate model are [

14]: Response Surface Method, Moving Least Square, Artificial Neural Networks, Radial Kernel Function, Kriging Differential, Support Vector Machine and so on. In particular, many NURBS-based methods have been developed in recent years. Audoux [

15] proposed a new metamodel based on NURBS hyper-surfaces and is able to fit non-convex sets of TPs. The proposed method aims at determining all the parameters involved in the definition of the NURBS hyper-surface such as control points (CPs) coordinates, weights, degrees, CPs number and knot-vector components. Moreover, they present an original metamodelling technique based on NURBS hyper-surfaces. The proposed approach is able to fit general non-convex sets of TPs by extending the NURBS formalism to the N-D case in 2020 [

16]. In this manuscript, a surrogate model constructed by improved support vector regression would be proposed.

According to the experimental measurement datum and the simulated calculation datum, the surrogate model of temperature residual sum was established. Then, a multi-objective optimization analysis was carried out using the surrogate model obtained in the previous step, which would obtain the results of the identification of the thermophysical parameters. Finally, the thermophysical parameter identification method and dynamic model updating approach proposed in this manuscript were discussed and verified by several simulation examples.

2. The FEM with Thermal Effect

Under the action of the steady-state temperature field and without considering the effect of damping, the free vibration equation of the structure can be expressed as:

where

M is the mass matrix,

K is the modified thermal stiffness matrix and

x is the displacement, the solution to the Equation (1) can be assumed to be of the following form:

where ω represents the natural frequency of the structure and

φ represents the amplitude.

Substituting Equation (2) into Equation (1) yields the generalized eigenvalue problem for matrices

K and

M.

Generally, when it is assumed that the material density does not vary with temperature, the structural mass matrix M can be assumed to be unaffected by temperature and that changes in the modal frequency and modal vibration mode of the structure due to temperature variations are mainly caused by changes in the stiffness matrix K.

On the one hand, the temperature changes the modulus of elasticity of the structural material, thus changing the original stiffness matrix to obtain a modified stiffness array denoted as

KT. The uneven temperature distribution leads to different degrees of degradation in the mechanical properties of the material of each part of the structure, resulting in a decrease in the structural stiffness; for the two-dimensional rod and plate model, the generalized stiffness matrix is a function of the material properties, the geometrical parameters of the structure, i.e.,

. Thus, the stiffness matrix associated with the temperature change can be expressed as:

where

B is the matrix representing the product between the linear differential operator and the shape function matrices of the generic element, whilst

DT is the temperature-dependent elasticity matrix of the material.

On the other hand, due to the presence of boundary constraints, temperature changes will produce temperature gradients within the structure, which will generate thermal stresses, causing the local stiffness of the structure to increase or decrease, changing the initial structural stiffness distribution and the additional obtained initial stress stiffness matrix is noted as:

where

KE is the so-called geometric stiffness matrix, whilst

G is the matrix containing the shape functions of the element arranged in a different order in order to relate

KE with the stress tensor of the element, and

ST is the stress matrix.

Hence, the stiffness matrix in Equation (1) can be rewritten as:

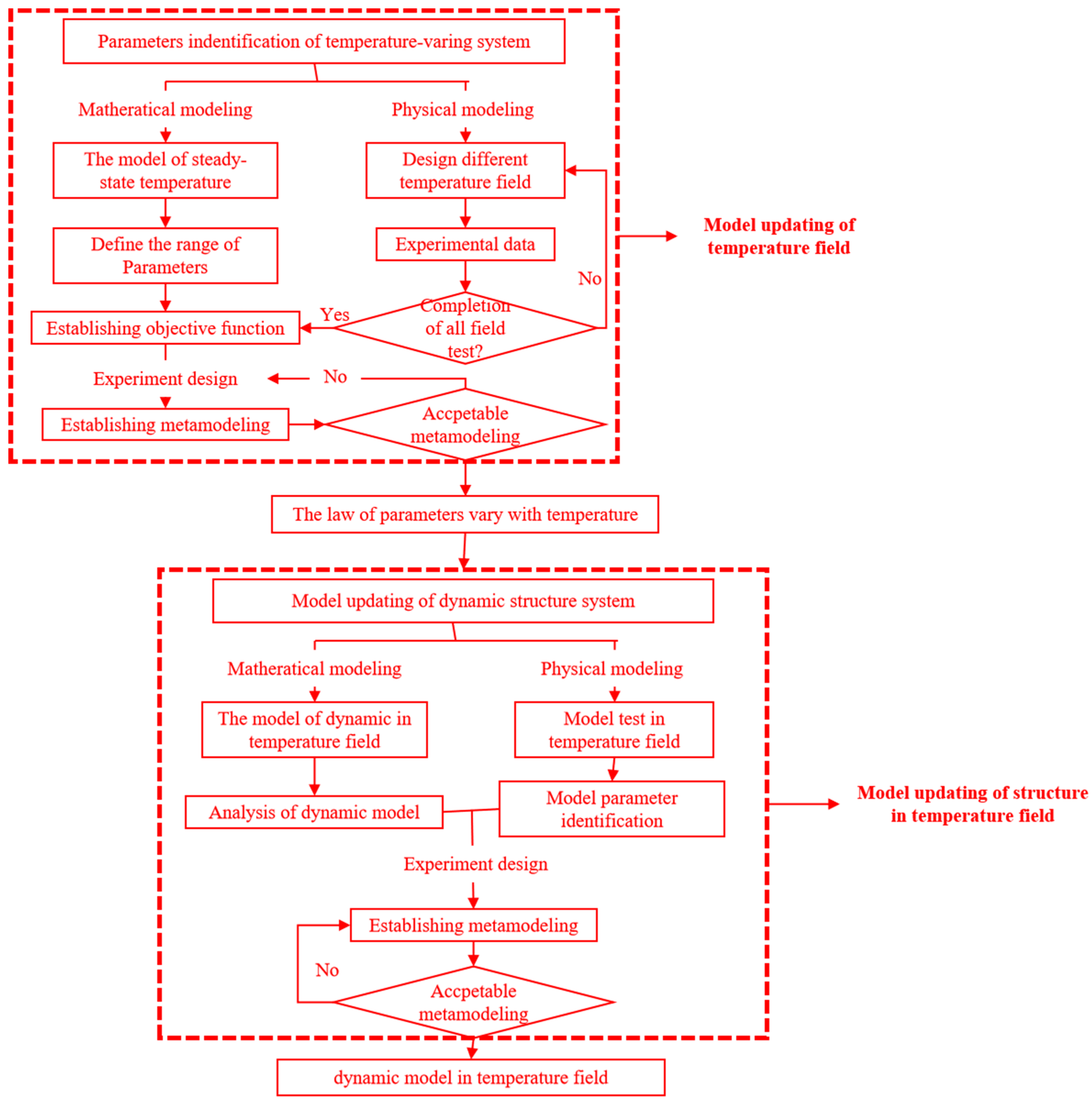

Therefore, a hierarchical correction method is introduced into the updating process of the structural dynamics of finite element model considering the temperature effect, which can be based on the different order of action of the thermal physical and structural dynamics parameters on the structural dynamics’ properties in the thermal environment, with the temperature field correction as the first level correction and the structural dynamics correction as the second level correction. The flow chart of hierarchical correction is shown in

Figure 1.

4. Thermophysical Parameters Identification

At present, is it common for methods to assume that modified thermophysical parameters are constants or known function forms. However, the variation in thermophysical parameters with temperature dependence is much more complicated in practical engineering. In this paper, a set of linear combinations of basis functions is used to define the function of thermophysical parameters in a temperature-dependent manner, in which the basis functions can be expressed by SVR:

where

is the number of thermophysical parameters,

is the basis function and

is the coefficient of the basis function. Then, the thermophysical parameters can be defined as the optimization variables, and the residual error between the experimentally measured datum and the datum calculated during simulations can be defined as the objective function; the objective function can be minimized to obtain the optimal results.

where

is the thermophysical parameter vector,

is the number of temperature measuring points, and

and

are the

th simulation calculated datum and experimentally measured datum, respectively.

Then, the thermophysical parameter identification problem is solved as an optimization problem; that is, the thermophysical parameters are defined as a temperature-dependent function, which satisfies the following:

where

is the thermophysical parameter matrix,

is the temperature matrix and

is the coefficient matrix.

According to the coefficient matrix identification model, which is used to minimize the residual error between the experimentally measured datum and simulation calculated datum, the surrogate model is used for further calculation. The flow chart of thermophysical parameter identification with temperature dependence is shown in

Figure 2.

5. The Numerical Examples

5.1. A Numerical Example of Two Parameters

According to a nonlinear function named Branin rcos, the precision of the global approximate function constructed by SVR-Polynomial, SVR-Gauss and improved SVR based on the hybrid basis function (improved SVR) are compared. There are two variables in this function:

where

and

.

The full factorial DOE is used to solve the above small-scale problem, which defines the normalized parameters

x1 and

x2 as

and

. The sample points and objective function values are shown in

Table 1.

The surrogate models using SVR based on different basis functions and the real function are shown in

Figure 3, the number of sample points is 1600.

From the figures above, we can find that SVR based on different basis functions can fit the real function according to the sample points. The difference is that the fitting results and accuracy of the constructor function based on SVR-Polynomial are the poorest and have severe overfitting phenomena. Even though the constructor function based on SVR-Gauss can describe the real function more accurately to some degree, from

Figure 3c, we can find that there is obvious deviation between the constructor function and real function in some areas. However, the constructor function based on improved SVR can exactly describe the real function, so its accuracy is the highest. To illustrate it more directly, we apply the method of comprehensive factorial experimental design to create a series of test samples to test the accuracy of the constructor function.

To further prove that the surrogate model based on improved SVR has the best fitting precision, a group of test sample points was constructed through the full factorial DOE method and the test sample points are listed in

Table 2.

According to Equations (27) and (28), R2 and RMSE can be obtained.

Table 3 shows that the

R2 value of the surrogate model based on improved SVR is larger than that based on SVR-Quad and SVR-Gauss, and the RMSE value of the surrogate model based on improved SVR is less than that based on SVR-Polynomial and SVR-Gauss. This means that among these three surrogate model construction methods, improved SVR obtains the best fitting precision and a more accurate description.

5.2. Thermophysical Parameters Identification of Aluminum Alloy Plate

This numerical example shows the general process of identifying the thermophysical parameters, which vary with the temperature of some aluminum alloy plates according to the heat transfer coefficient, with temperature dependence based on SVR. The aluminum alloy plate has a size of m, there are 750 quadrilateral shell elements in the finite element mode. In order to verify the accuracy of the thermal parameter identification method, we define the thermal boundary conditions as a heating temperature upper bound of 300 °C, and an ambient temperature of 20 °C, which is conducted from the short side of one end of the aluminum sheet to the other. To facilitate the calculation and comparison, the following assumptions are made:

- (1)

Assume that the real heat transfer coefficients satisfy the distribution in

Table 4.

- (2)

The emissivity of thermal radiation has been identified in previous work [

19] is 0.09 in this study.

- (3)

The influence of the screw thermal contract on the temperature distribution is ignored.

Table 5 shows the design space of the upper and lower boundaries of the modified thermophysical parameters.

The

Figure 4 shows that the real temperature distribution, the initial temperature distribution and the updated temperature distribution are generally consistent according to the comparison above. However, there is a dislocation in the position on the aluminum alloy plate when comparing the initial temperature distribution in the range of 200–80 °C with the real temperature distribution, and the updated temperature distribution and the real temperature distribution are almost the same. To further illustrate the consistency between the real temperature distribution and the updated temperature distribution based on the thermophysical parameter identification method proposed in this paper, seven typical nodes are selected in the finite element model to analyze the deviations among the real temperature, initial temperature and updated temperature.

Table 6 shows the deviation comparisons.

It is shown in

Table 6 that the deviation in the initial temperature distribution and the real temperature distribution is small in the high temperature range, and the deviation gradually increases as the temperature decreases. The deviation between the updated temperature distribution and the real temperature distribution is almost negligible in each temperature range. Therefore, the thermophysical parameter identification method proposed in this paper can obtain a consistent temperature distribution with the real distribution.

Assuming that the variation in the heat transfer coefficient with temperature dependence satisfies a higher-order polynomial form, which is shown in

Figure 5, the simulation result indicates that the method proposed in this paper has higher accuracy than the traditional parametric model updating method. According to the fitting results obtained in MATLAB, the variation in the real heat transfer coefficient with temperature dependence basically satisfies the cubic polynomial, which has the following function form:

Table 7 shows the design space of identified parameters.

Table 8 shows the comparison results of temperature distributions based on parametric updating method and functional updating method.

Table 8 shows that the accuracy of the identification temperature based on the functional updating method of nodes 32, 86, 151, 216 and 281 is higher than the accuracy based on the parametric updating method, while the accuracy of the identification temperature based on the functional updating method of nodes 346 and 411 is lower than the accuracy based on the parametric updating method. In general, the identification results based on the functional updating method have higher precision.

Figure 6 shows the comparison histogram of the identification temperature deviations obtained by the two methods above.

5.3. The Thermophysical Parameters Identification of Wing Structure

In this numerical example, a wing structure dynamical modal updating problem with temperature dependence is presented to verify the method proposed in this paper; the finite element model is shown in

Figure 7.

The wing chord length is 0.595 m, half span chord ratio is 2.81, wing thickness ratio is 0.12. There are 5446 quadrilateral shell elements in the finite element model of wing structure, and wing root is restrained by means of fixed restraints. According to the principle of hierarchical model updating, the temperature field is first applied to the finite element model to generate temperature stresses. Then, the temperature stresses are added to the model as pre-stresses for modal frequency analysis.

This numerical example is only used to verify the accuracy of the identification method, and some assumptions are made to complete the calculation.

- (1)

The wing structure material is aluminum alloy with a density of, 2800 kg/m

3, Poisson’s ratio is 0.33, heat transfer coefficient is shown in the

Table 1 and temperature-dependent elastic modulus is shown in

Table 9.

- (2)

The finite element model has been simplified, and the influences of rivets, bolts and other parts of the thermal contact with temperature-dependent to temperature distribution have been ignored.

5.3.1. The Temperature Distribution Model Updating

The temperature distribution is determined by material thermophysical parameters, the influence of the structural installation is ignored, and the external heating conditions are determined. In this numerical simulation, the heat transfer coefficient is identified with the method above, and the real temperature distribution, initial temperature distribution and identified temperature distribution are shown in

Figure 8.

There are 20 nodes selected in the finite element model, they are used to compare the deviations in the real temperature, initial temperature and identified temperature, and the results are shown in

Table 10.

Table 10 shows that the deviation between the real temperature and identified temperature is very small, and the maximum deviation is less than two thousandths. The results show that the temperature distribution is highly reliable and can be used in subsequent updating calculations.

5.3.2. Structural Dynamic Modal Updating

A structural dynamic model with temperature dependence is presented when the identified temperature distribution is loaded. Assuming the elastic modulus is the only source of model error, the influences of other parameters are not considered. The range of the identified elastic modulus with temperature dependence is shown in

Figure 9.

Due to the large size of the model and the complexity of the structure, it would be time-consuming to use a direct finite element model for modal frequency analysis considering pre-stress, so a surrogate model is used instead of a finite element model for calculations, the number of sample points is 2500.

The natural frequency calculated with the given elastic modulus is taken as the experimentally measured datum. The comparison of the first four orders of natural frequencies about the real natural frequency, initial natural frequency and updated natural frequency is shown in

Table 11, and the first four orders of mode shapes are shown in

Figure 9.

In

Table 12 and

Figure 9, it is obvious that the deviation between the real natural frequency and initial natural frequency of the first three bending modes and the first tensional mode is 6−8%, and the deviation between the real natural frequency and updated natural frequency is only 1%. This illustrates that a thermal structural dynamic model with high precision can be obtained by thermophysical parameter identification and the dynamic modal updating method proposed in this paper.