An Engineering Design Approach for the Development of an Autonomous Sailboat to Cross the Atlantic Ocean

Abstract

:1. Introduction

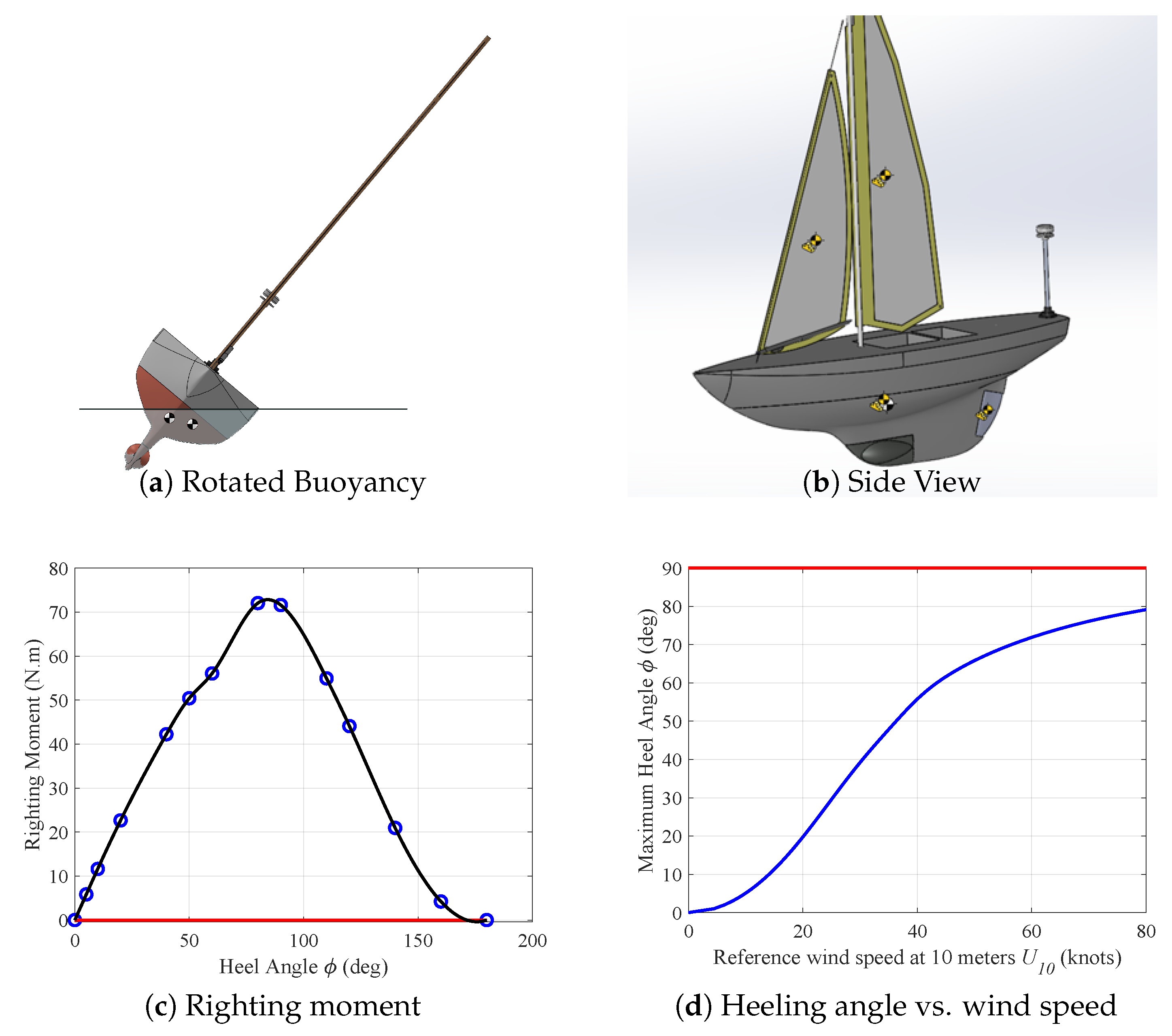

2. Sailboat Characteristics

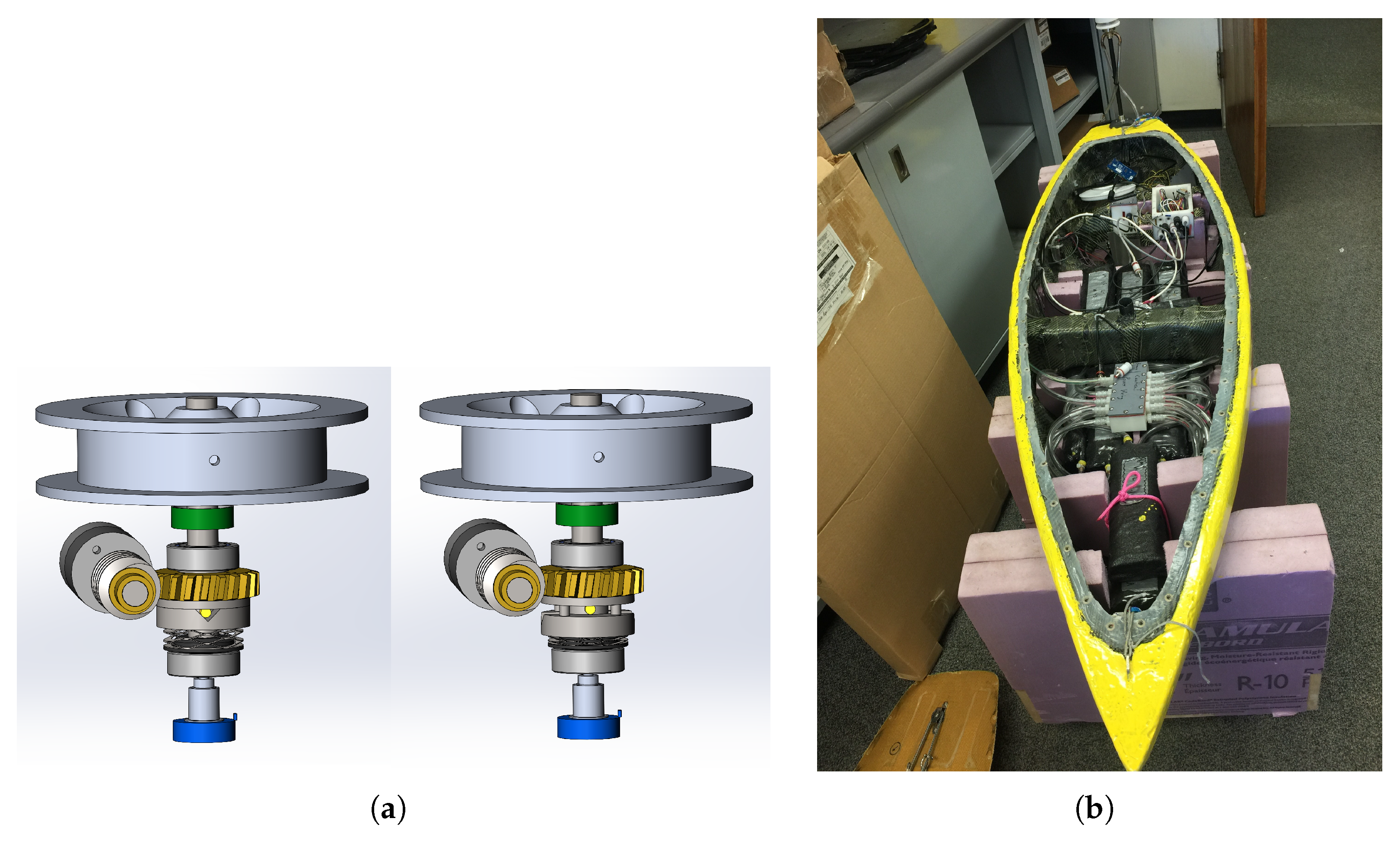

3. Mechanical Design

4. Electrical System

4.1. Real-Time Controller

4.2. Energy Supply

5. Testing and Navigation

5.1. Testing Strategy

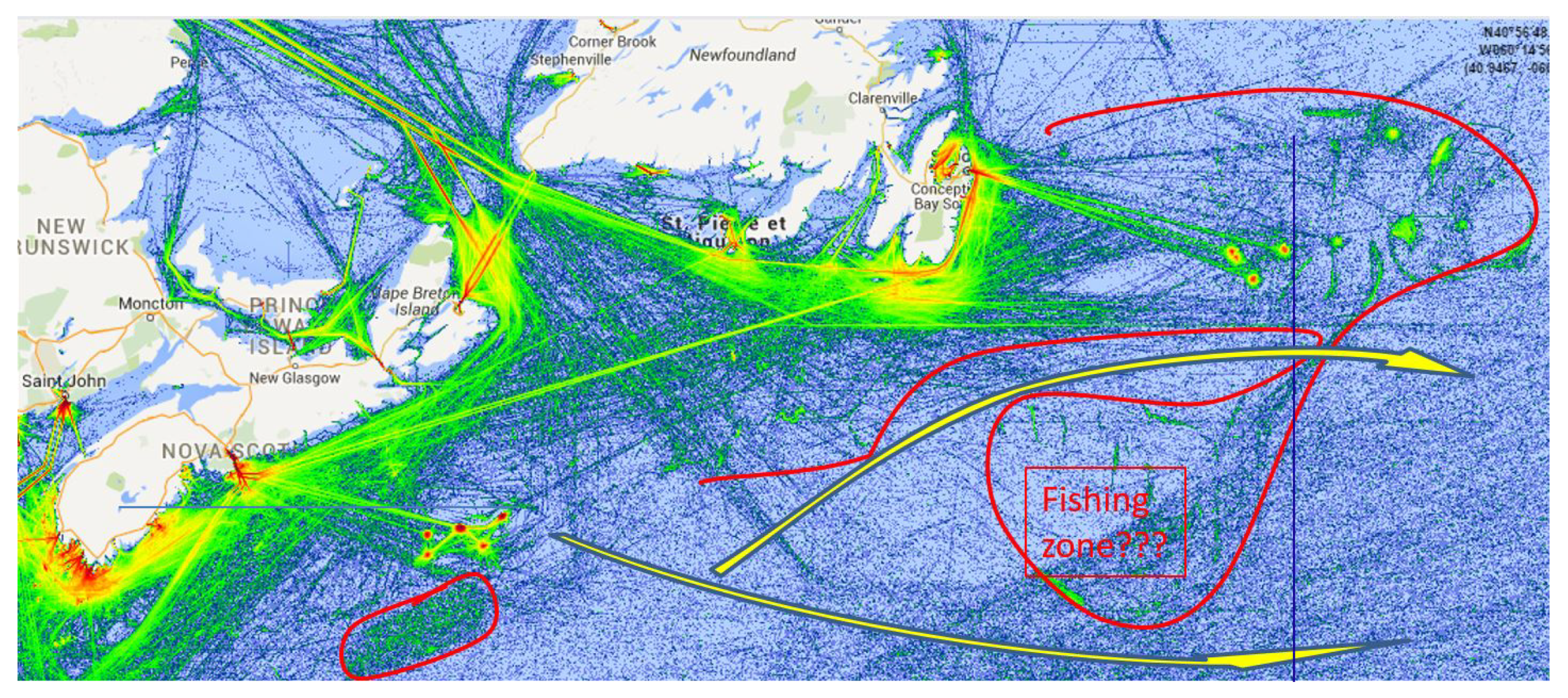

5.2. Collision Avoidance

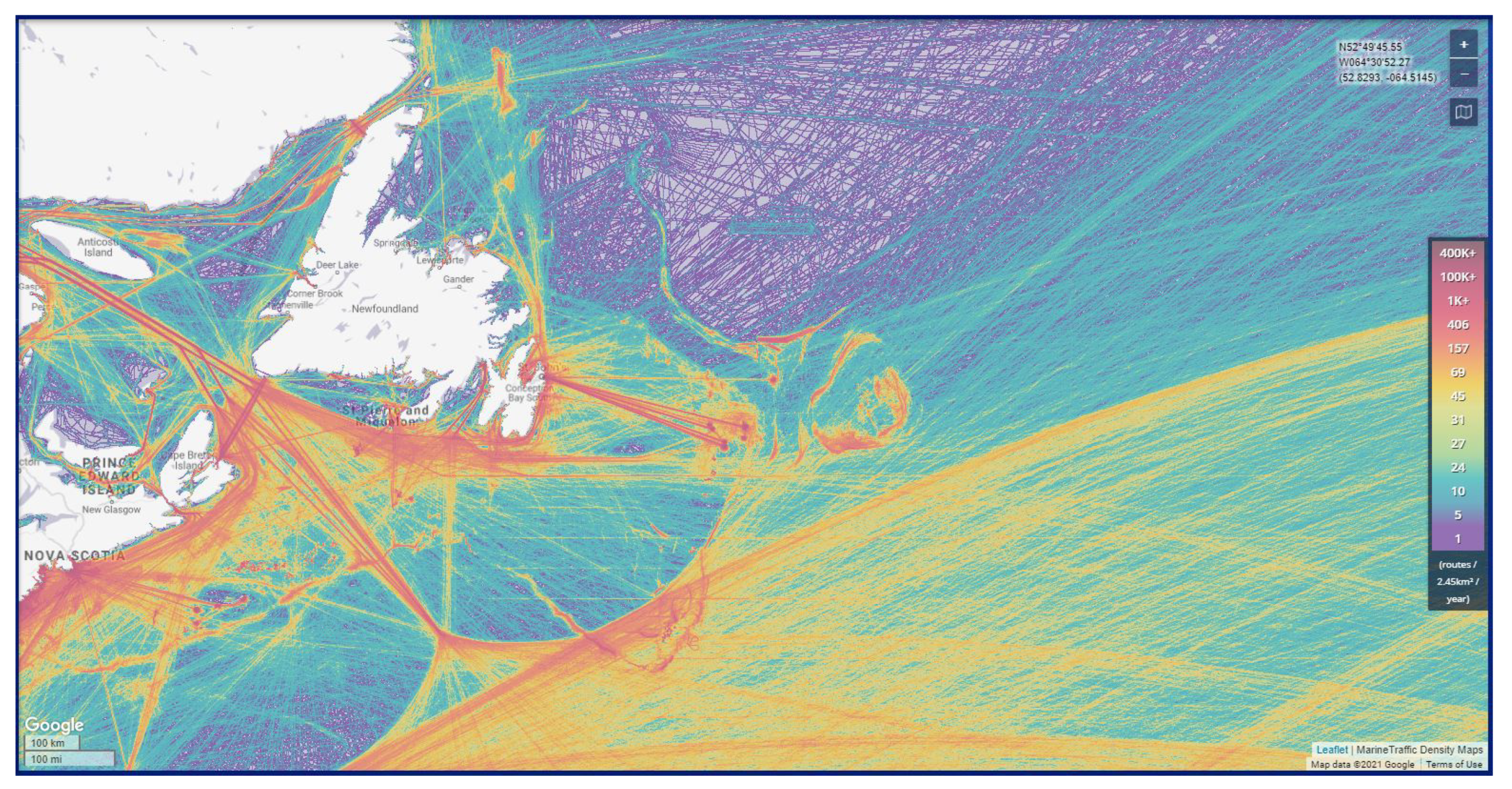

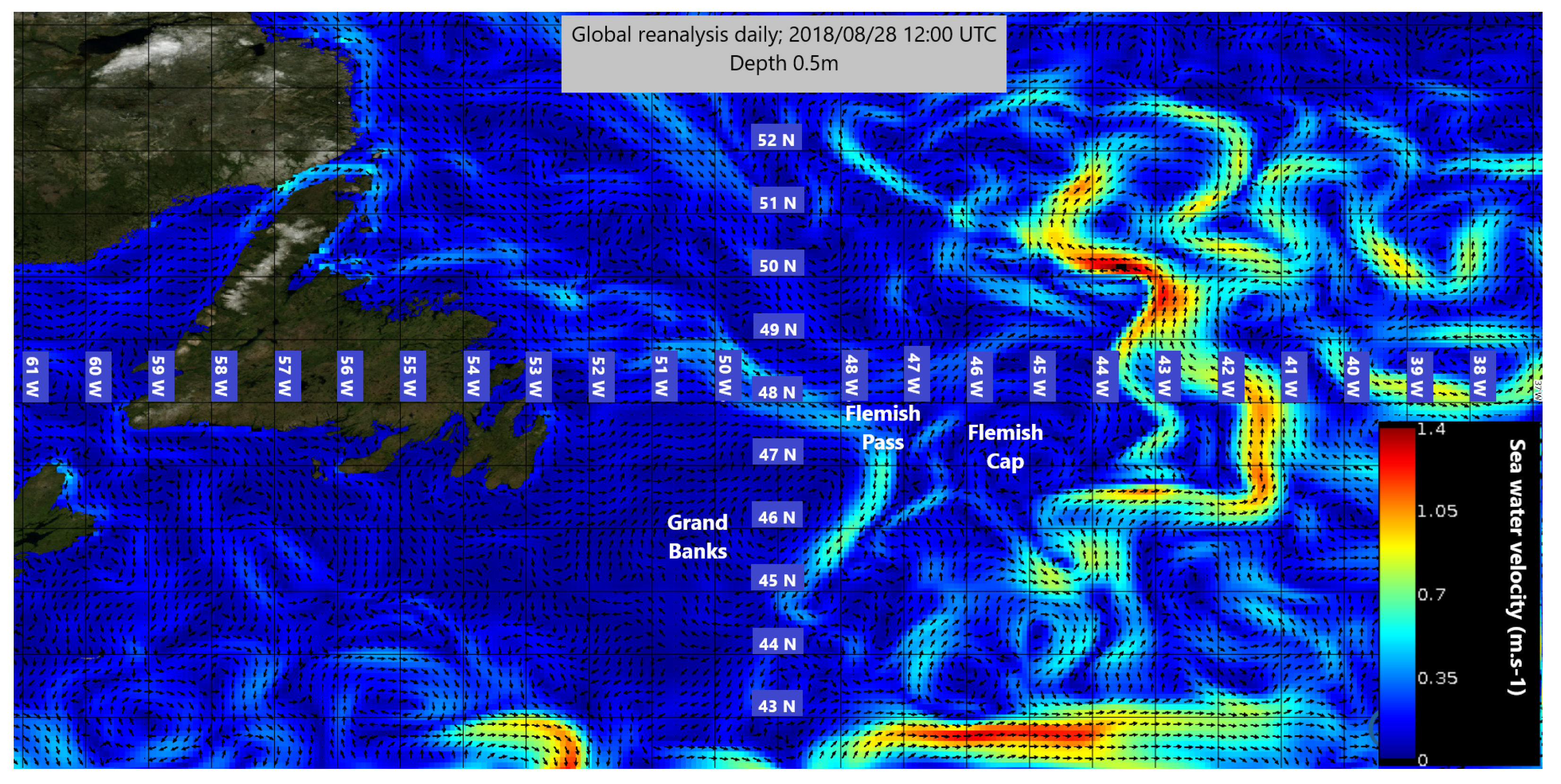

5.3. Path Planning and Weather Routing

5.4. Achievements

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Olson, R.A. Communications Architecture of the Liquid Robotics Wave Glider. IFAC Proc. Vol. 2012, 45, 255–259. [Google Scholar] [CrossRef]

- Mullison, J.; Symonds, D.; Trenaman, N. ADCP data collected from a Liquid Robotics Wave Glider®. In Proceedings of the 2011 IEEE/OES 10th Current, Waves and Turbulence Measurements (CWTM), Monterey, CA, USA, 20–23 March 2011; pp. 266–272. [Google Scholar] [CrossRef]

- Mellinger, D.K.; Klinck, H.; Bogue, N.M.; Luby, J.; Matsumoto, H.; Stelzer, R. Gliders, floats, and robot sailboats: Autonomous platforms for marine mammal research. J. Acoust. Soc. Am. 2012, 131, 3493. [Google Scholar] [CrossRef]

- Mordy, C.W.; Cokelet, E.D.; De Robertis, A.; Jenkins, R.; Kuhn, C.E.; Lawrence-Slavas, N.; Berchok, C.L.; Crance, J.L.; Sterling, J.T.; Cross, J.N.; et al. Advances in ecosystem research: Saildrone surveys of oceanography, fish, and marine mammals in the Bering Sea. Oceanography 2017, 30, 113–115. [Google Scholar] [CrossRef]

- Gentemann, C.; Scott, J.P.; Mazzini, P.L.; Pianca, C.; Akella, S.; Minnett, P.J.; Cornillon, P.; Fox-Kemper, B.; Cetinić, I.; Chin, T.M.; et al. Saildrone: Adaptively sampling the marine environment. Bull. Am. Meteorol. Soc. 2020, 101, E744–E762. [Google Scholar] [CrossRef] [Green Version]

- Stelzer, R.; Pröll, T. Autonomous sailboat navigation for short course racing. Robot. Auton. Syst. 2008, 56, 604–614. [Google Scholar] [CrossRef]

- Miller, P.; Sauzé, C.; Neal, M. Development of ARRTOO: A Long-Endurance, Hybrid-Powered, Oceanographic Research Vessel. In Robotic Sailing 2013; Bars, F.L., Jaulin, L., Eds.; Springer International Publishing: Cham, Switzerland, 2014; pp. 53–65. [Google Scholar]

- Ferl, T.; Hills, S. A Control System for a Small Autonomous Sailing Vessel Paper. In Proceedings of the ASEE Zone I Conference & Workshop, Niagara Falls, NY, USA, 15 April 2019. [Google Scholar]

- Erckens, H.; Beusser, G.; Pradalier, C.; Siegwart, R.Y. Avalon. IEEE Robot. Autom. Mag. 2010, 17, 45–54. [Google Scholar] [CrossRef]

- Tretow, C. Design of a Free-Rotating Wing Sail for an Autonomous Sailboat. Master’s Thesis, KTH, Naval Systems, Stockholm, Sweden, 2017. [Google Scholar]

- Stelzer, R.; Jafarmadar, K. The robotic sailing boat asv roboat as a maritime research platform. In Proceedings of the 22nd International HISWA Symposium, Amsterdam, The Netherland, 12–13 November 2012. [Google Scholar]

- Ganoulis, E.; Alcantara, A.; Niedermaier, J.; Winn, R.; Jones, N.; Tur, A.M.; Blake, J.; Townsend, N.; Schillai, S. Peruagus-a Transatlantic Autonomous Surface Vessel for the Microtransat Challenge. In Proceedings of the 11th International Robotic Sailing Conference, IRSC 2018, Southampton, UK, 31 August–1 September 2018. [Google Scholar]

- Stenersen, H.S. Construction and Control of an Autonomous Sail Boat. IFAC-PapersOnLine 2016, 49, 524–531. [Google Scholar] [CrossRef]

- Santos, D.; Silva Junior, A.G.; Negreiros, A.; Vilas Boas, J.; Alvarez, J.; Araujo, A.; Aroca, R.V.; Gonçalves, L.M.G. Design and Implementation of a Control System for a Sailboat Robot. Robotics 2016, 5, 5. [Google Scholar] [CrossRef] [Green Version]

- Silva, A.G.d., Jr.; Santos, D.H.d.; Negreiros, A.P.F.d.; Silva, J.M.V.B.d.S.; Gonçalves, L.M.G. High-Level Path Planning for an Autonomous Sailboat Robot Using Q-Learning. Sensors 2020, 20, 1550. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sun, Q.; Qiao, Z.; Strömbeck, C.; Qu, Y.; Liu, H.; Qian, H. Tacking Control of an Autonomous Sailboat Based on Force Polar Diagram. In Proceedings of the 2018 13th World Congress on Intelligent Control and Automation (WCICA), Changsha, China, 4–8 July 2018; pp. 467–473. [Google Scholar] [CrossRef]

- Sun, Q.; Qi, W.; Liu, H.; Sun, Z.; Lam, T.L.; Qian, H. OceanVoy: A Hybrid Energy Planning System for Autonomous Sailboat. In Proceedings of the 2020 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Las Vegas, NV, USA, 25–29 October 2020; pp. 2481–2487. [Google Scholar]

- Leloup, R.; Le Pivert, F.; Thomas, S.; Bouvart, G.; Douale, N.; De Malet, H.; Vienney, L.; Gallou, Y.; Roncin, K. Breizh Spirit, a Reliable Boat for Crossing the Atlantic Ocean. In Robotic Sailing; Schlaefer, A., Blaurock, O., Eds.; Springer: Berlin/Heidelberg, Germany, 2011; pp. 55–69. [Google Scholar]

- ITTC Quality Systems Group ITTC Symbols and Terminology List. In Proceedings of the International Towing Tank Conference, Copenhagen, Denmark, 31 August–5 September 2014.

- Association, D.W.I. Roughness and Wind Shear. Available online: http://xn–drmstrre-64ad.dk/wp-content/wind/miller/windpower%20web/en/tour/wres/shear.htm (accessed on 10 May 2021).

- Claughton, A. Developments in the IMS VPP Formulations. In Proceedings of the Fourteenth Chesapeake Sailing Yacht Symposium, Annapolis, MD, USA, 30 January 1999; pp. 1–20. [Google Scholar]

- International Technical Committee, Offshore Racing Congress VPP Documentation Guide. 2015. Available online: https://www.orc.org/rules/ORCVPPDocumentation2015.pdf (accessed on 8 August 2021).

- Sauzé, C.; Neal, M. Simulating Sailing Robots. In Robotic Sailing; Schlaefer, A., Blaurock, O., Eds.; Springer: Berlin/Heidelberg, Germany, 2011; pp. 113–124. [Google Scholar]

- Dhomé, U.; Tretow, C.; Kuttenkeuler, J.; Wängelin, F.; Fraize, J.; Fürth, M.; Razola, M. Development and initial results of an autonomous sailing drone for oceanic research. In Marine Design XIII; CRC Press: Boca Raton, FL, USA, 2018; pp. 633–644. [Google Scholar]

- Lee, M.K.; Park, Y.S.; Park, S.; Lee, E.; Park, M.; Kim, N.E. Application of Collision Warning Algorithm Alarm in Fishing Vessel’s Waterway. Appl. Sci. 2021, 11, 4479. [Google Scholar] [CrossRef]

- Ammann, N.; Hartmann, F.; Jauer, P.; Krüger, J.; Meyer, T.; Bruder, R.; Schlaefer, A. Global data storage for collision avoidance in robotic sailboat racing–the world server approach. In Robotic Sailing; Springer: Berlin/Heidelberg, Germany, 2011; pp. 157–166. [Google Scholar]

- Sauzé, C. ASVTrafficSim: A Simulator for Autonomous Surface Vehicle and Manned Vessel Collisions. In Robotic Sailing; Springer: Berlin/Heidelberg, Germany, 2018; pp. 63–67. [Google Scholar]

- Gibbons-Neff, P.; Miller, P. Route planning for a micro-transat voyage. In Robotic Sailing; Springer: Berlin/Heidelberg, Germany, 2011; pp. 183–194. [Google Scholar]

| Boat Name | Intended Route | Length L Beam B Draft T Mass | Hull | Sail Type (Sail Area) |

|---|---|---|---|---|

| Open Transat (2019) | West to east | 2.00 m 0.32 m 1.02 m 47 kg | Carbon fiber, Kevlar, and fiber glass. Foam core monohull. | Free rotating rigid wing sail |

| SeaLeon (2018) | West to east | 1.80 m 0.50 m 0.40 m 50 kg | Kevlar–Carbon hybrid cloth. Foam ribs internal bracing. | Sloop rig () |

| Breizh Tigresse (2015) | West to east | 1.44 m 0.55 m 0.60 m 28 kg | Closed cell foam and marine-grade plywood. Layers of fiber glass filled with epoxy. | Sloop rig () |

| A Boat Time (2014) | West to east | 1.20 m 0.35 m 0.41 m 18 kg | Polyester fiber glass hull with fiber-glass-coated plywood deck. | Free-standing rotating gaff with fixed boom |

| EC Crossing (2019) | East to west | 1.05 m 0.22 m 0.28 m 10 kg | Foam core fiber glass monohull with molded one piece keel. | Rigid sail |

| Task | Period (Seconds) |

|---|---|

| Data logging | 5 |

| GPS read | 10 |

| Wind read | 5 |

| Compass read | 0.5 |

| Rudder control | 1 |

| Course update | 60 |

| Boat Name (Year) | Energy System | Days Lasted |

|---|---|---|

| OpenTransat (2019) | Main system: 12.8 V 30 Ah LiFePo4 battery powered by 6, 24, and 18 watt peak solar panels; Wing sail: 12.8 V 1600 mAh LiFePo4 powered by W peak solar panels; Backup for tracking system: 3.7 V 3000 mAh lithium polymer battery. | 185 |

| SeaLeon (2018) | D-size lithium thionyl 3.6 V 19 Ah batteries. Voltage of 14.4 V and total capacity of 361 Ah. | 76 |

| Breizh Tigresse (2015) | D-size lithium thionyl 3.6 V 19 Ah batteries. Total capacity of 380 Ah. | 32 |

| ABoat Time (2014) | 12 V LiFePo charged by 15 W solar panel; 6 V LiPo charged by 3 W solar panel. | 5 |

| EC Crossing (2019) | 4.5 ah lead acid battery with 10 W peak 12 V solar panel. | 3 |

| Device | Qty. | Daily Use (h) | Power (watts) | Daily Power (Wh) |

|---|---|---|---|---|

| AT24C512 EEPROM | 1 | 24 | 0.02 | 0.48 |

| Brushless DC Motor | 2 | 2.8 | 8.4 | 47.04 |

| SAMD20J18A | 1 | 24 | 0.3 | 7.2 |

| Stream 211 (Transmitting) | 1 | 0.0222 | 3.96 | 0.087912 |

| Stream 211 (Standby) | 1 | 24 | 0.204 | 4.896 |

| Voltage Regulators | 1 | 24 | 0.085 | 2.04 |

| MAX13448E Transceiver | 1 | 24 | 0.075 | 1.8 |

| GPS | 1 | 24 | 0.066 | 1.584 |

| Compass | 1 | 24 | 0.01485 | 0.3564 |

| Wind sensor | 1 | 24 | 0.114 | 2.736 |

| 13.24 | 68.22 |

| Property | PT-2300 | LF280 |

|---|---|---|

| Voltage (V) | 14.8 | 12.8 |

| Capacity (Ah) | 19 | 280 |

| Unit Cost (USD) | 14 | 116 |

| Weight (g) | 388 | 20,880 |

| Volume (cm) | 267 | 10,168 |

| Cost/Cap. (USD/Ah) | 2.9 | 1.7 |

| Weight/Cap. (g/Ah) | 20 | 75 |

| Volume/Cap. (cm/Ah) | 14 | 36 |

| TWA∖TWS | 10 | 15 | 21 | 32 | 40 |

|---|---|---|---|---|---|

| 0 | 0 | 0 | 0 | 0 | 0 |

| 30 | 0.64 | 0.74 | 0.83 | 0.95 | 1.03 |

| 45 | 0.83 | 0.95 | 1.07 | 1.22 | 1.32 |

| 60 | 0.98 | 1.13 | 1.26 | 1.44 | 1.55 |

| 75 | 1.11 | 1.27 | 1.42 | 1.62 | 1.74 |

| 90 | 1.22 | 1.39 | 1.55 | 1.77 | 1.90 |

| 105 | 1.30 | 1.49 | 1.66 | 1.90 | 2.03 |

| 120 | 1.37 | 1.57 | 1.75 | 2.00 | 2.14 |

| 135 | 1.43 | 1.63 | 1.82 | 2.07 | 2.22 |

| 150 | 1.46 | 1.67 | 1.86 | 2.13 | 2.27 |

| 165 | 1.48 | 1.70 | 1.89 | 2.16 | 2.31 |

| 180 | 1.49 | 1.71 | 1.90 | 2.17 | 2.32 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akiyama, T.; Bousquet, J.-F.; Roncin, K.; Muirhead, G.; Whidden, A. An Engineering Design Approach for the Development of an Autonomous Sailboat to Cross the Atlantic Ocean. Appl. Sci. 2021, 11, 8046. https://doi.org/10.3390/app11178046

Akiyama T, Bousquet J-F, Roncin K, Muirhead G, Whidden A. An Engineering Design Approach for the Development of an Autonomous Sailboat to Cross the Atlantic Ocean. Applied Sciences. 2021; 11(17):8046. https://doi.org/10.3390/app11178046

Chicago/Turabian StyleAkiyama, Tanaka, Jean-Francois Bousquet, Kostia Roncin, Graham Muirhead, and Alexandra Whidden. 2021. "An Engineering Design Approach for the Development of an Autonomous Sailboat to Cross the Atlantic Ocean" Applied Sciences 11, no. 17: 8046. https://doi.org/10.3390/app11178046

APA StyleAkiyama, T., Bousquet, J.-F., Roncin, K., Muirhead, G., & Whidden, A. (2021). An Engineering Design Approach for the Development of an Autonomous Sailboat to Cross the Atlantic Ocean. Applied Sciences, 11(17), 8046. https://doi.org/10.3390/app11178046