Nutritional Composition and Sensory Evaluation of Cake Fortified with Moringa oleifera Leaf Powder and Ripe Banana Flour

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Moringa oleifera Leaf Flour

2.2. Preparation of Whole Ripe Banana Flour

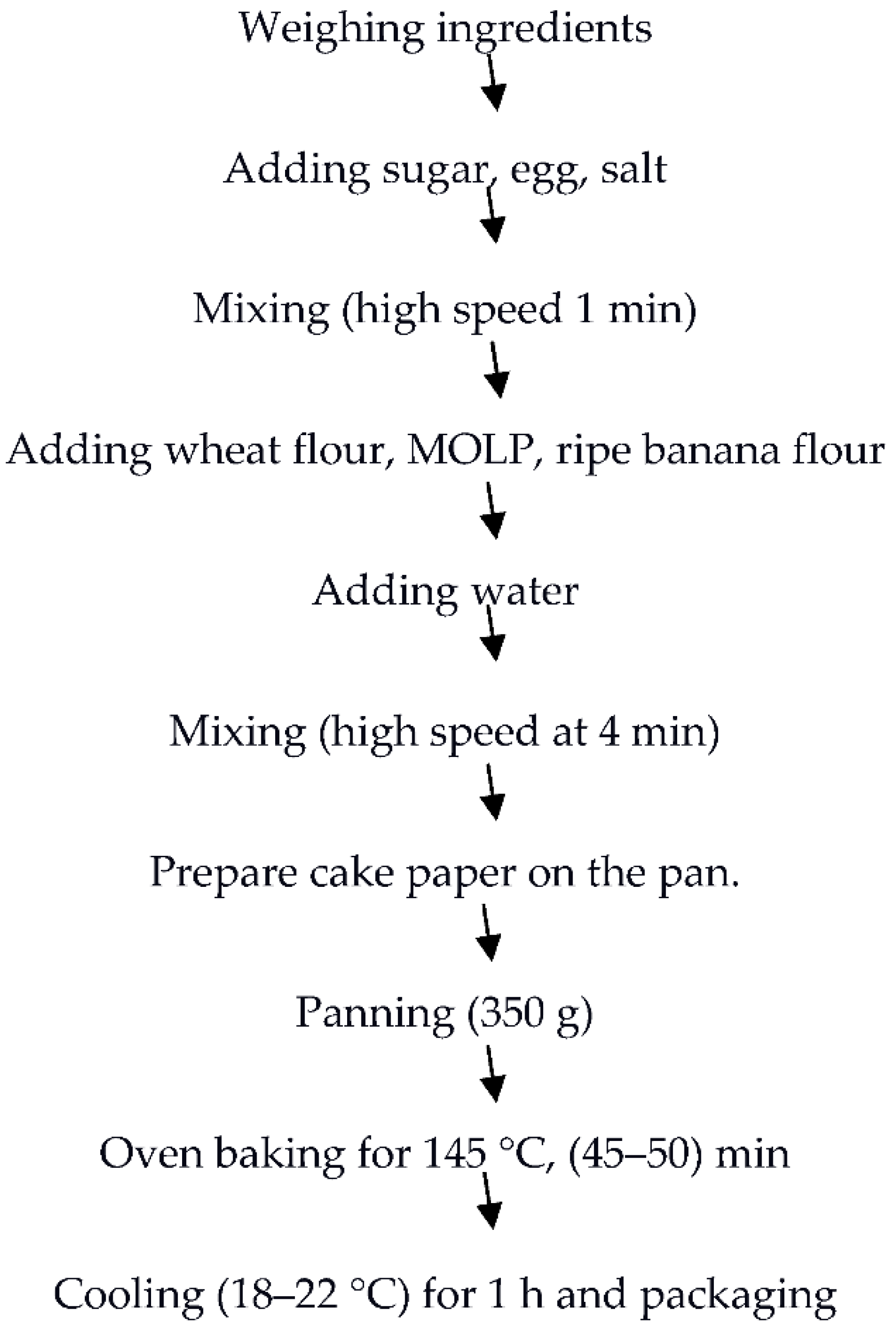

2.3. Preparation of Sponge Cake

2.4. Determination of Moisture Content

2.5. Determination of Ash Content

2.6. Determination of Acid-Insoluble Ash

2.7. Determination of Crude Fiber

- where W1 = weight in g of food sample taken;

- W2 = weight in g of the weight of basin + dried residue;

- W2 = weight in g of the weight of basin + ash.

2.8. Determination of Fat

2.9. Determination of Crude Protein

2.10. Total Carbohydrate

2.11. Energy Content

2.12. Determination of Mineral Content in Cake Samples

2.13. Determination of Vitamin A Content

2.14. Sensory Evaluation

2.15. Statistical Analysis

3. Results

3.1. Proximate Composition of the MOLP and RBF Fortified Cake

3.2. Mineral Composition and Vitamin A Content of MOLP and RBF Fortified Cake

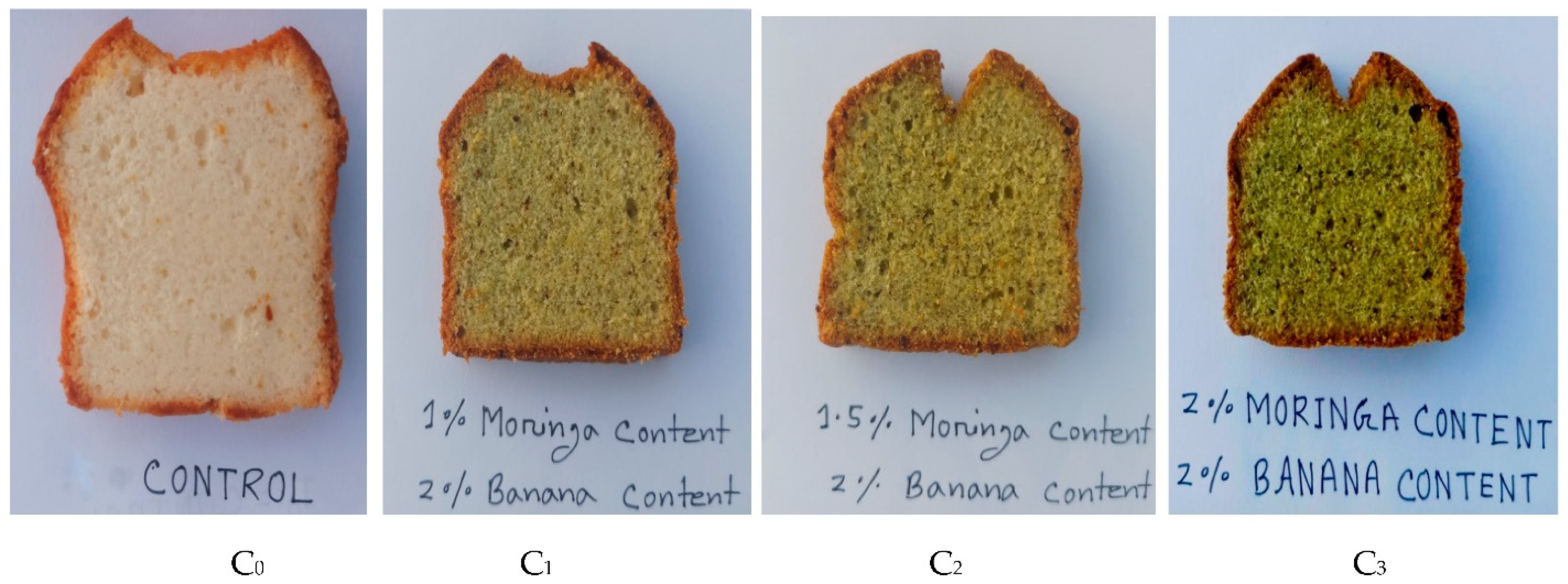

3.3. Sensory Attributes of Cake Fortified with MOLP and RBF

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Serrano, E.L.; Powell, A. Healthy Eating for Children Ages 2 to 5 Years Old: A Guide for Parents and Caregivers; Virginia State University: St. Petersburg, FL, USA, 2013. [Google Scholar]

- Huffman, S.L.; Piwoz, E.G.; Vosti, S.A.; Dewey, K.G. Babies, soft drinks and snacks: A concern in low-and middle-income countries? Matern. Child Nutri. 2014, 10, 562–574. [Google Scholar] [CrossRef]

- Ronquest-Ross, L.C.; Vink, N.; Sigge, G.O. Food consumption changes in South Africa since 1994. S. Afr. J. Sci. 2015, 111, 1–12. [Google Scholar] [CrossRef]

- Ben, J.K.; Bouaziz, F.; Zouari-Ellouzi, S.; Chaari, F.; Ellouz-Chaabouni, S.; Ellouz-Ghorbel, R.; Nouri-Ellouz, O. Improvement of texture and sensory properties of cakes by addition of potato peel powder with high level of dietary fiber and protein. Food Chem. 2017, 217, 668–677. [Google Scholar]

- Atef, A.M.A.Z.; Mostafa, T.R.; Al-Asklany, S.A. Utilization of faba bean and cowpea flours in gluten free cake production. Aust. J. Basic Appl. Sci. 2011, 5, 2665–2672. [Google Scholar]

- Ameh, M.O.; Gernah, D.I.; Igbabul, B.D. Physico-chemical and sensory evaluation of wheat bread supplemented with stabilized undefatted rice bran. Food Nutr. Sci. 2013, 4, 43. [Google Scholar] [CrossRef] [Green Version]

- World Health Organization. Set of Recommendations on the Marketing of Foods and Non-Alcoholic Beverages to Children; World Health Organization: Geneva, Switzerland, 2010. [Google Scholar]

- Black, R.E.; Victora, C.G.; Walker, S.P.; Bhutta, Z.A.; Christian, P.; De Onis, M. Maternal and child undernutrition and overweight in low-income and middle-income countries. Lancet 2013, 382, 427–451. [Google Scholar] [CrossRef]

- Moyo, B.; Masika, P.J.; Hugo, A.; Muchenje, V. Nutritional characterization of Moringa (Moringa oleifera Lam.) leaves. Afr. J. Biot. 2011, 10, 12925–12933. [Google Scholar]

- Khalafalla, M.M.; Abdellatef, E.; Dafalla, H.M.; Nassrallah, A.A.; Aboul-Enein, K.M.; Lightfoot, D.A.; El-Shemy, H.A. Active principle from Moringa oleifera Lam leaves effective against two leukemias and a hepatocarcinoma. Afr. J. Biot. 2010, 9, 8467–8471. [Google Scholar]

- Hsu, R.; Midcap, S.; Arbainsyah, D.W.L. Moringa oleifera Medicinal and Economic Uses; Internationa Course on Economic Botany; Nationaal Herbarium Nederland: Leiden, The Netherlands, 2006; Available online: http://www.koreascience.or.kr/article/JAKO201435648479194.page (accessed on 1 September 2021).

- Daba, M. Miracle Tree: A Review on Multi-purposes of Moringa oleifera and Its Implication for Climate Change Mitigation. J. Earth Sci. Clim. Chang. 2016, 7, 366. [Google Scholar] [CrossRef]

- Sengev, A.I.; Abu, J.O.; Gernah, D.I. Effect of Moringa oleifera leaf powder supplementation on some quality characteristics of wheat bread. Food Nutri. Sci. 2013, 4, 270. [Google Scholar]

- Nahriana Yahya, M.; Tawani, R. Development of Green Banana Cake (Pisang ijo) Products using Kelor Leaf (Moringa oleifera Lam) as a Food Dye and Flour Substitute. J. Phys. Conf. Ser. 2019, 1244, 6–11. [Google Scholar] [CrossRef]

- Oyeyinka, A.T.; Oyeyinka, S.A. Moringa oleifera as a food fortificant: Recent trends and prospects. J. Saudi Soc. Agric. Sci. 2018, 17, 127–136. [Google Scholar] [CrossRef] [Green Version]

- Devisetti, R.; Sreerama, Y.N.; Bhattacharya, S. Processing effects on bioactive components and functional properties of Moringa leaves: Development of a snack and quality evaluation. J. Food Sci. Tech. 2016, 53, 649–657. [Google Scholar] [CrossRef] [Green Version]

- Kraithong, S.; Issara, U. A strategic review on plant by-product from banana harvesting: A potentially bio-based ingredient for approaching novel food and agro-industry sustainability. J. Saudi Soc. Agric. Sci. 2021, in press. [Google Scholar]

- Wachirasiri, P.; Julakarangka, S.; Wanlapa, S. The effects of banana peel preparations on the properties of banana peel dietary fibre concentrate. Songklanakarin J. Sci. Tech. 2009, 31, 605–611. [Google Scholar]

- Khawas, P.; Deka, S.C. Comparative nutritional, functional, morphological, and diffractogram study on culinary banana (Musa ABB) peel at various stages of development. Int. J. Food Prop. 2016, 19, 2832–2853. [Google Scholar] [CrossRef] [Green Version]

- Rana, G.K.; Singh, Y.; Mishra, S.P.; Rahangdale, H.K. Potential use of banana and its by-products: A review. Int. J. Curr. Microbiol. App. Sci. 2018, 7, 1827–1832. [Google Scholar] [CrossRef]

- Anhwange, B.A.; Ugye, T.J.; Nyiaatagher, T.D. Chemical composition of Musa sapientum (banana) peels. Electron. J. Environ. Agric. Food Chem. 2009, 8, 437–442. [Google Scholar]

- Vu, H.T.; Scarlett, C.J.; Vuong, Q.V. Phenolic compounds within banana peel and their potential uses: A review. J. Funct. Foods 2018, 40, 238–248. [Google Scholar] [CrossRef]

- Martins, A.N.A.; Pasquali, M.A.d.B.; Schnorr, C.E.; Martins, J.J.A.; de Araujo, G.T.; Rocha, A.P.T. Development and characterization of blends formulated with banana peel and banana pulp for the production of blends powders rich in antioxidant properties. J. Food Sci. Tech. 2019, 56, 5289–5297. [Google Scholar] [CrossRef] [PubMed]

- Segundo, C.; Roman, L.; Lobo, M.; Martinez, M.M.; Gomez, M. Ripe Banana Flour as a Source of Antioxidants in Layer and Sponge Cakes. Plant Foods Hum. Nutri. 2017, 72, 365–371. [Google Scholar] [CrossRef] [Green Version]

- Association of Official Analytical Chemists (AOAC). Official Methods of Analysis, 19th ed.; Association of Official Analytical Chemists: Arlington, VA, USA, 2012. [Google Scholar]

- Van Keulen, J.Y.B.A.; Young, B.A. Evaluation of acid-insoluble ash as a natural marker in ruminant digestibility studies. J. of Animal Sci. 1977, 44, 282–287. [Google Scholar] [CrossRef]

- Association of Official Analytical Chemists (AOAC). Official Methods of Analysis, 18th ed.; Association of Official Analytical Chemists: Arlington, VA, USA, 2005. [Google Scholar]

- Association of Official Analytical Chemists (AOAC). Official Methods of Analysis, 20th ed.; Association of Official Analytical Chemists: Arlington, VA, USA, 2016. [Google Scholar]

- Singh, E.; Kalyani, B.; Reddy, B.S.; Kalyani, P.U.; Devi, H.; Ravi, L.; Shanti, M. Study on dehydration of papaya slices using osmotic dehydration mediated hot air oven drying. IOSR J. Environ. Sci. Toxicol. Food Tech. 2015, 9, 72–95. [Google Scholar]

- Watts, B.M.; Ylimaki, G.L.; Jeffery, L.E.; Elias, L.G. Basic Sensory Methods Food Evaluation; IDRC: Ottawa, ON, USA, 1989. [Google Scholar]

- Wichchukit, S.; O’Mahony, M. The 9-point hedonic scale and hedonic ranking in food science: Some reappraisals and alternatives. J. Sci. Food Agric. 2015, 95, 2167–2178. [Google Scholar] [CrossRef]

- Ohanenye, I.C.; Emenike, C.U.; Mensi, A.; Medina-Godoy, S.; Jin, J.; Ahmed, T.; Udenigwe, C.C. Food fortification technologies: Influence on iron, zinc and vitamin A bioavailability and potential implications on micronutrient deficiency in sub-Saharan Africa. Sci. Afr. 2020, 11, e00667. [Google Scholar]

- Gopalakrishnan, L.; Doriya, K.; Kumar, D.S. Moringa oleifera: A review on nutritive importance and its medicinal application. Food sci. Hum. Wellness 2016, 5, 49–56. [Google Scholar] [CrossRef] [Green Version]

- Abdel-Samie, M.A.; Abdulla, G. Effect of Moringa leaves (Moringa oleifera Lam.) on some physico-chemical and sensory properties of wheat flour cookies. Zagazig J. Agric. Res. 2014, 41, 305–314. [Google Scholar]

- Beswa, D.; Dlamini, N.R.; Amonsou, E.O.; Siwela, M.; Derera, J. Effects of amaranth addition on the pro-vitamin A content, and physical and antioxidant properties of extruded pro-vitamin A-biofortified maize snacks. J. Sci. Food Agric. 2016, 96, 287–294. [Google Scholar] [CrossRef] [PubMed]

- Abiodun, O.A.; Adegbite, J.A.; Omolola, A.O. Chemical and physicochemical properties of Moringa flours and oil. Glob. J. Sci. Front. Res. Biol. Sci. 2012, 12, 1–7. [Google Scholar]

- Sultana, S. Nutritional and functional properties of Moringa oleifera. Metab. Open 2020, 8, 100061. [Google Scholar] [CrossRef]

- Aleixandre, A.; Miguel, M. Dietary fiber and blood pressure control. Food Funct. 2016, 7, 1864–1871. [Google Scholar] [CrossRef]

- Ferreira, R.D.S.; Mendonça, L.A.B.M.; Santos, C.D.; Hiane, P.A.; Matias, R.; Franco, O.L.; Guimarães, R.D.C.A. Do Bioactive Food Compound with Avena sativa L., Linum usitatissimum L. and Glycine max L. Supplementation with Moringa oleifera Lam. Have a Role against Nutritional Disorders? An Overview of the In Vitro and In Vivo Evidence. Nutrients 2021, 13, 2294. [Google Scholar] [CrossRef] [PubMed]

- Mouminah, H.H.S. Effect of dried Moringa oleifera leaves on the nutritional and organoleptic characteristics of cookies. Alex. Sci. Exch. J. 2015, 36, 297–302. [Google Scholar]

- Leone, A.; Bertoli, S.; Di Lello, S.; Bassoli, A.; Ravasenghi, S.; Borgonovo, G.; Battezzati, A. Effect of Moringa oleifera leaf powder on postprandial blood glucose response: In vivo study on Saharawi people living in refugee camps. Nutrients 2018, 10, 1494. [Google Scholar] [CrossRef] [Green Version]

- Eke, J.; Achinewhu, S.C.; Sanni, L. Nutritional and sensory qualities of some Nigerian cakes. Niger. Food J. 2008, 26, 2. [Google Scholar] [CrossRef]

- Campuzano, A.; Rosell, C.M.; Cornejo, F. Physicochemical and nutritional characteristics of banana flour during ripening. Food Chem. 2018, 256, 11–17. [Google Scholar] [CrossRef]

- Zungu, N.; Van Onselen, A.; Kolanisi, U.; Siwela, M. Assessing the nutritional composition and consumer acceptability of Moringa oleifera leaf powder (MOLP)-based snacks for improving food and nutrition security of children. S. Afr. J. Bot. 2020, 129, 283–290. [Google Scholar] [CrossRef]

- Sanful, R.E.; Darko, S. Utilization of soybean flour in the production of bread. Pak. J. Nutri. 2010, 9, 815–818. [Google Scholar] [CrossRef] [Green Version]

- Mahmood, K.T.; Mugal, T.; Haq, I.U. Moringa oleifera: A natural gift—A review. J. Pharm. Sci. Res. 2010, 2, 775. [Google Scholar]

- Olusanya, R.N.; Kolanisi, U.; Van Onselen, A.; Ngobese, N.Z.; Siwela, M. Nutritional composition and consumer acceptability of Moringa oleifera leaf powder (MOLP)-supplemented mahewu. S. Afr. J. Bot. 2020, 129, 175–180. [Google Scholar] [CrossRef]

- Ma, Z.F.; Ahmad, J.; Zhang, H.; Khan, I.; Muhammad, S. Evaluation of phytochemical and medicinal properties of Moringa (Moringa oleifera) as a potential functional food. S. Afr. J. Bot. 2020, 129, 40–46. [Google Scholar] [CrossRef]

- Fuglie, L.J. The Moringa Tree: A local solution to malnutrition. Church World Serv. Senegal 2005, 5, 75–83. [Google Scholar]

- Bibiana, I.; Grace, N.; Julius, A. Quality evaluation of composite bread produced from wheat, maize and orange fleshed sweet potato flours. Am. J. Food Sci. Tech. 2014, 2, 109–115. [Google Scholar] [CrossRef] [Green Version]

- El-Gammal, R.E.; Ghoneim, G.A.; El-Shehawy, S.M. Effect of Moringa leaves powder (Moringa oleifera) on some chemical and physical properties of pan bread. J. Food Dairy Sci. 2016, 7, 307–314. [Google Scholar] [CrossRef]

- Bolarinwa, I.F.; Aruna, T.E.; Raji, A.O. Nutritive value and acceptability of bread fortified with Moringa seed powder. J. Saudi Soc. Agric. Sci. 2019, 18, 195–200. [Google Scholar] [CrossRef]

- Roohani, N.; Hurrell, R.; Kelishadi, R.; Schulin, R. Zinc and its importance for human health: An integrative review. J. Res. Med. Sci. 2013, 18, 144. [Google Scholar] [PubMed]

- Barminas, J.T.; Charles, M.; Emmanuel, D. Mineral composition of non-conventional leafy vegetables. Plant Foods Hum. Nutri. 1998, 53, 29–36. [Google Scholar] [CrossRef]

- Ekesa, B.; Nabuuma, D.; Blomme, G.; Van den Bergh, I. Provitamin A carotenoid content of unripe and ripe banana cultivars for potential adoption in eastern Africa. J. Food Compos. Anal. 2015, 43, 1–6. [Google Scholar] [CrossRef]

- Shar, Z.H.; Fletcher, M.T.; Sumbal, G.A.; Sherazi, S.T.H.; Giles, C.; Bhanger, M.I.; Nizamani, S.M. Banana peel: An effective biosorbent for aflatoxins. Food Addit. Contam.-Part A Chem. Anal. Control Expo. Risk Assess. 2016, 33, 849–860. [Google Scholar] [CrossRef]

- Bourekoua, H.; Rozyło, R.; Gawlik-Dziki, U.; Benatallah, L.; Zidoune, M.N.; Dziki, D. Evaluation of physical, sensorial, and antioxidant properties of gluten-free bread enriched with Moringa Oleifera leaf powder. Eur. Food Res. Tech. 2018, 244, 189–195. [Google Scholar] [CrossRef] [Green Version]

- Alam, M.; Alam, M.; Hakim, M.; Huq, A.O.; Moktadir, S.G. Development of fiber enriched herbal biscuits: A preliminary study on sensory evaluation and chemical composition. Int. J. Nutri. Food Sci. 2014, 3, 246–250. [Google Scholar] [CrossRef] [Green Version]

- Kolawole, F.; Balogun, M.; Opaleke, D.; Amali, H. An Evaluation of Nutritional and Sensory Qualities of Wheat -Moringa Cake. Agrosearch 2013, 13, 87. [Google Scholar] [CrossRef] [Green Version]

- Dachana, K.B.; Rajiv, J.; Indrani, D.; Prakash, J. Effect of dried Moringa (Moringa oleifera lam) leaves on rheological, microstructural, nutritional, textural and organoleptic characteristics of cookies. J. Food Qual. 2010, 33, 660–677. [Google Scholar] [CrossRef]

| Nutrition Value | Content (g/100 g Dry Matter) |

|---|---|

| Moisture (g) | 7.88 |

| Ash (g) | 5.95 |

| Acid insoluble Ash (g) | 0.58 |

| Fat (g) | 2.75 |

| Protein (g) | 28.01 |

| Fiber (g) | 23.24 |

| Iron (mg) | 25.61 |

| Potassium (mg) | 1231 |

| Calcium (mg) | 1875 |

| Carbohydrate (g) | 55.41 |

| Calories (cal) | 358.43 |

| Nutrition Value | Content (g/100 g Dry Matter) |

|---|---|

| Moisture (g) | 7.95 |

| Ash (g) | 6.81 |

| Acid insoluble Ash (g) | 0.31 |

| Fat (g) | 3.75 |

| Protein (g) | 6.01 |

| Fiber (g) | 45.02 |

| Iron (mg) | 2.61 |

| Potassium (mg) | 875 |

| Calcium (mg) | 19.20 |

| Carbohydrate (g) | 75.48 |

| Calories (cal) | 359.71 |

| Samples | Moisture (g/100 g) | Ash (g/100 g) | Acid insoluble Ash (g/100 g) | Fat (g/100 g) | Protein (g/100 g) | Carbohydrate (g/100 g) | Fiber (g/100 g) | Total Calories (g/100 g) |

|---|---|---|---|---|---|---|---|---|

| C0 | 17.77 ± 0.01 a | 1.25 ± 0.01 b | 0.054 ± 0.002 b | 20.16 ± 0.02 a | 5.79 ± 0.02 c | 53.03 ± 0.04 d | 2.70 ± 0.01 d | 434.73 ± 0.13 a |

| C1 | 16.34 ± 0.01 b | 1.29 ± 0.01 b | 0.054 ± 0.001 b | 18.68 ± 0.01 b | 6.57 ± 0.01 b | 57.12 ± 0.01 c | 5.48 ± 0.01 c | 422.87 ± 0.07 b |

| C2 | 14.96 ± 0.01 c | 1.61 ± 0.05 a | 0.074 ± 0.002 a | 16.50 ± 0.03 c | 8.90 ± 0.02 a | 58.38 ± 0.02 b | 6.78 ± 0.01 a | 417.66 ± 0.30 c |

| C3 | 13.54 ± 0.01 d | 1.66 ± 0.06 a | 0.077 ± 0.001 a | 13.06 ± 0.01 d | 8.81 ± 0.02 a | 60.88 ± 0.03 a | 6.98 ± 0.17 a | 393.51 ± 0.06 d |

| LSD | 0.26 | 0.05 | 0.003 | 0.85 | 0.32 | 0.73 | 0.64 | 3.88 |

| Samples | Iron (g/100 g) | Potassium (g/100 g) | Phosphorus (g/100 g) | Zinc (g/100 g) |

|---|---|---|---|---|

| C0 | 1.56 ± 0.02 c | 27.04 ± 0.03 c | 0.11 ± 0.007 c | 0.018 ± 0.0009 c |

| C1 | 10.57 ± 0.02 b | 3027.04 ± 0.48 b | 0.14 ± 0.007 b | 0.024 ± 0.0005 b |

| C2 | 14.00 ± 0.28 a | 3474.10 ± 49.89 a | 0.35 ± 0.011 a | 0.029 ± 0.0011 a |

| C3 | 14.47 ± 0.31 a | 3534.11 ± 63.33 a | 0.32 ± 0.009 a | 0.030 ± 0.003 a |

| LSD | 1.34 | 374.84 | 0.06 | 0.05 |

| Samples | Color | Shape | Texture | Sweetness | Flavor | Mouth Feel | Overall Acceptability |

|---|---|---|---|---|---|---|---|

| C0 | 7.40 ± 0.34 a | 5.65 ± 0.28 a | 6.40 ± 0.26 a | 5.20 ± 0.32 b | 4.20 ± 0.30 c | 6.45 ± 0.17 a | 7.20 ± 0.20 a |

| C1 | 6.45 ± 0.26 b | 5.50 ± 0.29 a | 6.25 ± 0.38 a | 5.30 ± 0.31 ab | 5.10 ± 0.36 b | 5.00 ± 0.32 b | 5.85 ± 0.25 b |

| C2 | 5.50 ± 0.24 bc | 5.95 ± 0.20 a | 5.60 ± 0.19 b | 5.70 ± 0.22 a | 7.60 ± 0.18 a | 6.10 ± 0.18 a | 6.95 ± 0.17 a |

| C3 | 5.10 ± 0.29 c | 5.40 ± 0.30 a | 5.15 ± 0.26 c | 4.05 ± 0.31 c | 5.10 ± 0.32 b | 3.95 ± 0.38 c | 5.50 ± 0.30 b |

| LSD | 0.16 | 0.16 | 0.15 | 0.18 | 0.20 | 0.19 | 0.14 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roni, R.A.; Sani, M.N.H.; Munira, S.; Wazed, M.A.; Siddiquee, S. Nutritional Composition and Sensory Evaluation of Cake Fortified with Moringa oleifera Leaf Powder and Ripe Banana Flour. Appl. Sci. 2021, 11, 8474. https://doi.org/10.3390/app11188474

Roni RA, Sani MNH, Munira S, Wazed MA, Siddiquee S. Nutritional Composition and Sensory Evaluation of Cake Fortified with Moringa oleifera Leaf Powder and Ripe Banana Flour. Applied Sciences. 2021; 11(18):8474. https://doi.org/10.3390/app11188474

Chicago/Turabian StyleRoni, Rabiul Alam, Md. Nasir Hossain Sani, Sirajum Munira, Md. Abdul Wazed, and Shafiquzzaman Siddiquee. 2021. "Nutritional Composition and Sensory Evaluation of Cake Fortified with Moringa oleifera Leaf Powder and Ripe Banana Flour" Applied Sciences 11, no. 18: 8474. https://doi.org/10.3390/app11188474

APA StyleRoni, R. A., Sani, M. N. H., Munira, S., Wazed, M. A., & Siddiquee, S. (2021). Nutritional Composition and Sensory Evaluation of Cake Fortified with Moringa oleifera Leaf Powder and Ripe Banana Flour. Applied Sciences, 11(18), 8474. https://doi.org/10.3390/app11188474