The Influence of Laboratory Scanner Versus Intra-Oral Scanner on Determining the Implant Axis by Using Three Different Scan Abutments

Abstract

:1. Introduction

2. Materials and Methods

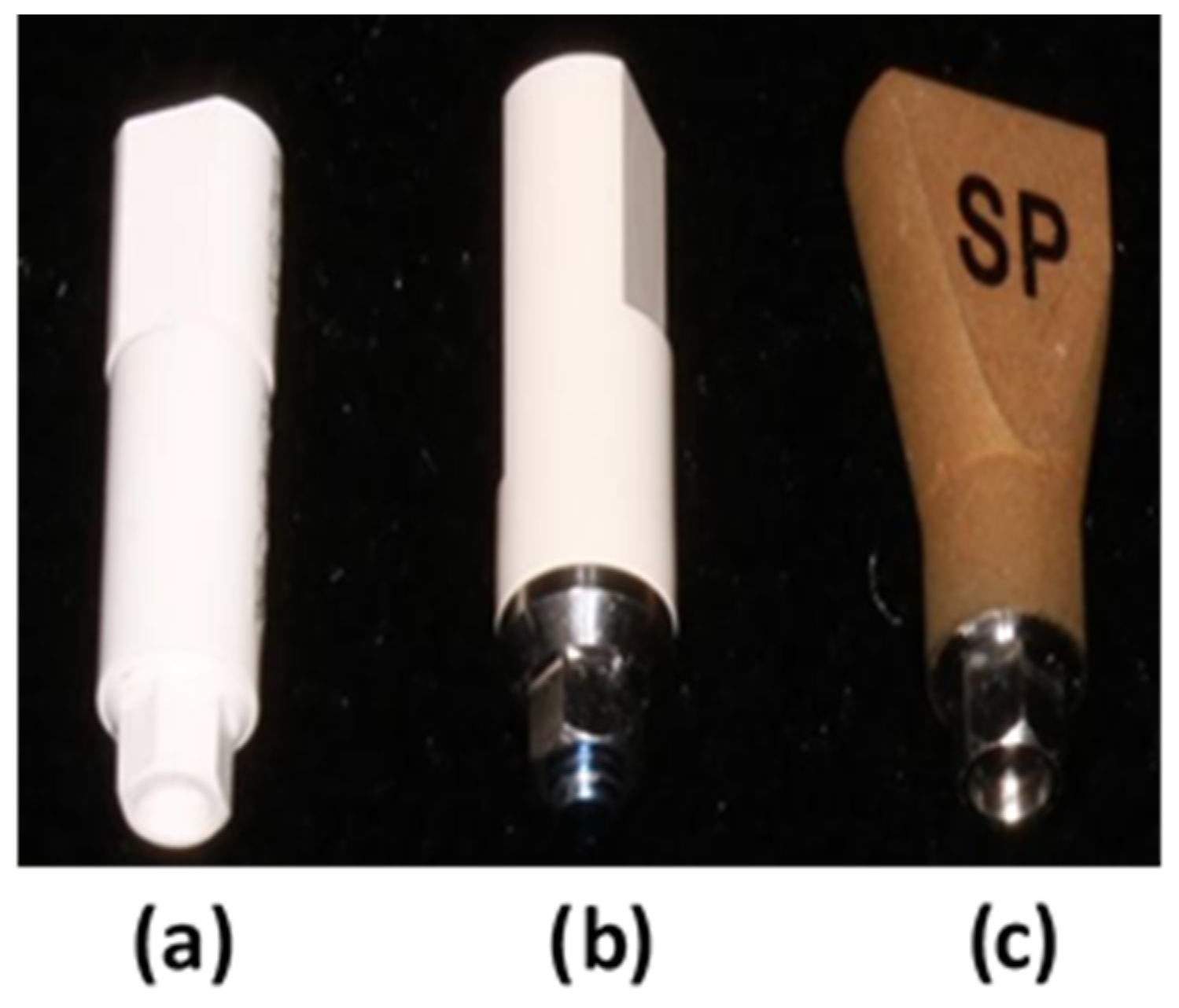

- MIS scan abutment (titanium, two-piece), asymmetrical geometry, internal hex connection.

- Alpha Bio (AB) scan abutment (PEEK and titanium, two-piece) cylindrical/asymmetric geometry, internal hex connection.

- Zirkonzahn (ZZ) scan abutment (PEEK, one-piece), cylindrical/asymmetric geometry, internal hex connection.

- Longitudinal axis of the scanning abutments is defined by the axis of the associated best-fitted cylinder to the abutment.

- The point of intersection between the longitudinal axis and the best-fitted associated top surface of the scanning abutment is the center of the top (occlusal) surface.

- The intersection between the top best-fitted (occlusal) surface and the best-fitted flat side surface is a straight edge. Based on this straight edge, we can calculate the angle of rotation of the scanning abutment (the angle of the scanning abutments relative to its longitudinal axis).

- 1.

- The distance between the center of the upper surface of the laboratory scan and the center of the upper surface of the intra-oral scan was defined as the shift of the scan abutment head with respect to the indirect scan from all the axes (purple dot in Figure 2). This was calculated as: .

- 2.

- The longitudinal axis angle was calculated as the three-dimensional angle between the longitudinal axis of the laboratory scan and the longitudinal axis of the intra-oral scan (red axis in Figure 2).

- 3.

- The rotational angle is the angle between the straight lines that comprise the intersection between the occlusal surface and the side surface of the abutments (the green straight line in Figure 2).

3. Results

3.1. Displacement in the Mesio-Distal Axis (x-Axis)

3.2. Displacement in the Bucco-Lingual Axis (y-Axis)

3.3. Displacement in the Occluso-Gingival Axis (z-Axis)

3.4. Absolute Distance from the Axes Origin (D)

3.5. Longitudinal Axis Angle

3.6. Rotational Angle

4. Discussion

- M–D displacement (x-axis) causes inaccurate seating due to inadequate contact with adjacent teeth.

- B–L displacement (y-axis) causes inaccurate buccal or lingual insertion which may lead to cheek or tongue biting, respectively.

- G–I displacement (z-axis) causes improper occlusal contacts.

- Geometry (cylindar versus square)

- Material (PEEK versus titanium)

- Scan abutment (one-piece versus two-piece)

5. Conclusions

- All three scan abutments showed a rotational deviation of the implant axis between the laboratory scanner and the intra-oral scanner.

- The AB scan abutment showed a deviation of 1.04 degrees while the other two scan abutments showed deviations of about half a degree in relation to the laboratory scan abutment.

- The MIS scan abutment is the only one which demonstrated no statistically significant displacement in the spatial position in relation to the X and Z axes.

- The one-piece PEEK ZZ scan abutment showed the lowest D which is under 50 microns while the other two scan abutment were above 50 microns.

- There is a need for further studies which will examine the influence of geometry, material, and scan abutment parts on the accuracy of the scan obtained.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rosenstiel, S.F.; Land, M.F. Contemporary Fixed Prosthodontics; Elsevier Health Sciences: St. Louis, MO, USA, 2015. [Google Scholar]

- Anadioti, E.; Lee, C.; Schweitzer, A. Fit of CAD/CAM Tooth-supported Single Crowns and Fixed Dental Prostheses. Curr. Oral Health Rep. 2017, 4, 142–150. [Google Scholar] [CrossRef]

- Allen, K.L.; Schenkel, A.B.; Estafan, D. An overview of the CEREC 3D CAD/CAM system. Gen. Dent. 2004, 52, 234–235. [Google Scholar]

- Culp, L.; Wong, N.Y.; Misch, C.E. Digital Technology in Implant Dentistry. In Dental Implant Prosthetics, 2nd ed.; Elsevier Mosby: St. Louis, MO, USA, 2015; pp. 700–723. [Google Scholar]

- Malaguti, G.; Rossi, R.; Marziali, B.; Esposito, A.; Bruno, G.; Dariol, C.; Dl Fiore, A. In vitro evaluation of prosthodontic impression on natural dentition: A comparison between traditional and digital techniques. Oral Implantol. 2016, 9, 21–27. [Google Scholar] [CrossRef] [PubMed]

- Alikhasi, M.; Siadat, H.; Nasirpour, A.; Hasanzade, M. Three-Dimensional Accuracy of Digital Impression versus Conventional Method: Effect of Implant Angulation and Connection Type. Int. J. Dent. 2018, 2018, 1–9. [Google Scholar] [CrossRef]

- Lee, H.; So, J.S.; Hochstedler, J.; Ercoli, C. The accuracy of implant impressions: A systematic review. J. Prosthet. Dent. 2008, 100, 285–291. [Google Scholar] [CrossRef]

- Amin, S.; Weber, H.P.; Finkelman, M.; El Rafie, K.; Kudara, Y.; Papaspyridakos, P. Digital vs. conventional full-arch implant impressions: A comparative study. Clin. Oral Implant. Res. 2017, 28, 1360–1367. [Google Scholar] [CrossRef] [PubMed]

- Basaki, K.; Alkumru, H.; De Souza, G.; Finer, Y. Accuracy of Digital vs Conventional Implant Impression Approach: A Three-Dimensional Comparative In Vitro Analysis. Int. J. Oral Maxillofac. Implant. 2017, 32, 792–799. [Google Scholar] [CrossRef] [Green Version]

- Chochlidakis, K.M.; Papaspyridakos, P.; Geminiani, A.; Chen, C.-J.; Feng, I.J.; Ercoli, C. Digital versus conventional impressions for fixed prosthodontics: A systematic review and meta-analysis. J. Prosthet. Dent. 2016, 116, 184–190.e12. [Google Scholar] [CrossRef] [PubMed]

- Magne, P.; Stanley, K.; Schlichting, L.H. Modeling of ultrathin occlusal veneers. Dent. Mater. 2012, 28, 777–782. [Google Scholar] [CrossRef]

- Skirbutis, G.; Dzingute, A.; Masiliunaite, V.; Sulcaite, G.; Zilinskas, J. PEEK polymer’s properties and its use in prosthodontics. A review. Stomatologija 2018, 20, 54–58. [Google Scholar]

- Fluegge, T.; Att, W.; Metzger, M.; Nelson, K. A Novel Method to Evaluate Precision of Optical Implant Impressions with Commercial Scan Bodies-An Experimental Approach. J. Prosthodont. 2017, 26, 34–41. [Google Scholar] [CrossRef] [PubMed]

- Siadat, H.; Beyabanaki, E.; Mousavi, N.; Alikhasi, M. Comparison of fit accuracy and torque maintenance of zirconia and titanium abutments for internal tri-channel and external-hex implant connections. J. Adv. Prosthodont. 2017, 9, 271–277. [Google Scholar] [CrossRef] [PubMed]

- Priest, G. Virtual-Designed and Computer-Milled Implant Abutments. J. Oral Maxillofac. Surg. 2005, 63, 22–32. [Google Scholar] [CrossRef]

- Tapie, L.; Lebon, N.; Mawussi, B.; Fron-Chabouis, H.; Duret, F.; Attal, J.-P. Understanding dental CAD/CAM for restorations--accuracy from a mechanical engineering viewpoint. Int. J. Comput. Dent. 2015, 18, 343–367. [Google Scholar]

- Mandelli, F.; Gherlone, E.; Gastaldi, G.; Ferrari, M. Evaluation of the accuracy of extraoral laboratory scanners with a single-tooth abutment model: A 3D analysis. J. Prosthodont. Res. 2017, 61, 363–370. [Google Scholar] [CrossRef]

- Gómez-Polo, M.; Ortega, R.; Gómez-Polo, C.; Celemin, A.; Highsmith, J.D.R. Factors Affecting the Decision to Use Cemented or Screw-Retained Fixed Implant-Supported Prostheses: A Critical Review. Int. J. Prosthodont. 2018, 31, 43–54. [Google Scholar] [CrossRef]

- Flügge, T.; Van Der Meer, W.J.; Gonzalez, B.G.; Vach, K.; Wismeijer, D.; Wang, P. The accuracy of different dental impression techniques for implant-supported dental prostheses: A systematic review and meta-analysis. Clin. Oral Implant. Res. 2018, 29, 374–392. [Google Scholar] [CrossRef] [Green Version]

- Waldecker, M.; Rues, S.; Rammelsberg, P.; Bömicke, W. Accuracy of complete-arch intraoral scans based on confocal microscopy versus optical triangulation: A comparative in vitro study. J. Prosthet. Dent. 2021, 126, 414–420. [Google Scholar] [CrossRef]

- Motel, C.; Kirchner, E.; Adler, W.; Wichmann, M.; Matta, R.E. Impact of Different Scan Bodies and Scan Strategies on the Accuracy of Digital Implant Impressions Assessed with an Intraoral Scanner: An In Vitro Study. J. Prosthodont. 2019, 29, 309–314. [Google Scholar] [CrossRef] [Green Version]

- Andriessen, F.S.; Rijkens, D.R.; van der Meer, W.J.; Wismeijer, D.W. Applicability and accuracy of an intraoral scanner for scanning multiple implants in edentulous mandibles: A pilot study. J. Prosthet. Dent. 2014, 111, 186–194. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.; Oh, T.-J.; Misch, C.E.; Wang, H.-L. Occlusal considerations in implant therapy: Clinical guidelines with biomechanical rationale. Clin. Oral Implant. Res. 2005, 16, 26–35. [Google Scholar] [CrossRef] [PubMed]

- Revilla-León, M.; Smith, Z.; Methani, M.M.; Zandinejad, A.; Özcan, M. Influence of scan body design on accuracy of the implant position as transferred to a virtual definitive implant cast. J. Prosthet. Dent. 2020. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.J.; Kim, S.-W.; Lee, J.J.; Cheong, C.W. Comparison of Intraoral and Extraoral Digital Scanners: Evaluation of Surface Topography and Precision. Dent. J. 2020, 8, 52. [Google Scholar] [CrossRef] [PubMed]

- Park, S.-W.; Choi, Y.-D.; Lee, D.-H. The effect of the improperly scanned scan body images on the accuracy of virtual implant positioning in computer-aided design software. J. Adv. Prosthodont. 2020, 12, 107–113. [Google Scholar] [CrossRef] [PubMed]

| Pin | Parameter | Mean | STD | p-Value |

|---|---|---|---|---|

| MIS | x (mm) | −0.007 | 0.083 | 0.656 |

| y (mm) | −0.082 | 0.072 | <0.001 | |

| z (mm) | −0.002 | 0.016 | 0.475 | |

| D (mm) | 0.125 | 0.058 | <0.001 | |

| rotational angle (deg) | 0.506 | 0.233 | <0.001 | |

| longitudinal angle (deg) | 0.324 | 0.236 | <0.001 | |

| ZZ | x (mm) | −0.013 | 0.015 | <0.001 |

| y (mm) | 0.03 | 0.024 | <0.001 | |

| z (mm) | 0.026 | 0.005 | <0.001 | |

| D (mm) | 0.046 | 0.022 | <0.001 | |

| rotational angle (deg) | 0.468 | 0.245 | <0.001 | |

| longitudinal angle (deg) | 0.304 | 0.269 | <0.001 | |

| AB | x (mm) | −0.033 | 0.02 | <0.001 |

| y (mm) | −0.025 | 0.016 | <0.001 | |

| z (mm) | −0.007 | 0.089 | <0.001 | |

| D (mm) | 0.069 | 0.075 | <0.001 | |

| rotational angle (deg) | 1.045 | 0.121 | <0.001 | |

| longitudinal angle (deg) | 0.194 | 0.165 | <0.001 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shely, A.; Livne, S.; Ben-Izhack, G.; Lokshin, M.; Har-Nes, S.; Zelikman, H.; Blumer, S.; Dolev, E. The Influence of Laboratory Scanner Versus Intra-Oral Scanner on Determining the Implant Axis by Using Three Different Scan Abutments. Appl. Sci. 2021, 11, 8543. https://doi.org/10.3390/app11188543

Shely A, Livne S, Ben-Izhack G, Lokshin M, Har-Nes S, Zelikman H, Blumer S, Dolev E. The Influence of Laboratory Scanner Versus Intra-Oral Scanner on Determining the Implant Axis by Using Three Different Scan Abutments. Applied Sciences. 2021; 11(18):8543. https://doi.org/10.3390/app11188543

Chicago/Turabian StyleShely, Asaf, Shiri Livne, Gil Ben-Izhack, Michal Lokshin, Shahar Har-Nes, Helena Zelikman, Sigalit Blumer, and Eran Dolev. 2021. "The Influence of Laboratory Scanner Versus Intra-Oral Scanner on Determining the Implant Axis by Using Three Different Scan Abutments" Applied Sciences 11, no. 18: 8543. https://doi.org/10.3390/app11188543

APA StyleShely, A., Livne, S., Ben-Izhack, G., Lokshin, M., Har-Nes, S., Zelikman, H., Blumer, S., & Dolev, E. (2021). The Influence of Laboratory Scanner Versus Intra-Oral Scanner on Determining the Implant Axis by Using Three Different Scan Abutments. Applied Sciences, 11(18), 8543. https://doi.org/10.3390/app11188543