Review of Materials and Fabrication Methods for Flexible Nano and Micro-Scale Physical and Chemical Property Sensors

Abstract

:1. Introduction

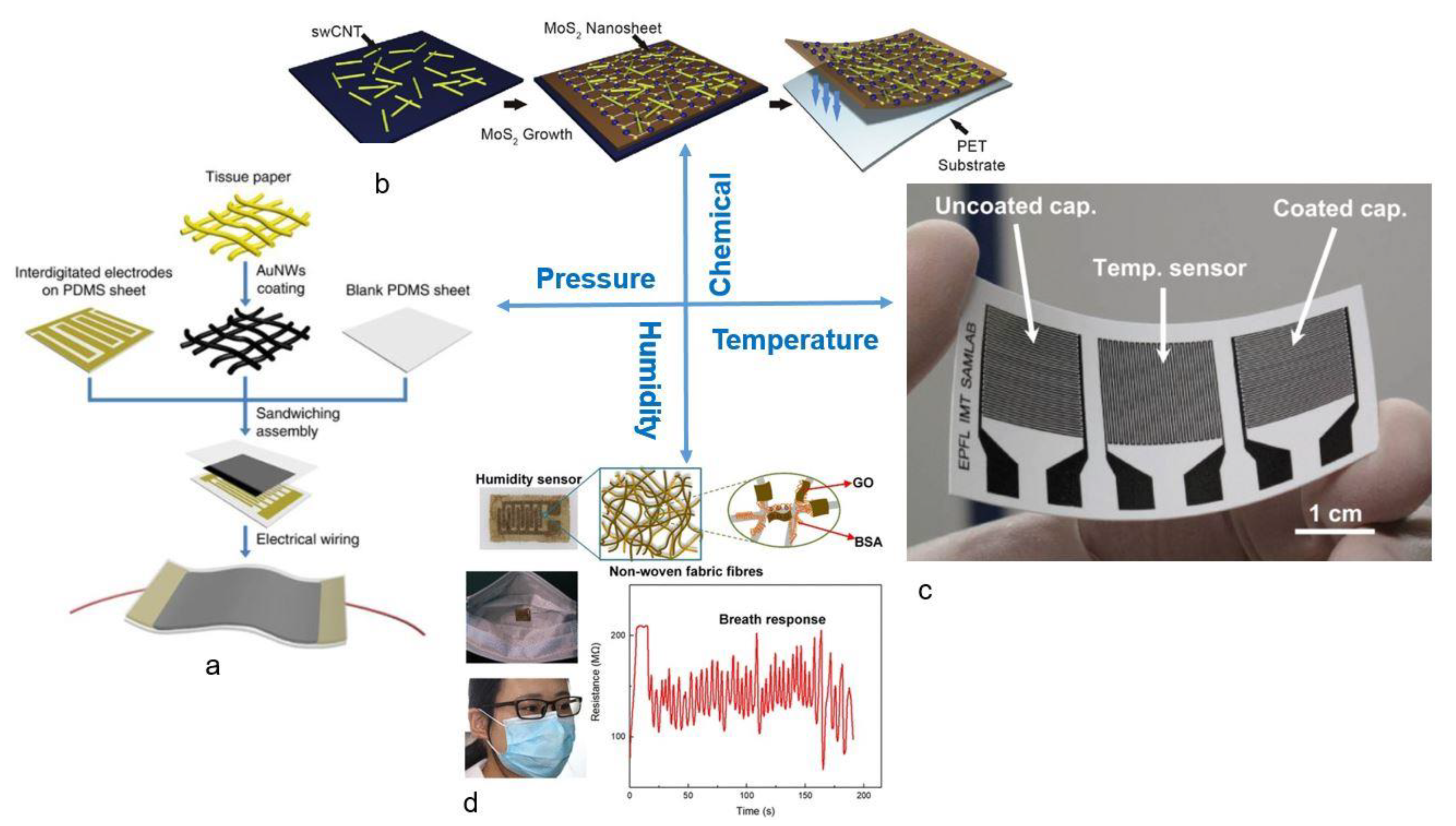

2. Various Types of Flexible Sensors (Temperature, Pressure, Humidity and Chemical)

2.1. Overview of Current Materials and Fabrication Methods

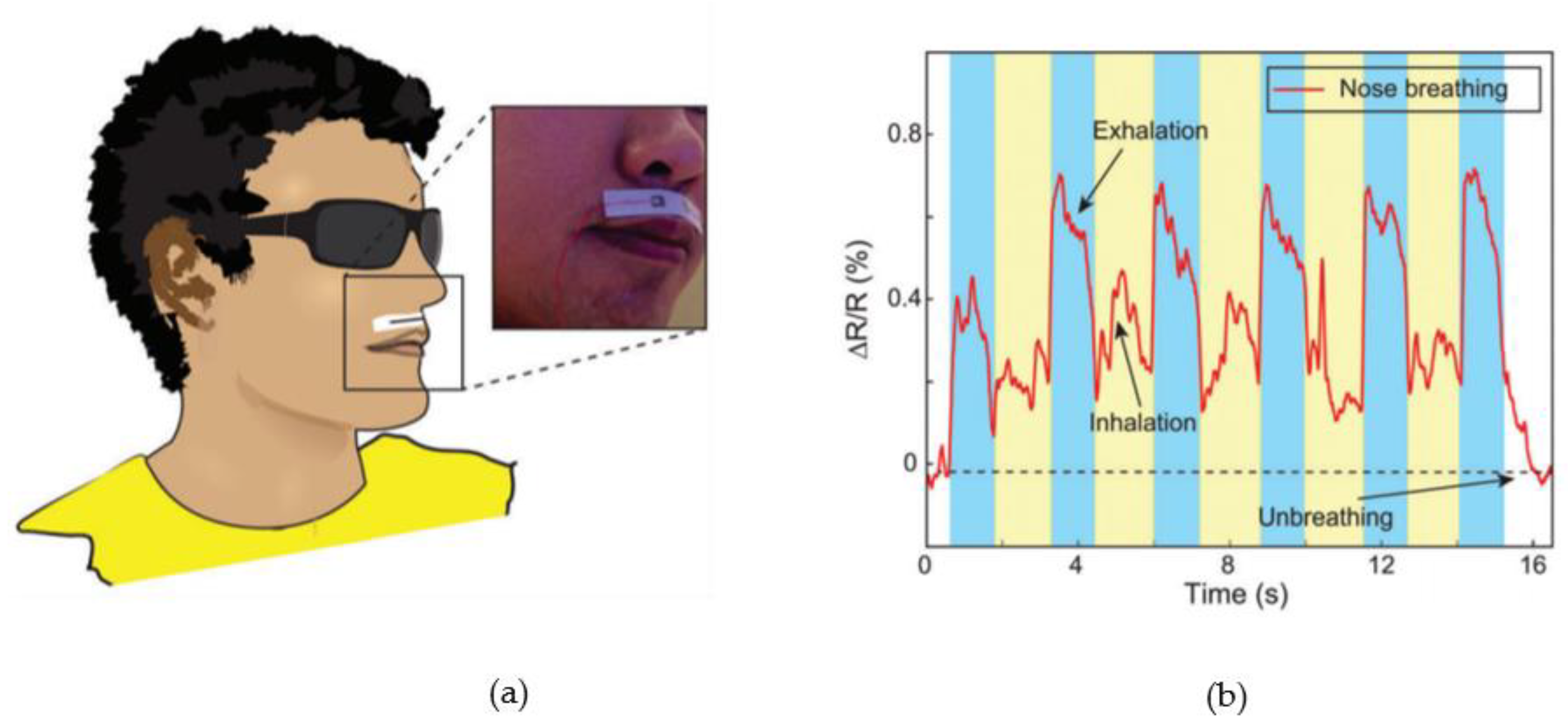

2.2. Humidity Sensors

2.3. Pressure Sensors

2.4. Temperature Sensors

2.4.1. Working Mechanism

2.4.2. Related Work

2.5. Chemical Sensors

3. Nanomaterials

Carbon Nanomaterials and Others

4. Polymers

4.1. Polydimethylsiloxane (PDMS)

4.2. Poly(N-Isopropylacrylamide) (PNIPAM)

4.3. Other Polymers

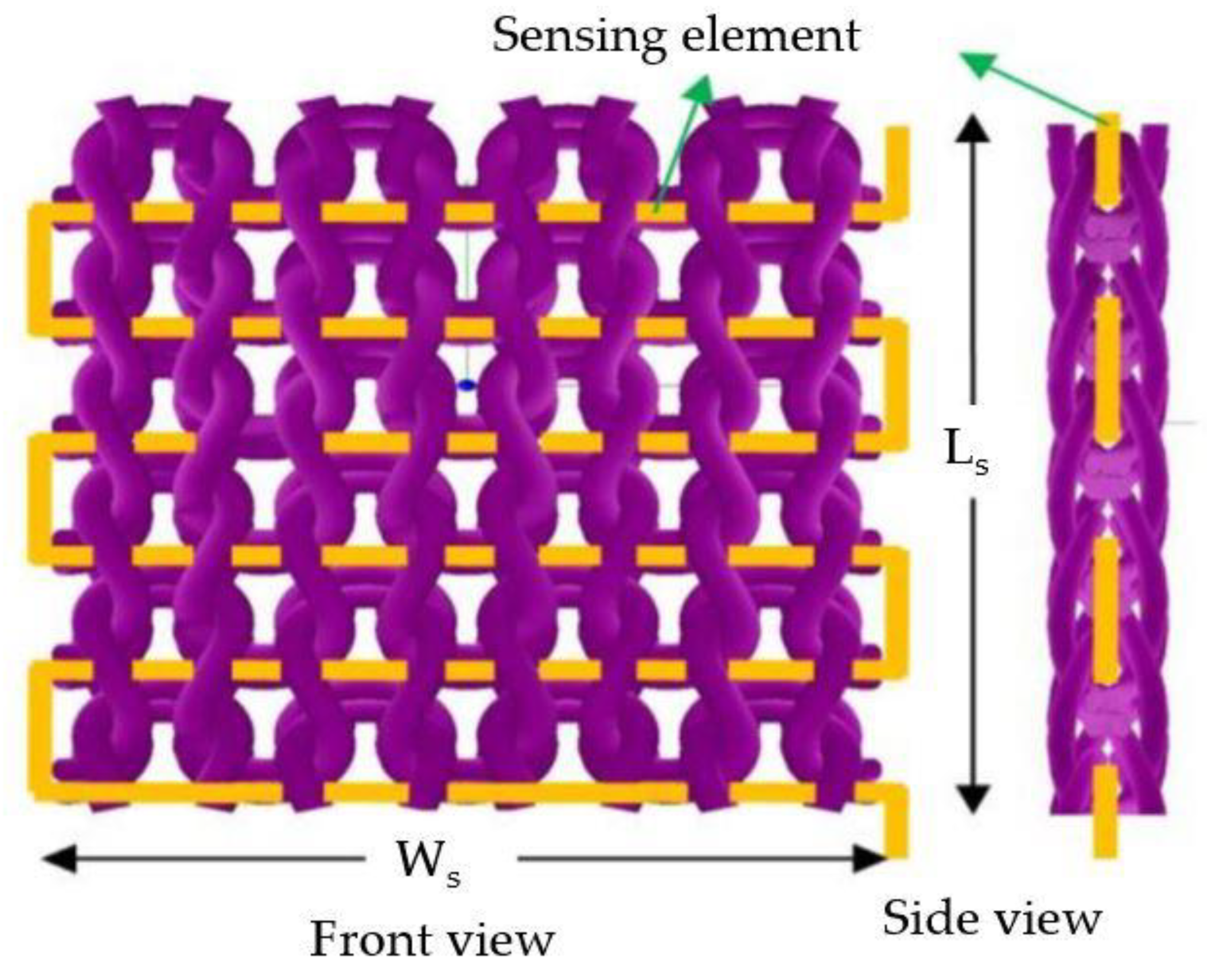

5. Additively Manufactured Flexible Sensors (3D Printing)

6. Self-Healing Flexible Sensors

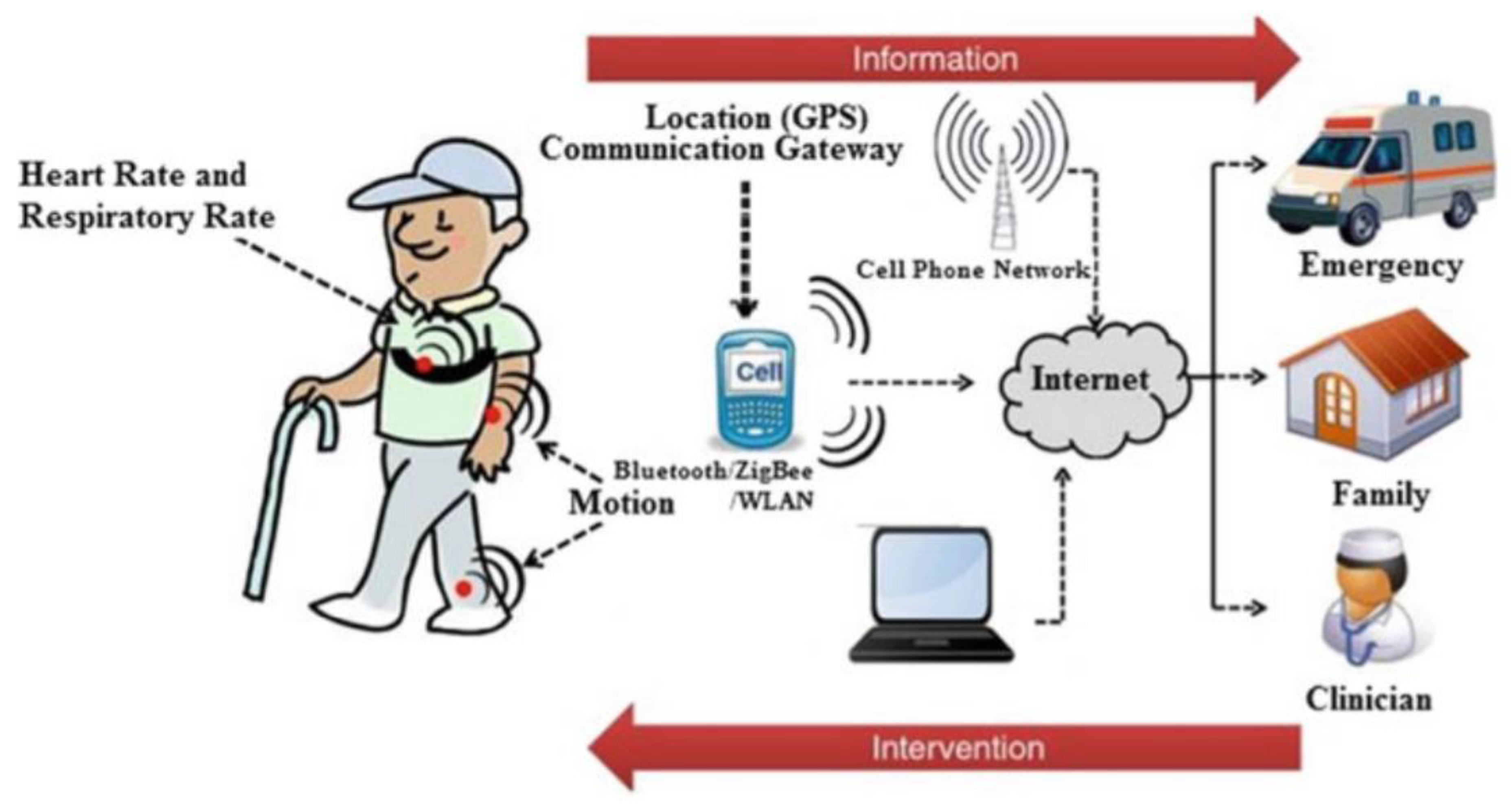

7. Wearables

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Soloman, S. Sensors Handbook, 2nd ed.; The McGraw-Hill Companies: New York, NY, USA, 2010; pp. 10–100. [Google Scholar]

- Megha, R.; Ali, F.A.; Ravikiran, Y.T.; Ramana, C.H.V.V.; Kiran Kumar, A.B.V.; Mishra, D.K.; Vijayakumari, S.C.; Kim, D. Conducting polymer nanocomposite based temperature sensors: A review. Inorg. Chem. Commun. 2018, 98, 11–28. [Google Scholar] [CrossRef]

- Wen, N.; Zhang, L.; Jiang, D.; Wu, Z.; Li, B.; Sun, C.; Guo, Z. Emerging flexible sensors based on nanomaterials: Recent status and applications. J. Mater. Chem. A 2020, 8, 25499–25527. [Google Scholar] [CrossRef]

- Dhinesh, S.K.; Senthil Kumar, K.L. A Review on 3D printed sensors. In Materials Science and Engineering, Proceedings of the International Conference on Advances in Materials Processing and Characterization, Sathyamangalam, India, 10–11 September 2019; IOP Conference Series; IOP Publishing: Bristol, UK, 2020; Volume 764. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Wei, Y.; Qiu, Y. Advanced flexible skin-like pressure and strain sensors for human health monitoring. Micromachines 2021, 12, 695. [Google Scholar] [CrossRef] [PubMed]

- Han, F.; Li, M.; Ye, H.; Zhang, G. Materials, electrical performance, mechanisms, applications, and manufacturing approaches for flexible strain sensors. Nanomaterials 2021, 11, 1220. [Google Scholar] [CrossRef]

- Gao, N.; Yu, J.; Tian, Q.; Shi, J.; Zhang, M.; Chen, S.; Zang, L. Application of PEDOT:PSS and Its Composites in Electrochemical and Electronic Chemosensors. Chemosensors 2021, 9, 79. [Google Scholar] [CrossRef]

- Xuan, W.; He, X.; Chen, J.; Wang, W.; Wang, X.; Xu, Y.; Xu, Z.; Fu, Y.Q.; Luo, J.K. High sensitivity flexible lamb-wave humidity sensors with a graphene oxide sensing layer. Nanoscale 2015, 7, 7430–7436. [Google Scholar] [CrossRef] [Green Version]

- Ling, H.; Chen, R.; Huang, Q.; Shen, F.; Wang, Y.; Wang, X. Transparent, flexible and recyclable nanopaper-based touch sensors fabricated: Via inkjet-printing. Green Chem. 2020, 22, 3208–3215. [Google Scholar] [CrossRef]

- Patel, S.; Park, H.; Bonato, P.; Chan, L.; Rodgers, M. A review of wearable sensors and systems with application in rehabilitation. J. Neuroeng. Rehabil. 2012, 9, 21. [Google Scholar] [CrossRef] [Green Version]

- Lee, W.S.; Jeon, S.; Oh, S.J. Wearable sensors based on colloidal nanocrystals. Nano Converg. 2019, 6, 10. [Google Scholar] [CrossRef]

- Gong, S.; Schwalb, W.; Wang, Y.; Chen, Y.; Tang, Y.; Si, J.; Shirinzadeh, B.; Cheng, W. A wearable and highly sensitive pressure sensor with ultrathin gold nanowires. Nat. Commun. 2014, 5, 3132. [Google Scholar] [CrossRef] [Green Version]

- Kim, S.; Han, J.; Kang, M.A.; Song, W.; Myung, S.; Kim, S.W.; Lee, S.S.; Lim, J.; An, K.S. Flexible chemical sensors based on hybrid layer consisting of molybdenum disulphide nanosheets and carbon nanotubes. Carbon 2018, 129, 607–612. [Google Scholar] [CrossRef]

- Courbat, J.; Kim, Y.B.; Briand, D.; De Rooij, N.F. Inkjet printing on paper for the realization of humidity and temperature sensors. In Proceedings of the 2011 16th International Solid-State Sensors, Actuators and Microsystems Conference (TRANSDUCERS’11), Beijing, China, 5–9 June 2011; pp. 1356–1359. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, L.; Zhang, Z.; Sun, P.; Chen, H. High-sensitivity wearable and flexible humidity sensor based on graphene oxide/non-woven fabric for respiration monitoring. Langmuir 2020, 36, 9443–9448. [Google Scholar] [CrossRef] [PubMed]

- Segev-Bar, M.; Haick, H. Flexible sensors based on nanoparticles. ACS Nano 2013, 7, 8366–8378. [Google Scholar] [CrossRef]

- Wang, Z.; Shaygan, M.; Otto, M.; Schall, D.; Neumaier, D. Flexible hall sensors based on graphene. Nanoscale 2016, 8, 7683–7687. [Google Scholar] [CrossRef] [Green Version]

- Lin, H.-J.; Fang, T.-H.; Chang, W.-Y.; Lin, Y.-C.; Shen, Y.-T. A Large area flexible array sensors using screen printing technology. J. Disp. Technol. 2009, 5, 178–183. [Google Scholar]

- Schuettler, M.; Stiess, S.; King, B.V.; Suaning, G.J. Fabrication of implantable microelectrode arrays by laser cutting of silicone rubber and platinum foil. J. Neural Eng. 2005, 2, S121. [Google Scholar] [CrossRef]

- Li, Q.; Yin, R.; Zhang, D.; Liu, H.; Chen, X.; Zheng, Y.; Guo, Z.; Liu, C.; Shen, C. Flexible conductive MXene/Cellulose nanocrystal coated nonwoven fabrics for tunable wearable strain/pressure sensors. J. Mater. Chem. A 2020, 8, 21131–21141. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, C.; Ding, L.; Zhang, L.; Chen, J.; Huang, H.; Jiang, D.; Chen, Z.; Pan, G. A flexible bifunctional sensor based on porous copper Nanowire@IonGel composite films for high-resolution stress/deformation detection. J. Mater. Chem. C 2020, 8, 4081–4092. [Google Scholar] [CrossRef]

- Jin, H.; Matsuhisa, N.; Lee, S.; Abbas, M.; Yokota, T.; Someya, T. Enhancing the performance of stretchable conductors for e-textiles by controlled ink permeation. Adv. Mater. 2017, 29, 1605848. [Google Scholar] [CrossRef]

- Jeong, G.S.; Baek, D.H.; Jung, H.C.; Song, J.H.; Moon, J.H.; Hong, S.W.; Kim, I.Y.; Lee, S.H. Solderable and electroplatable flexible electronic circuit on a porous stretchable elastomer. Nat. Commun. 2012, 3, 977. [Google Scholar] [CrossRef]

- Yeh, Y.C.; Highley, C.B.; Ouyang, L.; Burdick, J.A. 3D printing of photocurable Poly(Glycerol Sebacate) elastomers. Biofabrication 2016, 8, 045004. [Google Scholar] [CrossRef]

- Ji, Z.; Zhang, X.; Yan, C.; Jia, X.; Xia, Y.; Wang, X.; Zhou, F. 3D printing of photocuring elastomers with excellent mechanical strength and resilience. Macromol. Rapid Commun. 2019, 40, 1800873. [Google Scholar] [CrossRef] [PubMed]

- Dinh, T.; Phan, H.P.; Nguyen, T.K.; Qamar, A.; Foisal, A.R.M.; Nguyen Viet, T.; Tran, C.D.; Zhu, Y.; Nguyen, N.T.; Dao, D.V. Environment-friendly carbon nanotube based flexible electronics for noninvasive and wearable healthcare. J. Mater. Chem. C 2016, 4, 10061–10068. [Google Scholar] [CrossRef]

- Kang, B.S.; Kim, J.; Jang, S.; Ren, F.; Johnson, J.W.; Therrien, R.J.; Rajagopal, P.; Roberts, J.C.; Piner, E.L.; Linthicum, K.J.; et al. Capacitance pressure sensor based on GaN high-electron-mobility transistor-on-Si membrane. Appl. Phys. Lett. 2005, 86, 253502. [Google Scholar] [CrossRef]

- Zhu, S.E.; Krishna Ghatkesar, M.; Zhang, C.; Janssen, G.C.A.M. Graphene based piezoresistive pressure sensor. Appl. Phys. Lett. 2013, 102, 161904. [Google Scholar] [CrossRef] [Green Version]

- Mannsfeld, S.C.B.; Tee, B.C.K.; Stoltenberg, R.M.; Chen, C.V.H.H.; Barman, S.; Muir, B.V.O.; Sokolov, A.N.; Reese, C.; Bao, Z. Highly sensitive flexible pressure sensors with microstructured rubber dielectric layers. Nat. Mater. 2010, 9, 859–864. [Google Scholar] [CrossRef]

- Tobjörk, D.; Österbacka, R. Paper electronics. Adv. Mater. 2011, 23, 1935–1961. [Google Scholar] [CrossRef]

- Lee, W.S.; Lee, S.-W.; Joh, H.; Seong, M.; Kim, H.; Kang, M.S.; Cho, K.-H.; Sung, Y.-M.; Oh, S.J. Designing metallic and insulating nanocrystal heterostructures to fabricate highly sensitive and solution processed strain gauges for wearable sensors. Small 2017, 13, 1702534. [Google Scholar] [CrossRef] [PubMed]

- Smarr, B.L.; Aschbacher, K.; Fisher, S.M.; Chowdhary, A.; Dilchert, S.; Puldon, K.; Rao, A.; Hecht, F.M.; Mason, A.E. Feasibility of continuous fever monitoring using wearable devices. Sci. Rep. 2020, 10, 21640. [Google Scholar] [CrossRef] [PubMed]

- Konishi, S.; Hirata, A. Flexible temperature sensor integrated with soft pneumatic microactuators for functional microfingers. Sci. Rep. 2019, 9, 15634. [Google Scholar] [CrossRef] [Green Version]

- Arman Kuzubasoglu, B.; Kursun Bahadir, S. Flexible temperature sensors: A review. Sens. Actuators A 2020, 315, 112282. [Google Scholar] [CrossRef]

- Claggett, T.J.; Worrall, R.W.; Clayton, W.A.; Lipták, B.G. Resistance temperature detectors. In Instrument Engineers’ Handbook: Process Measurement and Analysis, 4th ed.; CRC Press: Boca Raton, FL, USA, 2003; pp. 645–656. [Google Scholar] [CrossRef]

- Bali, C.; Brandlmaier, A.; Ganster, A.; Raab, O.; Zapf, J.; Hübler, A. Fully inkjet-printed flexible temperature sensors based on carbon and PEDOT: PSS. Mater. Today Proc. 2016, 3, 739–745. [Google Scholar] [CrossRef]

- Liu, Y.; Tao, L.Q.; Wang, D.Y.; Zhang, T.Y.; Yang, Y.; Ren, T.L. Flexible, highly sensitive pressure sensor with a wide range based on graphene-silk network structure. Appl. Phys. Lett. 2017, 110, 123508. [Google Scholar] [CrossRef]

- Soni, M.; Bhattacharjee, M.; Ntagios, M.; Dahiya, R. Printed Temperature Sensor Based on PEDOT: PSS-graphene oxide composite. IEEE Sens. J. 2020, 20, 7525–7531. [Google Scholar] [CrossRef] [Green Version]

- Husain, M.D.; Kennon, R. Preliminary investigations into the development of textile based temperature sensor for healthcare applications. Fibers 2013, 1, 2–10. [Google Scholar] [CrossRef] [Green Version]

- Rajan, G.; Morgan, J.J.; Murphy, C.; Torres Alonso, E.; Wade, J.; Ott, A.K.; Russo, S.; Alves, H.; Craciun, M.F.; Neves, A.I.S. Low operating voltage carbon-graphene hybrid e-textile for temperature sensing. ACS Appl. Mater. Interfaces 2020, 12, 29861–29867. [Google Scholar] [CrossRef] [PubMed]

- Dankoco, M.D.; Tesfay, G.Y.; Benevent, E.; Bendahan, M. Temperature sensor realized by inkjet printing process on flexible substrate. Mater. Sci. Eng. B 2016, 205, 1–5. [Google Scholar] [CrossRef]

- Tortorich, R.P.; Song, E.; Choi, J.-W. Inkjet-printed carbon nanotube electrodes with low sheet resistance for electrochemical sensor applications. J. Electrochem. Soc. 2014, 161, B3044–B3048. [Google Scholar] [CrossRef]

- Choi, W.; Choudhary, N.; Han, G.H.; Park, J.; Akinwande, D.; Lee, Y.H. Recent development of two-dimensional transition metal dichalcogenides and their applications. Mater. Today 2017, 20, 116–130. [Google Scholar] [CrossRef]

- Cho, S.-Y.; Joon Kim, S.; Lee, Y.; Kim, J.-S.; Jung, W.-B.; Yoo, H.-W.; Kim, J.; Jung, H.-T. Highly enhanced gas adsorption properties in vertically aligned MoS2 layers. ACS Nano 2015, 9, 9314–9321. [Google Scholar] [CrossRef]

- Alvarado, M.; La Flor, S.D.; Llobet, E.; Romero, A.; Ramírez, J.L. Performance of flexible chemoresistive gas sensors after having undergone automated bending tests. Sensors 2019, 19, 5190. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, C.; Huang, N.; Xu, F.; Tong, J.; Chen, Z.; Gui, X.; Fu, Y.; Lao, C. 3D printing technologies for flexible tactile sensors toward wearable electronics and electronic skin. Polymers 2018, 10, 629. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Han, Z.; Li, H.; Xiao, J.; Song, H.; Li, B.; Cai, S.; Chen, Y.; Ma, Y.; Feng, X. Ultralow-Cost, Highly Sensitive, and Flexible Pressure Sensors Based on Carbon Black and Airlaid Paper for Wearable Electronics. ACS Appl. Mater. Interfaces 2019, 11, 33370–33379. [Google Scholar] [CrossRef] [PubMed]

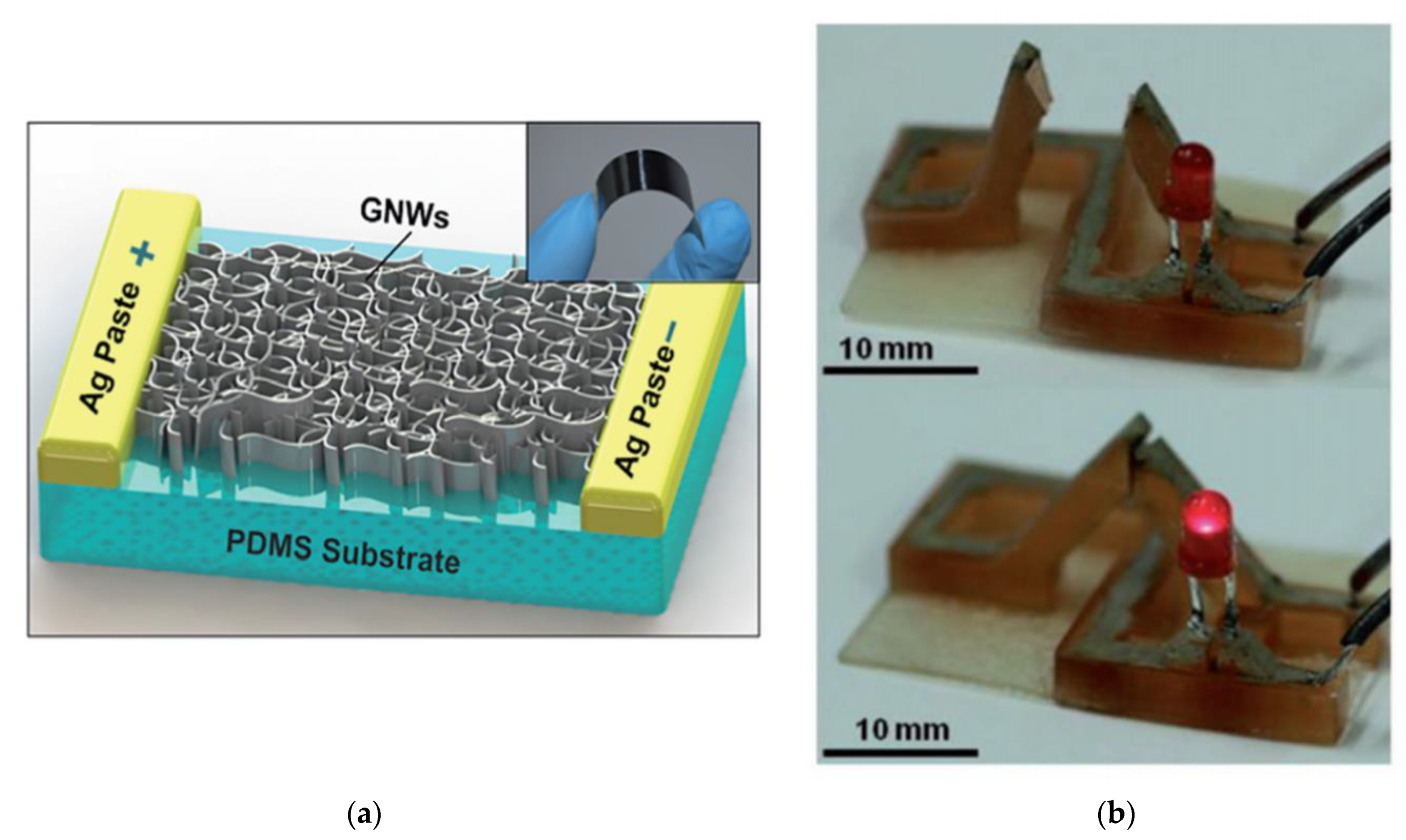

- Yang, J.; Wei, D.; Tang, L.; Song, X.; Luo, W.; Chu, J.; Gao, T.; Shi, H.; Du, C. Wearable temperature sensor based on graphene nanowalls. RSC Adv. 2015, 5, 25609–25615. [Google Scholar] [CrossRef]

- Sadasivuni, K.K.; Kafy, A.; Kim, H.C.; Ko, H.U.; Mun, S.; Kim, J. Reduced graphene oxide filled cellulose films for flexible temperature sensor application. Synth. Met. 2015, 206, 154–161. [Google Scholar] [CrossRef]

- Bae, G.Y.; Han, J.T.; Lee, G.; Lee, S.; Kim, S.W.; Park, S.; Kwon, J.; Jung, S.; Cho, K. Pressure/temperature sensing bimodal electronic skin with stimulus discriminability and linear sensitivity. Adv. Mater. 2018, 30, 1803388. [Google Scholar] [CrossRef]

- Choong, C.L.; Shim, M.B.; Lee, B.S.; Jeon, S.; Ko, D.S.; Kang, T.H.; Bae, J.; Lee, S.H.; Byun, K.E.; Im, J.; et al. Highly stretchable resistive pressure sensors using a conductive elastomeric composite on a micropyramid array. Adv. Mater. 2014, 26, 3451–3458. [Google Scholar] [CrossRef]

- Su, P.G.; Shiu, W.L.; Tsai, M.S. Flexible humidity sensor based on Au nanoparticles/graphene oxide/thiolated silica sol–gel film. Sens. Actuators B Chem. 2015, 216, 467–475. [Google Scholar] [CrossRef]

- Choi, T.Y.; Hwang, B.U.; Kim, B.Y.; Trung, T.Q.; Nam, Y.H.; Kim, D.N.; Eom, K.; Lee, N.E. Stretchable, transparent, and stretch-unresponsive capacitive touch sensor array with selectively patterned silver nanowires/reduced graphene oxide electrodes. ACS Appl. Mater. Interfaces 2017, 9, 18022–18030. [Google Scholar] [CrossRef]

- Chun, K.Y.; Oh, Y.; Rho, J.; Ahn, J.H.; Kim, Y.J.; Choi, H.R.; Baik, S. Highly conductive, printable and stretchable composite films of carbon nanotubes and silver. Nat. Nanotechnol. 2010, 5, 853–857. [Google Scholar] [CrossRef]

- Bagga, K.; McCann, R.; Wang, M.; Stalcup, A.; Vázquez, M.; Brabazon, D. Laser assisted synthesis of carbon nanoparticles with controlled viscosities for printing applications. J. Colloid Interface Sci. 2015, 447, 263–268. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nyabadza, A.; Kane, J.; Sreenilayam, S.; Vázquez, M.; Brabazon, D. Multi-material production of 4D shape memory polymer composites. Encycl. Mater. Compos. 2021, 2, 879–894. [Google Scholar] [CrossRef]

- Conductive Ink Market Size & Share. Industry Report. 2016. Available online: https://www.grandviewresearch.com/industry-analysis/conductive-ink-market (accessed on 27 December 2020).

- Amjadi, M.; Pichitpajongkit, A.; Lee, S.; Ryu, S.; Park, I. Highly stretchable and sensitive strain sensor based on silver nanowire-elastomer nanocomposite. ACS Nano 2014, 8, 5154–5163. [Google Scholar] [CrossRef]

- Zarek, M.; Layani, M.; Cooperstein, I.; Sachyani, E.; Cohn, D.; Magdassi, S. 3D printing of shape memory polymers for flexible electronic devices. Adv. Mater. 2016, 28, 4449–4454. [Google Scholar] [CrossRef]

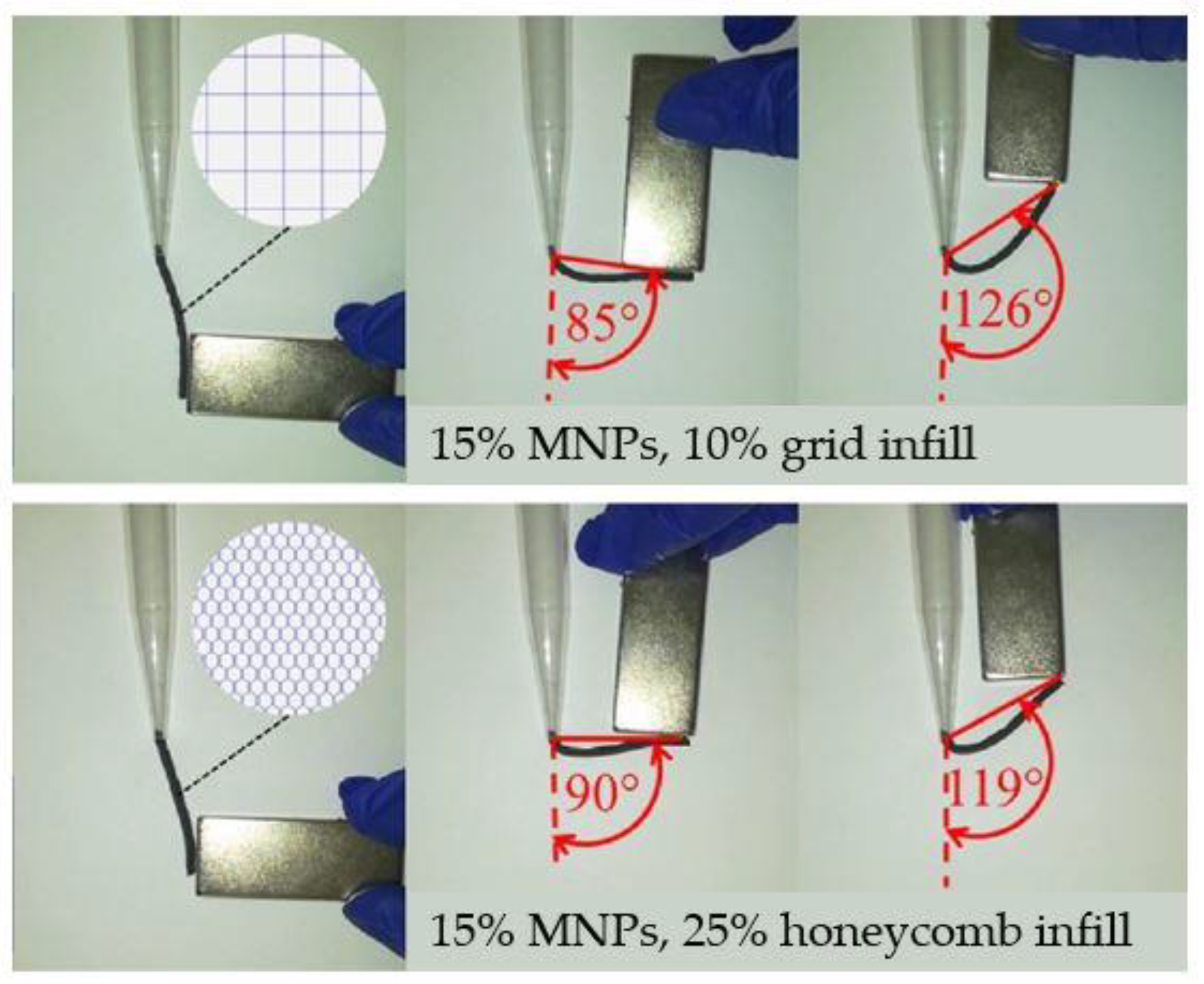

- Podstawczyk, D.; Nizioł, M.; Szymczyk, P.; Wiśniewski, P.; Guiseppi-Elie, A. 3D printed stimuli-responsive magnetic nanoparticle embedded alginate-methylcellulose hydrogel actuators. Addit. Manuf. 2020, 34, 101275. [Google Scholar] [CrossRef]

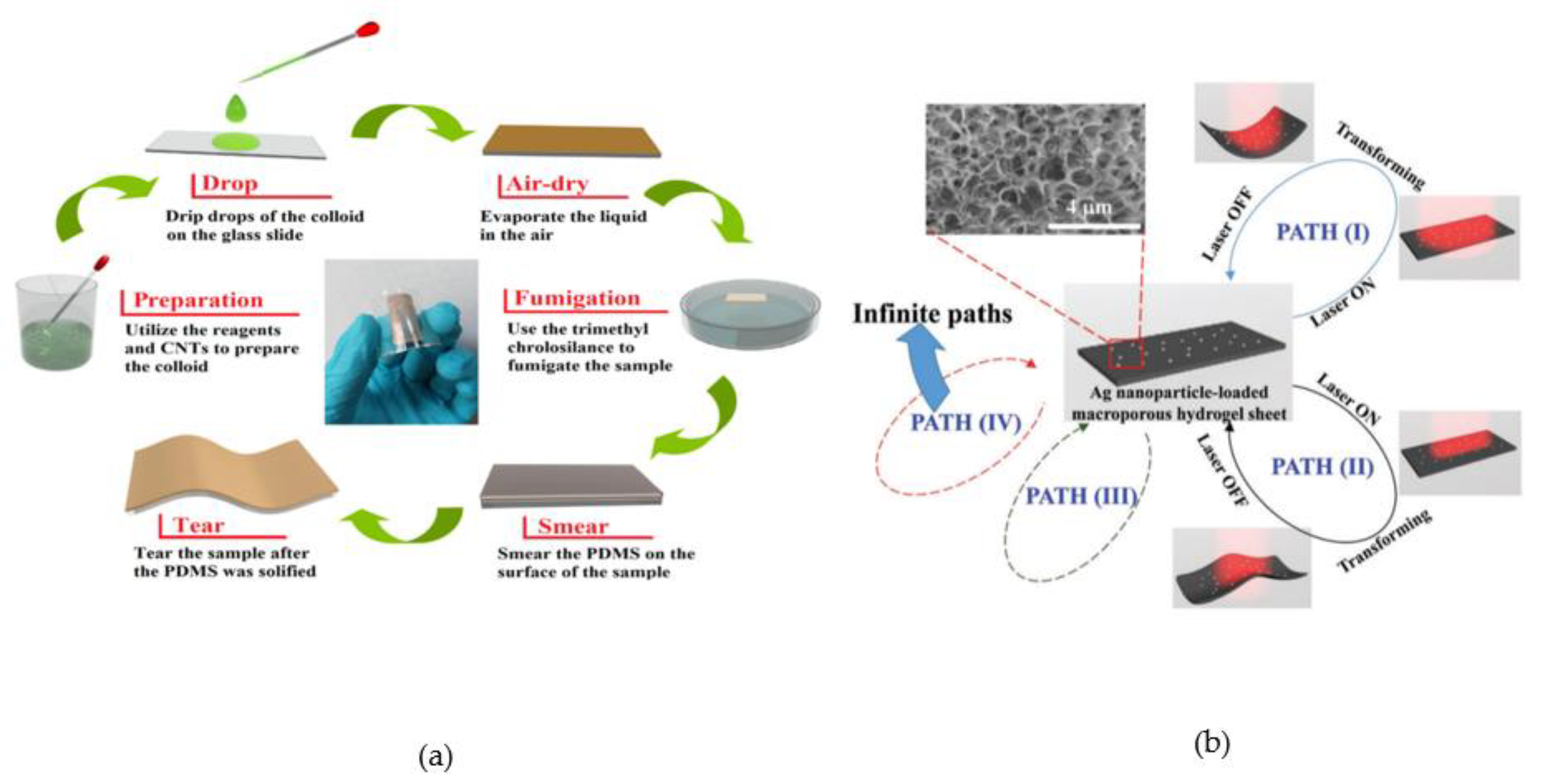

- Guo, H.; Cheng, J.; Wang, J.; Huang, P.; Liu, Y.; Jia, Z.; Chen, X.; Sui, K.; Li, T.; Nie, Z. Reprogrammable ultra-fast shape-transformation of macroporous composite hydrogel sheets. J. Mater. Chem. B 2017, 5, 2883–2887. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, C.L.; Cao, F.H.; Wang, J.L.; Yu, Z.L.; Ge, J.; Lu, Y.; Wang, Z.H.; Yu, S.H. Highly stimuli-responsive Au nanorods/Poly(N-Isopropylacrylamide) (PNIPAM) composite hydrogel for smart switch. ACS Appl. Mater. Interfaces 2017, 9, 24857–24863. [Google Scholar] [CrossRef]

- Li, W.; Hu, L.; Zhu, J.; Li, D.; Luan, Y.; Xu, W.; Serpe, M.J. Comparison of the responsivity of solution-suspended and surface-bound Poly(N-Isopropylacrylamide)-based microgels for sensing applications. ACS Appl. Mater. Interfaces 2017, 9, 26539–26548. [Google Scholar] [CrossRef]

- Wang, X.; Gu, Y.; Xiong, Z.; Cui, Z.; Zhang, T. Silk-molded flexible, ultrasensitive, and highly stable electronic skin for monitoring human physiological signals. Adv. Mater. 2014, 26, 1336–1342. [Google Scholar] [CrossRef]

- Hong, S.; Lee, H.; Lee, J.; Kwon, J.; Han, S.; Suh, Y.D.; Cho, H.; Shin, J.; Yeo, J.; Ko, S.H. Highly stretchable and transparent metal nanowire heater for wearable electronics applications. Adv. Mater. 2015, 27, 4744–4751. [Google Scholar] [CrossRef]

- Lu, N.; Lu, C.; Yang, S.; Rogers, J. Highly sensitive skin-mountable strain gauges based entirely on elastomers. Adv. Funct. Mater. 2012, 22, 4044–4050. [Google Scholar] [CrossRef]

- Yamada, T.; Hayamizu, Y.; Yamamoto, Y.; Yomogida, Y.; Izadi-Najafabadi, A.; Futaba, D.N.; Hata, K. A Stretchable carbon nanotube strain sensor for human-motion detection. Nat. Nanotechnol. 2011, 6, 296–301. [Google Scholar] [CrossRef]

- Tybrandt, K.; Khodagholy, D.; Dielacher, B.; Stauffer, F.; Renz, A.F.; Buzsáki, G.; Vörös, J. High-density stretchable electrode grids for chronic neural recording. Adv. Mater. 2018, 30, 1706520. [Google Scholar] [CrossRef]

- Kim, I.; Woo, K.; Zhong, Z.; Ko, P.; Jang, Y.; Jung, M.; Jo, J.; Kwon, S.; Lee, S.H.; Lee, S.; et al. A photonic sintering derived Ag flake/nanoparticle-based highly sensitive stretchable strain sensor for human motion monitoring. Nanoscale 2018, 10, 7890–7897. [Google Scholar] [CrossRef] [PubMed]

- Zhang, E.; Wang, T.; Hong, W.; Sun, W.; Liu, X.; Tong, Z. Infrared-driving actuation based on bilayer graphene oxide-Poly(N-Isopropylacrylamide) nanocomposite hydrogels. J. Mater. Chem. A 2014, 2, 15633–15639. [Google Scholar] [CrossRef]

- Tang, L.; Wang, L.; Yang, X.; Feng, Y.; Li, Y.; Feng, W. Poly(N-Isopropylacrylamide)-based smart hydrogels: Design, properties and applications. Prog. Mater. Sci. 2021, 115, 100702. [Google Scholar] [CrossRef]

- Zhao, Y.; Xuan, C.; Qian, X.; Alsaid, Y.; Hua, M.; Jin, L.; He, X. Soft phototactic swimmer based on self-sustained hydrogel oscillator. Sci. Robot. 2019, 4, eaax7112. [Google Scholar] [CrossRef]

- Zhou, L.Y.; Gao, Q.; Zhan, J.F.; Xie, C.Q.; Fu, J.Z.; He, Y. Three-dimensional printed wearable sensors with liquid metals for detecting the pose of snakelike soft robots. ACS Appl. Mater. Interfaces 2018, 10, 23208–23217. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.Y.; Yang, C.; Hsu, W.; Lin, L. 3D-printed microelectronics for integrated circuitry and passive wireless sensors. Microsyst. Nanoeng. 2015, 1, 15013. [Google Scholar] [CrossRef] [Green Version]

- Leigh, S.J.; Bradley, R.J.; Purssell, C.P.; Billson, D.R.; Hutchins, D.A. A simple, low-cost conductive composite material for 3D printing of electronic sensors. PLoS ONE 2012, 7, e49365. [Google Scholar] [CrossRef]

- Christ, J.F.; Aliheidari, N.; Ameli, A.; Pötschke, P. 3D printed highly elastic strain sensors of multiwalled carbon nanotube/thermoplastic polyurethane nanocomposites. Mater. Des. 2017, 131, 394–401. [Google Scholar] [CrossRef]

- Kim, K.; Park, J.; Suh, J.h.; Kim, M.; Jeong, Y.; Park, I. 3D printing of multiaxial force sensors using Carbon Nanotube (CNT)/Thermoplastic Polyurethane (TPU) filaments. Sens. Actuators A Phys. 2017, 263, 493–500. [Google Scholar] [CrossRef]

- Lee, H.; Lee, J.; Seong, B.; Jang, H.-S.; Byun, D. Printing conductive micro-web structures via capillary transport of elastomeric ink for highly stretchable strain sensors. Adv. Mater. Technol. 2018, 3, 1700228. [Google Scholar] [CrossRef]

- Wu, Q.; Zou, S.; Gosselin, F.P.; Therriault, D.; Heuzey, M.C. 3D printing of a self-healing nanocomposite for stretchable sensors. J. Mater. Chem. C 2018, 6, 12180–12186. [Google Scholar] [CrossRef]

- Schouten, M.; Sanders, R.; Krijnen, G. 3D printed flexible capacitive force sensor with a simple micro-controller based readout. In Proceedings of the IEEE Sensors, Glasgow, UK, 29 October–1 November 2017; pp. 1–3. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Liu, N.; Tao, J.; Yang, C.; Liu, W.; Shi, Y.; Wang, Y.; Su, J.; Li, L.; Gao, Y. Inkjet printing of conductive patterns and supercapacitors using a multi-walled carbon nanotube/Ag nanoparticle based ink. J. Mater. Chem. A 2015, 3, 2407–2413. [Google Scholar] [CrossRef]

- Yang, H.; Leow, W.R.; Wang, T.; Wang, J.; Yu, J.; He, K.; Qi, D.; Wan, C.; Chen, X. 3D printed photoresponsive devices based on shape memory composites. Adv. Mater. 2017, 29, 1701627. [Google Scholar] [CrossRef]

- Ota, H.; Emaminejad, S.; Gao, Y.; Zhao, A.; Wu, E.; Challa, S.; Chen, K.; Fahad, H.M.; Jha, A.K.; Kiriya, D.; et al. Application of 3D printing for smart objects with embedded electronic sensors and systems. Adv. Mater. Technol. 2016, 1, 1600013. [Google Scholar] [CrossRef] [Green Version]

- Yang, H.; Qi, D.; Liu, Z.; Chandran, B.K.; Wang, T.; Yu, J.; Chen, X. Soft thermal sensor with mechanical adaptability. Adv. Mater. 2016, 28, 9175–9181. [Google Scholar] [CrossRef] [PubMed]

- Chun, S.; Hong, A.; Choi, Y.; Ha, C.; Park, W. A tactile sensor using a conductive graphene-sponge composite. Nanoscale 2016, 8, 9185–9192. [Google Scholar] [CrossRef]

- Persano, L.; Dagdeviren, C.; Su, Y.; Zhang, Y.; Girardo, S.; Pisignano, D.; Huang, Y.; Rogers, J.A. High performance piezoelectric devices based on aligned arrays of nanofibers of Poly(Vinylidenefluoride-Co-Trifluoroethylene). Nat. Commun. 2013, 4, 1633. [Google Scholar] [CrossRef]

- Vatani, M.; Lu, Y.; Engeberg, E.D.; Choi, J.W. Combined 3D printing technologies and material for fabrication of tactile sensors. Int. J. Precis. Eng. Manuf. 2015, 16, 1375–1383. [Google Scholar] [CrossRef]

- Agarwala, S.; Goh, G.L.; Yap, Y.L.; Goh, G.D.; Yu, H.; Yeong, W.Y.; Tran, T. Development of bendable strain sensor with embedded microchannels using 3D printing. Sens. Actuators A Phys. 2017, 263, 593–599. [Google Scholar] [CrossRef]

- Ambrosi, A.; Moo, J.G.S.; Pumera, M. Helical 3D-printed metal electrodes as custom-shaped 3D platform for electrochemical devices. Adv. Funct. Mater. 2016, 26, 698–703. [Google Scholar] [CrossRef]

- Bai, S.; Sun, C.; Yan, H.; Sun, X.; Zhang, H.; Luo, L.; Lei, X.; Wan, P.; Chen, X. Healable, transparent, roomerature electronic sensors based on carbon nanotube network-coated polyelectrolyte multilayers. Small 2015, 11, 5807–5813. [Google Scholar] [CrossRef]

- Zhang, K.; Song, C.; Wang, Z.; Gao, C.; Wu, Y.; Liu, Y. A stretchable and self-healable organosilicon conductive nanocomposite for a reliable and sensitive strain sensor. J. Mater. Chem. C 2020, 8, 17277–17288. [Google Scholar] [CrossRef]

- Dhasmana, A.; Singh, S.; Kadian, S.; Singh, L. Skin tissue engineering: Principles and advances. J. Dermatol. Skin Care 2018, 1, 101. [Google Scholar]

- Peng, W.; Han, L.; Huang, H.; Xuan, X.; Pan, G.; Wan, L.; Lu, T.; Xu, M.; Pan, L. A direction-aware and ultrafast self-healing dual network hydrogel for a flexible electronic skin strain sensor. J. Mater. Chem. A 2020, 8, 26109–26118. [Google Scholar] [CrossRef]

- Fan, L.; Xie, J.; Zheng, Y.; Wei, D.; Yao, D.; Zhang, J.; Zhang, T. Antibacterial, self-adhesive, recyclable, and tough conductive composite hydrogels for ultrasensitive strain sensing. ACS Appl. Mater. Interfaces 2020, 12, 22225–22236. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Zhu, B.; Yin, D.; Wei, J. Flexible self-healing nanocomposites for recoverable motion sensor. Nano Energy 2015, 17, 1–9. [Google Scholar] [CrossRef]

- Homes, C.C.; Vogt, T.; Shapiro, S.M.; Wakimoto, S.; Ramirez, A.P. Optical response of high-dielectric-constant perovskite-related oxide. Science 2001, 293, 673–676. [Google Scholar] [CrossRef] [Green Version]

- Tang, M.; Zheng, P.; Wang, K.; Qin, Y.; Jiang, Y.; Cheng, Y.; Li, Z.; Wu, L. Autonomous self-healing, self-adhesive, highly conductive composites based on a silver-filled polyborosiloxane/polydimethylsiloxane double-network elastomer. J. Mater. Chem. A 2019, 7, 27278–27288. [Google Scholar] [CrossRef]

- Heidarian, P.; Yousefi, H.; Kaynak, A.; Paulino, M.; Gharaie, S.; Varley, R.J.; Kouzani, A.Z. Dynamic nanohybrid-polysaccharide hydrogels for soft wearable strain sensing. Sensors 2021, 21, 3574. [Google Scholar] [CrossRef] [PubMed]

- Liu, B.; Han, L.; Pan, L.; Li, H.; Zhao, J.; Dong, Y.; Wang, X. Flexible multiscale pore hybrid self-powered sensor for heart sound detection. Sensors 2021, 21, 4508. [Google Scholar] [CrossRef] [PubMed]

- Xue, Y. A review on intelligent wearables: Uses and risks. Hum. Behav. Emerg. Technol. 2019, 1, 287–294. [Google Scholar] [CrossRef]

- Peake, J.M.; Kerr, G.; Sullivan, J.P. A critical review of consumer wearables, mobile applications, and equipment for providing biofeedback, monitoring stress, and sleep in physically active populations. Front. Physiol. 2018, 9, 743. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, H.; Han, W.; Lin, H.; Li, R.; Zhu, J.; Huang, W. 3D printed flexible strain sensors: From printing to devices and signals. Adv. Mater. 2021, 33, 2004782. [Google Scholar] [CrossRef]

- Smartwatch Market Size, Share & Industry Growth. Analysis—2027. Available online: https://www.alliedmarketresearch.com/smartwatch-market (accessed on 30 August 2021).

- Global Smart Watch Market Report (2021 to 2030)—COVID-19 Growth and Change—ResearchAndMarkets.com. Business Wire. Available online: https://www.businesswire.com/news/home/20210526005524/en/Global-Smart-Watch-Market-Report-2021-to-2030---COVID-19-Growth-and-Change—ResearchAndMarkets.com (accessed on 30 August 2021).

| Sensor Type | Materials | Potential Applications |

|---|---|---|

| Temperature | 1. PDMS and graphene nanowalls (GNWs) | Monitoring body temperature. [48] |

| 2. Cellulose and graphene oxide | Electronics. [49] | |

| 3. PDMS and graphene oxide | Electronic skin. [50] | |

| 4. Parylene and silver nanoparticles | Environmental sensing. [14] | |

| 5. Kapton and silver nanoparticles | Monitoring body temperature. [41] | |

| 6. PDMS, chromel and alumel | Microactuators. [33] | |

| 7. PEDOT:PSS and carbon nanoparticles | Skin temperature sensing. [36] | |

| 8. PEDOT:PSS, graphene oxide and silver | Robotics. [38] | |

| 9. Polypropylene and graphene | Clothing. [40] | |

| Pressure | 1. PDMS and graphene oxide | Electronic skin. [50] |

| 2. Cellulose and MXene | Wearables. [20] | |

| 3. Silicon and AlGaN/GaN | Wearables. [27] | |

| 4. Silicon nitride and graphene oxide | Wearables. [28] | |

| 5. Tissue paper, PDMS and Au nanorods | Wearables. [12] | |

| 6. Silicon and PDMS | Electronic skin. [29] | |

| 7. Airlaid Paper (AP) and Carbon Black | Healthcare/wearables. [47] | |

| 8. PEDOT:PSS and PDMS | Wearables. [51] | |

| 9. Silk and graphene | Clothing/skin sensing. [37] | |

| Humidity | 1. PDMS, ZnO and graphene oxide | Flexible electronics. [8] |

| 2. Parylene and silver nanoparticles | Environmental sensing. [14] | |

| 3. Fabric and graphene oxide | Respiration Monitoring. [15] | |

| 4. PET, Au nanoparticles and graphene oxide | Environmental sensing. [52] | |

| Chemical | 1. Sodium n-dodecyl sulfate and SWCNTs | Electrochemical sensing. [42] |

| 2. MoS2 and SWCNTs | NH3 and NO2 gas sensing. [13] | |

| 3. Kapton and Ag/Pt and WO3 nanowires | H2 gas sensing. [45] |

| Printing Method | Type of Sensor | Stability/Minimum Bending Cycles | Sensitivity (Smallest Detectable Quantity) |

|---|---|---|---|

| Coaxial extrusion. [73] | Inductive sensor | 500 bending/stretching cycles | 0.001–0.25 μH/mm |

| FDM. [74] | Inductor–capacitor-resonant tank circuitry for monitoring the quality of liquid food. | n/a | 4.3% resonance frequency shift |

| FDM. [75] | Capacitive and piezoresistive sensors | n/a | n/a |

| FDM. [77] | Multiaxial force sensor | 1 000 bending cycles | ~2.11 N/mm |

| FDM. [80] | Force sensor | 38 MPa Young’s modulus | n/a |

| FDM. [82] | Environmental monitoring | 30 °C Tg | 76 mW/cm2 |

| FDM. [83] | Wearable (programmable heater, temperature sensor and circuitry) | 0–80 °C | n/a |

| FDM. [85] | Tactile sensors | 5 Pa–100 Kpa | n/a |

| FDM. [84] | Wearable (temperature sensor) | ~0.225 kΩ/°C | |

| DIW. [78] | Strain sensors | 1–30% stain | |

| DIW. [79] | Strain sensor | Strain at break of 180% | |

| Inkjet printing. [81] | Supercapacitors | 3 000 bending cycles | 300Ω/sq sheet resistance, power density 96 mW/cm3 |

| Inkjet printing. [41] | Temperature sensor | 20–60 °C | 2.23 × 10−3/°C |

| Stereolithography. [59] | Temperature sensor | ~27–~39 °C | >98% strain fixity rate, >93% strain recovery rate |

| Photopolymerisation. [88] | Piezoresistive sensor | 5.5 MPa Young’s modulus, elongation at break of 18.3% | n/a |

| SLM. [89] | pH sensing | n/a | n/a |

| Directprint/cure (DPC) and projection-based stereolithography. [87] | Piezoresistive tactile sensor | n/a | n/a |

| 3D Printing Technique | General Advantages | General Disadvantages |

|---|---|---|

| FDM/FFF |

|

|

| Inkjet printing |

|

|

| Stereolithography (SLA) |

|

|

| Aerosol jetting |

|

|

| Direct ink writing (DIW) |

|

|

| Type of Sensor | Materials | Recovery Time | Recovery Temperature/Mechanism |

|---|---|---|---|

| Capacitive sensor. [95] | CaCu3Ti4O12 and SWCNTs | 30 min | Heating at 150 °C |

| Ammonia gas sensor. [90] | Polyethylenimine (bPEI), polyacrylic acid (PAA), polyethylene terephthalate (PET) and MWCNTs | 30 min | Exposure to DI water |

| Temperature sensor. [84] | Fatty polybasic/diethylenediamine-based oligomers and SWCNTs | 45 min | Heating at room temperature |

| Human–machine interaction/soft robots. [91] | PDMS and silver nanoparticles | ~24 h | Heating at room temperature |

| Human motion detection/electronic skin. [93] | Polyurethane, epoxidized natural rubber and CNTs | 0.06 s | Heating at room temperature |

| Finger motion sensor. [95] | CaCu3Ti4O12 and SWCNTs | 30 min | Heating at 150 °C |

| Pressure sensor. [97] | PBS/ PDMS and silver microflakes | 6 h | Heating at room temperature |

| Wearable strain sensors. [98] | Nano-chitin, ferric ions, tannic acid and starch/polyvinyl alcohol/polyacrylic acid (St/PVA/PAA) hydrogel | ~60 min | Heating at room temperature |

| Type of Sensor | Sensitivity (Smallest Detectable Quantity) | Stability/Minimum Bending Cycles | Mean Response Time |

|---|---|---|---|

| Pressure sensor. [12] | >1.14/ kPa | 50,000 bending cycles | 17 ms |

| Respiration monitoring. [15] | 44% relative humidity | 20 bending cycles | 8.9 s |

| Capacitance pressure sensor. [27] | 0.86 pF/bar | n/a | n/a |

| Piezoresistive pressure sensor. [28] | 8.5 mV/bar | 22 bending cycles | 15 s |

| Pressure sensors. [29] | 0.02-0.55 /kPa | n/a | 1 ms–10 s |

| Temperature sensors. [36] | 0.4 mV°/C | 600 h | n/a |

| Temperature sensor. [41] | 2.23 × 10−3/°C | −269 and 400 °C | n/a |

| Pressure sensors. [47] | 1.80/kPa | 3000 bending cycles | 200 ms |

| Temperature sensor. [48] | 0.214 Ω°/C | 35 to 45 °C | 1.6 s |

| Pressure sensor. [50] | 0.7 kPa−1 (up to 25kPa) | 100,000 bending cycles | 50 ms |

| Temperature sensor. [50] | 0.83%/K | 22–70 °C | 100 ms |

| Piezoelectric-heartrate monitor with self-powering. [99] | 3312 pC/N | 2500 bending cycles | n/a |

| Strain sensing with self-healing. [98] | n/a | 1503% stretchability, 184.1 kPa strength | 60 min (healing time) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nyabadza, A.; Vázquez, M.; Coyle, S.; Fitzpatrick, B.; Brabazon, D. Review of Materials and Fabrication Methods for Flexible Nano and Micro-Scale Physical and Chemical Property Sensors. Appl. Sci. 2021, 11, 8563. https://doi.org/10.3390/app11188563

Nyabadza A, Vázquez M, Coyle S, Fitzpatrick B, Brabazon D. Review of Materials and Fabrication Methods for Flexible Nano and Micro-Scale Physical and Chemical Property Sensors. Applied Sciences. 2021; 11(18):8563. https://doi.org/10.3390/app11188563

Chicago/Turabian StyleNyabadza, Anesu, Mercedes Vázquez, Shirley Coyle, Brian Fitzpatrick, and Dermot Brabazon. 2021. "Review of Materials and Fabrication Methods for Flexible Nano and Micro-Scale Physical and Chemical Property Sensors" Applied Sciences 11, no. 18: 8563. https://doi.org/10.3390/app11188563

APA StyleNyabadza, A., Vázquez, M., Coyle, S., Fitzpatrick, B., & Brabazon, D. (2021). Review of Materials and Fabrication Methods for Flexible Nano and Micro-Scale Physical and Chemical Property Sensors. Applied Sciences, 11(18), 8563. https://doi.org/10.3390/app11188563