Physical Alteration and Color Change of Granite Subjected to High Temperature

Abstract

1. Introduction

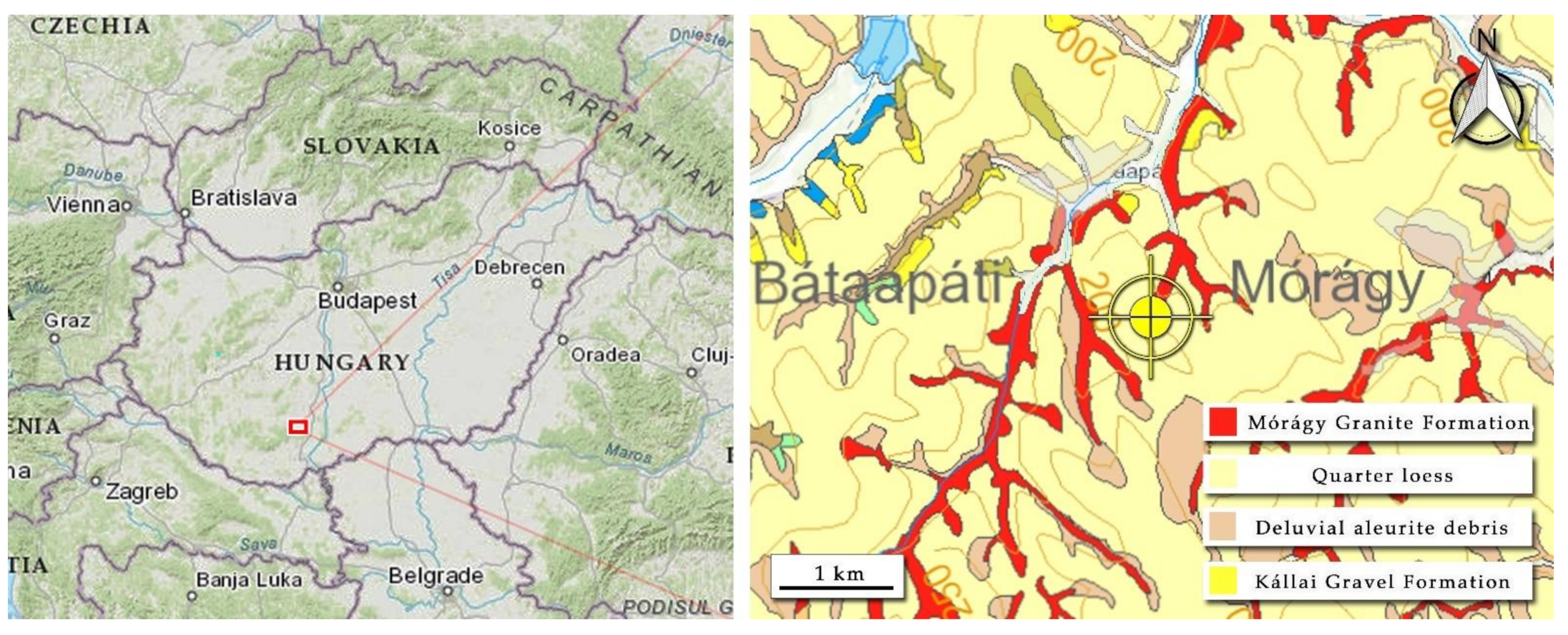

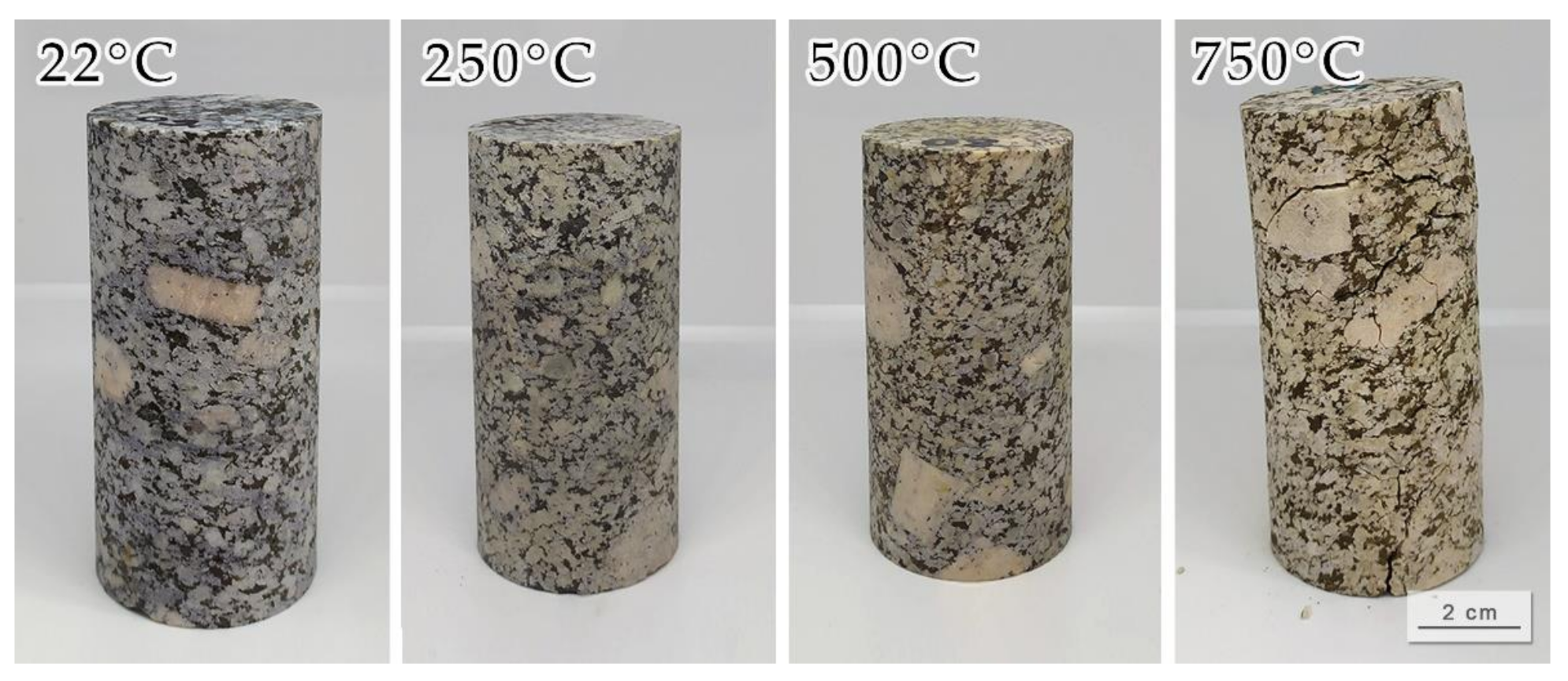

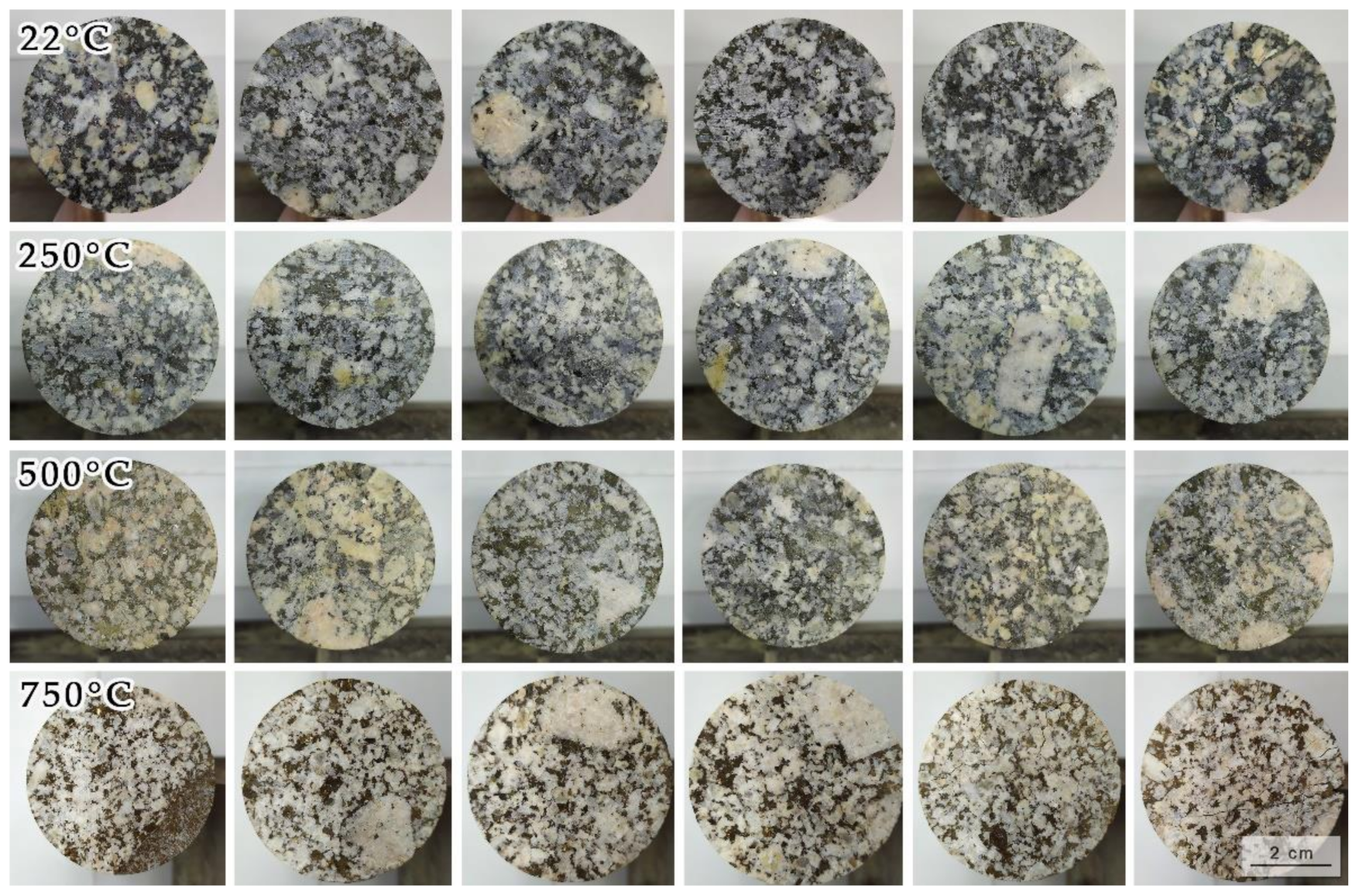

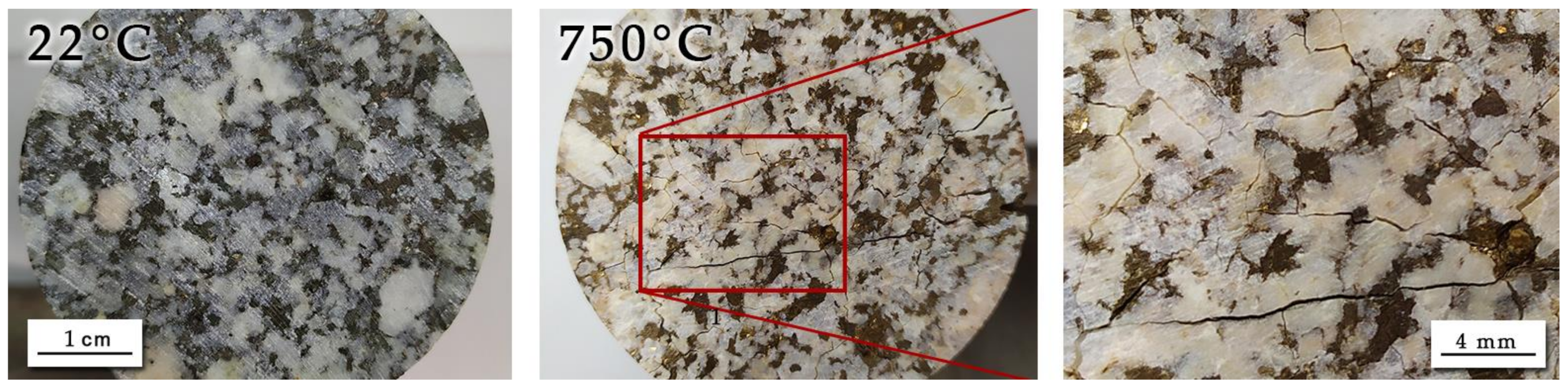

2. Materials and Methods

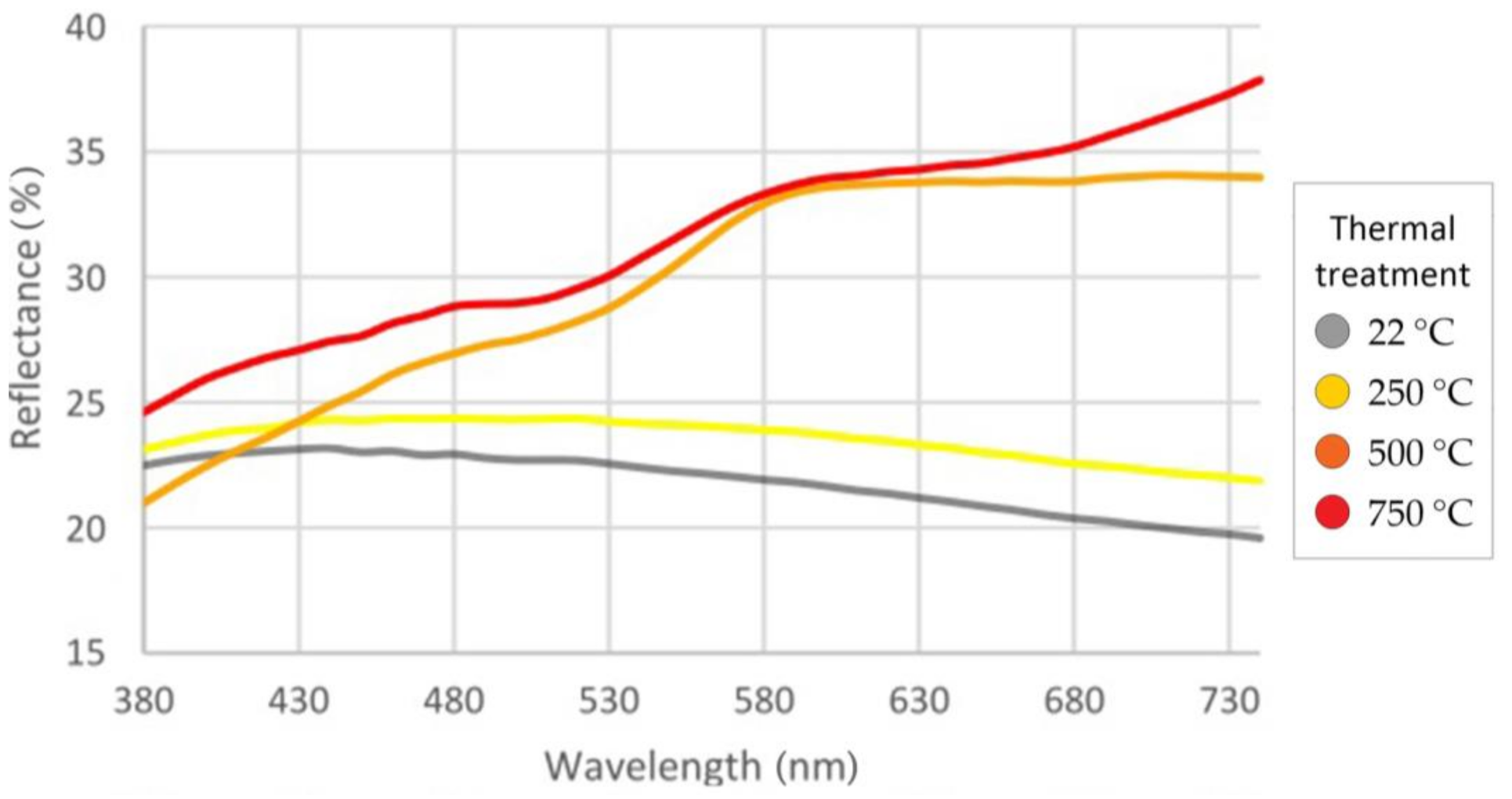

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Neumann, P.A. The geological disposal of nuclear waste. J. Environ. Radioact. 1988, 6, 92–94. [Google Scholar] [CrossRef][Green Version]

- Freiesleben, H. Final disposal of radioactive waste. In Proceedings of the EPJ Web Conference, Varenna, Italy, 30 July–4 August 2012; Volume 54, p. 1006. [Google Scholar] [CrossRef]

- Chapman, N.; Hooper, A. The Disposal of Radioactive Wastes Underground. In Proceedings of the Geologists’ Association 2012. Volume 123, pp. 46–63. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0016787811000940 (accessed on 17 September 2021). [CrossRef]

- Geological Society of London. Geological Disposal of Radioactive Waste. A Policy Briefing Note from the Geological Society of London. The Briefing Note. 2020. Available online: https://www.geolsoc.org.uk/~/media/shared/documents/policy/briefing%20notes/geological%20disposal%20radioactive%20waste%20policy%20briefing%20note.pdf?la=en (accessed on 15 September 2021).

- Istovics, K.; Tóth, M.T. Fracture network modeling around the Radioactive Waste Repository in Bátaapáti, based on BN2-1 pre-boring. In Mérnökgeológia-Kőzetmechanika; Török, Á., Görög, P., Vásárhelyi, B., Eds.; Hantken Kiadó: Budapest, Hungary, 2016; pp. 119–128. [Google Scholar]

- Balla, Z.; Gyalog, L.A. Mórágyi-Rög Eszakkeleti Részének Földtana. Magyarázó a Mórágyi-rög ÉK-i Részének Földtani TérképsoRozatához (1:10 000); (in Hungarian, translated title: Geology of the north-eastern part of the Mórágy Block: Explanatory notes to the geological map-series of the north-eastern part of the Mórágy Block (1:10 000)); Magyar Állami Földtani Intézet: Budapest, Hungary, 2009; Volume 15–17, pp. 58–69. [Google Scholar]

- Martinho, E.; Dionisio, A. Assessment Techniques for Studying the Effects of Fire on Stone Materials: A Literature Review. Int. J. Archit. Herit. 2020, 14, 275–299. [Google Scholar] [CrossRef]

- Ozguven, A.; Ozcelik, Y. Effects of high temperature on physico-mechanical properties of Turkish natural building stones. Eng. Geol. 2014, 183, 127–136. [Google Scholar] [CrossRef]

- Brotóns, V.; Tomás, R.; Ivorra, S.; Alarcón, J.C. Temperature influence on the physical and mechanical properties of a porous rock: San Julian’s calcarenite. Eng. Geol. 2013, 167, 117–127. [Google Scholar] [CrossRef]

- Tian, H.; Kempka, T.; Yu, S.; Ziegler, M. Mechanical Properties of Sandstones Exposed to High Temperature. Rock Mech. Rock Eng. 2016, 49, 321–327. [Google Scholar] [CrossRef]

- Sirdesai, N.N.; Singh, T.N.; Pathegama Gamage, R. Thermal alterations in the poro-mechanical characteristic of an Indian sandstone—A comparative study. Eng. Geol. 2017, 226, 208–220. [Google Scholar] [CrossRef]

- Li, Y.; Zhai, Y.; Wang, C.; Meng, F.; Lu, M. Mechanical properties of Beishan granite under complex dynamic loads after thermal treatment. Eng. Geol. 2020, 267, 105481. [Google Scholar] [CrossRef]

- Heuze, F.E. High-temperature mechanical, physical and Thermal properties of granitic rocks—A review. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1983, 20, 3–10. [Google Scholar] [CrossRef]

- Fan, L.F.; Wu, Z.J.; Wan, Z.; Gao, J.W. Experimental investigation of thermal effects on dynamic behavior of granite. Appl. Therm. Eng. 2017, 125, 94–103. [Google Scholar] [CrossRef]

- Siegesmund, S.; Sousa, L.; Knell, C. Thermal expansion of granitoids. Environ. Earth Sci. 2018, 77. [Google Scholar] [CrossRef]

- Shang, X.; Zhang, Z.; Xu, X.; Liu, T.; Xing, Y. Mineral Composition, Pore Structure, and Mechanical Characteristics of Pyroxene Granite Exposed to Heat Treatments. Minerals 2019, 9, 553. [Google Scholar] [CrossRef]

- Martínez-Ibáñez, V.; Garrido, M.E.; Hidalgo Signes, C.; Tomás, R. Micro and macro-structural effects of high temperatures in Prada limestone: Key factors for future fire-intervention protocols in Tres Ponts Tunnel (Spain). Constr. Build. Mater. 2021, 286, 122960. [Google Scholar] [CrossRef]

- Martínez-Ibáñez, V.; Garrido, M.E.; Hidalgo Signes, C.; Basco, A.; Miranda, T.; Tomás, R. Thermal Effects on the Drilling Performance of a Limestone: Relationships with Physical and Mechanical Properties. Appl. Sci. 2021, 11, 3286. [Google Scholar] [CrossRef]

- Martínez-Ibáñez, V.; Benavente, D.; Hidalgo, S.C.; Tomás, R.; Garrido, M.E. Temperature-Induced Explosive Behaviour and Thermo-Chemical Damage on Pyrite-Bearing Limestones: Causes and Mechanisms. Rock Mech. Rock Eng. 2021, 54, 219–234. [Google Scholar] [CrossRef]

- Isaka, B.; Gamage, R.; Rathnaweera, T.; Perera, M.; Chandrasekharam, D.; Kumari, W. An Influence of Thermally-Induced Micro-Cracking under Cooling Treatments: Mechanical Characteristics of Australian Granite. Energies 2018, 11, 1338. [Google Scholar] [CrossRef]

- Gomez-Heras, M.; Bernard, J.S.; Fort, R. Influence of surface heterogeneities of building granite on its thermal response and its potential for the generation of thermoclasty. Environ. Geol. 2008, 56, 547–560. [Google Scholar] [CrossRef]

- Shao, S.; Wasantha, P.L.P.P.G.; Chen, R.B.K. Effect of cooling rate on the mechanical behavior of heated Strathbogie granite with different grain sizes. Int. J. Rock Mech. Min. Sci. 2014, 70, 381–387. [Google Scholar] [CrossRef]

- Freire-Lista, D.; Gomez-Villalba, L.; Fort, R. Microcracking of granite feldspar during thermal artificial processes. Period. Mineral. 2015, 84, 519–537. [Google Scholar] [CrossRef]

- Freire-Lista, D.M.; Fort, R.; Varas-Muriel, M.J. Thermal stress-induced microcracking in building granite. Eng. Geol. 2016, 206, 83–93. [Google Scholar] [CrossRef]

- Vázquez, P.; Shushakova, V.; Gómez-Heras, M. Influence of mineralogy on granite decay induced by temperature increase: Experimental observations and stress simulation. Eng. Geol. 2015, 189, 58–67. [Google Scholar] [CrossRef]

- Přikryl, R. Some microstructural aspects of strength variation in rocks. Int. J. Rock Mech. Min. Sci. 2001, 38, 671–682. [Google Scholar] [CrossRef]

- Forestieri, G.; Freire-Lista, D.; Francesco, A.; Fort, R.; Ponte, M. Strength anisotropy in building granites. Int. J. Archit. Herit. 2017. [Google Scholar] [CrossRef]

- NEA. Interim Report on Fire Risk Management. Radioactive Waste Management, NEA/RWM/R(2015)6. Nuclear Energy Agency. 2015, p. 32. Available online: https://www.oecd-nea.org/jcms/pl_55414/interim-report-on-fire-risk-management?details=true (accessed on 15 September 2021).

- MBFSZ Mining and Geological Survey of Hungary. Geological Base Sections of Hungary on the 1:100.000 Scale Surface Geology Base Map of Hungary. Mining and Geological Survey of Hungary: Budapest, Hungary. 2021. Available online: https://map.mbfsz.gov.hu/fdt_alapszelvenyek/ (accessed on 15 September 2021).

- Maros Gy Borsody, J.; Füri, J.; Koroknai, B.; Palotás, K.; Rálischné, F.E. A Mórágyi-rög ÉK-i Részének Szerkezetföldtani Ertékelése a Töréses Szerkezetekre; Magyar Állami Földtani Intézet: Budapest, Hungary, 2011; [Structural Geological Evaluation of the North-Eastern Part of the Mórágyi Block for Fractured Structures]; Magyar Állami Földtani Intézet: Budapest, Hungary, 2009; pp. 338–359. (In Hungarian) [Google Scholar]

- Peregi, Z.; Gulácsi, Z. Mórágyi Gránit Formáció, alsó-karbon. (in Hungarian, translated title: Mórágy Granite Formation, Lower Carboniferous). In Geology of the North-Eastern Part of the Mórágy Block: Explanatory Notes to the Geological Map-Series of the North-Eastern Part of the Mórágy Block (1:10 000); Balla, Z., Gyalog, L., Eds.; Magyar Állami Földtani Intézet: Budapest, Hungary, 2009; Chapter 3.1.1.3; pp. 338–359. [Google Scholar]

- Király, E.; Gulácsi, Z. Mórágyi Gránit Formáció, alsó-karbon (in Hungarian, translated title: Mórágy Granite Formation, Lower Carboniferous). In Geology of the North-Eastern Part of the Mórágy Block: Explanatory Notes to the Geological Map-Series of the North-Eastern Part of the Mórágy Block (1:10 000); Balla, Z., Gyalog, L., Eds.; Magyar Állami Földtani Intézet: Budapest, Hungary, 2009; Chapter 3.1.1.3; pp. 386–445, In Hungarian: A Mórágyi-rög északkeleti részének földtana. Magyarázó a Mórágyi-rög ÉK-i részének földtani térképsorozatához (1:10 000). [Google Scholar]

- Gulácsi, Z.; Király, E. Alsó-karbon, Mórágyi Gránit Formáció. In Geology of the North-Eastern Part of the Mórágy Block: Explanatory Notes to the Geological Map-Series of the North-Eastern Part of the Mórágy Block (1:10 000); Balla, Z., Gyalog, L., Eds.; Magyar Állami Földtani Intézet: Budapest, Hungary, 2009; Volume 15–17, 58–68, In Hungarian: A Mórágyi-rög északkeleti részének földtana. Magyarázó a Mórágyi-rög ÉK-i részének földtani térképsorozatához (1:10 000). [Google Scholar]

- Szebényi, G.; Török, P.; András, E.; Szamos, I.; Gyalog, L.; Borsody, J.; Füri, J.; Gulácsi, Z.; Maros, G.; Deák, F.; et al. Az NRHT I-K1 és I-K2 Tárolókamra Kivitelezés Vágatdokumentációs Zelentése; (in Hungarian, translatated title: Section documentation report for the NRHT I-K1 and I-K2 storage chamber construction). Mecsekérc Zrt., RHK Kft. Irattár, RHK-K-075/11; RHK Kft.: Budaörs, Hungary, 2011; pp. 109–162. [Google Scholar]

- Annerel, E.; Taerwe, L. Methods to quantify the color development of concrete exposed to fire. Constr. Build. Mater. 2011, 25, 3989–3997. [Google Scholar] [CrossRef]

- Short, N.R.; Purkiss, J.A.; Guise, S.E. Assessment of fire damaged concrete using color image analysis. Constr. Build. Mater. 2001, 15, 9–15. [Google Scholar] [CrossRef]

- MacAdam, D.L. Color-Matching Functions. In Color. Measurement, Springer Series in Optical Sciences; Springer: Berlin/Heidelberg, Germany, 1981; Volume 27. [Google Scholar] [CrossRef]

- Hunt, R.W. Measuring Color, 3rd ed.; Fountain Press: Kingston-upon-Thames, UK, 1998; Volume 493, pp. 33–38. [Google Scholar]

- Carter, E.C.; Ohno, Y.; Pointer, M.R.; Robertson, A.R.; Seve, R.; Schanda, J.D.; Witt, K. CIE 15: Technical Report: Colorimetry, 3rd ed.; International Commission on Illumination: Vienna, Austria, 2004. [Google Scholar]

- Wyszecki, G.; Stiles, W.S. Color Science: Concepts and Methods, Quantitative Data and Formulae; Wiley-Interscience: Hoboken, NJ, USA, 2000. [Google Scholar] [CrossRef]

- ISO 11664-4:2008(E)/CIE S 014-4/E:2007. Superseded by CIE Colorimetry-Part 4: 1976 L*a*b* Color Space, 2nd ed.; CIE Central Bureau: Vienna, Austria, 2007. [Google Scholar]

- Schwiegerling, J. Field Guide to Visual and Ophthalmic Optics, Volume: FG04; SPIE Press: Bellingham, WA, USA, 2004; Volume 124. [Google Scholar] [CrossRef]

- EN 1936:2006. Natural Stone Test Methods. Determination of Real Density and Apparent Density, and of Total and Open Porosity. Available online: https://cdn.standards.iteh.ai/samples/25272/d65343542525484cbe5d0f3c0e776345/SIST-EN-1936-2007.pdf (accessed on 20 September 2021).

- EN 14579:2005-01-17. Natural Stone Test Methods-Determination of Sound Speed Propagation. Available online: https://cdn.standards.iteh.ai/samples/11489/020e8caa1e6b4acaba88f15af259ef55/SIST-EN-14579-2004.pdf (accessed on 20 September 2021).

- Török, Á. Surface strength and mineralogy of weathering crusts on limestone buildings in Budapest. Build. Environ. 2003, 38, 1185–1192. [Google Scholar] [CrossRef]

- Török, Á. In Situ Methods of Testing Stone Monuments and the Application of Nondestructive Physical Properties Testing in Masonry Diagnosis. In Materials, Technologies and Practice in Historic Heritage Structures; Dan, M.B., Přikryl, R., Török, Á., Eds.; Springer: Dordrecht, The Netherlands, 2010. [Google Scholar] [CrossRef]

- Török, Á. Non-destructive Surface Strength Test—Duroskop a Forgotten Tool; Comparison to Schmidt Hammer Rebound Values of Rocks. In Proceedings of the IAEG/AEG Annual Meeting, San Francisco, CA, USA, 17–21 September 2018; Volume 6, pp. 129–135. [Google Scholar] [CrossRef]

- Beck, K.; Janvier-Badosa, S.; Brunetaud, X.; Török, Á.; Al-Mukhtar, M. Non-destructive diagnosis by colorimetry of building stone subjected to high temperatures. Eur. J. Environ. Civ. Eng. 2016, 20, 643–655. [Google Scholar] [CrossRef]

- Hager, I. Color Change in Heated Concrete. Fire Technol. 2014, 50, 945–958. [Google Scholar] [CrossRef]

- Ozguven, A.; Ozcelik, Y. Investigation of some property changes of natural building stones exposed to fire and high heat. Constr. Build. Mater. 2013, 38, 813–821. [Google Scholar] [CrossRef]

- Gomez-Heras, M.; Figueiredo, C.; Varas-Muriel, M.; Maurício, A.; Alvarez de Buergo, M.; Aires-Barros, L.; Fort, R. Digital Image Analysis Contribution to the Evaluation of the Mechanical Decay of Granitic Stones Affected by Fire. In Fracture Failure of Natural Buildings Stones; Kourkoulis, S.K., Ed.; Springer: Dordrecht, The Netherlands, 2006. [Google Scholar] [CrossRef]

- Chakrabarti, B.; Yates, T.; Lewry, A. Effect of fire damage on natural stonework in buildings. Constr. Build. Mater. 1996, 10, 539–544. [Google Scholar] [CrossRef]

- Yang, S.; Ranjith, P.; Jing, H.; Tian, W.; Ju, Y. An experimental investigation on thermal damage and failure mechanical behavior of granite after exposure to different high-temperature treatments. Geothermics 2017, 65, 180–197. [Google Scholar] [CrossRef]

- Zhu, Z.; Ranjith, P.G.; Tian, H.; Jiang, G.; Dou, B.; Mei, G. Relationships between P-wave velocity and mechanical properties of granite after exposure to different cyclic heating and water-cooling treatments. Renew. Energy 2021, 168, 375–392. [Google Scholar] [CrossRef]

- Török, A.; Török, Á. The effect of temperature on the strength of two different granites. Cent. Eur. Geol. 2015, 58, 356–369. [Google Scholar] [CrossRef]

- Liu, S.; Xu, J. An experimental study on the physico-mechanical properties of two post-high-temperature rocks. Eng. Geol. 2015, 185, 63–70. [Google Scholar] [CrossRef]

- Jin, P.; Hu, Y.; Shao, J.; Zhao, G.; Zhu, X.; Li, C. Influence of different thermal cycling treatments on the physical, mechanical and transport properties of granite. Geothermics 2019, 78, 118–128. [Google Scholar] [CrossRef]

- Wang, F.; Frühwirt, T.; Konietzky, H. Influence of repeated heating on physical-mechanical properties and damage evolution of granite. Int. J. Rock Mech. Min. Sci. 2020, 136, 104514. [Google Scholar] [CrossRef]

- Németh, A.; Török, Á. Thermal shock-induced physical changes of granitic rocks of a radioactive waste disposal site. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Mechanics and Rock Engineering, from Theory to Practice, Turin, Italy, 20–25 September 2021; Volume 833, p. 12035. [Google Scholar] [CrossRef]

- Németh, A.; Török, Á. Heat-related Changes of Density, P-wave Velocity, and Surface Hardness of Granite. Period. Polytech. Civ. Eng. 2021, 7. [Google Scholar] [CrossRef]

| Group | Bulk Density | P-Wave Vel. (PUNDIT) | P-Wave Vel. (GEOTRON) | S-Wave Vel. (GEOTRON) | Duroskop Value | Color Index |

|---|---|---|---|---|---|---|

| [EN 1936:2007] | [EN 14579:2005] | [-] | [-] | |||

| 22 °C | 6 | 72 | 36 | 36 | 72 | 20 |

| 250 °C | 12 | 144 | 36 | 36 | 143 | 20 |

| 500 °C | 12 | 78 | 36 | 36 | 144 | 20 |

| 750 °C | 12 | 144 | 0 | 0 | 144 | 20 |

| ∑ | 42 | 438 | 108 | 108 | 503 | 80 |

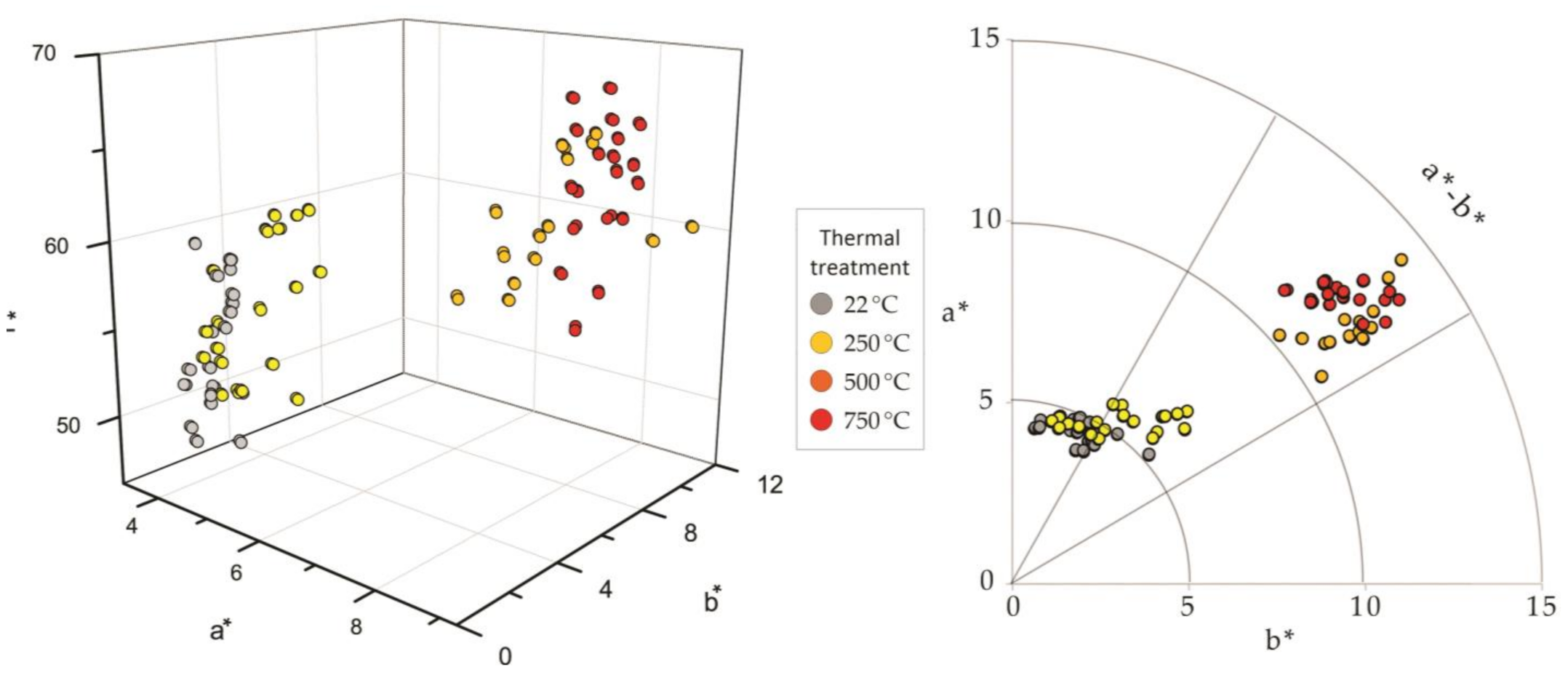

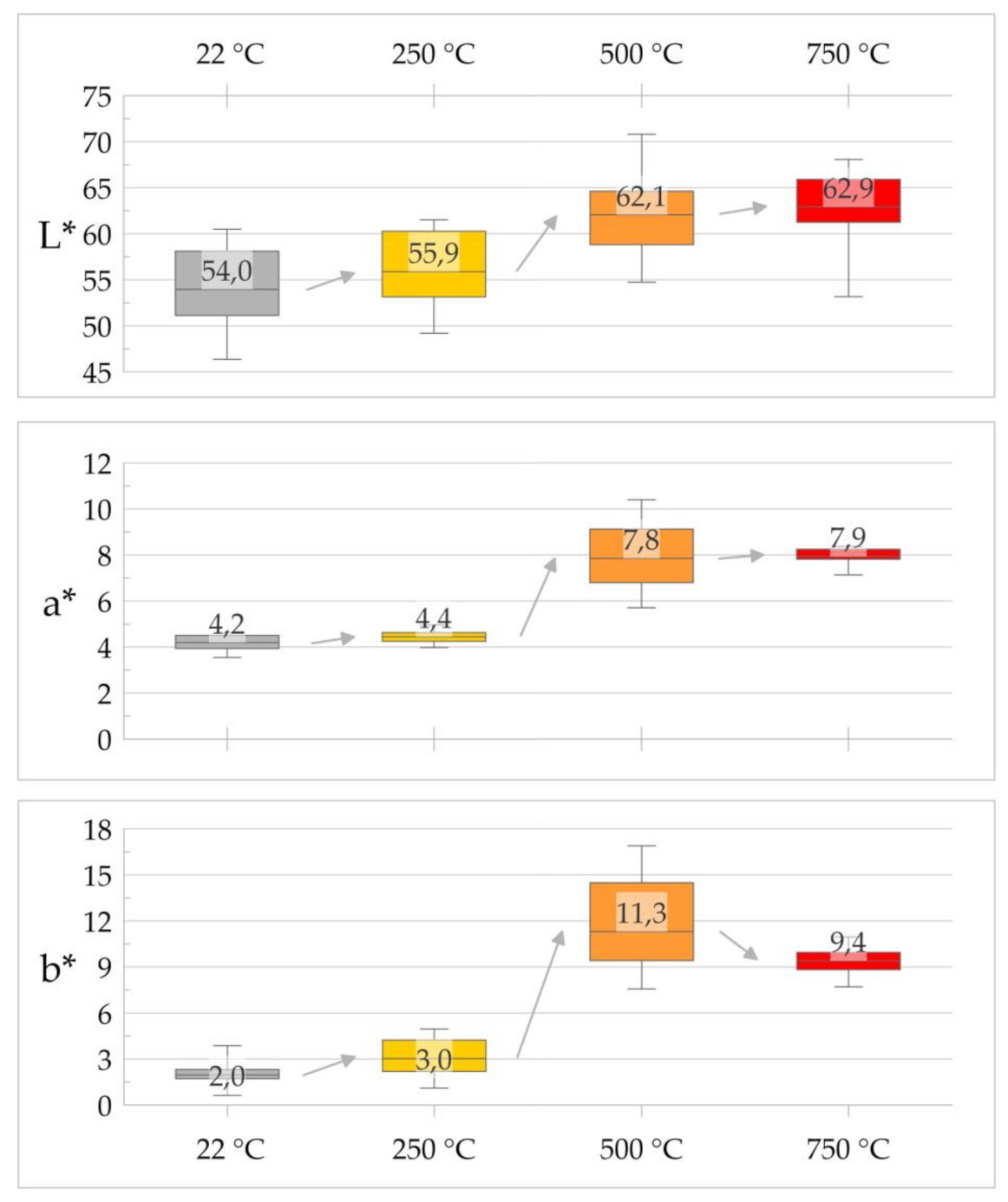

| Thermal Treatment Group | L* | a* | b* |

|---|---|---|---|

| (Std) | (Std) | (Std) | |

| 22 °C | 53.96 (4.10) | 4.19 (0.32) | 1.96 (0.74) |

| 250 °C | 55.88 (3.93) | 4.45 (0.27) | 3.03 (1.23) |

| 500 °C | 62.05 (4.60) | 7.85 (1.36) | 11.30 (2.94) |

| 750 °C | 62.92 (3.82) | 7.94 (0.33) | 9.40 (0.86) |

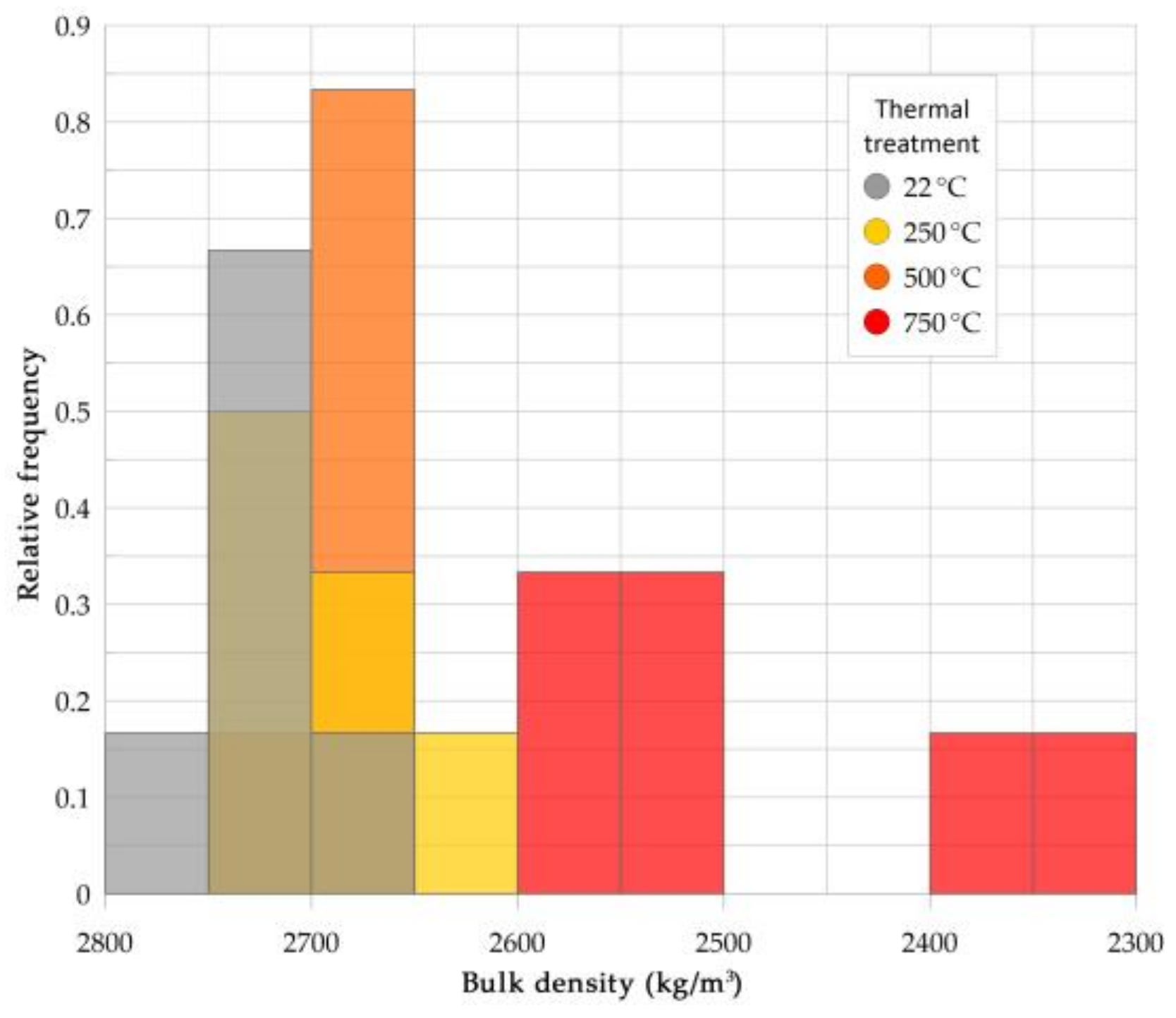

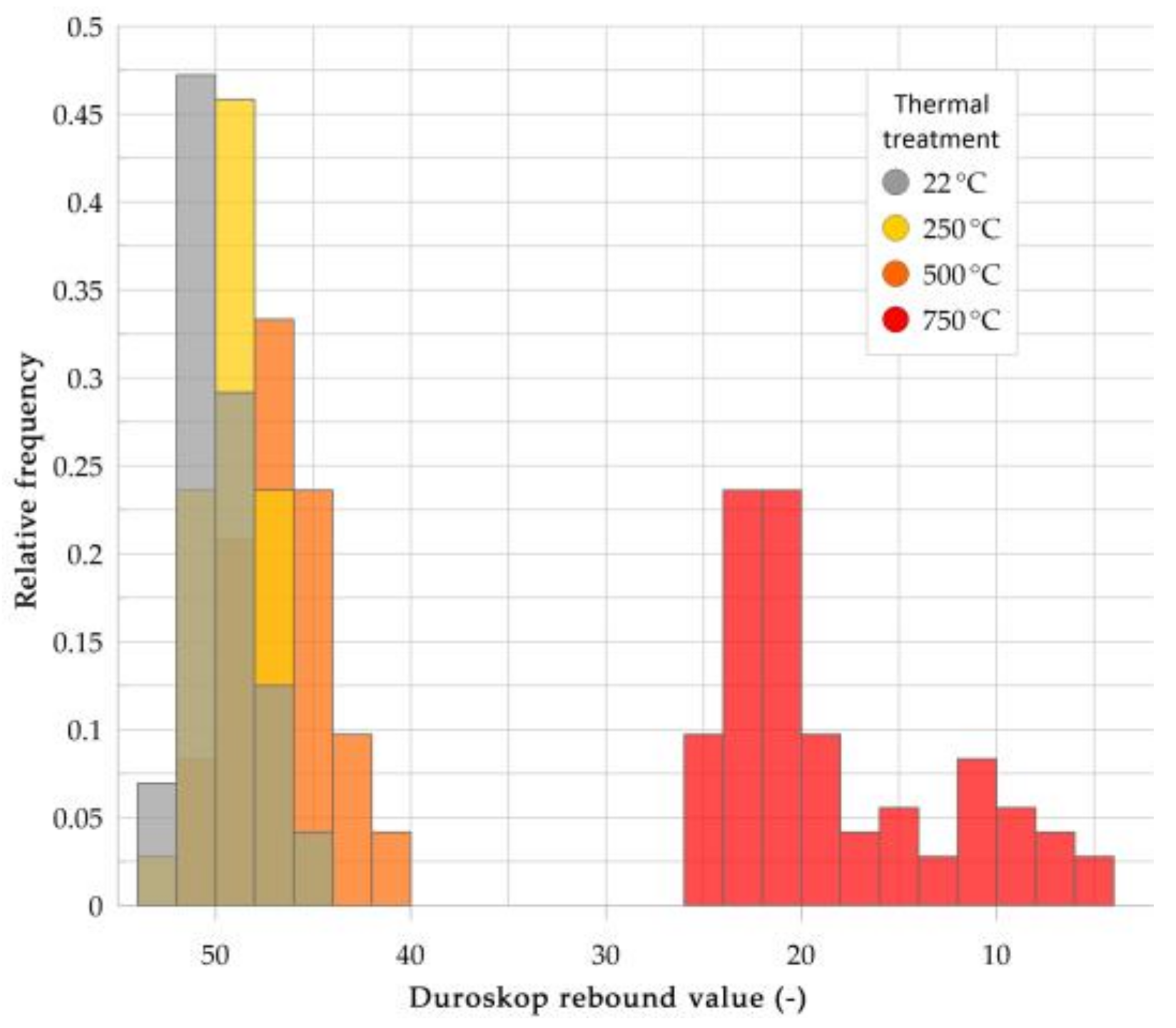

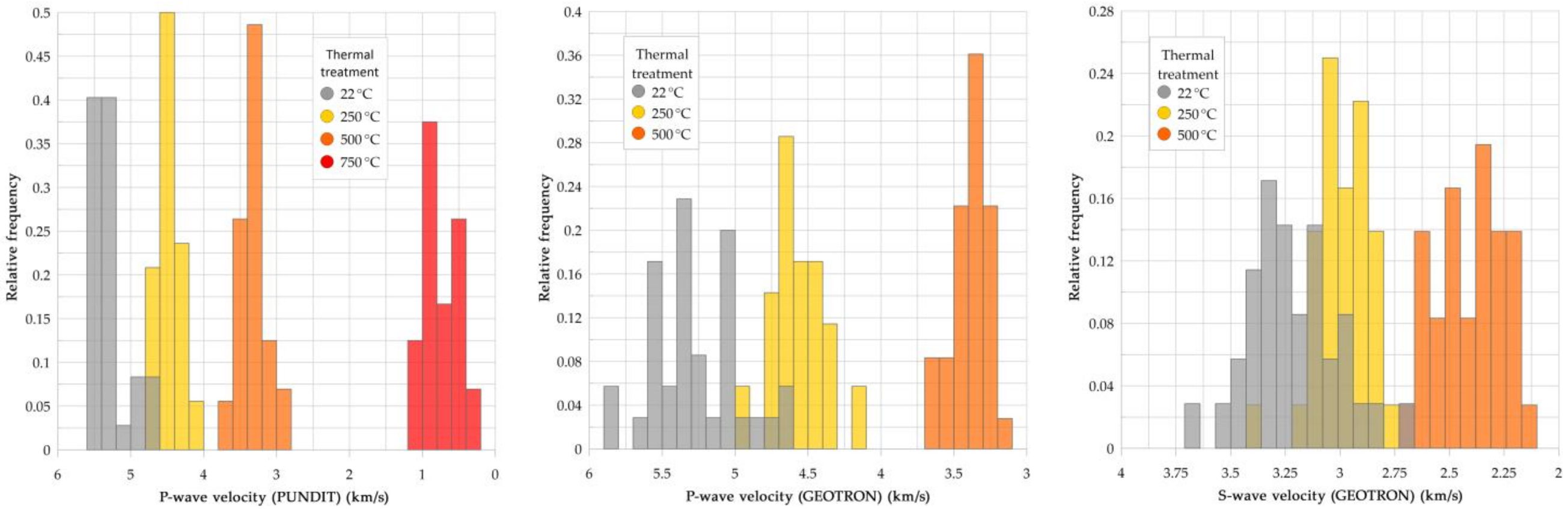

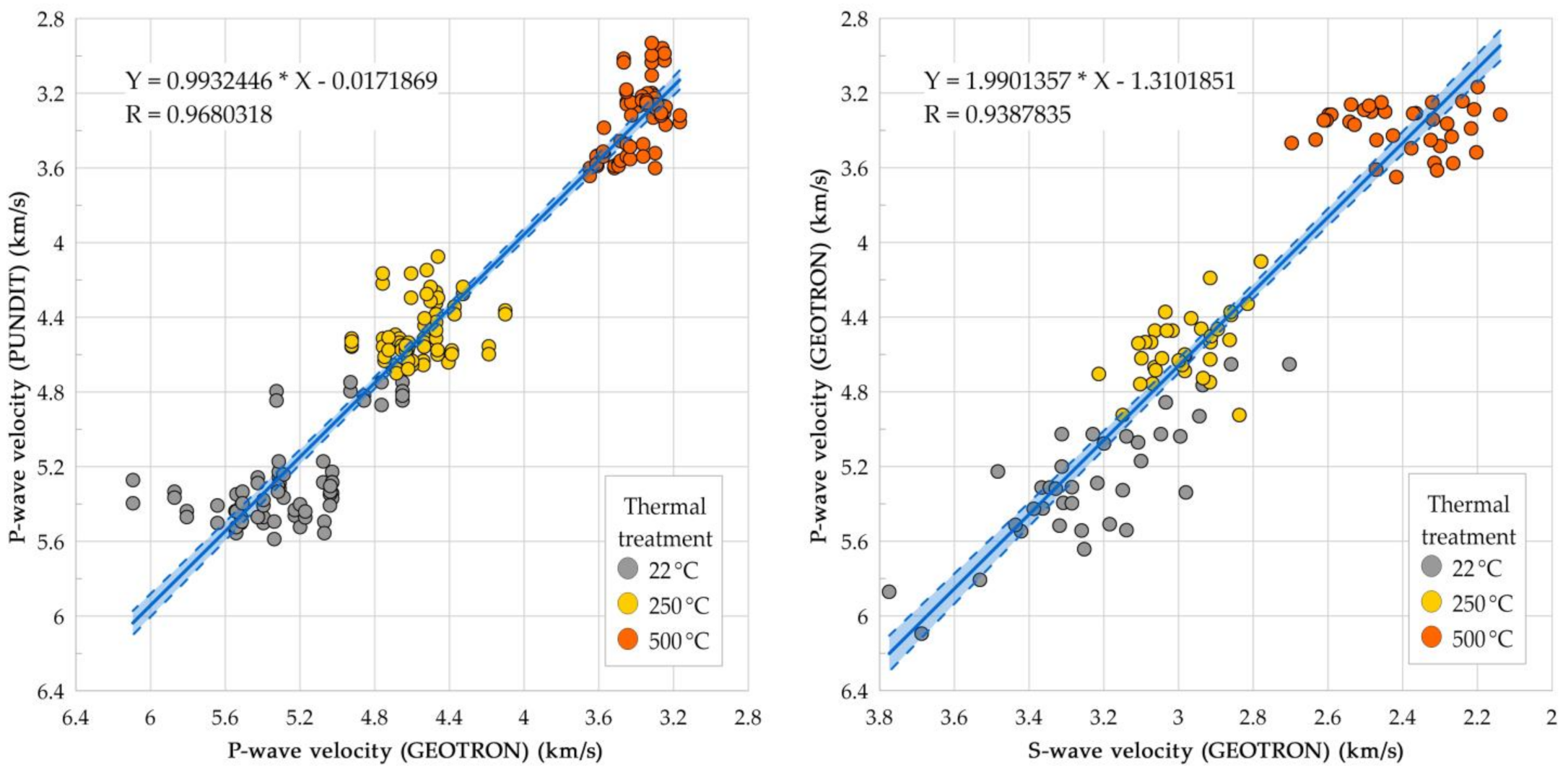

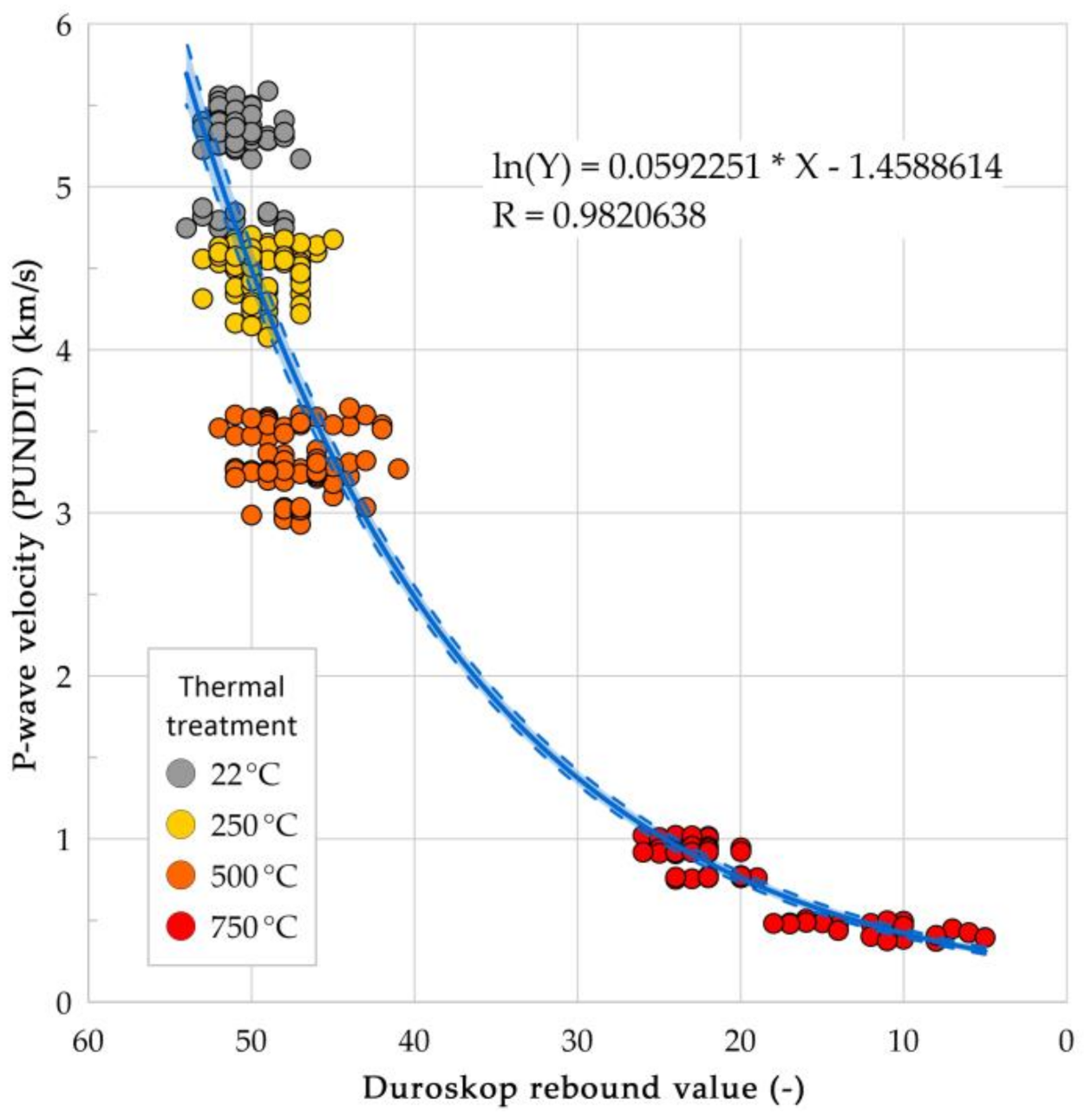

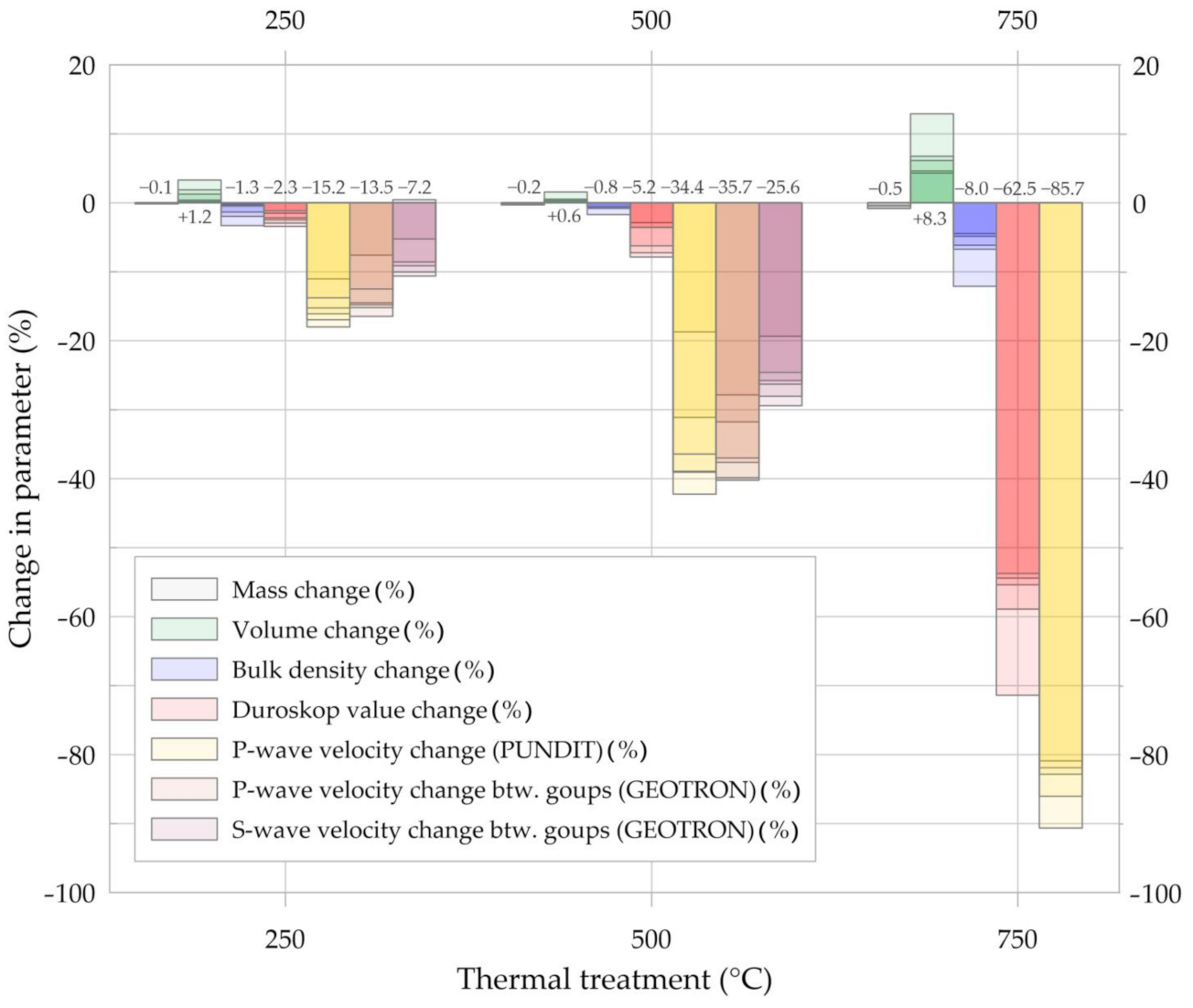

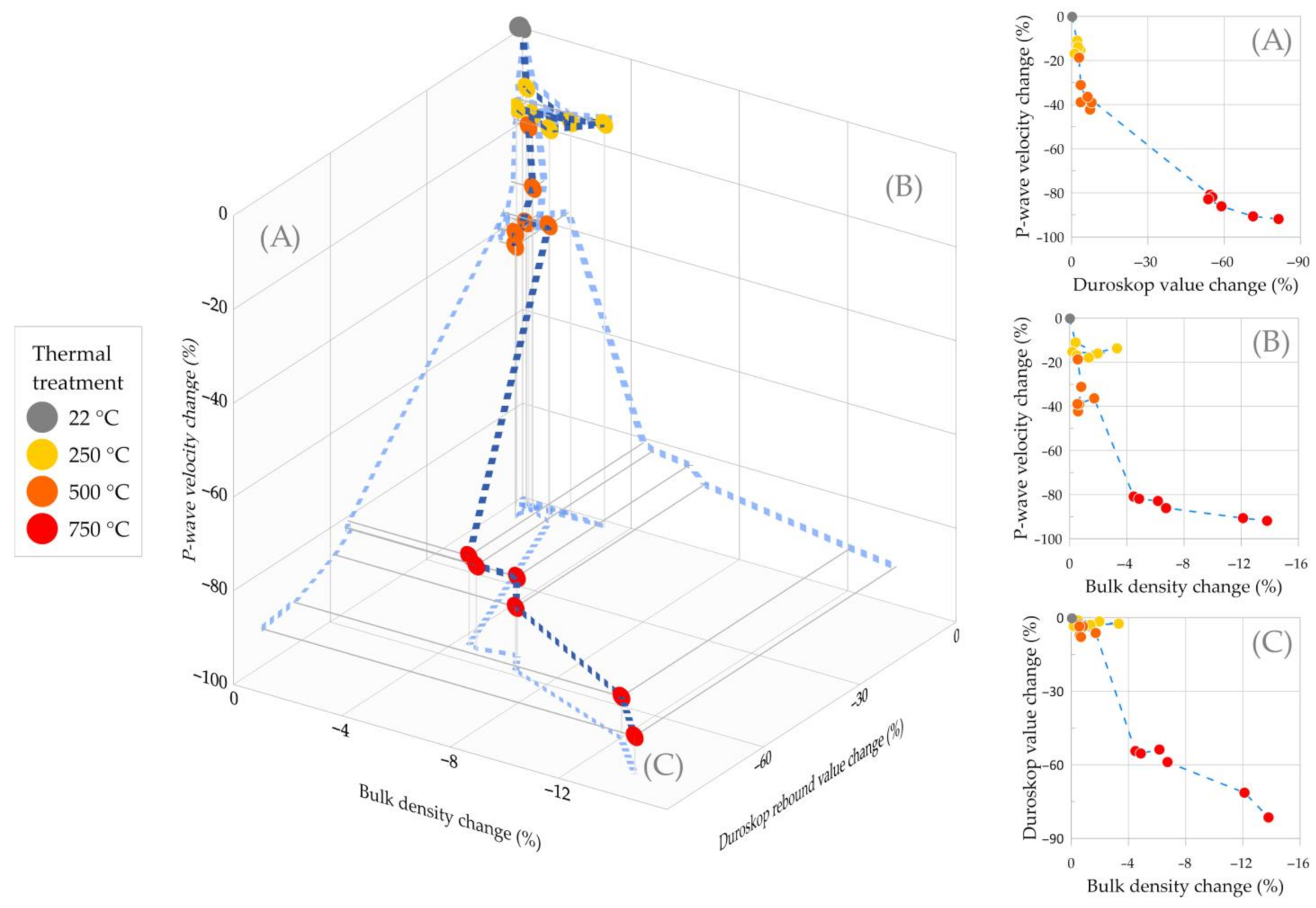

| Thermal Treatment Group | Bulk Density (Std) | Duroskop Value (Std) | P-Wave Vel. [PUNDIT] (Std) | P-Wave Vel. [GEOTRON] (Std) | S-Wave Vel. [GEOTRON] (Std) |

|---|---|---|---|---|---|

| (kg/m3) | (-) | (km/s) | (km/s) | (km/s) | |

| 22 °C | 2716.0 (23.6) | 51 (1.5) | 5.29 (0.24) | 5.28 (0.32) | 3.23 (0.22) |

| 250 °C | 2678.1 (34.0) | 49 (1.7) | 4.49 (0.15) | 4.56 (0.18) | 3.00 (0.12) |

| 500 °C | 2694.7 (27.1) | 47 (2.4) | 3.32 (0.19) | 3.39 (0.12) | 2.40 (0.15) |

| 750 °C | 2493.3 (125.0) | 19 (5.7) | 0.76 (0.23) | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Németh, A.; Antal, Á.; Török, Á. Physical Alteration and Color Change of Granite Subjected to High Temperature. Appl. Sci. 2021, 11, 8792. https://doi.org/10.3390/app11198792

Németh A, Antal Á, Török Á. Physical Alteration and Color Change of Granite Subjected to High Temperature. Applied Sciences. 2021; 11(19):8792. https://doi.org/10.3390/app11198792

Chicago/Turabian StyleNémeth, Andor, Ákos Antal, and Ákos Török. 2021. "Physical Alteration and Color Change of Granite Subjected to High Temperature" Applied Sciences 11, no. 19: 8792. https://doi.org/10.3390/app11198792

APA StyleNémeth, A., Antal, Á., & Török, Á. (2021). Physical Alteration and Color Change of Granite Subjected to High Temperature. Applied Sciences, 11(19), 8792. https://doi.org/10.3390/app11198792