Modelling Spray Pressure Effects on Droplet Size Distribution from Agricultural Nozzles

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. The Test Bench for Drop Size Measurement

2.2. The Experimental Trials

2.3. Spray Parameters Calculation

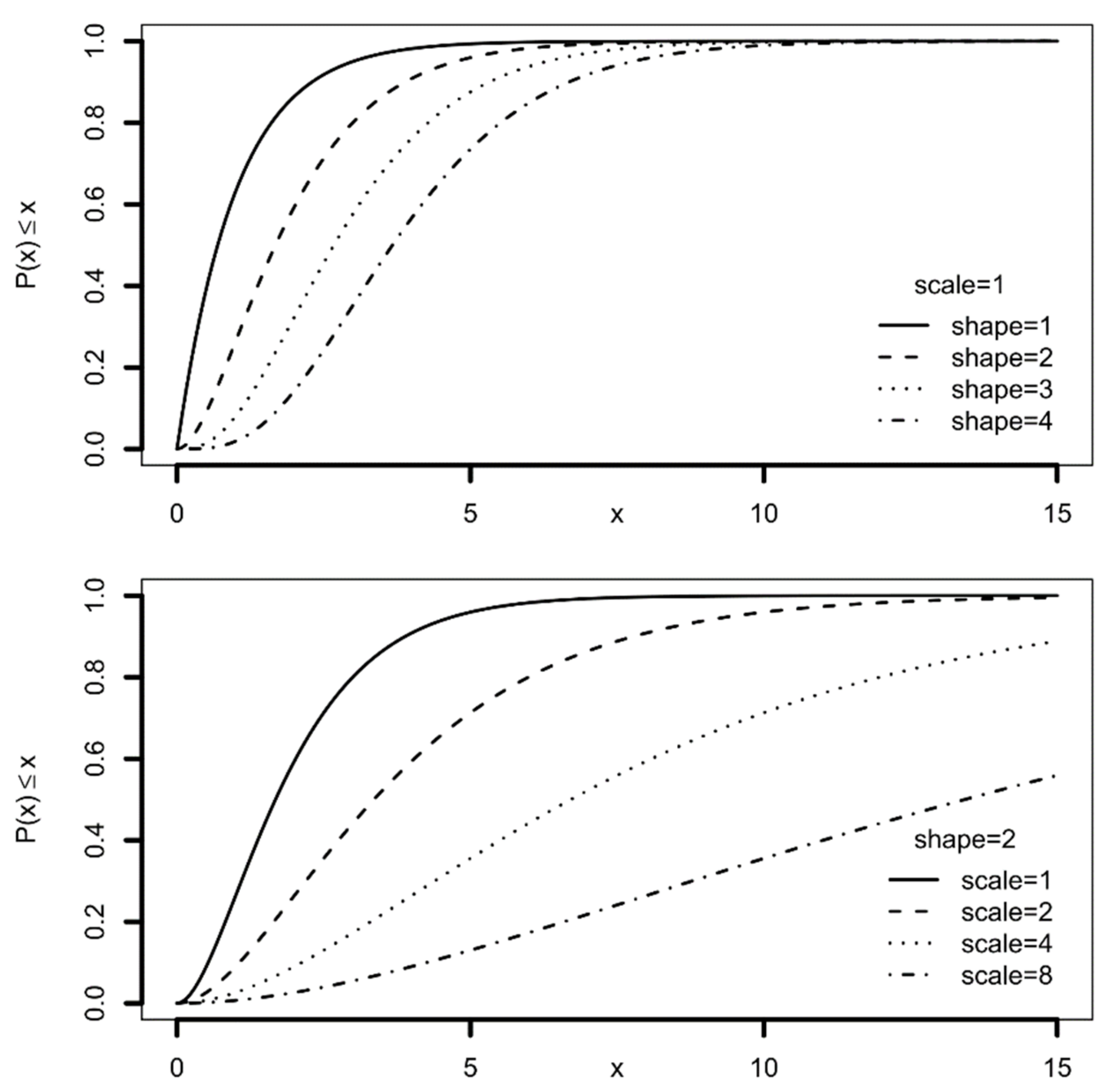

2.4. Drop Size Distribution Modelling

3. Results

3.1. General Results

3.2. Drop Size Parameters

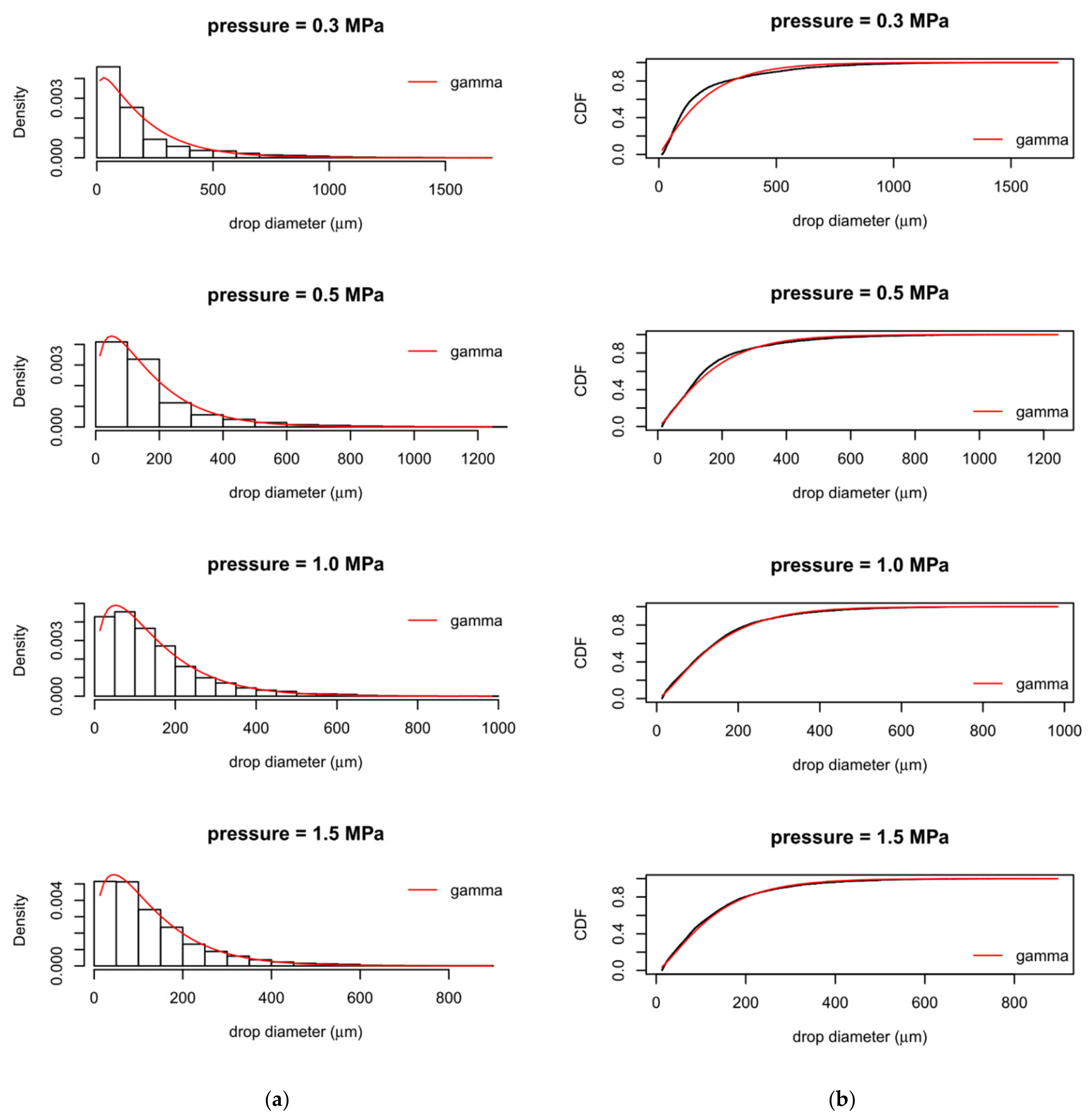

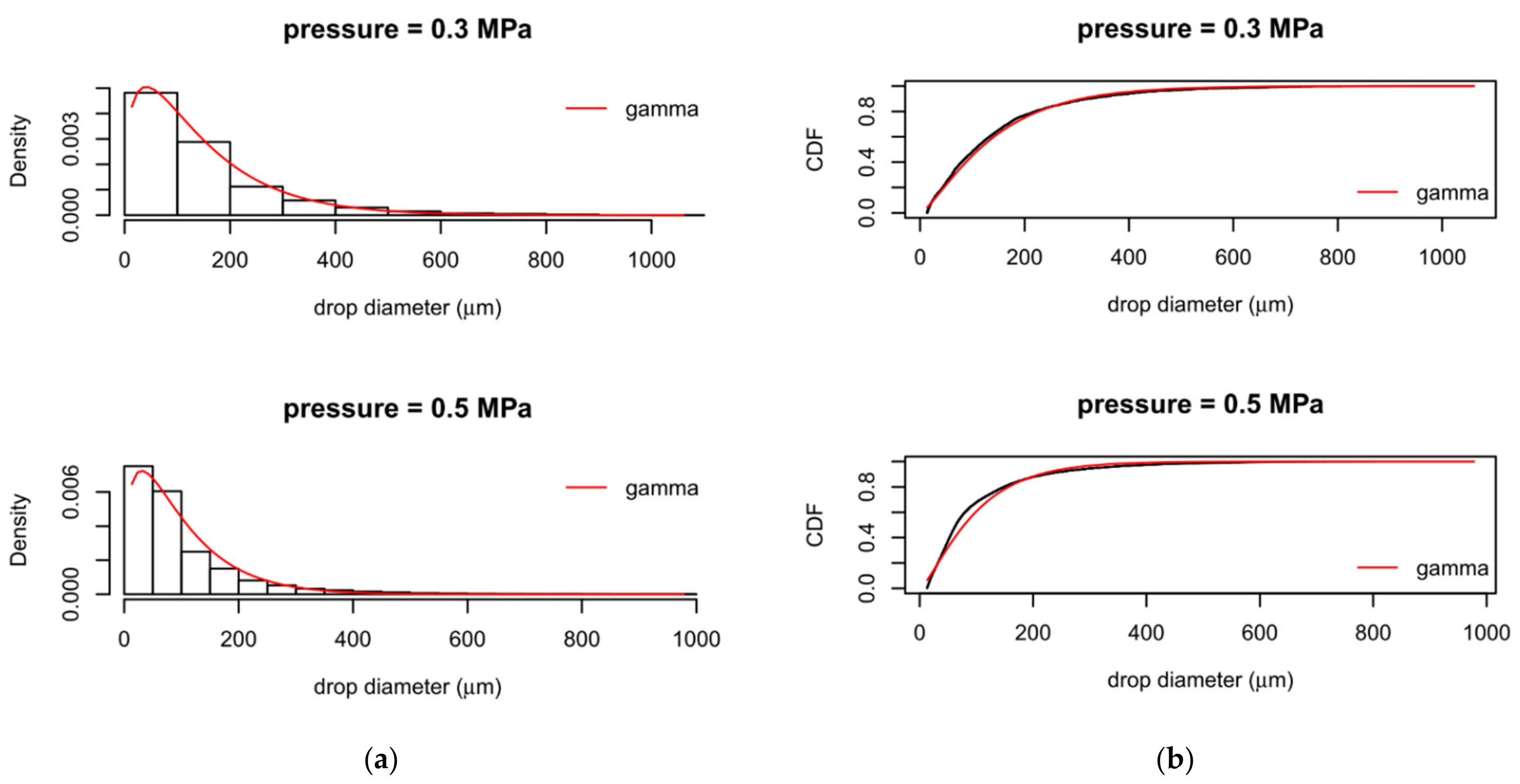

3.3. Drop Size Distribution Modelling

4. Discussion

4.1. Drop Diameters

4.2. Drop Size Distribution

5. Conclusions and Future Developments

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Symbols | |

| particle area (pixel) | |

| particle diameter (pixel) | |

| particle diameter (µm) | |

| calibration factor (µm/pixel) | |

| arithmetic mean diameter (µm) | |

| surface mean diameter (µm) | |

| volume mean diameter (µm) | |

| Sauter mean diameter (µm) | |

| droplet volume (μm3) | |

| cumulative volume corresponding to the diameter (%) | |

| the diameter such that | |

| the diameter such that | |

| the diameter such that | |

| probability distribution function of the drop number | |

| gamma function | |

| shape parameter | |

| scale parameter | |

| Acronyms | |

| AD | Anderson–Darling test |

| CDF | Cumulative Distribution Function |

| CSV | Comma Separated Value |

| DSLR | Digital Single-Lens Reflex |

| HSI | High Speed Imaging |

| LD | Laser Diffraction |

| MLE | Maximum Likelihood Estimation method |

| Probability Density Function | |

| PDPA | Phase Doppler Particle Analyzer |

| PPP | Plant Protection Product |

| RSF | Relative Span Factor |

| SMD | Sauter Mean Diameter |

| VMD | Volumetric Median Diameter |

| WSP | Water Sensitive Paper |

References

- Matthews, G.A. How was the pesticide applied? Crop Prot. 2004, 23, 651–653. [Google Scholar] [CrossRef]

- De Cock, N.; Massinon, M.; Salah, S.O.T.; Lebeau, F. Investigation on optimal spray properties for ground based agricultural applications using deposition and retention models. Biosyst. Eng. 2017, 162, 99–111. [Google Scholar] [CrossRef] [Green Version]

- Chen, S.; Lan, Y.; Zhou, Z.; Ouyang, F.; Wang, G.; Huang, X.; Deng, X.; Cheng, S. Effect of droplet size parameters on droplet deposition and drift of aerial spraying by using plant protection UAV. Agronomy 2020, 10, 195. [Google Scholar] [CrossRef] [Green Version]

- Nuyttens, D.; Braekman, P.; Windey, S.; Sonck, B. Potential dermal pesticide exposure affected by greenhouse spray application technique. Pest Manag. Sci. 2009, 65, 781–790. [Google Scholar] [CrossRef]

- Cao, L.; Zhang, H.; Li, F.; Zhou, Z.; Wang, W.; Ma, D.; Yang, L.; Zhou, P.; Huang, Q. Potential dermal and inhalation exposure to imidacloprid and risk assessment among applicators during treatment in cotton field in China. Sci. Total Environ. 2018, 624, 1195–1201. [Google Scholar] [CrossRef]

- Cerruto, E.; Manetto, G.; Santoro, F.; Pascuzzi, S. Operator dermal exposure to pesticides in tomato and strawberry greenhouses from hand-held sprayers. Sustainability 2018, 10, 2273. [Google Scholar] [CrossRef] [Green Version]

- Ferguson, J.C.; Chechetto, R.G.; Hewitt, A.J.; Chauhan, B.S.; Adkins, S.W.; Kruger, G.R.; O’Donnell, C.C. Assessing the deposition and canopy penetration of nozzles with different spray qualities in an oat (Avena sativa L.) canopy. Crop Prot. 2016, 81, 14–19. [Google Scholar] [CrossRef] [Green Version]

- Zwertvaegher, I.K.; Verhaeghe, M.; Brusselman, E.; Verboven, P.; Lebeau, F.; Massinon, M.; Nicolaı, B.M.; Nuyttens, D. The impact and retention of spray droplets on a horizontal hydrophobic surface. Biosyst. Eng. 2014, 126, 82–91. [Google Scholar] [CrossRef] [Green Version]

- Al Heidary, M.; Douzals, J.P.; Sinfort, C.; Vallet, A. Influence of spray characteristics on potential spray drift of field crop sprayers: A literature review. Crop Prot. 2014, 63, 120–130. [Google Scholar] [CrossRef]

- Torrent, X.; Garcerá, C.; Moltó, E.; Chueca, P.; Abad, R.; Grafulla, C.; Planas, S. Comparison between standard and drift reducing nozzles for pesticide application in citrus: Part, I. Effects on wind tunnel and field spray drift. Crop Prot. 2017, 96, 130–143. [Google Scholar] [CrossRef] [Green Version]

- Garcerá, C.; Román, C.; Moltó, E.; Abad, R.; Insa, J.A.; Torrent, X.; Chueca, P. Comparison between standard and drift reducing nozzles for pesticide application in citrus: Part II. Effects on canopy spray distribution, control efficacy of Aonidiella aurantii (Maskell), beneficial parasitoids and pesticide residues on fruit. Crop Prot. 2017, 94, 83–96. [Google Scholar] [CrossRef] [Green Version]

- Fornasiero, D.; Mori, N.; Tirello, P.; Pozzebon, A.; Duso, C.; Tescari, E.; Bradascio, R.; Otto, S. Effect of spray drift reduction techniques on pests and predatory mites in orchards and vineyards. Crop Prot. 2017, 98, 283–292. [Google Scholar] [CrossRef]

- Pergher, G. Field evaluation of a calibration method for air-assisted sprayers involving the use of a vertical patternator. Crop Prot. 2004, 23, 437–446. [Google Scholar] [CrossRef]

- Pascuzzi, S.; Cerruto, E.; Manetto, G. Foliar spray deposition in a “tendone” vineyard as affected by airflow rate, volume rate and vegetative development. Crop Prot. 2017, 91, 34–48. [Google Scholar] [CrossRef]

- Pascuzzi, S.; Santoro, F.; Manetto, G.; Cerruto, E. Study of the correlation between foliar and patternator deposits in a “tendone” vineyard. Agric. Eng. Int. CIGR J. 2018, 20, 97–107. [Google Scholar]

- Jiao, L.; Dong, D.; Feng, H.; Zhao, X.; Chen, L. Monitoring spray drift in aerial spray application based on infrared thermal imaging technology. Comput. Electron. Agric. 2016, 121, 135–140. [Google Scholar] [CrossRef]

- Grella, M.; Gallart, M.; Marucco, P.; Balsari, P.; Gil, E. Ground deposition and airborne spray drift assessment in vineyard and orchard: The influence of environmental variables and sprayer settings. Sustainability 2017, 9, 728. [Google Scholar] [CrossRef] [Green Version]

- Balsari, P.; Gil, E.; Marucco, P.; van de Zande, J.C.; Nuyttens, D.; Herbst, A.; Gallart, M. Field-crop-sprayer potential drift measured using test bench: Effects of boom height and nozzle type. Biosyst. Eng. 2017, 154, 3–13. [Google Scholar] [CrossRef] [Green Version]

- Grella, M.; Marucco, P.; Balsari, P. Toward a new method to classify the airblast sprayers according to their potential drift reduction: Comparison of direct and new indirect measurement methods. Pest Manag. Sci. 2019, 75, 2219–2235. [Google Scholar] [CrossRef]

- Syngenta. Water-Sensitive Paper for Monitoring Spray Distribution. Technical Data Sheet. Available online: https://www.agroconsultasonline.com.ar//ticket.html/Water%20Sensitive%20Paper%20Syngenta%20Agro.pdf?op=d&ticket_id=2388&evento_id=4891 (accessed on 8 April 2021).

- Sánchez-Hermosilla, J.; Medina, R. Adaptive threshold for droplet spot analysis using water-sensitive paper. Appl. Eng. Agric. 2011, 20, 547–551. [Google Scholar] [CrossRef]

- Cunha, M.; Carvalho, C.; Marcal, A.R.S. Assessing the ability of image processing software to analyse spray quality on water-sensitive papers used as artificial targets. Biosyst. Eng. 2012, 111, 11–23. [Google Scholar] [CrossRef] [Green Version]

- Salyani, M.; Zhu, H.; Sweeb, R.D.; Pai, N. Assessment of spray distribution with water-sensitive paper. Agric. Eng. Int. CIGR J. 2013, 15, 101–111. [Google Scholar]

- Cerruto, E.; Manetto, G.; Longo, D.; Failla, S.; Papa, R. A model to estimate the spray deposit by simulated water sensitive papers. Crop Prot. 2019, 124, 104861. [Google Scholar] [CrossRef]

- Cerruto, E.; Aglieco, C.; Failla, S.; Manetto, G. Parameters influencing deposit estimation when using water sensitive papers. J. Agric. Eng. 2013, 44, 62–70. [Google Scholar] [CrossRef]

- Kathiravelu, G.; Lucke, T.; Nichols, P. Rain drop measurement techniques: A review. Water 2016, 8, 29. [Google Scholar] [CrossRef] [Green Version]

- Fujimatsu, T.; Kito, M.; Kondo, K. Droplet Size Measurement of Liquid Atomization by the Immersion Liquid Method (Droplet Coalescence and Solution into the Immersion Liquid); WIT Transactions on Engineering Sciences; WIT Press: Southampton, UK, 2014; Volume 82. [Google Scholar]

- Lad, N.; Aroussi, E.A.; Muhamad Said, M.F. Droplet size measurement for liquid spray using digital image analysis technique. J. Appl. Sci. 2011, 11, 1966–1972. [Google Scholar] [CrossRef] [Green Version]

- Massinon, M.; Lebeau, F. Experimental method for the assessment of agricultural spray retention based on high-speed imaging of drop impact on a synthetic superhydrophobic surface. Biosyst. Eng. 2012, 112, 56–64. [Google Scholar] [CrossRef]

- De Cock, N.; Massinon, M.; Nuyttens, D.; Dekeyser, D.; Lebeau, F. Measurements of reference ISO nozzles by high-speed imaging. Crop Prot. 2016, 89, 105–115. [Google Scholar] [CrossRef] [Green Version]

- Fritz, B.K.; Hoffmann, W.C. Measuring spray droplet size from agricultural nozzles using laser diffraction. J. Vis. Exp. 2016, 115, e54533. [Google Scholar] [CrossRef] [Green Version]

- Liao, J.; Luo, X.; Wang, P.; Zhou, Z.; O’Donnell, C.C.; Zang, Y.; Hewitt, A.J. Analysis of the influence of different parameters on droplet characteristics and droplet size classification categories for air induction nozzle. Agronomy 2020, 10, 256. [Google Scholar] [CrossRef] [Green Version]

- ISO (International Organization of Standardization). ISO 13320:2020 Particle Size Analysis—Laser Diffraction Methods; ISO: Geneva, Switzerland, 2020; Available online: https://www.iso.org/obp/ui/#iso:std:iso:13320:en (accessed on 15 June 2021).

- Nuyttens, D.; Baetens, K.; De Schampheleire, M.; Sonck, B. PDPA Laser Based Characterisation of Agricultural Sprays. Agric. Eng. Int. CIGR J. 2006, 8. [Google Scholar]

- Nuyttens, D.; Baetens, K.; De Schampheleire, M.; Sonck, B. Effect of nozzle type, size and pressure on spray droplet characteristics. Biosyst. Eng. 2007, 97, 333–345. [Google Scholar] [CrossRef]

- Lodwik, D.; Pietrzyk, J.; Malesa, W. Analysis of volume distribution and evaluation of the spraying spectrum in terms of spraying quality. Appl. Sci. 2020, 10, 2395. [Google Scholar] [CrossRef] [Green Version]

- Schick, R.J. Spray Technology Reference Guide: Understanding drop size. In Spraying Systems Bulletin no. 459C; Spraying Systems Co.: Wheaton, IL, USA, 2008; Available online: https://www.spray.com/literature_pdfs/B459C_Understanding_Drop_Size.pdf (accessed on 4 August 2021).

- Sijs, R.; Kooij, S.; Holterman, H.J.; van de Zande, J.; Bonn, D. Drop size measurement techniques for sprays: Comparison of image analysis, phase Doppler particle analysis, and laser diffraction. AIP Adv. 2021, 11, 015315. [Google Scholar] [CrossRef]

- ISO (International Organization for Standardization). ISO 25358:2018, Crop Protection Equipment—Droplet-Size Spectra from Atomizers—Measurement and Classification; ISO: Geneva, Switzerland, 2018; Available online: https://www.iso.org/standard/66412.html (accessed on 4 August 2021).

- ISO (International Organization for Standardization). ISO 5682-1, Equipment for Crop Protection—Spraying Equipment—Part 1: Test Methods for Sprayer Nozzle; ISO: Geneva, Switzerland, 2017; Available online: https://www.iso.org/standard/60053.html (accessed on 9 July 2021).

- Longo, D.; Manetto, G.; Papa, R.; Cerruto, E. Design and construction of a low-cost test bench for testing agricultural spray nozzles. Appl. Sci. 2020, 10, 5221. [Google Scholar] [CrossRef]

- Cerruto, E.; Manetto, G.; Longo, D.; Failla, S.; Schillaci, G. A laboratory system for nozzle spray analysis. Chem. Eng. Trans. 2017, 58, 751–756. [Google Scholar] [CrossRef]

- Abramoff, M.D.; Magelhaes, P.J.; Ram, S.J. Image processing with Image. J. Biophot. Int. 2004, 11, 36–42. [Google Scholar]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2019; Available online: https://www.R-project.org (accessed on 1 July 2021).

- Babinsky, E.; Sojka, P.E. Modelling drop size distribution. Prog. Energy Combust. Sci. 2002, 28, 303–329. [Google Scholar] [CrossRef]

- Cerruto, E.; Failla, S.; Longo, D.; Manetto, G. Simulation of water sensitive papers for spray analysis. Agric. Eng. Int. CIGR J. 2016, 18, 22–29. [Google Scholar]

- Panão, M.O.; Moita, A.S.; Moreira, A.L. On the statistical characterization of sprays. Appl. Sci. 2020, 10, 6122. [Google Scholar] [CrossRef]

- Delignette-Muller, M.L.; Dutang, C. Fitdistrplus: An R package for fitting distributions. J. Stat. Softw. 2015, 64, 1–34. [Google Scholar] [CrossRef] [Green Version]

- ISO (International Organization for Standardization). ISO 10625, Equipment for Crop Protection—Sprayer Nozzles—Colour Coding for Identification; ISO: Geneva, Switzerland, 2018; Available online: https://www.iso.org/standard/70624.html (accessed on 1 July 2021).

- Lefebvre, A.H.; McDonell, V.G. Drop size distributions of sprays. In Atomization and Sprays, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2017; pp. 55–70. [Google Scholar]

- Villermaux, E.; Marmottant, P.; Duplat, J. Ligament-mediated spray formation. Phys. Rev. Lett. 2004, 92, 074501. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sellens, R.W.; Brzustowski, T.A. A prediction of the drop size distribution in a spray from first principles. At. Spray Technol. 1985, 1, 89–102. [Google Scholar]

- Li, X.; Tankin, R.S. Droplet size distribution: A derivation of a Nukiyama-Tanasawa type distribution function. Combust. Sci. Technol. 1987, 56, 65–76. [Google Scholar]

- Lee, T.-W.; An, K. Quadratic formula for determining the drop size in pressure-atomized sprays with and without swirl. Phys. Fluids 2016, 28, 063302. [Google Scholar] [CrossRef]

- Lee, T.-W.; Park, J.E. Determination of the drop size during air-blast atomization. J. Fluids Eng. 2019, 141, 1–6. [Google Scholar] [CrossRef]

- Urbán, A.; Zaremba, M.; Malý, M.; Józsa, V.; Jedelský, J. Droplet dynamics and size characterization of high-velocity airblast atomization. Int. J. Multiph. Flow 2017, 95, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Li, S.; Chen, C.; Wang, Y.; Kang, F.; Li, W. Study on the atomization characteristics of flat fan nozzles for pesticide application at low pressures. Agriculture 2021, 11, 309. [Google Scholar] [CrossRef]

- Post, S.L.; Hewitt, A.J. Flat fan spray atomization model. Trans. ASABE 2018, 61, 1249–1256. [Google Scholar] [CrossRef] [Green Version]

| Nozzle Type | Measured Pressure, MPa | Measured Flow Rate, L/min | Reference Pressure, MPa | Reference Flow Rate, L/min |

|---|---|---|---|---|

| ATR 80 orange | 0.311 | 0.78 | 0.3 | |

| 0.517 | 0.98 | 0.5 | 0.99 | |

| 0.988 | 1.37 | 1.0 | 1.39 | |

| 1.445 | 1.64 | 1.5 | 1.69 | |

| TVI 8002 | 0.306 | 0.80 | 0.3 | |

| 0.518 | 1.05 | 0.5 | 1.03 | |

| 1.031 | 1.47 | 1.0 | 1.46 | |

| 1.484 | 1.76 | 1.5 | 1.79 | |

| AVI 11003 | 0.296 | 1.18 | 0.3 | 1.20 |

| 0.500 | 1.53 | 0.5 | 1.55 |

| Pressure, MPa | RSF | |||||||

|---|---|---|---|---|---|---|---|---|

| ATR 80 orange | ||||||||

| 0.3 | 81 | 97 | 112 | 150 | 94 | 174 | 263 | 97 |

| 0.5 | 70 | 83 | 95 | 126 | 79 | 147 | 236 | 107 |

| 1.0 | 57 | 69 | 82 | 115 | 70 | 138 | 227 | 114 |

| 1.5 | 54 | 67 | 79 | 112 | 66 | 136 | 220 | 113 |

| TVI 8002 | ||||||||

| 0.3 | 195 | 293 | 391 | 695 | 440 | 861 | 1345 | 105 |

| 0.5 | 166 | 229 | 295 | 489 | 286 | 624 | 995 | 114 |

| 1.0 | 148 | 194 | 240 | 368 | 212 | 457 | 736 | 115 |

| 1.5 | 130 | 173 | 216 | 334 | 195 | 415 | 662 | 113 |

| AVI 11003 | ||||||||

| 0.3 | 147 | 201 | 254 | 407 | 239 | 506 | 807 | 112 |

| 0.5 | 101 | 145 | 193 | 343 | 194 | 449 | 731 | 120 |

| Pressure, MPa | Shape Parameter and 95% Confidence Interval of the Median | Scale Parameter and 95% Confidence Interval of the Median | AD Test | ||||

|---|---|---|---|---|---|---|---|

| α | 2.5% | 97.5% | β | 2.5% | 97.5% | p-value | |

| ATR 80 orange | |||||||

| 0.3 | 2.3319 | 2.3101 | 2.3609 | 34.3492 | 33.9444 | 34.7725 | 0.2060 |

| 0.5 | 2.5450 | 2.5248 | 2.5720 | 27.4295 | 27.1150 | 27.7032 | 0.2043 |

| 1.0 | 2.4367 | 2.4205 | 2.4486 | 23.1820 | 23.0522 | 23.3008 | 0.0006 |

| 1.5 | 2.4511 | 2.4394 | 2.4626 | 22.1915 | 22.0771 | 22.3346 | 0.0006 |

| TVI 8002 | |||||||

| 0.3 | 1.1703 | 1.1344 | 1.2068 | 166.3876 | 160.1959 | 173.6039 | 0.0506 |

| 0.5 | 1.4243 | 1.3825 | 1.4638 | 116.5647 | 112.6313 | 120.4293 | 0.2788 |

| 1.0 | 1.5321 | 1.4890 | 1.5704 | 96.5119 | 93.5747 | 99.5777 | 0.4038 |

| 1.5 | 1.5101 | 1.4829 | 1.5482 | 86.3048 | 84.2055 | 87.8912 | 0.2655 |

| AVI 11003 | |||||||

| 0.3 | 1.3864 | 1.3524 | 1.4267 | 104.8953 | 101.6836 | 108.2892 | 0.2418 |

| 0.5 | 1.4305 | 1.4029 | 1.4475 | 70.3632 | 69.0494 | 71.9837 | 0.0114 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cerruto, E.; Manetto, G.; Papa, R.; Longo, D. Modelling Spray Pressure Effects on Droplet Size Distribution from Agricultural Nozzles. Appl. Sci. 2021, 11, 9283. https://doi.org/10.3390/app11199283

Cerruto E, Manetto G, Papa R, Longo D. Modelling Spray Pressure Effects on Droplet Size Distribution from Agricultural Nozzles. Applied Sciences. 2021; 11(19):9283. https://doi.org/10.3390/app11199283

Chicago/Turabian StyleCerruto, Emanuele, Giuseppe Manetto, Rita Papa, and Domenico Longo. 2021. "Modelling Spray Pressure Effects on Droplet Size Distribution from Agricultural Nozzles" Applied Sciences 11, no. 19: 9283. https://doi.org/10.3390/app11199283

APA StyleCerruto, E., Manetto, G., Papa, R., & Longo, D. (2021). Modelling Spray Pressure Effects on Droplet Size Distribution from Agricultural Nozzles. Applied Sciences, 11(19), 9283. https://doi.org/10.3390/app11199283