Methodology for Efficient Bitumen Storage with Reduced Energy Consumption

Abstract

:1. Introduction

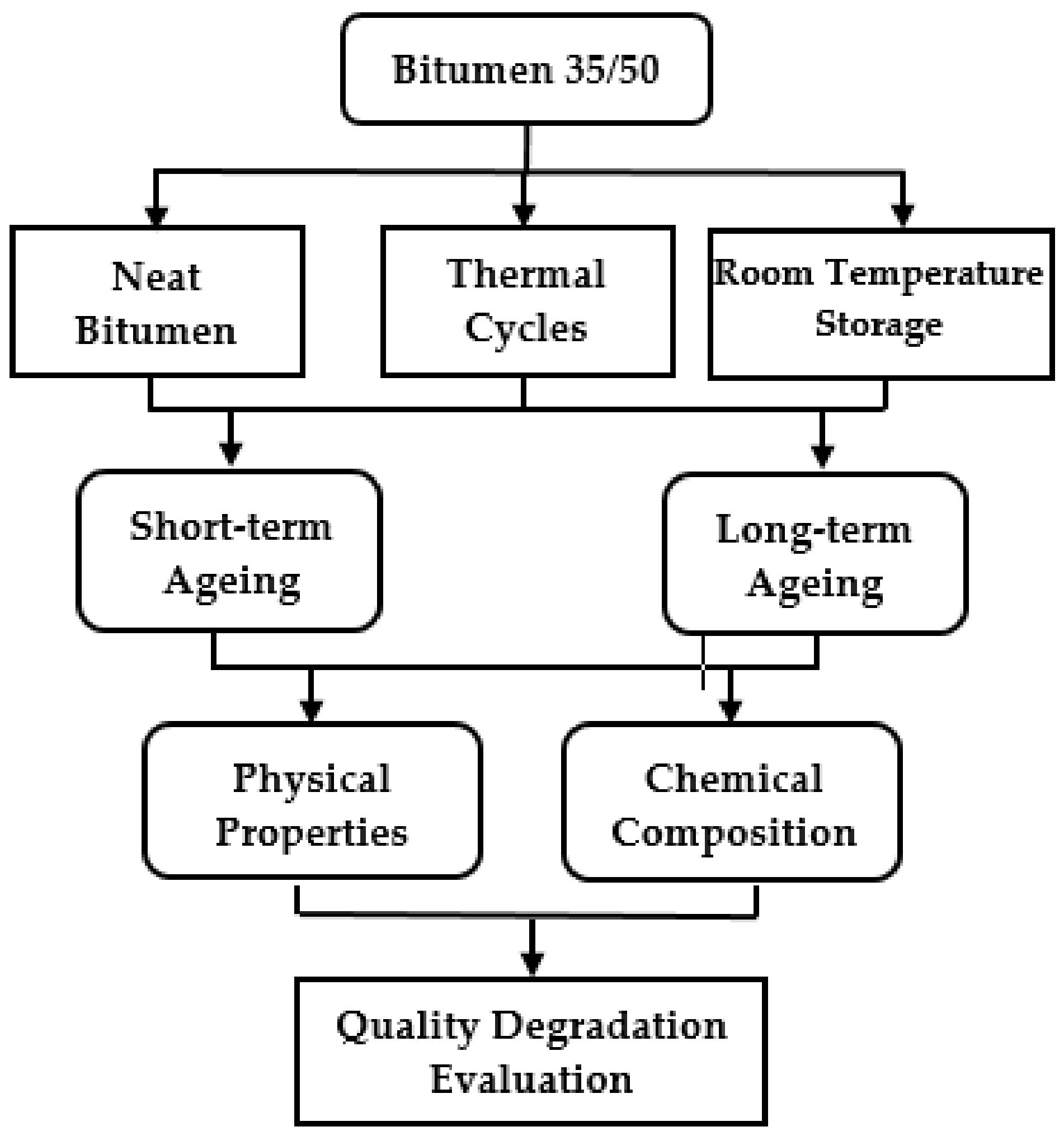

2. Materials and Methods

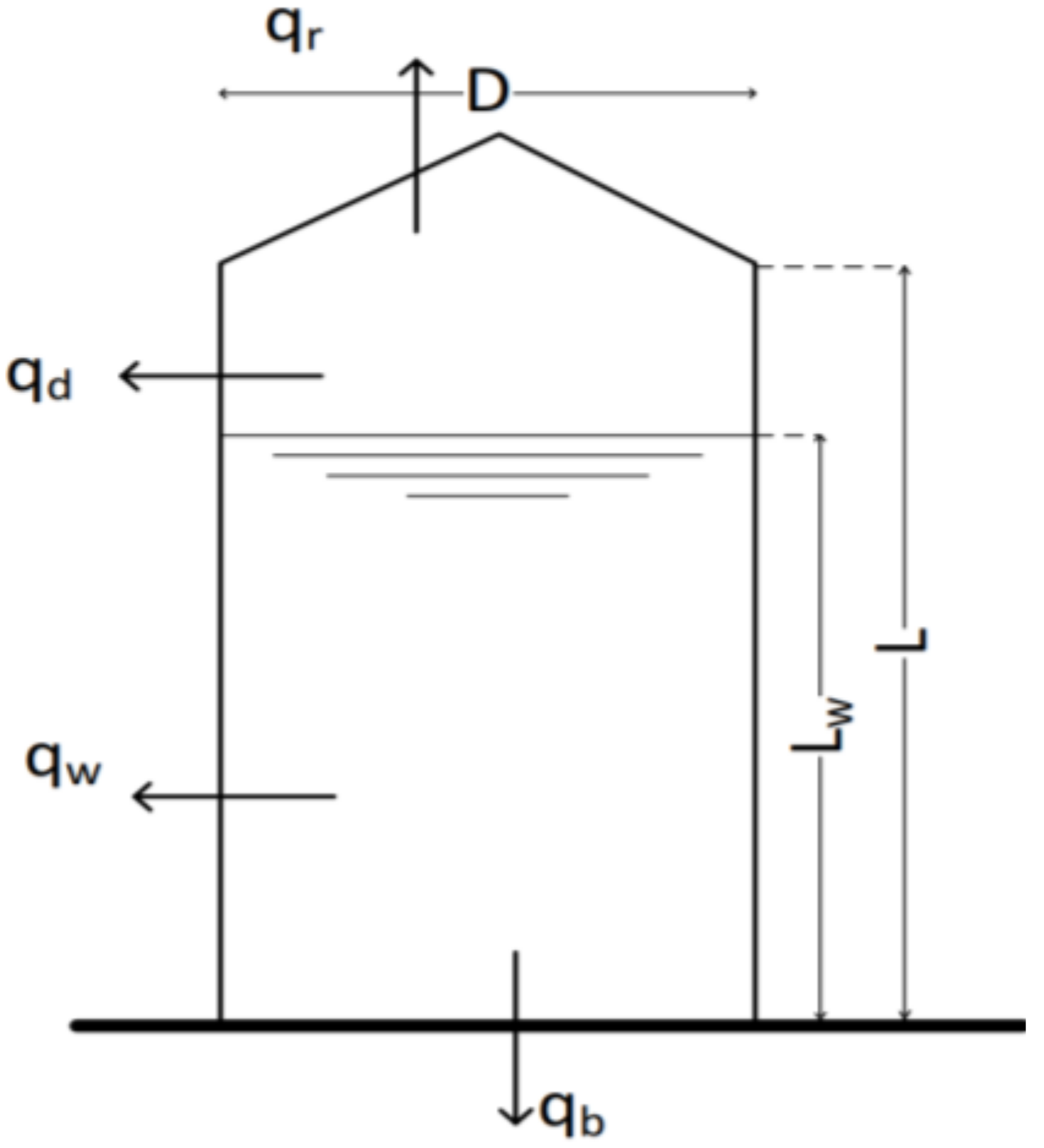

2.1. Bitumen Thermal Storage Analysis

2.1.1. Problem Formulation

2.1.2. Thermal Loss Calculation

- ✓ For dry sidewall

- ✓ For wet sidewall

- ✓ For tank-bottom

- ✓ For tank roof

2.2. Ageing Procedures

2.3. Physical Properties Testing

2.4. Chemical Composition: ATR-FTIR

3. Results and Discussion

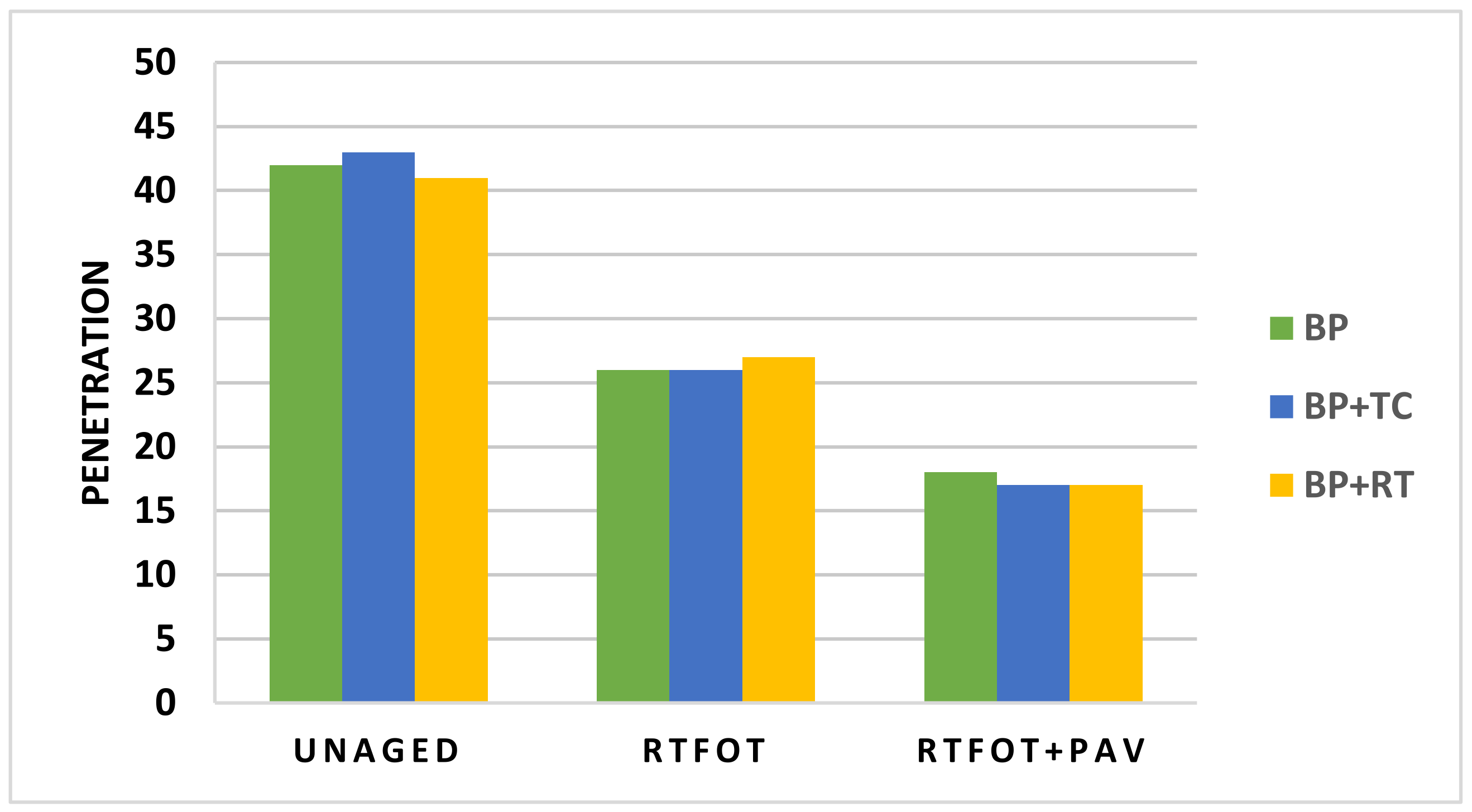

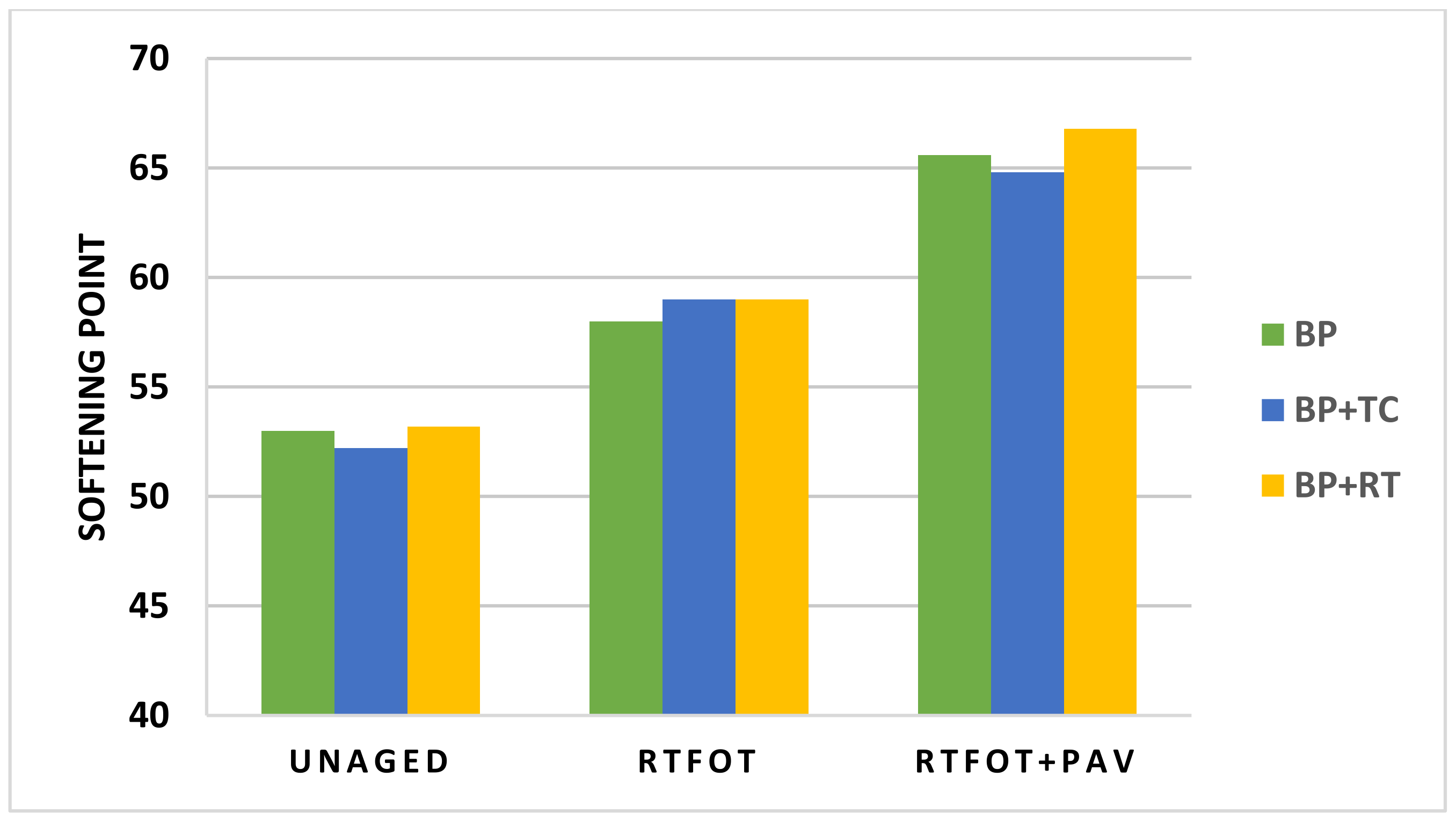

3.1. Physical Properties Evaluation

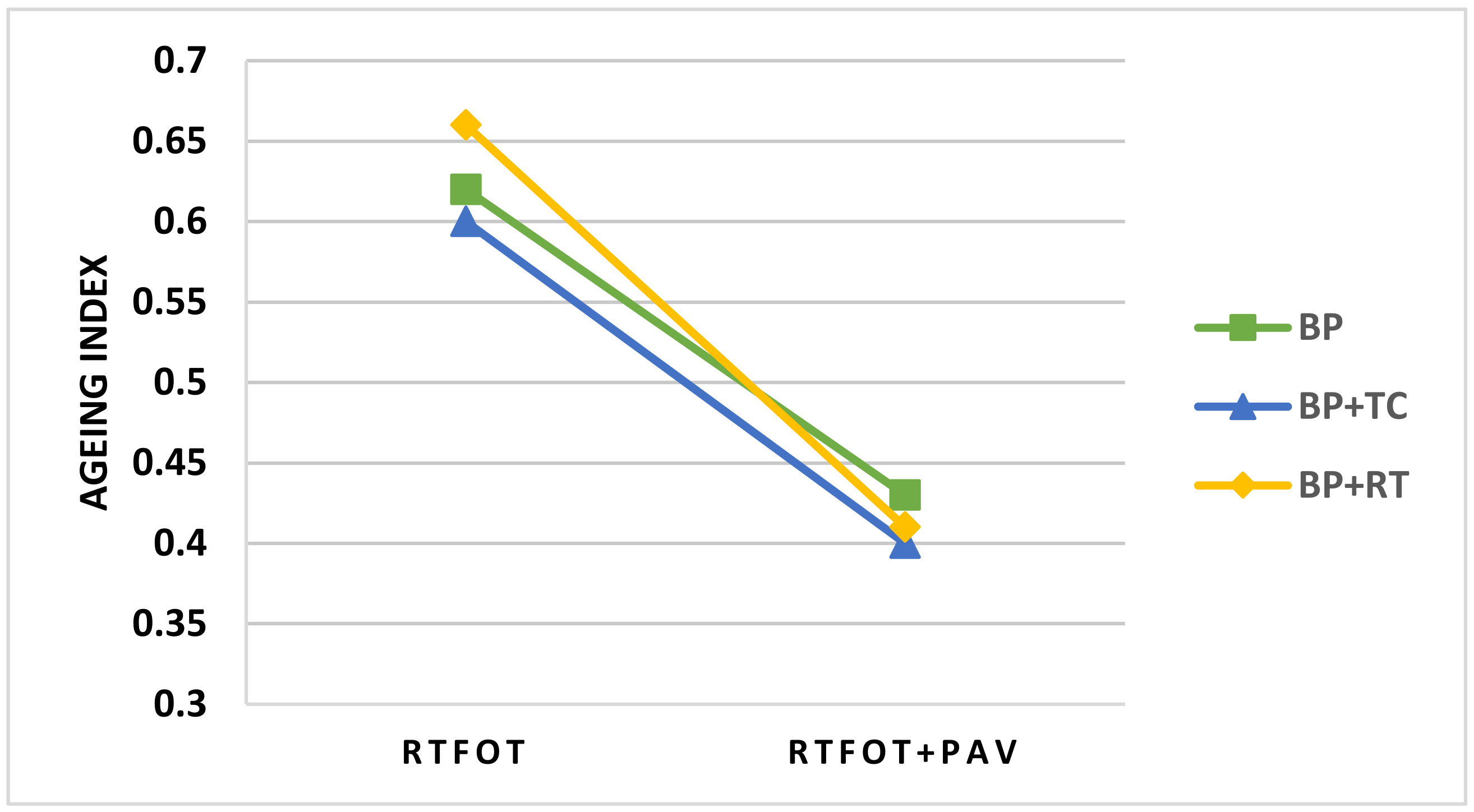

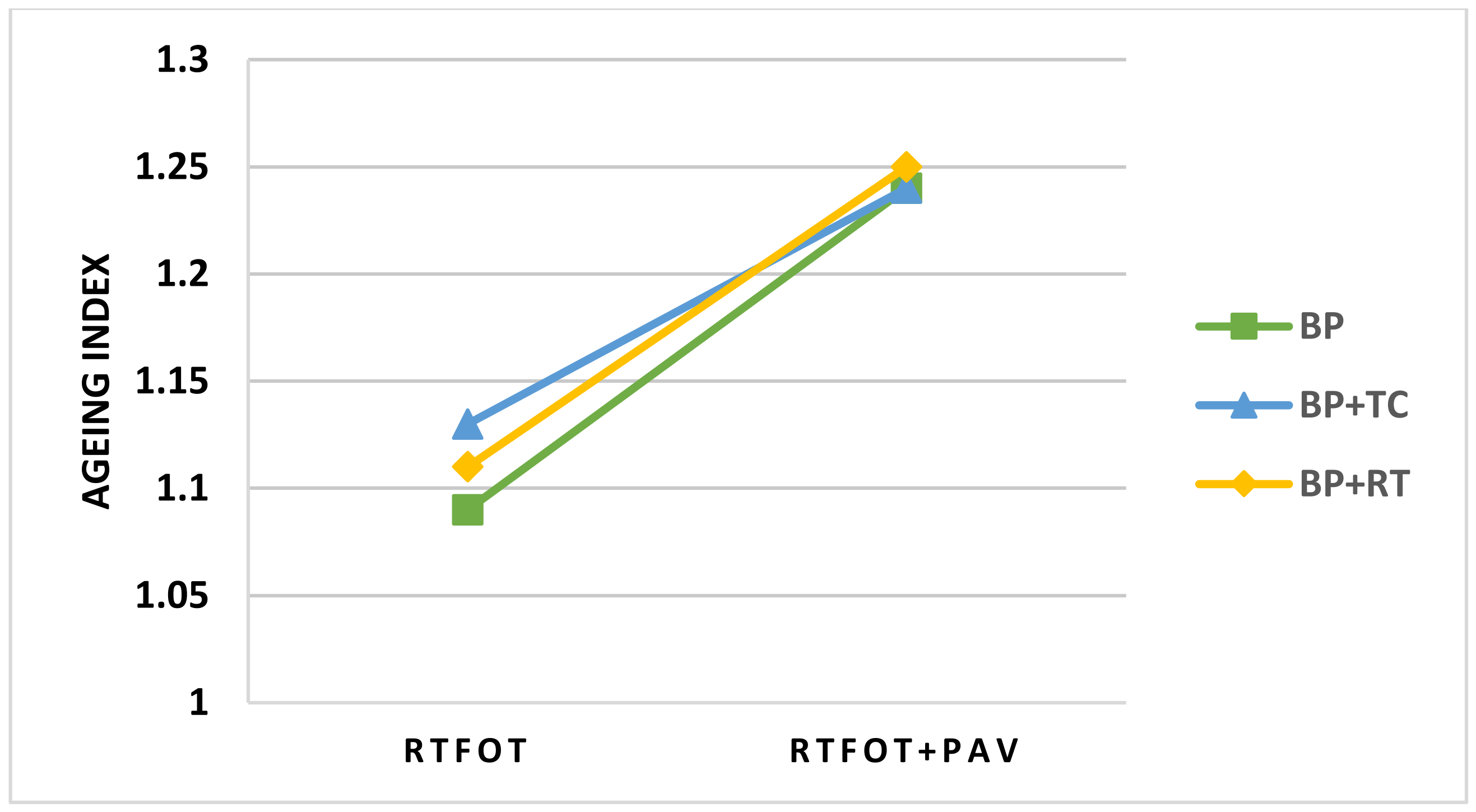

3.2. Ageing Index

3.3. Penetration Index and Temperature Susceptibility

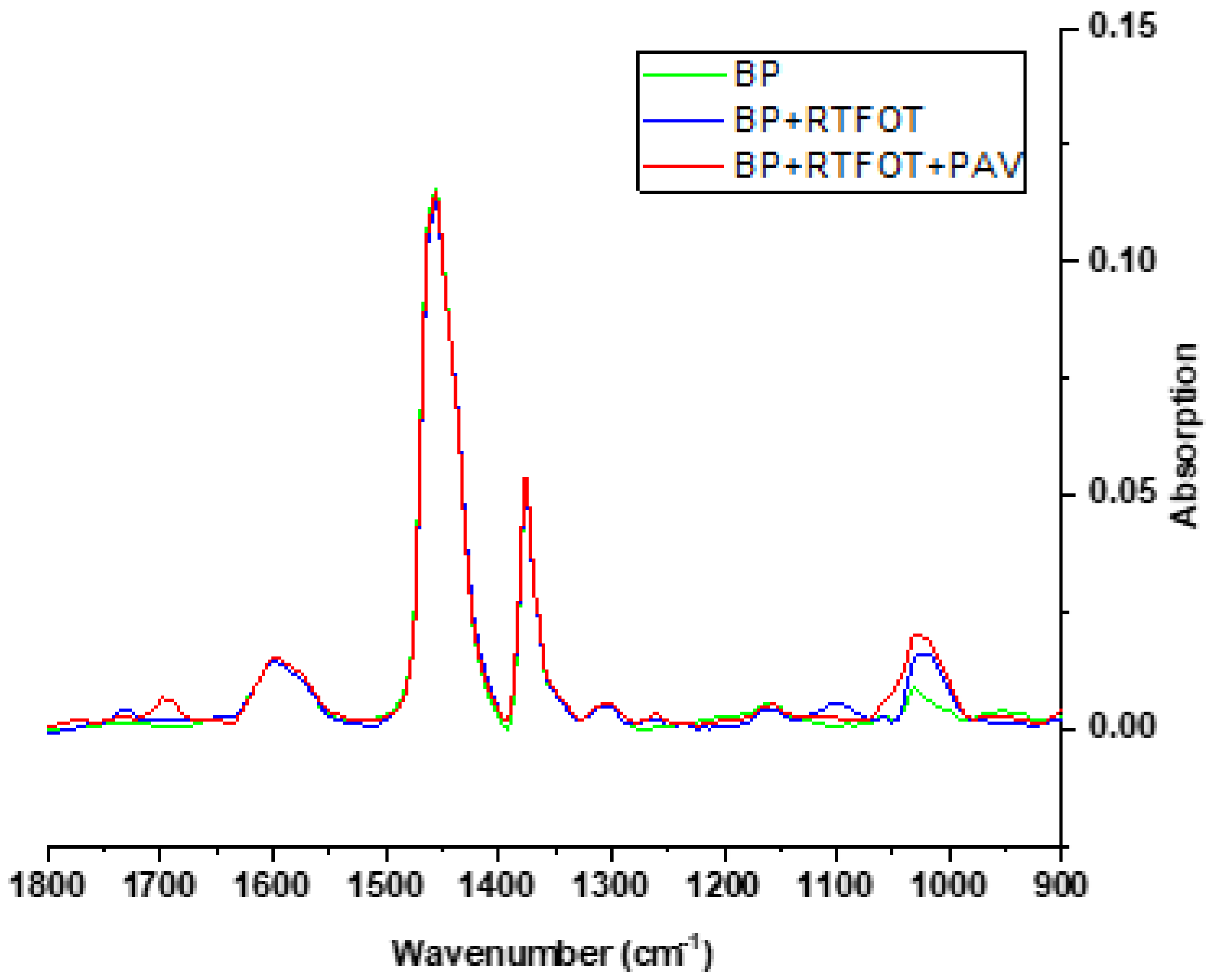

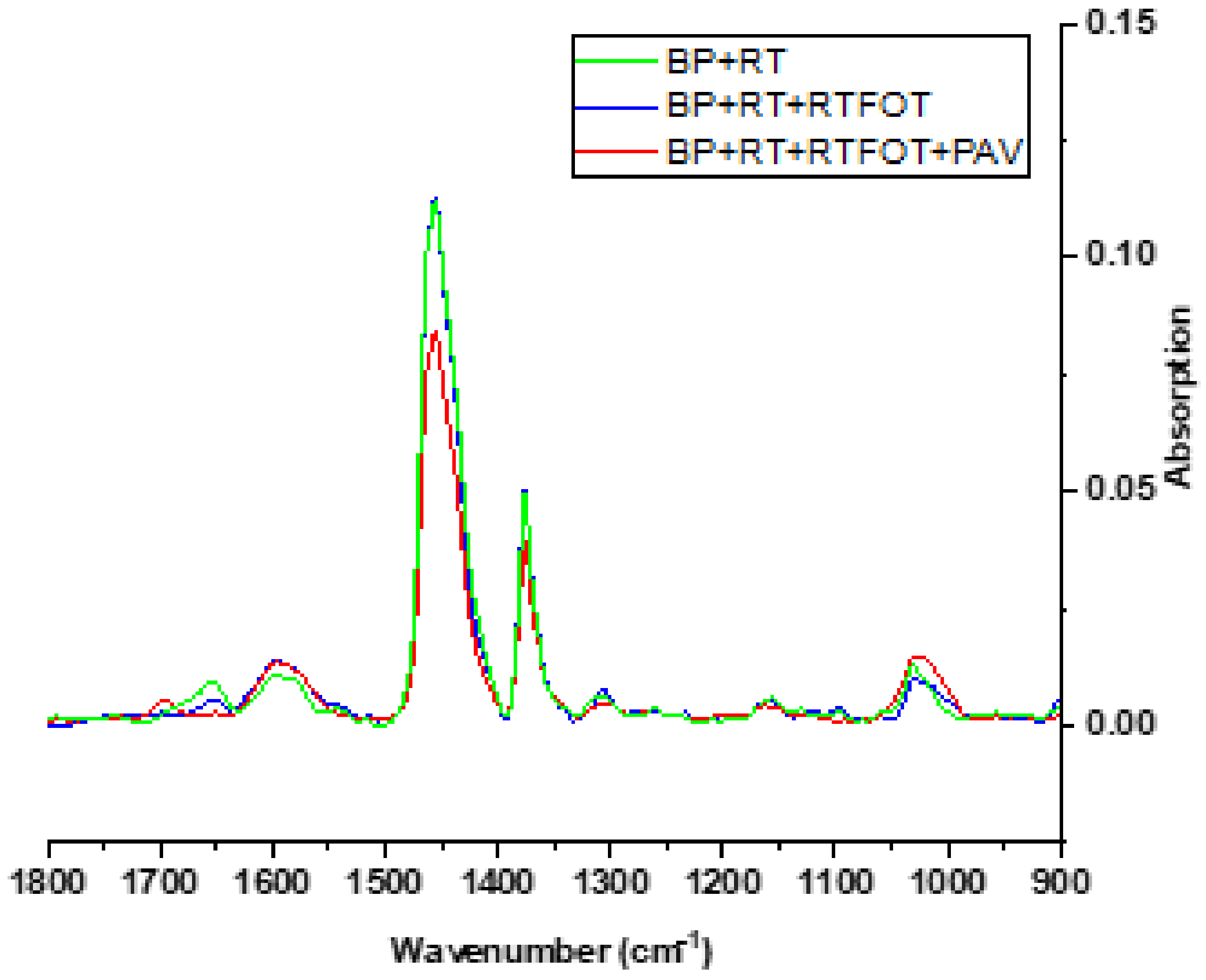

3.4. ATR-FTIR Analysis

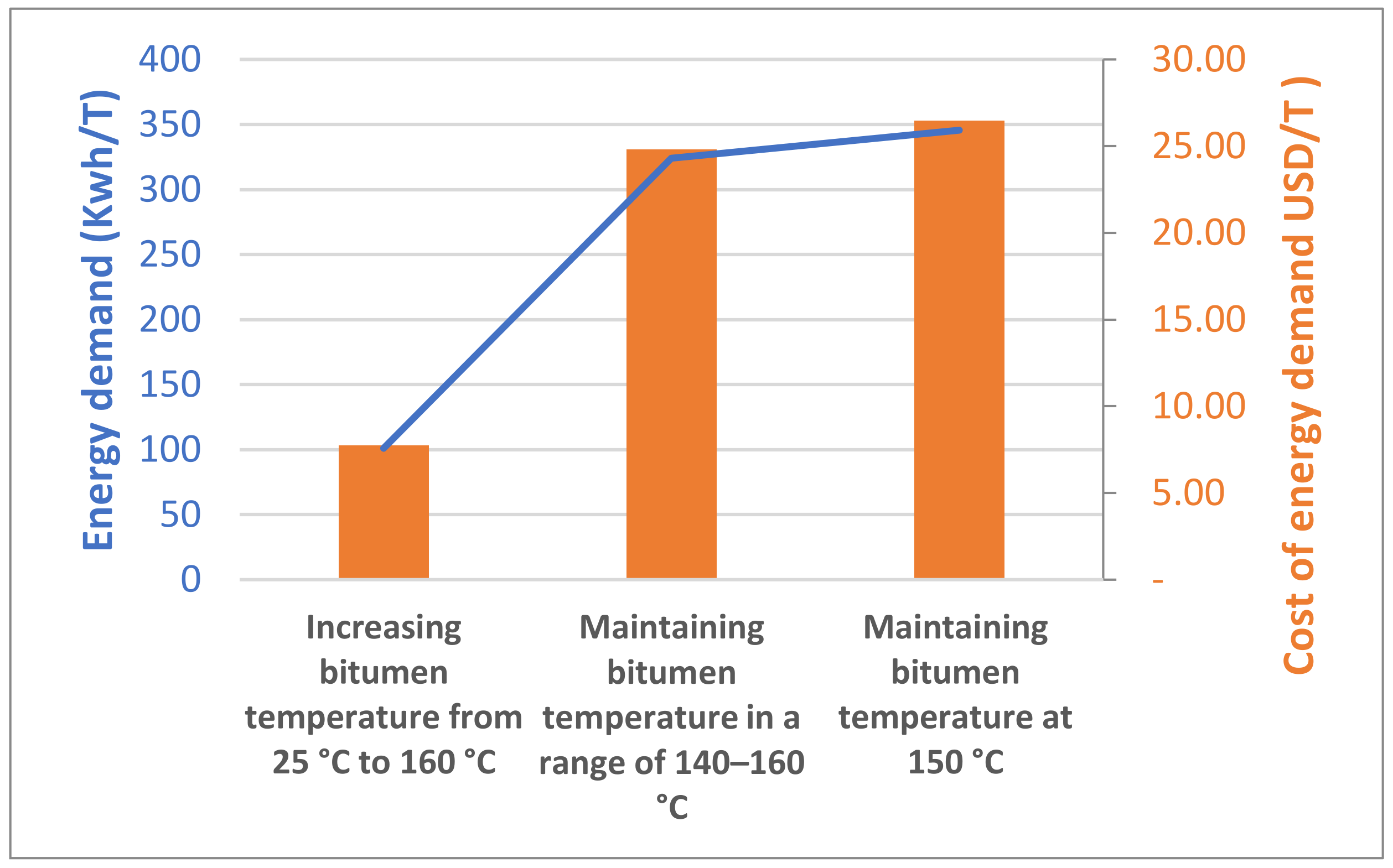

3.5. Thermal Heat Loss Scenarios

4. Conclusions

- On the physical aspect, a minor change was observed after each thermal storage method compared to the control sample. Bitumen kept its conformity to 35/50 bitumen standards at every ageing stage, and the ageing degree was the same for the three specimens after long-term ageing;

- On the chemical aspect, both the storage processes studied affected bitumen oxidative behavior differently. In the long term, ambient temperature storage minimized the sulfoxide group formation, whereas dynamic temperature storage caused an increase in the latter. This impact is acceptable and will be less if we store bitumen for a period less than the maximum storage period that we studied (90 days);

- On the energetic aspect, the calculations showed that the thermal fluctuation storage saved 6% and the ambient temperature storage saved 71% compared to the energy consumption in Bituma Company storage tanks;

- On the economic aspect, these energy savings applied to a storage period of 90 days translate into an economy of 18.8 USD/T and 1.58 USD/T when we store at room temperature and using thermal fluctuations, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lombardi, B.; Kazziha, S. Bitume.Info: Aménager, Construire, Innover; Special Issue-1; Groupement Professionnel des Bitumes (GPB): Paris, France, 2005; p. 33. [Google Scholar]

- Petersen, J.C.; Branthaver, J.F.; Robertson, R.E.; Harnsberger, P.M.; Duvall, J.J.; Ensley, E.K. Effects of physicochemical factors on asphalt oxidation kinetics. Transport. Res. Rec. 1993, 1391, 1–10. [Google Scholar]

- Lu, X.; Issacson, U. Laboratory study on the low temperature physical hardening of conventional and polymer modified bitumen. Constr. Build. Mater. 2000, 14, 79–88. [Google Scholar] [CrossRef]

- Curtis, C.W.; Ensley, K.; Epps, J. Fundamental Properties of Asphalt-Aggregate Interactions Including Adhesion and Absorption, SHRP-A-341; National Research Council: Washington, DC, USA, 1993. [Google Scholar]

- Afechkhar, M. Vieillissement des Bitumes et Effet sur les Performances des Enrobés Bitumineux. Centre National des Etudes et Recherche, Direction des Routes et de la Circulation Routière. In Proceedings of the 7ème Congrés National de la Route, Ouarzazate, Morocco, 9–10 November 2007; Available online: www.ampcr.ma/actes/7eme_congres_national_de_la_route/CONGRE/TH4/TH4_17.pdf (accessed on 13 September 2021).

- Freeston, J.L.; Gillespie, G.; Hesp, S.A.M.; Paliukaite, M.; Taylor, R. Physical Hardening in Asphalt. In Proceedings of the Canadian Technical Asphalt Association 60th Annual Conference, Ottawa, ON, Canada, 15–18 November 2015; Volume LX, pp. 54–81. [Google Scholar]

- Petersen, J.C. Chemical composition of asphalt as related to asphalt durability: State of the art. In Asphaltenes and Asphalts, 2. Development in Petroleum Science; Yen, T.F., Chilingarian, G.V., Eds.; Elsevier: Amsterdam, The Netherlands, 1984; Volume 40, Part B, pp. 363–399. [Google Scholar]

- Read, J.; Whiteoak, D. The Shell Bitumen Handbook, 5th ed.; Thomas Telford Publishing: London, UK, 2003. [Google Scholar]

- Tauste, R.; Moreno-Navarro, F.; Sol-Sánchez, M.; Rubio-Gámez, M.C. Understanding the bitumen ageing phenomenon: A review. Constr. Build. Mater. 2018, 192, 593–609. [Google Scholar] [CrossRef]

- Wu, J. The Influence of Mineral Aggregates and Binder Volumetrics on Bitumen Ageing. Ph.D. Thesis, The University of Nottingham, Nottingham, UK, May 2009. [Google Scholar]

- Mirwald, J.; Maschauer, D.; Hofko, B.; Grothe, H. Impact of reactive oxygen species on bitumen aging—The Viennese binder aging method. Constr. Build. Mater. 2020, 257, 119–495. [Google Scholar] [CrossRef]

- Corigliano, O.; Fragiacomo, P. Extensive analysis of SOFC fed by direct syngas at different anodic compositions by using two numerical approaches. Energy Convers. Manag. 2020, 209, 112664. [Google Scholar] [CrossRef]

- Corigliano, O.; Florio, G.; Fragiacomo, P. A performance analysis of an anaerobic digester—High temperature fuel cells fed by urban solid waste biogas. Energy Source Part A 2011, 34, 207–218. [Google Scholar] [CrossRef]

- Luminosu, I.; Fara, L. Experimental research on bitumen preheating (fluidization) by using solar energy in passive mode. Int. J. Therm. Sci. 2009, 48, 209–217. [Google Scholar] [CrossRef]

- Anoune, K.; Laknizi, A.; Bouya, M.; Astito, A.; Ben Abdellah, A. Sizing a PV-Wind hybrid system using deterministic approach. Energy Convers. Manag. 2018, 169, 137–148. [Google Scholar] [CrossRef]

- Ghazouani, M.; Bouya, M.; Benaissa, M.; Anoune, K.; Ghazi, M. Thermal energy management optimization of solar thermal energy system based on small parabolic trough collectors for bitumen maintaining on heat process. Solar Energy 2020, 211, 1403–1421. [Google Scholar] [CrossRef]

- Shah, S.A.R.; Arshad, H.; Waqar, A.; Saeed, M.H.; Hafeez, S.; Mansoor, J.; Sadiq, A.N.; Malik, M.A. Saving energy in the transportation sector: An analysis of modified bitumen application based on Marshall test. Energies 2018, 11, 3025. [Google Scholar] [CrossRef] [Green Version]

- Merbouh, M. Effect of thermal cycling on the creep-recovery behavior of road bitumen. Energy Procedia 2012, 18, 1106–1114. [Google Scholar] [CrossRef] [Green Version]

- Glaoui, B.; Merbouh, M.; Ven, M.; Chialleux, E.; Youcefi, A. How thermal fatigue cycles change the rheological behavior of polymer-modified bitumen. Proceedings of TerraGreen 13 International Conference 2013—Advancements in renewable energy and clean environment. Energy Procedia 2013, 36, 844–851. [Google Scholar] [CrossRef] [Green Version]

- Tarsi, G.; Varveri, A.; Lantieri, C.; Scarpas, A.; Sangiorgi, C. Effects of different aging methods on chemical and rheological properties of bitumen. J. Mater. Civ. Eng. 2018, 30. [Google Scholar] [CrossRef] [Green Version]

- European Committee for Standardization. EN 12607-1:2014. Bitumen and Bituminous Binders—Determination of the Resistance to Hardening under the Influence of Heat and Air. 2014. Available online: https://standards.iteh.ai/catalog/standards/cen/5e1f0c0a-99bc-4c99-a191-cf07c1482527/en-12607-1-2014 (accessed on 13 September 2021).

- European Committee for Standardization. EN 14769:2013. Bitumen and Bituminous Binders—Accelerated Long-Term Ageing Simulated by a Pressure Ageing Vessel (PAV), AFNOR, France. 2013. Available online: https://infostore.saiglobal.com/en-au/standards/nf-en-14769-2013-36667_saig_afnor_afnor_82014/ (accessed on 13 September 2021).

- European Committee for Standardization. EN 1426:2015. Bitumen and Bituminous Binders—Determination of Needle Penetration. 2015. Available online: https://standards.iteh.ai/catalog/standards/cen/853455a7-1455-4f3e-a2b8-60d17bfdf3df/en-1426-2015 (accessed on 13 September 2021).

- European Committee for Standardization. EN 1427:2015. Bitumen and Bituminous Binders—Determination of the Softening Point. Ring and Ball Method. 2015. Available online: https://standards.iteh.ai/catalog/standards/cen/0edd2612-e3e1-43b4-b533-8debe5c55040/en-1427-2015 (accessed on 13 September 2021).

- Petersen, J.C.; Glacer, R. Asphalt oxidation mechanisms and the role of oxidation products on age hardening revisited. Road Mater. Pavement Des. 2011, 12, 795–819. [Google Scholar] [CrossRef]

- Lu, X.; Isacsson, U. Effect of ageing on bitumen chemistry and rheology. Constr. Build. Mater. 2002, 16, 15–22. [Google Scholar] [CrossRef]

- Ongel, A.; Hugener, M. Impact of rejuvenators on ageing properties of bitumen. Constr. Build. Mater. 2015, 94, 467–474. [Google Scholar] [CrossRef]

- Pfeiffer, J.; Van Doormaal, P. The rheological properties of asphaltic bitumens. J. Inst. Pet. 1936, 22, 414–440. [Google Scholar]

- Normativa de Carreteras. NLT-181/99 Indice de Penetracion de los Betunes Asfalticos, Spain. 1999. Available online: https://normativadecarreteras.com/listing/nlt-18199-indice-penetracion-los-betunes-asfalticos/ (accessed on 13 September 2021).

- Olugbenga, A.E.; Olugbenga, A.F.; Jonathan, G. Softening point and penetration index of bitumen from parts of southwestern Nigeria. Nafta Zagreb 2012, 63, 319–323. [Google Scholar]

- Yao, H.; Dai, Q.; You, Z. Fourier Transform Infrared Spectroscopy characterization of aging-related properties of original and nano-modified asphalt binders. Constr. Build. Mater. 2015, 101, 1078–1087. [Google Scholar] [CrossRef]

- Institut Français des Sciences et Techniques des Réseaux, de l’Aménagement et des Transports (IFSTTAR). French MLPC Method, No.69 for Binders: Identification et Dosage des Fonctions Oxygénées Présentes dans les Liants Bitumi-neux—Analyse par Spectrométrie Infrarouge à Transformée de Fourier. 2010. Available online: https://www.ifsttar.fr/fileadmin/user_upload/editions/lcpc/MethodeDEssai/MethodeDEssai-LCPC-ME69.pdf (accessed on 13 September 2021).

| Functional Group | Bond Vibration | Absorption Wavenumber (cm−1) |

|---|---|---|

| Carbonyls | C=O stretching | 1740–1690 |

| Aromatic structures | C=C stretching | 1620–1560 |

| Aliphatic structures (Methyl) | CH3 asymmetric bending | 1460 |

| Branched aliphatic structures (Methylene) | CH3 symmetric bending | 1375 |

| Sulfoxides | S=O stretching | 1055–1030 |

| Aromatic structures | C–H 1,3-disubstituted bending | 864 |

| Aromatic structures | C–H 1,4-disubstituted bending | 814 |

| Aromatic structures | C–H monosubstituted bending | 743 |

| Aromatic structures | C–H monosubstituted bending | 724 |

| Sample | Ageing Stage | Penetration at 25 °C ([0.1 mm]) | Softening Point R&B (°C) | Residual Penetration (%) | Increment of Softening Point (°C) |

|---|---|---|---|---|---|

| BP | Unaged | 42 | 53.0 | - | - |

| BP + TC | 43 | 52.2 | - | - | |

| BP + RT | 41 | 53.2 | - | - | |

| BP | RTFOT-aged | 26 | 58.0 | 61.90 | 5.0 |

| BP + TC | 26 | 59.0 | 60.46 | 6.8 | |

| BP + RT | 27 | 59.0 | 65.85 | 5.8 | |

| BP | RTFOT + PAV-aged | 18 | 65.6 | - | - |

| BP + TC | 17 | 64.8 | - | - | |

| BP + RT | 17 | 66.8 | - | - |

| Ageing Stage | Unaged | ||

|---|---|---|---|

| Sample | BP | BP + TC | BP + RT |

| PI | −0.87 | −1.01 | −0.88 |

| Sample | I(CO) | I(SO) | ||

|---|---|---|---|---|

| Unaged to RTFOT | RTFOT to PAV | Unaged to RTFOT | RTFOT to PAV | |

| BP | 0.0071 | 0.0317 | 0.0649 | 0.0614 |

| BP + TC | 0.0282 | 0.0006 | 0.0349 | 0.1376 |

| BP + RT | 0.0038 | 0.0343 | 0.0014 | 0.0896 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tahri, A.; Bouya, M.; Ghazouani, M.; Achak, O.; Chafik, T. Methodology for Efficient Bitumen Storage with Reduced Energy Consumption. Appl. Sci. 2021, 11, 9319. https://doi.org/10.3390/app11199319

Tahri A, Bouya M, Ghazouani M, Achak O, Chafik T. Methodology for Efficient Bitumen Storage with Reduced Energy Consumption. Applied Sciences. 2021; 11(19):9319. https://doi.org/10.3390/app11199319

Chicago/Turabian StyleTahri, Amina, Mohsine Bouya, Mokhtar Ghazouani, Ouafae Achak, and Tarik Chafik. 2021. "Methodology for Efficient Bitumen Storage with Reduced Energy Consumption" Applied Sciences 11, no. 19: 9319. https://doi.org/10.3390/app11199319

APA StyleTahri, A., Bouya, M., Ghazouani, M., Achak, O., & Chafik, T. (2021). Methodology for Efficient Bitumen Storage with Reduced Energy Consumption. Applied Sciences, 11(19), 9319. https://doi.org/10.3390/app11199319