Research on Improved OEE Measurement Method Based on the Multiproduct Production System

Abstract

Featured Application

Abstract

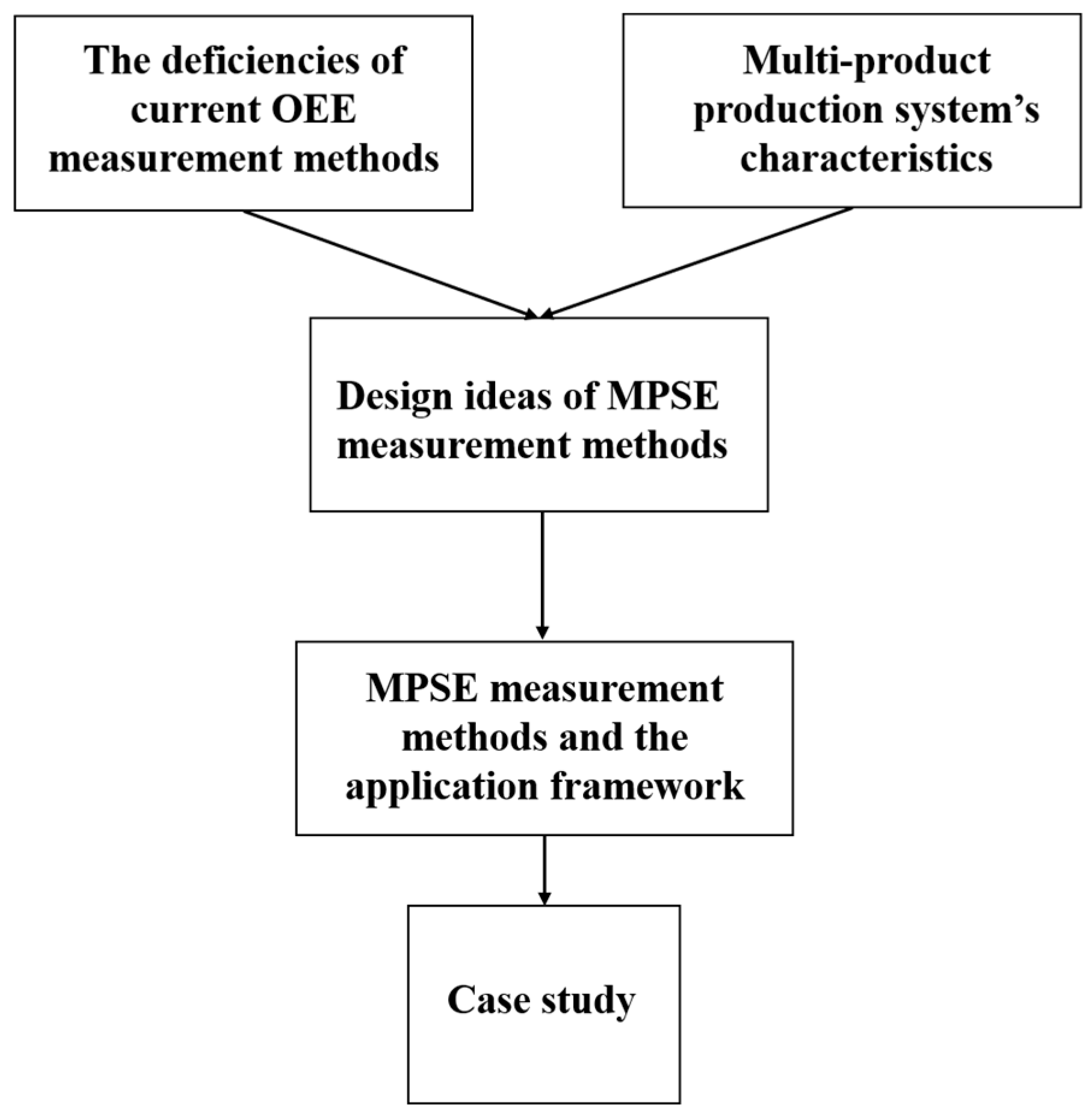

1. Introduction

- The deficiencies of mainstream OEE measurement methods in the multiproduct production system are concluded, and the characteristics of the multiproduct production system are summarized;

- MPSE is proposed to measure the production effectiveness of the multiproduct production system, improving the production effectiveness and operation performances of the multiproduct production system;

- The application framework of MPSE is introduced, which is based on the Plan-Do-Check-Action cycle (PDCA), is available for the improvement of the multiproduct production system continuously.

2. Mainstream OEE Measurement Methods and Their Deficiencies

2.1. Introduction of Mainstream OEE Measurement Methods

2.2. The Defficiencies of Mainstream OEE Measurement Methods

- Inadequacy. Some of the measurement methods above focus on single equipment or single production line rather than the whole production system which would cause the omission of measurement values [33]. Therefore, these measurement methods cannot be used to calculate the indicators of the multiproduct production system precisely, such as production effectiveness and measuring losses [34]. Hence, a specific indicator representing the whole effectiveness of the production system should be established in order to eliminate the measurement errors [35].

- Inflexibility. The indicators in these measurement methods are fixed. Therefore, they cannot be adjusted quickly when the production conditions change. In a real manufacturing environment, the production plans in the multiproduct production system are flexible and changeable. Consequently, the actual losses would be concealed, and the measured production effectiveness in the system may be inexact if these measurement methods are still adopted in the multiproduct production system, which would cause that the observational values are in an abnormal fluctuation. Thus, the measurement methods should be dynamic to adapt to a dynamic environment [36,37].

- Difficulties in continuous improvement of the production system. It is reasonable to diagnose the negative factors which lead to the losses in the production system and propose the countermeasures to the managers in order to improve the overall production system continuously [38]. However, the negative factors in the multiproduct production system cannot be reflected by former measurement methods sufficiently since these measurement methods did not take into account the complex manufacturing process in the multiproduct production system. As a result, the negative factors in the system are difficult to find [39] and related managerial enlightenments are hardly indicated, which is not beneficial to the continuous improvement of the multiproduct production system.

3. Methodology

3.1. Characteristics of the Multiproduct Production System

- Organizational complexity. Multiproduct production system is composed of the diverse manufacturing equipment, products, and so on. Therefore, there are more manufacturing strategies compared with a single product manufacturing system because of the customized demands, which implies a more complex production system [40,41,42].

- Bottleneck variability. The production system, which produces a variety of products, has different production bottlenecks [43,44], such as the machines, raw materials, specifications, production speeds, and the like. Even in the same production line, different bottlenecks may appear because of the changes in the manufacturing environment, the device types, and equipment status [45]. Thus, the bottlenecks in the multiproduct production system are variable and may bring an adverse effect on the flow of products [46].

- Product specification diversity. In a multiproduct production system, the products with different specifications including colors, sizes, and other attributes should be manufactured in one production line [47]. Hence, the product specifications are quite varied and diverse based on the perspective of the holistic system.

3.2. Design Ideas of MPSE

- Integration idea. The idea of integration has been widely adopted in many other research fields, such as business, programming, and so on. In the process of manufacturing, the idea of integration can be effectively used in multitasking project management, system design, and the like [48,49,50]. Similarly, in the multiproduct production system, the idea of integration is often applied in the manufacturing industry by solving multiple subproblems to achieve an overall goal, such as the capacity improvement and quality improvement [51,52]. Therefore, based on the integration idea, we can simplify the measurement for whole system indicators by measuring several subsystem indicators, which is more accessible in the multiproduct production environment. Hence, the integration idea should be applied into the design of MPSE.

- Dynamic idea. The dynamic disturbance is commonly found in production systems because of unpredictable real-time events. In the environment of the production system, the occurrence of some random internal and external noises, such as machine tool failure, new order entry, would cause the infeasibility of original optimal scheduling [53,54,55]. Thus, we have to adjust the scheduling plan dynamically. If we still adopt the static measurement method, the data we collect would not be accurate. Therefore, the dynamic idea is often used to solve these problems by designing a dynamic management system to adapt to the manufacturing environment’s change, especially in the multiproduct production system [56,57]. In addition, the dynamic idea can still support the dynamic measurement index of MPSE although there are some changes in the bottleneck, load time, and so on.

- Standardization idea. In the statistical model, data should be standardized to eliminate the impact of dimension [58]. Similarly, the measurement indicators of different dimensions, which are caused by the different product’s technologies, the different units of measurement for bottleneck velocity, and so on, should be converted in the same dimension since the data in manufacturing system may in different units, for example the output of product with different specifications. Therefore, the standardization idea should be used in MPSE to eliminate the negative effect caused by the variety of products in the multiproduct production system [59].

4. MPSE

4.1. Calculation Steps of MPSE

- 1.

- To measure the theoretical bottleneck speed of each product:

- 2.

- To measure the actual bottleneck speed of each product:

- 3.

- To calculate theoretical load time of each product:

- 4.

- To calculate the actual load time of each product:

- 5.

- To calculate the production capacity:

- 6.

- To integrate all into a complete arithmetic:

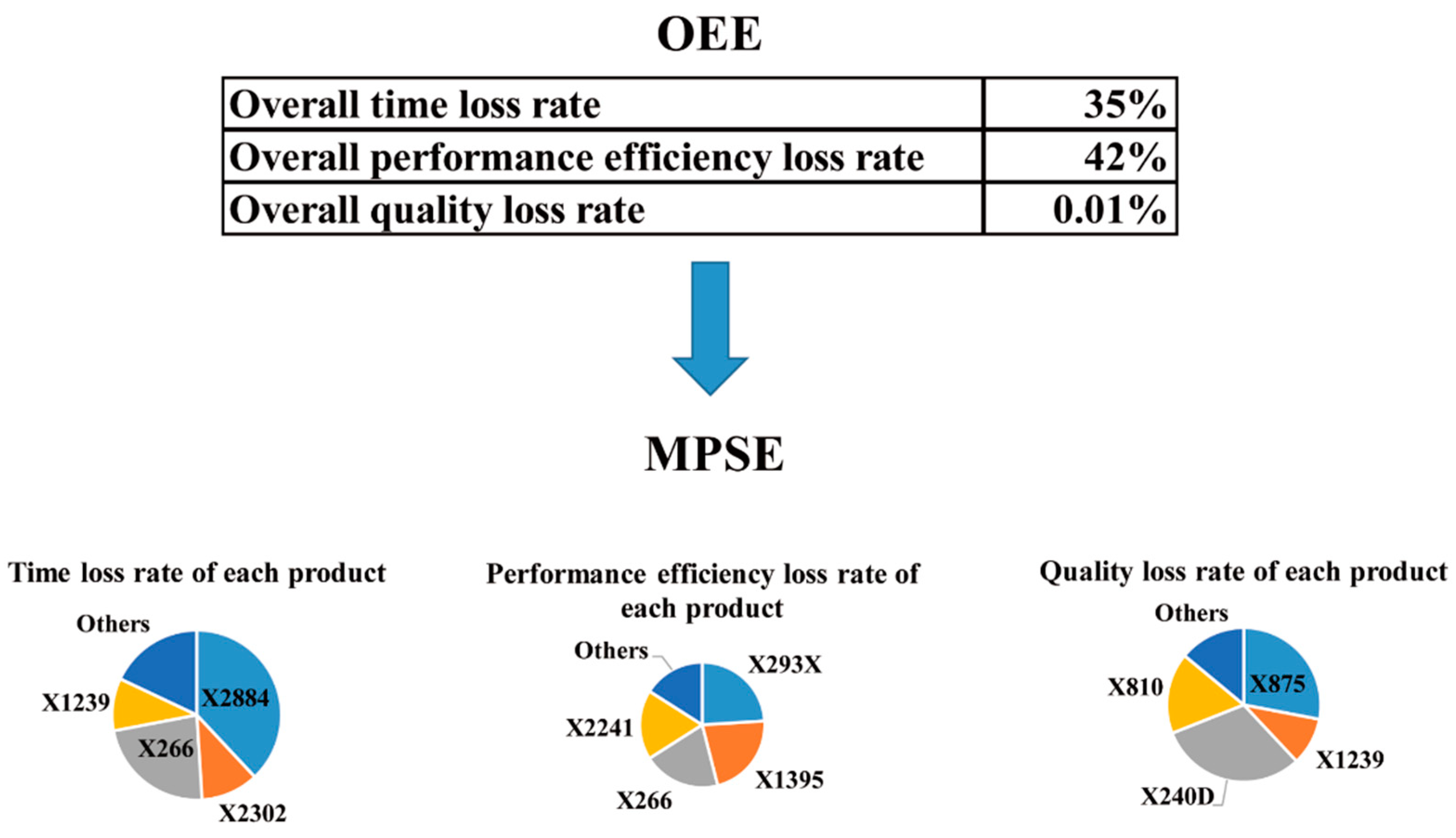

4.2. Information Obtained from MPSE

4.3. Application Framework of MPSE

- The production capacities of each product and the overall production effectiveness of the multiproduct production system in the statistical time are calculated by Equations (16) and (17).

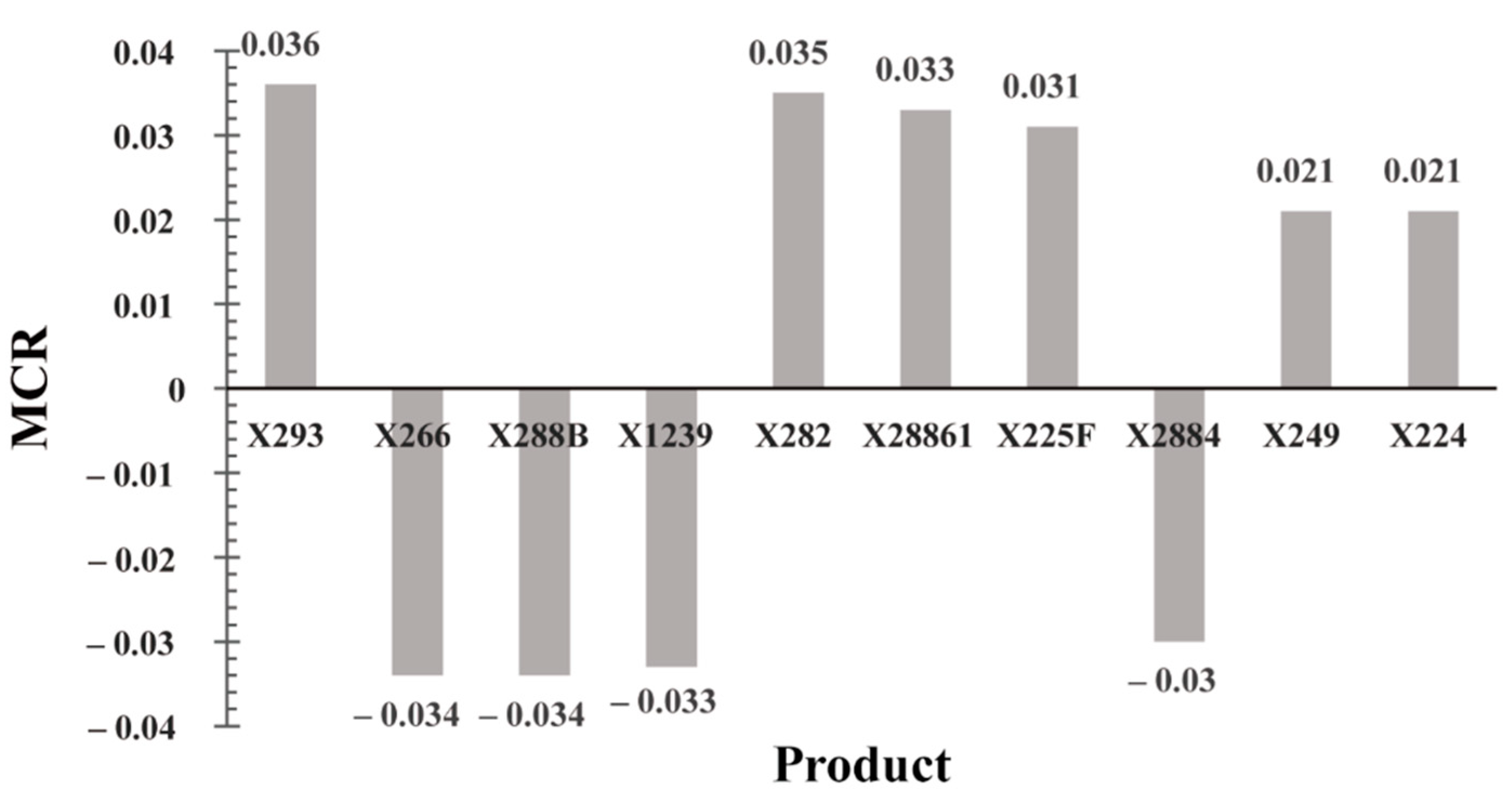

- In this step, the s and s of products can be calculated based on Equations (32) and (33), respectively, and then, we can find the product with a minimum value based on the value of s, which is selected as the object to be improved. Specifically, is a comprehensive indicator that can be used to find those products with large gaps between the theoretical performances and actual performances in terms of , and which are important criteria of the ability of product manufacturing [63]. Thus, is chosen as the indicator to find the products to be improved in this paper.

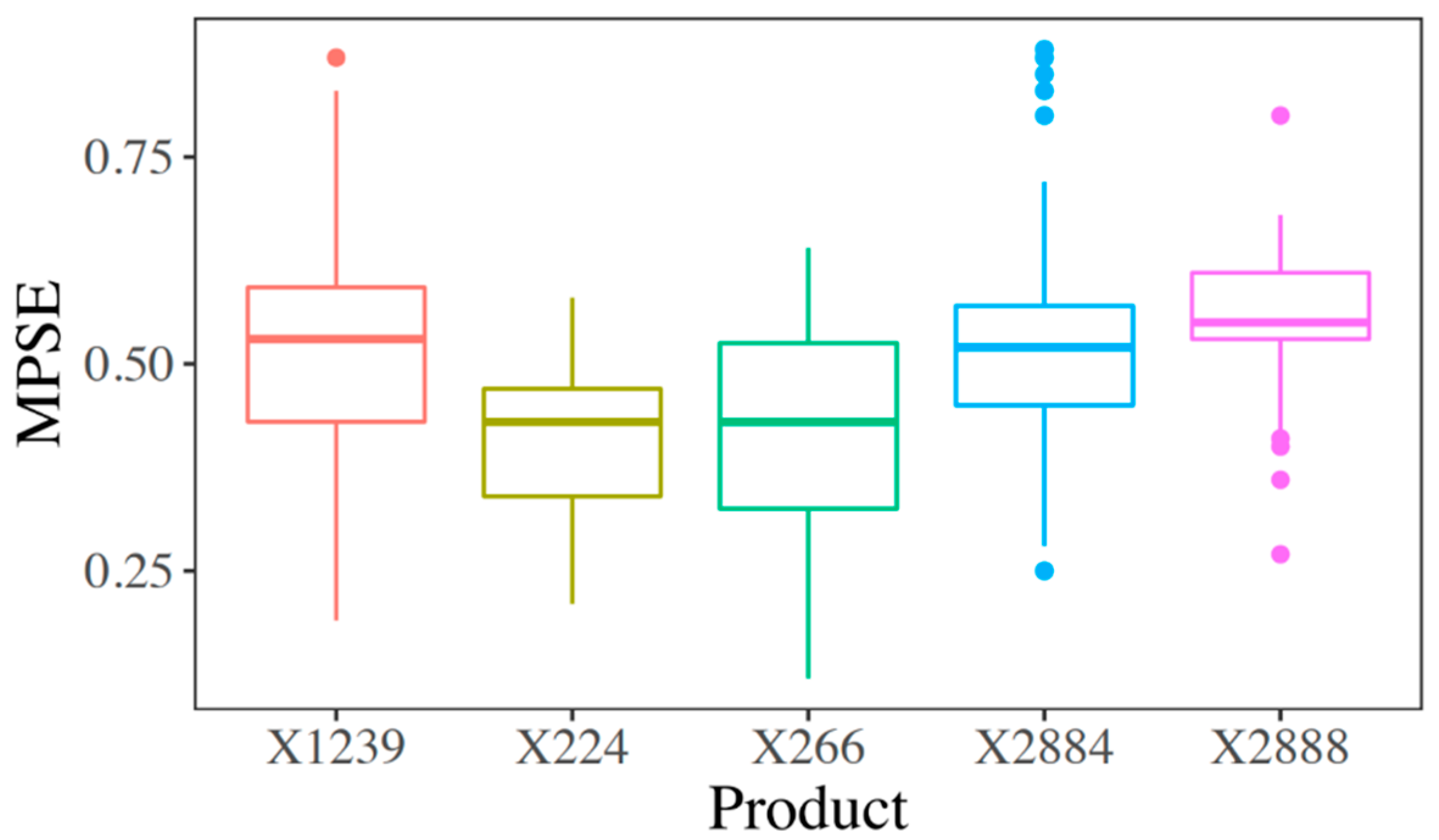

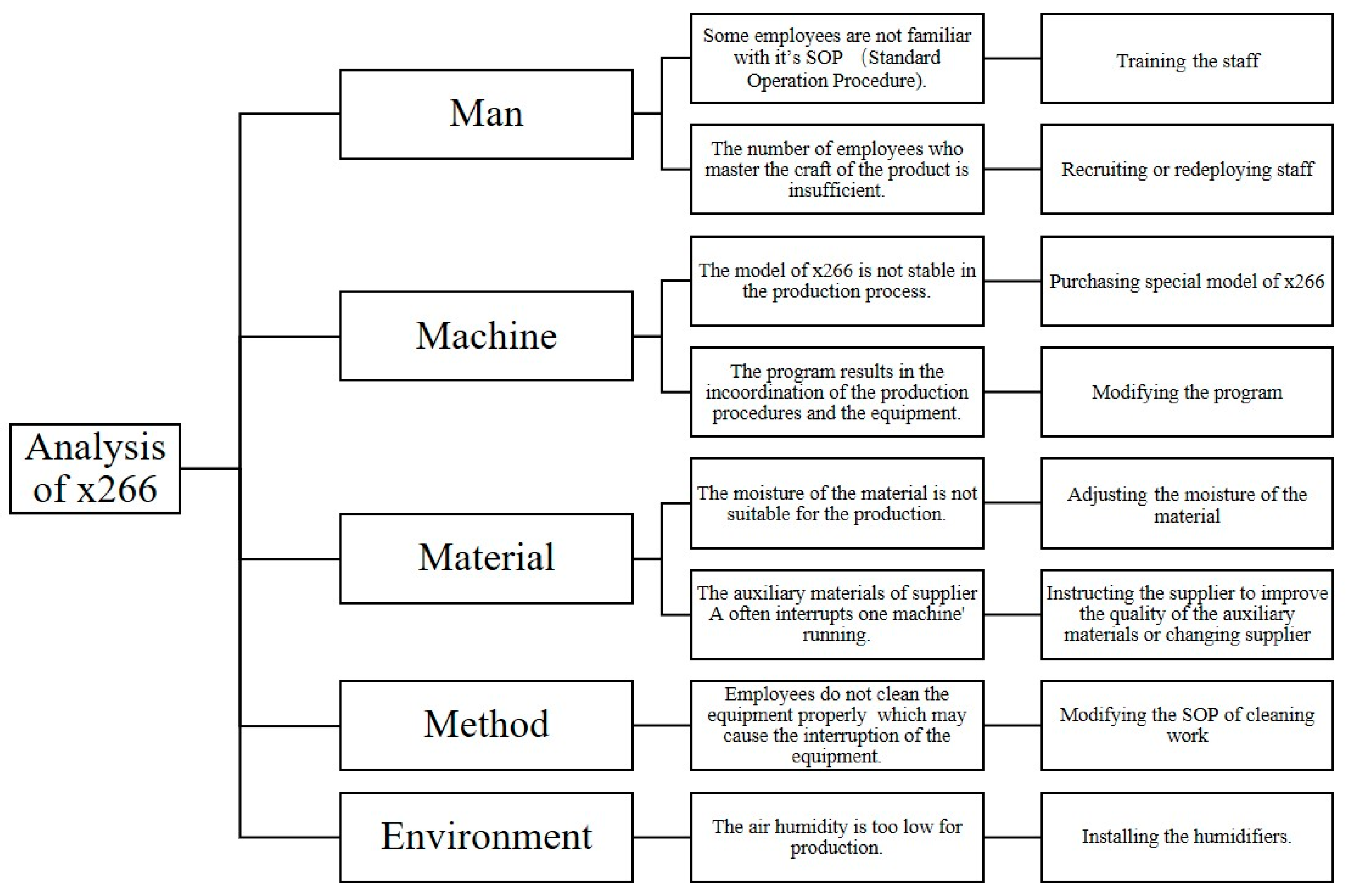

- At this stage, some improvement plans for the products can be made by the analysis instruments, such as box plot and 4M1E analysis (analyzing problem by five factors, man, machine, material, method, and environment) [64]. In addition, these improvement plans should be executed.

- The improvements are checked, and the process should return to step 3 if the improvements are dissatisfactory during this step.

- A new cycle starts again by repeating step 1.

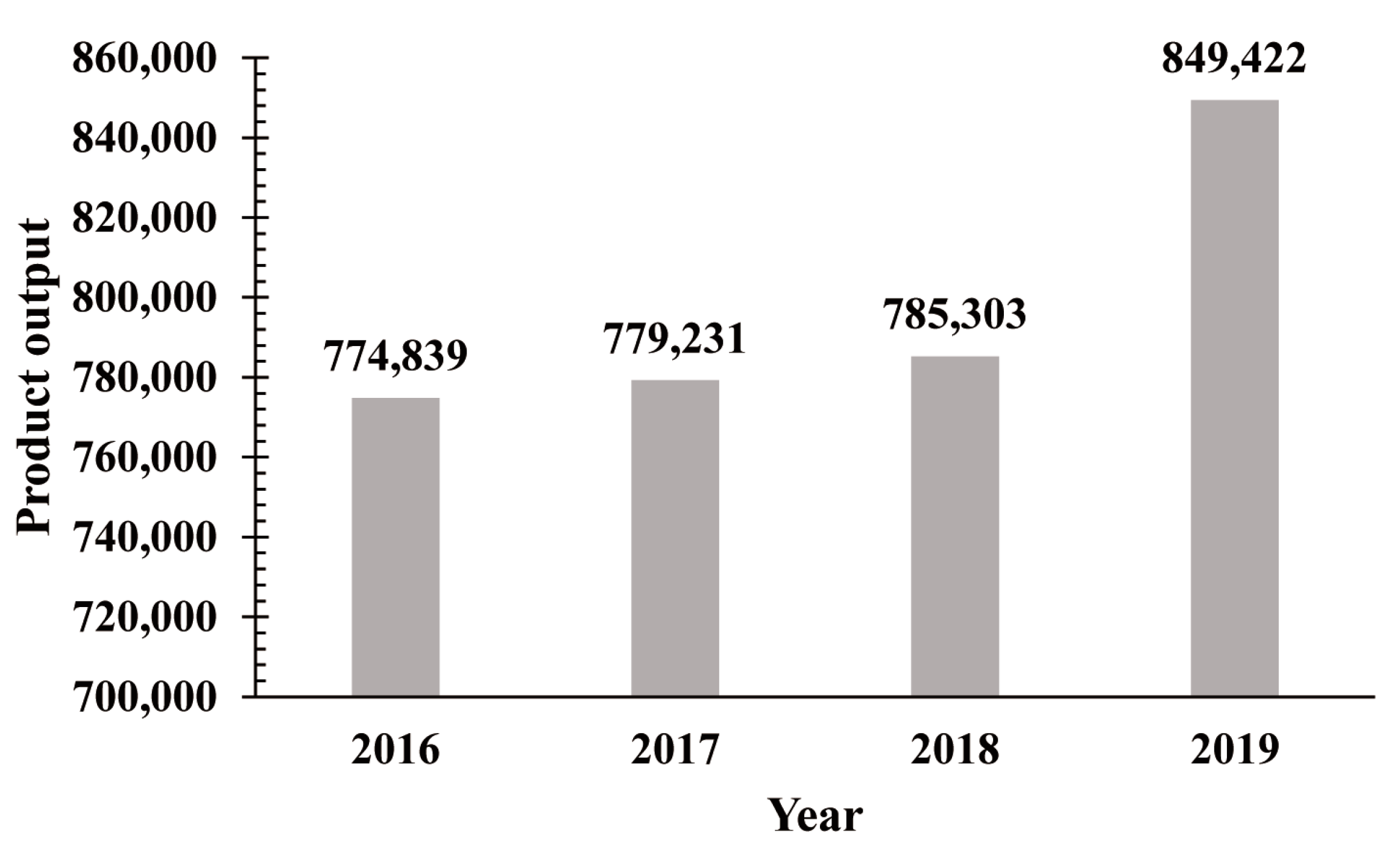

5. Case Study

5.1. Introduction of Enterprise Q

5.2. Implementation Process

5.2.1. Calculating the Overall Production Effectiveness in All Statistical Times

- The theoretical bottleneck speeds () of each product are measured by Equation (12). There are six manufacturing procedures in the process of manufacturing and the designed production speeds in the procedures are 75 pieces/min, 61 pieces/min, 84 pieces/min, 53 pieces/min, 73 pieces/min, and 72 pieces/min respectively.

- The actual bottleneck speeds () are measured. In the actual process of manufacturing , the speeds in these manufacturing procedures are 64 pieces/min, 41 pieces/min, 66 pieces/min, 44 pieces/min, 58 pieces/min, and 69 pieces/min. Therefore, according to Equation (13):

- The theoretical load times are calculated. The planned working time of in a work shift is 480 min, and the planned downtime including cleaning time, maintenance time, adjustment time, and rest time is 55 min. According to Equation (14):

- The actual load time of is measured by Equation (15). The unplanned downtime such as equipment failure time, supply delay time, and unplanned adjustment time, in total is 62 min, thus,

- The production capacity of is calculated. The number of defective products in the statistical time is 63, and the figure can be calculated by Equation (16):

- All s are integrated together by Equation (17). Actually, there are 43 kinds of products in the product production system during this statistical time. The is:

- Using the steps of 1–6 to calculate the . These data are concluded in Table 4:

5.2.2. Selecting Products for Improvement

5.2.3. Making and Executing Improvement Plans

5.2.4. Checking the Improvements for All Selected Objectives

5.2.5. Restarting a Cycle

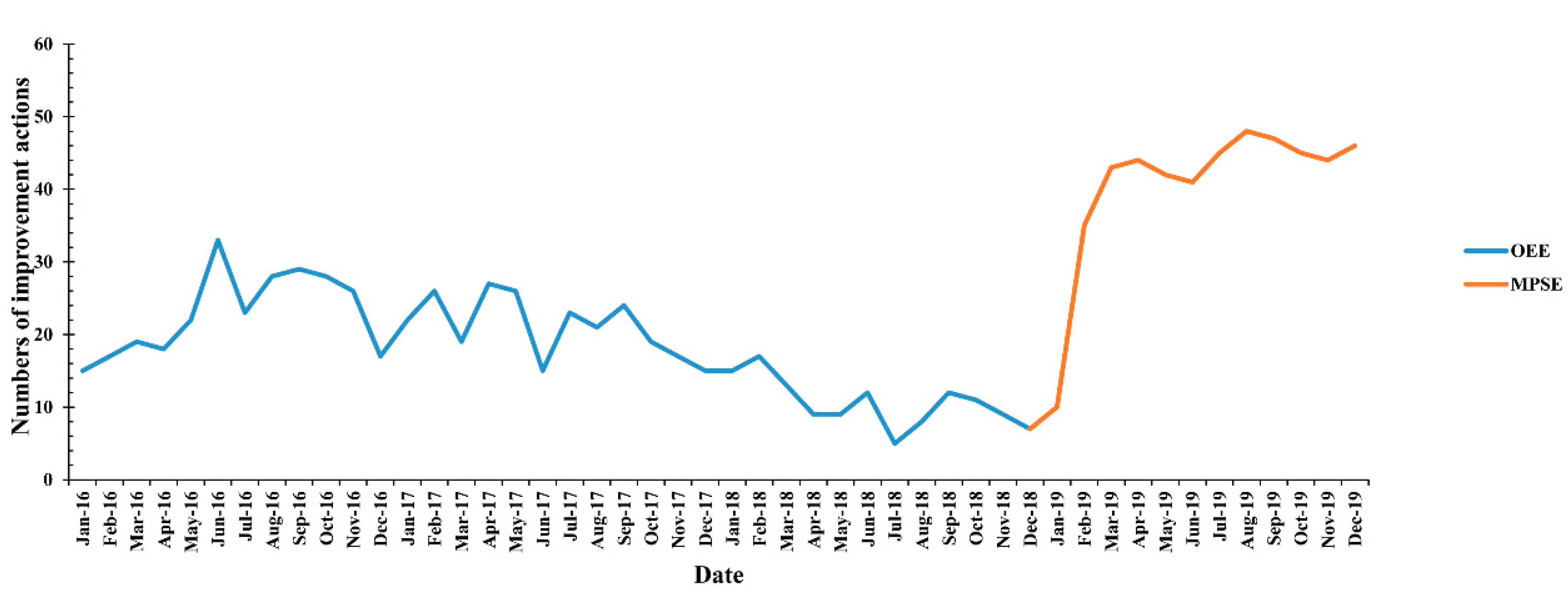

6. Result Analysis

6.1. Improvement of Production Effectiveness

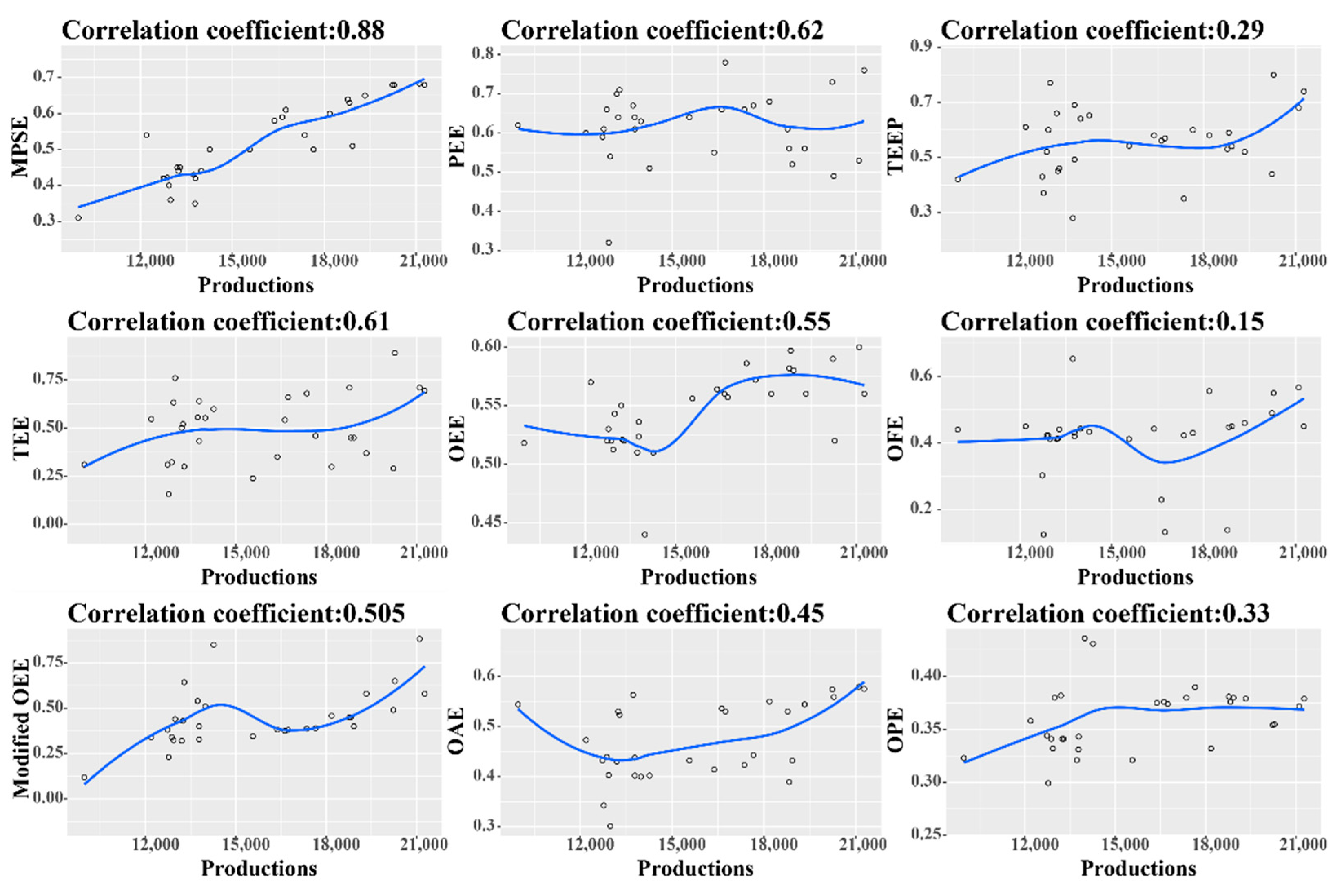

6.2. Improvements in the Measurement Effects

7. Discussion, Research Implications and Further Research Directions

7.1. Discussion

7.2. Research Implications

7.2.1. Theoretical Implications

7.2.2. Managerial Implications

7.3. Further Research Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Torales, J.; O’Higgins, M.; Castaldelli-Maia, J.; Ventriglio, A. The outbreak of COVID-19 coronavirus and its impact on global mental health. Int. J. Soc. Psychiatr. 2020, 66, 317–320. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Zhao, Y.; Liu, J.; He, X.; Wang, B.; Fu, S.; Yan, J.; Niu, J.; Zhou, J.; Luo, B. Effects of temperature variation and humidity on the death of COVID-19 in Wuhan, China. Sci. Total Environ. 2020, 724, 138226. [Google Scholar] [CrossRef] [PubMed]

- Feng, L. Robustness Evaluation of Flexible Manufacturing System Considering the Static & Dynamic Manufacturing Environment. In Proceedings of the 2009 International Conference on Information Management, Innovation Management and Industrial Engineering, Xi’an, China, 26–27 December 2009. [Google Scholar]

- Zhu, X.P. Analysis and Improvement of Enterprise’s Equipment Effectiveness Based on OEE. In Proceedings of the 2011 International Conference on Electronics, Communications and Control (ICECC), Ningbo, China, 9–11 September 2011. [Google Scholar]

- Tang, H.; Li, D.; Wang, S.; Dong, Z. CASOA: An architecture for agent-based manufacturing system in the context of Industry 4.0. IEEE Access. 2018, 6, 12746–12754. [Google Scholar] [CrossRef]

- Koch, A. OEE für das Produktionsteam. Das Vollständige OEE-Benutzerhandbuch—Oder Wie Sie Die Verborgene Maschine Entdecken, 3rd ed.; CETPM Publishing: Herrieden, Germany, 2016. [Google Scholar]

- Schmitt, J.; Engelmann, B.; Brutigam, V.; Miller, E.; Schmitt, S. Advances in Machine Learning Detecting Changeover Processes in Cyber Physical Production Systems. J. Manuf. Mater. Process. 2020, 4, 108. [Google Scholar]

- Focke, M.; Steinbeck, J. Steigerung der Anlagenproduktivität Durch OEE-Management. Definitionen, Vorgehen und Methoden—Von Manuell bis Industrie 4.0, 1st ed.; Springer Gabler: Wiesbaden, Germany, 2018. [Google Scholar]

- Ng Corrales, L.C.; Lambán, M.P.; Hernandez Korner, M.E.; Royo, J. Overall Equipment Effectiveness: Systematic Literature Review and Overview of Different Approaches. Appl. Sci. 2020, 10, 6469. [Google Scholar] [CrossRef]

- Hwang, G.; Lee, J.; Park, J.; Chang, T. Developing performance measurement system for internet of things and smart factory environment. Int. J. Prod. Res. 2017, 55, 2590–2602. [Google Scholar] [CrossRef]

- Dovere, E.; Cavalieri, S.; Ierace, S. RFID systems for moveable asset management: An assessment model. Int. J. Prod. Res. 2017, 55, 1336–1349. [Google Scholar] [CrossRef]

- Poorya, G.Y.; Aydin, A.; Majid, H. An empirical investigation of the relationship between overall equipment efficiency (OEE) and manufacturing sustainability in industry 4.0 with time study approach. Sustainability 2018, 10, 3031. [Google Scholar]

- Maideen, N.C.; Sahudin, S.; Yahya, N.H.M.; Norliawati, A.O. Practical framework: Implementing OEE method in manufacturing process environment. In Proceedings of the 2015 2nd International Manufacturing Engineering Conference(iMEC)/3rd Asia-Pacific Conference on Manufacturing Systems (APCOMS), Kuala Lumpur, Malaysia, 12–14 November 2015. [Google Scholar]

- Domingo, R.; Aguado, S. Overall environmental equipment effectiveness as a metric of a lean and green manufacturing system. Sustainability 2015, 7, 1–17. [Google Scholar]

- Mahmoud, A.A.; Aly, M.F.; Mohib, A.M.; Afefy, I.H. New optimization model for multi-period multi-product production planning system with uncertainty. Ind. Eng. Manag. Syst. 2019, 18, 872–883. [Google Scholar] [CrossRef]

- Talay, I.; Ozdemirakyildirim, O.O. Optimal procurement and production planning for multi-product multi-stage production under yield uncertainty. Eur. J. Oper. Res. 2019, 275, 536–551. [Google Scholar] [CrossRef]

- Liu, X.J.; Zhao, F.; Ma, X.Y. Joint optimal multi-product production and non-cyclical preventive maintenance planning model. Chin. J. Manag. Sci. 2017, 25, 189–196. (In Chinese) [Google Scholar]

- Ettaye, G.; El Barkany, A.; Jabri, A.; El Khalfi, A. Optimizing the integrated production and maintenance planning using genetic algorithm. Int. J. Eng. Bus. Manag. 2018, 10, 1847979018773260. [Google Scholar] [CrossRef]

- Lu, S.; Xie, L.; Zhu, L.; Su, H.Y. Integrated scheduling of a hybrid manufacturing and recovering system in a multi-product multi-stage environment with carbon emission. J. Clean. Prod. 2019, 222, 695–709. [Google Scholar] [CrossRef]

- Rauf, M.; Guan, Z.; Yue, L.; Guo, Z.; Mumtaz, J.; Ullah, S. Integrated planning and scheduling of multiple manufacturing projects under resource constraints using raccoon family optimization algorithm. IEEE Access. 2020, 8, 151279–151295. [Google Scholar] [CrossRef]

- Oyebolu, F.B.; Allmendinger, R.; Farid, S.S.; Branke, J. Dynamic scheduling of multi-product continuous biopharmaceutical facilities: A hyper-heuristic framework. Comput. Chem. Eng. 2019, 125, 71–88. [Google Scholar] [CrossRef]

- Du, S.C.; Xu, R.; Li, L. Modeling and analysis of multiproduct multistage manufacturing system for quality improvement. IEEE Trans. Syst. Man Cybern. Syst. 2018, 48, 801–820. [Google Scholar]

- Zhang, Y.J.; Gu, C.C.; Wang, J.; Zhang, L.G.; Hu, X.; Ma, X.D. Dynamic modeling method of mission reliability of a multi-state manufacturing system with multiple production lines. IEEE Access 2020, 8, 57012–57023. [Google Scholar] [CrossRef]

- Nakajima, S. Introduction to TPM; Productivity Press: Portland, OR, USA, 1988. [Google Scholar]

- Kumar, U.; Galar, D.; Parida, A.; Stenstrom, C.; Berges, L. Maintenance performance metrics: A state-of-the-art review. J. Qual. Maint. Eng. 2013, 19, 233–277. [Google Scholar] [CrossRef]

- Ivancic, I. Development of maintenance in modern production. In Proceedings of the Euromaintenance’98 Conference, Dubrovnik, Hrvatska, 5–7 October 1998. [Google Scholar]

- Raouf, A. Improving capital productivity through maintenance. Int. J. Oper. Prod. Man. 1994, 14, 44–52. [Google Scholar] [CrossRef]

- Scott, D.; Pisa, R. Can overall factory effectiveness prolong Moore’s law? Solid State Technol. 1998, 41, 75–82. [Google Scholar]

- Huang, S.H.; Dismukes, J.P.; Shi, J.; Su, Q.; Razzak, M.A.; Bodhale, R.; Robinson, D.E. Manufacturing productivity improvement using effectiveness metrics and simulation analysis. Int. J. Prod. Res. 2003, 41, 513–527. [Google Scholar] [CrossRef]

- Jonsson, P.; Lesshammar, M. Evaluation and improvement of manufacturing performance measurement system—The role of OEE. Int. J. Oper. Prod. Man. 1999, 19, 55–78. [Google Scholar]

- Sheu, D.D. Overall input efficiency and total equipment efficiency. IEEE Trans. Semicond. Manuf. 2006, 19, 496–501. [Google Scholar] [CrossRef]

- Ron, A.J.D.; Rooda, J.E. Equipment effectiveness: OEE revisited. IEEE Trans. Semicond. Manuf. 2005, 18, 190–196. [Google Scholar]

- Chien, C.; Chen, H.; Wu, J.; Hu, C. Constructing the OGE for promoting tool group productivity in semiconductor manufacturing. Int. J. Prod. Res. 2007, 45, 509–524. [Google Scholar] [CrossRef]

- Raja, P.N.; Kannan, S.M.; Jeyabalan, V. Overall line effectiveness—A performance evaluation index of a manufacturing system. Int. J. Product. Qual. Manag. 2010, 5, 38–59. [Google Scholar] [CrossRef]

- Chen, W.; Chien, C. Measuring relative performance of wafer fabrication operations: A case study. J. Intell. Manuf. 2011, 22, 447–457. [Google Scholar]

- Ghalayini, A.M.; Noble, J.S. The changing basis of performance measurement. Int. J. Oper. Prod. Man. 1996, 16, 63–80. [Google Scholar] [CrossRef]

- Pinto, J.K.; Slevin, D.P. Critical factors in successful project implementation. IEEE Trans. Eng. Manag. 1987, 34, 22–27. [Google Scholar] [CrossRef]

- Ylipaa, T.; Skoogh, A.; Bokrantz, J.; Gopalakrishnan, M. Identification of maintenance improvement potential using OEE assessment. Int. J. Product. Qual. Manag. 2017, 66, 126–143. [Google Scholar] [CrossRef]

- Mathur, A.; Dangayach, G.S.; Mittal, M.L.; Sharma, M.K. Performance measurement in automated manufacturing. Meas. Bus. Excell. 2011, 15, 77–91. [Google Scholar] [CrossRef]

- Yu, M.C.; Greene, T.J. An operational measure of routing flexibility in a multi-stage multi-product production system. Int. J. Adv. Manuf. Technol. 2009, 43, 357–364. [Google Scholar] [CrossRef]

- Vogelheuser, B.; Schutz, D.; Frank, T.; Legat, C. Model-driven engineering of manufacturing automation software projects—A SysML-based approach. Mechatronics. 2014, 24, 883–897. [Google Scholar] [CrossRef]

- Weber, C.; Fayed, A. Scale, scope, and speed—managing the challenges of multiproduct manufacturing. IEEE Trans. Semicond. Manuf. 2009, 23, 30–38. [Google Scholar] [CrossRef]

- Nakata, T.; Matsui, K.; Miyake, Y.; Nishioka, K. Dynamic bottleneck control in wide variety production factory. IEEE Trans. Semicond. Manuf. 1999, 12, 273–280. [Google Scholar] [CrossRef]

- Zhao, C.; Li, J.S. Analysis and improvement of multiproduct Bernoulli serial lines: Theory and application. IEEE Trans. Syst. Man Cybern. Syst. 2015, 45, 1218–1230. [Google Scholar] [CrossRef]

- Rofstad, E.K. Microenvironment-induced cancer metastasis. Int. J. Radiat. Biol. 2000, 76, 589–605. [Google Scholar] [CrossRef]

- Hoshino, S.; Seki, H.; Naka, Y.; Ota, J. Multirobot coordination for flexible batch manufacturing systems experiencing bottlenecks. IEEE Trans. Autom. Sci. Eng. 2010, 7, 887–901. [Google Scholar] [CrossRef]

- Kotler, P.; Keller, K. Marketing Management, 15th ed.; Pearson Education Limited: Harlow, UK, 2015. [Google Scholar]

- Kirsila, J.; Hellstrom, M.; Wikstrom, K. Integration as a project management concept: A study of the commissioning process in industrial deliveries. Int. J. Proj. Manag. 2007, 25, 714–721. [Google Scholar] [CrossRef]

- Boschmauchand, M.; Belkadi, F.; Bricogne, M.; Eynard, B. Knowledge-based assessment of manufacturing process performance: Integration of product lifecycle management and value-chain simulation approaches. Int. J. Comput. Integ. M. 2013, 26, 453–473. [Google Scholar] [CrossRef]

- Kong, T.; Li, G.; Feng, T.W.; Sun, L.Y. Effects of marketing–manufacturing integration across stages of new product development on performance. Int. J. Prod. Res. 2015, 53, 2269–2284. [Google Scholar] [CrossRef]

- Mohammad, R.; Mostafa, N. Integration of Production Planning and Scheduling in Multi-Products Continuous Process Industries. Int. J. Prod. Econ. 2011, 22, 113–126. [Google Scholar]

- Swink, M.; Narasimhan, R.; Kim, S.W. Manufacturing Practices and Strategy Integration: Effects on Cost Efficiency, Flexibility, and Market-Based Performance. Decision. Sci. 2005, 36, 427–457. [Google Scholar] [CrossRef]

- Nejad, H.T.N.; Sugimura, N.; Iwamura, K. Agent-based dynamic integrated process planning and scheduling in flexible manufacturing systems. Int. J. Prod. Res. 2011, 49, 1373–1389. [Google Scholar] [CrossRef]

- Shen, X.N.; Yao, X. Mathematical modeling and multi-objective evolutionary algorithms applied to dynamic flexible job shop scheduling problems. Inform. Sci. 2015, 298, 198–224. [Google Scholar] [CrossRef]

- Mahadevan, S. Automated simulation analysis of overall equipment effectiveness metrics. Int. J. Numer. Methods Eng. 2004, 57, 1577–1602. [Google Scholar]

- Yao, Y.; Kaihara, T.; Fujii, N. 212 A Study on Integration of Interdivisional Scheduling in Dynamically Changing Manufacturing Environment: Cooperation of Divisional and Interdivisional Scheduling. J. Adv. Mech. Des. Syst. 2011, 6, 572–580. [Google Scholar] [CrossRef][Green Version]

- Ma, J.; Chen, H.; Zhang, Y.; Guo, H.; Liu, L. A digital twin-driven production management system for production workshop. Int. J. Adv. Manuf. Tech. 2020, 110, 1385–1397. [Google Scholar] [CrossRef]

- Shanker, M.; Hu, M.Y.; Hung, M.S. Effect of data standardization on neural network training. Omega Int. J. Manage. S. 1996, 24, 385–397. [Google Scholar] [CrossRef]

- Mark, E.; Jan, C. Standardization and Certification Challenges for Biopharmaceutical Plants. Computer 2017, 50, 83–86. [Google Scholar]

- Jones, E.C.; Parast, M.M.; Adams, S.G. A framework for effective six sigma implementation. Total Qual. Manag. Bus. 2010, 21, 415–424. [Google Scholar] [CrossRef]

- Matsuo, M.; Nakahara, J. The effects of the PDCA cycle and OJT on workplace learning. Int. J. Hum. Resour. Man. 2013, 24, 195–207. [Google Scholar] [CrossRef]

- Ren, M.M.; Ling, N.; Wei, X.; Fan, S.H. The application of PDCA cycle management in project management. In Proceedings of the 2015 International Conference on Computer Science and Applications (CSA), Wuhan, China, 20–22 November 2015. [Google Scholar]

- Muchiri, P.; Pintelon, L. Performance measurement using overall equipment effectiveness (OEE): Literature review and practical application discussion. Int. J. Prod. Res. 2008, 46, 3517–3535. [Google Scholar] [CrossRef]

- Mao, Y.H.; Xu, T. Research of 4m1e’s effect on engineering quality based on structural equation model. Syst. Eng. Procedia. 2011, 1, 213–220. [Google Scholar]

- Wang, J.; Zheng, N. A novel fractal image compression scheme with block classification and sorting based on Pearson’s Correlation Coefficient. IEEE Trans. Image Process. 2013, 22, 3690–3702. [Google Scholar] [CrossRef]

- Mu, Y.; Liu, X.; Wang, L. A Pearson’s Correlation Coefficient based decision tree and its parallel implementation. Inf. Sci. 2018, 435, 40–58. [Google Scholar] [CrossRef]

| Author (Year) | Research Objective | Main Finding |

|---|---|---|

| Hwang et al. (2017) | OEE’s application based on the IoT and smart manufacturing environment | Proposed model can be used to measure the real-time performance indicators. |

| Dovere et al. (2016) | OEE’s application in tool management | The RFID-based automatic processes are more accurate than the manual process, especially for the tool management and human errors. |

| Poorya et al. (2018) | OEE’s application in manufacturing sustainability | The solution, including the intelligent system and control algorithm, has been provided to implement a sustainable, intelligent manufacturing system smoothly. |

| Maideen et al. (2016) | OEE’s application in manufacturing process environment | A framework of implementing OEE method in manufacturing process environment is presented. |

| Domingo and Aguado (2015) | OEE’s application in the lean and green manufacturing system | OEEE allows sustainability to be one part of the business decision. |

| Fung et al. (2003) | Multiproduct aggregate production planning | These models can be used to improve the capability of an aggregate plan under fuzzy demands and capacity. |

| Mahmoud et al. (2019) | Multiperiod Multiproduct Production planning system | New optimization model for MPMP with seasonal demand is proposed. |

| Talay and Ozdemirakyildirim (2019) | Production planning for multiproduct multistage production | The improvements in different stages would contribute to the cost saving and production may not be improved by a higher demand. |

| Liu et al. (2017) | Multiproduct production and non-cyclical preventive maintenance | Optimal production plan and maintenance schedule are determined simultaneously. Optimal maintenance schedule is not cyclical. |

| Ettaye et al. (2018) | Production and maintenance planning in multiperiod, multiproduct, single-line production system | Genetic algorithm is suitable for the integrated planning in the context of industrial sector. |

| Lu et al. (2019) | Hybrid manufacturing and recovering system in a multiproduct multistage environment with carbon emission | The control of carbon emission would reduce the recycling of material, thereby increasing the operation cost. |

| Rauf et al. (2020) | Planning and scheduling of multiple manufacturing projects under resource constraints | Raccoon family optimization algorithm performs much better than the genetic algorithm, raccoon optimization algorithm and artificial bee colonial algorithm in terms of effectiveness and efficiency. |

| Oyebolu et al. (2019) | Multiproduct continuous biopharmaceutical facilities | The tuned policies outperform a policy that estimates policy parameters and a policy based on a fixed cyclical sequence. |

| Du et al. (2018) | Quality improvement of multiproduct multistage manufacturing system | Two novel Markov models are proposed for the quality improvement of multiproduct multistage manufacturing system. Meanwhile, product flexibility and quality prorogation are taken into account by these models. |

| Zhao et al. (2020) | Multistate manufacturing system with multiple production lines | The characteristic of multistate manufacturing system operation is concluded and a modeling method for the mission reliability of manufacturing system is conducted. |

| Arithmetic | Description | Disadvantages in Multiproduct Production System |

|---|---|---|

| OEE | Integrates different important aspects of production into a single algorithm. | These methods focus on a single piece of equipment or single production line, and do not calculate product production effectiveness and losses, which means that they cannot accurately assess the overall system, and most detailed losses cannot be discovered. |

| PEE | Offers a more flexible way than original OEE to measure production capacity. | |

| Revised OEE | Provides a way to exclude external factors and only focuses on the equipment itself. | |

| TEEP | Measures time loss more accurately than the original OEE. | |

| TEE | Adds the costs associated with the production process to the arithmetic. | |

| OAE and OPE | Expand the range of losses calculated. | Although they can measure production effectiveness from a holistic perspective, the flaws still remain in measuring each product, so the actual production effectiveness and losses measurements are still inaccurate. |

| OFE | Calculates and analyzes losses from a broader perspective (the entire factory). |

| Information from MPSE | Equation |

|---|---|

| Production capacity of each product | Equation (16) |

| Actual production effectiveness of the overall manufacturing system | Equation (17) |

| Performance Effectiveness (PE) of each product | ; , (18) |

| Performance Effectiveness Loss (PEL) of each product | ; , (19) |

| Availability Rate (AR) of each product | ; , (20) |

| Availability Rate Loss (ARL) of each product | ; , (21) |

| Quality Rate (QR) of each product | ; , (22) |

| Quality Rate Loss (QRL) of each product | ; , (23) |

| Overall Performance Effectiveness (OPE) of the factory | ; , (24) |

| Overall Performance Effectiveness Loss (OPEL) of the factory | ; , (25) |

| Overall Availability Rate (OAR) of the factory | ; , (26) |

| Overall Availability Rate Loss (OARL) of the factory | ; , (27) |

| Overall Quality Rate (OQR) of the factory | ; , (28) |

| Overall Quality Rate Losses (OQRL) of the factory | ; , (29) |

| Theoretical Contribution Rate (TCR) of product in multiproduct production system | ; , (30) |

| Actual Contribution Rate (ACR) of product in multiproduct production system | ; , (31) |

| Contribution Changes (CC) of product in multiproduct production system | ; , (32) |

| Minus Contribution Rate (MCR) of product in multiproduct production system | ; , (33) |

| Performance Effectiveness Loss Rate (PELR) of each product in overall performance effectiveness losses | ; , (34) |

| Availability Loss Rate (ALR) of each product in overall time losses | ; , (35) |

| Quality Loss Rate (QLR) of each product in overall quality losses | (36) |

| MPSE | |||||||

|---|---|---|---|---|---|---|---|

| 0.58 | 0.65 | 0.69 | 0.53 | 0.71 | 0.40 | 0.60 | |

| 0.62 | 0.71 | 0.58 | 0.69 | 0.57 | 0.39 | 0.66 | |

| 0.73 | 0.58 | 0.78 | 0.64 | ||||

| 0.63 | 0.57 | 0.42 | 0.68 | 0.46 | 0.38 | 0.70 | |

| 0.55 | 0.66 | 0.43 | 0.59 | 0.86 | 0.53 | 0.69 | |

| … | |||||||

| 0.58 | 0.50 | 0.71 | 0.49 | 0.62 | 0.53 | ||

| 0.59 | 0.57 | 0.62 | 0.59 | 0.57 | 0.45 | 0.56 | |

| 0.69 | 0.66 | 0.64 | 0.67 | 0.67 | 0.69 | ||

| 0.61 | 0.56 | 0.60 | 0.75 | 0.59 | 0.68 | ||

| 0.57 | 0.52 | 0.58 | 0.68 | 0.55 | 0.61 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Liu, G.; Hao, X. Research on Improved OEE Measurement Method Based on the Multiproduct Production System. Appl. Sci. 2021, 11, 490. https://doi.org/10.3390/app11020490

Li X, Liu G, Hao X. Research on Improved OEE Measurement Method Based on the Multiproduct Production System. Applied Sciences. 2021; 11(2):490. https://doi.org/10.3390/app11020490

Chicago/Turabian StyleLi, Xiaoyan, Guangfu Liu, and Xinyu Hao. 2021. "Research on Improved OEE Measurement Method Based on the Multiproduct Production System" Applied Sciences 11, no. 2: 490. https://doi.org/10.3390/app11020490

APA StyleLi, X., Liu, G., & Hao, X. (2021). Research on Improved OEE Measurement Method Based on the Multiproduct Production System. Applied Sciences, 11(2), 490. https://doi.org/10.3390/app11020490