1. Introduction

In recent years, basic isolation technology has been extensively applied in building construction and bridge engineering in China and overseas [

1,

2,

3]. By the end of 2020, China had constructed more than 8000 seismic-isolated buildings. The rubber isolation system is currently the most widely used and mature isolation technology, among which the common isolation devices include the ordinary rubber bearing, natural rubber bearing (NRB) [

4], LRB [

5], HDRB [

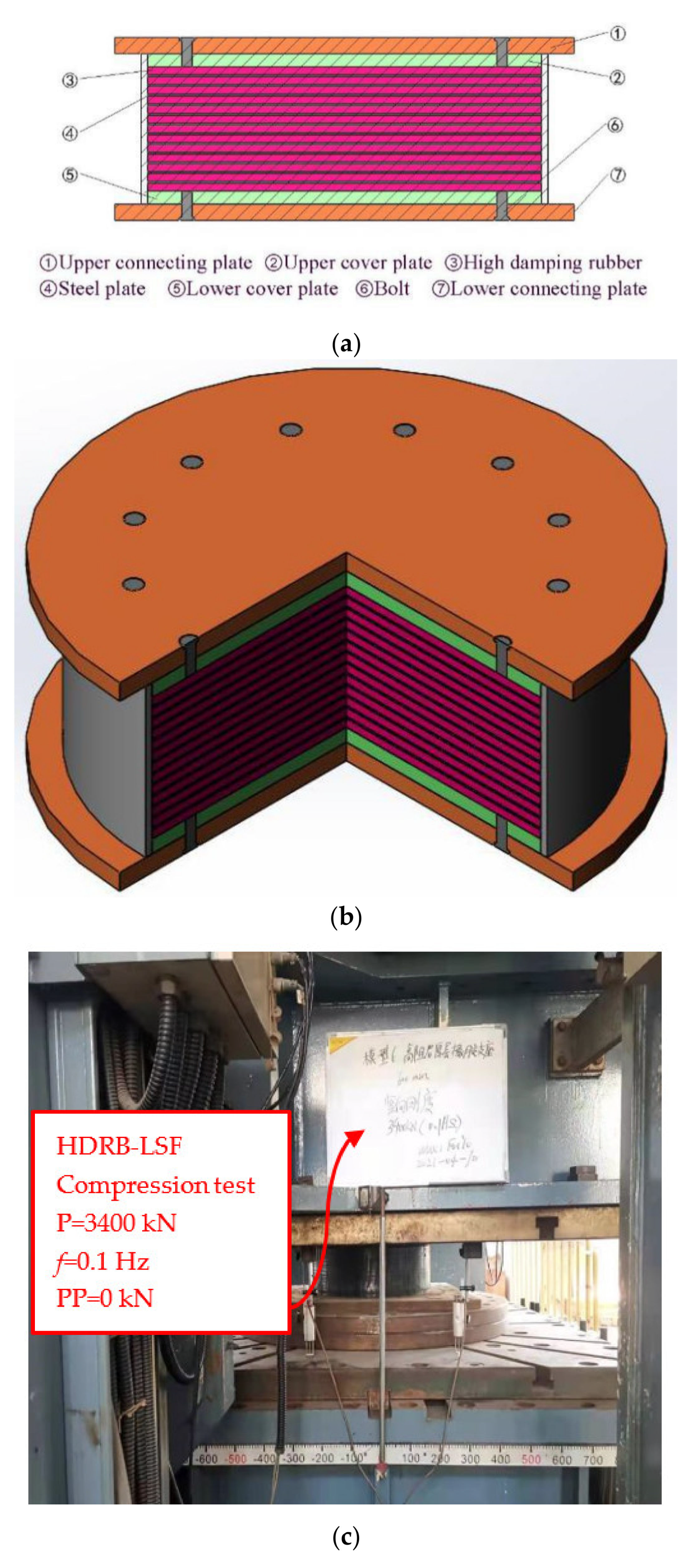

6], etc. The HDRB has plentiful advantages—such as a simple structure, stable mechanical performance, strong energy dissipation capacity, large stiffness before yielding, environmental protection, etc.—that make it an excellent choice for base-isolation structures. It is made of laminated rubber pads with multi-layer steel plates that are vulcanized and bonded at a high temperature, where the steel plate layers restrain the vertical deformation of the rubber layers from guaranteeing a certain vertical stiffness of the bearing. The rubber layers adapt the high damping material with graphite and other additives to be capable of simultaneously withstanding a vertical load and resist a large horizontal shear displacement. Compared with the ordinary rubber bearing, HDRB can achieve a higher equivalent damping ratio of more than 20% without matching dampers, which saves installation space. HDRB possesses greater stiffness before yielding, a better braking effect on the structure subjected to wind load, more minor damage caused by lead when processing, and is more applicable for those places with special requirements for environmental protection, especially in contrast with the lead–rubber bearing. When the structures are subjected to an earthquake, the HDRB will produce a large deformation and reduce the stiffness, thus achieving a better isolation effect. In recent years, many researchers have conducted studies on HDRB. Burtscher et al. [

7] conducted experimental studies on different forms of HDRB and analyzed the influence of the shape factor and steel plate forms on the performance of the bearings. Yamamoto et al. [

8] took bidirectional coupling factors into consideration when testing the horizontal shear performance of HDRB. Chen et al. [

9] and Xue et al. [

10] carried out vertical compression tests along with horizontal shear tests for loading on the designed HDRB. Their results proclaimed a good energy dissipation effect. Bhuiyan et al. [

11] proposed a rheological model considering the nonlinear characteristics of HDRB based on the cyclic shear test, monotone relaxation test, and multi-step relaxation test. Dong et al. [

12] studied the influence of shear strain and vertical compressive stress on the shear performance of HDRB through the compression–shear performance test, and made an improvement to the restoring force model of the bearing with certain accuracy. Fabio Mazza et al. [

13] applied the HDRBs to two typical r.c. framed structures and conducted the structural nonlinear incremental dynamic analyses based on the refined three-spring–two-dashpot model of the bearing.

Rubber bearings, including HDRBs, are generally horizontal isolation bearings, which can reduce the horizontal seismic acceleration response of a structure by about 60%. They are incapable of decreasing or even amplifying vertical seismic effect effectively. This can be explained by the fact that ordinary rubber bearings have a vertical stiffness equivalent to thousands of times their horizontal stiffness, which means that it is likely to obtain a smaller vertical basic period of around 0.1 s and is liable to fall within the striking part of the vertical acceleration spectrum, thus resulting in poor vertical isolation. However, recent large (extra-large) earthquakes in China and abroad indicate that strong vertical ground motions that occur in high-intensity areas, especially near faults areas, may even exceed the horizontal seismic action component. After horizontal seismic action is reduced, vertical ground motion with a high peak value will become the main cause of structural destruction, particularly for medical buildings and industrial facilities. Once damaged, the function of these buildings will be disrupted and the resilience of society will be seriously affected. Hence, scholars have developed several vertical isolation devices and three-dimensional isolation devices. Jia et al. [

14] designed a new three-dimensional isolation device containing lead-core rubber pads combined with dish-shaped springs and steel plate dampers. Of those devices, some have undergone complex modeling, which is not conducive to processing, while some need additional dampers to enhance their vertical damping and causing greater vertical stiffness of the bearing. Thick rubber bearings have become one of the most important vertical isolation forms. Compared with an ordinary rubber bearing, there is a conspicuous increase in the thickness of HDRB, generally 4 to 6 times higher than that of the former. The shape factor of ordinary rubber bearing typically ranges from 15 to 30 or more, while that of HDRB is designed to vary from 2 to 5. In 1989, Aiken et al. [

15] set the shape factor of the individual 1/4 scale bearings as 2.4 and characterization tests were then conducted. Warn and Vu [

16] found that three-dimensional isolation for low and mid-rise structures would be achieved if the shape factors of the elastomeric bearings was set to be less than 4 and significant vertical damping was supplemented. Kanazawa et al. [

17] designed a thick rubber bearing with the second shape factor of 4.1, aiming to study the damping effect on the equipment in a nuclear reactor. Zhu et al. [

18] selected three thick lead-core rubber bearings with shape factors of 8.0, 12.0, and 16.7, respectively, to conduct basic mechanical properties tests on them. Wang [

19] carried out studies on the basic mechanical properties of five thick rubber bearings with shape factors between 4.13 and 5.37 and with different diameters, summarized the law of vertical stiffness parameters of new thick rubber bearings, and then proposed a design method of anti-buckling low-frequency seismic isolation bearings. Liu and Huang [

20] compared the vertically seismic response spectrum between prestressed and non-prestressed thick rubber bearings with the shape factor of 3.29. Li et al. [

21] conducted a series of experimental studies on shear stiffness, vertical stiffness, deformation performance, fatigue performance, creep performance, and aging performance of thick rubber bearings with the second shape factor of 1.85. The research results of many scholars around the world illustrate that compared with ordinary rubber bearings, thick rubber bearings have smaller vertical stiffness and superior vertical isolation performance, which can avoid the adverse resonance effect caused by the vertical period of vibration coupling with the structure.

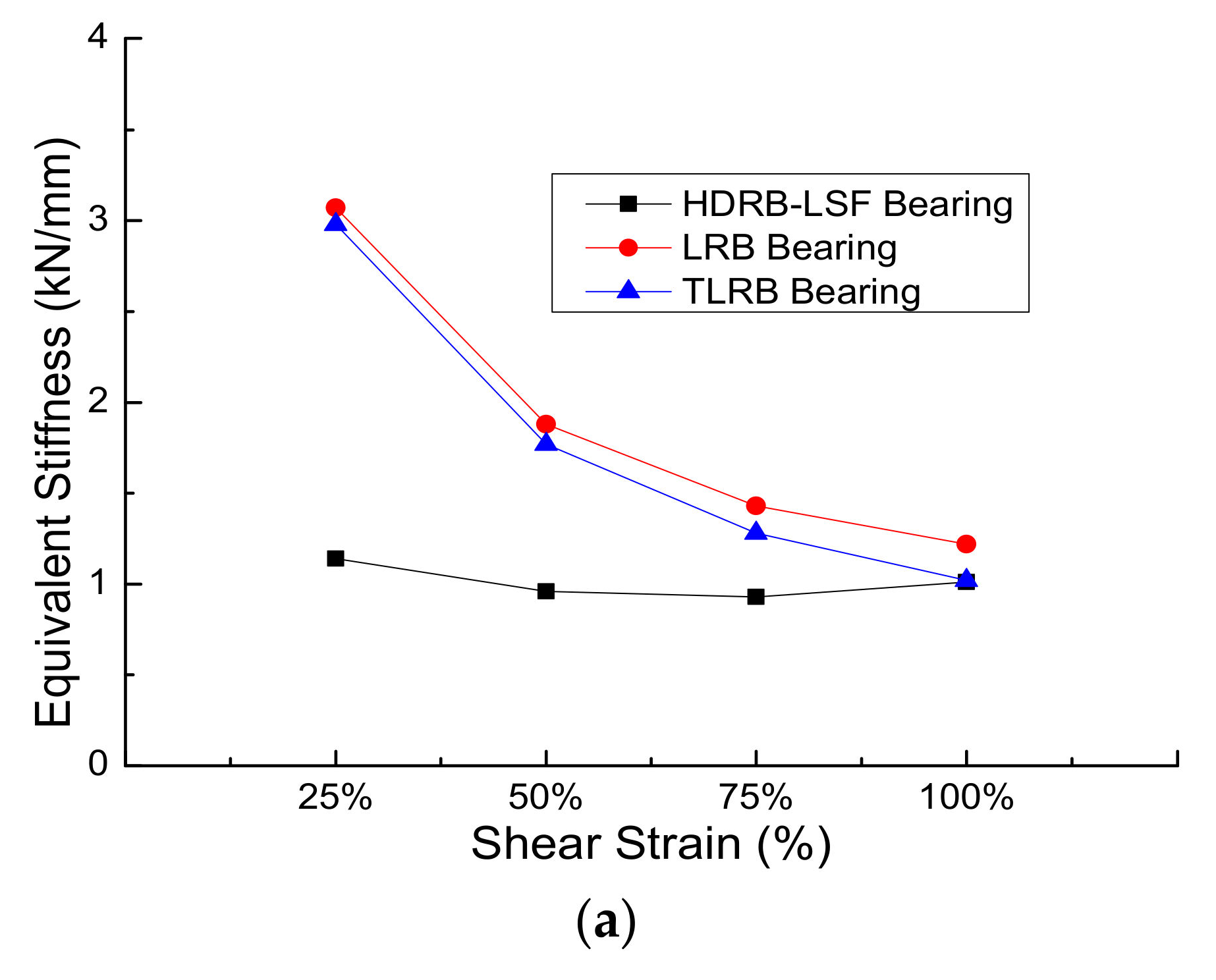

In this paper, three bearings, including HDRB-LSF, TLRB, and LRB, were designed. Then, vertical compression performance tests, horizontal shear performance tests, vertical compression correlation tests, and horizontal shear correlation tests were carried out. The effects of vertical compressive stress, pre-pressure, shear strain, and loading frequency on the performance of the above three bearings were studied. The performance differences of the bearings were compared. Considering that the experimental results of HDRB-LSF displayed a big discrepancy with the theoretical values, a correction method for vertical stiffness of HDRB-LSF was proposed, and the modified values were found to be in good agreement with the experimental results.