Study on Nanosecond Laser Ablation of 40Cr13 Die Steel Based on ANOVA and BP Neural Network

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

2.2. Experimental Equipment

2.3. Measurements and Characterisation

- Ablation depth (D): the distance from the lowest point of the cross-section to the upper surface.

- Ablation width (W): the maximum distance between the two sides of the cross-section.

- MRR: the product of the cross-sectional area and the distance that the laser moves per unit time.

2.4. Experimental Parameters

- Laser Power (LP): the real power value reaching the surfaces of tested samples considering the lost through a series of optical devices.

- Pulse Frequency (PF): the number of laser pulses repeated in one second.

- Scan Speed (SS): the moving speed of the laser focus on the surfaces of tested samples.

2.5. Fundamental Theory

3. Effects of Process Parameters on Ablation Results

3.1. Effects of Process Parameters on Ablation Depth

3.2. Effects of Process Parameters on Ablation Width

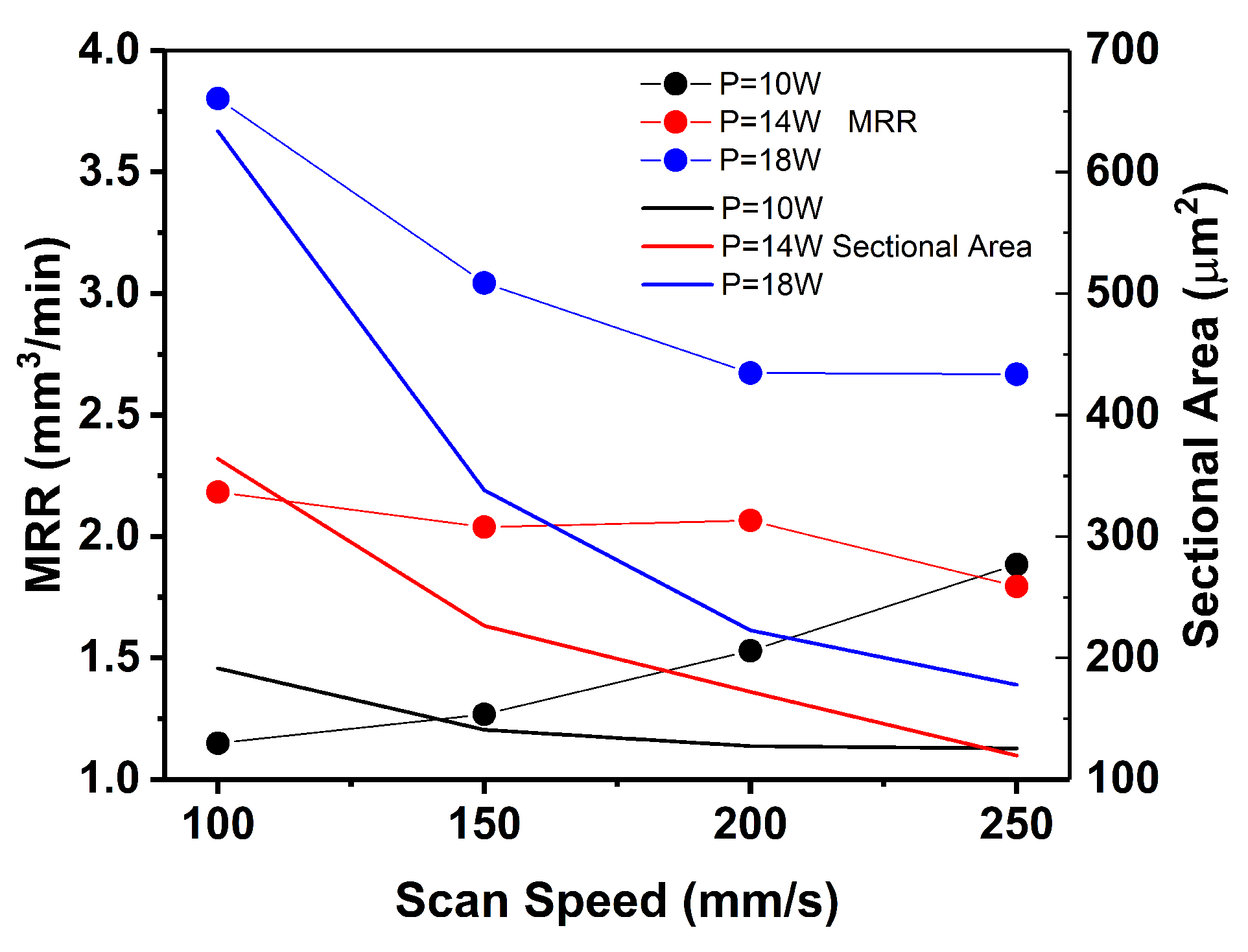

3.3. Effects of Process Parameters on Material Removal Rate

4. Prediction of Ablation Results Based on BP Neural Network

4.1. Establishment of BP Neural Network Model

4.2. Analysis of Prediction Results

5. Conclusions and Future Work

- Laser power had the strongest influence on D, W, and the MRR; the influence levels were 52.5%, 60.9%, and 70.4%, respectively. The main reason is that laser power mainly determines the single-pulse energy, which is the decisive factor for the ablation results.

- The scan speed had an effect on D and W to a certain extent; the influence levels were 28.9% and 30.6%, respectively. However, the effect of the scan speed on the MRR was only minor, with an influence level of 2.1%. The main reason is that scan speed and pulse frequency jointly determine the pulse coincidence rate, which is another factor that affects the ablation results.

- The influence of pulse frequency on D and the MRR was non-negligible; the influence levels were 18.6% and 27.4%, respectively. The pulse frequency had little effect on W; the influence level was 8.5%.

- Three types of BP neural network models were used to predict the ablation results. The results show that the prediction accuracy for the W was the highest, followed by MRR and D. The average prediction accuracies reached 96.0%, 93.5% and 84.4%, respectively.

- The network model with the 3-10-3 structure had the highest prediction accuracy for D and the MRR, the minimum RMSEs reached 0.096 and 1.660, the network model with the 3-8-3 structure had the highest prediction accuracy for W with the minimum RMSE of 0.940.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ANOVA | Analysis of variance |

| BP | Back propagation |

| MRR | Material removal rate |

| W | Ablation width |

| D | Ablation depth |

| LP | Laser power |

| PF | Pulse frequency |

| SS | Scan speed |

Appendix A

| Group No. | LP (W) | PF (kHz) | SS (mm/s) | D (mm) | W (mm) | MRR (mm/min) | Group No. | LP (W) | PF (kHz) | SS (mm/s) | D (mm) | W (mm) | MRR (mm/min) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 10 | 40 | 100 | 4.710 | 36.320 | 1.105 | 25 | 14 | 60 | 150 | 9.102 | 40.871 | 2.474 |

| 2 | 10 | 40 | 150 | 3.504 | 35.470 | 1.166 | 26 | 14 | 60 | 200 | 8.812 | 37.007 | 2.500 |

| 3 | 10 | 40 | 200 | 2.710 | 32.544 | 1.391 | 27 | 14 | 60 | 250 | 7.024 | 34.157 | 2.341 |

| 4 | 10 | 40 | 250 | 2.040 | 31.157 | 1.457 | 28 | 14 | 70 | 100 | 17.312 | 43.919 | 3.184 |

| 5 | 10 | 50 | 100 | 5.928 | 37.769 | 1.149 | 29 | 14 | 70 | 200 | 10.878 | 39.783 | 3.062 |

| 6 | 10 | 50 | 150 | 4.841 | 36.310 | 1.268 | 30 | 14 | 70 | 250 | 7.965 | 35.157 | 2.669 |

| 7 | 10 | 50 | 200 | 3.700 | 33.166 | 1.529 | 31 | 18 | 40 | 100 | 14.575 | 46.128 | 2.603 |

| 8 | 10 | 50 | 250 | 3.170 | 32.032 | 1.885 | 32 | 18 | 40 | 150 | 9.374 | 43.166 | 2.333 |

| 9 | 10 | 60 | 100 | 8.365 | 38.769 | 1.291 | 33 | 18 | 40 | 200 | 7.041 | 41.972 | 2.258 |

| 10 | 10 | 60 | 200 | 5.044 | 33.660 | 1.829 | 34 | 18 | 40 | 250 | 5.231 | 37.051 | 2.333 |

| 11 | 10 | 60 | 250 | 4.044 | 32.320 | 1.997 | 35 | 18 | 50 | 100 | 20.385 | 49.208 | 3.802 |

| 12 | 10 | 70 | 100 | 9.453 | 40.204 | 1.776 | 36 | 18 | 50 | 150 | 12.270 | 45.340 | 3.043 |

| 13 | 10 | 70 | 150 | 7.580 | 39.810 | 2.191 | 37 | 18 | 50 | 200 | 8.811 | 40.191 | 2.674 |

| 14 | 10 | 70 | 200 | 5.624 | 38.395 | 2.582 | 38 | 18 | 50 | 250 | 6.703 | 38.369 | 2.668 |

| 15 | 10 | 70 | 250 | 4.243 | 33.837 | 2.608 | 39 | 18 | 60 | 100 | 25.609 | 51.713 | 4.905 |

| 16 | 14 | 40 | 100 | 7.476 | 40.408 | 1.975 | 40 | 18 | 60 | 150 | 14.685 | 47.270 | 3.649 |

| 17 | 14 | 40 | 150 | 6.130 | 38.708 | 1.916 | 41 | 18 | 60 | 250 | 8.321 | 39.969 | 3.108 |

| 18 | 14 | 40 | 200 | 4.288 | 35.245 | 1.914 | 42 | 18 | 70 | 100 | 33.557 | 58.532 | 5.783 |

| 19 | 14 | 40 | 250 | 3.052 | 32.096 | 1.573 | 43 | 18 | 70 | 150 | 17.000 | 52.575 | 4.280 |

| 20 | 14 | 50 | 100 | 8.146 | 41.272 | 2.184 | 44 | 18 | 70 | 200 | 12.086 | 42.954 | 3.708 |

| 21 | 14 | 50 | 150 | 6.348 | 39.048 | 2.039 | 45 | 18 | 70 | 250 | 9.282 | 40.840 | 3.301 |

| 22 | 14 | 50 | 200 | 5.549 | 36.511 | 2.066 | 46 | 10 | 60 | 150 | 6.590 | 36.341 | 1.730 |

| 23 | 14 | 50 | 250 | 4.746 | 33.123 | 1.794 | 47 | 14 | 70 | 150 | 15.415 | 41.633 | 3.591 |

| 24 | 14 | 60 | 100 | 10.268 | 42.599 | 2.629 | 48 | 18 | 60 | 200 | 10.545 | 41.798 | 3.144 |

References

- Aggarwal, S.; Pandey, R.K. Frictional and load-carrying behaviours of micro-textured sector shape pad thrust bearing incorporating the cavitation and thermal effects. Lubr. Sci. 2017, 29, 255–277. [Google Scholar] [CrossRef]

- Mao, B.; Siddaiah, A.; Liao, Y.; Menezes, P.L. Laser surface texturing and related techniques for enhancing tribological performance of engineering materials: A review. J. Manuf. Process. 2020, 53, 153–173. [Google Scholar] [CrossRef]

- Wu, B.; Liu, P.; Duan, J.; Deng, L.; Zeng, X.; Wang, X. Study on picosecond pulse laser ablation of Cr12MoV cold work mold steel. Mater. Des. 2016, 110, 549–557. [Google Scholar] [CrossRef]

- Schreck, S.; Zum Gahr, K.H. Laser-assisted structuring of ceramic and steel surfaces for improving tribological properties. Appl. Surf. Sci. 2005, 247, 616–622. [Google Scholar] [CrossRef]

- Goeke, A.; Emmelmann, C. Influence of laser cutting parameters on CFRP part quality. Phys. Procedia 2010, 5, 253–258. [Google Scholar] [CrossRef] [Green Version]

- Kasman, S. Impact of parameters on the process response: A Taguchi orthogonal analysis for laser engraving. Measurement 2013, 46, 2577–2584. [Google Scholar] [CrossRef]

- Dubey, A.K.; Yadava, V. Laser beam machining-A review. Int. J. Mach. Tools Manuf. 2008, 48, 609–628. [Google Scholar] [CrossRef]

- Madić, M.; Antucheviciene, J.; Radovanović, M.; Petković, D. Determination of laser cutting process conditions using the preference selection index method. Opt. Laser Technol. 2017, 89, 214–220. [Google Scholar] [CrossRef]

- Xiuming, L.; Zhaoyao, S. Development and application of convex hull in the assessment of roundness error. Int. J. Mach. Tools Manuf. 2008, 48, 135–139. [Google Scholar] [CrossRef]

- Mills, B.; Grant-Jacob, J.A. Lasers that learn: The interface of laser machining and machine learning. IET Optoelectron. 2021, 15, 207–224. [Google Scholar] [CrossRef]

- Chen, L.; Yin, Y.; Li, Y.; Hong, M. Multifunctional inverse sensing by spatial distribution characterization of scattering photons. Opto-Electron. Adv. 2019, 2, 19001901–19001908. [Google Scholar] [CrossRef] [Green Version]

- Saetchnikov, A.V.; Tcherniavskaia, E.A.; Saetchnikov, V.A.; Ostendorf, A. Deep-learning powered whispering gallery mode sensor based on multiplexed imaging at fixed frequency. Opto-Electron. Adv. 2020, 3, 200048. [Google Scholar] [CrossRef]

- Parandoush, P.; Hossain, A. A review of modeling and simulation of laser beam machining. Int. J. Mach. Tools Manuf. 2014, 85, 135–145. [Google Scholar] [CrossRef]

- Jimin, C.; Jianhua, Y.; Shuai, Z.; Tiechuan, Z.; Dixin, G. Parameter optimization of non-vertical laser cutting. Int. J. Adv. Manuf. Technol. 2007, 33, 469–473. [Google Scholar] [CrossRef]

- Teixidor, D.; Grzenda, M.; Bustillo, A.; Ciurana, J. Modeling pulsed laser micromachining of micro geometries using machine-learning techniques. J. Intell. Manuf. 2015, 26, 801–814. [Google Scholar] [CrossRef] [Green Version]

- Dixit, S.R.; Das, S.R.; Dhupal, D. Parametric optimization of Nd:YAG laser microgrooving on aluminum oxide using integrated RSM-ANN-GA approach. J. Ind. Eng. Int. 2019, 15, 333–349. [Google Scholar] [CrossRef] [Green Version]

- Yousef, B.F.; Knopf, G.K.; Bordatchev, E.V.; Nikumb, S.K. Neural network modeling and analysis of the material removal process during laser machining. Int. J. Adv. Manuf. Technol. 2003, 22, 41–53. [Google Scholar] [CrossRef]

- Qian, K.; Hou, Z.; Sun, D. Sound Quality Estimation of Electric Vehicles Based on GA-BP Artificial Neural Networks. Appl. Sci. 2020, 10, 5567. [Google Scholar] [CrossRef]

- Pei, G.; Yu, M.; Xu, Y.; Ma, C.; Lai, H.; Chen, F.; Lin, H. An Improved PID Controller for the Compliant Constant-Force Actuator Based on BP Neural Network and Smith Predictor. Appl. Sci. 2021, 11, 2685. [Google Scholar] [CrossRef]

- Bai, Y.; Luo, M.; Pang, F. An Algorithm for Solving Robot Inverse Kinematics Based on FOA Optimized BP Neural Network. Appl. Sci. 2021, 11, 7129. [Google Scholar] [CrossRef]

- Lehr, J.; Kietzig, A.M. Production of homogenous micro-structures by femtosecond laser micro-machining. Opt. Lasers Eng. 2014, 57, 121–129. [Google Scholar] [CrossRef]

- Dhupal, D.; Doloi, B.; Bhattacharyya, B. Optimization of process parameters of Nd:YAG laser microgrooving of Al2TiO5 ceramic material by response surface methodology and artificial neural network algorithm. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2007, 221, 1341–1350. [Google Scholar] [CrossRef]

- Dhupal, D.; Doloi, B.; Bhattacharyya, B. Modeling and optimization on Nd:YAG laser turned micro-grooving of cylindrical ceramic material. Opt. Lasers Eng. 2009, 47, 917–925. [Google Scholar] [CrossRef]

| C | Si | Mn | S | P | Cr | Ni |

|---|---|---|---|---|---|---|

| 0.36–0.45 | ≤0.60 | ≤0.80 | ≤0.03 | ≤0.035 | 12.00-14.00 | ≤0.60 |

| Parameter | Value | Unit |

|---|---|---|

| Wavelength | 355 | nm |

| Maximum Power | >25 | W |

| M Factor | <1.2 | - |

| Beam Diameter | ≈0.55 | mm |

| Pulse Width | <20 | ns |

| Repetition Rate | 40–300 | kHz |

| Measurement Condition | Description |

|---|---|

| Objective Lens | MPLAPON20xLEXT |

| Zoom | 1× |

| Image Size | 1024 × 1024 |

| Laser Brightness | 35.2 |

| Automatic Gain | Open |

| Process Parameter | Value | |||

|---|---|---|---|---|

| Laser Power (W) | 10 | 14 | 18 | |

| Pulse Frequency (kHz) | 40 | 50 | 60 | 70 |

| Scan Speed (mm/s) | 100 | 150 | 200 | 250 |

| Process Parameter | Degree of Freedom | Sum of Square | Mean Square | F-Value | p-Value | Influence Level |

|---|---|---|---|---|---|---|

| Laser Power | 2 | 571.197 | 285.598 | 30.092 | 0.000 | 52.5% |

| Pulse Frequency | 3 | 303.424 | 101.141 | 10.657 | 0.000 | 18.6% |

| Scan Speed | 3 | 472.076 | 157.359 | 16.580 | 0.000 | 28.9% |

| Process Parameter | Degree of Freedom | Sum of Square | Mean Square | F-Value | p-Value | Influence Level |

|---|---|---|---|---|---|---|

| Laser Power | 2 | 733.699 | 366.850 | 117.493 | 0.000 | 60.9% |

| Pulse Frequency | 3 | 153.075 | 51.025 | 16.342 | 0.000 | 8.5% |

| Scan Speed | 3 | 553.007 | 184.336 | 59.038 | 0.000 | 30.6% |

| Process Parameter | Degree of Freedom | Sum of Square | Mean Square | F-Value | p-Value | Influence Level |

|---|---|---|---|---|---|---|

| Laser Power | 2 | 22.407 | 11.204 | 51.282 | 0.000 | 70.4% |

| Pulse Frequency | 3 | 13.088 | 4.363 | 19.970 | 0.000 | 27.4% |

| Scan Speed | 3 | 1.012 | 0.337 | 1.544 | 0.218 | 2.1% |

| Group No. | AblationDepth (m) | |||

| Prediction Values | Measurement Value | |||

| 3-8-3 | 3-10-3 | 3-12-3 | ||

| 46 | 6.110 | 5.390 | 5.172 | 6.590 |

| 47 | 10.361 | 12.843 | 9.912 | 15.415 |

| 48 | 10.223 | 10.085 | 10.710 | 10.545 |

| Group No. | Ablation Width (m) | |||

| Prediction Values | Measurement Value | |||

| 3-8-3 | 3-10-3 | 3-12-3 | ||

| 46 | 36.437 | 36.530 | 37.548 | 36.341 |

| 47 | 43.052 | 49.423 | 44.389 | 41.633 |

| 48 | 42.592 | 41.995 | 41.581 | 41.798 |

| Group No. | MRR (mm/min) | |||

| Prediction Values | Measurement Value | |||

| 3-8-3 | 3-10-3 | 3-12-3 | ||

| 46 | 1.618 | 1.634 | 1.324 | 1.730 |

| 47 | 3.106 | 3.470 | 3.693 | 3.591 |

| 48 | 3.101 | 3.208 | 3.149 | 3.144 |

| Indexes | NetworkModels | ||

| 3-8-3 | 3-10-3 | 3-12-3 | |

| D (m) | 2.937 | 1.660 | 3.283 |

| W (m) | 0.940 | 4.500 | 1.742 |

| (mm/min) | 0.289 | 0.096 | 0.237 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, Z.; Liu, Q.; Sun, P.; Wang, J. Study on Nanosecond Laser Ablation of 40Cr13 Die Steel Based on ANOVA and BP Neural Network. Appl. Sci. 2021, 11, 10331. https://doi.org/10.3390/app112110331

Yin Z, Liu Q, Sun P, Wang J. Study on Nanosecond Laser Ablation of 40Cr13 Die Steel Based on ANOVA and BP Neural Network. Applied Sciences. 2021; 11(21):10331. https://doi.org/10.3390/app112110331

Chicago/Turabian StyleYin, Zhenshuo, Qiang Liu, Pengpeng Sun, and Jian Wang. 2021. "Study on Nanosecond Laser Ablation of 40Cr13 Die Steel Based on ANOVA and BP Neural Network" Applied Sciences 11, no. 21: 10331. https://doi.org/10.3390/app112110331