Cloud-Based Analytics Module for Predictive Maintenance of the Textile Manufacturing Process

Abstract

1. Introduction

1.1. Textile Manufacturing

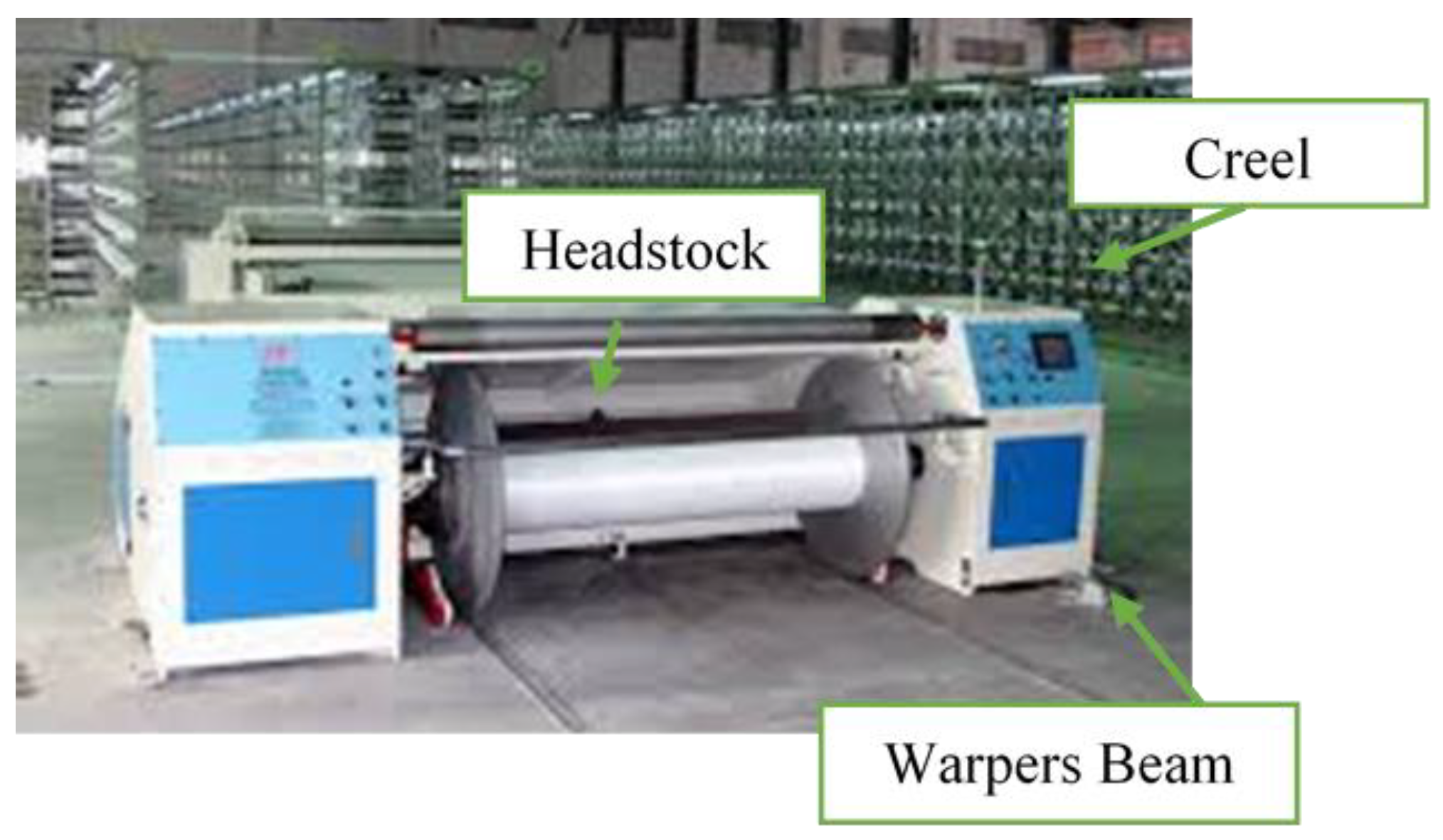

- Warping

- 2.

- Sizing

- 3.

- Beaming

- 4.

- Weaving

1.2. IIoT and Textile Manufacturing

- To predict textile production quality using ML.

- To create a PdM API for cloud data analytics that can be integrated with third party IoT.

- To enhance production line performance and enable smart manufacturing.

1.3. Current Trends in IIoT and PdM

2. Preliminary Function

2.1. Linear Regression

2.2. Least Absolute Shrinkage Selector Operator Regression

2.3. Ridge Regression

2.4. Elastic Net Regression

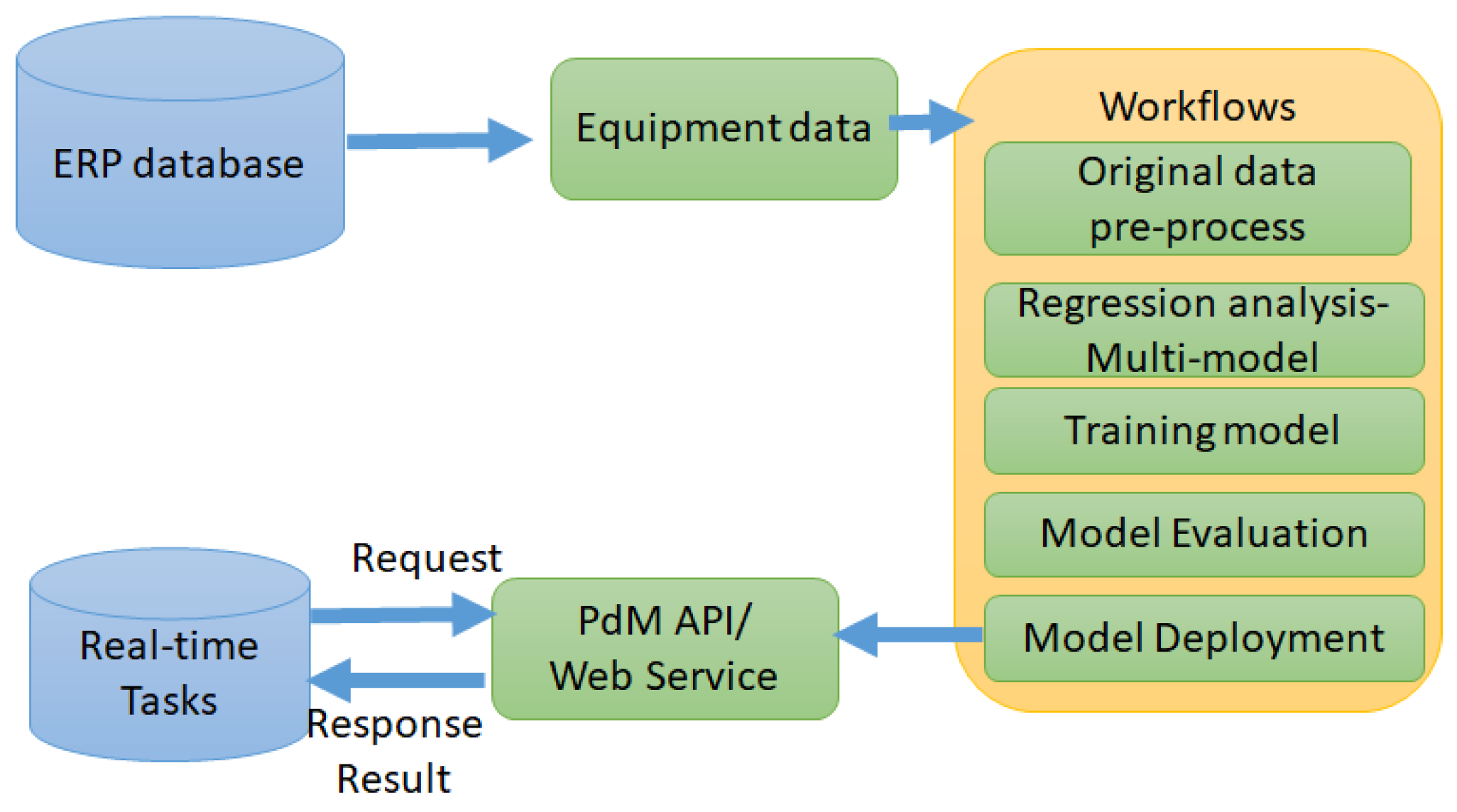

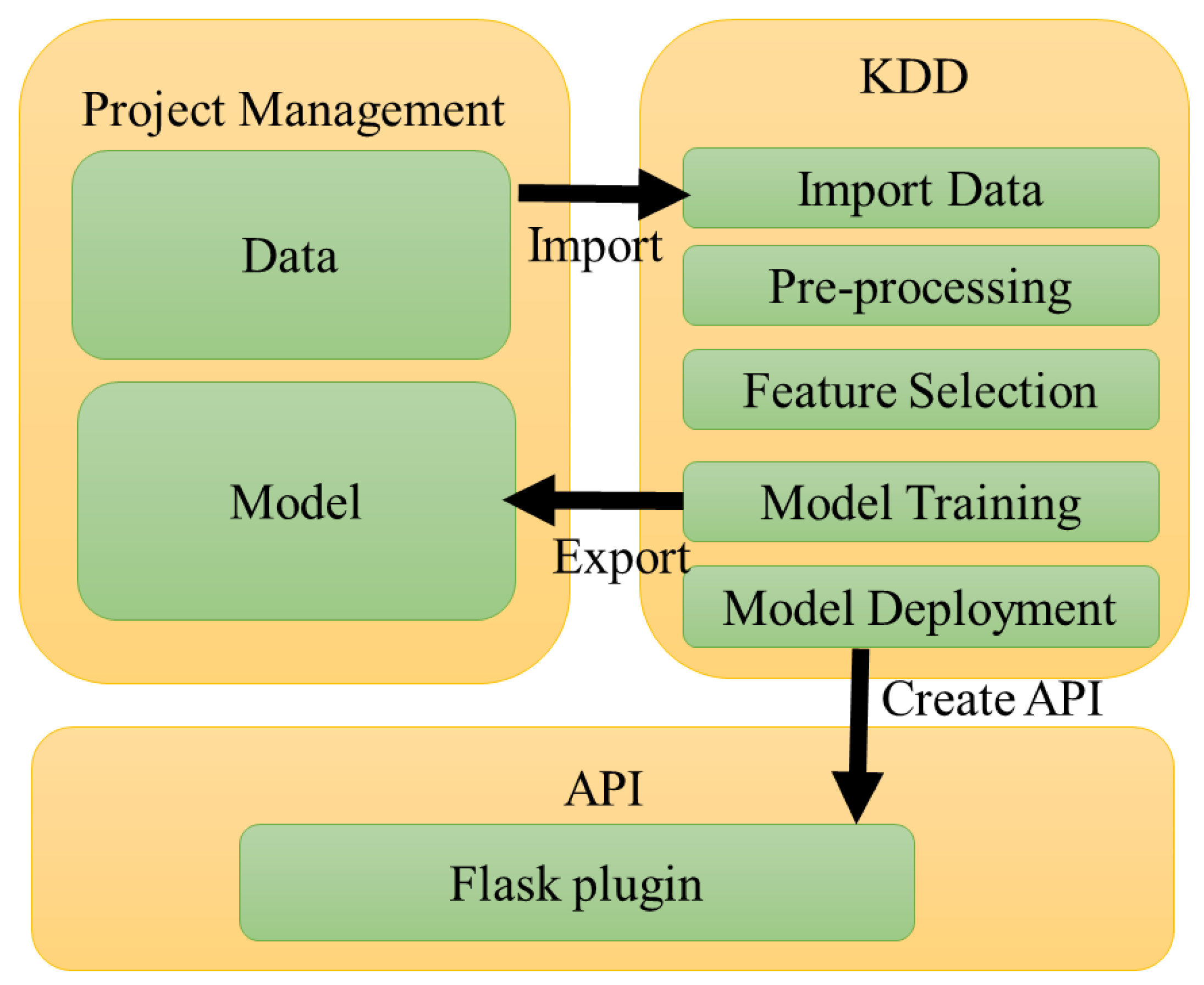

3. Method

3.1. Data Model

3.2. Original Data Preprocessing

3.3. Data Training-Regression Analysis

3.4. Model Deployment

4. Experiments

4.1. Use Case

4.2. Dataset Description

4.3. Evaluation Criteria

- Mean-squared error

- 2.

- Mean absolute error

- 3.

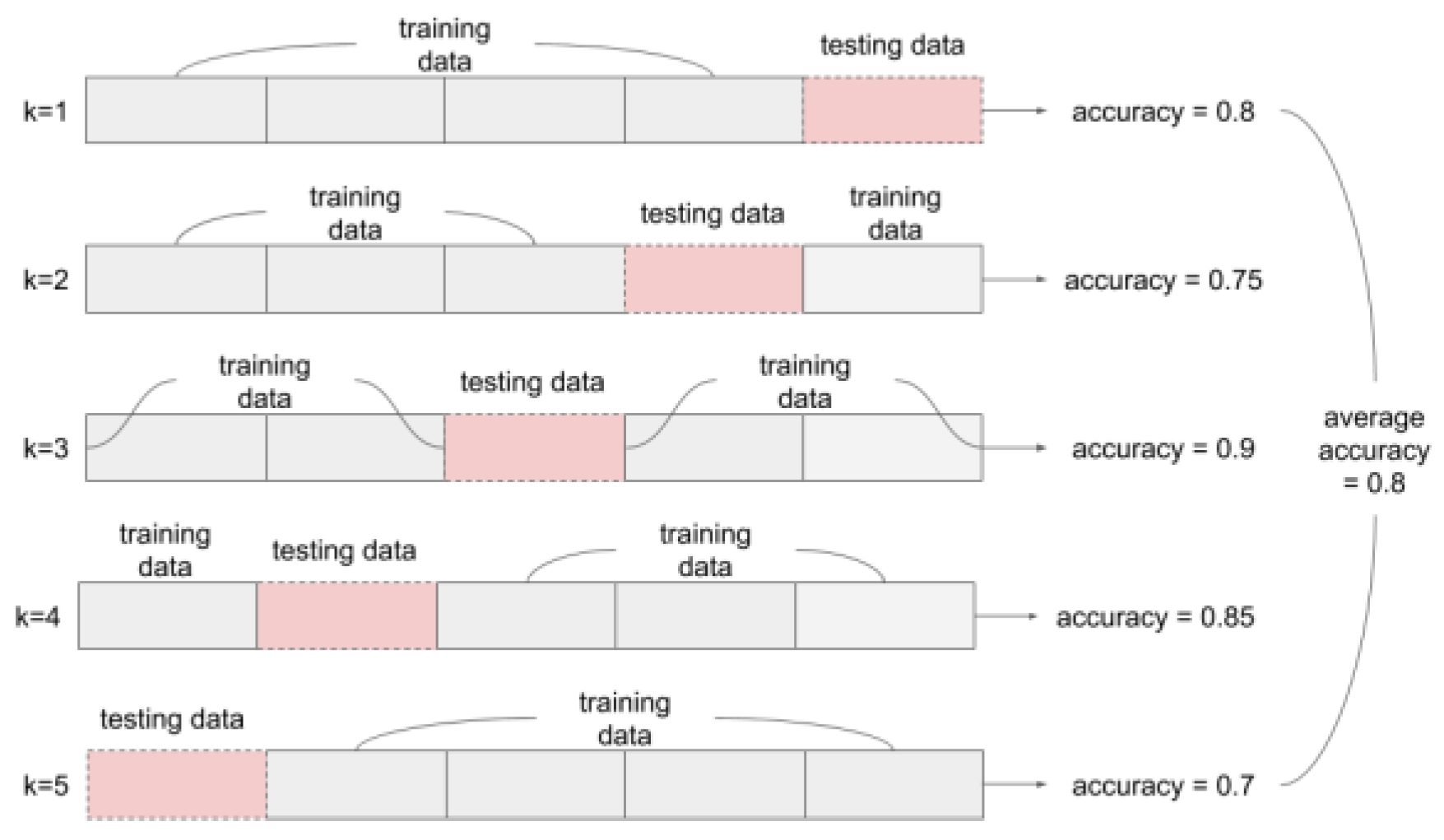

- K-fold cross-validation

5. Results

5.1. Data Preprocessing and Feature Selection

5.2. Machine-Learning Modeling and Evaluation

5.2.1. Warping Process Prediction

5.2.2. Sizing Process Prediction

5.2.3. Beaming Process Prediction

5.3. Trained Model Deployment

6. Discussion

6.1. Potential of Machine Vision

6.2. Use of Edge Computing

7. Conclusions

7.1. Study Limitation

7.2. Future Work

Author Contributions

Funding

Conflicts of Interest

References

- Centerity, “IoT & IIoT Making Data-Driven Business Decisions. Available online: http://www.centerity.com/wp-content/uploads/2016/11/IoT-WhitePaper.pdf (accessed on 1 January 2019).

- Advantech Inc. IoT Applications and Upgrades in Textile Plant. Available online: https://www.iotone.com/casestudy/iot-applications-and-upgrades-in-textile-plant/c749 (accessed on 10 October 2019).

- Gandhi, K. (Ed.) Woven Textiles: Principles, Technologies and Applications, 2nd ed.; Woodhead Publishing: Sawston, UK, 2019. [Google Scholar]

- Adanur, S. Handbook of Weaving, 1st ed.; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar]

- Dorgham, M.E. Warping parameters influence on warp yarns properties: Part 1: Warping speed and warp yarn tension. J. Text. Sci. Eng. 2013, 3, 1–6. [Google Scholar] [CrossRef]

- Gloy, Y.S.; Renkens, W.; Herty, M.; Gries, T. Simulation and optimisation of warp tension in the weaving process. J. Text. Sci. Eng. 2015, 5, 179. [Google Scholar] [CrossRef]

- Karnoub, A.; Kadi, N.; Azari, Z.; Bakeer, E.S. Find the suitable warp tension to get the best resistance for jacquard fabric. J. Text. Sci. Eng. 2015, 5, 222. [Google Scholar] [CrossRef]

- Perez, J.B.; Arrieta, A.G.; Encinas, A.H.; Queiruga-Dios, A. Industrial cyber-physical systems in textile engineering. In Proceedings of the International Joint Conference SOCO’16-CISIS’16-ICEUTE’16, San Sebastián, Spain, 19–21 October 2016; Springer: Cham, Switzerland, 2016; pp. 126–135. [Google Scholar]

- Nurwaha, D.; Wang, X. Prediction of rotor spun yarn strength using support vector machines method. Fibers Polym. 2011, 12, 546–549. [Google Scholar] [CrossRef]

- Pavlinić, D.Z.; Geršak, J.; Demšar, J.; Bratko, I. Predicting seam appearance quality. Text. Res. J. 2006, 76, 235–242. [Google Scholar] [CrossRef]

- IDC. 2019. Available online: https://www.idc.com/getdoc.jsp?containerId=prUS45197719 (accessed on 15 October 2020).

- Grand View Research Inc. 2019. Available online: https://www.grandviewresearch.com/press-release/global-industrial-internet-of-things-iiot-market (accessed on 6 December 2019).

- Marketsandmarkets Inc. 2019. Available online: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=129733727 (accessed on 1 March 2020).

- Zhou, L.; Wu, D.; Chen, J.; Dong, Z. When computation hugs intelligence: Content-aware data processing for industrial IoT. IEEE Internet Things J. 2017, 5, 1657–1666. [Google Scholar] [CrossRef]

- Heng, J.; Chen, W.; Tao, F.; Lin, C.-L. Industrial IoT in 5G environment towards smart manufacturing. J. Ind. Inf. Integr. 2018, 10, 10–19. [Google Scholar] [CrossRef]

- Zhang, Q.; Yang, L.T.; Chen, Z.; Li, P.; Bu, F. An adaptive dropout deep computation model for industrial IoT big data learning with crowdsourcing to cloud computing. IEEE Trans. Ind. Inform. 2018, 15, 2330–2337. [Google Scholar] [CrossRef]

- Hung, Y.-H. Investigating how the cloud computing transforms the development of industries. IEEE Access 2019, 7, 181505–181517. [Google Scholar] [CrossRef]

- Esfahani, A.; Mantas, G.; Matischek, R.; Saghezchi, F.B.; Rodriguez, J.; Bicaku, A.; Maksuti, S.; Tauber, M.G.; Schmittner, C.; Bastos, J. A lightweight authentication mechanism for M2M communications in industrial IoT environment. IEEE Internet Things J. 2017, 6, 288–296. [Google Scholar] [CrossRef]

- Pinto, S.; Gomes, T.; Pereira, J.; Cabral, J.; Tavares, A. IIoTEED: An enhanced, trusted execution environment for industrial IoT edge devices. IEEE Internet Comput. 2017, 21, 40–47. [Google Scholar] [CrossRef]

- Teslya, N.; Ryabchikov, I. Blockchain-based platform architecture for industrial IoT. In Proceedings of the 2017 21st Conference of Open Innovations Association (FRUCT), Helsinki, Finland, 6–10 November 2017; IEEE: New York, NY, USA, 2017; pp. 321–329. [Google Scholar]

- Zhang, Y.; Guo, Z.; Lv, J.; Liu, Y. A Framework for smart production-logistics systems based on CPS and industrial IoT. IEEE Trans. Ind. Inform. 2018, 14, 4019–4032. [Google Scholar] [CrossRef]

- Mahmoodpour, M.; Lobov, A.; Lanz, M.; Mäkelä, P.; Rundas, N. Role-based visualization of industrial IoT-based systems. In Proceedings of the 2018 14th IEEE/ASME International Conference on Mechatronic and Embedded Systems and Applications (MESA), Oulo, Finland, 2–4 July 2018; IEEE: New York, NY, USA, 2018; pp. 1–8. [Google Scholar]

- Civerchia, F.; Bocchino, S.; Salvadori, C.; Rossi, E.; Maggiani, L.; Petracca, M. Industrial internet of things monitoring solution for advanced predictive maintenance applications. J. Ind. Inf. Integr. 2017, 7, 4–12. [Google Scholar] [CrossRef]

- De Faria, H.J.; Costa, J.G.S.; Olivas, J.L.M. A review of monitoring methods for predictive maintenance of electric power transformers based on dissolved gas analysis. Renew. Sustain. Energy Rev. 2015, 46, 201–209. [Google Scholar] [CrossRef]

- Yan, J.; Meng, Y.; Lu, L.; Li, L. Industrial big data in an industry 4.0 environment: Challenges, schemes, and applications for predictive maintenance. IEEE Access 2017, 5, 23484–23491. [Google Scholar] [CrossRef]

- Nguyen, K.-A.; Do, P.; Grall, A. Multi-level predictive maintenance for multi-component systems. Reliab. Eng. Syst. Saf. 2015, 144, 83–94. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, L.; Duan, L.; Gao, R.X. A new paradigm of cloud-based predictive maintenance for intelligent manufacturing. J. Intell. Manuf. 2017, 28, 1125–1137. [Google Scholar] [CrossRef]

- Selcuk, S. Predictive maintenance, its implementation and latest trends. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2017, 231, 1670–1679. [Google Scholar] [CrossRef]

- Wang, K. Intelligent predictive maintenance (IPdM) system–Industry 4.0 scenario. WIT Trans. Eng. Sci. 2016, 113, 259–268. [Google Scholar]

- Dhall, R.; Solanki, V. An IoT based predictive connected car maintenance. Int. J. Interact. Multimed. Artif. Intell. 2017, 4, 16–22. [Google Scholar] [CrossRef]

- Baptista, M.; Sankararaman, S.; de Medeiros, I.P.; Nascimento, C.J.; Prendinger, H.; Henriques, E.M. Forecasting fault events for predictive maintenance using data-driven techniques and ARMA modeling. Comput. Ind. Eng. 2018, 115, 41–53. [Google Scholar] [CrossRef]

- Canizo, M.; Onieva, E.; Conde, A.; Charramendieta, S.; Trujillo, S. Real-time predictive maintenance for wind turbines using Big Data frameworks. In Proceedings of the 2017 IEEE International Conference on Prognostics and Health Management (ICPHM), Dallas, TX, USA, 19–21 June 2017; IEEE: New York, NY, USA, 2017. [Google Scholar]

- Şuteu, M.D.; Baban, C.F.; Baban, M.; Dragomir, G.; Toth, K.E. Predictive Maintenance of the Automated Sewing Machines in Textitle Industry; Universitatea din Oradea: Oradea, Romania, 2019. [Google Scholar]

- Baban, C.F.; Baban, M.; Suteu, M.D. Using a fuzzy logic approach for the predictive maintenance of textile machines. J. Intell. Fuzzy Syst. 2016, 30, 999–1006. [Google Scholar] [CrossRef]

- Baban, M.; Baban, C.F.; Suteu, M.D. Maintenance decision-making support for textile machines: A knowledge-based approach using fuzzy logic and vibration monitoring. IEEE Access 2019, 7, 83504–83514. [Google Scholar] [CrossRef]

- Boukili, A.; Hammoumi, M.E.; Haouache, S. Statistical study on the use of the measurement techniques in predictive maintenance taking Moroccan companies as an example. Int. J. Ind. Syst. Eng. 2019, 31, 38–69. [Google Scholar]

- Pech, M.; Vrchota, J.; Bednář, J. Predictive maintenance and intelligent sensors in smart factory: Review. Sensors 2021, 21, 1470. [Google Scholar] [CrossRef] [PubMed]

- Calabrese, F.; Regattieri, A.; Bortolini, M.; Gamberi, M.; Pilati, F. Predictive maintenance: A novel framework for a data-driven, semi-supervised, and partially online prognostic health management application in industries. Appl. Sci. 2021, 11, 3380. [Google Scholar] [CrossRef]

- Bergmann, A. Data Mining for Manufacturing: Preventive Maintenance, Failure Prediction, Quality Control; Salzgitter Mannesmann Forschung GmbH: Duisburg, Germany, 2012. [Google Scholar]

- IIoT World. 2019. Available online: https://iiot-world.com/connected-industry/industrial-iot-and-the-data-sharing-economy/ (accessed on 31 December 2019).

- McKinsey. The Age of Analytics: Competing in a Data-Driven World. 2016. Available online: http://www.cosmeticinnovation.com.br/wp-content/uploads/2017/01/MGI-The-Age-of-Analytics-Full-report.pdf (accessed on 23 June 2019).

- Mou, X.G.; Cai, Y.; Zhou, X.; Chen, G. On-line yarn cone defects detection system based on machine vision. J. Text. Res. 2018, 39, 139–145. [Google Scholar]

- Dema, M.; Turner, C.; Sari-Sarraf, H.; Hequet, E. Machine vision system for characterizing horizontal wicking and drying using an infrared camera. IEEE Trans. Ind. Inform. 2016, 12, 493–502. [Google Scholar] [CrossRef]

- Varghese, B.; Wang, N.; Barbhuiya, S.; Kilpatrick, P.; Nikolopoulos, D.S. Challenges and opportunities in edge computing. In Proceedings of the 2016 IEEE International Conference on Smart Cloud (SmartCloud), New York, NY, USA, 18–20 November 2016; IEEE: New York, NY, USA, 2016; pp. 20–26. [Google Scholar]

- Yin, S.; Bao, J.; Li, J.; Zhang, J. Real-time task processing method based on edge computing for spinning CPS. Front. Mech. Eng. 2019, 14, 320–331. [Google Scholar] [CrossRef]

- Hawkins, M. Cyber-physical production networks, internet of things-enabled sustainability, and smart factory performance in industry 4.0-based manufacturing systems. Econ. Manag. Financ. Mark. 2021, 16, 73–83. [Google Scholar]

- Chen, T.; Lin, C.-W. Smart and automation technologies for ensuring the long-term operation of a factory amid the COVID-19 pandemic: An evolving fuzzy assessment approach. Int. J. Adv. Manuf. Technol. 2020, 111, 3545–3558. [Google Scholar] [CrossRef] [PubMed]

- Rahman, A.; Chakraborty, C.; Anwar, A.; Karim, R.; Islam, J.; Kundu, D.; Rahman, Z.; Band, S.S. SDN–IoT empowered intelligent framework for industry 4.0 applications during COVID-19 pandemic. Clust. Comput. 2021, 1–18. [Google Scholar] [CrossRef]

| Year | Highlights of Thestudies | |

|---|---|---|

| [23] | 2017 | Proposed an intelligent system for maintaining vibration and temperature in an electricity power plant |

| [24] | 2015 | Predicted electric power transformer failure by monitoring dissolved gases in oil |

| [25] | 2017 | Analyzed industrial data to predict the remaining life of important components of machining equipment |

| [26] | 2015 | Proposed a cost evaluation model for optimizing maintenance decision variables |

| [27] | 2017 | Predicted fault diagnosis and remaining useful life and implemented a maintenance schedule based on the proposed system |

| [28] | 2017 | Surveyed PdM-related trends and techniques and provided suggestions for implementing factory PdM |

| [29] | 2016 | Reported that intelligent PdM can satisfy customers’ needs and change global markets in the manufacturing industry |

| [30] | 2017 | Discussed vehicular IoT and car PdM with connected technologies |

| [31] | 2018 | Used data analytics to predict airline maintenance scheduling |

| [32] | 2017 | Reported the evolution of PdM-related solutions in a Big Data environment |

| Type | Main Equipment |

|---|---|

| Polyamide Main Factory |

|

| Weaving Plant |

|

| Weaving and Dyeing Plant |

|

| Product Name | Capacity | Unit |

|---|---|---|

| Nylon Chip | 580,000 | ton/year |

| Filament Yarn | 36,000 | ton/year |

| Weaving | 5,000,000 | yards/month |

| Piece Dye | 8,000,000 (Woven) 700,000 (Knitting) | yards/month kg/month |

| Yarn Dye | 250,000 | kg/month |

| Filename (.csv) | Size (MB) | Number of Columns | Number of Raw Data | Description |

|---|---|---|---|---|

| warpop | 7.1 | 37 | 26,103 | operation parameters in the warping process |

| sizeop | 5 | 46 | 15,950 | operation parameters in the sizing process |

| beamop | 8.6 | 31 | 37,089 | operation parameters in the beaming process |

| weaveop | 50.9 | 25 | 161,821 | operation parameters in the weaving process |

| Process | Name | Description |

|---|---|---|

| warping | WARPSPEED | The speed of warping |

| WARPPRES | The tension of the Warper’s Beam | |

| SSTENSION | The tension of monofilament | |

| WARPTENSION | The tension of warping | |

| HYDRATENSION | The tension of hydraulic warping. | |

| sizing | SIZINGSPEED | The speed of sizing. |

| SIZINGBPRES | The pressure of sizing | |

| SIZINGATENSION | The tension of sizing (roll-out) | |

| SIZINGBTENSION | The tension of sizing (winding) | |

| CONSISTENCY | The density of forming polymeric material | |

| DENSITY | The density of the sizing | |

| beaming | BEAMSPEED | The speed of beaming |

| BEAMATENSION | The tension of roll-out | |

| BEAMBTENSION | The tension of winding | |

| BEAMTENSION | The tension of beaming |

| Attribute Name | Description | Data Type | Process Stage | |

|---|---|---|---|---|

| 1 | WARPTOTAL | The number of warp | NUMBER | Warping Sizing Beaming |

| 2 | TOTALLENGTH | The actual total length of warping | NUMBER | |

| 3 | THEORYLENGTH | The theoretical total length of warping | NUMBER | |

| 4 | YARNSPECDENIM | The denier number of yarn specification | NUMBER | |

| 5 | YARNSPECFIBERBASE | The fiber number of yarn specification | NUMBER | |

| 6 | DENIM | The theoretical denier number | NUMBER | |

| 7 | FIBERBASE | The theoretical fiber number | NUMBER | |

| 8 | UNITWEIGHT | The weight per unit | NUMBER | |

| 9 | GRANULARITY | The granularity of yarn | NUMBER | Sizing |

| 10 | WARPLENGTH | The length of warp | NUMBER | |

| 11 | WARPSTRIP | The length of beaming | NUMBER | |

| 12 | WARPLENGHT | The length of the warping | NUMBER | |

| 13 | SIZINGLENGTH | The length of the sizing | NUMBER |

| Parameters | MSE | MAE |

|---|---|---|

| WARPSPEED | 0.05441 | 0.19 |

| WARPPRES | 0.00074 | 0.02 |

| SSTENSION | 0.00347 | 0.03 |

| WARPTENSION | 0.03161 | 0.11 |

| HYDRATENSION | 0.01704 | 0.08 |

| Parameters | MSE | MAE |

|---|---|---|

| WARPSPEED | 0.05720 | 0.18 |

| WARPPRES | 0.00085 | 0.02 |

| SSTENSION | 0.02379 | 0.13 |

| WARPTENSION | 0.06067 | 0.17 |

| HYDRATENSION | 0.04003 | 0.14 |

| Parameters | MSE | MAE |

|---|---|---|

| WARPSPEED | 0.05503 | 0.17 |

| WARPPRES | 0.00077 | 0.02 |

| SSTENSION | 0.00387 | 0.04 |

| WARPTENSION | 0.06067 | 0.01 |

| HYDRATENSION | 0.01689 | 0.08 |

| Parameters | MSE | MAE |

|---|---|---|

| WARPSPEED | 0.05730 | 0.18 |

| WARPPRES | 0.00084 | 0.02 |

| SSTENSION | 0.02370 | 0.13 |

| WARPTENSION | 0.06032 | 0.17 |

| HYDRATENSION | 0.03911 | 0.13 |

| Parameters | MSE | MAE |

|---|---|---|

| SIZINGSPEED | 0.05162 | 0.19 |

| SIZINGBPRES | 0.05851 | 0.21 |

| DENSITY | 0.00171 | 0.02 |

| CONSISTENCY | 0.00085 | 0.02 |

| SIZINGATENSION | 0.00422 | 0.04 |

| SIZINGBTENSION | 0.00611 | 0.05 |

| Parameters | MSE | MAE |

|---|---|---|

| SIZINGSPEED | 0.07731 | 0.24 |

| SIZINGBPRES | 0.07120 | 0.25 |

| DENSITY | 0.00202 | 0.03 |

| CONSISTENCY | 0.00124 | 0.02 |

| SIZINGATENSION | 0.00821 | 0.07 |

| SIZINGBTENSION | 0.01160 | 0.09 |

| Parameters | MSE | MAE |

|---|---|---|

| SIZINGSPEED | 0.05270 | 0.19 |

| SIZINGBPRES | 0.06080 | 0.21 |

| DENSITY | 0.00170 | 0.02 |

| CONSISTENCY | 0.00084 | 0.02 |

| SIZINGATENSION | 0.00482 | 0.05 |

| SIZINGBTENSION | 0.06980 | 0.06 |

| Parameters | MSE | MAE |

|---|---|---|

| SIZINGSPEED | 0.07701 | 0.24 |

| SIZINGBPRES | 0.07111 | 0.24 |

| DENSITY | 0.00201 | 0.03 |

| CONSISTENCY | 0.00123 | 0.03 |

| SIZINGATENSION | 0.00814 | 0.07 |

| SIZINGBTENSION | 0.01157 | 0.09 |

| Parameters | MSE | MAE |

|---|---|---|

| BEAMSPEED | 0.00723 | 0.07 |

| BEAMATENSION | 0.00072 | 0.01 |

| BEAMBTENSION | 0.00071 | 0.01 |

| BEAMTENSION | 0.00056 | 0.01 |

| Parameters | MSE | MAE |

|---|---|---|

| BEAMSPEED | 0.00790 | 0.08 |

| BEAMATENSION | 0.00085 | 0.01 |

| BEAMBTENSION | 0.00088 | 0.01 |

| BEAMTENSION | 0.00153 | 0.03 |

| Parameters | MSE | MAE |

|---|---|---|

| BEAMSPEED | 0.00735 | 0.07 |

| BEAMATENSION | 0.00075 | 0.01 |

| BEAMBTENSION | 0.00075 | 0.01 |

| BEAMTENSION | 0.00080 | 0.01 |

| Parameters | MSE | MAE |

|---|---|---|

| BEAMSPEED | 0.00780 | 0.08 |

| BEAMATENSION | 0.00084 | 0.01 |

| BEAMBTENSION | 0.00087 | 0.01 |

| BEAMTENSION | 0.00150 | 0.03 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, R.-I.; Lee, C.-Y.; Hung, Y.-H. Cloud-Based Analytics Module for Predictive Maintenance of the Textile Manufacturing Process. Appl. Sci. 2021, 11, 9945. https://doi.org/10.3390/app11219945

Chang R-I, Lee C-Y, Hung Y-H. Cloud-Based Analytics Module for Predictive Maintenance of the Textile Manufacturing Process. Applied Sciences. 2021; 11(21):9945. https://doi.org/10.3390/app11219945

Chicago/Turabian StyleChang, Ray-I, Chia-Yun Lee, and Yu-Hsin Hung. 2021. "Cloud-Based Analytics Module for Predictive Maintenance of the Textile Manufacturing Process" Applied Sciences 11, no. 21: 9945. https://doi.org/10.3390/app11219945

APA StyleChang, R.-I., Lee, C.-Y., & Hung, Y.-H. (2021). Cloud-Based Analytics Module for Predictive Maintenance of the Textile Manufacturing Process. Applied Sciences, 11(21), 9945. https://doi.org/10.3390/app11219945