1. Introduction

The impact the temperature has on the remodeling and healing processes of the bone during implant site preparation has been extensively described in the literature [

1]. The shape of the drill, its design, fatigue, cooling technique, cooling material, the force applied during drilling and the rotation speed have been considered crucial factors [

1]. Different temperature measuring tools have been used to analyze temperature changes including: real time infrared thermography [

2], type T thermocouples [

3], type K thermocouples [

4], thermographic digital camera [

5], digital thermometer [

6], type K thermocouples and digital thermometer [

7].

Eriksson and Albrektsson [

8] reported that the temperature generated by the drill while preparing the implant site should not exceed 47 °C for more than 1 min, as such overheating causes irreversible osteonecrosis. Other reported factors influencing the overall success of osseointegration are implant biocompatibility, design, surface, condition of the host bed, surgical technique, and loading [

9].

El-Kholey et al. [

10] suggested that the number of drills used during implant bed preparation has no significant influence on the bone temperature increase following either conventional or simplified drilling procedure. What is more, the drilling technique (continuous versus intermittent) did not cause rise in the temperature and subsequent bone overheating (i.e., above 47 °C) [

11]. Nevertheless, there are some techniques which utilize bone collected from the drill as a graft material and while applying them it is recommended not to use cooling water and a decreased drilling speed [

6].

Polyurethane (PUR) foam blocks have been commonly used in experimental studies replacing cadaver or animal bone specimens [

4,

7,

12,

13,

14,

15,

16,

17]. According to Schim [

18] and Horn [

19] polyurethane foam is a good alternative for human cancellous bone as it displays similar mechanical properties and may be used as a medium for implant testing. Horak et al. [

17] conducted experimental studies to evaluate its mechanical properties (temperature, strain and density) and reported that it is not only suitable for mechanical investigations but also for investigations involving surgical instruments that generate heat. Moreover, this type of foam meets the ASTM F-1839-08 “Standard Specification for Rigid Polyurethane Foam for Use as a Standard Material for Testing Orthopaedic Devices and Instruments” which makes it an ideal material for comparative testing of bone screws and other medical devices and instruments.

The aim of the present in vitro study was to measure and verify the maximum temperature of the drills used for placing crestal and lateral basal implants, with different drill shapes. We hypothesized that disc cutters for lateral basal implants, regardless of their design, would not exceed the temperature of 47 °C and could be safely used while preparing the implant bed site. Therefore we aimed to evaluate disc cutters safety protocol in terms of maintaining non-hazardous bone temperature levels.

2. Materials and Methods

Polyurethane (PUR) foam blocks (Sawbones, Vashon Island, WA, USA) used in the present studies simulate the clinical conditions encountered during implant bed preparation. Artificial bone blocks made from solid rigid polyurethane foam (

Figure 1) are similar to human D1 bone i.e., primarily dense cortical bone according to Misch’s classification [

20] and offer uniform and consistent physical properties that eliminate the variability encountered when testing with human cadaver bone. For this experiment foam blocks with a thickness of 10 mm, a width of 15 mm, a length of 15 mm, and density of 0.64 g/cm

3 (40 pounds per cubic foot = 40 pcf) were used.

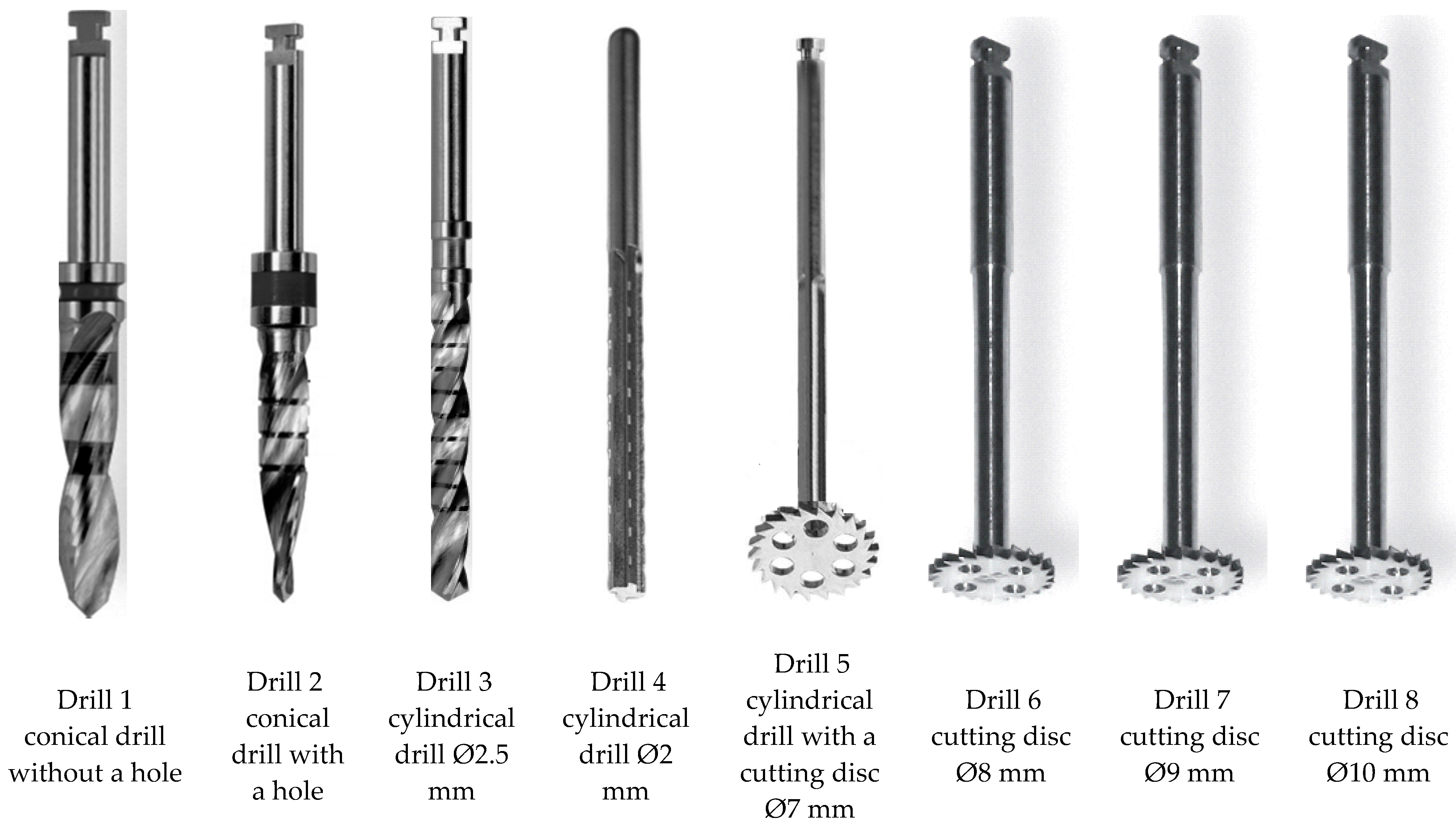

The experiment was carried out with eight different drills from the same manufacturer (Ihde Dental, Gommiswald, Switzerland), i.e.:

Group 1: Conical drills with (drill 1) and without (drill 2) a hole for standard implants with conical core.

Group 2: Cylindrical drills Ø 2.0 mm (drill 3), Ø 2.5 mm (drill 4) and with cutting disc Ø7 mm (drill 5).

Group 3: Cutting discs Ø8 mm (drill 6), Ø9 mm (drill 7) and Ø10 mm (drill 8) as presented in

Figure 2.

The experimental setup, as shown in

Figure 3, consisted of the surgical drilling machine (Implantmed, W&H, Bürmoos, Austria) fixed in a three- axis movement CNC machine. A PUR block with thermocouples to detect the temperature changes inside the foam was fixed on a table in the same horizontal axis as the surgical drilling machine (drills 1 and 2) and in the same drilling direction. An IR camera (FLIR T1020, FLIR Systems, Wilsonville, OR, USA) was mounted in front of the PUR block to record the temperature at the cutting edge of the experimental drills while perforating the PUR block.

In this study, a load of 2 kg was applied, in accordance with the procedures described by Misir et al. [

21]. For the cutting disc measurement, drills 3, 4, 5, 6, 7 and 8 were installed in the vertical axis with the rotary function of the CNC machine, as shown in

Figure 4. In front of the PUR block the FLIR T1020HD thermal camera was mounted to record the temperature in the cutting edge while drilling [

18]. The experiment was done at three different rotational speeds of 800, 3000 and 5000 rpm. Each measurement combination of the drill type and rpm was performed only with cooling, for which the surgical drilling machine cooling system was used with water as a cooling medium. Cooling water was showered on the drill or cutting disc while performing experiment. Three holes were drilled with each drill to test the samples of the polyurethane foam.

Drills 1 and 2 were used in horizontal axis 2 mm/30 mm/min axial movement of a drill (drilling) and then the load was reduced by moving the drill 1 mm back (with an axial movement of a drill 500 mm/min). Using this interrupted drilling technique it was possible to drill through the PUR block. According to some researchers one of the benefits of this type of interrupted drilling protocol is lower heat production [

22]. Interrupted drilling protocol 5 mm/min was also used for drills 3, 4, 5, 6, 7 and 8 (drilling was 2 mm by 5 mm/min and then 1 mm back by 500 mm/min).

3. Results

The data obtained from the experiments are presented in

Table 1 and

Figure 5. The results of the investigation showed that drill 1 without a hole (with increasing groove helix) generated the temperature of 38.4 °C at the speed of 800 rpm with cooling. When the speed increased the heat production increased accordingly, but the maximum values were still acceptable (T

3000max = 61.5 °C and T

5000max = 63.8 °C).

On the other hand, drill 2 with a hole showed that even if the interrupted drilling protocol was used, the temperatures were higher than those produced by drill 1. The maximum temperatures generated by the drill were T

5000max = 75.4 °C, T

3000max = 65.5 °C and at the speed of 800 rpm the drill was completely blocked inside the PUR foam interrupting the experiment (

Figure 6).

Drills 3 and 4, which are usually used to cut material in radial direction, had been moving 5 mm/min towards a PUR block. In this case, it was shown that this experimental setup with interrupted drilling protocol, cooling and drill speed of 3000 rpm was not suitable for making the hole in the radial direction of the PUR foam as drill #3 fractured and the experiment with drill #4 was stopped so that the drill would not break (

Figure 7).

For drills with cutting discs (5, 6, 7, 8) a similar experimental setup as for drills 3 and 4 was used, as shown in

Figure 3. It could have been observed that the disc-drill was self-carrying cooling medium into the depth of the slot (

Figure 8).

Drill 5 cut the PUR foam very easily but with the vertical part, which was in this case made for radial cutting. The vertical part of this drill that is used for making the slot, did not manage to cut the PUR foam with the 5 mm/min cutting movement and 3000 rpm rotational speed. The drill 5 then bent and the experiment was stopped so as not to destroy the drill.

For cutting discs 6, 7, and 8 the vertical slots with 2.7 mm thickness were first milled as shown in

Figure 9a (drills number 7 and 8), and then horizontal slots were made by the cutting discs (

Figure 9b). The horizontal slots were made by interrupted drilling protocol and with 5 mm/min horizontal cutting speed.

Experiments with drills 6, 7, and 8 were made with cooling, interrupted drilling protocol and the maximum measured temperature did not exceed 30 °C (

Table 1,

Figure 2).

The results obtained for axial conical drills (drills 1 and 2) with the interrupted drilling protocol and cooling were similar to the results after drilling at one time (uninterrupted drilling protocol), i.e., the produced heat was about 10–15% lower. With increased rotation speed, the maximum temperatures measured by IR camera increased for both tested drills. The drill without a hole provided better results than the drill with a hole (2) even if the cooling medium was flowing through the drill’s hole.

Experiments with drills number 3 and 4 showed that the experimental setup with interrupted drilling, cooling and the drill speed of 3000 rpm was not suitable for making the slot in the radial direction in the PUR foam. Drill 3 fractured and the experiment with drill 4 was stopped so that the drill would not break. Experiments with drills 6, 7, and 8 were made with cooling, interrupted drilling protocol and the maximum measured temperature was below 30 °C.

4. Discussion

While preparing implant bed various factors need to be taken into consideration, including the drill’s shape, drilling technique, cooling material and drilling speed and torque, as well as the implant system used [

23,

24,

25,

26]. In some systems there is a tendency to minimize the number of drills to simplify the procedure and lower the overall costs [

27,

28]. In other systems, a large number of drills allows for safe and precise bed preparation in risky recipients [

29]. As far as the heat production is concerned, Watanabe et al. [

30] reported that maximum heat temperature without irrigation was higher than that with irrigation, which contradicts our observations, whereas Gehrke et al. [

23] suggested that the double irrigation technique produced a significantly smaller increase in the temperature in the cortical bone during both continuous and intermittent drilling movement. It is worth highlighting that while using disc drills the temperature decreased in proportion to the increasing drilling speed, which, so far, has not been described in the literature. This may have some clinical implications as disk implants are used in cranio-facial surgery for epithesis anchorage in auricular and orbital regions [

31,

32]. Since in these regions there is a close vicinity of anatomical structures and the bone often undergoes irradiation, high temperature during bed preparation may be undesirable.

Gaspar et al. [

25] showed that the effects of the bone preparation by low speed drilling (50 rpm) without irrigation and conventional drilling (800 rpm) with irrigation are similar, which means that both drilling techniques are successful in keeping bone cells alive. In our study, one drill fractured during drilling and the experiment with drill 4 was stopped so that the drill would not break. It might have been due to the fact that the PUR foam is harder than the real bone of the mandible, or cylindrical part of these drills were not sharp enough for radial drill cutting. In our opinion the radial movement 5 mm/min is very slow to be performed in clinical environment while drilling into the patient’s bone.

In this study, the drill without a hole (1) provided better results than the drill with a hole (2) even if the cooling medium was flowing throughout the hole. These results confirm findings presented by Strbac et al. [

15] for twist drills with 2 mm diameter and 10 mm drilling depth. They reported the lowest temperature change of 20.45 °C for external irrigation in comparison with internal irrigation where the temperature rose to 28.30 °C. We have concluded that the amount of metal-mass in the drill helps to absorb and distribute the heat better than the through-and-through irrigation of the cutting part of the drill.

There are also numerous articles regarding the importance and differences between simplified and conventional drilling techniques in regards to their numbers, which show that the outcome on the bone is the same [

10]. Jimbo et al. [

33] evaluated the combined effect of drilling sequence and implant diameter. It turned out that the simplified technique did not influence bone formation. What is more, studies conducted by El-Kholey and Elkomy [

34] showed that a simplified drilling technique generates as much heat as the conventional one. To prove their hypothesis they used 80 implants with 2 different diameters placed in bovine ribs.

Guazi et al. [

35] tested implants placed in sites prepared with a simplified protocol with one drill and multiple conventional drilling steps. Their results showed that both drilling techniques are successful, but single-bur technique was less time consuming and caused less pain. Additionally, Sarendranath et al. [

36] compared simplified protocols with conventional ones in terms of biological response. The authors concluded that the simplified procedure provides biological outcomes comparable to those achieved following the conventional one. El-Kholey et al. [

10] evaluated 120 implant site preparations with three different diameters following simplified and conventional drilling procedures and measured the bone temperature using K-type thermocouple and a sensitive thermometer before and after each drill was used. They concluded that there was no significant difference in temperature increase when implants were prepared by either of methods.

5. Conclusions

Basing on the above results, we may conclude that since the temperature during drilling with disc cutters for lateral basal implants did not exceed 33 °C and, what is more, it decreased in proportion to higher drill speed, this design is safe and will not cause bone overheating. Thus, a high drilling speed with irrigation for disc cutters seems to be safe protocol for lateral basal implant osteotomy site preparation.

Author Contributions

Conceptualization, S.I. and Ł.P.; methodology, S.I.; software, S.I.; validation, S.I., Ł.P. and B.D.; formal analysis, Ł.P.; investigation, S.I.; resources, S.I.; data curation, B.D.; writing—original draft preparation, Ł.P.; writing—review and editing, S.I., Ł.P. and B.D.; supervision, Ł.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are available upon request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mishra, S.; Chowhardy, R. Heat generated by dental implant drills during osteotomy—A review: Heat generated by dental implant drills. J. Indian Prosthodont. Soc. 2014, 14, 131–143. [Google Scholar] [CrossRef] [PubMed]

- Lucchiari, N.; Frigo, A.C.; Stellini, E.; Coppe, M.; Berengo, M.; Bacci, C. In Vitro Assessment with the Infrared Thermometer of Temperature Differences Generated During Implant Site Preparation: The Traditional Technique Versus the Single-Drill Technique. Clin. Implant. Dent. Relat. Res. 2014, 18, 182–191. [Google Scholar] [CrossRef]

- Calvo-Guirado, J.L.; Delgado-Peña, J.; Maté-Sánchez, J.E.; Mareque Bueno, J.; Delgado-Ruiz, R.A.; Romanos, G.E. Novel hybrid drilling protocol: Evaluation for the implant healing--thermal changes, crestal bone loss, and bone-to-implant contact. Clin. Oral Implant Res. 2015, 26, 753–760. [Google Scholar] [CrossRef]

- Oh, J.-H.; Fang, Y.; Jeong, S.-M.; Choi, B.-H. The effect of low-speed drilling without irrigation on heat generation: An experimental study. J. Korean Assoc. Oral Maxillofac. Surg. 2016, 42, 9–12. [Google Scholar] [CrossRef] [Green Version]

- José, L.F.D.S.; Ruggeri, F.M.; Rucco, R.; Zubizarreta-Macho, A.; Pérez-Barquero, J.A.; Deglow, E.R.; Montero, S.H. Influence of Drilling Technique on the Radiographic, Thermographic, and Geomorphometric Effects of Dental Implant Drills and Osteotomy Site Preparations. J. Clin. Med. 2020, 9, 3631. [Google Scholar] [CrossRef]

- Anitua, E.; Carda, C.; Andia, I. A novel drilling procedure and subsequent bone autograft preparation: A technical note. Int. J. Oral Maxillofac. Implants 2007, 22, 309. [Google Scholar]

- Salomó-Coll, O.; Auriol-Muerza, B.; Lozano-Carrascal, N.; Hernández-Alfaro, F.; Wang, H.-L.; Gargallo-Albiol, J. Influence of bone density, drill diameter, drilling speed, and irrigation on temperature changes during implant osteotomies: An in vitro study. Clin. Oral Investig. 2020, 25, 1047–1053. [Google Scholar] [CrossRef]

- Eriksson, A.; Albrektsson, T. Temperature threshold levels for heat-induced bone tissue injury: A vital-microscopic study in the rabbit. J. Prosthet. Dent. 1983, 50, 101–107. [Google Scholar] [CrossRef]

- Albrektsson, T.; Branemark, P.I.; Hansson, H.A.; Lindstrom, J. Osseointegrated titanium implants: Requirements for ensuring a long-lasting, direct bone-to-implant anchorage in man. Acta Orthop. Scand. 1981, 52, 155–170. [Google Scholar] [CrossRef] [Green Version]

- El-Kholey, K.E.; Ramasamy, S.; Kumar, S.; Elkomy, A. Effect of simplifying drilling technique on heat generation during os-teotomy preparation for dental implant. Implant Dent. 2017, 26, 888–891. [Google Scholar] [CrossRef]

- Di Fiore, A.; Sivolella, S.; Stocco, E.; Favero, V.; Stellini, E. Experimental analysis of temperature differences during implant site preparation: Continuous drilling technique versus intermittent drilling technique. J. Oral Implantol. 2018, 44, 46–50. [Google Scholar] [CrossRef] [PubMed]

- Yang, B.; Irastorza-Landa, A.; Heuberger, P.; Ploeg, H.-L. Effect of insertion factors on dental implant insertion torque/energy-experimental results. J. Mech. Behav. Biomed. Mater. 2020, 112, 103995. [Google Scholar] [CrossRef] [PubMed]

- Oh, H.J.; Wikesjö, U.M.; Kang, H.-S.; Ku, Y.; Eom, T.-G.; Koo, K.-T. Effect of implant drill characteristics on heat generation in osteotomy sites: A pilot study. Clin. Oral Implant. Res. 2010, 22, 722–726. [Google Scholar] [CrossRef] [PubMed]

- Strbac, G.D.; Giannis, K.; Unger, E.; Mittlböck, M.; Watzek, G.; Zechner, W. A novel standardized bone model for thermal evaluation of bone osteotomies with various irrigation methods. Clin. Oral Implant. Res. 2013, 25, 622–631. [Google Scholar] [CrossRef] [PubMed]

- Strbac, G.D.; Giannis, K.; Unger, E.; Mittlböck, M.; Vasak, C.; Watzek, G.; Zechner, W. Drilling- and Withdrawing-Related Thermal Changes during Implant Site Osteotomies. Clin. Implant. Dent. Relat. Res. 2013, 17, 32–43. [Google Scholar] [CrossRef]

- Gehrke, S.A.; Bettach, R.; Taschieri, S.; Boukhris, G.; Corbella, S.; Del Fabbro, M. Temperature Changes in Cortical Bone after Implant Site Preparation Using a Single Bur versus Multiple Drilling Steps: An In Vitro Investigation. Clin. Implant. Dent. Relat. Res. 2013, 17, 700–707. [Google Scholar] [CrossRef]

- Horak, Z.; Dvorak, K.; Zarybnicka, L.; Vojackova, H.; Dvorakova, J.; Vilimek, M. Experimental Measurements of Mechanical Properties of PUR Foam Used for Testing Medical Devices and Instruments Depending on Temperature, Density and Strain Rate. Materials 2020, 13, 4560. [Google Scholar] [CrossRef]

- Shim, V.; Boheme, J.; Josten, C.; Anderson, C.J.A.I. Use of Polyurethane Foam in Orthopaedic Biomechanical Experimentation and Simulation, Polyurethane; Fahmina Zafar, F., Ed.; InTech: London, UK, 2012. [Google Scholar] [CrossRef] [Green Version]

- Horn, T.J.; Harrysson, O.L.A.; Little, J.P.; West, H.A.; Marcellin-Little, D.J. Design and manufacturing of bone analog models for the mechanical evaluation of custom medical implants. In Proceedings of the 21st Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, SFF 2010, Austin, TX, USA, 9–11 August 2010; University of Texas at Austin (freeform): Austin, TX, USA, 2010; pp. 864–875. [Google Scholar]

- E Misch, C.; Bidez, M.W. Implant-protected occlusion: A biomechanical rationale. Compendium 1994, 15, 1330–1344. [Google Scholar]

- Misir, A.F.; Sumer, M.; Yenisey, M.; Egrioglu, E. Effect of Surgical Drill Guide on Heat Generated from Implant Drilling. J. Oral Maxillofac. Surg. 2009, 67, 2663–2668. [Google Scholar] [CrossRef]

- Tuijthof, G.; Frühwirt, C.; Kment, C. Influence of tool geometry on drilling performance of cortical and trabecular bone. Med Eng. Phys. 2013, 35, 1165–1172. [Google Scholar] [CrossRef]

- Gehrke, S.A.; Neto, H.L.; Mardegan, F.E. Investigation of the effect of movement and irrigation systems on temperature in the conventional drilling of cortical bone. Br. J. Oral Maxillofac. Surg. 2013, 51, 953–957. [Google Scholar] [CrossRef] [PubMed]

- Liu, D.-Y.; Wu, Y.-N.; Peng, W.; Liao, W.-Q.; Wang, Y.-L. The influence of drilling pulling ways and cooling systems on dental implant surgery. Shanghai Kou Qiang Yi Xue Shanghai J. Stomatol. 2014, 23, 149–153. [Google Scholar]

- Gaspar, J.; Borrecho, G.; Oliveira, P.; Salvado, F.J.; Dos Santos, J.M. Osteotomy at low-speed drilling without irrigation versus high-speed drilling with irrigation: An experimental study. Acta Med. Port. 2013, 26, 231–236. [Google Scholar] [PubMed]

- Kosior, P.; Kuropka, P.; Janeczek, M.; Mikulewicz, M.; Zakrzewski, W.; Dobrzyński, M. The Influence of Various Preparation Parameters on the Histological Image of Bone Tissue during Implant Bed Preparation—An In Vitro Study. Appl. Sci. 2021, 11, 1916. [Google Scholar] [CrossRef]

- Ihde, S.; Pałka, Ł.; Janeczek, M.; Kosior, P.; Kiryk, J.; Dobrzynski, M. Bite Reconstruction in the Aesthetic Zone Using One-Piece Bicortical Screw Implants. Case Rep. Dent. 2018, 2018, 4671482. [Google Scholar] [CrossRef] [Green Version]

- Pałka, Ł.R.; Lazarov, A. Immediately Loaded Bicortical Implants Inserted in Fresh Extraction and Healed Sites in Patients with and Without a History of Periodontal Disease. Ann. Maxillofac. Surg. 2019, 9, 371–378. [Google Scholar] [CrossRef]

- Gehrke, S.A.; Bettach, R.; Júnior, J.S.A.; Prados-Frutos, J.C.; Del Fabbro, M.; Shibli, J.A. Peri-Implant Bone Behavior after Single Drill versus Multiple Sequence for Osteotomy Drill. BioMed Res. Int. 2018, 2018, 9756043. [Google Scholar] [CrossRef] [Green Version]

- Watanabe, F.; Tawada, Y.; Komatsu, S.; Hata, Y. Heat distribution in bone during preparation of implant sites: Heat analysis by real-time thermography. Int. J. Oral Maxillofac. Implant. 1992, 7, 212–219. [Google Scholar]

- Ivanjac, F.; Konstantinovic, V.; Lazić, V.; Dordević, I.; Ihde, S. Assessment of Stability of Craniofacial Implants by Resonant Frequency Analysis. J. Craniofacial Surg. 2016, 27, e185–e189. [Google Scholar] [CrossRef]

- Vitomir, K.S.; Filip, I.; Vojkan, L.; Igor, Đ.; Lukasz, P. Survival rate of disk and screw-type implants used for the retention of extraoral prostheses. J. Prosthet. Dent. 2020. [Google Scholar] [CrossRef]

- Jimbo, R.; Giro, G.; Marin, C.; Granato, R.; Suzuki, M.; Tovar, N.; Lilin, T.; Janal, M.; Coelho, P.G. Simplified Drilling Technique Does Not Decrease Dental Implant Osseointegration: A Preliminary Report. J. Periodontol. 2012, 84, 1599–1605. [Google Scholar] [CrossRef] [PubMed]

- El-Kholey, K.E.; Elkomy, A. Effect of the Drilling Technique on Heat Generation During Osteotomy Preparation for Wide-Diameter Implants. Implant. Dent. 2016, 25, 825–828. [Google Scholar] [CrossRef]

- Guazzi, P.; Grandi, T.; Grandi, G. Implant site preparation using a single bur versus multiple drilling steps: 4-month post-loading results of a multicenter randomised controlled trial. Eur. J. Oral Implant. 2015, 8, 283–290. [Google Scholar]

- Sarendranath, A.; Khan, R.; Tovar, N.; Marin, C.; Yoo, D.; Redisch, J.; Jimbo, R.; Coelho, P.G. Effect of low speed drilling on os-se-ointegration using simplified drilling procedures. Br. J. Oral Maxillofac. Surg. 2015, 53, 550–556. [Google Scholar] [CrossRef]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).